Impact of Phase Locked Loop with Different Types and Control Dynamics on Resonance of DFIG System

Abstract

1. Introduction

2. Small-Signal Impedance Model of PLL

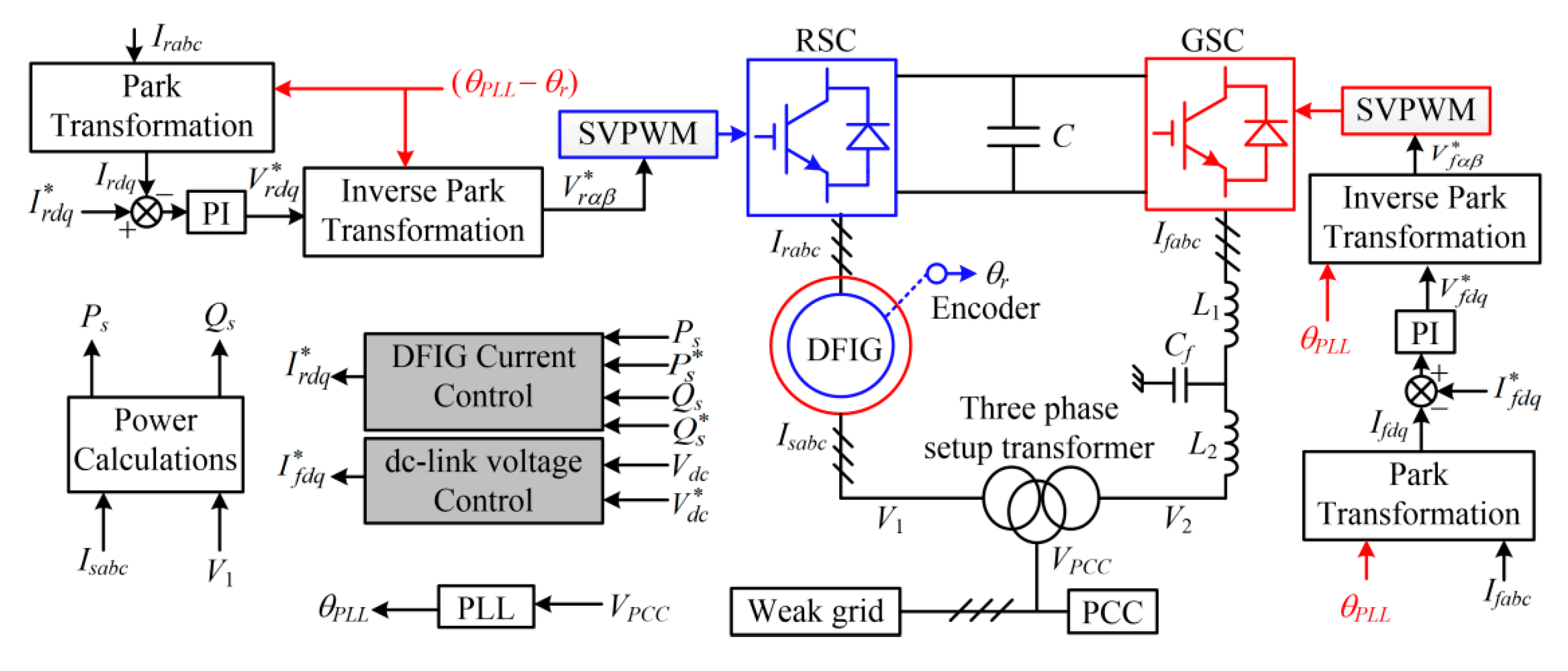

2.1. Common Sketch of Studied System

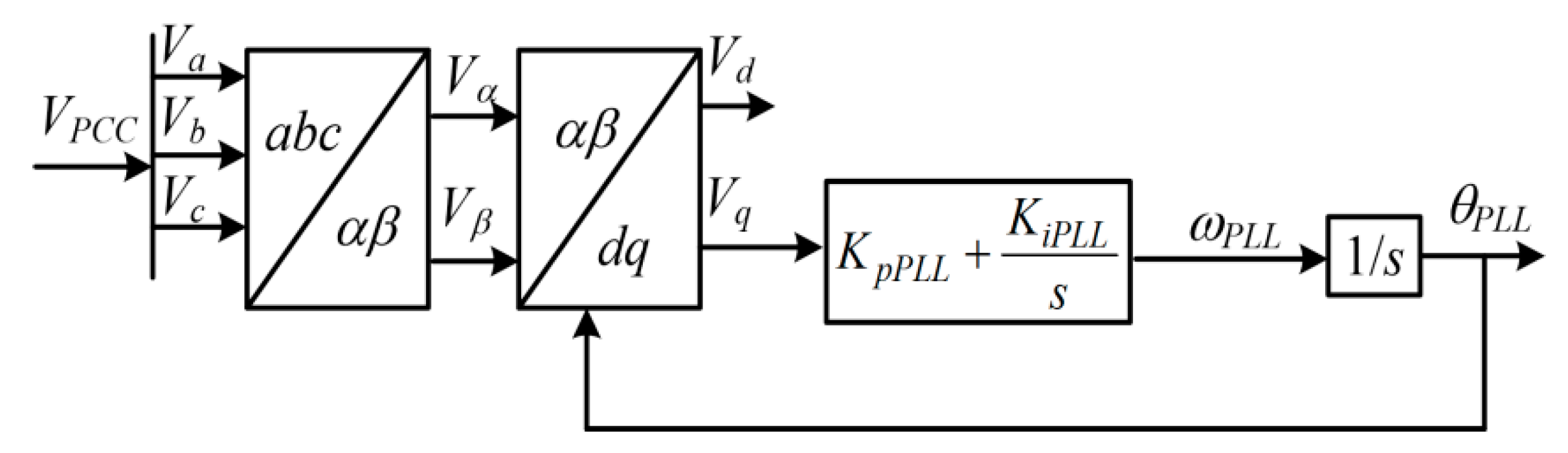

2.2. Synchronous reference frame-PLL (SRF-PLL): Small Signal Impedance Modeling

