Pore-Fractures of Coalbed Methane Reservoir Restricted by Coal Facies in Sangjiang-Muling Coal-Bearing Basins, Northeast China

Abstract

:1. Introduction

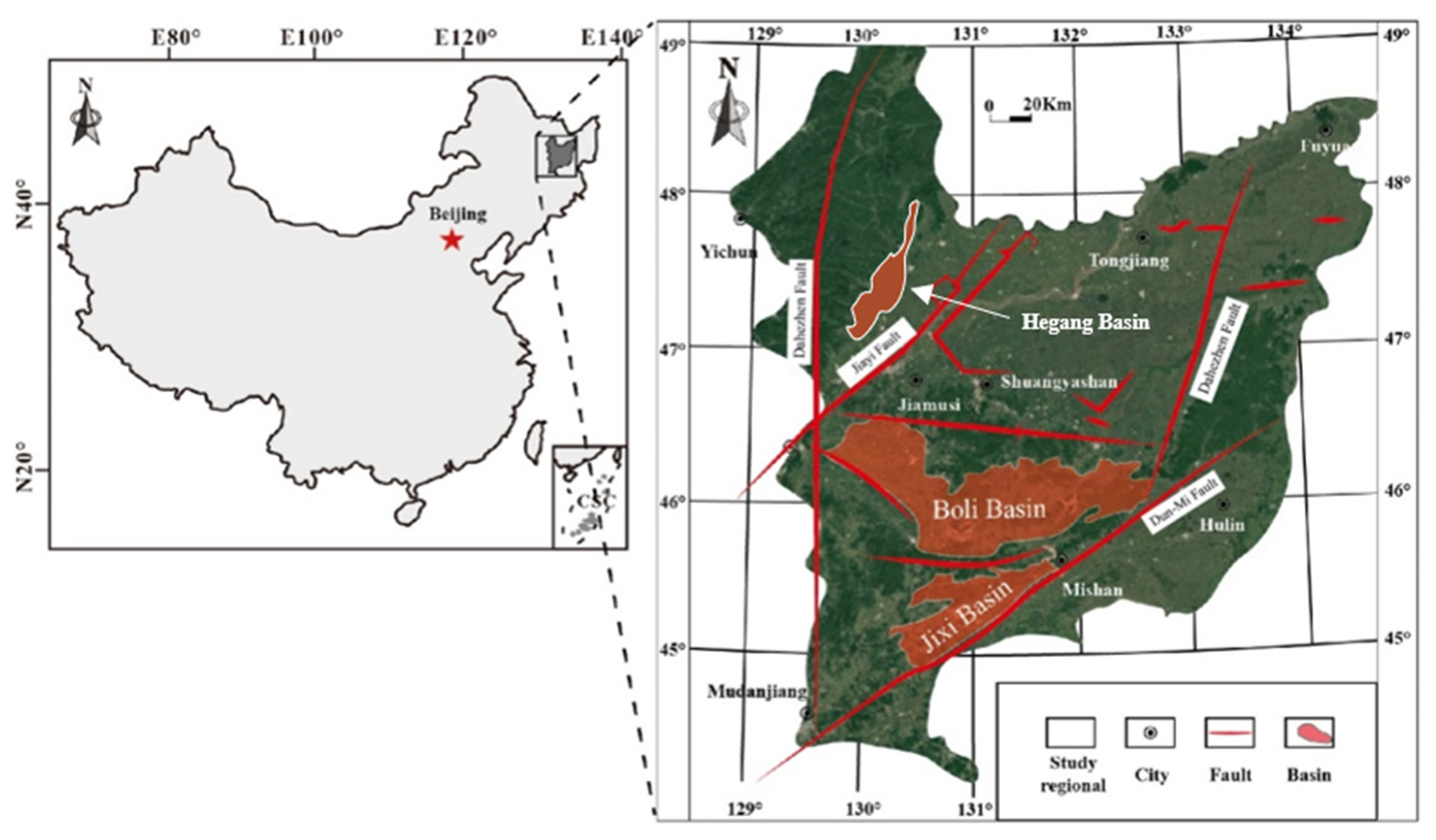

2. Geologic Settings

3. Sampling

4. Experiments and Methods

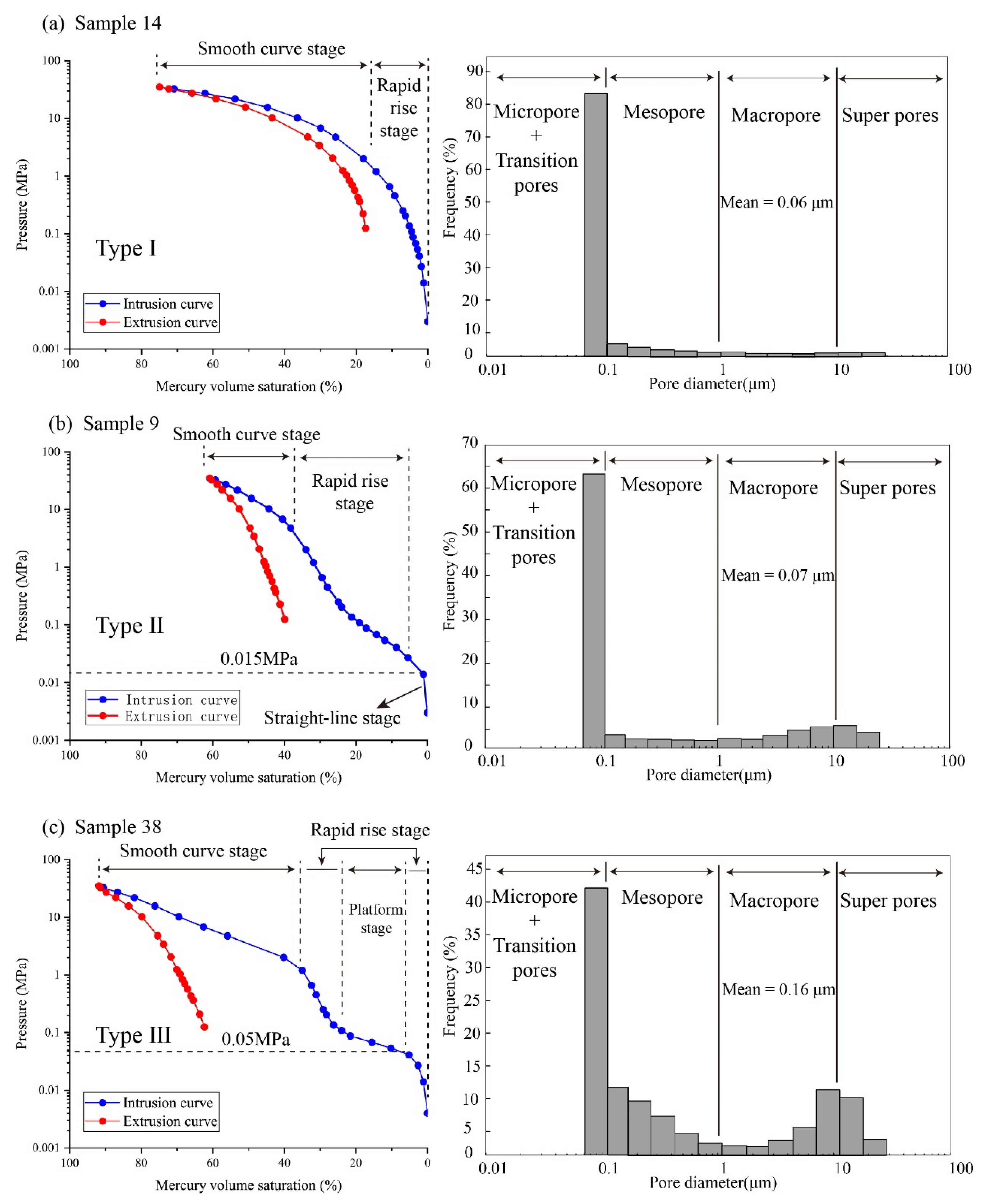

4.1. Mercury Intrusion Porosimetry

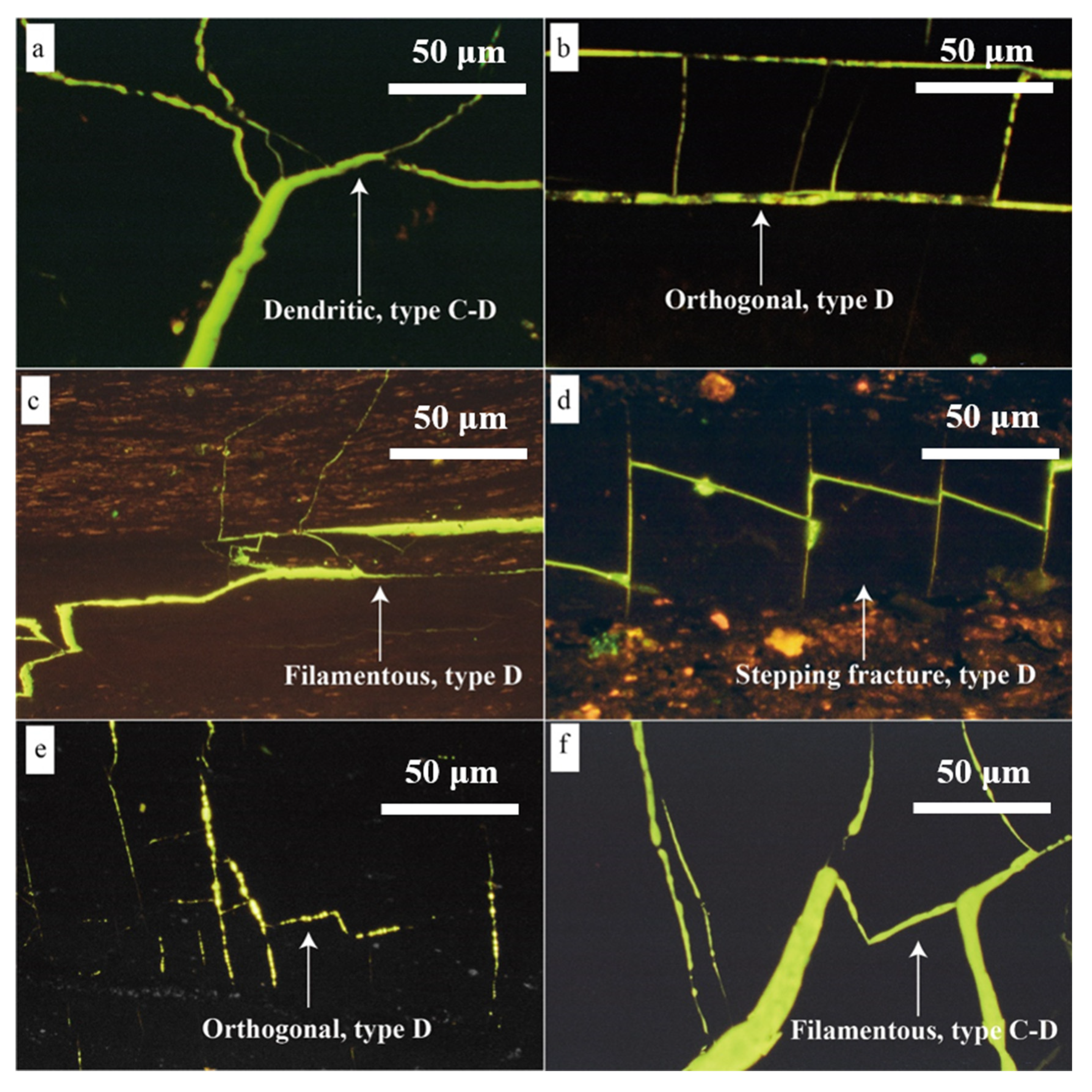

4.2. Microfractures Statistics by Optical Microscope

4.3. Coal Facies Identification

5. Results

5.1. Standard Coal Qualty Parameters

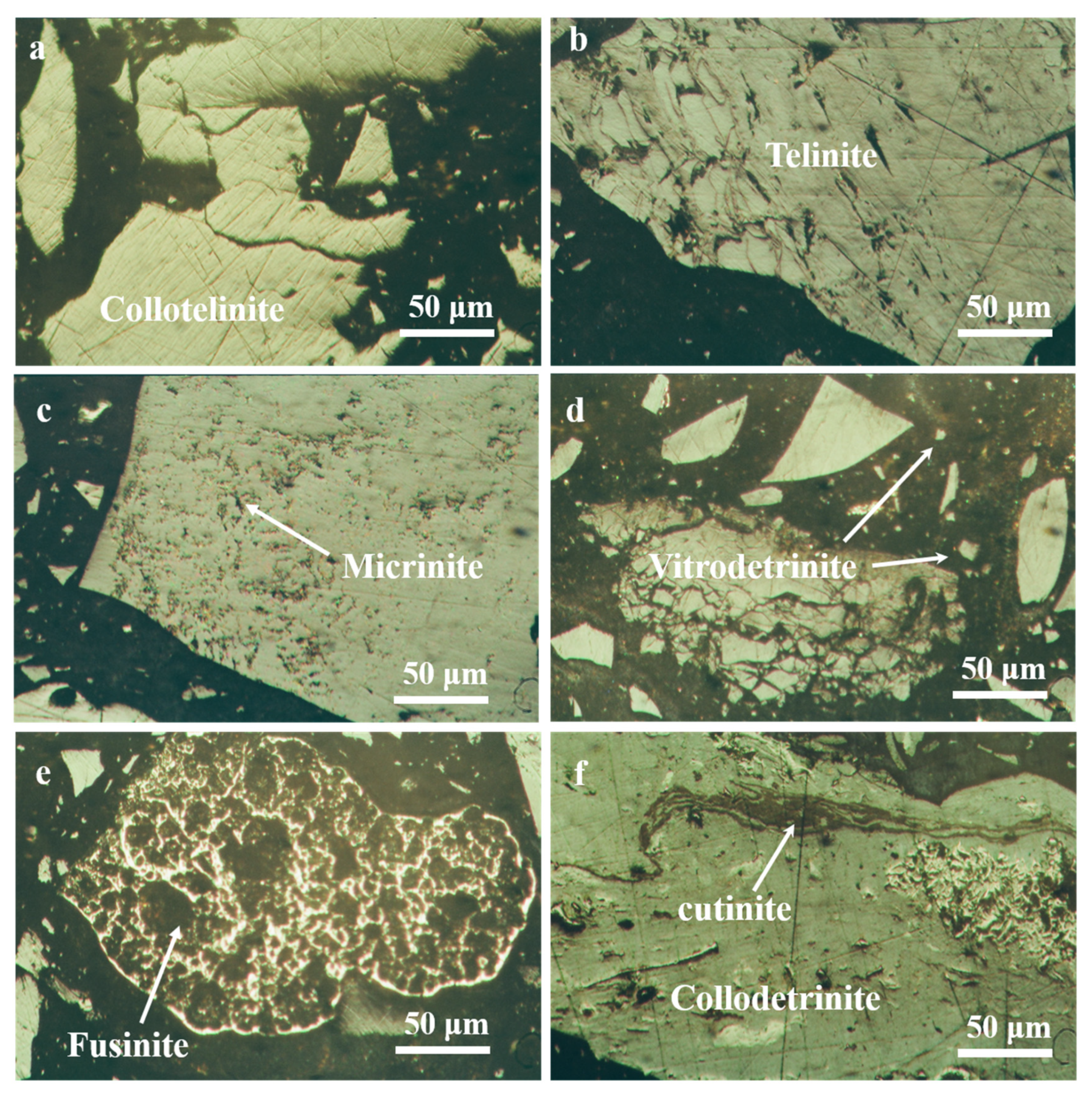

5.2. Maceral Compositions

5.3. Pore Characteristics

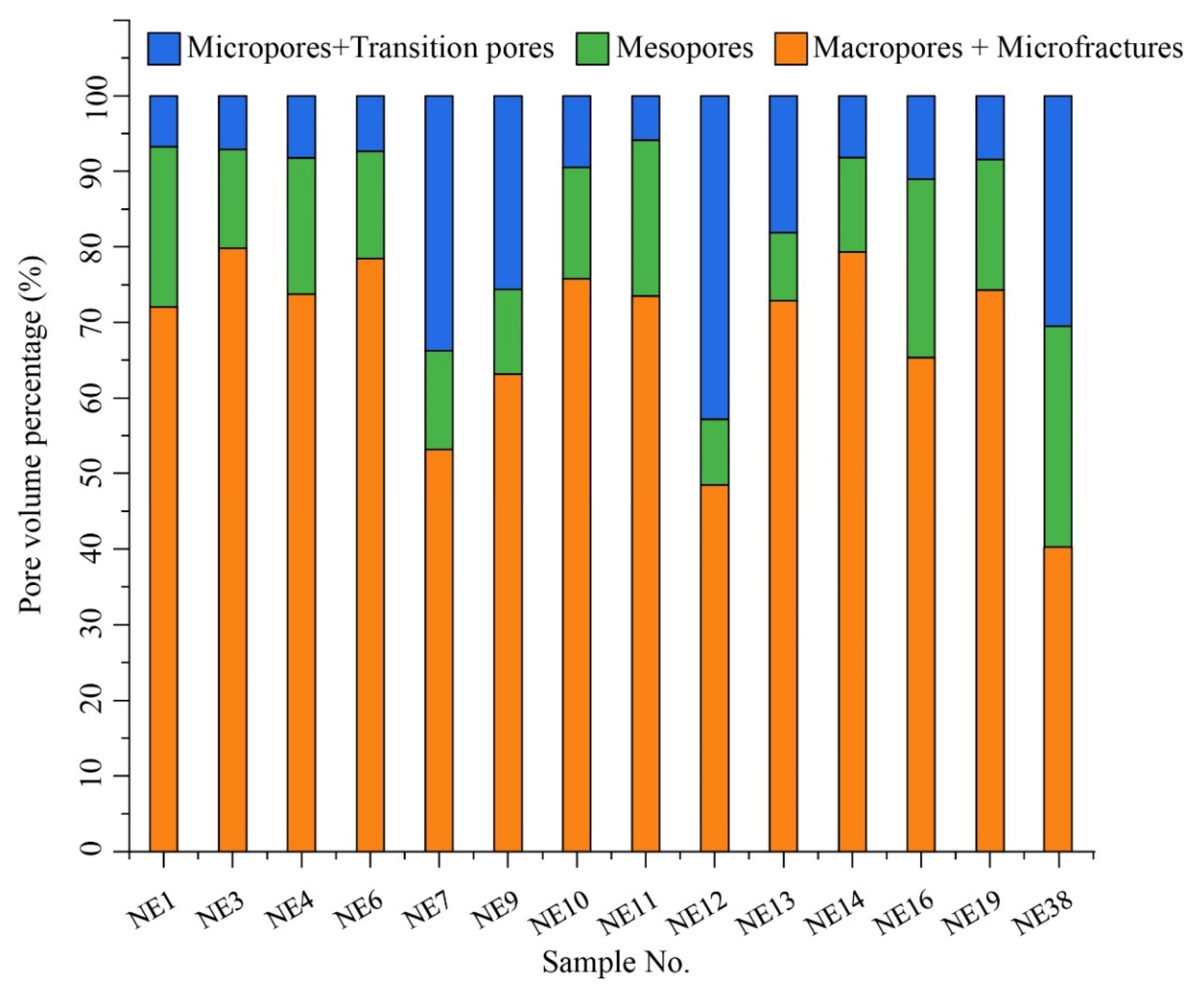

5.4. Microfracture Characteristics

6. Discussions

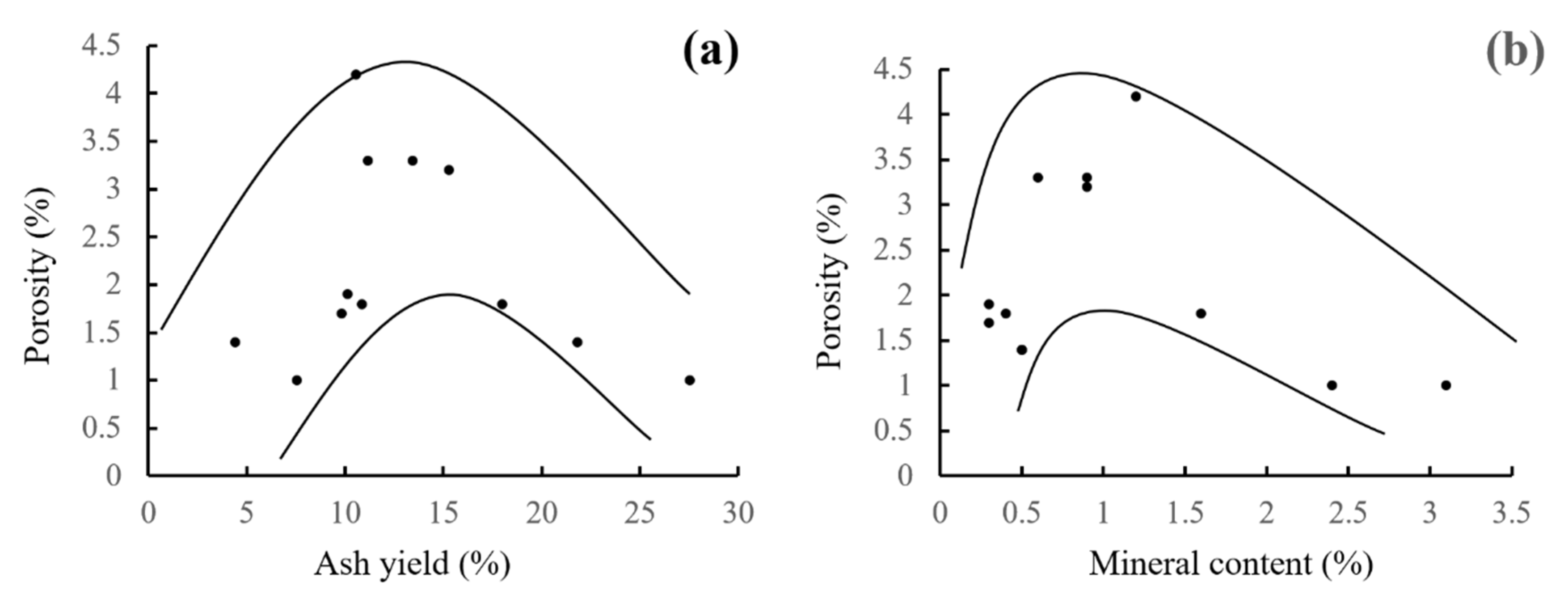

6.1. Effects of Coal Facies on Pore-Fracture Performance

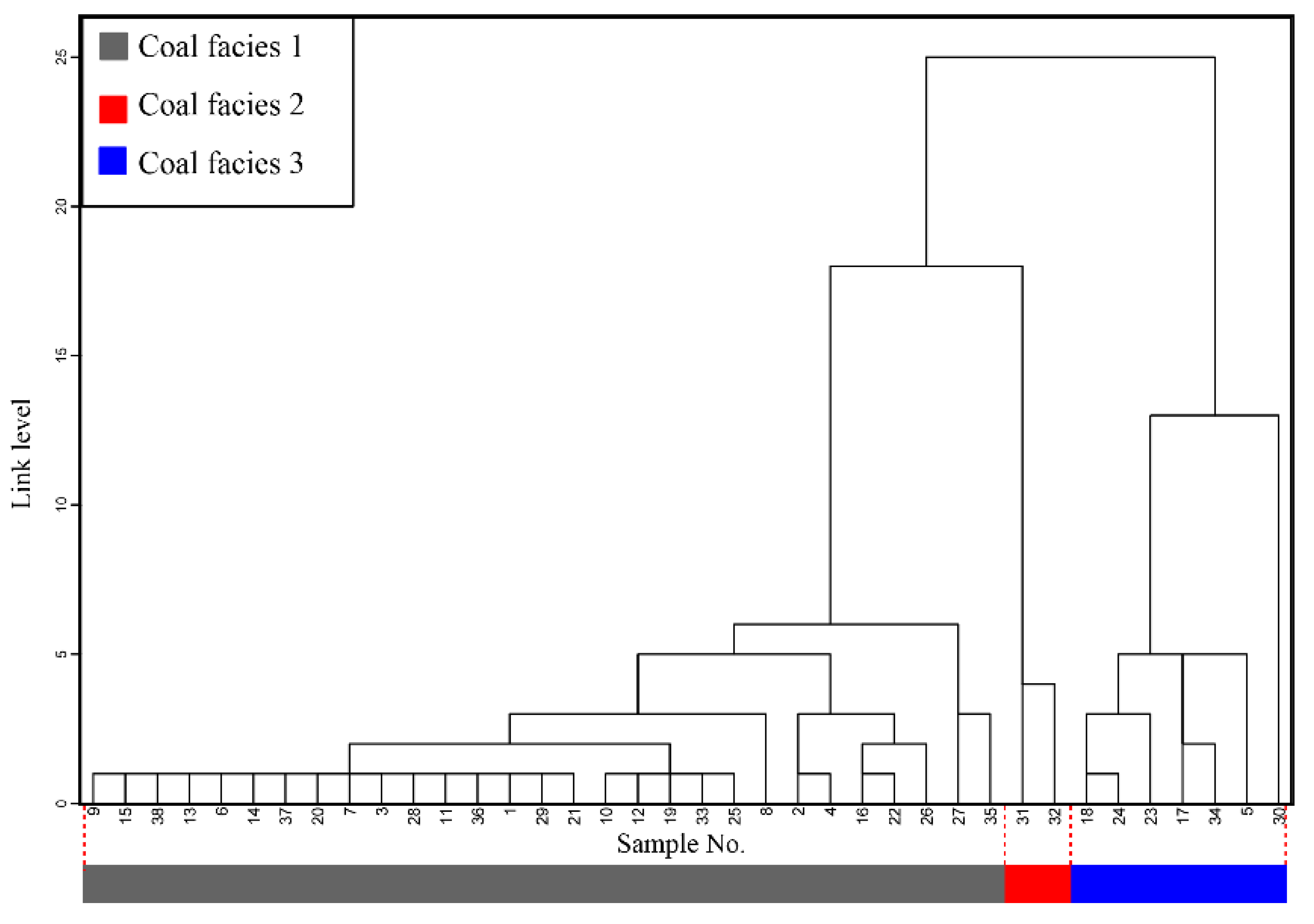

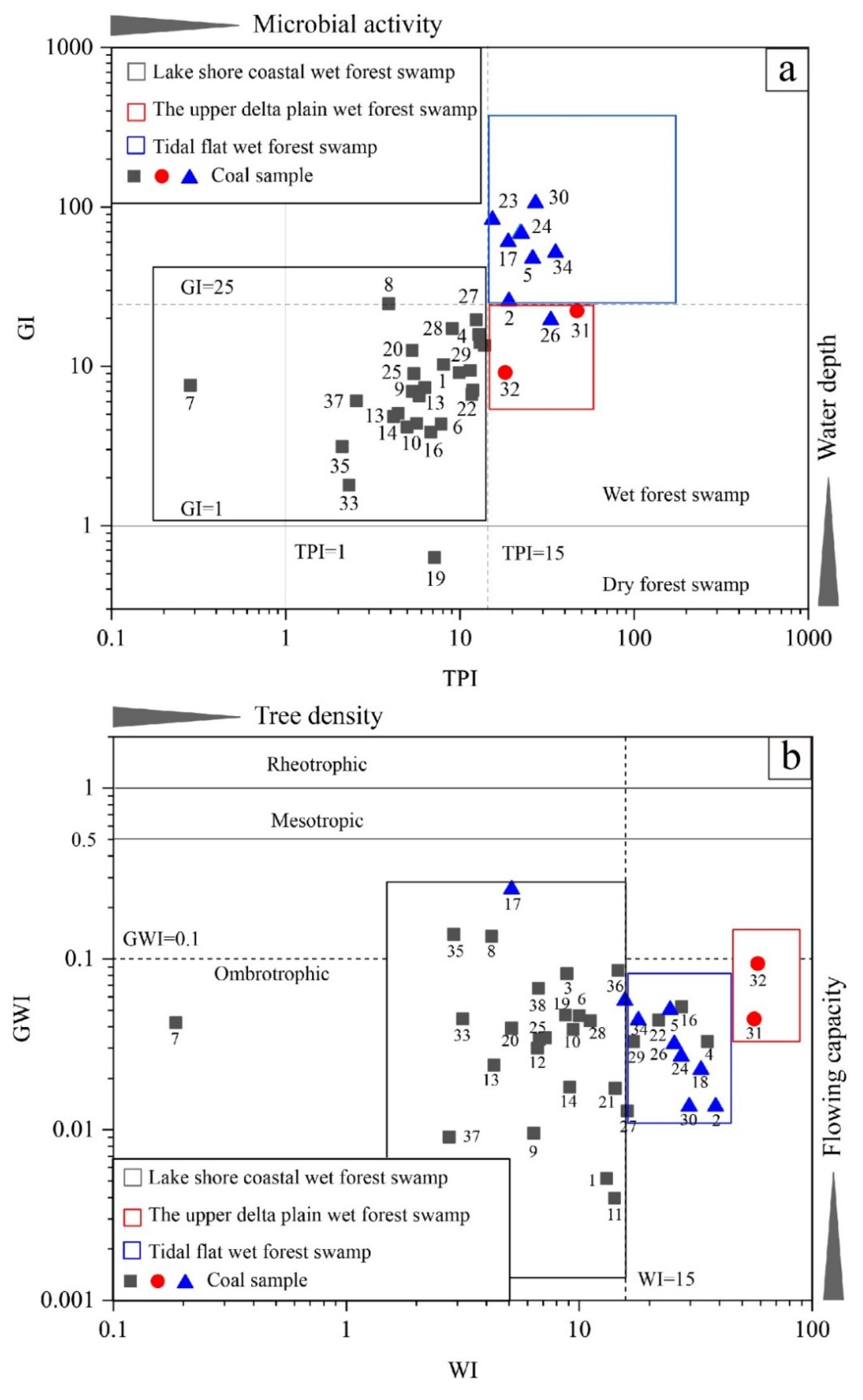

6.1.1. Characteristics of Coal Facies

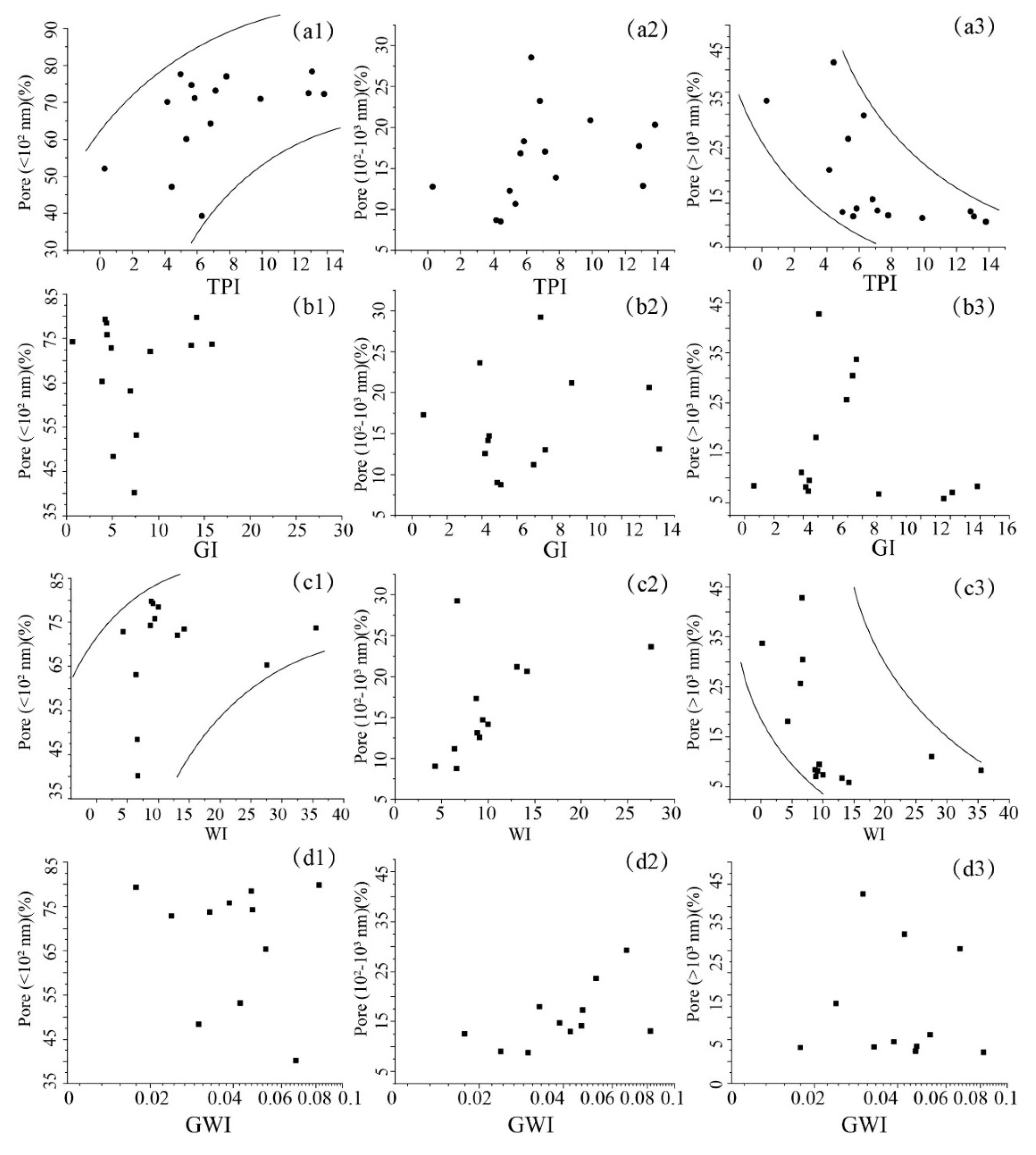

6.1.2. Effects of Coal Facies on Pore Development

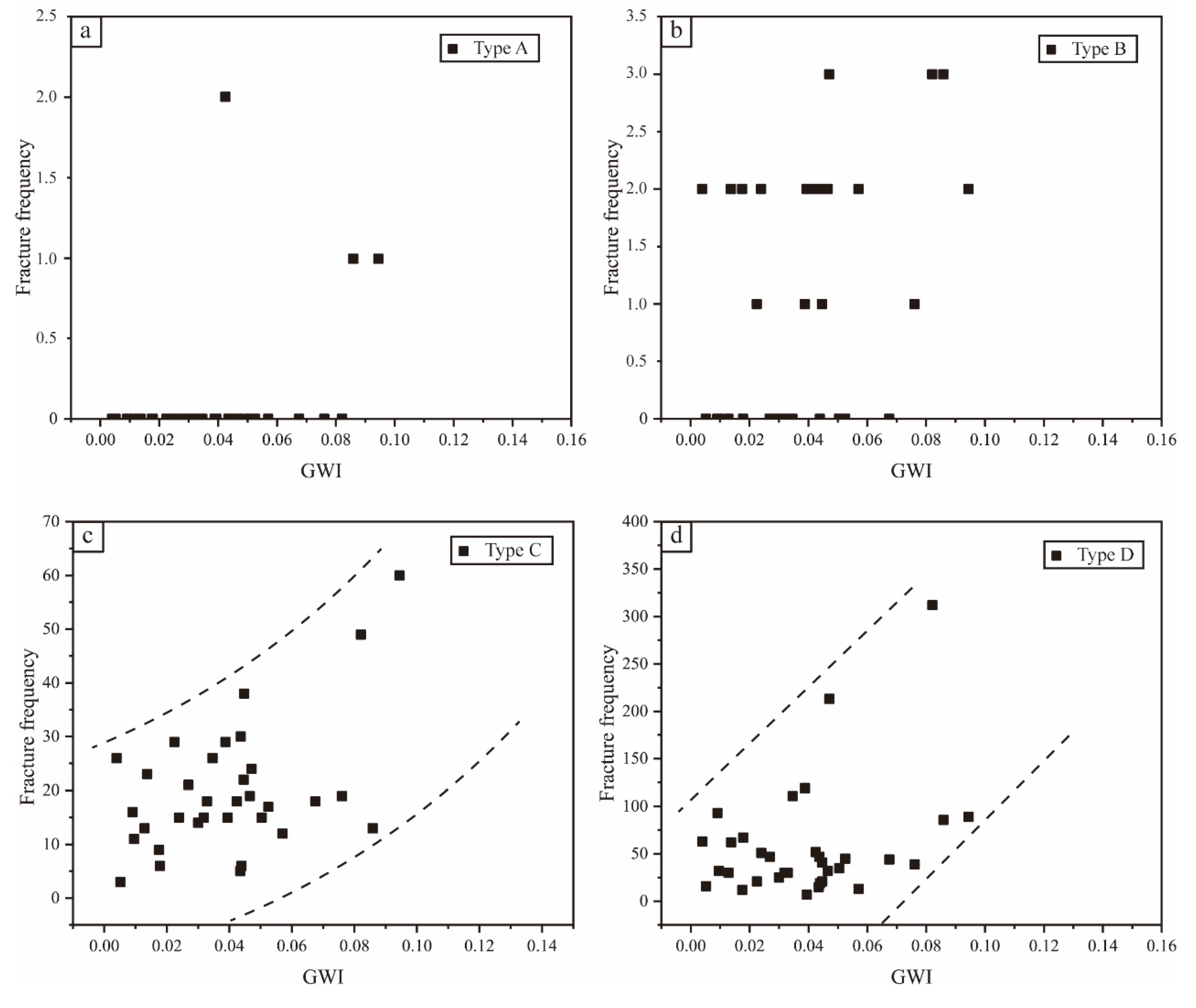

