Optimal Design and Comparison of High-Frequency Resonant and Non-Resonant Rotary Transformers †

Abstract

1. Introduction

2. Materials and Methods

2.1. Wireless Power Transfer System

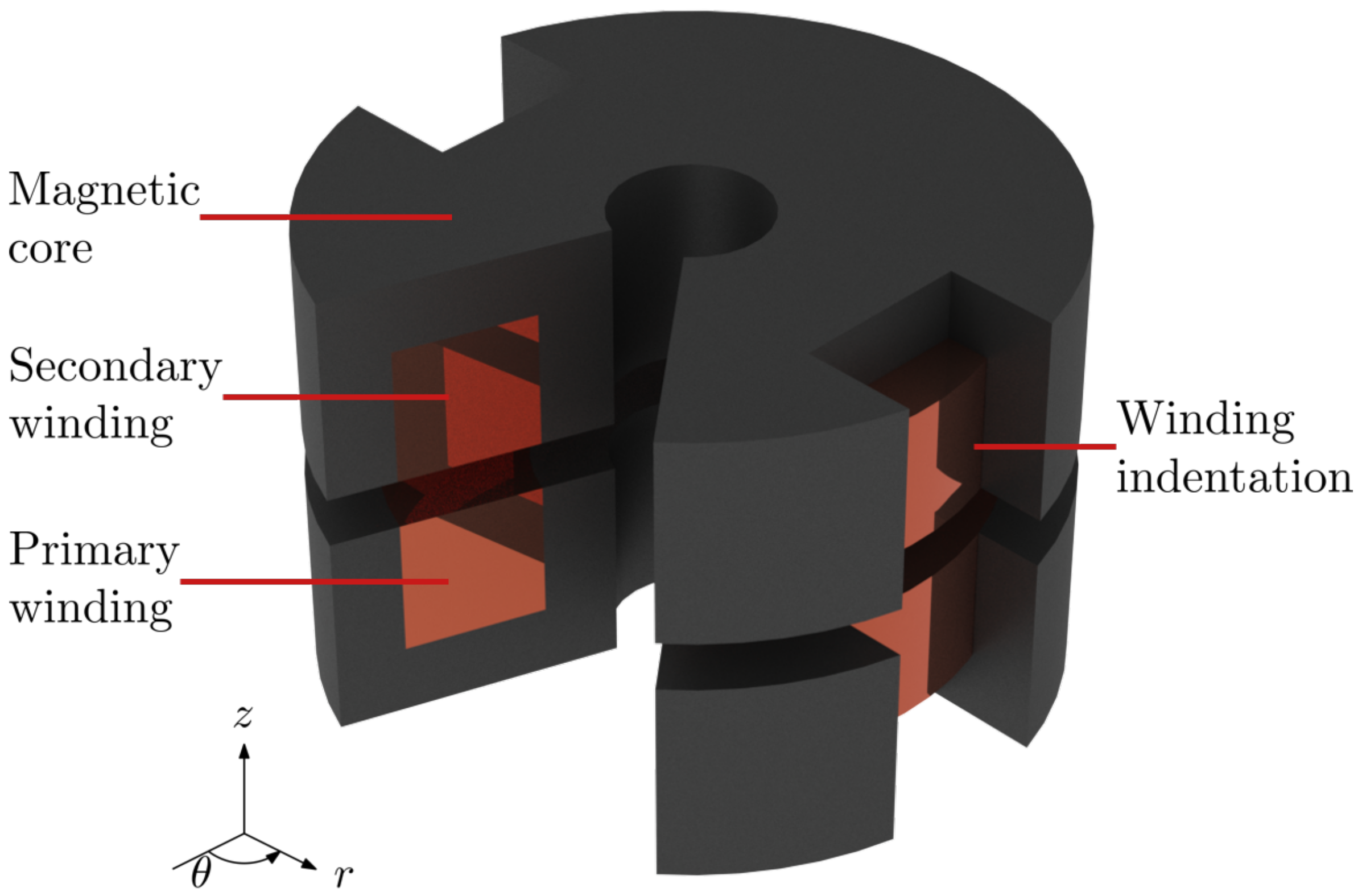

2.2. Magnetic Model

2.3. Electrical Model

