A Layered Bidirectional Active Equalization Method for Retired Power Lithium-Ion Batteries for Energy Storage Applications

Abstract

1. Introduction

2. Selection of Retired Battery Pack for Equalization

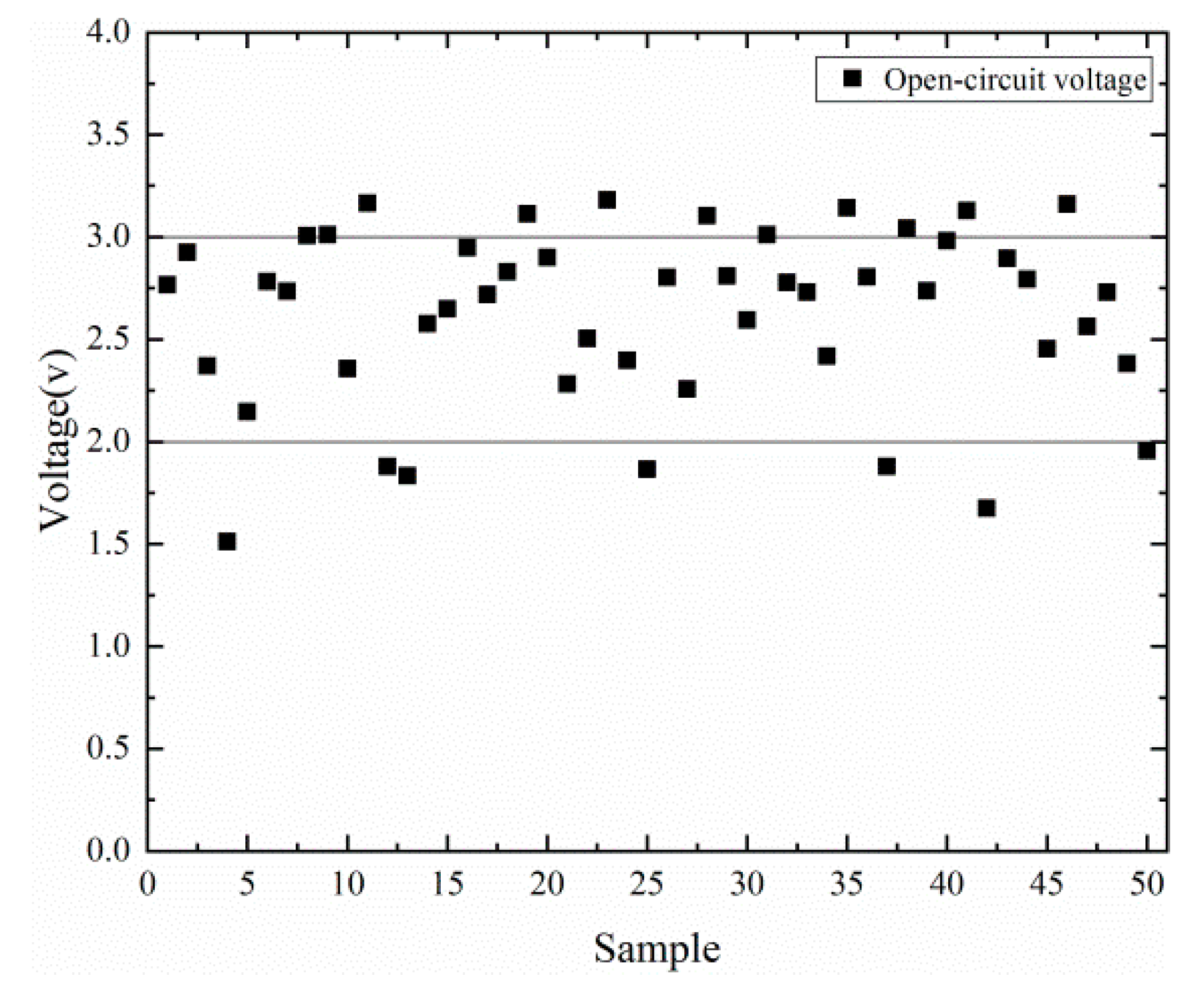

