1. Introduction

PMSMs have been used in many variable speed-driving applications in industry and home appliances such as robotic actuators, computer disk drives, domestic application, automotive and renewable energy conversion systems because of their advantages namely small size, less maintenance, reliability, high efficiency, and high power density.

In the control of electrical motor drivers, vector-based linear cascaded proportional integral (PI) control approach is widely used since it is quite reliable and easy to implement, where inner loop is responsible for regulating the currents in the d-q rotating reference framework and the outer loop provides the reference current for the inner loop to regulate the speed [

1]. Moreover, in the industrial applications, PMSMs are exposed to different disturbances such as parameter uncertainty, some nonlinearities [

2], and external load disturbances [

3]. As long as the operating conditions are not changed, the PI controller can provide satisfactory control performance [

2]. However, parameter changes and load disturbances are very common in PMSMs, which may lead to deterioration in the control quality in PI control [

3]. Therefore, much more sophisticated control mechanisms are required for PMSMs since they have variable dynamics with various disturbances.

For that purpose, recently, many nonlinear control methods have been proposed for controlling PMSMs. One of them is the so-called model based predictive control (MPC) that has been introduced as the most robust control technique for PMSMs [

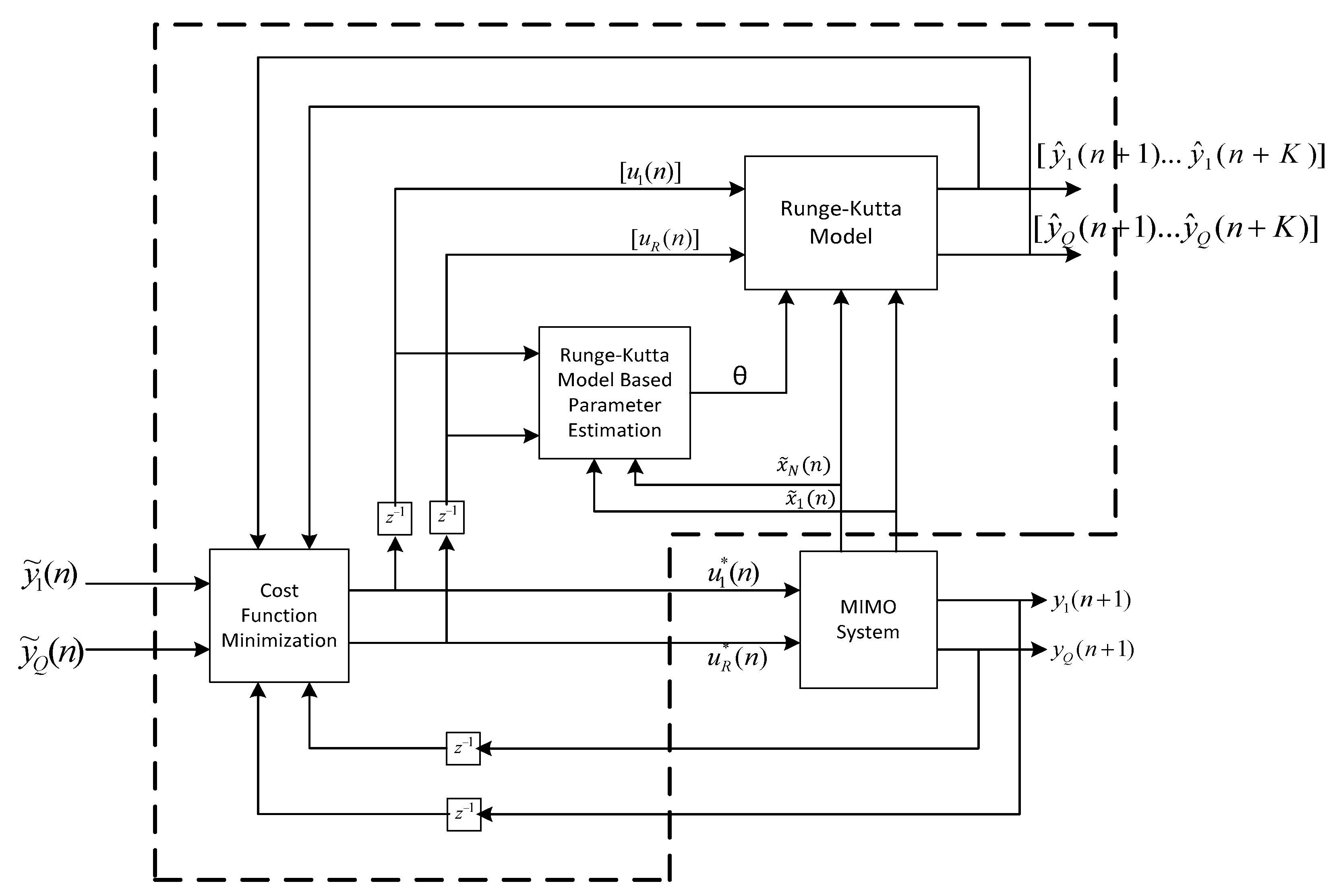

4]. MPC is an optimization-based control strategy that tries to minimize the difference between the reference trajectory and the predicted trajectory of the system [

1]. For many years, MPC has been applied for only slow systems since it requires intensive computations in each sampling period [

5] and has not been used for electrical drives [

6]. Today, owing to the rapid developments in the digital signal processing (DSP) and field programmable gate array (FPGA) technologies it is well possible to implement real-time MPC for fast systems like power electronic converters and variable speed drivers [

4].

There are many MPC methods for PMSMs in the literature. In [

7], a speed control strategy is proposed as an alternative to the standard vector control, where MPC is applied by using a linear model of a PMSM. Similarly, in [

1], a linearized state space model of a PMSM is used in the MPC loop for speed control by taking the constraints into consideration. In another application [

5], MPC is used in loop to speed and current control of PMSM, where a state space model with all state variables is used and current and voltage constraints are taken into consideration. A robust nonlinear predictive controller with a disturbance observer has been used for PMSM control [

4]. In their other application, a robust cascaded nonlinear predictive controller with anti-windup compensator [

8] has been proposed for speed control. In [

9], a model predictive direct torque control technique with load angle limitation for surface-mounted PMSM (SMPMSM) has been proposed. A cascaded adaptive explicit model predictive controller has been proposed for torque control without sensors to provide high dynamic performance for PMSM drivers [

10]. In [

11], an improved predictive current control technique has been applied for interior PMSM (IPMSM) driver systems by using current difference detection technique. Another sensorless control application for PMSM driver systems has been demonstrated in [

12], where sensorless direct current control is achieved by a MPC with a novel second-order PLL observer. In [

13] a self-tuning based MPC has been applied to a higher-order nonlinear proportional servo motor.

In [

14], a stable and robustness enhanced finite control set model predictive control (FCS-MPC) for 2-level voltage source inverter (VSI)-fed SPMSM drives was designed and compared to conventional FCS-MPC. In [

15], a new speed finite control set MPC algorithm has been implemented which is be applied to a PMSM driven by a matrix converter (MC). In this method, motor currents and speed are realized in a single control loop. In [

16] direct speed control based on finite control set-model predictive speed control (FCS-MPSC) with voltage smoothing is presented to reduce current fluctuations. With this control method, sudden changes in the output voltage caused by large current ripple are avoided. Finally, variable switching frequency in FCS-MPC method causes negative effect in the design of output filters and converter efficiency. Therefore, they have presented a new MPC method with fixed switching frequency, which is simple to implement and only needs small computation time [

17].