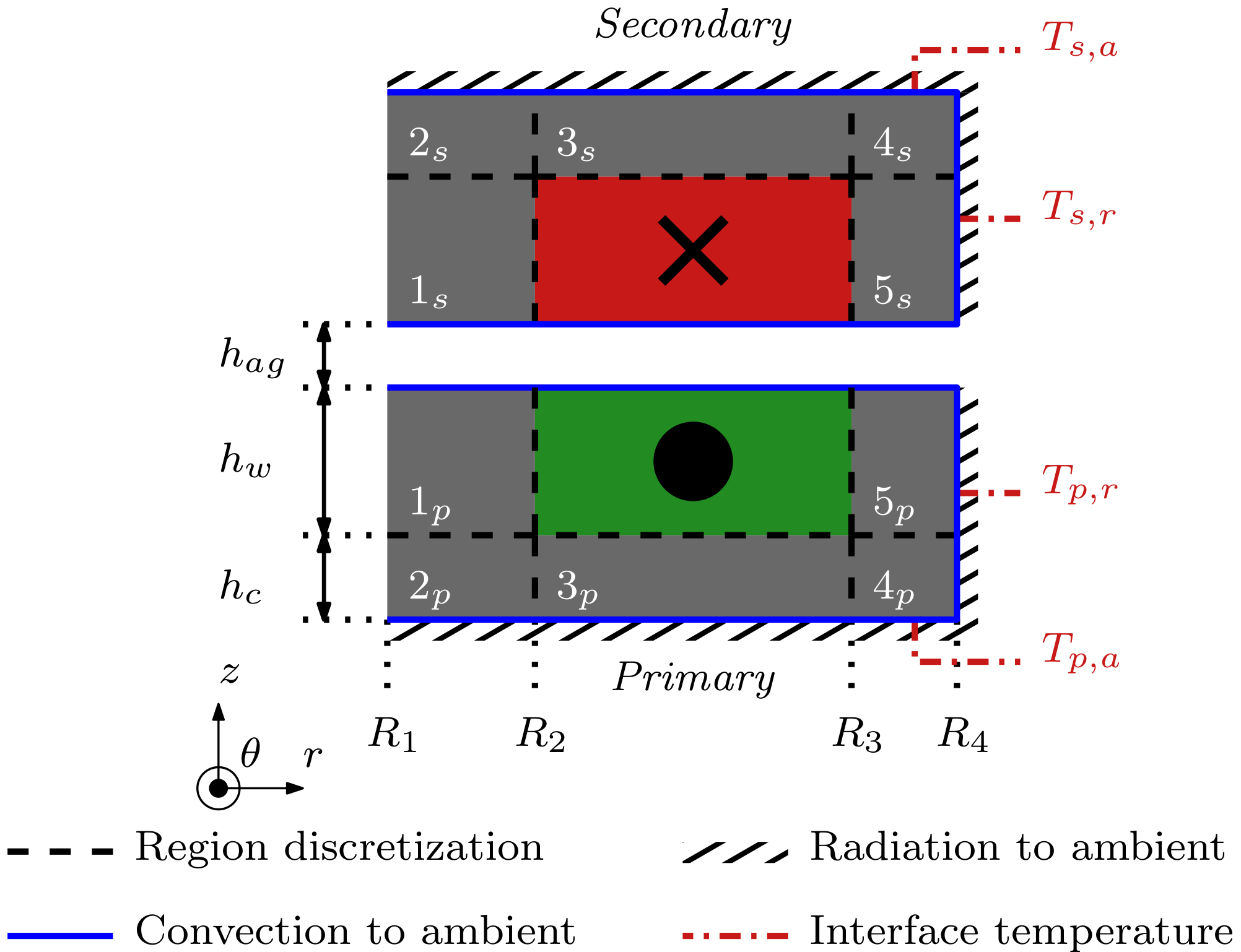

2.4. Thermal Model

2.5. Pot Core Design Optimization

2.6. Experimental Verification

2.7. Geometrical Optimization

3. Results

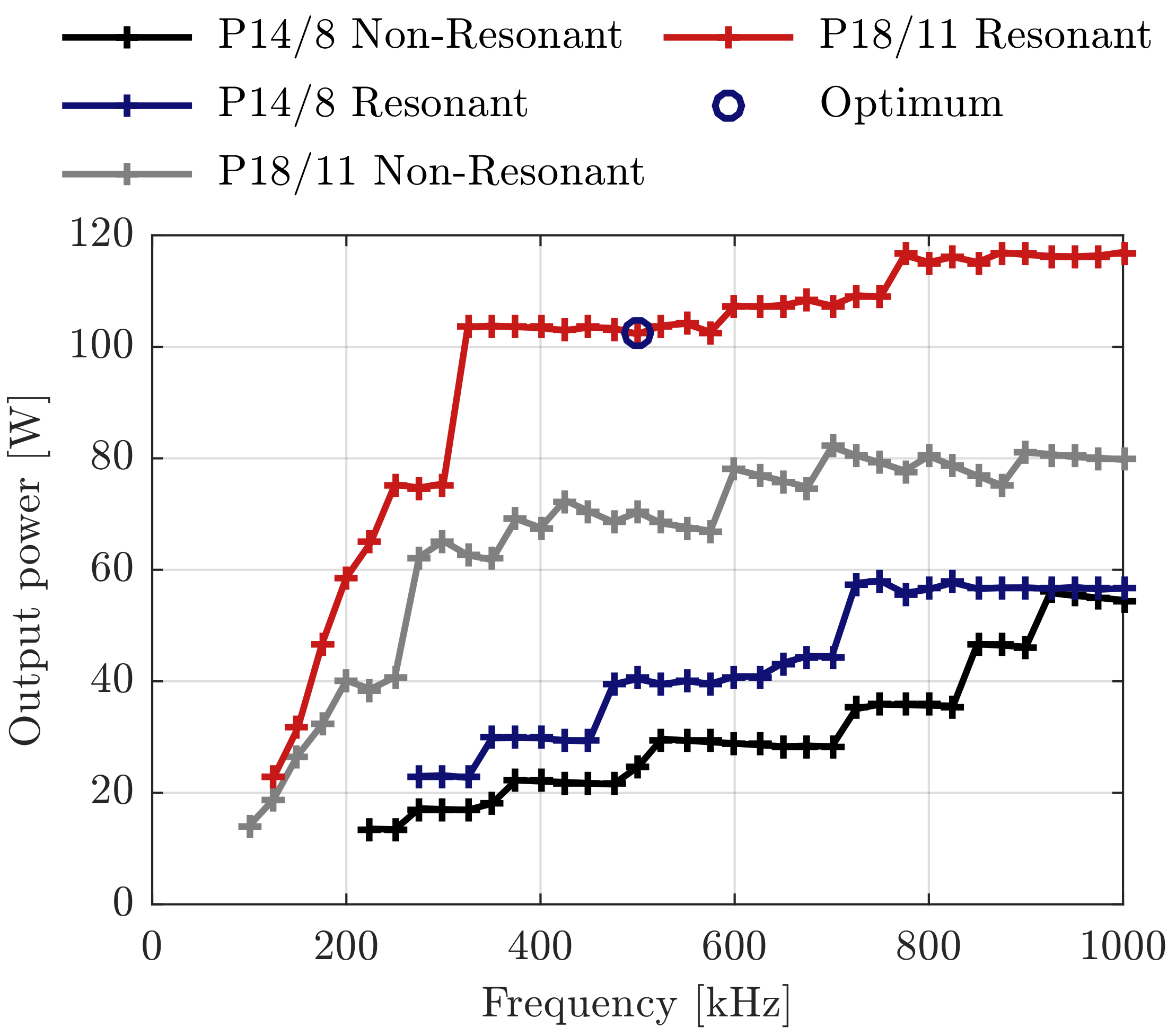

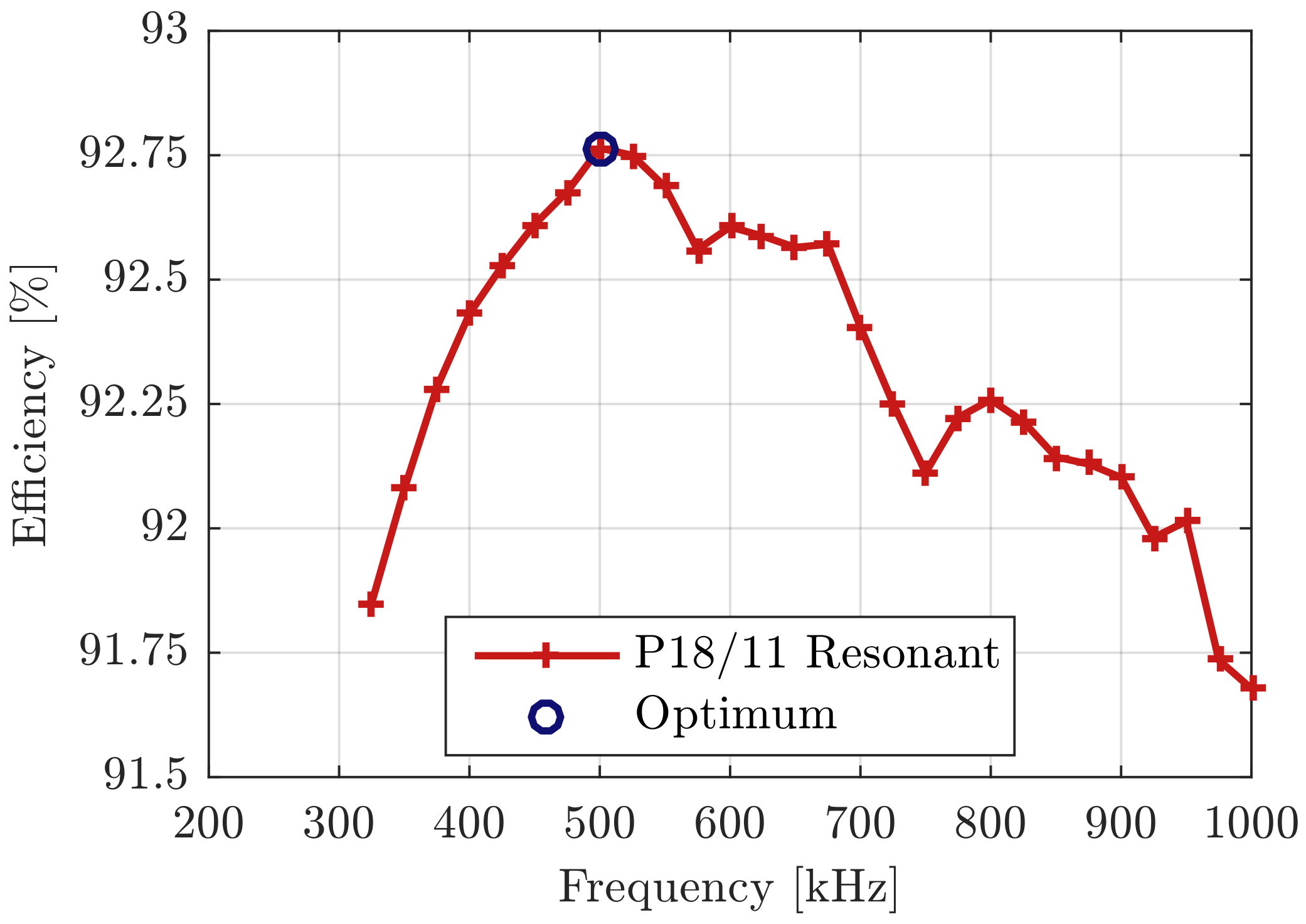