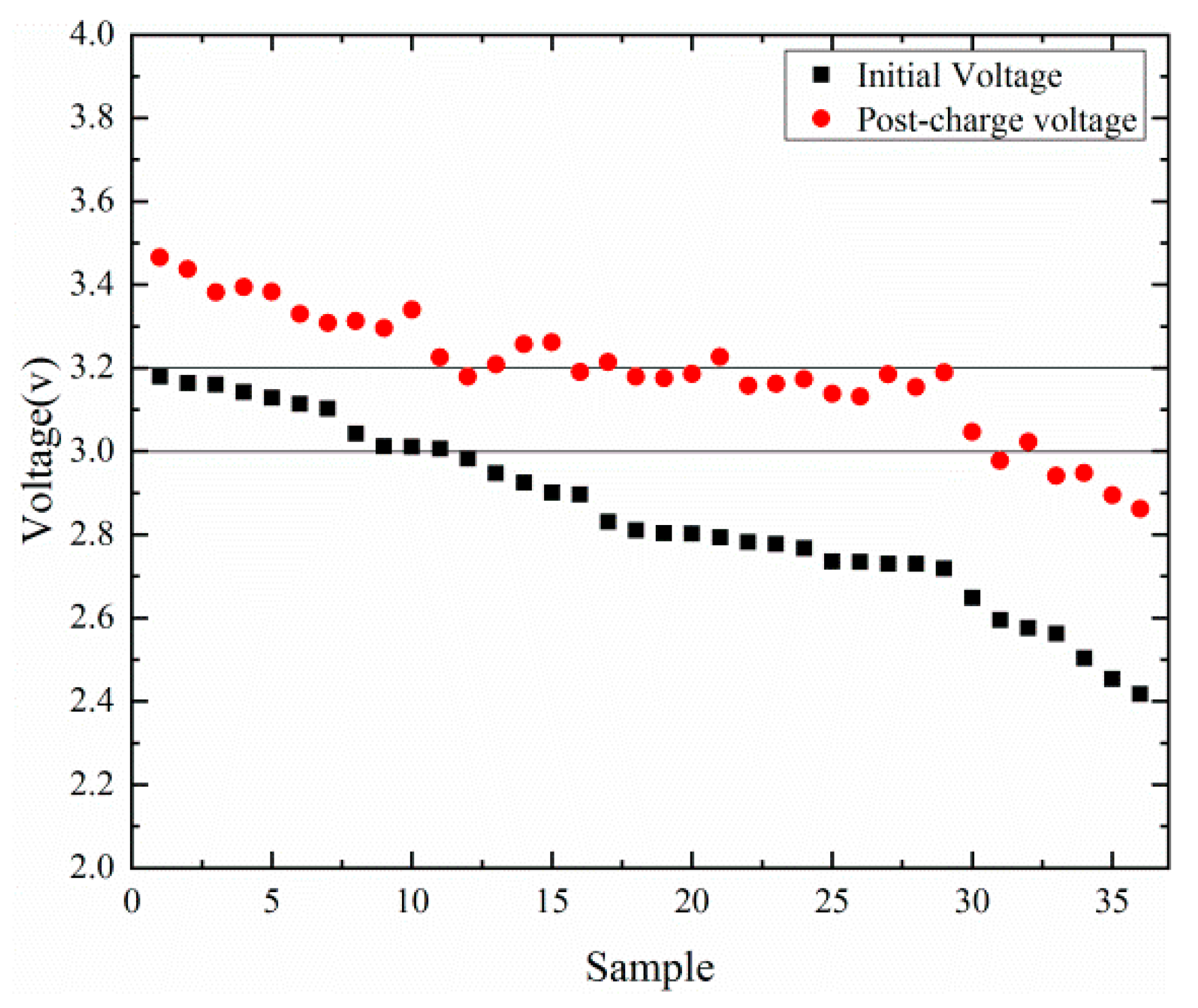

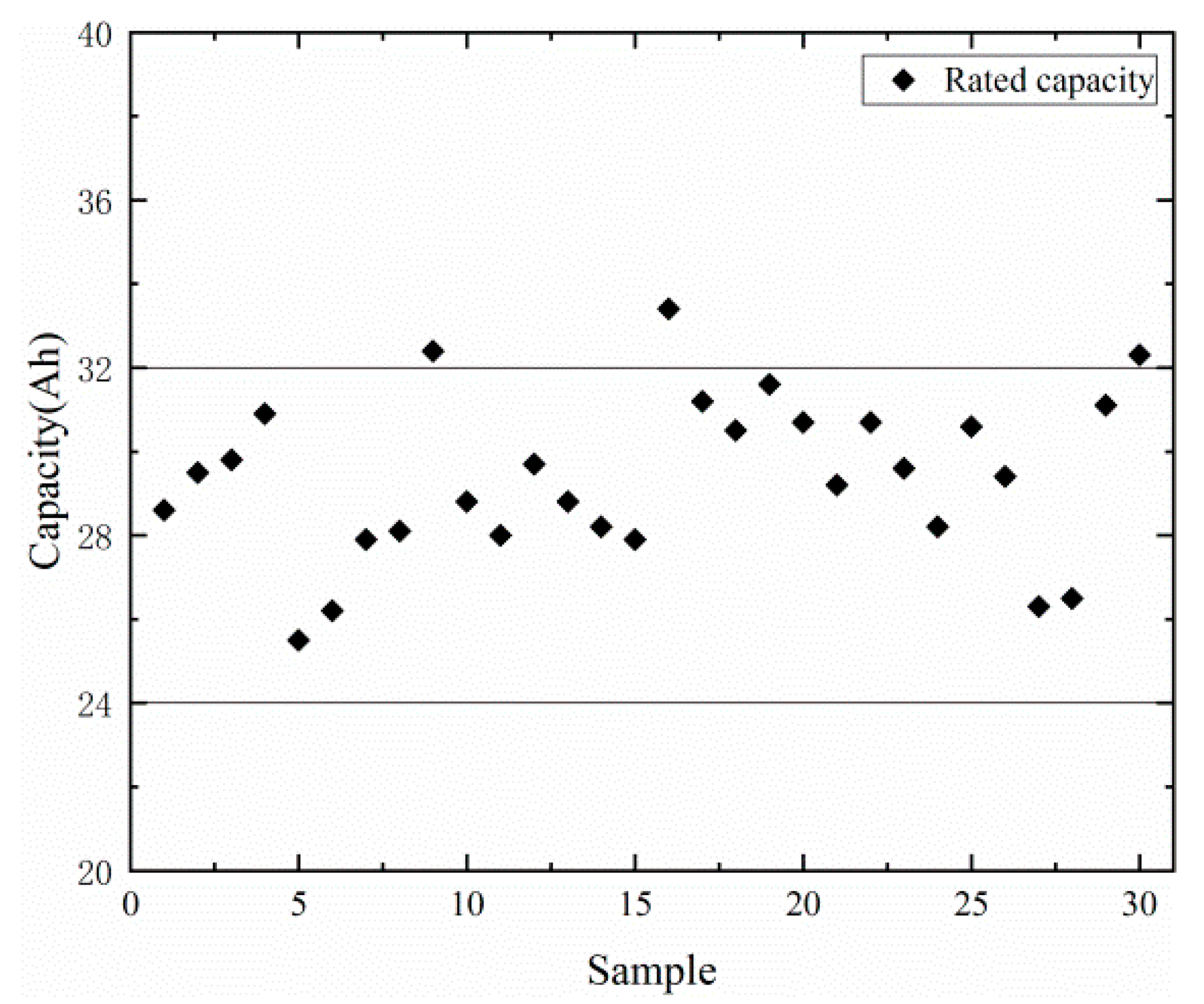

2.1. Retiring Standards for Lithium-Ion Batteries

2.2. Selecting Process of the Retired Battery Pack

3. Proposed Active Equalization Strategy

