A Review on the Potential of Forest Biomass for Bioenergy in Australia

Abstract

1. Introduction

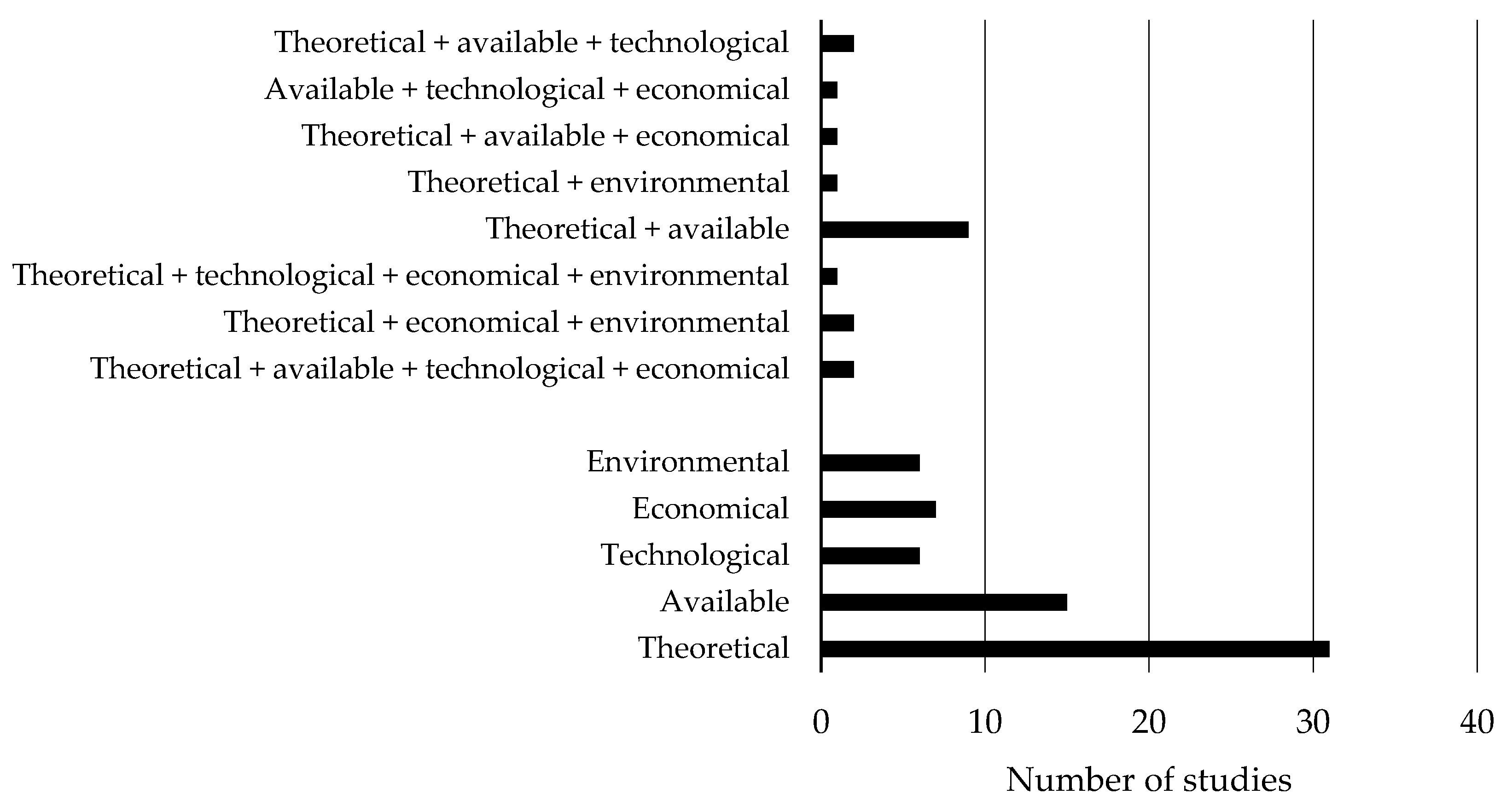

2. Scope and Methods

- 1)

- Primary publication data: year of publication, author(s), affiliations and journal titles;

- 2)

- Abstract and keywords;

- 3)

- Presence of the five biomass potentials;

- 4)

- Measures and attributes included in the calculation of the theoretical, available, technological, economical or environmental biomass potential.