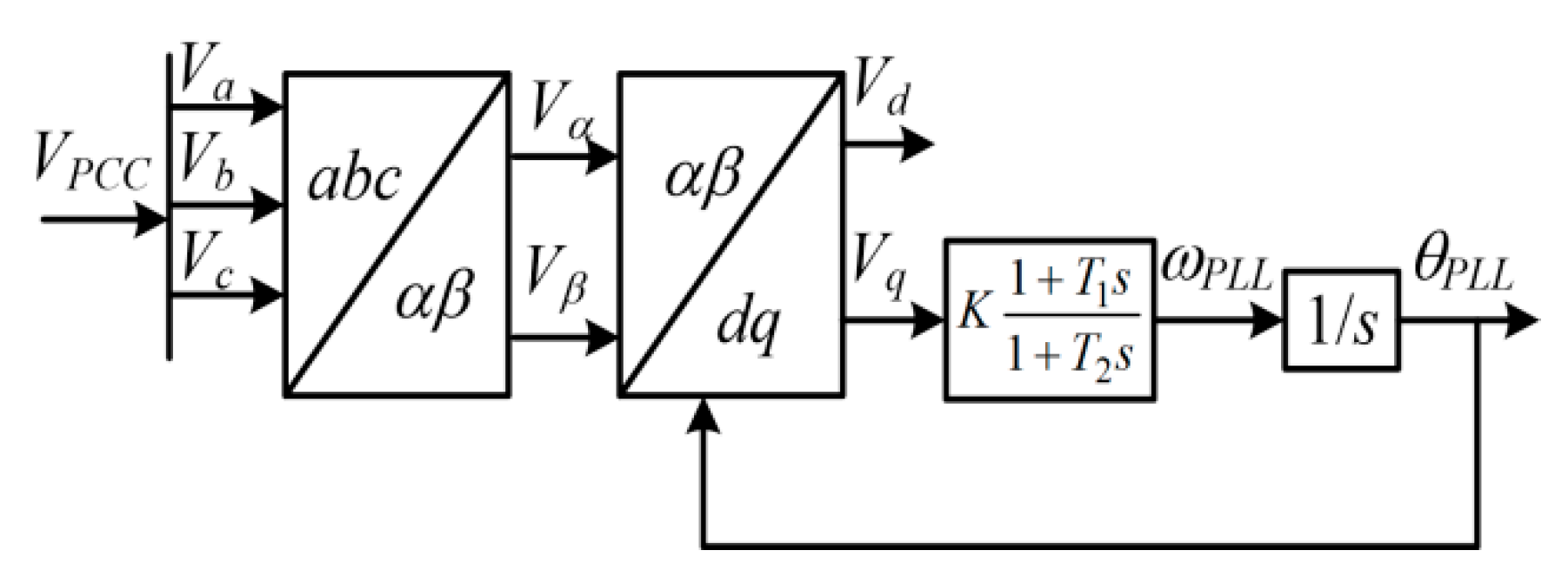

2.3. Small Signal Modeling of Lead/Lag PLL

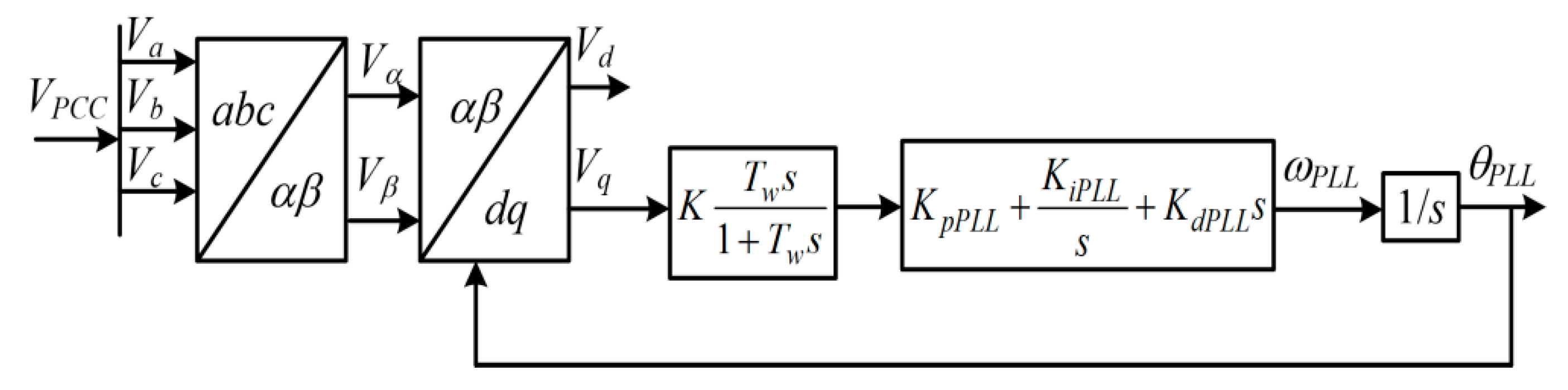

2.4. Small Signal Modeling of Improved PLL

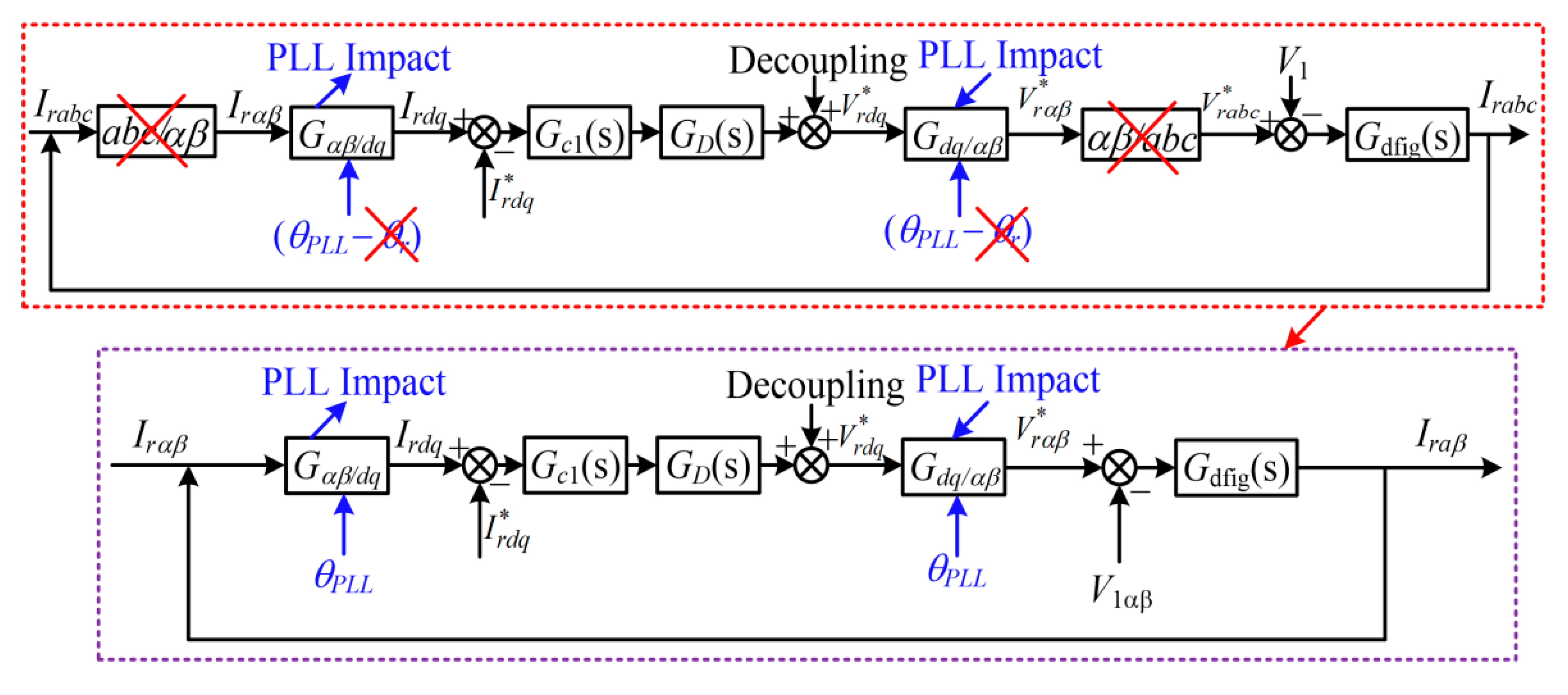

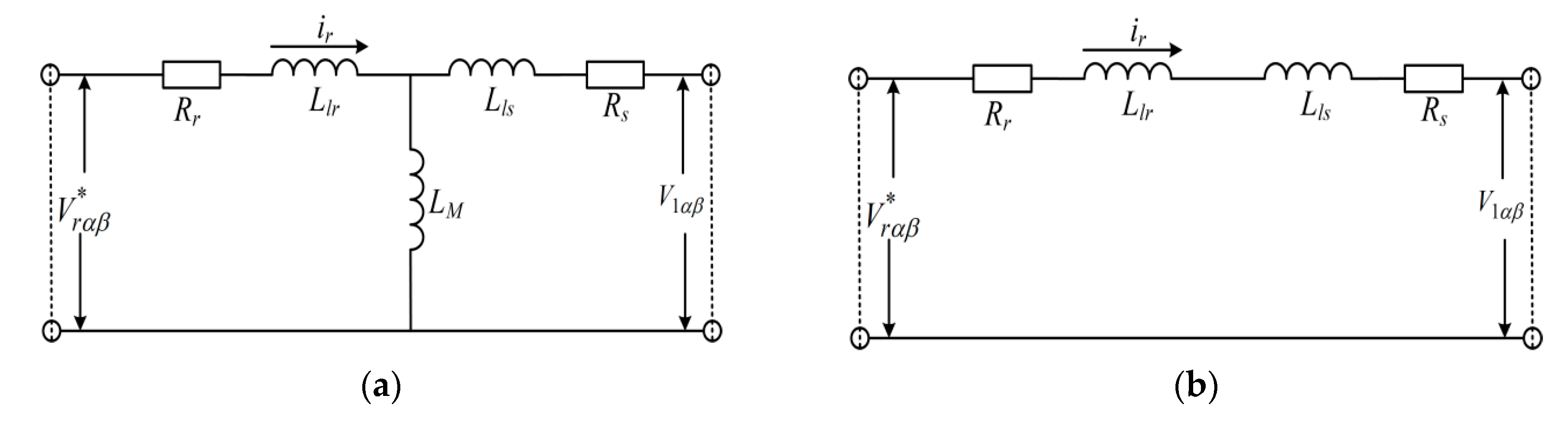

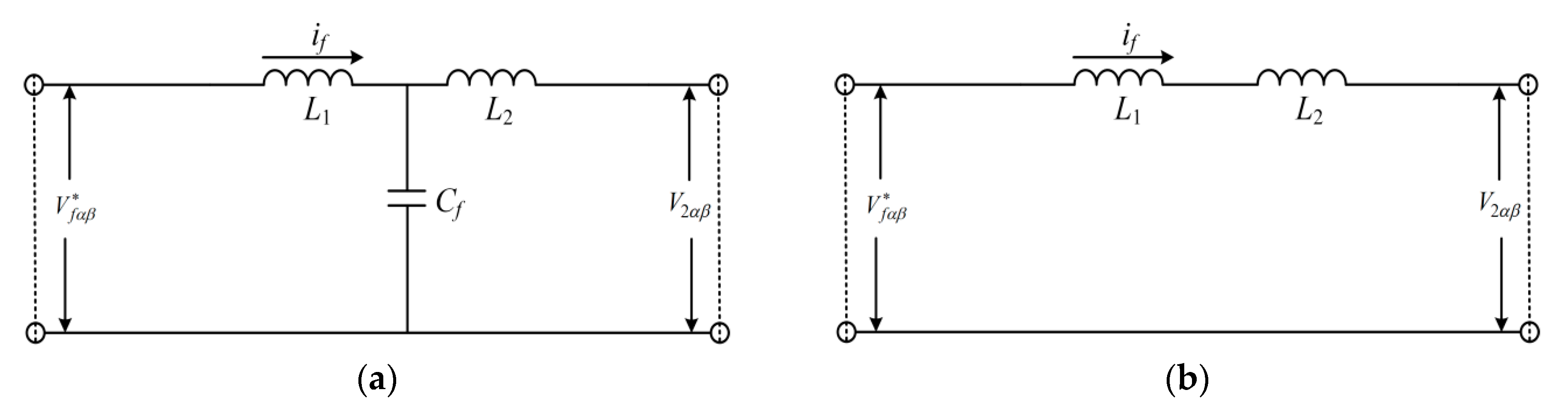