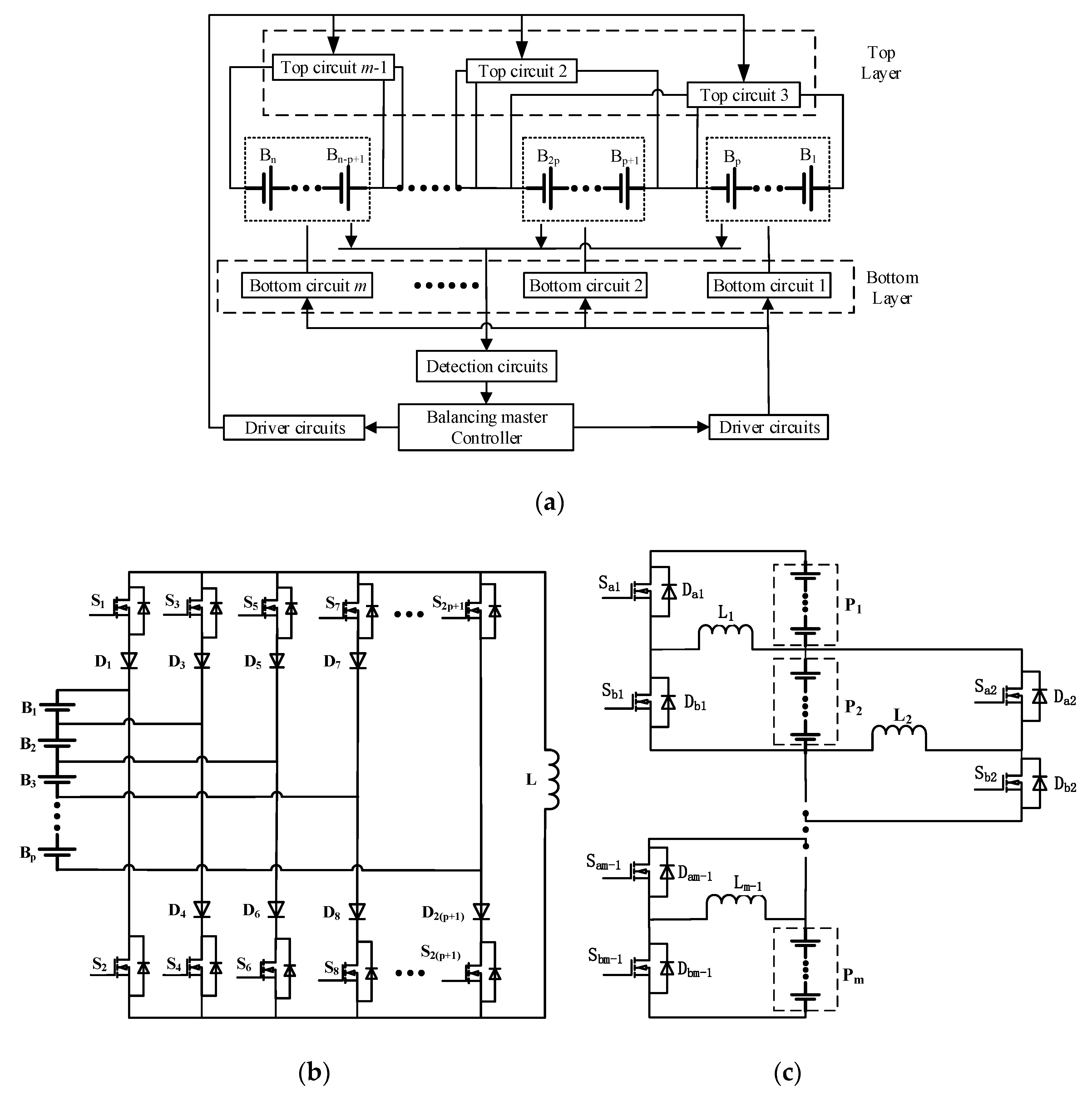

3.1. Equalization Topology

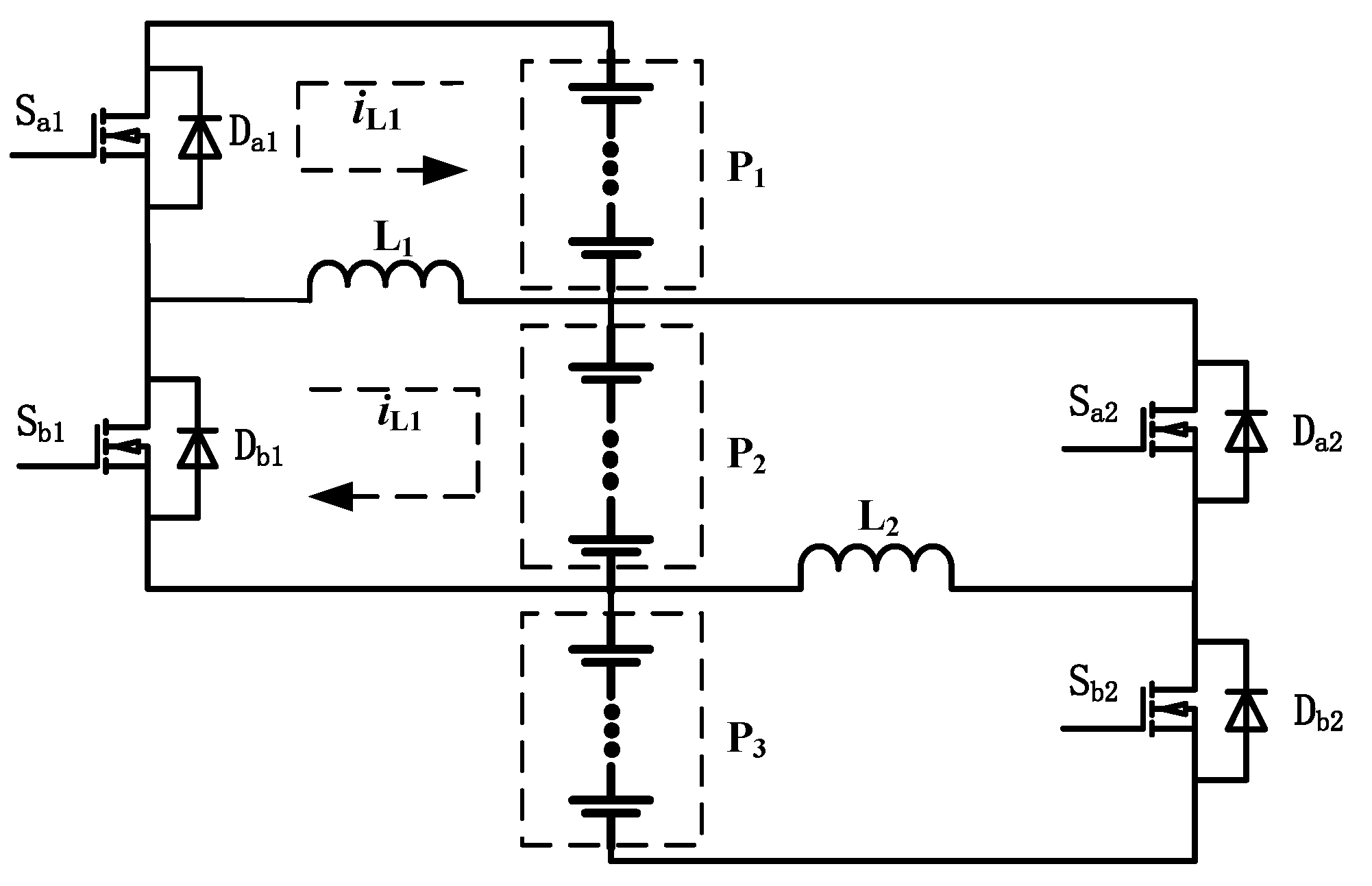

3.1.1. Proposed Equalization Topology

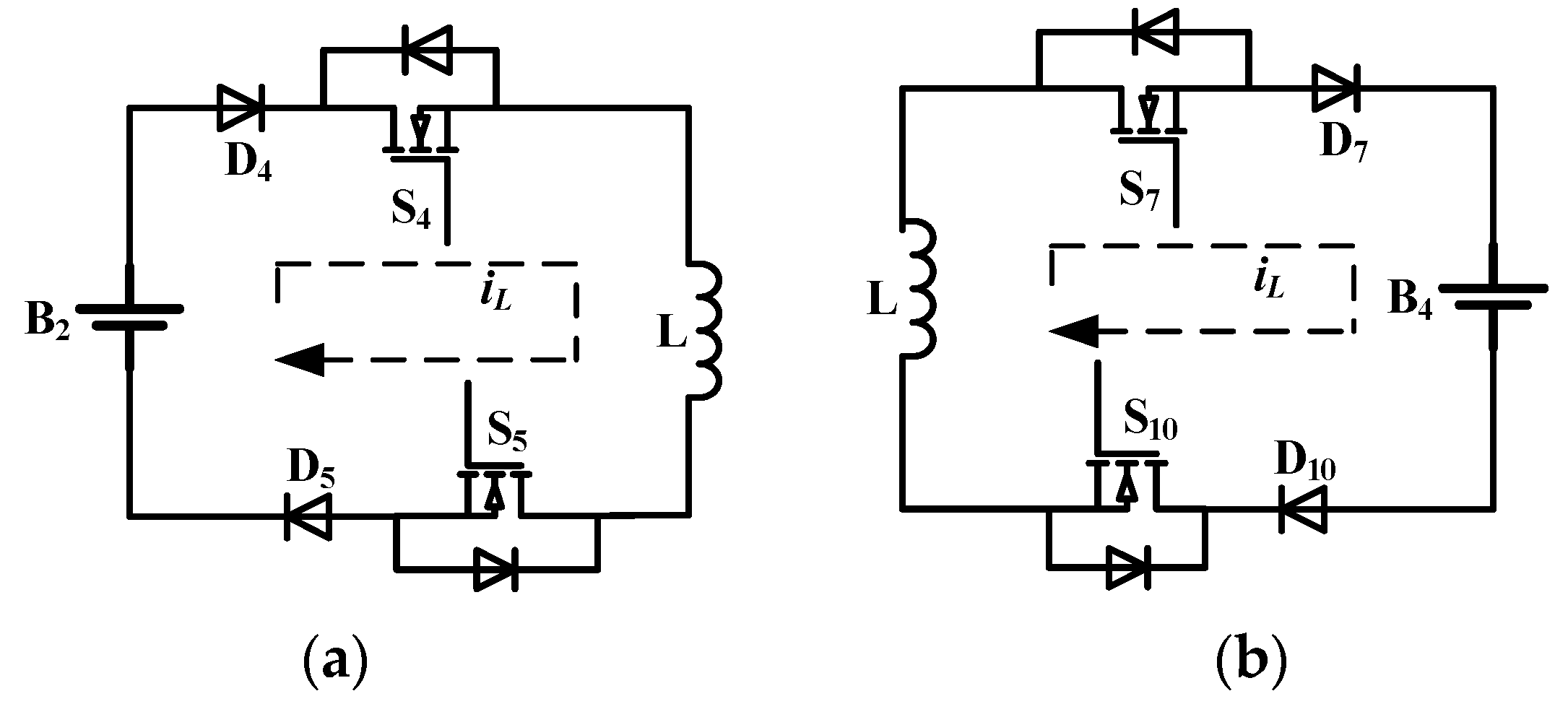

3.1.2. Equalization Principle of the Bottom Layer Circuits