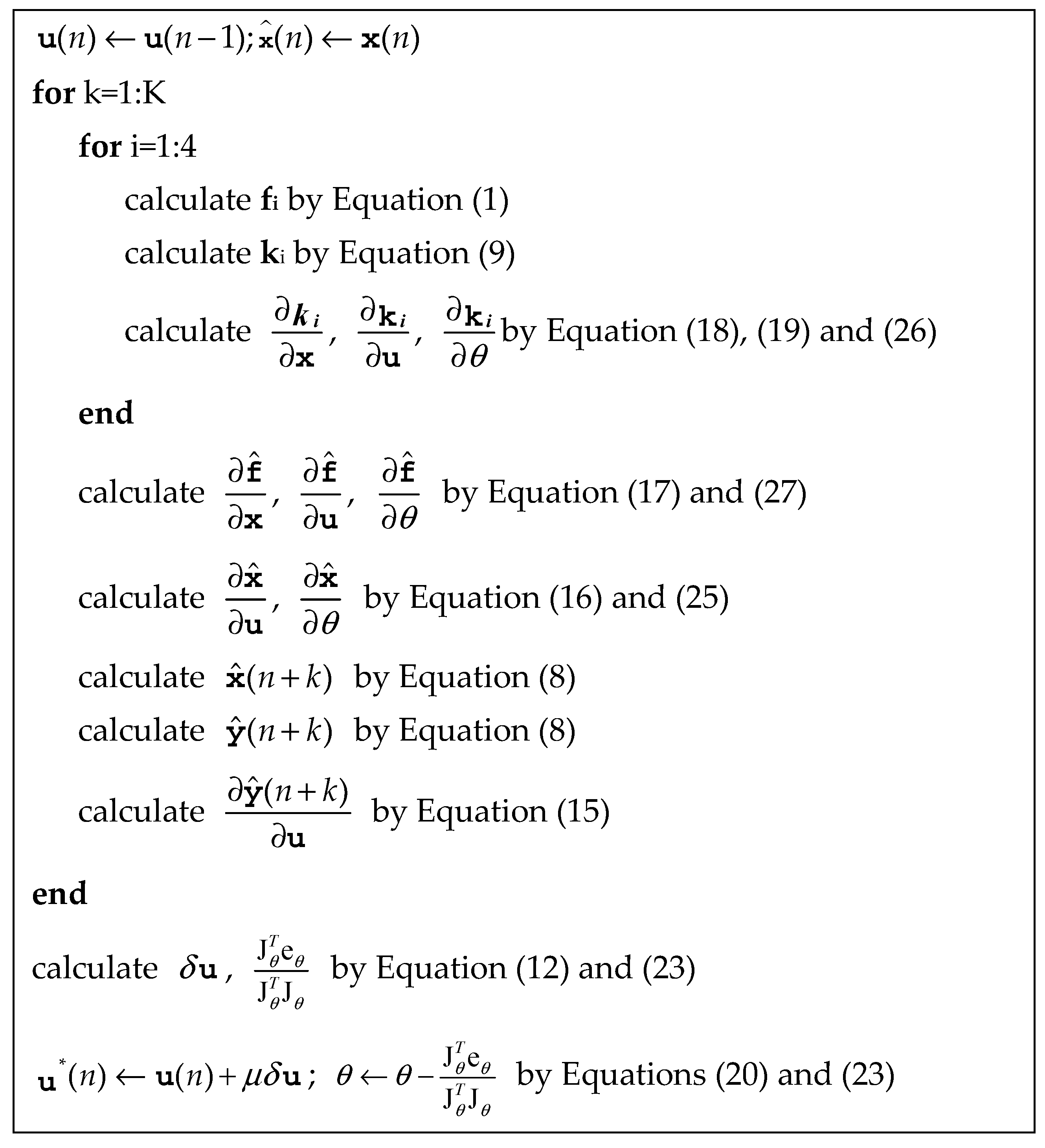

In this study, on the other hand, a novel control mechanism, RKMPC has been used for speed control of PMSM, where the current constraint

and the voltage constraint

of PMSM are combined and both current and voltage control of the system are controlled in a single loop. Also,

id current is kept at zero for no attenuation in the field. Furthermore, the RKMPC method has been utilized for the adaptation of the speed of the motor under load variations via RKMPC-based online parameter estimation. RKMPC calculates future predictions and derivatives in each sampling period and minimizes the cost function. RKMPC method increases the computation burden while doing all these operations. Therefore, dSPACE DS1104 is used to make the calculations very fast in the PMSM speed control with RKMPC. The innovation of this study has been carried out via DS1104 to realize a PMSM speed control with nonlinear dynamics, the recently intended RKMPC method [

18].

In traditional MPC, error minimization between reference and model prediction is essential and modulation is updated. In the RKMPC proposed in this study, modulation is not updated until it produces a control sign that will provide error optimization. Therefore, there may be a difference between the two when the controller is activated rather than the calculation load. In this respect, RKMPC is more stable, but it is an algorithm that is activated later for reference points that are far from reference. Although this seems to be a disadvantage, every control sign produced does not apply to the system and produces the optimum control sign that will provide more stable results. Instead of applying the control signal obtained in traditional MPC directly to the system, an optimization algorithm that will minimize the error is aimed. Thus, the most important motivation of this study is that the control sign obtained at the end of each calculation should be searched for the optimum control sign that will make the motor behavior more stable instead of driving the motor.

The paper is organized as follows: in

Section 2, the mathematical model of PMSM is given. The RKMPC-based control and parameter estimation mechanism are introduced in

Section 3. The details of the real-time implementation of the application are given in

Section 4.

Section 5 includes the experimental results, and the paper concludes with the conclusions and future work.