3. Impedance Modeling: DFIG System with PLL Inclusions

3.1. Impedance Modeling with SRF-PLL

3.2. Impedance Modeling with Lead/Lag PLL

3.3. Impedance Modeling with Improved PLL

4. Simulation Results

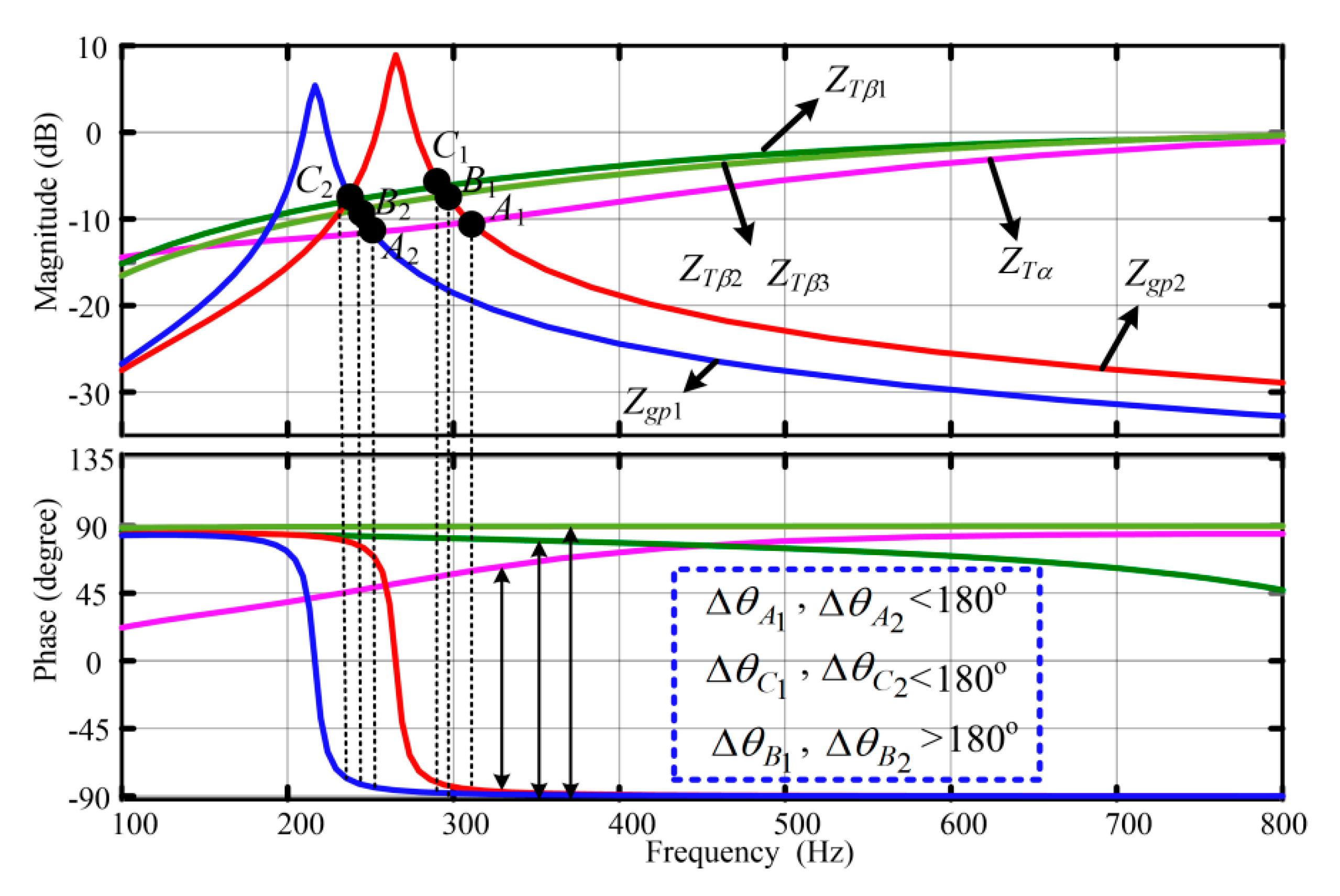

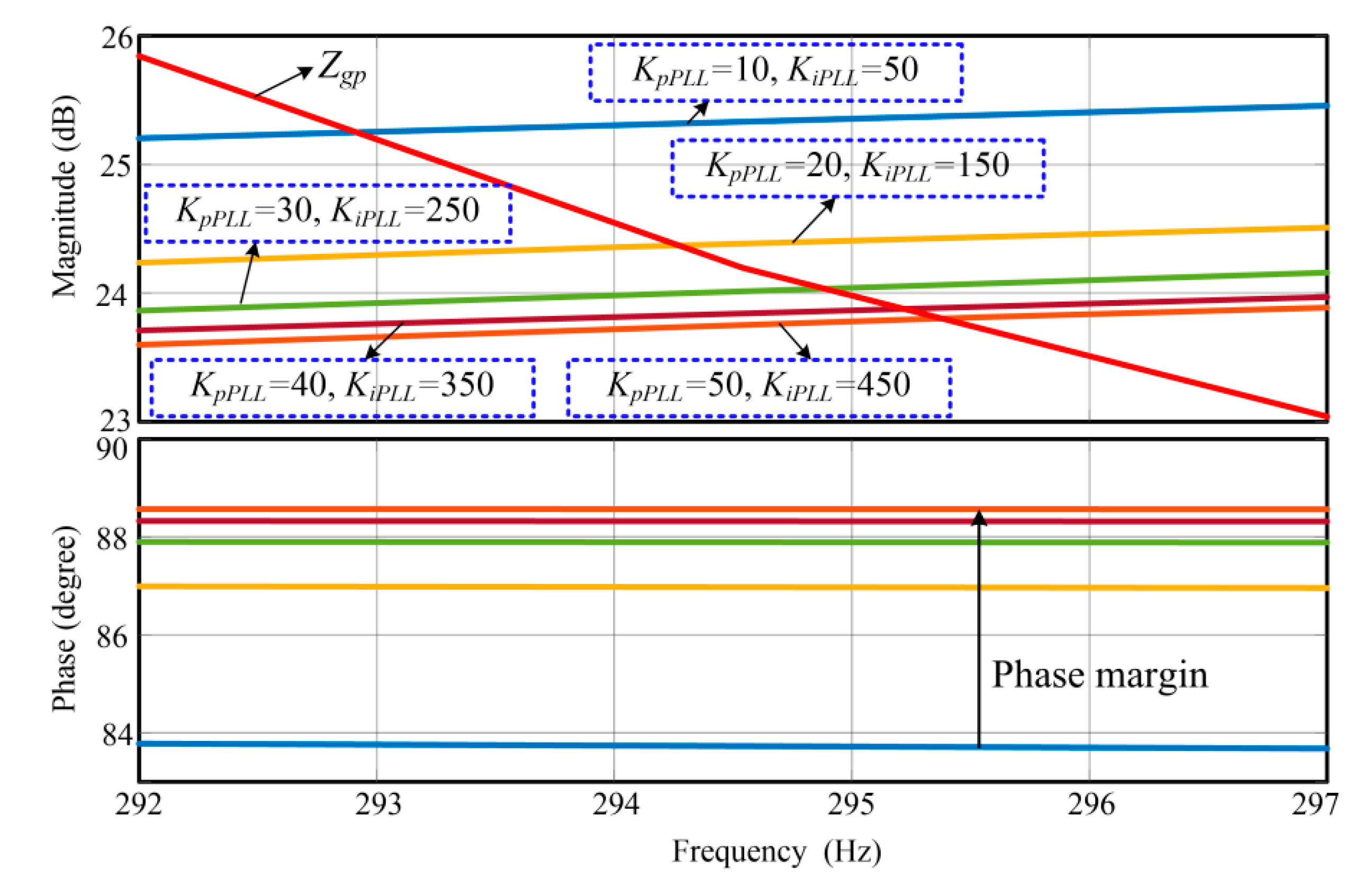

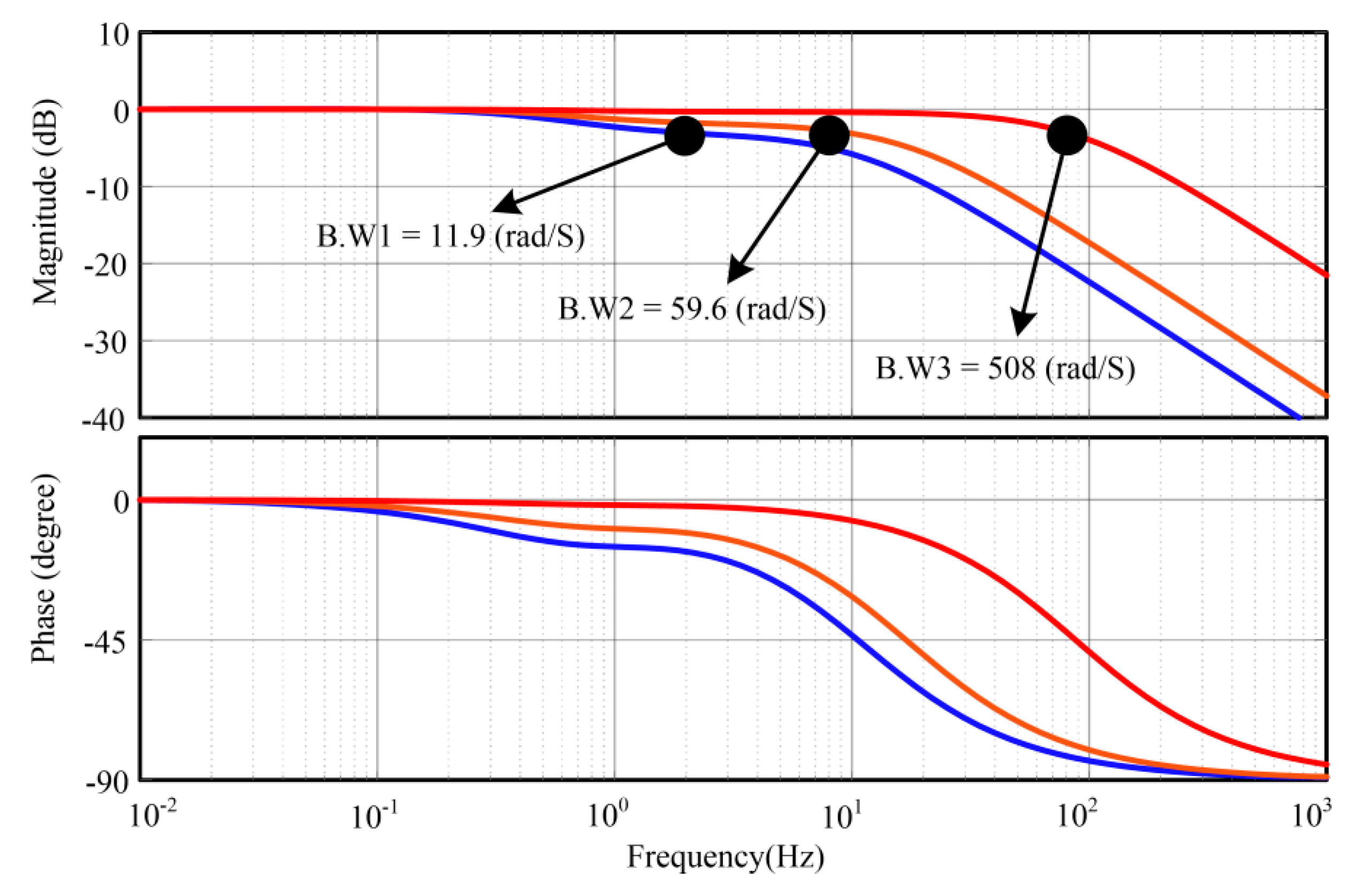

4.1. Simulation Results with SRF-PLL