3.1.3. Equalization Principle of the Top Layer Circuits

3.2. Equalization Algorithm

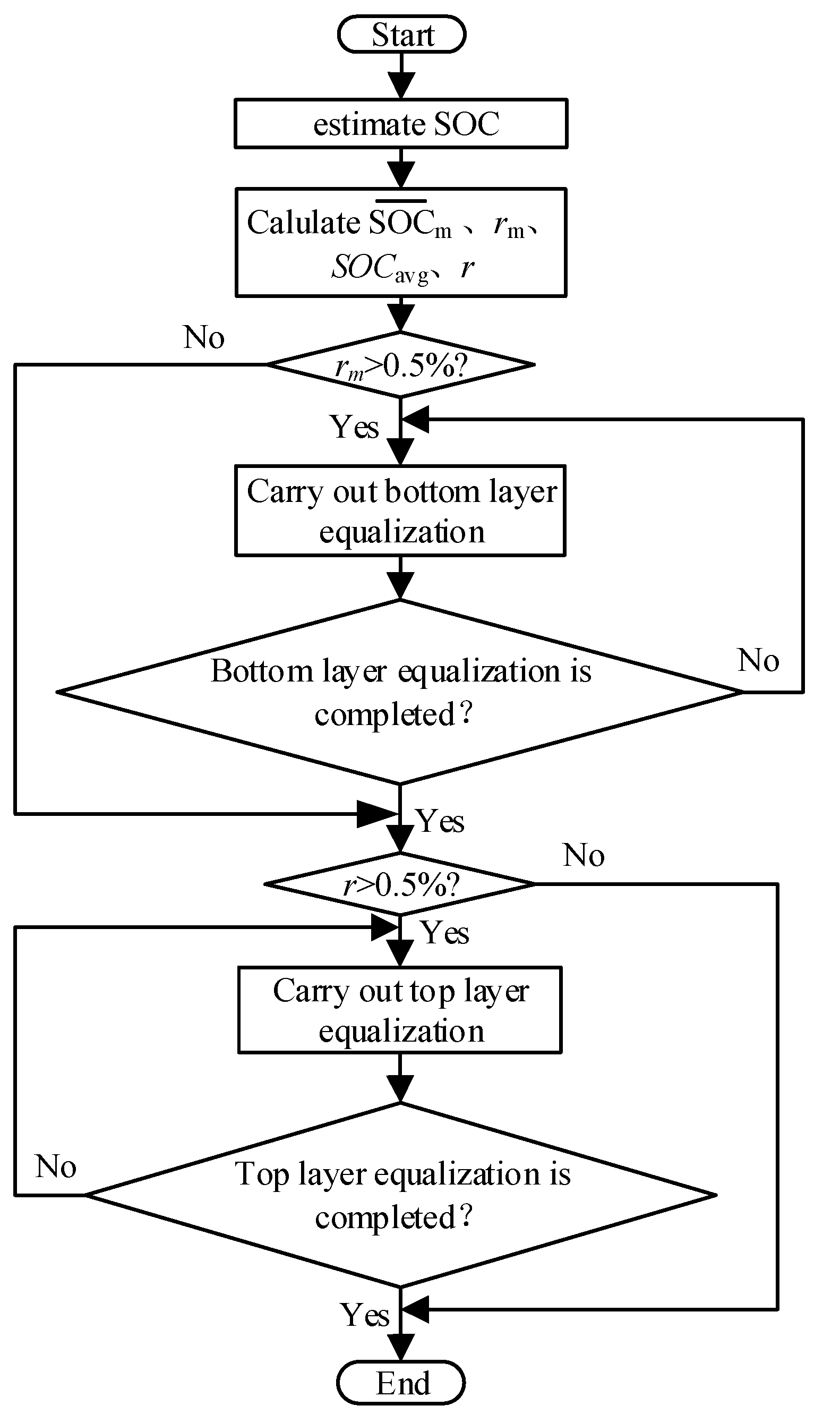

- (1)

- Estimate the SOC of each single retired battery;

- (2)

- Calculate the , rm, SOCavg and r;

- (3)

- Assume that the set bottom layer equalization threshold value Δm is 0.5%, check the rm, if rm > Δm, go to Step 4, and execute bottom layer equalization algorithm. If rm ≤ Δm, then go to Step 6;

- (4)