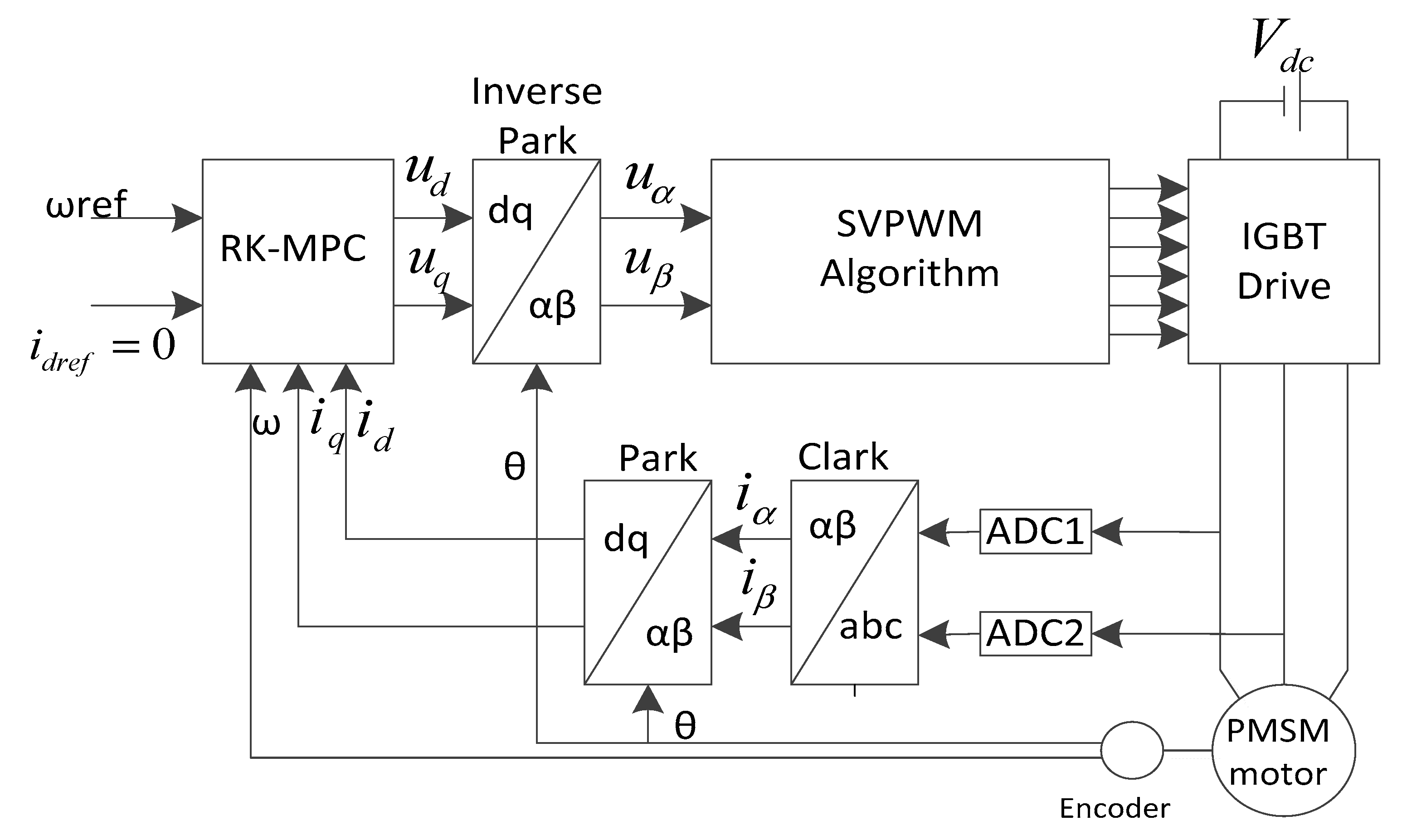

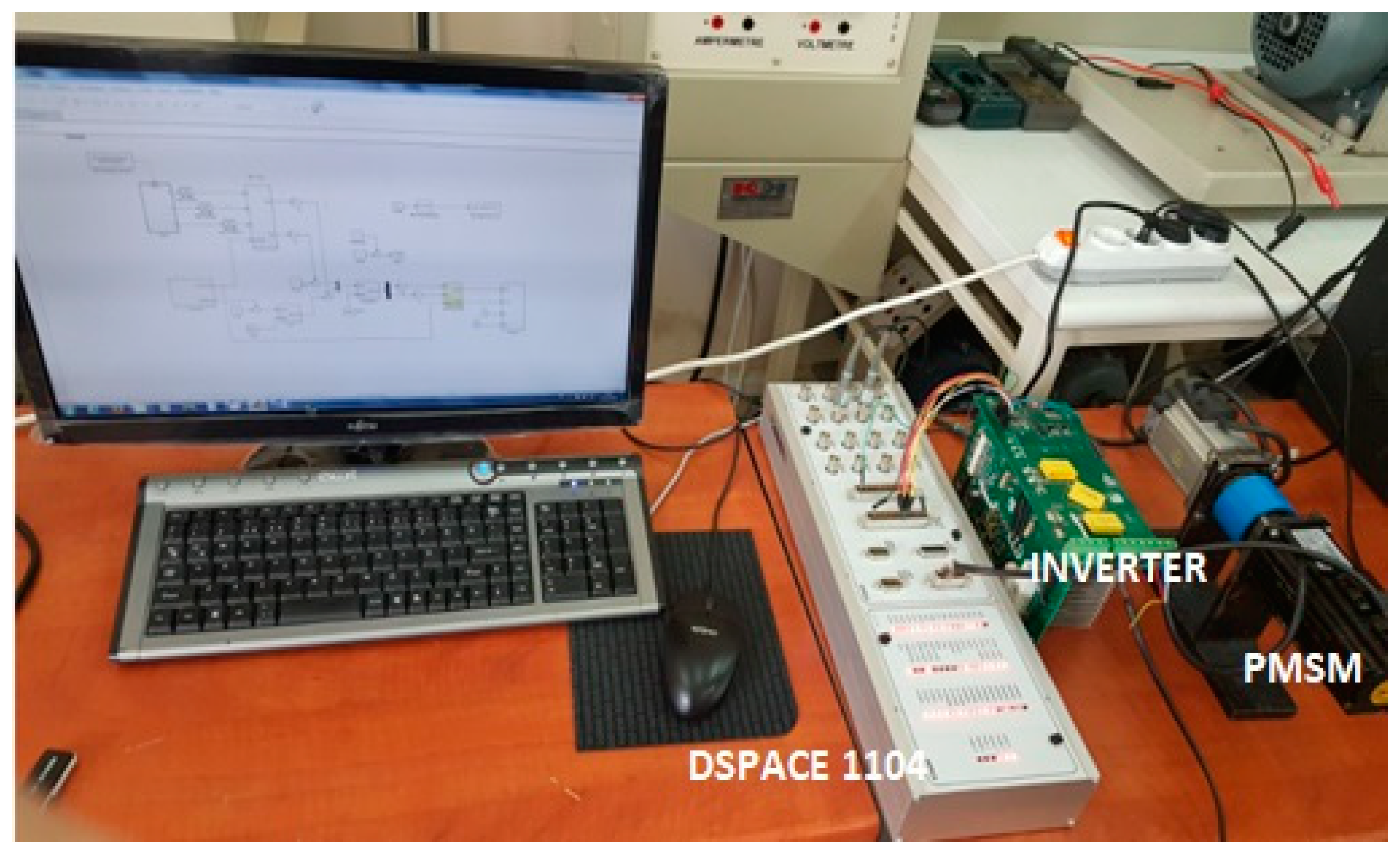

4. Real-Time Application

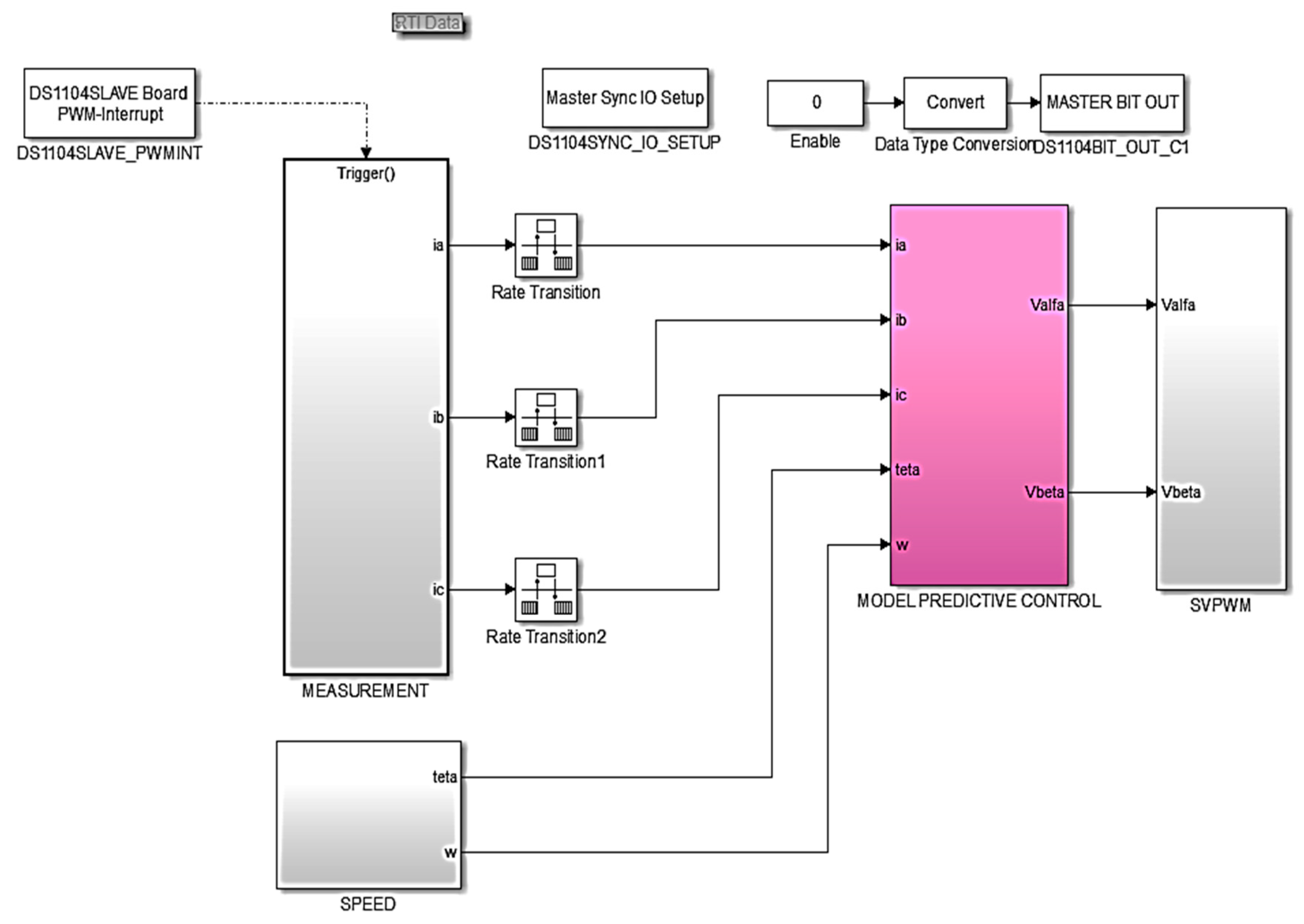

In order to test the RKMPC mechanism on the PMSM system, an experimental setup has been established, which can be seen in

Figure 4. The setup is composed of a dSPACE DS1104 ACE Kit, a PMSM, a speed sensor, and a IGBT inverter. Moreover, another PMSM generator is coupled as the load.

The dSPACE 1104 board is a powerful tool for rapid control applications, which consists of a master processor PowerPC603 with speed of 250 MHz, 64-bit floating-point processor, and a slave-DSP subsystem based on the Texas Instruments TMS320F240 DSP microcontroller 20 MHz. The RKMPC algorithm has been implemented on the main processor and the slave unit has been dedicated to the SVPWM signals generation and to the management of the digital I/O signals.

As can be seen in

Figure 5, a real-time overall MATLAB/Simulink block is developed to use the dSPACE1104 board in the control loop, where voltages and currents are obtained in the measurement block, while speed and position information are obtained in the speed block. The RKMPC algorithm is implemented in the MPC block. PWM signals are obtained in the SVPWM block at the 5 kHz constant sampling frequency.