6.1.3. The Effects of Coal Facies on Fracture

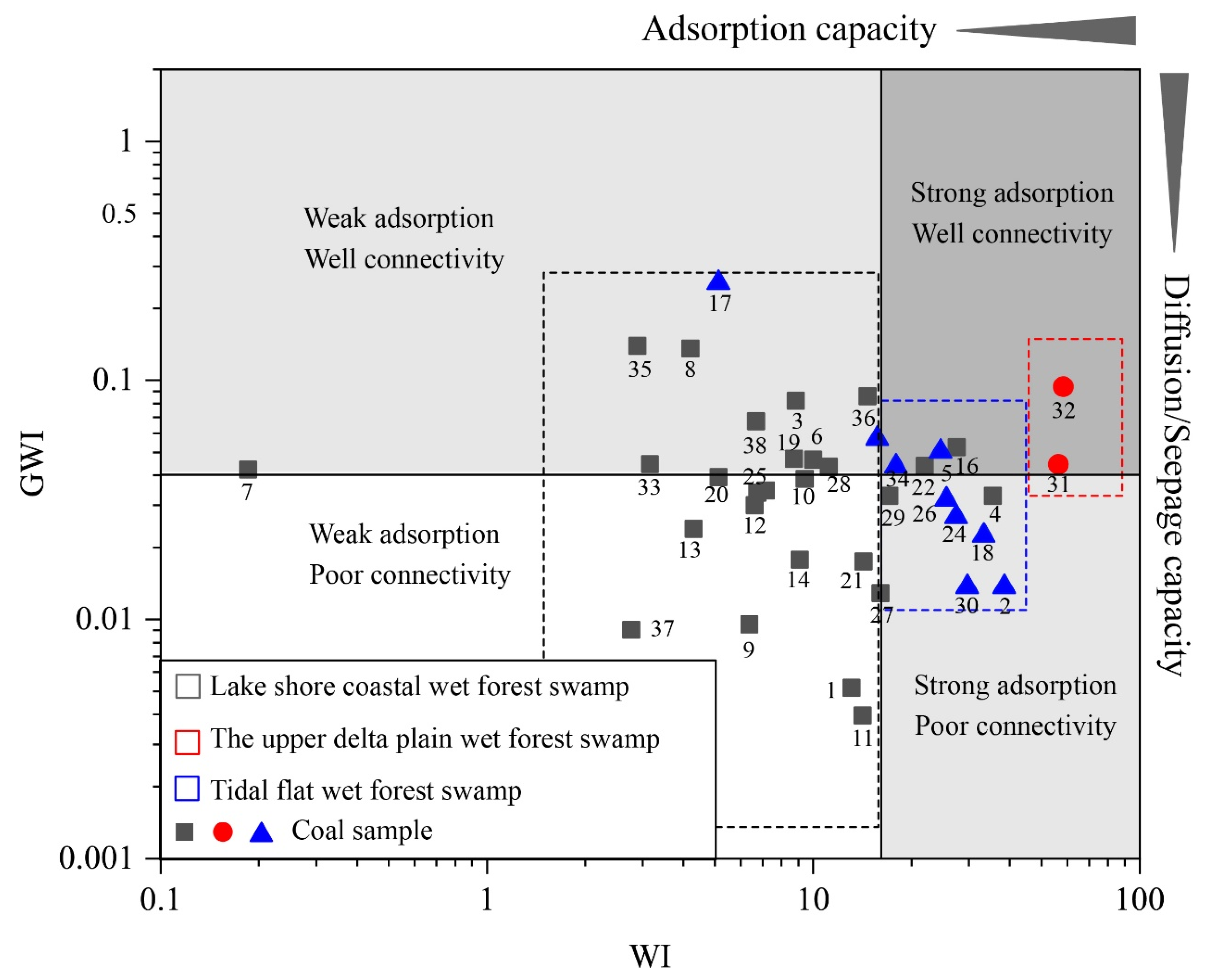

6.2. Prediction of CBM Reservoir Favorable Areas with Coal Facies

- strong adsorption, well connectivity area,

- weak adsorption, well connectivity area,

- weak adsorption, poor connectivity area, and

- strong adsorption, poor connectivity area, as shown in Figure 11.

7. Conclusions

- (1)

- Micropores and transition (<100 nm) pores are most abundant and display the best developed for all coal samples, with an average percentage of 68.25%. Three types of mercury injection curve were classified based on MIP experiment, and type Ⅱ is good for CBM flow in the coal reservoir due to the high porosity of macropores and well connectivity of pores in coal reservoir.

- (2)

- Type D microfractures are most abundant and display the best-developed microfractures, which account for more than 70% of the total microfractures. The hydration of minerals has little effect on type A and type B fractures, whereas it has great effect on type C and type D fractures developed in coal.

- (3)