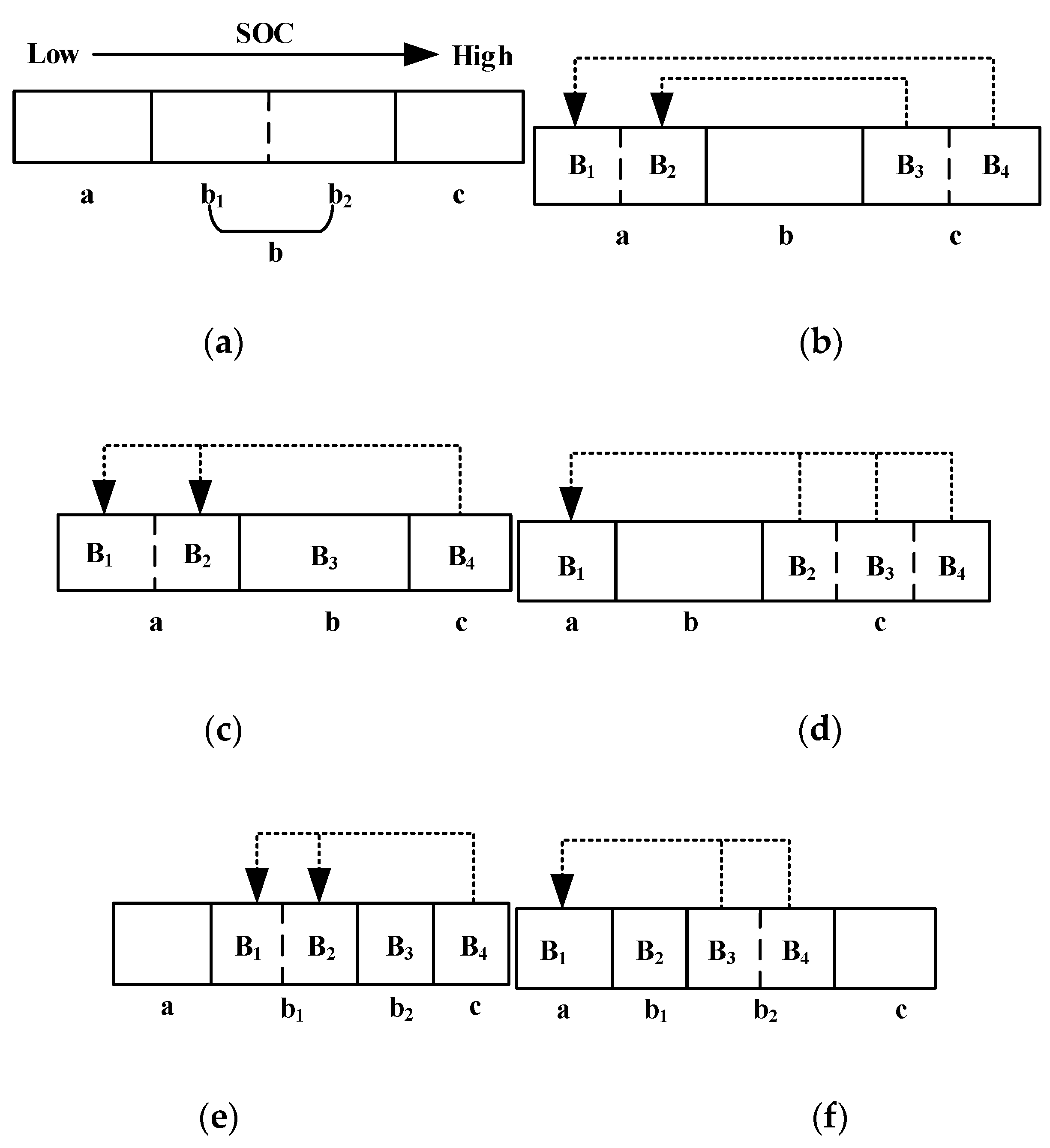

- Carry out bottom layer equalization algorithm. In order to improve the equalization efficiency, the “partition” idea is introduced and equalization paths are optimized. As shown in Figure 8a, according to SOC from low to high, batteries in the same retired battery group are sorted. The SOC values of retired batteries in area a are lower and need to be charged. Area b is divided into area b1 and area b2, the difference between the SOC values of batteries in area b and is within the threshold range. The SOC values of retired batteries in area c are higher and need to be discharged.Which areas the batteries in the mth retired battery group belong to can be expressed by a piecewise function, where i represents the ith retired battery in the mth retired battery group.

- (5)

- According to the energy complementary pairs established in Step 4, set switching frequency and duty cycle, control the switching of the corresponding MOSFET switch tubes. If rm ≤ Δm, bottom layer equalization has completed and go to Step 6; if rm > Δm, go to Step 4 to continue the bottom layer equalization;

- (6)

- Assume that the set top layer equalization threshold value Δ is 0.5%, check the r, if r > Δ, go to Step 7 and execute the top layer equalization algorithm; if r ≤ Δ, then go to Step 9;

- (7)

- Carry out top layer equalization algorithm. The three retired battery groups are sorted according to (m = 1, 2, 3) from low to high, and then top layer equalization paths are determined. There are the following six sorting cases: ① > > , ② > > , ③ > > , ④ > > , ⑤ > > , ⑥ > > . It can be divided into two categories: (1) cases ②, ③, ④, and ⑤ belong to direct equalization and transfer energy between adjacent battery groups; case ① and case ⑥ belong to indirect equalization, the battery group P1 and the battery group P3 are not adjacent, the battery group P2 is taken as the energy transmission medium to achieve the equalization between them;

- (8)

- Check the r. If r > Δ, the retired battery pack is unbalanced, go to Step 7 to continue top layer equalization; if r ≤ Δ, then go to Step 9;

- (9)

- End of the whole retired battery pack equalization.