3.1. Pot Core Design Optimization Results

3.2. Experimental Results

3.3. Geometrical Optimization Results

4. Discussion

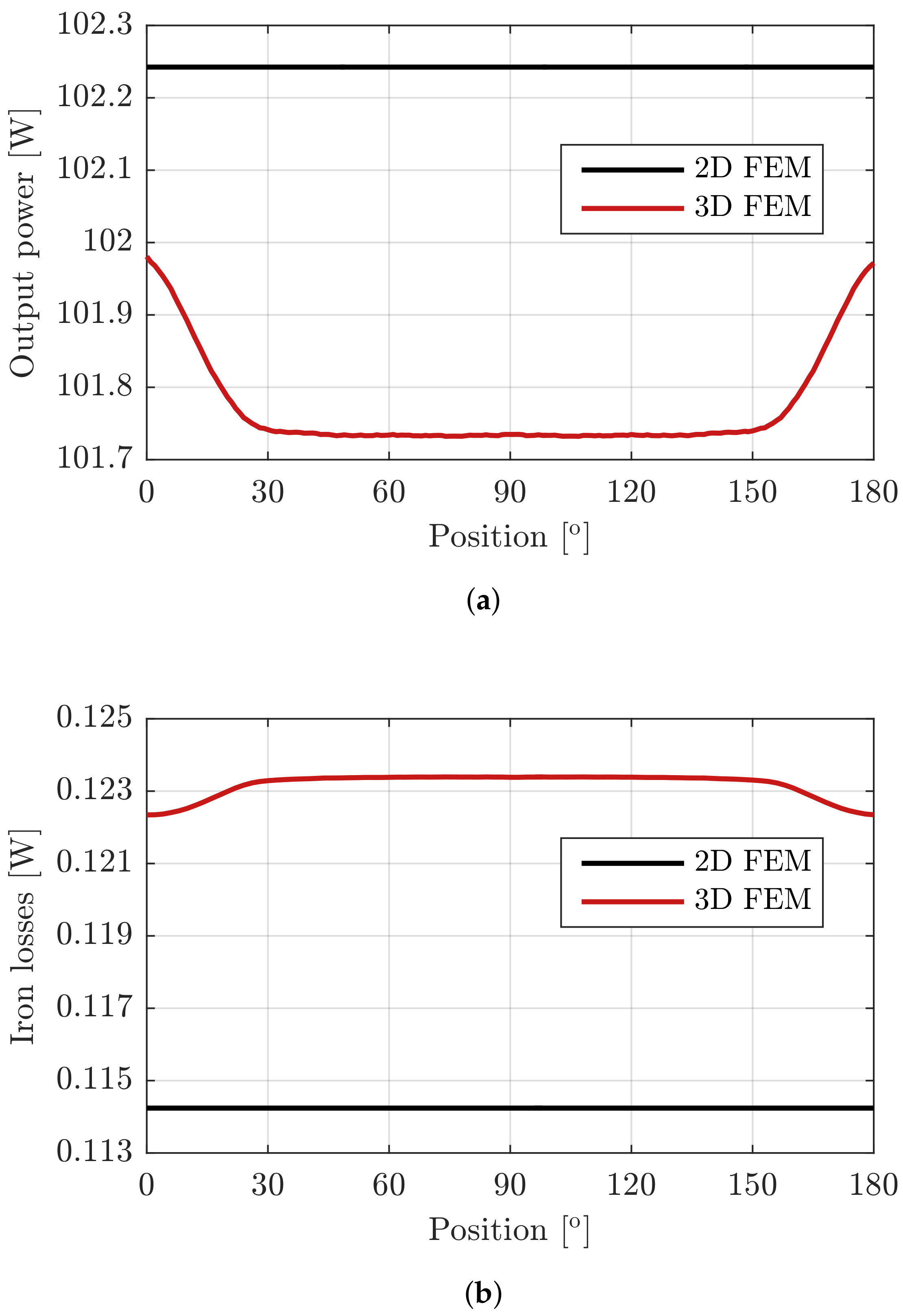

4.1. Three-Dimensional Effects

4.2. Recommendations

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| FEM | Finite Element Method |

| GaN | Gallium-Nitride |

| PCB | Printed Circuit Board |

| rms | Root-Mean-Square |

| WPT | Wireless Power Transfer |

References

- Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Innovative Design of Drone Landing Gear Used as a Receiving Coil in Wireless Charging Application. Energies 2019, 12, 3483. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, D.; Hui, S.Y.R. Ball-Joint Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2018, 33, 65–72. [Google Scholar] [CrossRef]