- Three types of coal facies were identified based on the Q-cluster analysis, GI-TPI, and GWI-WI diagrams, including lake shore coastal wet forest swamp, the upper delta plain wet forest swamp, tidal flat wet forest swamp, respectively. There is positive correction between TPI, WI, and micropores, a negative correlation between TPI, WI, and macropores/fractures.

- (4)

- The WI-GWI diagram could also be used to evaluate favorable areas in CBM reservoir based on the effects of WI, GWI on pore and fracture characteristics. The upper delta plain wet forest swamp is an optimization of favorable areas of the CBM reservoir, with strong adsorption and well connectivity of pores for Sangjiang-Muling coal-bearing basins.

Author Contributions

Funding

Conflicts of Interest

References

- Yao, Y.B.; Liu, D.M.; Liu, J.G.; Xie, S.B. Assessing the Water Migration and Permeability of Large Intact Bituminous and Anthracite Coals Using NMR Relaxation Spectrometry. Trans. Porous Med. 2015, 107, 527–542. [Google Scholar] [CrossRef]

- Scott, A.R. Hydrogeologic factors affecting gas content distribution in coal beds. Int. J. Coal Geol. 2002, 50, 363–387. [Google Scholar] [CrossRef]

- Wang, B.; Sun, F.J.; Tang, D.Z.; Zhao, Y.; Song, Z.H.; Tao, Y. Hydrological control rule on coalbed methane enrichment and high yield in FZ Block of Qinshui Basin. Fuel 2015, 140, 568–577. [Google Scholar] [CrossRef]

- Li, Z.T.; Liu, D.M.; Cai, Y.D.; Ranjith, P.G.; Yao, Y.B. Multi-scale quantitative characterization of 3-D pore-fracture networks in bituminous and anthracite coals using FIB-SEM tomography and X-ray Μ-CT. Fuel 2017, 209, 43–53. [Google Scholar] [CrossRef]

- Pashin, J.C. Variable gas saturation in coalbed methane reservoirs of the Black Warrior Basin: Implications for exploration and production. Int. J. Coal Geol. 2010, 82, 135–146. [Google Scholar] [CrossRef]

- Cai, Y.D.; Liu, D.M.; Yao, Y.B.; Li, J.Q.; Qiu, Y.K. Geological controls on prediction of coalbed methane of No. 3 coal seam in Southern Qinshui Basin, North China. Int. J. Coal Geol. 2011, 88, 101–112. [Google Scholar] [CrossRef]