3. Theoretical Biomass Potential

4. Available Biomass Potential

5. Technological Biomass Potential

6. Economical Biomass Potential

7. Environmental Biomass Potential

8. Discussion

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IEA Bioenergy. Sustainable Production of Woody Biomass for Energy A Position Paper Prepared by IEA Bioenergy; IEA Bioenergy: Rotorua, New Zealand, 2002; Volume 03. [Google Scholar]

- Sharma, B.; Ingalls, R.G.; Jones, C.L.; Khanchi, A. Biomass supply chain design and analysis: Basis, overview, modeling, challenges, and future. Renew. Sustain. Energy Rev. 2013, 24, 608–627. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Toft, A.J.; Brammer, J.G. A Techno-Economic Comparison of Power Production by Biomass Fast Pyrolysis with Gasification and Combustion. Renew. Sustain. Energy Rev. 2002, 6, 181–246. [Google Scholar] [CrossRef]

- IEA. Key World Energy Statistics; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Raison, R.J. Opportunities and impediments to the expansion of forest bioenergy in Australia. Biomass Bioenergy 2006, 30, 1021–1024. [Google Scholar] [CrossRef]

- KPMG. Bioenergy State of the Nation Report; Bioenergy Australia: Canberra, Australia, 2018. [Google Scholar]

- Department of the Environment and Energy. Australian Energy Update 2018; Australian Government: Canberra, Australia, 2018.

- Shabani, N.; Akhtari, S.; Sowlati, T. Value chain optimization of forest biomass for bioenergy production: A review. Renew. Sustain. Energy Rev. 2013, 23, 299–311. [Google Scholar] [CrossRef]

- Malladi, K.T.; Sowlati, T. Biomass logistics: A review of important features, optimization modeling and the new trends. Renew. Sustain. Energy Rev. 2018, 94, 587–599. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T.; Pavel, M. Economic and life cycle environmental optimization of forest-based biorefinery supply chains for bioenergy and biofuel production. Chem. Eng. Res. Des. 2016, 107, 218–235. [Google Scholar] [CrossRef]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and climate change mitigation: An assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef]

- Voivontas, D.; Assimacopoulos, D.; Koukios, E.G. Assessment of biomass potential for power production: A GIS based method. Biomass Bioenergy 2001, 20, 101–112. [Google Scholar] [CrossRef]

- Shi, X.; Elmore, A.; Li, X.; Gorence, N.J.; Jin, H.; Zhang, X.; Wang, F. Using spatial information technologies to select sites for biomass power plants: A case study in Guangdong Province, China. Biomass Bioenergy 2008, 32, 35–43. [Google Scholar] [CrossRef]

- Hock, B.K.; Blomqvist, L.; Hall, P.; Jack, M.; Möller, B.; Wakelin, S.J. Understanding forest-derived biomass supply with GIS modelling. J. Spat. Sci. 2012, 57, 213–232. [Google Scholar] [CrossRef]

- Szulecka, J. Towards sustainablewood-based energy: Evaluation and strategies for mainstreaming sustainability in the sector. Sustainability 2019, 11, 493. [Google Scholar] [CrossRef]

- Thiffault, E.; Hannam, K.D.; Paré, D.; Titus, B.D.; Hazlett, P.W.; Maynard, D.G.; Brais, S. Effects of forest biomass harvesting on soil productivity in boreal and temperate forests—A review. Environ. Rev. 2011, 19, 278–309. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T.J. Sustainability considerations for electricity generation from biomass. Renew. Sustain. Energy Rev. 2010, 14, 1419–1427. [Google Scholar] [CrossRef]

- Stupak, I.; Lattimore, B.; Titus, B.D.; Tattersall Smith, C. Criteria and indicators for sustainable forest fuel production and harvesting: A review of current standards for sustainable forest management. Biomass Bioenergy 2011, 35, 3287–3308. [Google Scholar] [CrossRef]

- FSC Australia. The FSC National Forest Stewardship Standard of Australia; FSC Australia: Melbourne, Australia, 2016. [Google Scholar]

- Responsible Wood. Australian Standard Sustainable Forest Management; Responsible Wood: Brisbane, Australia, 2013. [Google Scholar]

- Meyer, J.; Hobson, P.; Schultmann, F. The potential for centralised second generation hydrocarbons and ethanol production in the Australian sugar industry. In Proceedings of the 34th Annual Conference of the Australian Society of Sugar Cane Technologists, Palm Cove, Australia, 1–4 May 2012; Volume 34, pp. 585–596. [Google Scholar]