- Bao, Y.; Zhong, Z.; Hu, C.; Qin, Y. Rotor Field Oriented Control of Resonant Wireless Electrically Excited Synchronous Motor. World Electr. Veh. J 2019, 10, 62. [Google Scholar] [CrossRef]

- Maier, M.; Parspour, N. Operation of an Electrical Excited Synchronous Machine by Contactless Energy Transfer to the Rotor. IEEE Trans. Ind Appl. 2018, 54, 3217–3225. [Google Scholar] [CrossRef]

- Bortis, D.; Fässler, L.; Looser, A.; Kolar, J.W. Analysis of Rotary Transformer Concepts for High-Speed Applications. In Proceedings of the 28th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 3262–3269. [Google Scholar]

- Chen, X.Y.; Jin, J.X.; Zheng, L.H.; Wu, Z.H. A Rotary-Type Contactless Power Transfer System Using HTS Primary. IEEE Trans. Appl. Supercond. 2016, 26, 1–6. [Google Scholar] [CrossRef]

- Qian, W.; Zhang, X.; Fu, Y.; Lu, J.; Bai, H. Applying Normally-Off GaN HEMTs for Coreless High-Frequency Wireless Chargers. CES TEMS 2017, 1, 418–427. [Google Scholar] [CrossRef]

- Kazmierkowski, M.P.; Moradewicz, A.; Duarte, J.; Lomonova, E.; Sonntag, C. Contactless Energy Transfer. In Power Electronics and Motor Drives, 2nd ed.; Wilamowski, B., Irwin, J., Eds.; CRC Press: Boca Rotan, FL, USA, 2011; Chapter 35; pp. 1–17. ISBN 978-1-4398-0285-4. [Google Scholar]

- Shin, J.; Shin, S.; Kim, Y.; Ahn, S.; Lee, S.; Jung, G.; Jeon, S.J.; Cho, D.H. Design and Implementation of Shaped Magnetic-Resonance-Based Wireless Power Transfer System for Roadway-Powered Moving Electric Vehicles. IEEE Trans. Ind. Electron. 2014, 61, 1179–1192. [Google Scholar] [CrossRef]

- Trevisan, R.; Costanzo, A. A 1-kW Contactless Energy Transfer System Based on a Rotary Transformer for Sealing Rollers. IEEE Trans. Ind. Electron. 2014, 61, 6337–6345. [Google Scholar] [CrossRef]

- Godbehere, J.; Hopkins, A.; Yuan, X. Design and Thermal Analysis of a Rotating Transformer. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 2144–2151. [Google Scholar]

- Smeets, J.P.C.; Krop, D.C.J.; Jansen, J.W.; Hendrix, M.A.M.; Lomonova, E.A. Optimal Design of a Pot Core Rotating Transformer. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 4390–4397. [Google Scholar]

- Ditze, S.; Endruschat, A.; Schriefer, T.; Rosskopf, A.; Heckel, T. Inductive Power Transfer System with a Rotary Transformer for Contactless Energy Transfer on Rotating Applications. In Proceedings of the IEEE International Symposium on Circuits and Systems (ISCAS), Montreal, QC, Canada, 22–25 May 2016; pp. 1622–1625. [Google Scholar]

- Legranger, J.; Friedrich, G.; Vivier, S.; Mipo, J.C. Comparison of Two Optimal Rotary Transformer Designs for Highly Constrained Applications. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), Antalya, Turkey, 3–5 May 2007; pp. 1546–1551. [Google Scholar]

- Zhong, H.; Zhao, L.; Li, X. Design and Analysis of a Three-Phase Rotary Transformer for Doubly Fed Induction Generators. IEEE Trans. Ind. Appl. 2015, 51, 2791–2796. [Google Scholar] [CrossRef]

- Zietsman, N.L.; Gule, N. Optimal Design Methodology of a Three Phase Rotary Transformer for Doubly Fed Induction Generator Application. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 763–768. [Google Scholar]

- Sudhoff, S. Power Magnetic Devices; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; ISBN 978-1-118-48999-4. [Google Scholar]

- Altair Engineering, Inc. Available online: https://www.altair.com/flux/ (accessed on 10 February 2020).