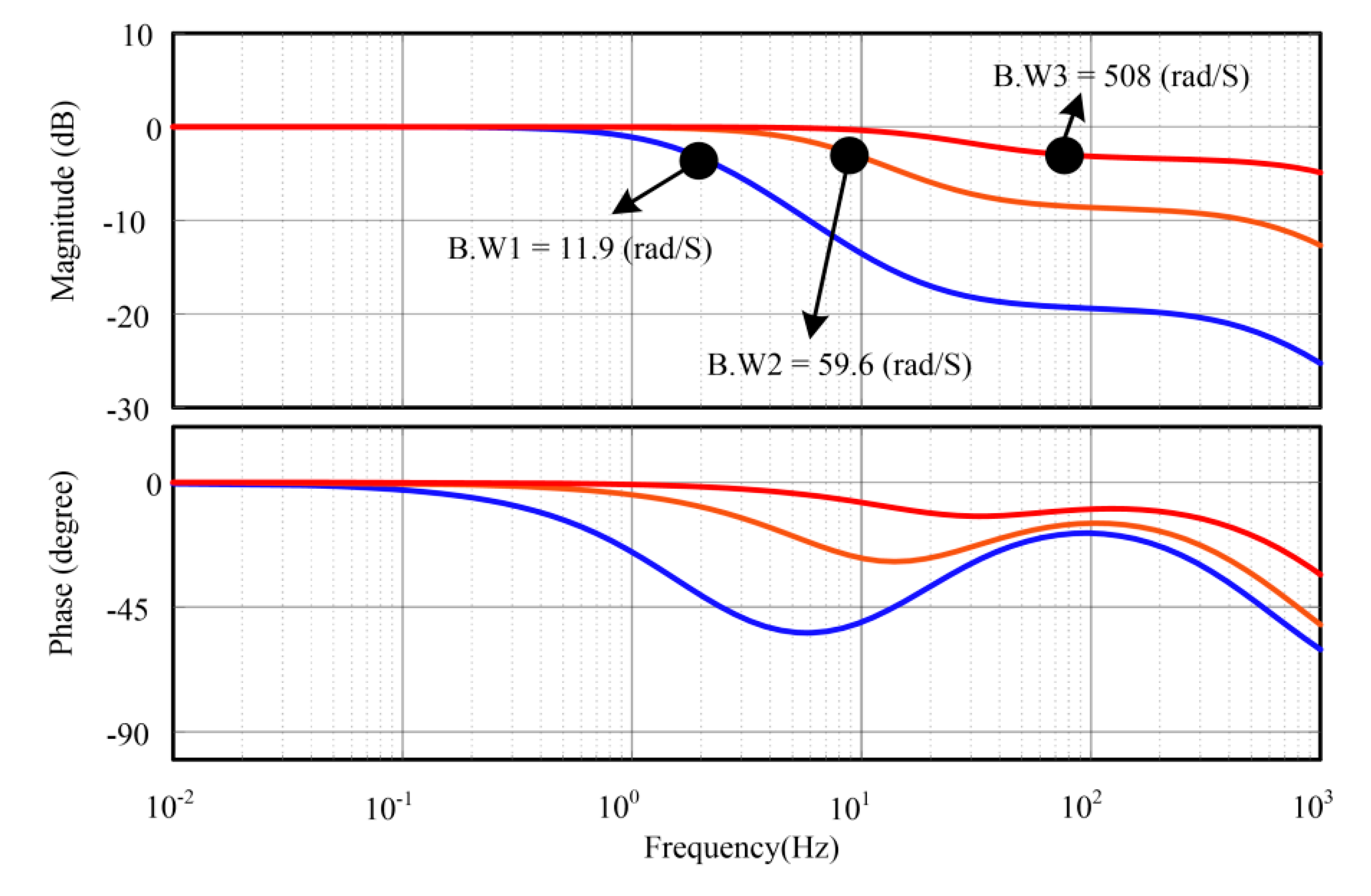

4.2. Simulation Results with Lead/Lag PLL

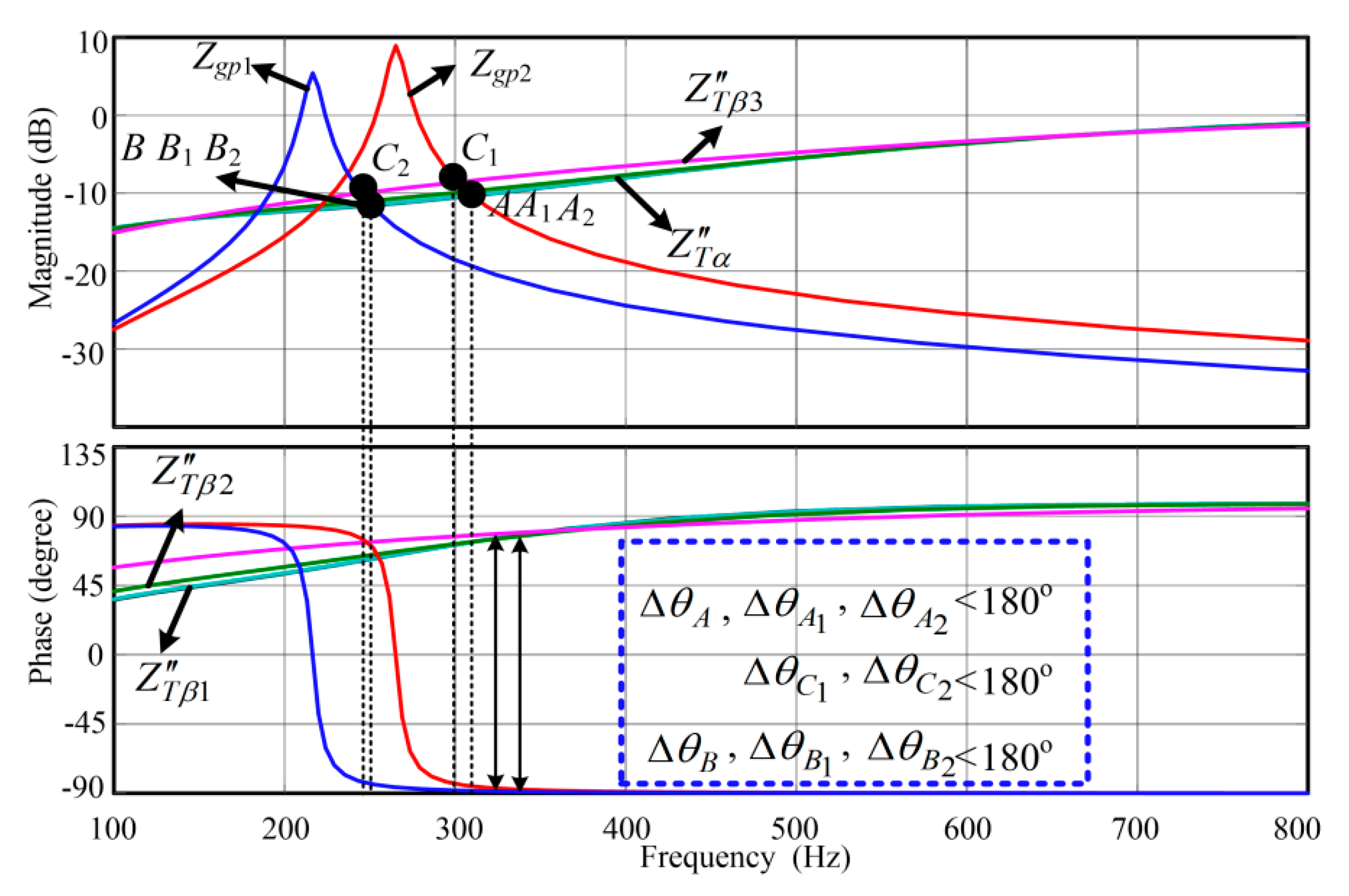

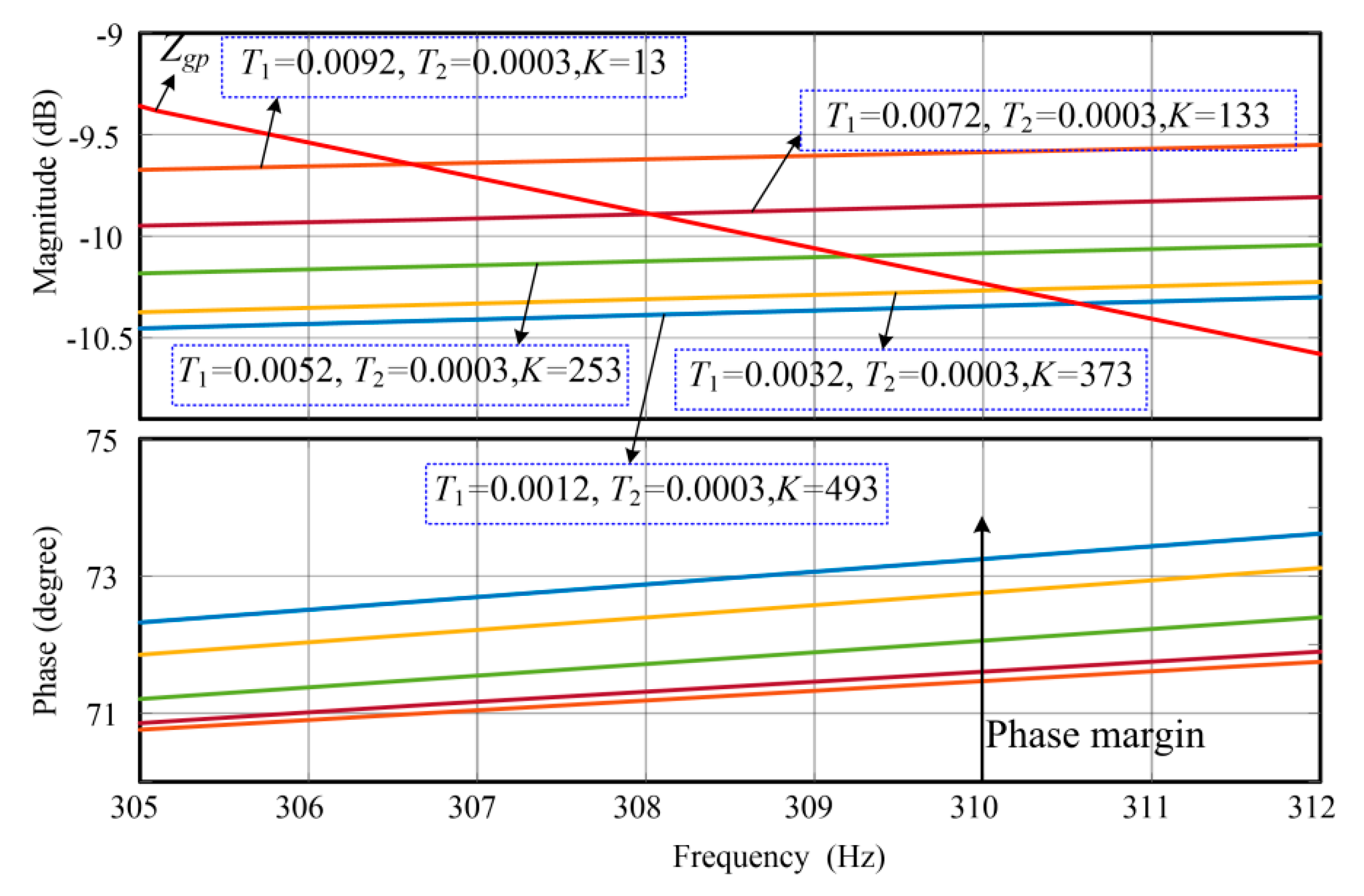

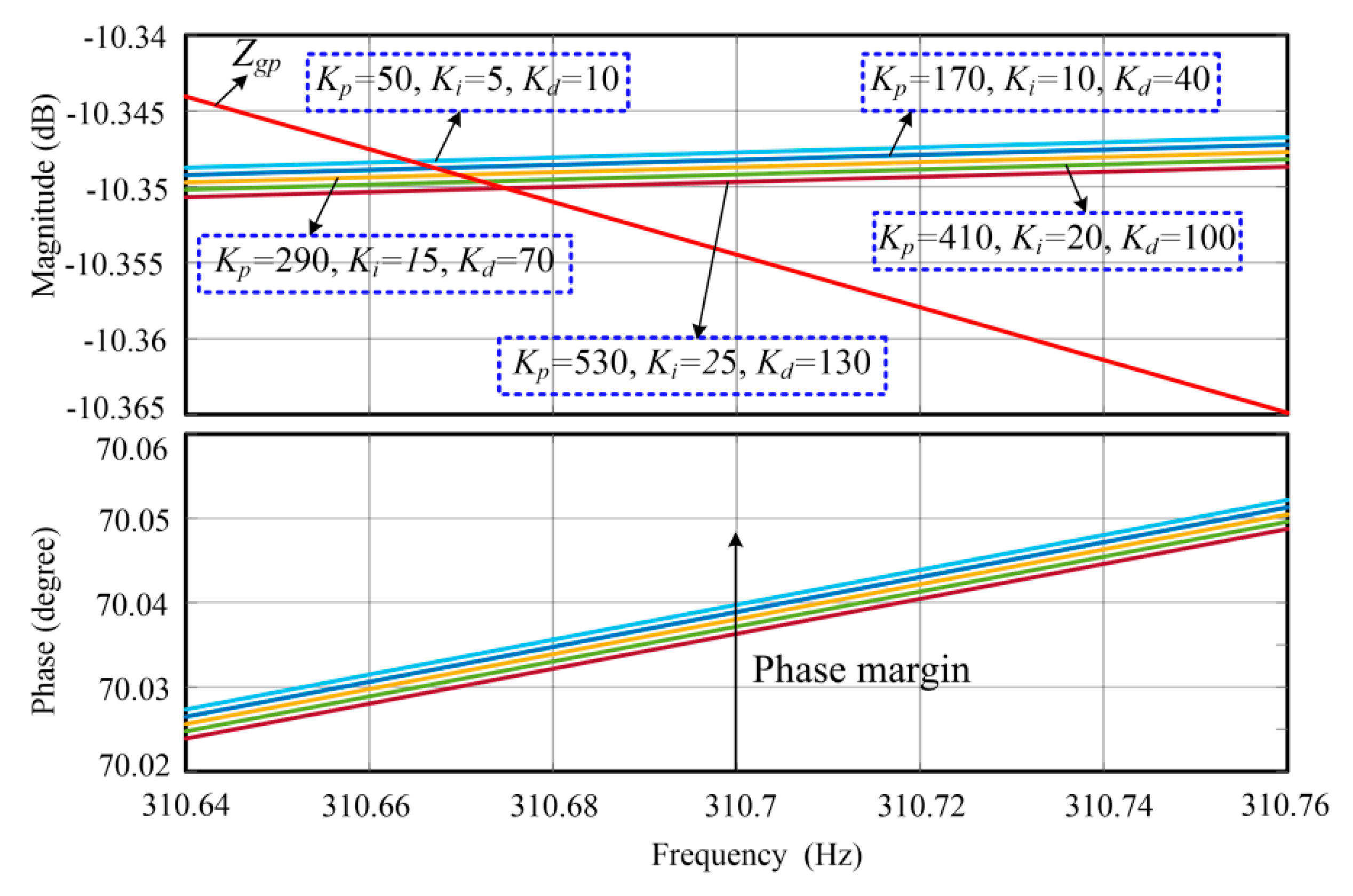

4.3. Simulation Results with Improved PLL

5. Time Domain Simulations

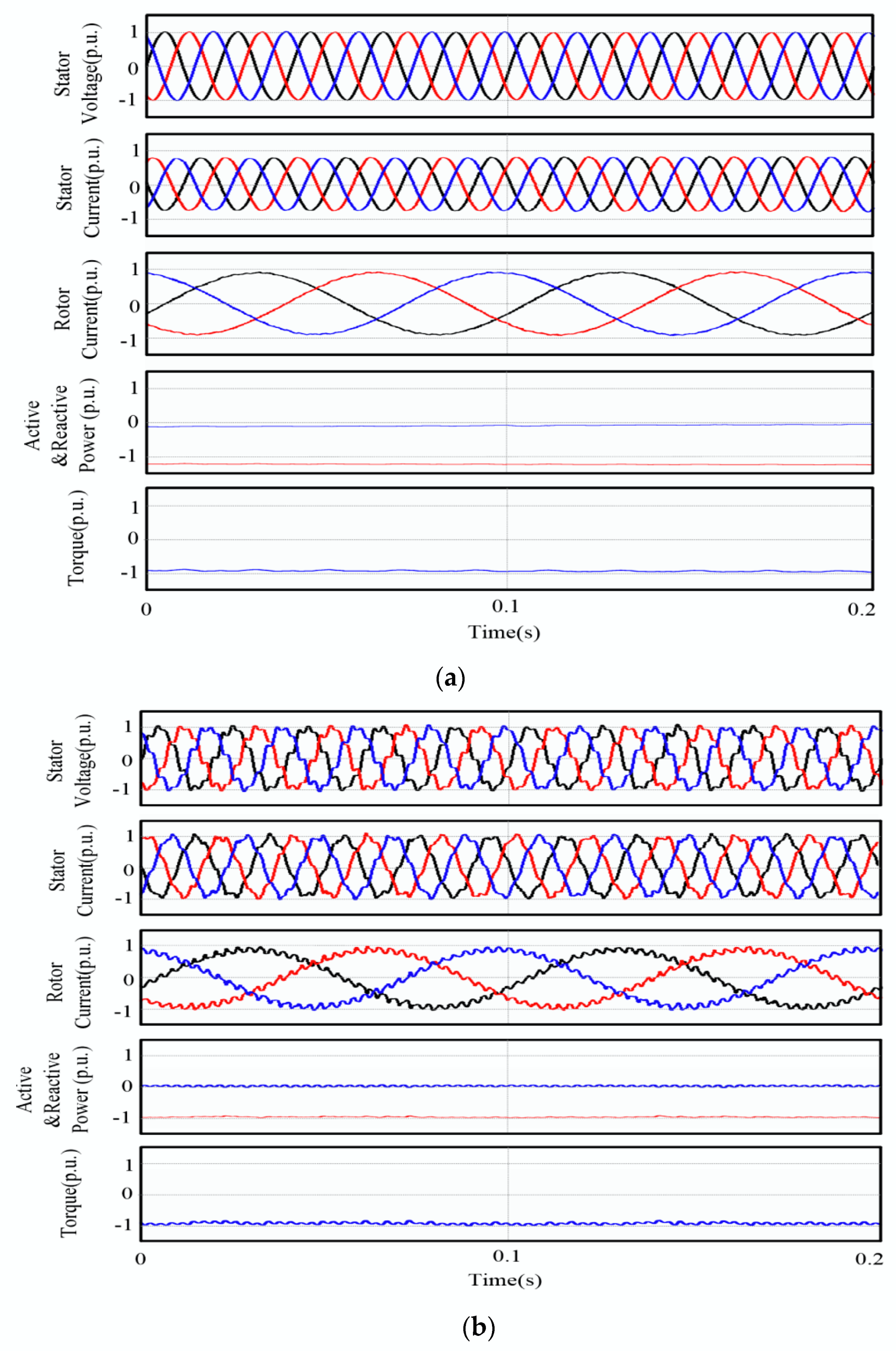

5.1. Simulation Results with SRF-PLL