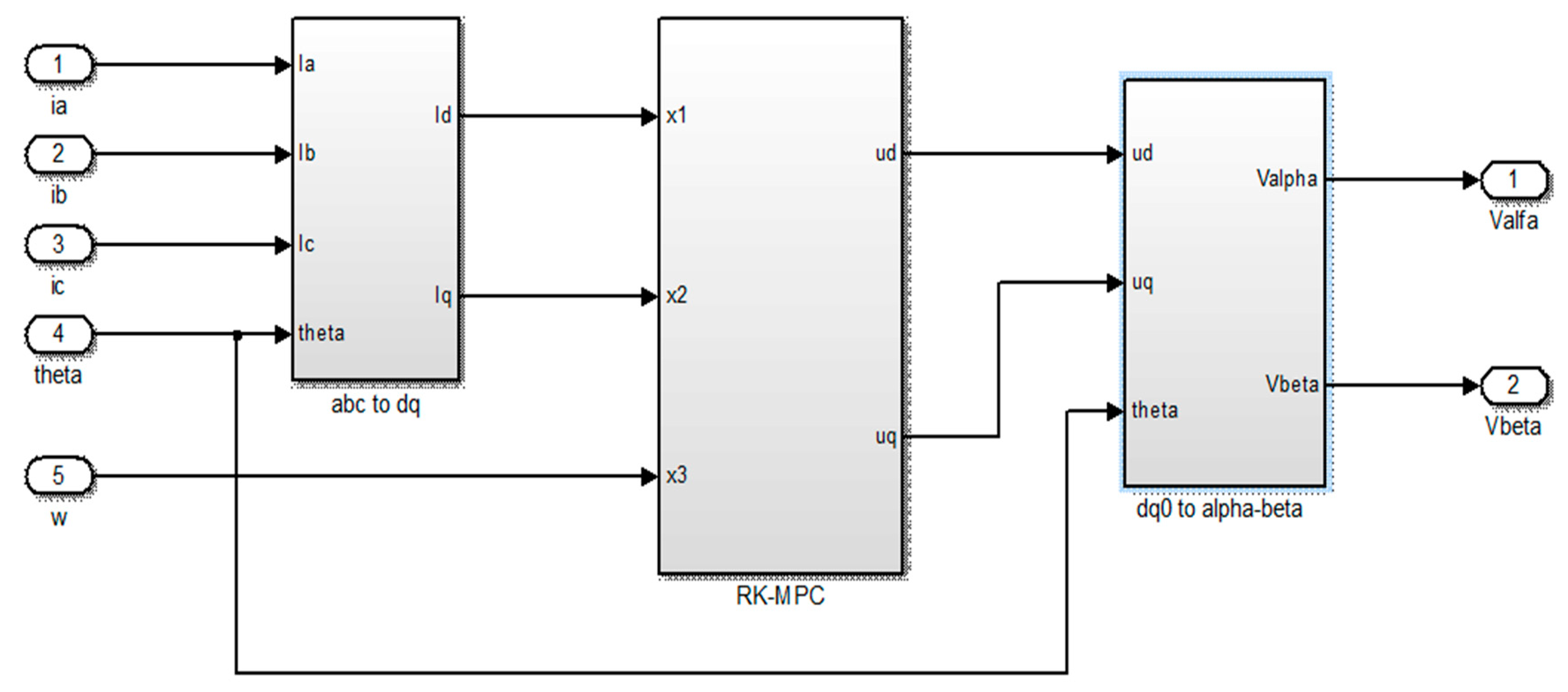

Model predictive control block is shown in

Figure 6. In this block, Clark transform (a, b, c → α, β) and then Park transform (α, β → d, q) are also made. All algorithms are implemented in the RKMPC block.

The parameter values of the used PMSM driver are tabulated in

Table 1.

5. Experimental Results and Comparisons

In order show the efficiency of the RKMPC method, it has been tested in different operating conditions. In the first case, PMSM has no load, while in the second case PMSM is loaded.