4. Simulation and Experimental Verification

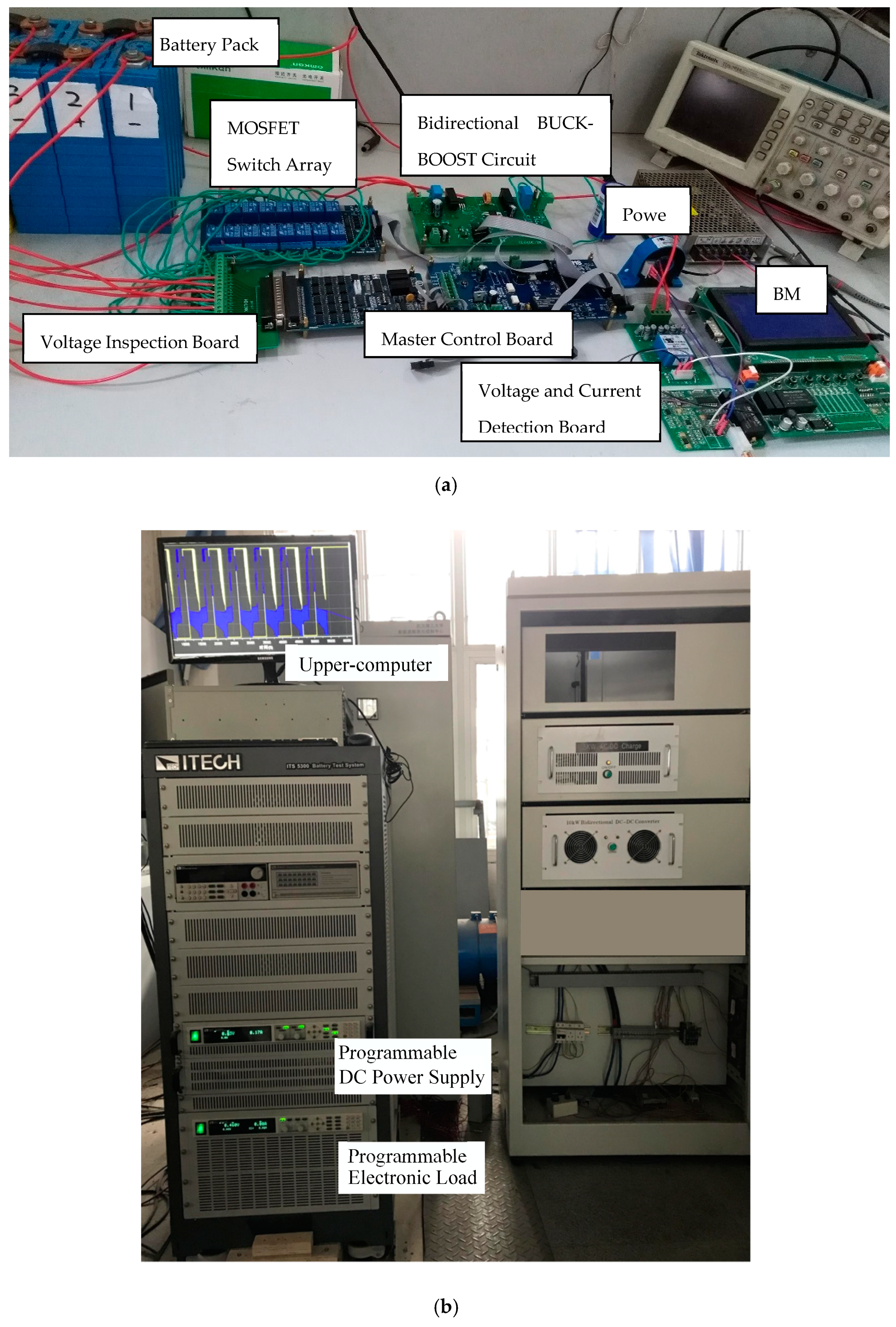

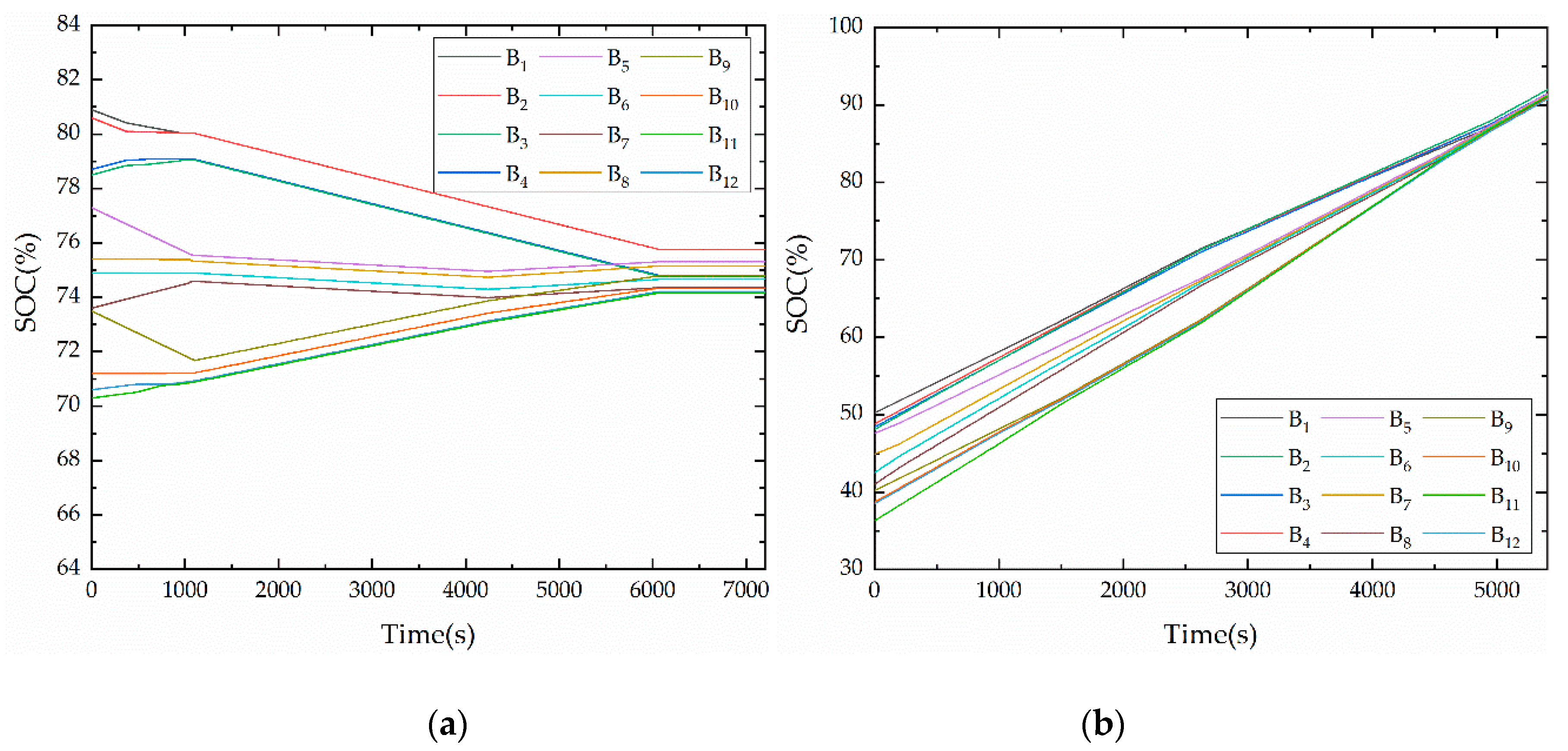

4.1. Static Equalization Experiment

4.2. Charging Equalization Experiment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xie, C.; Xu, X.; Bujlo, P.; Shen, D.; Zhao, H.; Quan, S. Fuel cell and lithium iron phosphate battery hybrid powertrain with an ultracapacitor bank using direct parallel structure. J. Power Sources 2015, 279, 487–494. [Google Scholar] [CrossRef]

- Farmann, A.; Sauer, D.U. A comprehensive review of on-board State-of-Available-Power prediction techniques for lithium-ion batteries in electric vehicles. J. Power Sources 2016, 329, 123–137. [Google Scholar] [CrossRef]

- Li, X.; Xie, C.; Quan, S.; Huang, L.; Fang, W. Energy management strategy of thermoelectric generation for localized air conditioners in commercial vehicles based on 48 V electrical system. Appl. Energy 2018, 231, 887–900. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Chen, Z. An adaptive remaining energy prediction approach for lithium-ion batteries in electric vehicles. J. Power Sources 2016, 305, 80–88. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Gao, Y.; Guo, Q. Recognition of battery aging variations for LiFePO4 batteries in 2nd use applications combining incremental capacity analysis and statistical approaches. J. Power Sources 2017, 360, 180–188. [Google Scholar] [CrossRef]

- Liao, Q.; Mu, M.; Zhao, S.; Zhang, L.; Jiang, T.; Ye, J.; Shen, X.; Zhou, G. Performance assessment and classification of retired lithium ion battery from electric vehicles for energy storage. Int. J. Hydrog. Energy 2017, 42, 18817–18823. [Google Scholar] [CrossRef]