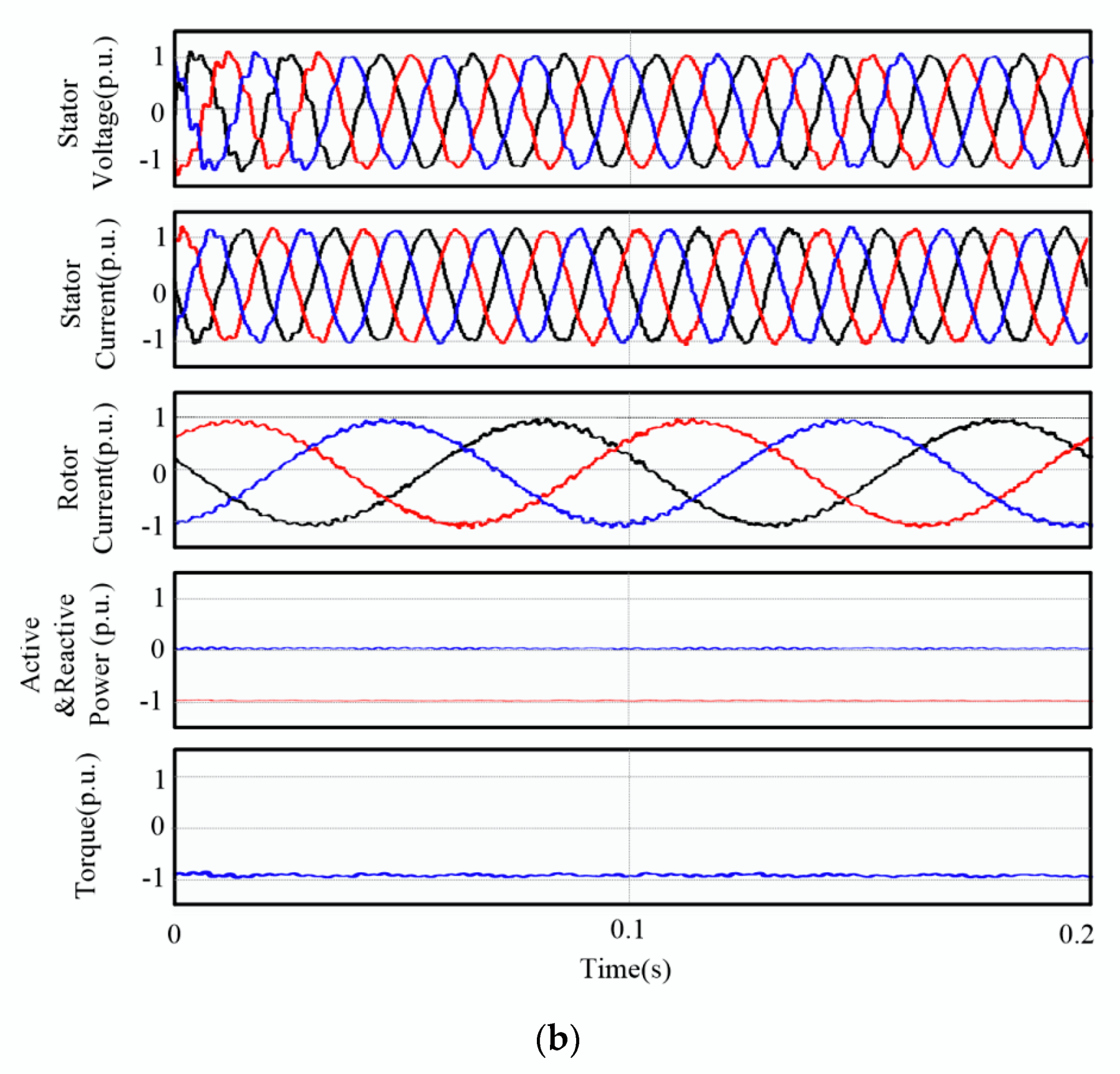

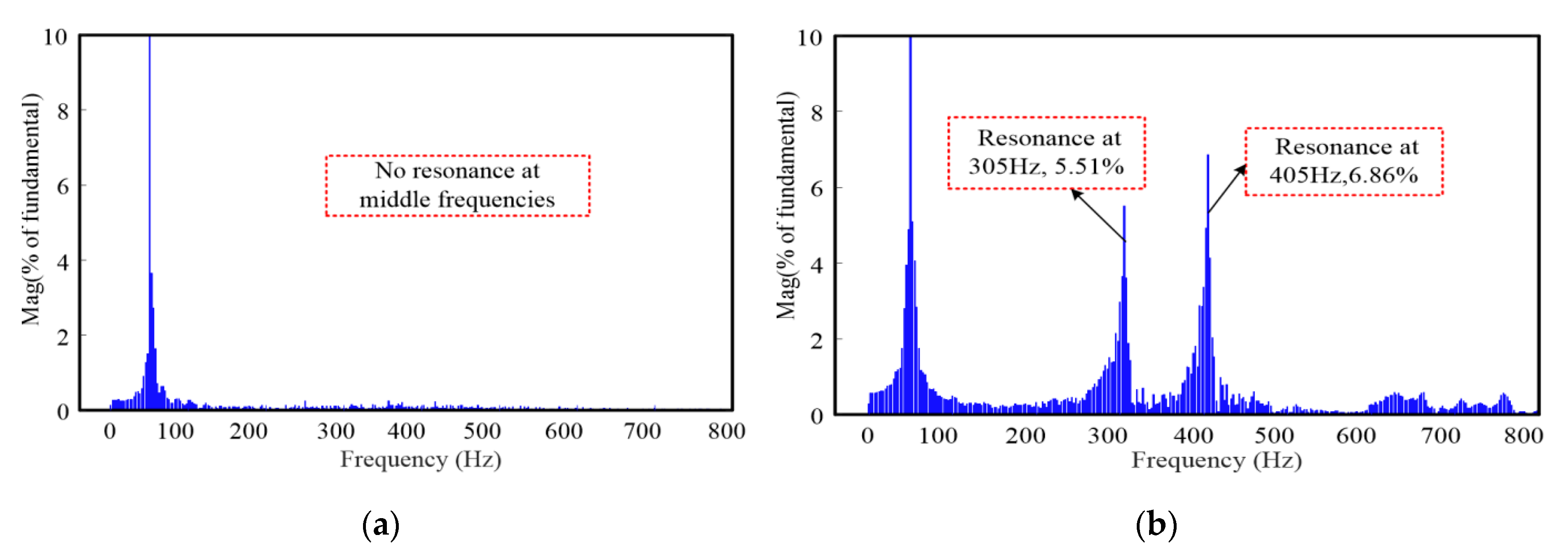

5.2. Simulation Results with Lead/Lag PLL

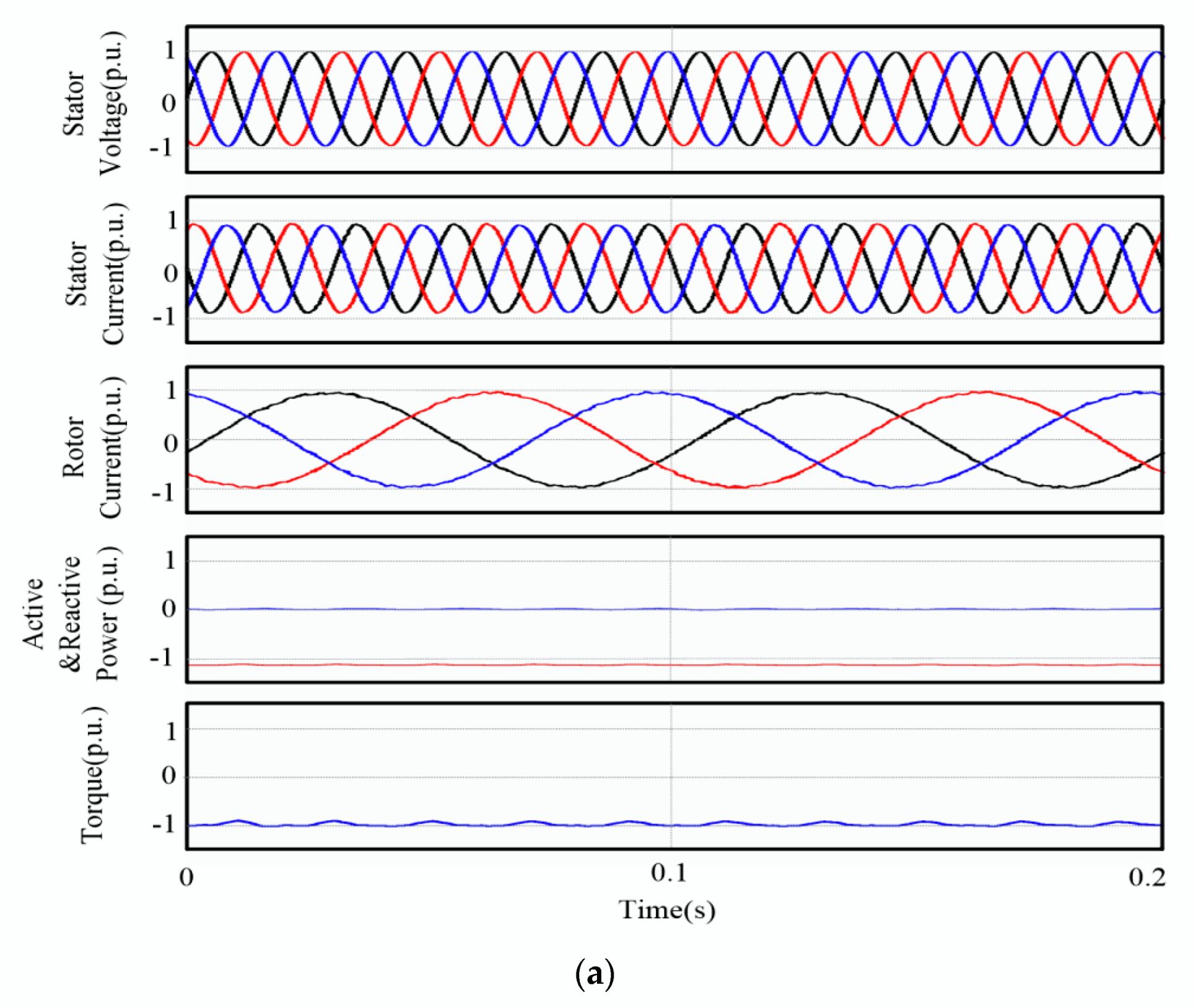

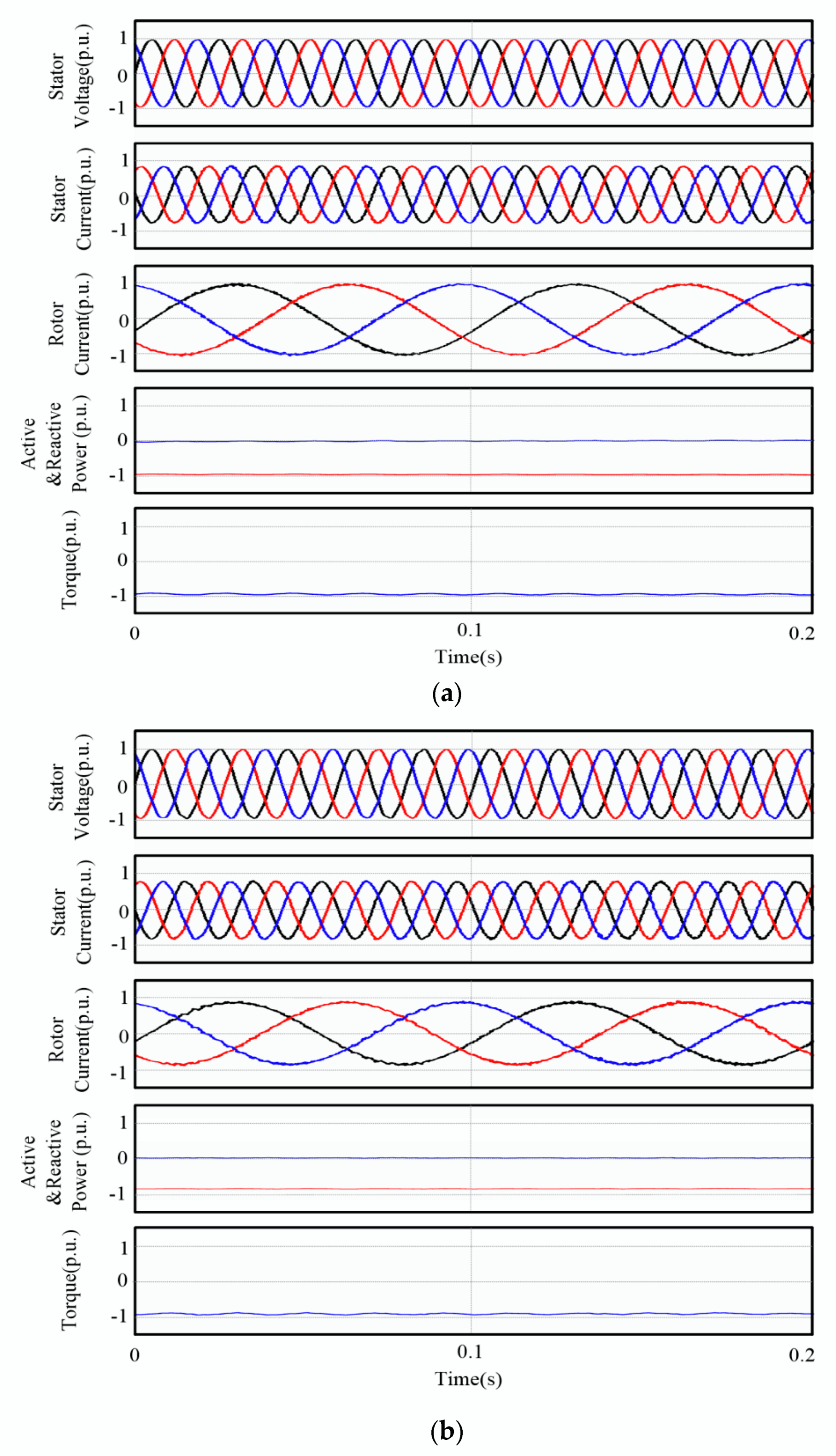

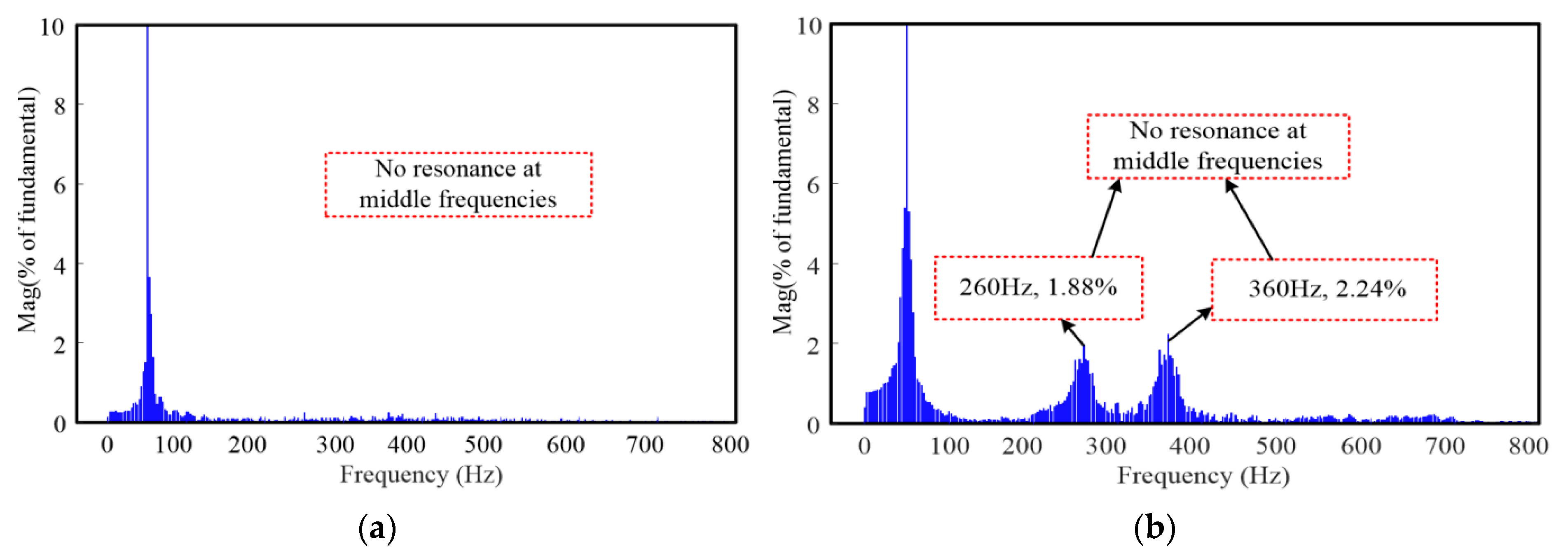

5.3. Simulation Results with Improved PLL

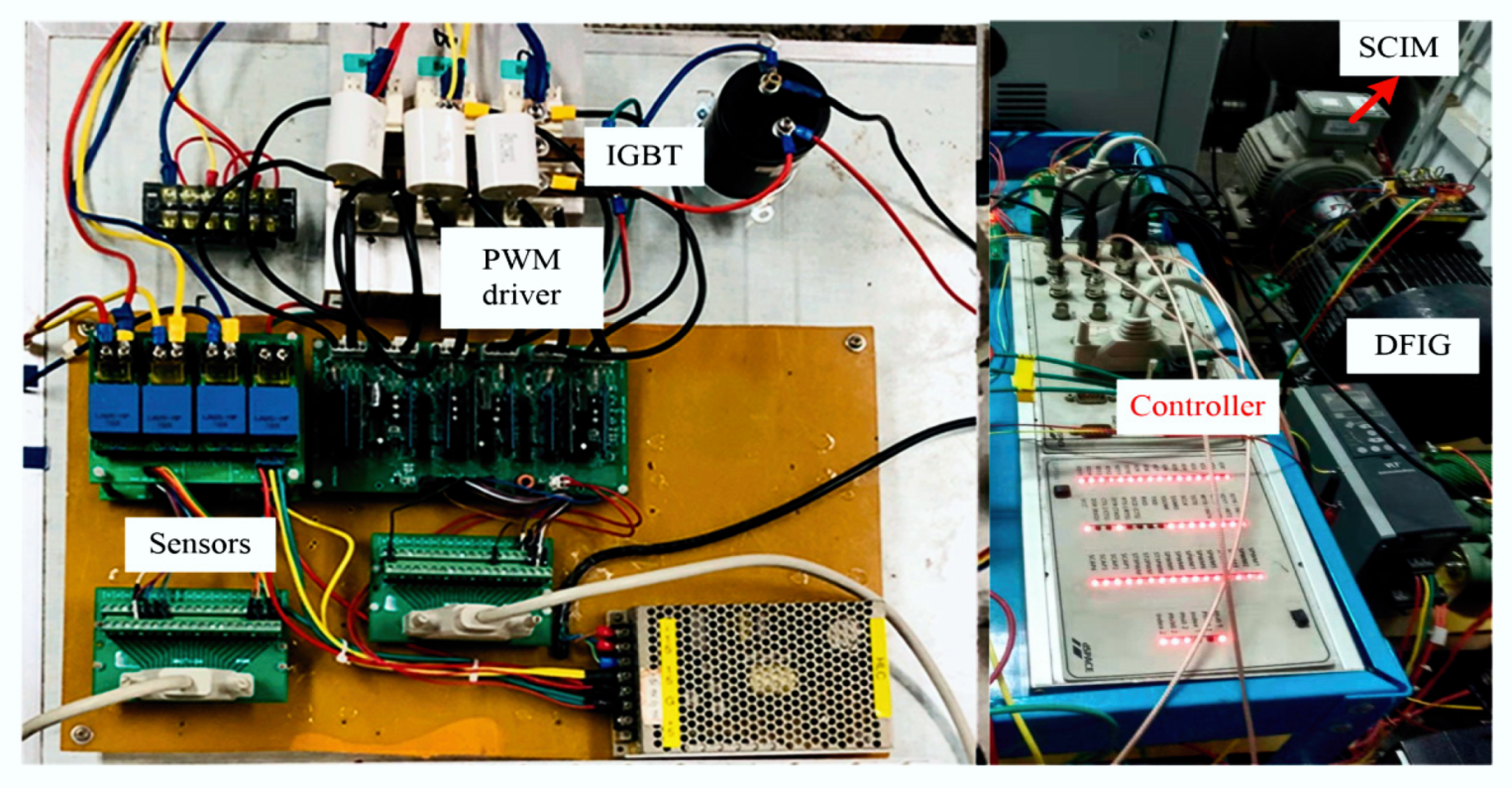