- Van den Bossche, A.; Valchev, V.C. Inductors and Transformers for Power Electronics; Taylor & Francis Group: New York, NY, USA, 2005; ISBN 978-1-4200-2728-0. [Google Scholar]

- Fair-Rite Products Corp. Available online: https://www.fair-rite.com/78-material-data-sheet/ (accessed on 10 February 2020).

- Bertotti, G. Hysteresis in Magnetism; Academic Press, Inc.: San Diego, CA, USA, 1998; ISBN 978-0-12-093270-2. [Google Scholar]

- Efficient Power Conversion Corporation. Available online: http://epc-co.com/epc/Portals/0/epc/documents/guides/EPC9035_qsg.pdf (accessed on 10 February 2020).

- Nexperia. Available online: https://www.nexperia.com/products/diodes/schottky-rectifiers/medium-power-low-vf-schottky-rectifiers-single-200-ma/PMEG6030ETP.html (accessed on 10 February 2020).

- Smeets, J.P.C. Contactless Transfer of Energy: 3D Modeling and Design of a Position-Independent Inductive Coupling Integrated in a Planar Motor. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 19 March 2015. [Google Scholar]

- Sinha, D.; Sadhu, P.K.; Pal, N.; Bandyopadhyay, A. Computation of Inductance and AC Resistance of a Twisted Litz-Wire for High Frequency Induction Cooker. In Proceedings of the International Conference on Industrial Electronics, Control and Robotics, Orissa, India, 27–29 December 2010; pp. 85–90. [Google Scholar]

- Tang, X.; Sullivan, C.R. Optimization of Stranded-Wire Windings and Comparison with Litz Wire on the Basis of Cost and Loss. In Proceedings of the IEEE 35th Annual Power Electronics Specialists Conference, Aachen, Germany, 20–25 June 2004; pp. 854–860. [Google Scholar]

- Pack Litz Wire. Available online: https://www.packlitzwire.com/products/litz-wires/rupalit-classic/ (accessed on 10 February 2020).

- Analog Devices. Available online: https://www.analog.com/en/design-center/design-tools-and-calculators/ltspice-simulator.html (accessed on 10 February 2020).

- Development Board EPC9035Quick Start Guide. Available online: https://epc-co.com/epc/Products/eGaNFETsandICs/EPC2022.aspx (accessed on 10 February 2020).

- Holman, J. Heat Transfer; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2010; ISBN 978-0-07-352936-3. [Google Scholar]

- Wong, H.Y. Handbook of Essential Formulae and Data on Heat Transfer for Engineers; William Clowes & Sons Limited: London, UK, 1977; ISBN 0-582-46050-6. [Google Scholar]

- Hendershot, J.R.; Miller, T.J.E. Design of Brushless Permanent-Magnet Machines; Motor Design Books LLC: Venice, FL, USA, 2010; ISBN 978-0-9840687-0-8. [Google Scholar]

- Mathworks. Available online: https://nl.mathworks.com/help/optim/ug/constrained-nonlinear-optimization-algorithms.html#brnpd5f (accessed on 11 February 2020).