- Cambero, C.; Sowlati, T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives—A review of literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Sessions, J.; Brown, M. Evaluating productivity, cost, chip quality and biomass recovery for a mobile chipper in Australian roadside chipping operations. J. For. Sci. 2012, 58, 530–535. [Google Scholar] [CrossRef]

- Acuna, M. Timber and biomass transport optimization: A review of planning issues, solution techniques and decision support tools. Croat. J. For. Eng. 2017, 38, 279–290. [Google Scholar]

- Ghaffariyan, M.R.; Brown, M.; Acuna, M.; Sessions, J.; Gallagher, T.; Kühmaier, M.; Spinelli, R.; Visser, R.; Devlin, G.; Eliasson, L.; et al. An international review of the most productive and cost effective forest biomass recovery technologies and supply chains. Renew. Sustain. Energy Rev. 2017, 74, 145–158. [Google Scholar] [CrossRef]

- Acuna, M.; Anttila, P.; Sikanen, L.; Prinz, R.; Asikainen, A. Predicting and controlling moisture content to optimise forest biomass logistics. Croat. J. For. Eng. 2012, 33, 225–238. [Google Scholar]

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Comput. Chem. Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Lattimore, B.; Smith, C.T.; Titus, B.D.; Stupak, I.; Egnell, G. Environmental factors in woodfuel production: Opportunities, risks, and criteria and indicators for sustainable practices. Biomass Bioenergy 2009, 33, 1321–1342. [Google Scholar] [CrossRef]

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Caputo, A.C.; Palumbo, M.; Pelagagge, P.M.; Scacchia, F. Economics of biomass energy utilization in combustion and gasification plants: Effects of logistic variables. Biomass Bioenergy 2005, 28, 35–51. [Google Scholar] [CrossRef]

- Hall, D.O.; Scrase, J.I. Will biomass be the environmentally friendly fuel of the future? Biomass Bioenergy 1998, 15, 357–367. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Shahrukh, H.; Oyedun, A.O.; Kumar, A.; Ghiasi, B.; Kumar, L.; Sokhansanj, S. Comparative net energy ratio analysis of pellet produced from steam pretreated biomass from agricultural residues and energy crops. Biomass Bioenergy 2016, 90, 50–59. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Zhuang, X.S. Conceptual net energy output for biofuel production from lignocellulosic biomass through biorefining. Prog. Energy Combust. Sci. 2012, 38, 583–598. [Google Scholar] [CrossRef]

- Timmons, D.; Mejía, C.V. Biomass energy from wood chips: Diesel fuel dependence? Biomass Bioenergy 2010, 34, 1419–1425. [Google Scholar] [CrossRef]

- Repo, A.; Tuovinen, J.P.; Liski, J. Can we produce carbon and climate neutral forest bioenergy? GCB Bioenergy 2015, 7, 253–262. [Google Scholar] [CrossRef]

- Berndes, G.; Abts, B.; Asikainen, A.; Cowie, A.; Dale, V.; Egnell, G.; Lindner, M.; Marelli, L.; Paré, D.; Pingoud, K.; et al. Forest Biomass, Carbon Neutrality and Climate Change Mitigation; European Forest Institute: Joensuu, Finland, 2016. [Google Scholar]

- Bright, R.M.; Cherubini, F.; Astrup, R.; Bird, N.; Cowie, A.L.; Ducey, M.J.; Marland, G.; Pingoud, K.; Savolainen, I.; Strømman, A.H. A comment to “Large-scale bioenergy from additional harvest of forest biomass is neither sustainable nor greenhouse gas neutral”: Important insights beyond greenhouse gas accounting. GCB Bioenergy 2012, 4, 617–619. [Google Scholar] [CrossRef]

- Cowie, A.; Berndes, G.; Jungigner, M.; Ximenes, F. Response to Chatham House Report “Woody Biomass for Power and Heat: Impacts on the Global Climate”; IEA Bioenergy: Lismore, Australia, 2017. [Google Scholar]

- Helin, T.; Sokka, L.; Soimakallio, S.; Pingoud, K.; Pajula, T. Approaches for inclusion of forest carbon cycle in life cycle assessment—A review. GCB Bioenergy 2013, 5, 475–486. [Google Scholar] [CrossRef]

- Pingoud, K.; Ekholm, T.; Soimakallio, S.; Helin, T. Carbon balance indicator for forest bioenergy scenarios. GCB Bioenergy 2016, 8, 171–182. [Google Scholar] [CrossRef]