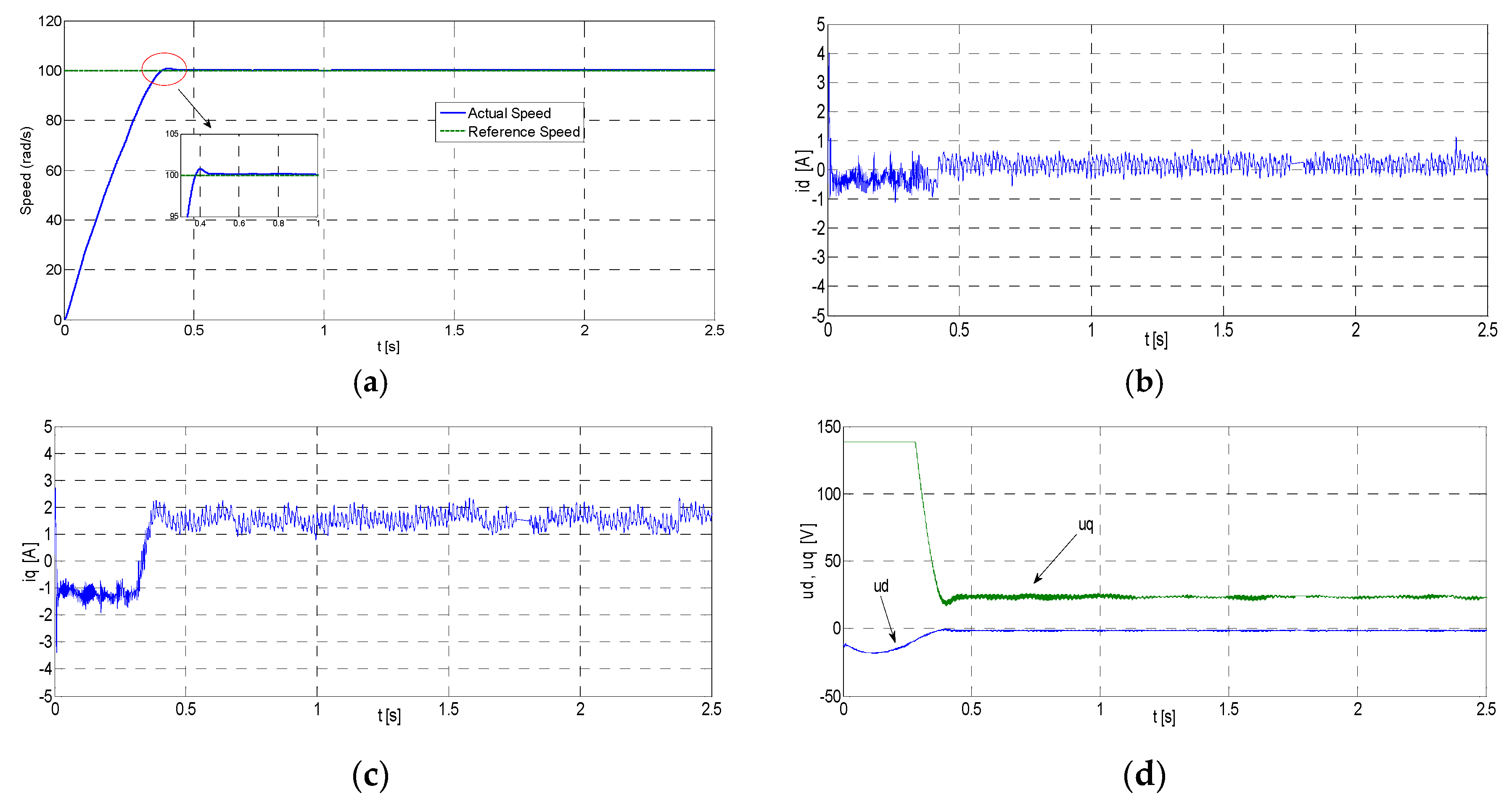

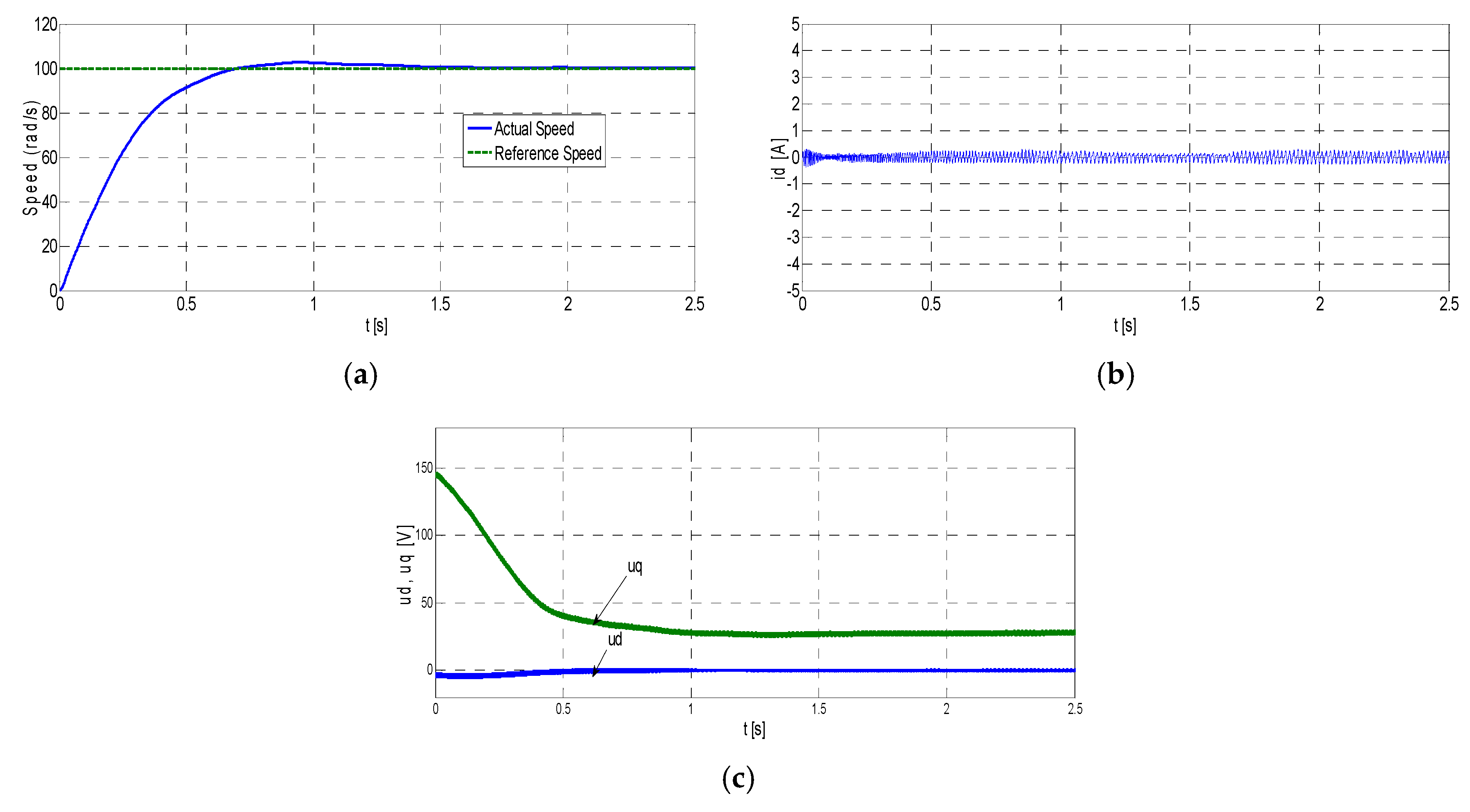

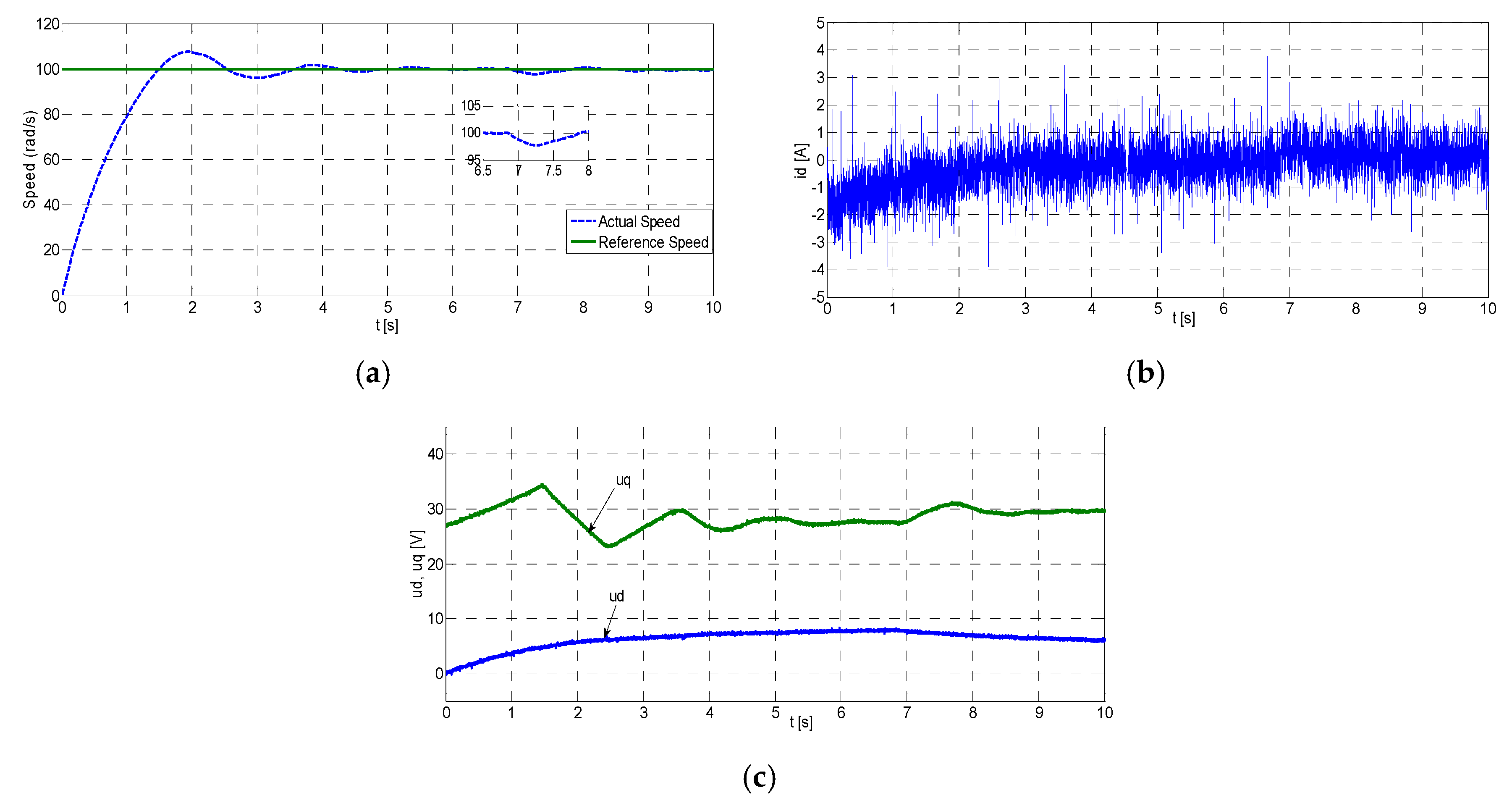

Figure 7 shows the experimental results for RKMPC, where

,

, and

of PMSM are obtained under the nominal conditions for 100 rad/s reference speed without load, respectively. As can be seen from

Figure 7, outputs of the system rise to the desired values very fast and then follow the reference trajectories accurately with zero steady state errors. Furthermore, RKMPC has been compared to a conventional PI controller, the parameters of which are tuned by trial-and-error.

Figure 8 shows the experimental results for PI, where

,

and

of PMSM are obtained under the nominal conditions for 100 rad/s reference speed without load, respectively.