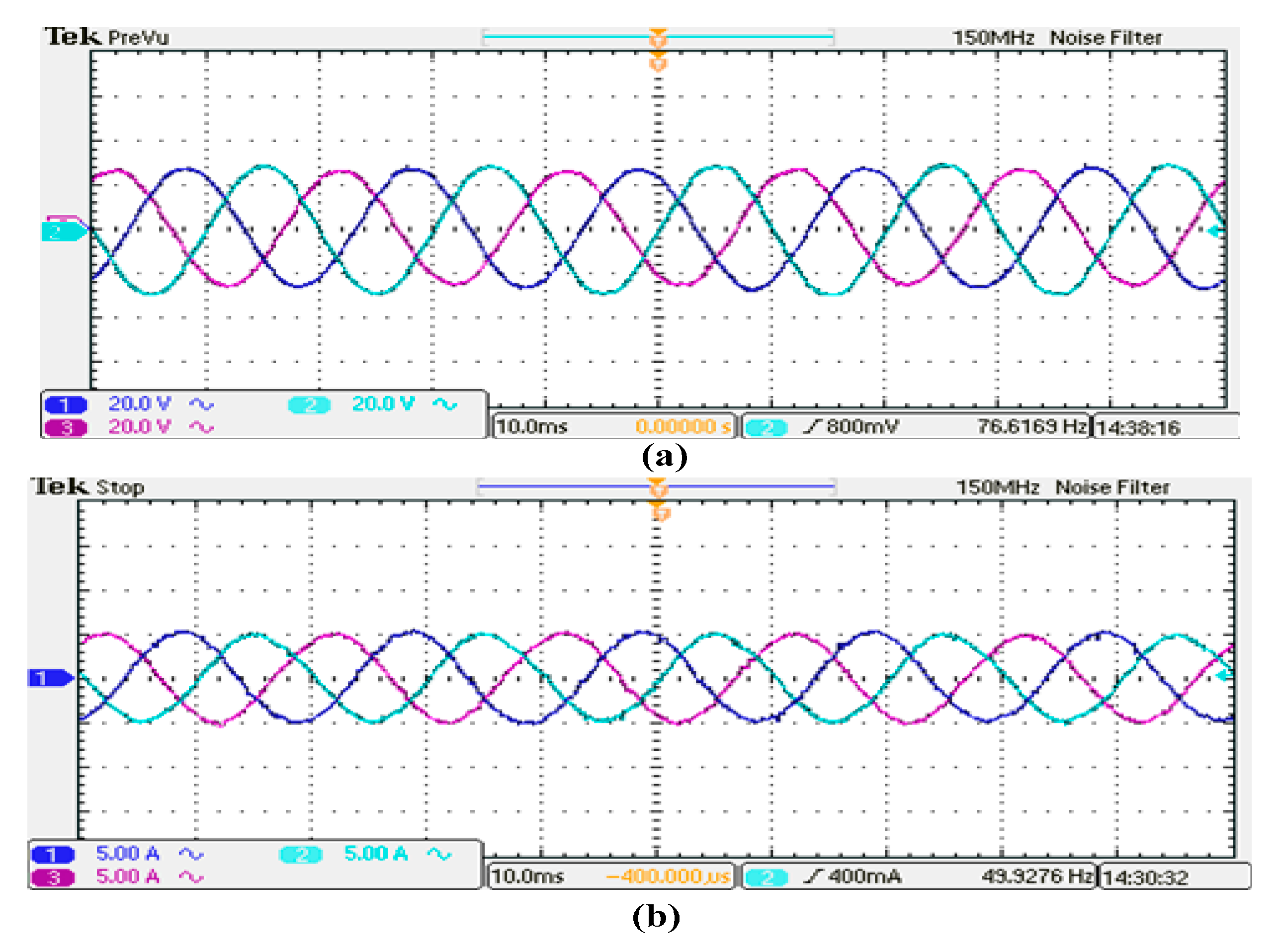

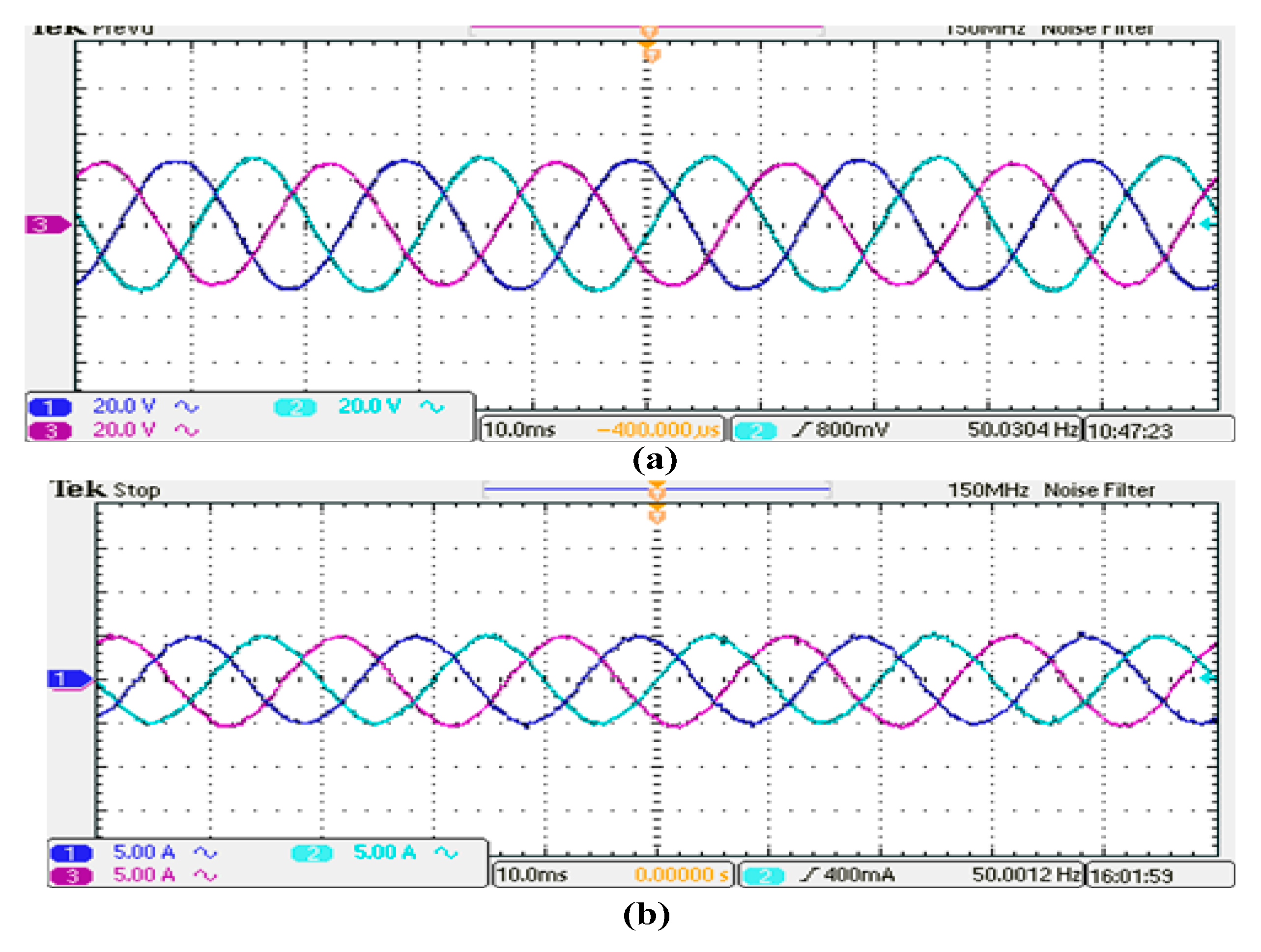

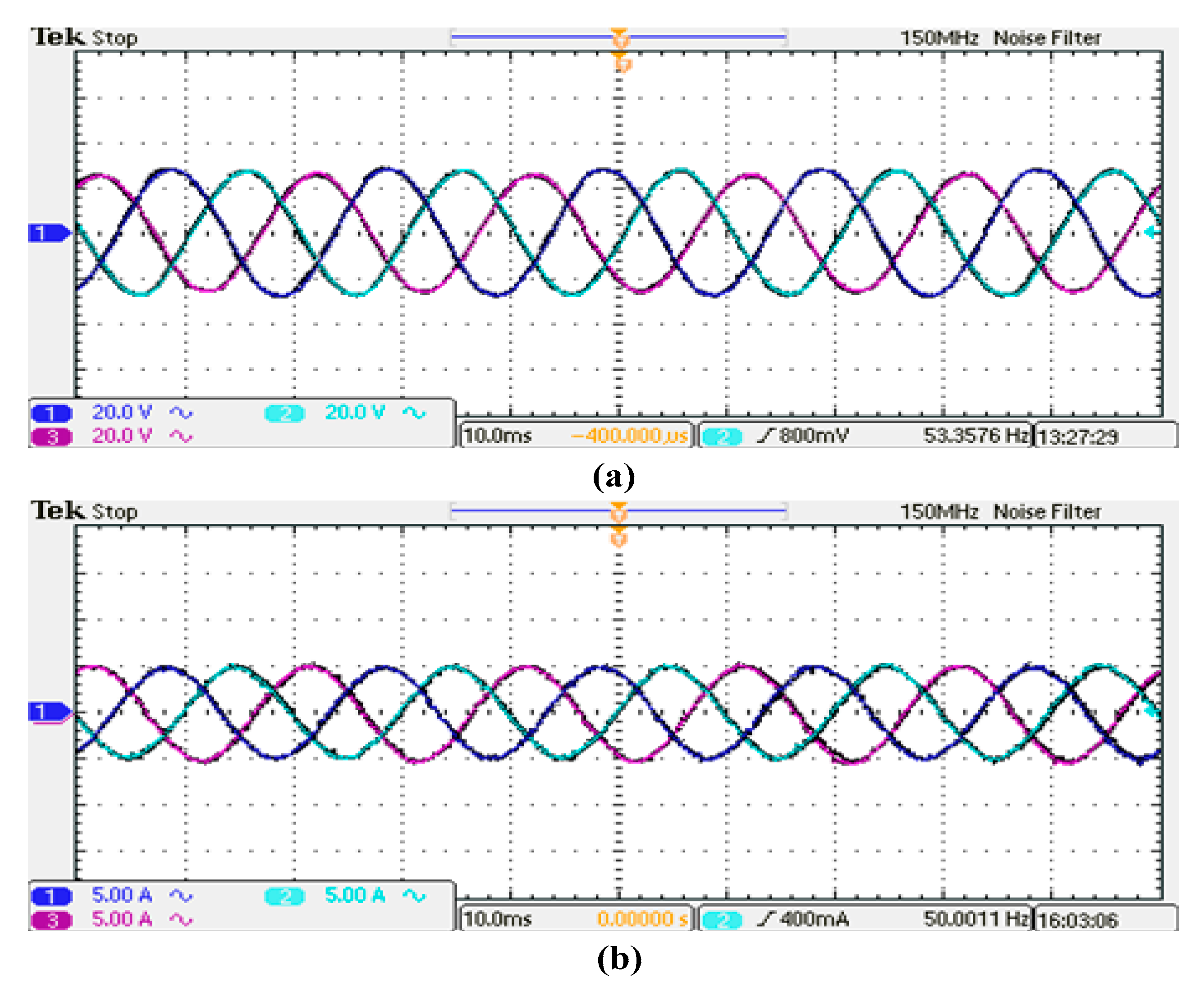

6. Experimental Results

7. Conclusions

- The low bandwidth of any PLL (SRF, Lead/Lag, and improved) has no effect on the resonance at middle frequencies due to an acceptable phase margin.

- Resonance at middle frequencies exists in the DFIG system with high bandwidth SRF, and Lead/Lag PLL. However, there is no resonance at middle frequencies with the employment of improved PLL, even with the high bandwidth.

- The performance of the Lead/Lag PLL is superior to the same high bandwidth SRF-PLL due to the higher phase margin of the Lead/Lag PLL.