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 emissions from biomass combustion for bioenergy: Atmospheric decay and contribution to global warming. GCB Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- IPCC. IPCC Special Report on Renewable Energy Sources and Climate Change Mitigation; IPCC: Cambridge, UK; New York, NY, USA, 2011. [Google Scholar]

- Sochacki, S.J.; Harper, R.J.; Smettem, K.R.J. Bio-mitigation of carbon following afforestation of abandoned salinized farmland. GCB Bioenergy 2012, 4, 193–201. [Google Scholar] [CrossRef]

- Berndes, G.; Hoogwijk, M.; Van Den Broek, R. The contribution of biomass in the future global energy supply: A review of 17 studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

- Berndes, G.; Bird, N.; Cowie, A. Bioenergy, Land Use Change and Climate Change Mitigation Background Technical Report; IEA Bioenergy: Goteborg, Sweden, 2011. [Google Scholar]

- Cummins, J.; Skennar, C.; Cassidy, M.; Palmer, G.; Capill, L. Using small hardwood logs to produce liquid fuels and electricity. Aust. For. 2016, 79, 189–195. [Google Scholar] [CrossRef]

- Threlfall, C.G.; Law, B.S.; Peacock, R.J. Benchmarks and predictors of coarse woody debris in native forests of eastern Australia. Austral Ecol. 2019, 44, 138–150. [Google Scholar] [CrossRef]

- Ximenes, F.; Stephens, M.; Brown, M.; Law, B.; Mylek, M.; Schirmer, J.; Sullivan, A.; McGuffog, T. Mechanical fuel load reduction in Australia: A potential tool for bushfire mitigation. Aust. For. 2017, 80, 1–11. [Google Scholar] [CrossRef]

- Murphy, H.T.; O’Connell, D.A.; Raison, R.J.; Warden, A.C.; Booth, T.H.; Herr, A.; Braid, A.L.; Crawford, D.F.; Hayward, J.A.; Jovanovic, T.; et al. Biomass production for sustainable aviation fuels: A regional case study in Queensland. Renew. Sustain. Energy Rev. 2015, 44, 738–750. [Google Scholar] [CrossRef]

- Hayward, J.A.; O’Connell, D.A.; Raison, R.J.; Warden, A.C.; O’Connor, M.H.; Murphy, H.T.; Booth, T.H.; Braid, A.L.; Crawford, D.F.; Herr, A.; et al. The economics of producing sustainable aviation fuel: A regional case study in Queensland, Australia. GCB Bioenergy 2015, 7, 497–511. [Google Scholar] [CrossRef]

- Farine, D.R.; O’Connell, D.A.; Raison, R.J.; May, B.M.; O’Connor, M.H.; Crawford, D.F.; Herr, A.; Taylor, J.A.; Jovanovic, T.; Campbell, P.K.; et al. An assessment of biomass for bioelectricity and biofuel, and for greenhouse gas emission reduction in Australia. GCB Bioenergy 2012, 4, 148–175. [Google Scholar] [CrossRef]

- Ritson, P.; Sochacki, S. Measurement and prediction of biomass and carbon content of Pinus pinaster trees in farm forestry plantations, south-western Australia. For. Ecol. Manag. 2003, 175, 103–117. [Google Scholar] [CrossRef]

- Specht, A.; West, P.W.W. Estimation of biomass and sequestered carbon on farm forest plantations in northern New South Wales, Australia. Biomass Bioenergy 2003, 25, 363–379. [Google Scholar] [CrossRef]

- Bi, H.; Long, Y.; Turner, J.; Lei, Y.; Snowdon, P.; Li, Y.; Harper, R.; Zerihun, A.; Ximenes, F. Additive prediction of aboveground biomass for Pinus radiata (D. Don) plantations. For. Ecol. Manag. 2010, 259, 2301–2314. [Google Scholar] [CrossRef]

- Wang, X.; Bi, H.; Ximenes, F.; Ramos, J.; Li, Y. Product and residue biomass equations for individual trees in rotation age Pinus radiata stands under three thinning regimes in New South Wales, Australia. Forests 2017, 8, 439. [Google Scholar] [CrossRef]

- Ngugi, M.R.; Neldner, V.J.; Ryan, S.; Lewis, T.; Li, J.; Norman, P.; Mogilski, M. Estimating potential harvestable biomass for bioenergy from sustainably managed private native forests in Southeast Queensland, Australia. For. Ecosyst. 2018, 5, 1–15. [Google Scholar] [CrossRef]