- Zhao, J.L.; Tang, D.Z.; Xu, H.; Lv, Y.M.; Tao, S. High production indexes and the key factors in coalbed methane production: A case in the Hancheng block, southeastern Ordos Basin, China. J. Pet. Sci. Eng. 2015, 130, 55–67. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Pan, J.N.; Hou, Q.L.; Yu, B.S.; Li, M.; Niu, Q.H. Anisotropic characteristics of low-rank coal fractures in the Fukang mining area, China. Fuel 2018, 211, 182–193. [Google Scholar] [CrossRef]

- Ouyang, Z.Q.; Liu, D.M.; Cai, Y.D.; Yao, Y.B. Investigating the fractal characteristics of pore-fractures in bituminous coals and anthracites through fluid flow behavior. Energy Fuels 2016, 30, 10348–10357. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Mathews, J.P.; Pan, Z.; Elsworth, D.; Yao, Y.; Li, J.; Guo, X. Permeability evolution in fractured coal—Combining triaxial confinement with X-ray computed tomography, acoustic emission and ultrasonic techniques. Int. J. Coal Geol. 2014, 122, 91–104. [Google Scholar] [CrossRef]

- Hodot, B.B. Outburst of Coal and Coalbed Gas (Chinese Translation); China Coal Industry Press: Beijing, China, 1966; Volume 318. [Google Scholar]