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Strand radius | 0.016 | mm | |

| Number of strands | 250 | - | |

| Nominal dc resistance (20 C) | 0.0987 | /m | |

| Total wire diameter including wrapping | 0.52 | mm |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Frequency | f | 500 | kHz |

| Number of primary turns | 5 | - | |

| Number of secondary turns | 11 | - | |

| Number of parallel paths primary side | 2 | - | |

| Number of parallel paths secondary side | 1 | - | |

| Magnetizing inductance | 2.125 | H | |

| Primary leakage inductance | 430.4 | nH | |

| Secondary leakage inductance | 430.4 | nH | |

| Magnetic coupling coefficient | k | 0.893 | - |

| Primary resonant capacitance | 240.0 | nF | |

| Secondary resonant capacitance | 237.2 | nF |

| Quantity | Symbol | Measurement | Simulation | Unit | Discrepancy [%] |

|---|---|---|---|---|---|

| Output current | 2.11 | 2.09 | A | −0.95 | |

| Output voltage | 48.1 | 49.0 | V | +1.9 | |

| Output power | 101.7 | 102.2 | W | +0.49 | |

| Input power | 113.6 | 110.1 | W | −3.1 | |

| Efficiency | 89.6 | 92.8 | % | +3.1 | |

| Secondary core axial interface temperature | 72.5 | 74.0 | C | +2.1 | |

| Secondary core radial interface temperature | 69.9 | 73.7 | C | +5.4 | |

| Primary core axial interface temperature | 76.5 | 82.8 | C | +8.2 | |

| Primary core radial interface temperature | 73.9 | 81.4 | C | +10.1 |

| Geometrical Design | ||||

| Parameter | Symbol | Non-Resonant | Resonant | Unit |

| Inner radius core | 1.60 | 1.60 | mm | |

| Inner radius winding area | 3.91 | 3.23 | mm | |

| Outer radius winding area | 8.52 | 6.48 | mm | |

| Outer radius core | 9.52 | 7.48 | mm | |

| Winding area height | 2.05 | 3.38 | mm | |

| Height bottom core part | 1.02 | 1.00 | mm | |

| Core inertia | 112.2 | 61.1 | g·mm | |

| Core volume | 0.481 | 0.400 | cm | |

| Transformer Design | ||||

| Parameter | Symbol | Non-Resonant | Resonant | Unit |

| Frequency | f | 850 | 950 | kHz |

| Number of primary turns | 3 | 4 | - | |

| Number of secondary turns | 8 | 9 | - | |

| Number of parallel paths primary side | 2 | 2 | - | |

| Number of parallel paths secondary side | 1 | 1 | - | |

| Magnetizing inductance | 0.801 | 0.974 | H | |

| Primary leakage inductance | 86.3 | 248.0 | nH | |

| Secondary leakage inductance | 86.3 | 248.0 | nH | |

| Magnetic coupling coefficient | k | 0.949 | 0.888 | - |

| Primary resonant capacitance | - | 110.0 | nF | |

| Secondary resonant capacitance | - | 111.4 | nF | |

| Physical Quantities | ||||

| Quantity | Symbol | Non-Resonant | Resonant | Unit |

| Output power | 100.6 | 110.0 | W | |

| Efficiency | 91.3 | 91.7 | % | |

| Max. temperature primary core | 94.6 | 95.1 | C | |

| Max. temperature secondary core | 78.7 | 84.4 | C | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastiaens, K.; Krop, D.C.J.; Jumayev, S.; Lomonova, E.A. Optimal Design and Comparison of High-Frequency Resonant and Non-Resonant Rotary Transformers. Energies 2020, 13, 929. https://doi.org/10.3390/en13040929

Bastiaens K, Krop DCJ, Jumayev S, Lomonova EA. Optimal Design and Comparison of High-Frequency Resonant and Non-Resonant Rotary Transformers. Energies. 2020; 13(4):929. https://doi.org/10.3390/en13040929

Chicago/Turabian StyleBastiaens, Koen, Dave C. J. Krop, Sultan Jumayev, and Elena A. Lomonova. 2020. "Optimal Design and Comparison of High-Frequency Resonant and Non-Resonant Rotary Transformers" Energies 13, no. 4: 929. https://doi.org/10.3390/en13040929

APA StyleBastiaens, K., Krop, D. C. J., Jumayev, S., & Lomonova, E. A. (2020). Optimal Design and Comparison of High-Frequency Resonant and Non-Resonant Rotary Transformers. Energies, 13(4), 929. https://doi.org/10.3390/en13040929