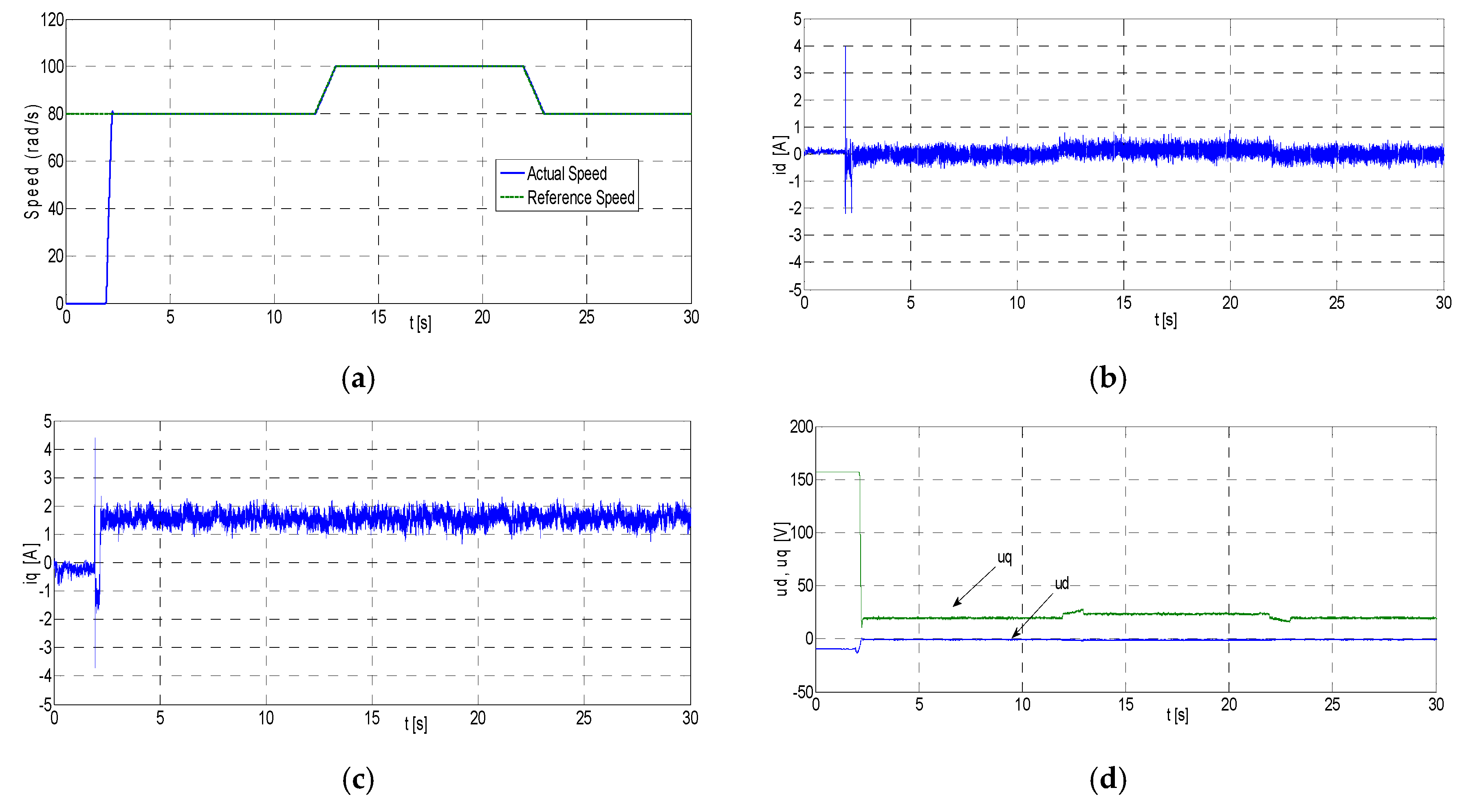

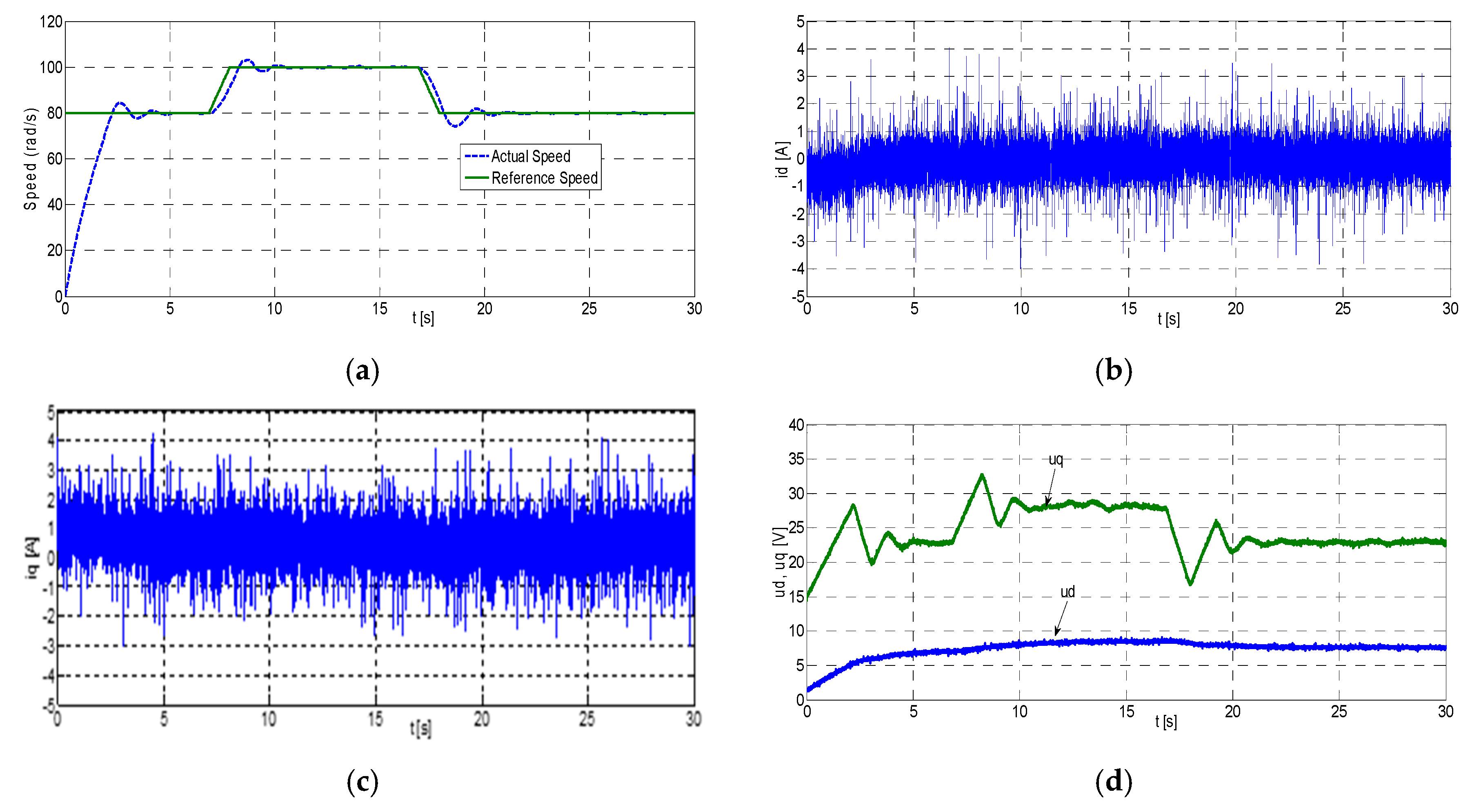

Afterwards, tests are repeated under the same conditions except for the reference signal is stepwise, i.e., it is initially set to 80 rad/s and then set to 100 rad/s for 10 s, then set back to 80 rad/s.

Figure 9 shows the experimental results for RKMPC, where

,

and

of PMSM are obtained under the nominal conditions for the stepwise reference speed without load, respectively. As can be seen from the figure, outputs of the system rise to the desired values very fast and then follow the reference trajectories accurately with zero steady state errors.