- Cai, Y.D.; Liu, D.M.; Pan, Z.J.; Yao, Y.B.; Li, J.Q.; Qiu, Y.K. Pore structure and its impact on CH4 adsorption capacity and flow capability of bituminous and subbituminous coals from Northeast China. Fuel 2013, 103, 258–268. [Google Scholar] [CrossRef]

- Wang, H.C.; Fu, X.H.; Jian, K.; Li, T.; Luo, P.P. Changes in coal pore structure and permeability during N2 injection. J. Nat. Gas Sci. Eng. 2015, 27, 1234–1241. [Google Scholar] [CrossRef]

- Rodrigues, C.F.; Lemos De Sousa, M.J. The measurement of coal porosity with different gases. Int. J. Coal Geol. 2002, 48, 245–251. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Qin, X.J.; Shen, J.N.; Zhang, Z.Y.; Han, D.Y.; Jiang, C.H. Quantitative analysis of microscopic structure and gas seepage characteristics of low-rank coal based on CT three-dimensional reconstruction of CT images and fractal theory. Fuel 2019, 256, 115900. [Google Scholar] [CrossRef]

- Chalmers, G.R.L.; Ross, D.J.K.; Bustin, R.M. Geological controls on matrix permeability of Devonian Gas Shales in the Horn River and Liard basins, northeastern British Columbia, Canada. Int. J. Coal Geol. 2012, 103, 120–131. [Google Scholar] [CrossRef]

- Huang, B.X.; Liu, C.Y.; Fu, J.H.; Guan, H. Hydraulic fracturing after water pressure control blasting for increased fracturing. Int. J. Rock Mech. Min. Sci. 2011, 48, 976–983. [Google Scholar] [CrossRef]

- Cheng, W.; Jin, Y.; Chen, M. Reactivation mechanism of natural fractures by hydraulic fracturing in naturally fractured shale reservoirs. J. Nat. Gas Sci. Eng. 2015, 27, 1357–1365. [Google Scholar] [CrossRef]

- Wang, F.; Cheng, Y.P.; Lu, S.Q.; Jin, K.; Zhao, W. Influence of coalification on the pore characteristics of middle-high rank coal. Energy Fuels 2014, 28, 5729–5736. [Google Scholar] [CrossRef]

- Pan, J.N.; Zhu, H.T.; Hou, Q.L.; Wang, H.H.; Wang, S. Macromolecular and pore structures of Chinese tectonically deformed coal studied by atomic force microscopy. Fuel 2015, 139, 94–101. [Google Scholar] [CrossRef]

- Zhang, S.H.; Tang, S.H.; Tang, D.Z.; Pan, Z.J.; Yang, F. The characteristics of coal reservoir pores and coal facies in Liulin district, Hedong coal field of China. Int. J. Coal Geol. 2010, 81, 117–127. [Google Scholar] [CrossRef]

- Cecil, C.B.; Stanton, R.W.; Neuzil, S.G.; Dulong, F.T.; Ruppert, L.F.; Pierce, B.S. Paleoclimate controls on late Paleozoic sedimentation and peat formation in the central Appalachian basin (U.S.A.). Int. J. Coal Geol. 1985, 5, 195–230. [Google Scholar] [CrossRef]

- Mastalerz, M.; Kvale, E.P.; Stankiewicz, B.A.; Portle, K. Organic geochemistry in Pennsylvanian tidally influenced sediments from SW Indiana. Org. Geochem. 1999, 30, 57–73. [Google Scholar] [CrossRef]

- Zhao, X.Q.; Chen, H.L.; Zhang, F.Q.; Sun, M.D.; Yang, J.G.; Tan, B.D. Characteristics, structural styles and tectonic implications of Mesozoic-Cenozoic faults in the eastern Heilongjiang basins (NE China). J. Asian Earth Sci. 2017, 146, 196–210. [Google Scholar] [CrossRef]

- Shan, C.G.; Zhang, T.S.; Liang, X.; Zhang, Z.; Wang, M.; Zhang, K.; Zhu, H.H. On the fundamental difference of adsorption-pores systems between vitrinite- and inertinite-rich anthracite derived from the southern Sichuan basin, China. J. Nat. Gas Sci. Eng. 2018, 53, 32–44. [Google Scholar] [CrossRef]

- Hou, H.H.; Shao, L.Y.; Li, Y.H.; Li, Z.; Wang, S.; Zhang, W.L.; Wang, X.T. Influence of coal petrology on methane adsorption capacity of the Middle Jurassic coal in the Yuqia Coalfield, northern Qaidam Basin, China. J. Pet. Sci. Eng. 2017, 149, 218–227. [Google Scholar] [CrossRef]

- ICCP. The new vitrinite classification (ICCP System 1994). Fuel 1998, 77, 349–358. [Google Scholar] [CrossRef]

- Cai, Y.D.; Li, Q.; Liu, D.M.; Zhou, Y.F.; Lv, D.W. Insights into matrix compressibility of coals by mercury intrusion porosimetry and N2 adsorption. Int. J. Coal Geol. 2018, 200, 199–212. [Google Scholar] [CrossRef] [Green Version]

- Zeng, F.H.; Peng, F.; Guo, J.C.; Wang, D.Y.; Zhang, S.R.; Zhang, P.; Zhang, B. Gas transport study in the confined microfractures of coal reservoirs. J. Nat. Gas Sci. Eng. 2019, 68, 102920. [Google Scholar] [CrossRef]

- Cai, Y.D.; Liu, D.M.; Pan, Z.J.; Che, Y.; Liu, Z.H. Investigating the Effects of Seepage-Pores and Fractures on Coal Permeability by Fractal Analysis. Trans. Porous Med. 2016, 111, 479–497. [Google Scholar] [CrossRef]

- Zhao, J.L.; Xu, H.; Tang, D.Z.; Mathews, J.P.; Li, S.; Tao, S. Coal seam porosity and fracture heterogeneity of macrolithotypes in the Hancheng Block, eastern margin, Ordos Basin, China. Int. J. Coal Geol. 2016, 159, 18–29. [Google Scholar] [CrossRef]

- Calder, J.H.; Gibling, M.R.; Mukhopadhyay, P. Peat formation in a Westphalian B piedmont setting, Cumberland basin, Nova Scotia: Implications for the maceral-based interpretation of rheotrophic and raised paleomires. Bull. Soc. Geol. Fr. 1991, 162, 283–298. [Google Scholar]

- Diessel, C.F.K. Coal-bearing Depositional Systems; Springer: Berlin, Germany, 1992; p. 721. [Google Scholar]

- Diessel, C.F.K. The correlation between coal facies and depositional environments. In Advances in the Study of the Sydney Basin; The University of Newcastle: Newcastle, UK, 1986; pp. 19–22. [Google Scholar]

- Bechtel, A.; Sachsenhofer, R.F.; Kolcon, I.; Gratzer, R.; Otto, A.; Püttmann, W. Organic geochemistry of the Lower Miocene Oberdorf lignite (Styrian Basin, Austria): Its relation to petrography, palynology and the palaeoenvironment. Int. J. Coal Geol. 2002, 1, 31–57. [Google Scholar] [CrossRef]

- Çelik, Y.; Karayiğit, A.İ.; Querol, X.; Oskay, R.G.; Mastalerz, M.; Özer, M.S.K. Coal characteristics, palynology, and palaeoenvironmental interpretation of the Yeniköy coal of Late Oligocene age in the Thrace Basin (NW Turkey). Int. J. Coal Geol. 2017, 181, 103–123. [Google Scholar]

- Oskay, R.G.; Bechtel, A.; Karayiğit, A.İ. Mineralogy, petrography and organic geochemistry of Miocene coal seams in the Kınık coalfield (Soma Basin-Western Turkey): Insights into depositional environment and palaeovegetation. Int. J. Coal Geol. 2019, 210, 103205. [Google Scholar] [CrossRef]

- Jasper, K.; Hartkopf-Fröder, C.; Flajs, G.; Littke, R. Evolution of Pennsylvanian (late Carboniferous) peat swamps of the Ruhr Basin, Germany: Comparison of palynological, coal petrographical and organic geochemical data. Int. J. Coal Geol. 2010, 83, 346–365. [Google Scholar] [CrossRef]

- Zdravkov, A.; Bechtel, A.; Sachsenhofer, R.F.; Kortenski, J.; Gratzer, R. Vegetation differences and diagenetic changes between two Bulgarian lignitedeposits—Insights from coal petrology and biomaker composition. Org. Geochem. 2011, 42, 237–254. [Google Scholar] [CrossRef]

- Oikonomopoulos, I.K.; Kaouras, G.; Tougiannidis, F.; Ricken, W.; Gurk, M.; Antoniadis, P. The depositional conditions and the palaeoenvironment of the Achlada xylite-dominated lignite in western Makedonia, Greece. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2015, 440, 777–792. [Google Scholar] [CrossRef]

- Omodeo-Salé, S.; Deschamps, R.; Michel, P.; Chauveau, B.; Suárez-Ruiz, I. The coal-bearing strata of the Lower Cretaceous Mannville Group (Western Canadian Sedimentary Basin, South Central Alberta), PART 2: Factors controlling the composition of organic matter accumulations. Int. J. Coal Geol. 2017, 179, 219–241. [Google Scholar] [CrossRef]