- Mendham, D.S.; Ogden, G.N.; Short, T.; O’Connell, T.M.; Grove, T.S.; Rance, S.J. Repeated harvest residue removal reduces E. globulus productivity in the 3rd rotation in south-western Australia. For. Ecol. Manag. 2014, 329, 279–286. [Google Scholar] [CrossRef]

- Garcia_Florez, L.; Vanclay, J.K.; Glencross, K.; Nichols, J.D. Developing biomass estimation models for above-ground compartments in Eucalyptus dunnii and Corymbia citriodora plantations. Biomass Bioenergy 2019, 130, 105353. [Google Scholar] [CrossRef]

- Ximenes, F.A.; Gardner, W.D.; Richards, G.P. Total above-ground biomass and biomass in commercial logs following the harvest of spotted gum (Corymbia maculata) forests of SE NSW. Aust. For. 2006, 69, 213–222. [Google Scholar] [CrossRef]

- Ximenes, F.A.; Gardner, W.D.; Kathuria, A. Proportion of above-ground biomass in commercial logs and residues following the harvest of five commercial forest species in Australia. For. Ecol. Manag. 2008, 256, 335–346. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Acuna, M.; Wiedemann, J.; Mitchell, R. Productivity of the Bruks chipper when harvesting forest biomass in pine plantations. CRC For. 2011, 1, 5. [Google Scholar]

- Walsh, D.; Strandgard, M. Productivity and cost of harvesting a stemwood biomass product from integrated cut-to-length harvest operations in Australian Pinus radiata plantations. Biomass Bioenergy 2014, 66, 93–102. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Brown, M.; Acuna, M.; Sessions, J.; Kuehmaier, M.; Wiedemann, J. Biomass harvesting in Eucalyptus plantations in Western Australia. South. For. A J. For. Sci. 2011, 73, 149–154. [Google Scholar]

- Ghaffariyan, M.R. Remaining slash in different harvesting operation sites in Australian plantations. Silva Balc. 2013, 14, 83–93. [Google Scholar]

- Ghaffariyan, M.R.; Sessions, J.; Brown, M. Collecting harvesting residues in pine plantations using a mobile chipper in Victoria (Australia). Silva Balc. 2014, 15, 81–95. [Google Scholar]

- Ghaffariyan, M.R.; Apolit, R. Harvest residues assessment in pine plantations harvested by whole tree and cut-to-length harvesting methods (a case study in Queensland, Australia). Silva Balc. 2015, 16, 113–122. [Google Scholar]

- Ghaffariyan, M.R.; Spinelli, R.; Magagnotti, N.; Brown, M. Integrated harvesting for conventional log and energy wood assortments: A case study in a pine plantation in Western Australia. South. For. A J. For. Sci. 2015, 77, 249–254. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Acuna, M.; Brown, M. Analysing the effect of five operational factors on forest residue supply chain costs: A case study in Western Australia. Biomass Bioenergy 2013, 59, 486–493. [Google Scholar] [CrossRef]

- May, B.; England, J.R.; Raison, R.J.; Paul, K.I. Cradle-to-gate inventory of wood production from Australian softwood plantations and native hardwood forests: Embodied energy, water use and other inputs. For. Ecol. Manag. 2012, 264, 37–50. [Google Scholar] [CrossRef]

- Crawford, D.F.; O’Connor, M.H.; Jovanovic, T.; Herr, A.; Raison, R.J.; O’Connell, D.A.; Baynes, T. A spatial assessment of potential biomass for bioenergy in Australia in 2010, and possible expansion by 2030 and 2050. GCB Bioenergy 2016, 8, 707–722. [Google Scholar] [CrossRef]

- Meadows, J.; Coote, D.; Brown, M. The Potential Supply of Biomass for Energy from Hardwood Plantations in the Sunshine Coast Council Region of South-East Queensland, Australia. Small Scale For. 2014, 13, 461–481. [Google Scholar] [CrossRef]

- Rothe, A.; Moroni, M.; Neyland, M.; Wilnhammer, M. Current and potential use of forest biomass for energy in Tasmania. Biomass Bioenergy 2015, 80, 162–172. [Google Scholar] [CrossRef]

- Gupta, R.; Sharma, L.K. The process-based forest growth model 3-PG for use in forest management: A review. Ecol. Modell. 2019, 397, 55–73. [Google Scholar] [CrossRef]

- Rodriguez, L.C.; May, B.; Herr, A.; O’Connell, D. Biomass assessment and small scale biomass fired electricity generation in the Green Triangle, Australia. Biomass Bioenergy 2011, 35, 2589–2599. [Google Scholar] [CrossRef]