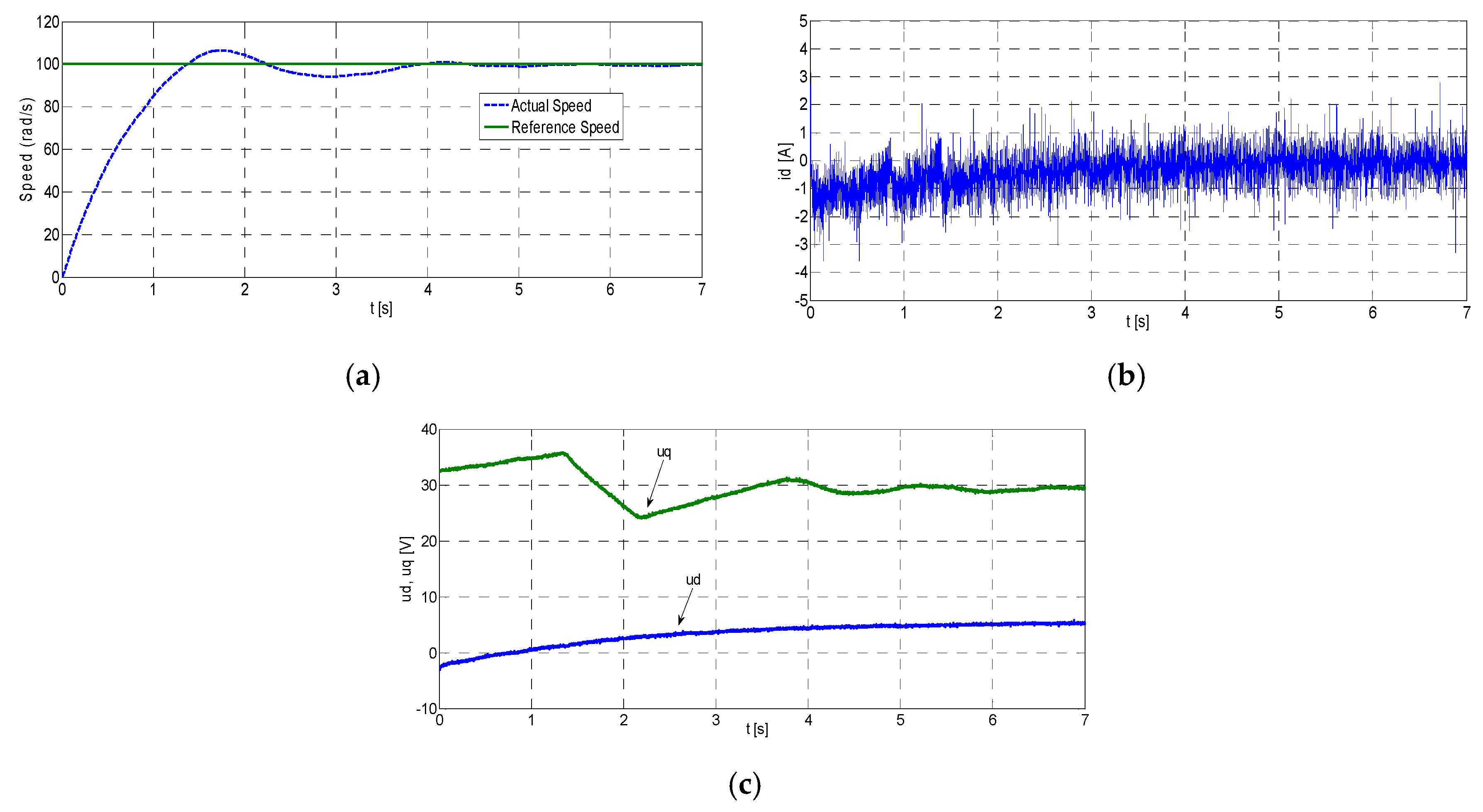

Figure 10 shows the experimental results for PI, where

,

, and

of PMSM are obtained under the nominal conditions for the stepwise reference speed without load, respectively.

Afterwards, the tests are repeated for another operating condition where PMSM is loaded with a load of 70%. The results for the constant reference at 100 rad/s have been shown in

Figure 11, where load is estimated by the RK model-based parameter estimation algorithm, thereby making RKMPC adaptive to the load changes.

Figure 11 shows the experimental results for RKMPC, where

,

, and

of PMSM are obtained under the nominal conditions for 100 rad/s reference speed with load, respectively.

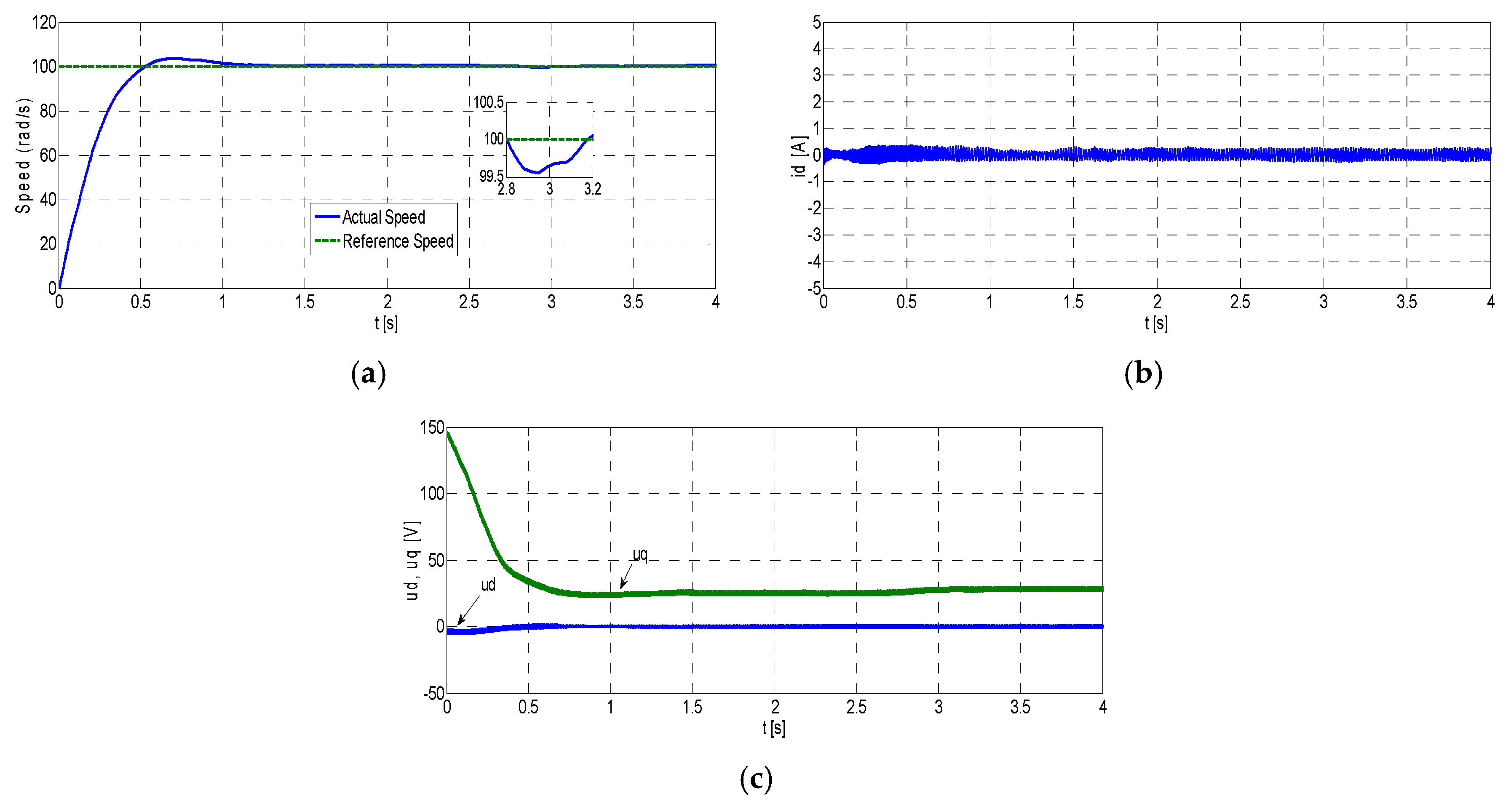

Figure 12 shows the experimental results for PI, where

,

and

of PMSM are obtained under the nominal conditions for 100 rad/s reference speed with unknown load, respectively.

Finally, the experimental setup is started without load and the control mechanism forced PMSM to follow the constant speed reference at 100 rad/s. Afterwards, at a specific time at

s, PMSM is loaded abruptly to 70% load to check the ability of RKMPC compensating the abrupt load disturbances. As can be seen from

Figure 13, RKMPC adapts to the abrupt load changes so that the output of the system follows the reference trajectory very rapidly.

Figure 14 shows the experimental results for PI, where

,

and

of PMSM are obtained under the nominal conditions for abrupt load disturbance, respectively.