- Karayiğit, A.İ.; Bircan, C.; Mastalerz, M.; Oskay, R.G.; Querol, X.; Lieberman, N.R.; Türkmen, I. Coal characteristics, elemental composition and modes of occurrence of some elements in the İsaalan coal (Balıkesir, NW Turkey). Int. J. Coal Geol. 2017, 172, 43–59. [Google Scholar] [CrossRef]

- Karayiğit, A.İ.; Littke, R.; Querol, X.; Jones, T.; Oskay, R.G.; Christanis, K. The Miocene coal seams in the Soma Basin (W. Turkey): Insights from coal petrography, mineralogy and geochemistry. Int. J. Coal Geol. 2017, 173, 110–128. [Google Scholar] [CrossRef]

- Zhang, P.F.; Jin, K.L.; Wu, T.; Wang, C.G. Coal-Bearing Sedimentary and Coal Formed Oil, Turpan-Hami Basin; China Coal Industry Press: Beijing, China, 1997; pp. 168–176. [Google Scholar]

- Petersen, H.I.; Ratanasthien, B. Coal facies in a Cenozoic paralic lignite bed, Krabi Basin, southern Thailand: Changing peat-forming conditions related to relative sea-level controlled water table variations. Int. J. Coal Geol. 2011, 87, 2–12. [Google Scholar] [CrossRef]

- Oskay, R.G.; Christanis, K.; İnaner, H.; Salman, M.; Taka, M. Palaeoenvironmental reconstruction of the eastern part of the Karapınar-Ayrancı coal deposit (Central Turkey). Int. J. Coal Geol. 2016, 163, 100–111. [Google Scholar] [CrossRef]

- Siavalas, G.; Linou, M.; Chatziapostolou, A.; Kalaitzidis, S.; Papaefthymiou, H.; Christanis, K. Palaeoenvironment of Seam I in the Marathousa Lignite Mine, Megalopolis Basin (Southern Greece). Int. J. Coal Geol. 2009, 78, 233–248. [Google Scholar] [CrossRef]

- Janssen, C.; Wirth, R.; Reinicke, A.; Rybacki, E.; Naumann, R.; Wenk, H.-R.; Dresen, G. Nanoscale porosity in SAFOD core samples (San Andreas Fault). Earth Planet. Sci. Lett. 2011, 301, 179–189. [Google Scholar] [CrossRef]

- Li, Z.T.; Liu, D.M.; Cai, Y.D.; Shi, Y.L. Investigation of methane diffusion in low-rank coals by a multiporous diffusion model. J. Nat. Gas Sci. Eng. 2016, 33, 97–107. [Google Scholar] [CrossRef]

- Mitrović, D.; Đoković, N.; Životić, D.; Bechtel, A.; Šajnović, A.; Stojanović, K. Petrographical and organic geochemical study of the Kovin lignite deposit, Serbia. Int. J. Coal Geol. 2016, 168, 80–107. [Google Scholar]

- Khare, N.; Nigam, R.; Mayenkar, D.N.; Saraswat, R. Cluster analysis of benthic foraminiferal morpho-groups from the western margin of India reflects its depth preference. Cont. Shelf Res. 2017, 151, 72–83. [Google Scholar] [CrossRef]

- Peng, S.; Xiao, X.H. Investigation of multiphase fluid imbibition in shale through synchrotron-based dynamic micro-CT imaging. J. Geophys. Res. Solid Earth 2017, 122, 4475–4491. [Google Scholar] [CrossRef]

- Busch, A.; Gensterblum, Y. CBM and CO2-ECBM related sorption processes in coal: A review. Int. J. Coal Geol. 2011, 87, 49–71. [Google Scholar] [CrossRef]

- Clarkson, C.; Bustin, R. Variation in permeability with lithotype and maceral composition of Cretaceous coals of the Canadian Cordillera. Int. J. Coal Geol. 1997, 33, 135–151. [Google Scholar] [CrossRef]

- Karayiğit, A.İ.; Mastalerz, M.; Oskay, R.G. Meso-and microporosity of the subbituminous kM2 coal seam (Soma, Turkey) and its relationship with coal characteristics. Int. J. Coal Geol. 2017, 184, 73–87. [Google Scholar]

- Karayiğit, A.İ.; Mastalerz, M.; Oskay, R.G.; Buzkan, İ. Bituminous coal seams from underground mines in the Zonguldak Basin (NW Turkey): Insights from mineralogy, coal petrography, Rock-Eval pyrolysis, and meso- and microporosity. Int. J. Coal Geol. 2018, 199, 91–122. [Google Scholar] [CrossRef]

- Mastalerz, M.; Drobniak, A.; Rupp, J. Meso- and micropore characteristics of coal lithotypes: Implications for CO2 adsorption. Energy Fuels 2008, 22, 4049–4061. [Google Scholar] [CrossRef]

- Laxminarayana, C.; Crosdale, P. Role of coal type and rank on methane sorption characteristics of Bowen Basin, Australia coals. Int. J. Coal Geol. 1999, 40, 309–325. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Lebedev, M.; Sarmadicaleh, M.; Barifcani, A.; Rahman, T.; Lglauer, S.J. Swelling effect on coal micro structure and associated permeability reduction. Fuel 2016, 182, 568–576. [Google Scholar] [CrossRef] [Green Version]

- Mastalerz, M.; Drobniak, A.; Strąpoć, D.; Solano Acosta, W.; Rupp, J. Variations in pore characteristics in high volatile bituminous coals: Implications for coal bed gas content. Int. J. Coal Geol. 2008, 76, 205–216. [Google Scholar] [CrossRef]

| Sample No. | Basin | GA | %R max | Coal Petrography Composition | Proximate Analysis | Micro-Fractures (per 9 cm2) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V | I | L | MM | C,ad | H,ad | M,ad | A,ad | A | B | C | D | Total | ||||

| NE1 | Jixi | K1 | 0.49 | 77.5 | 8.5 | 13.6 | 0.4 | 70.94 | 4.87 | 2.06 | 10.85 | 0 | 0 | 3 | 16 | 19 |

| NE7 | Hegang | K1 | 0.61 | 78.3 | 10.3 | 11.1 | 0.3 | 74.88 | 7.76 | 1.48 | 9.81 | 2 | 2 | 18 | 52 | 74 |

| NE10 | Jixi | K1 | 0.77 | 76.8 | 17.5 | 4.8 | 0.9 | 71.6 | 4.5 | 1.43 | 13.42 | 0 | 1 | 29 | 119 | 149 |

| NE6 | Boli | K1 | 0.8 | 73.7 | 19.6 | 6.2 | 0.5 | 82.21 | 4.86 | 0.86 | 4.41 | 0 | 2 | 19 | 32 | 53 |

| NE11 | Boli | K1 | 0.81 | 75.9 | 5.6 | 18.2 | 0.3 | 76.28 | 5.05 | 1.02 | 10.14 | 0 | 2 | 26 | 63 | 91 |

| NE26 | Hegang | K1 | 0.83 | 93.6 | 4.8 | 1.2 | 0.4 | 65.1 | 4.01 | 1.18 | 22.03 | * | * | * | * | * |

| NE18 | Jixi | K1 | 0.87 | 89.2 | 1.3 | 7.5 | 2 | 57.48 | 3.88 | 1.16 | 30.67 | 0 | 1 | 29 | 21 | 51 |

| NE19 | Jixi | K1 | 0.9 | 34 | 62.7 | 1.7 | 1.6 | 71.5 | 4.04 | 0.72 | 18 | 0 | 3 | 24 | 213 | 240 |

| NE14 | Boli | K1 | 0.95 | 79.7 | 19.1 | 0.7 | 0.5 | 67.5 | 3.75 | 0.92 | 21.81 | 0 | 0 | 6 | 67 | 73 |

| NE13 | Boli | K1 | 1.05 | 77.1 | 15.9 | 7 | 0 | 75.78 | 4.4 | 0.77 | 12.72 | 0 | 2 | 15 | 51 | 68 |

| NE12 | Boli | K1 | 1.14 | 81.5 | 16.1 | 1.5 | 0.9 | 74.27 | 4. 0 | 0.9 | 15. 3 | 0 | 0 | 14 | 25 | 39 |

| NE5 | Boli | K1 | 1.4 | 94.7 | 2 | 0 | 3.3 | 64.58 | 3.48 | 0.65 | 27.54 | 0 | 0 | 15 | 35 | 50 |

| NE3 | Boli | K1 | 1.6 | 90.5 | 6.4 | 0 | 3.1 | 85.14 | 3.42 | 0.18 | 7.54 | 0 | 3 | 49 | 312 | 364 |

| Sample No. | Porosity (%) | IMS (%) | EMS (%) | PTM (μm) | Total Volume (cm3) | Pore Volume Distribution (%) | Type of IMC | ||