- Ximenes, F.A.; George, B.H.; Cowie, A.; Williams, J.; Kelly, G. Greenhouse gas balance of native forests in New South Wales, Australia. Forests 2012, 3, 653–683. [Google Scholar] [CrossRef]

- Woo, H.; Acuna, M.; Moroni, M.; Taskhiri, M.S.; Turner, P. Optimizing the location of biomass energy facilities by integrating Multi-Criteria Analysis (MCA) and Geographical Information Systems (GIS). Forests 2018, 9, 585. [Google Scholar] [CrossRef]

- Cowie, A.L.; Gardner, D.W.; David Gardner, W.; Gardner, D.W. Competition for the biomass resource: Greenhouse impacts and implications for renewable energy incentive schemes. Biomass Bioenergy 2007, 31, 601–607. [Google Scholar] [CrossRef]

- Strandgard, M.; Turner, P.; Mirowski, L.; Acuna, M. Potential application of overseas forest biomass supply chain experience to reduce costs in emerging Australian forest biomass supply chains—A literature review. Aust. For. 2019, 82, 1–9. [Google Scholar] [CrossRef]

- Fung, P.; Kirschbaum, M.U.F.; Raison, R.J.; Stucley, C. The potential for bioenergy production from Australian forests, its contribution to national greenhouse targets and recent developments in conversion processes. Biomass Bioenergy 2002, 22, 223–236. [Google Scholar] [CrossRef]

- Moroni, M.T. Simple models of the role of forests and wood products in greenhouse gas mitigation. Aust. For. 2013, 76, 50–57. [Google Scholar] [CrossRef]

- Tucker, S.N.; Tharumarajah, A.; May, B.; England, J.; Paul, K.; Hall, M.; Mitchell, P.; Rouwette, R.; Seo, S.; Syme, M. Life Cycle Inventory of Australian Forestry and Wood Products; Forest & Wood Products Australia: Melbourne, Australia, 2009; Available online: https://www.fwpa.com.au/images/marketaccess/PNA008-0708_Research_Report_LCI_Timber_0.pdf (accessed on 21 November 2019).

- England, J.R.; May, B.; Raison, R.J.; Paul, K.I. Cradle-to-gate inventory of wood production from Australian softwood plantations and native hardwood forests: Carbon sequestration and greenhouse gas emissions. For. Ecol. Manag. 2013, 302, 295–307. [Google Scholar] [CrossRef]

- Pang, X.; Trubins, R.; Lekavicius, V.; Galinis, A.; Mozgeris, G.; Kulbokas, G.; Mörtberg, U. Forest bioenergy feedstock in Lithuania – Renewable energy goals and the use of forest resources. Energy Strategy Rev. 2019, 24, 244–253. [Google Scholar] [CrossRef]

- Mansuy, N.; Paré, D.; Thiffault, E.; Bernier, P.Y.; Cyr, G.; Manka, F.; Lafleur, B.; Guindon, L. Estimating the spatial distribution and locating hotspots of forest biomass from harvest residues and fire-damaged stands in Canada’s managed forests. Biomass Bioenergy 2017, 97, 90–99. [Google Scholar] [CrossRef]

- Sacchelli, S.; Fagarazzi, C.; Bernetti, I. Economic evaluation of forest biomass production in central Italy: A scenario assessment based on spatial analysis tool. Biomass Bioenergy 2013, 53, 1–10. [Google Scholar] [CrossRef]

- Verkerk, P.J.; Fitzgerald, J.B.; Datta, P.; Dees, M.; Hengeveld, G.M.; Lindner, M.; Zudin, S. Spatial distribution of the potential forest biomass availability in europe. For. Ecosyst. 2019, 6, 1–11. [Google Scholar] [CrossRef]

- Comber, A.; Dickie, J.; Jarvis, C.; Phillips, M.; Tansey, K. Locating bioenergy facilities using a modified GIS-based location-allocation-algorithm: Considering the spatial distribution of resource supply. Appl. Energy 2015, 154, 309–316. [Google Scholar] [CrossRef]

- Fernandes, U.; Costa, M. Potential of biomass residues for energy production and utilization in a region of Portugal. Biomass Bioenergy 2010, 34, 661–666. [Google Scholar] [CrossRef]

- Noon, C.E.; Daly, M.J. GIS-based biomass resource assessment with BRAVO. Biomass Bioenergy 1996, 10, 101–109. [Google Scholar] [CrossRef]