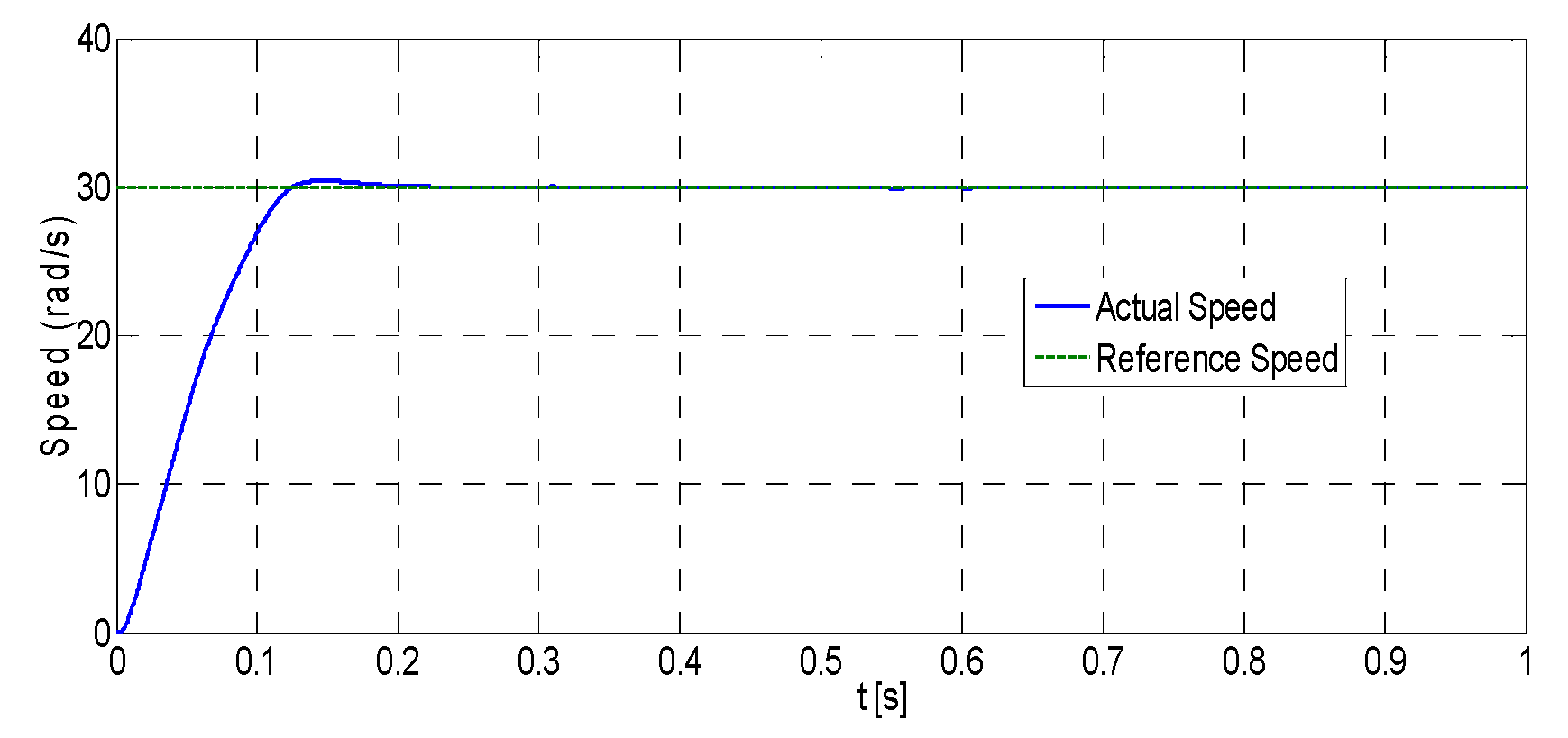

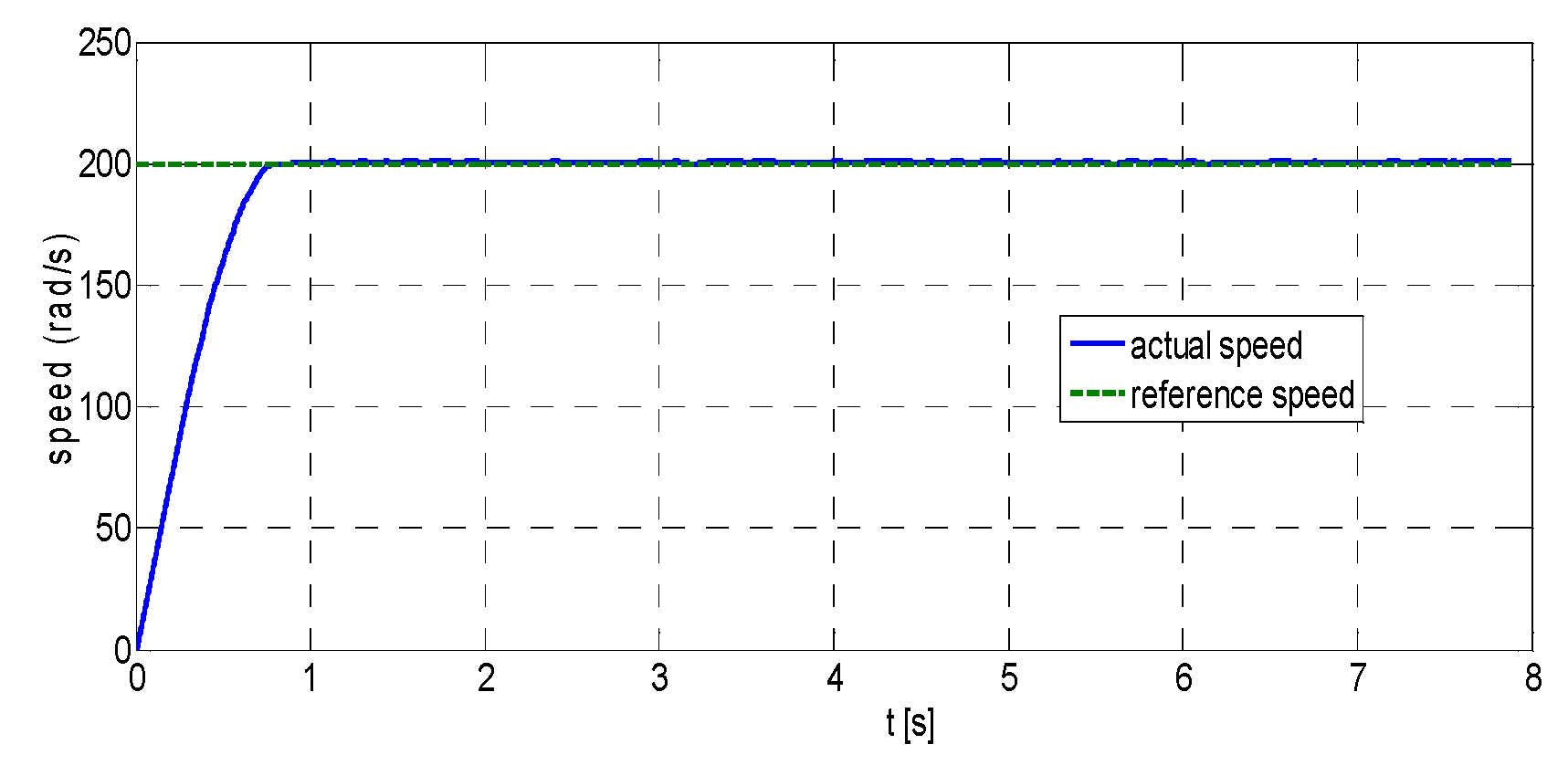

Moreover, RKMPC is evaluated at 30 rad/s and 200 rad/s reference speed values.

Figure 15 shows the results for the 30 rad/s reference speed under the unloaded condition. Similarly,

Figure 16 shows the results for the 200 rad/s reference speed under the unloaded condition.

In this study, under the same conditions, both RKMPC and traditional PI control methods were applied in loaded, unloaded, and abrupt load conditions. When both experimental results were compared, it was seen that RKMPC quickly reached the reference speed with almost zero excess. In conventional PI, it was seen that it reached the reference speed in a longer time and with a certain excess.

The same measuring circuits were used on the ds1104 board for the same parameters both in the use of the PI controller and in the application of the proposed RKMPC model. Therefore, measurement and evaluation units are the same in terms of measured variables. These noises are inevitable unless adaptive tuning of PI parameters is performed in real time.

6. Conclusions and Future Work

In this study, a recently proposed nonlinear control mechanism, which is referred to as the RKMPC method that combines the well-known numerical integration method Runge Kutta with the model predictive control framework, has been employed for control and load estimation of a commercial PMSM, where the constraints on the voltage and current of the system are taken into account. In the experiments, id current kept at zero for no attenuation in the field. It has been shown in the study that RKMPC mechanism can also estimate the load changes and unknown load disturbances to eliminate their undesired effects for a desirable control accuracy. RKMPC algorithm has been implemented on a dSPACE 1104 board. Then, its performance has been tested on a 0.4 kW PMSM motor experimentally for different conditions and compared to the conventional PI method. The tests have shown the efficiency of RKMPC for PMSMs, where RKMPC has provided satisfactory control performance even under load disturbances.

In future work, a new study using adaptive error method and adaptive hysteresis flux band needs to be done. In this way, for the big error values at the beginning, it will be ensured that the algorithm left in the loop to set the control condition to its optimum value will work with an increasingly adaptive error band. Thus, the proposed control algorithm will be enabled to control the system in closed loop from the beginning.