|---|---|---|---|---|---|---|---|---|---|

| V1 | V2 | V3 | |||||||

| NE 1 | 1.8 | 64.9 | 26.869 | 0.12 | 10.26 | 72.07 | 21.2 | 6.73 | Ⅰ |

| NE 3 | 1 | 68.82 | 16.41 | 0.06 | 10.69 | 79.8 | 13.12 | 7.08 | Ⅰ |

| NE 4 | 1 | 70.69 | 18.16 | 0.1 | 11.7 | 73.72 | 18.02 | 8.27 | Ⅰ |

| NE 6 | 1.4 | 69.31 | 14.55 | 0.1 | 8.23 | 78.48 | 14.15 | 7.37 | Ⅰ |

| NE 7 | 1.7 | 84.02 | 39.23 | 0.07 | 9.58 | 53.21 | 13.03 | 33.76 | Ⅲ |

| NE 9 | 4.9 | 60.89 | 39.95 | 0.07 | 10.53 | 63.12 | 11.2 | 25.68 | Ⅱ |

| NE 10 | 3.3 | 52.23 | 25.13 | 0.17 | 10.66 | 75.81 | 14.72 | 9.47 | Ⅰ |

| NE 11 | 1.9 | 70.83 | 19.32 | 0.12 | 8.06 | 73.49 | 20.66 | 5.85 | Ⅰ |

| NE 12 | 3.2 | 83.02 | 55.38 | 0.03 | 11 | 48.44 | 8.75 | 42.81 | Ⅲ |

| NE 13 | 2.7 | 56.93 | 28.94 | 0.04 | 9.62 | 72.86 | 9.02 | 18.12 | Ⅲ |

| NE 14 | 1.5 | 63.65 | 16.01 | 0.06 | 10.29 | 79.31 | 12.53 | 8.16 | Ⅰ |

| NE 16 | 4.2 | 66.38 | 40.31 | 0.36 | 10.64 | 65.32 | 23.64 | 11.05 | Ⅱ |

| NE 19 | 1.8 | 34.99 | 20.87 | 0.11 | 10.57 | 74.28 | 17.32 | 8.4 | Ⅰ |

| NE 38 | 3.3 | 91.86 | 62.37 | 0.16 | 10.23 | 40.24 | 29.26 | 30.46 | Ⅲ |

| Sample No. | Basin | GA | Coal Petrography Composition | Coal Face Indexes | Coal Facies Types | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| V | I | L | MM | TPI | GI | WI | GWI | ||||

| NE1 | Jixi | K1 | 77.5 | 8.5 | 13.6 | 0.4 | 9.9 | 9.1 | 13 | 0.01 | Type Ⅰ |

| NE2 | Jixi | K1 | 95 | 3.7 | 0 | 1.3 | 19.1 | 25.7 | 38 | 0.01 | Type Ⅲ |

| NE3 | Boli | K1 | 90.5 | 6.4 | 0 | 3.1 | 13.1 | 14.1 | 8.8 | 0.08 | Type Ⅰ |

| NE4 | Boli | K1 | 91.8 | 5.8 | 0 | 2.4 | 12.9 | 15.8 | 36 | 0.03 | Type Ⅰ |

| NE5 | Boli | K1 | 94.7 | 2 | 0 | 3.3 | 26.2 | 47.4 | 25 | 0.05 | Type Ⅲ |

| NE6 | Boli | K1 | 73.7 | 19.6 | 6.2 | 0.5 | 7.8 | 4.3 | 10 | 0.05 | Type Ⅰ |

| NE7 | Hegang | K1 | 78.3 | 10.3 | 11.1 | 0.3 | 0.3 | 7.6 | 0.2 | 0.04 | Type Ⅰ |

| NE8 | Jixi | K1 | 78.1 | 4.1 | 14.8 | 3 | 3.9 | 24.7 | 4.2 | 0.14 | Type Ⅰ |

| NE9 | Jixi | K1 | 84.1 | 12.1 | 3 | 0.8 | 5.3 | 7 | 6.4 | 0.01 | Type Ⅰ |

| NE10 | Jixi | K1 | 76.8 | 17.5 | 4.8 | 0.9 | 6 | 4 | 9 | 0.04 | Type Ⅰ |

| NE11 | Boli | K1 | 75.9 | 5.6 | 18.2 | 0.3 | 14 | 14 | 14 | 0 | Type Ⅰ |

| NE12 | Boli | K1 | 81.5 | 16.1 | 1.5 | 0.9 | 4 | 5 | 7 | 0.03 | Type Ⅰ |

| NE13 | Boli | K1 | 77.1 | 15.9 | 7 | 0 | 4 | 5 | 4 | 0.02 | Type Ⅰ |

| NE14 | Boli | K1 | 79.7 | 19.1 | 0.7 | 0.5 | 5 | 4 | 9 | 0.02 | Type Ⅰ |

| NE15 | Boli | K1 | 82.1 | 12.6 | 5 | 0.3 | 6 | 7 | 7 | 0.03 | Type Ⅰ |

| NE16 | Boli | K1 | 77 | 21.8 | 0 | 1.2 | 7 | 4 | 28 | 0.05 | Type Ⅰ |

| NE17 | Jixi | K1 | 90.2 | 1.5 | 0 | 8.3 | 19 | 60 | 5 | 0.26 | Type Ⅲ |

| NE18 | Jixi | K1 | 89.2 | 1.3 | 7.5 | 2 | 22 | 69 | 33 | 0.02 | Type Ⅲ |

| NE19 | Jixi | K1 | 34 | 62.7 | 1.7 | 1.6 | 7 | 1 | 9 | 0.05 | Type Ⅰ |

| NE20 | Hegang | K1 | 83.9 | 7.3 | 8.3 | 0.5 | 5 | 13 | 5 | 0.04 | Type Ⅰ |

| NE21 | Hegang | K1 | 81.1 | 12.7 | 5.8 | 0.4 | 12 | 7 | 14 | 0.02 | Type Ⅰ |

| NE22 | Boli | K1 | 85 | 12 | 0 | 3 | 12 | 7 | 22 | 0.04 | Type Ⅰ |

| NE23 | Boli | K1 | 82.8 | 1.3 | 13.4 | 2.5 | 15 | 83 | 16 | 0.06 | Type Ⅲ |

| NE24 | Boli | K1 | 95.1 | 1.4 | 3 | 0.5 | 23 | 68 | 27 | 0.03 | Type Ⅲ |

| NE25 | Boli | K1 | 88.8 | 10.4 | 0 | 0.8 | 5 | 9 | 7 | 0.03 | Type Ⅰ |

| NE26 | Hegang | K1 | 93.6 | 4.8 | 1.2 | 0.4 | 33 | 20 | 26 | 0.03 | Type Ⅲ |

| NE27 | Jixi | K1 | 93.9 | 4.8 | 0.8 | 0.5 | 12 | 20 | 16 | 0.01 | Type Ⅰ |

| NE28 | Jixi | K1 | 86.1 | 5.2 | 6 | 2.7 | 9 | 17 | 11 | 0.04 | Type Ⅰ |

| NE29 | Jixi | K1 | 85.2 | 9.9 | 2.3 | 2.6 | 11 | 9 | 17 | 0.03 | Type Ⅰ |

| NE30 | Jixi | K1 | 95.1 | 0.9 | 2.7 | 1.3 | 27 | 106 | 30 | 0.01 | Type Ⅲ |

| NE31 | Jixi | K1 | 93.9 | 4.2 | 0 | 1.9 | 47 | 22 | 56 | 0.04 | Type Ⅱ |

| NE32 | Jixi | K1 | 87.9 | 9.6 | 0 | 2.5 | 18 | 9 | 58 | 0.09 | Type Ⅱ |

| NE33 | Jixi | K1 | 58.4 | 32.5 | 8.9 | 0.2 | 2 | 2 | 3 | 0.04 | Type Ⅰ |

| NE34 | Jixi | K1 | 92.8 | 1.8 | 5 | 0.4 | 35 | 52 | 18 | 0.04 | Type Ⅲ |

| NE35 | Jixi | K1 | 65.6 | 23.1 | 9.9 | 1.4 | 2 | 3 | 3 | 0.14 | Type Ⅰ |

| NE36 | Jixi | K1 | 84.5 | 8.2 | 3.3 | 4 | 8 | 10 | 15 | 0.09 | Type Ⅰ |

| NE37 | Jixi | K1 | 77.3 | 15.2 | 6.8 | 0.7 | 3 | 6 | 3 | 0.01 | Type Ⅰ |

| NE38 | Hegang | K1 | 70.6 | 11.6 | 17.2 | 0.6 | 6 | 7 | 7 | 0.07 | Type Ⅰ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Liu, D.; Cai, Y.; Li, Q.; Jia, Q. Pore-Fractures of Coalbed Methane Reservoir Restricted by Coal Facies in Sangjiang-Muling Coal-Bearing Basins, Northeast China. Energies 2020, 13, 1196. https://doi.org/10.3390/en13051196

Lu Y, Liu D, Cai Y, Li Q, Jia Q. Pore-Fractures of Coalbed Methane Reservoir Restricted by Coal Facies in Sangjiang-Muling Coal-Bearing Basins, Northeast China. Energies. 2020; 13(5):1196. https://doi.org/10.3390/en13051196

Chicago/Turabian StyleLu, Yuejian, Dameng Liu, Yidong Cai, Qian Li, and Qifeng Jia. 2020. "Pore-Fractures of Coalbed Methane Reservoir Restricted by Coal Facies in Sangjiang-Muling Coal-Bearing Basins, Northeast China" Energies 13, no. 5: 1196. https://doi.org/10.3390/en13051196

APA StyleLu, Y., Liu, D., Cai, Y., Li, Q., & Jia, Q. (2020). Pore-Fractures of Coalbed Methane Reservoir Restricted by Coal Facies in Sangjiang-Muling Coal-Bearing Basins, Northeast China. Energies, 13(5), 1196. https://doi.org/10.3390/en13051196