- Castellano, P.J.; Volk, T.A.; Herrington, L.P. Estimates of technically available woody biomass feedstock from natural forests and willow biomass crops for two locations in New York State. Biomass Bioenergy 2009, 33, 393–406. [Google Scholar] [CrossRef]

- Ranta, T. Logging residues from regeneration fellings for biofuel production-a GIS-based availability analysis in Finland. Biomass Bioenergy 2005, 28, 171–182. [Google Scholar] [CrossRef]

- Vasco, H.; Costa, M. Quantification and use of forest biomass residues in Maputo province, Mozambique. Biomass Bioenergy 2009, 33, 1221–1228. [Google Scholar] [CrossRef]

- Zhan, F.B.; Chen, X.; Noon, C.E.; Wu, G. A GIS-enabled comparison of fixed and discriminatory pricing strategies for potential switchgrass-to-ethanol conversion facilities in Alabama. Biomass Bioenergy 2005, 28, 295–306. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.M.; Sutherland, J.W. A GIS-based method for identifying the optimal location for a facility to convert forest biomass to biofuel. Biomass Bioenergy 2011, 35, 3951–3961. [Google Scholar] [CrossRef]

- Freppaz, D.; Minciardi, R.; Robba, M.; Rovatti, M.; Sacile, R.; Taramasso, A. Optimizing forest biomass exploitation for energy supply at a regional level. Biomass Bioenergy 2004, 26, 15–25. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Baruah, D.C.; Singh, A.; Kataki, S.; Medhi, K.; Kumari, S.; Ramachandra, T.V.; Jenkins, B.M.; Thakur, I.S. Emerging role of Geographical Information System (GIS), Life Cycle Assessment (LCA) and spatial LCA (GIS-LCA) in sustainable bioenergy planning. Bioresour. Technol. 2017, 242, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Johnson, D.; Johnson, M.; Watkins, D.; Froese, R.; Wang, J. Decision support system integrating GIS with simulation and optimisation for a biofuel supply chain. Renew. Energy 2016, 85, 740–748. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, J.; Liu, S.; Zhang, S.; Sutherland, J.W. Integrating GIS with optimization method for a biofuel feedstock supply chain. Biomass Bioenergy 2017, 98, 194–205. [Google Scholar] [CrossRef]

| Reference | Case | Theoretical | Available | Technological | Economical | Environmental |

|---|---|---|---|---|---|---|

| Fung et al. 2002 | Outlining technologies for the conversion of woody biomass for heat and power generation. | × | × | × | × | |

| Specht and West 2003 | Predicting biomass availability and carbon stock on farm forest plantations in northern New South Wales. | × | ||||

| Ritson and Sochacki 2003 | Predicting biomass and carbon stock of Pinus pinaster trees in farm forestry plantations, southwest Australia | × | ||||

| Ximenes et al. 2006 | Predicting the proportion of above-ground biomass in commercial logs and residues of spotted gum forest in southeast NSW. | × | ||||

| Raison 2006 | Reviewing biomass supply technology, policy, availability and other impediments to expand forest bioenergy. | × | × | × | ||

| Cowie and Gardner 2007 | Assessing GHG mitigation impacts of sawmill residues used either for the generation of electricity or the manufacture of particleboard. | × | × | × | × | |

| Ximenes et al. 2008 | Predicting the proportion of above-ground biomass in commercial logs and residues of five commercial forest species. | × | ||||

| Bi et al. 2010 | Predicting above-ground biomass of Pinus radiata plantations from stand variables, geographical growth and yield models. | × | ||||

| Ghaffariyan et al. 2011 | Evaluating biomass harvest in a poor-quality eucalypt plantation on yield and the productivity rates of equipment for harvesting. | × | × | |||

| Rodriguez et al. 2011 | Predicting the potential biomass availability for energy generation from forestry and agriculture in the Green Triangle. | × | × | × | × | |

| Farine et al. 2012 | Predicting current and future biomass feedstocks for bioenergy, and associated estimates of the GHG mitigation. | × | × | × | ||

| Ximenes et al. 2012 | Estimating GHG balance and emissions of two critical native forest areas managed for production in New South Wales in comparison with a conservation only scenario. | × | × | |||

| Ghaffariyan et al. 2012 | Assessing biomass harvest using the Bruks mobile chipper for non-merchantable stem wood at the roadside in a pine plantation in Victoria. | × | × | |||