- The phase margin with the Lead/Lag PLL is less dependent on the PLL controller parameters as compared to SRF-PLL.

- The improved PLL controller parameters have an insignificant effect on the impedance modeling, as the phase margin is approximately the same for different bandwidth improved PLL.

- The α and β component DFIG system impedance with improved PLL has approximately the same impedance shape. Additionally, a high phase margin with improved PLL guaranteed better dynamic performance than the SRF-PLL and Lead/Lag PLL.

- The experimental results are in good agreement with the time domain simulations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Müller, S.; Deicke, M.; Rik Doncker, D.W. Doubly fed induction generator systems for wind turbines. Ind. Appl. Mag. IEEE 2002, 8, 26–33. [Google Scholar] [CrossRef]

- Cai, L.J.; Erlich, I. Doubly Fed Induction Generator Controller Design for the Stable Operation in Weak Grids. IEEE Trans. Sustain. Energy 2015, 6, 1078–1084. [Google Scholar] [CrossRef]

- Grunau, S.; Fuchs, F.W. Effect of wind-energy power injection into weak grids. In Proceedings of the 2012 European Wind Energy Conference and Exhibition (EWEC), Copenhagen, Denmark, 16–19 April 2012; pp. 1150–1156. [Google Scholar]

- Blaabjerg, F.; Ma, K. Future on power electronics for wind turbine systems. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 139–152. [Google Scholar] [CrossRef]

- Vieto Sun, J. Sequence Impedance Modeling and Analysis of Type-III Wind Turbines. IEEE Trans. Energy Convers. 2018, 33, 537–545. [Google Scholar] [CrossRef]

- Chen, W.; Xie, X.; Wang, D.; Liu, H.; Liu, H. Probabilistic stability analysis of subsynchronous resonance for series-compensated DFIG-based wind farms. IEEE Trans. Sustain. Energy 2018, 9, 400–409. [Google Scholar] [CrossRef]

- Miao, Z. Impedance-model-based SSR analysis for type 3 wind generator and series-compensated network. IEEE Trans. Energy Convers. 2012, 27, 984–991. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Fang, R.; Xu, D. Impedance Modeling and SSR Analysis of DFIG Using Complex Vector Theory. IEEE Access 2019, 7, 155860–155870. [Google Scholar] [CrossRef]

- Huang, P.; Shawky, M.; Moursi, E.; Xiao, W.; Member, S.; Kirtley, J.L. Subsynchronous Resonance Mitigation for Series-Compensated DFIG-Based Wind Farm by Using Two-Degree-of-Freedom Control Strategy. IEEE Trans. Power Syst. 2015, 30, 1442–1454. [Google Scholar] [CrossRef]

- Du, W.; Ren, B.; Wang, H.; Wang, Y. Comparison of Methods to Examine Sub-Synchronous Oscillations Caused by Grid-Connected Wind Turbine Generators. IEEE Trans. Power Syst. 2019, 34, 4931–4943. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, X.; Liu, H.; Liu, H.; Li, Y.; Zhang, C. Characteristic Analysis of Subsynchronous Resonance in Practical Wind Farms Connected to Series-Compensated Transmissions. IEEE Trans. Energy Convers. 2017, 32, 1117–1126. [Google Scholar] [CrossRef]

- Din, Z.; Zhang, J.; Zhang, Y.; Xu, Z.; Zhao, J.; Song, Y. Active damping of resonances in DFIG system with cascade converter under weak grid. Int. Trans. Electr. Energy Syst. 2019, 29, e12118. [Google Scholar] [CrossRef]

- Song, Y.; Wang, X.; Blaabjerg, F. Impedance-Based High-Frequency Resonance Analysis of DFIG System in Weak Grids. IEEE Trans. Power Electron. 2017, 32, 3536–3548. [Google Scholar] [CrossRef]

- Song, Y.; Blaabjerg, F. High-Frequency Resonance Damping of DFIG-Based Wind Power System UnderWeak Network. IEEE Trans. Power Electron. 2017, 32, 4370–4394. [Google Scholar] [CrossRef]

- Song, Y.; Blaabjerg, F.; Wang, X. Analysis and Active Damping of Multiple High Frequency Resonances in DFIG System. IEEE Trans. Energy Convers. 2017, 32, 369–381. [Google Scholar] [CrossRef]

- Din, Z.; Zhang, J.; Xu, Z.; Zhang, Y. Phase Angle Compensation of Virtual Impedance for Resonance Mitigation in DFIG System under Weak Grid. In Proceedings of the 8th IET International Conference on Renewable Power Generation (RPG 2019), Shanghai, China, 24–25 October 2019; pp. 1–8. [Google Scholar]

- Nian, H.; Cheng, P.; Zhu, Z.Q. Independent operation of DFIG-based WECS using resonant feedback compensators under unbalanced grid voltage conditions. IEEE Trans. Power Electron. 2015, 30, 3650–3661. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Y.; Tian, Y.; Wang, L. Phase-locked loop research of grid-connected inverter based on impedance analysis. Energies 2018, 11, 3077. [Google Scholar] [CrossRef]

- Qian, Q.; Xie, S.; Xu, J.; Xu, K.; Bian, S.; Zhong, N. Output Impedance Modeling of Single-Phase Grid-Tied Inverters with Capturing the Frequency-Coupling Effect of PLL. IEEE Trans. Power Electron. 2019, 35, 5479–5495. [Google Scholar] [CrossRef]

- Zhu, D.; Zhou, S.; Zou, X.; Kang, Y. Improved Design of PLL Controller for $LCL$-Type Grid-Connected Converter in Weak Grid. IEEE Trans. Power Electron. 2019, 35, 4715–4727. [Google Scholar] [CrossRef]

- Wang, X.; Harnefors, L.; Blaabjerg, F. Unified Impedance Model of Grid-Connected Voltage-Source Converters. IEEE Trans. Power Electron. 2018, 33, 1775–1787. [Google Scholar] [CrossRef]

- Wen, B.; Boroyevich, D.; Burgos, R.; Mattavelli, P.; Shen, Z. Analysis of D-Q Small-Signal Impedance of Grid-Tied Inverters. IEEE Trans. Power Electron. 2016, 31, 675–687. [Google Scholar] [CrossRef]

- Wen, B.; Boroyevich, D.; Burgos, R.; Mattavelli, P.; Shen, Z. Small-Signal Stability Analysis of Three-Phase AC Systems in the Presence of Constant Power Loads Based on Measured d-q Frame Impedances. IEEE Trans. Power Electron. 2015, 30, 5952–5963. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Wang, Y.; Gong, C. Analysis of frequency characteristics of phase-locked loops and effects on stability of three-phase grid-connected inverter. Int. J. Electr. Power Energy Syst. 2019, 113, 652–663. [Google Scholar] [CrossRef]

- Yang, D.; Wang, X.; Liu, F.; Xin, K.; Liu, Y.; Blaabjerg, F. Symmetrical PLL for SISO impedance modeling and enhanced stability in weak grids. IEEE Trans. Power Electron. 2020, 35, 1473–1483. [Google Scholar] [CrossRef]

- Chou, S.-F.; Wang, X.; Blaabjerg, F. Two-Port Network Modeling and Stability Analysis of Grid-Connected Current-Controlled VSCs. IEEE Trans. Power Electron. 2019, 35, 3519–3529. [Google Scholar] [CrossRef]

- Li, Y.; Fan, L.; Miao, Z. Wind in Weak Grids: Low-Frequency Oscillations, Subsynchronous Oscillations, and Torsional Interactions. IEEE Trans. Power Syst. 2019, 35, 109–118. [Google Scholar] [CrossRef]

- Vieto Sun, J. Small-signal impedance modelling of type-III wind turbine. In Proceedings of the 2015 IEEE Power & Energy Society General Meeting, Denver, CO, USA, 26–30 July 2015; pp. 1–5. [Google Scholar]

- Song, Y.; Blaabjerg, F. Analysis of Middle Frequency Resonance in DFIG System Considering Phase-Locked Loop. IEEE Trans. Power Electron. 2018, 33, 343–356. [Google Scholar] [CrossRef]

- Zhan, C.; Fitzer, C.; Ramachandaramurthy, V.K.; Arulampalam, A.; Barnes, M.; Jenkins, N. Software phase-locked loop applied to dynamic voltage restorer (DVR). In Proceedings of the 2001 IEEE Power Engineering Society Winter Meeting, Conference Proceedings (Cat. No.01CH37194), Columbus, OH, USA, 28 January–1 Feberuary 2001; pp. 1033–1038. [Google Scholar]

| Element | Symbol | Value | Symbol | Value | |

|---|---|---|---|---|---|

| DFIG | Ps | 2 MW | TD | 300 µs | |

| Vnom | 690 V | Pole pairs | 3 | ||

| Pbase | 2 MW | Vbase | 563 V | ||

| Nbase | 750 rpm | ωr | 0.8 p.u. | ||

| Rs | 0.0067 p.u. | Rr | 0.0063 p.u. | ||

| Lls | 0.0528 p.u. | Llr | 0.0792 p.u. | ||

| LM | 3.9592 p.u. | p | 3 | ||

| fs | 5 kHz | fsw | 2.5 kHz | ||

| L1 | 125 µH | L2 | 125 µH | ||

| Cf | 220 µF | V1 | 480 V | ||

| V2 | 690 V | VPCC | 1 KV | ||

| Kr | 2.08 | Kg | 1.45 | ||

| Kp1 | 0.2 | Ki1 | 2 | ||

| Kp2 | 0.2 | Ki2 | 2 | ||

| Weak Grid | Rg2 | 3.2 mΩ | Lg2 | 0.058 mH | |

| Cg2 | 0.0032 F | ||||

| PLL | SRF | KpPLL1 | 5 | KiPLL1 | 50 |

| KpPLL2 | 50 | KiPLL2 | 500 | ||

| KpPLL3 | 500 | KiPLL3 | 5000 | ||

| Lead/Lag | K1 | 13 | T1a | 0.0092 | |

| T2a | 0.0003 | K2 | 79 | ||

| T1b | 0.0072 | T2b | 0.0003 | ||

| K3 | 444 | T1c | 0.0045 | ||

| T2c | 0.0003 | ||||

| Improved | KpPLL1 | 50 | KiPLL1 | 5 | |

| KdPLL1 | 10 | Tw1 | 0.04 | ||

| KpPLL2 | 90.9 | KiPLL2 | 9 | ||

| KdPLL2 | 18.12 | Tw2 | 0.04 | ||

| KpPLL3 | 540.3 | KiPLL3 | 18 | ||

| KdPLL3 | 110.3 | Tw3 | 0.04 | ||

| K1 | 4.8 | K2 | 4.8 | ||

| K3 | 4.8 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Din, Z.; Zhang, J.; Bassi, H.; Rawa, M.; Song, Y. Impact of Phase Locked Loop with Different Types and Control Dynamics on Resonance of DFIG System. Energies 2020, 13, 1039. https://doi.org/10.3390/en13051039

Din Z, Zhang J, Bassi H, Rawa M, Song Y. Impact of Phase Locked Loop with Different Types and Control Dynamics on Resonance of DFIG System. Energies. 2020; 13(5):1039. https://doi.org/10.3390/en13051039

Chicago/Turabian StyleDin, Zakiud, Jianzhong Zhang, Hussain Bassi, Muhyaddin Rawa, and Yipeng Song. 2020. "Impact of Phase Locked Loop with Different Types and Control Dynamics on Resonance of DFIG System" Energies 13, no. 5: 1039. https://doi.org/10.3390/en13051039

APA StyleDin, Z., Zhang, J., Bassi, H., Rawa, M., & Song, Y. (2020). Impact of Phase Locked Loop with Different Types and Control Dynamics on Resonance of DFIG System. Energies, 13(5), 1039. https://doi.org/10.3390/en13051039