| May et al. 2012 | Assessing the energy balance of wood from softwood plantations and native hardwood forests, using a cradle-to-gate inventory. | × | × | |||

| Moroni 2013 | Reviewing GHG mitigation trade-off between storing carbon in forests and providing society with wood products. | × | ||||

| England et al. 2013 | Estimating GHG emissions associated with wood from softwood plantations and regrowth hardwood native forests. | × | ||||

| Ghaffariyan 2013 | Predicting remaining slash in different sites of plantations harvested by cut-to-length and whole tree method. | × | ||||

| Ghaffariyan et al. 2013 | Estimating BSC cost influenced by five operational factors: energy demand, moisture mass fraction, interest rate, transport distance, and truck payload. | × | × | × | ||

| Walsh and Strandgard 2014 | Predicting remaining slash after harvest stem wood biomass product from integrated cut-to-length harvest operations in Pinus radiata plantations. | × | × | |||

| Mendham et al. 2014 | Predicting the impact of repeated residue removal, retention, or retention of double the quantity of residues over two rotations of Eucalyptus globulus in southwest Australia. | × | ||||

| Ghaffariyan et al. 2014 | Evaluating biomass harvest using a mobile chipper in a clear-felled area of pine plantations in Victoria. | × | × | |||

| Meadows et al. 2014 | Predicting the potential biomass for energy supply from hardwood plantations within the Sunshine Coast Council region of southeast Queensland. | × | ||||

| Ghaffariyan and Apolit 2015 | Predicting remaining slash in Queensland pine plantations harvested by cut-to-length and whole tree method. | × | ||||

| Ghaffariyan et al. 2015 | Evaluating biomass harvest of an integrated energy wood harvesting system compared to conventional log harvesting in a 32-year-old Pinus radiata plantation located in southwest Western Australia. | × | × | |||

| Rothe et al. 2015 | Predicting the current use and the potential sustainable supply of forest biomass in Tasmania. | × | × | |||

| Cummins et al. 2016 | Reviewing the biomass supply to produce liquid fuels and electricity using small hardwood logs. | × | × | × | ||

| Crawford et al. 2016 | Predicting spatial availability of biomass for bioenergy in Australia in 2010, 2030 and 2050. | × | ||||

| Wang et al. 2017 | Predicting residue weight of individual trees in rotation age (28 to 42 years) Pinus radiata stands under three thinning regimes. | × | ||||

| Ximenes et al. 2017 | Reviewing biomass harvest from mechanical fuel load reduction. | × | × | × | ||

| Ghaffariyan et al. 2017 | Reviewing biomass supply and recovery technologies from forests to gate. | × | ||||

| Ngugi et al. 2018 | Predicting potential harvestable biomass for bioenergy from sustainably managed private native forests in southeast Queensland. | × | ||||

| Woo et al. 2018 | Optimizing biomass energy facility locations, and allocation for supply. | × | × | × | ||

| Garcia_Florez et al. 2019 | Developing species-specific biomass estimation models (BEMs) for stem, bark, branch and crown compartments in 16-year old plantations of Eucalyptus dunnii and Corymbia citriodora. | × | ||||

| Threlfall et al. 2019 | Predicting the amount of CWD in the harvested and unharvested native forest of eastern Australia. | × | ||||

| Strandgard et al. 2019 | Reviewing BSC experience applied to reduce costs in emerging Australian forest BSC. | × | × |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Holsbeeck, S.; Brown, M.; Srivastava, S.K.; Ghaffariyan, M.R. A Review on the Potential of Forest Biomass for Bioenergy in Australia. Energies 2020, 13, 1147. https://doi.org/10.3390/en13051147

Van Holsbeeck S, Brown M, Srivastava SK, Ghaffariyan MR. A Review on the Potential of Forest Biomass for Bioenergy in Australia. Energies. 2020; 13(5):1147. https://doi.org/10.3390/en13051147

Chicago/Turabian StyleVan Holsbeeck, Sam, Mark Brown, Sanjeev Kumar Srivastava, and Mohammad Reza Ghaffariyan. 2020. "A Review on the Potential of Forest Biomass for Bioenergy in Australia" Energies 13, no. 5: 1147. https://doi.org/10.3390/en13051147

APA StyleVan Holsbeeck, S., Brown, M., Srivastava, S. K., & Ghaffariyan, M. R. (2020). A Review on the Potential of Forest Biomass for Bioenergy in Australia. Energies, 13(5), 1147. https://doi.org/10.3390/en13051147