- Lai, X.; Qiao, D.; Zheng, Y.; Ouyang, M.; Han, X.; Zhou, L. A rapid screening and regrouping approach based on neural networks for large-scale retired lithium-ion cells in second-use applications. J. Clean Prod. 2019, 213, 776–791. [Google Scholar] [CrossRef]

- China Energy Storage Alliance. Energy Storage Industry Research White Paper 2019. Available online: http://www.cnesa.org/index/inform_detail?cid=5cf0ef98b1fd3772048b4567 (accessed on 18 May 2019).

- Zhang, Y.; Li, Y.; Tao, Y.; Ye, J.; Pan, A.; Li, X.; Liao, Q.; Wang, Z. Performance assessment of retired EV battery modules for echelon use. Energy 2020, 193, 116555. [Google Scholar] [CrossRef]

- Debnath, U.K.; Ahmad, I.; Habibi, D. Quantifying economic benefits of second life batteries of gridable vehicles in the smart grid. Int. J. Electr. Power Energy Syst. 2014, 63, 577–587. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A. The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J. Power Sourcesces 2011, 196, 10351–10358. [Google Scholar] [CrossRef]

- Debnath, U.K.; Ahmad, I.; Habibi, D. Gridable vehicles and second life batteries for generation side asset management in the Smart Grid. Int. J. Electr. Power Energy Syst. 2016, 82, 114–123. [Google Scholar] [CrossRef]

- Madlener, R.; Kirmas, A. Economic Viability of Second Use Electric Vehicle Batteries for Energy Storage in Residential Applications. Energy Procedia 2017, 105, 3806–3815. [Google Scholar] [CrossRef]

- Huang, W.; Abu Qahouq, J.A. Energy Sharing Control Scheme for State-of-Charge Balancing of Distributed Battery Energy Storage System. IEEE Trans. Ind. Electron. 2015, 62, 2764–2776. [Google Scholar] [CrossRef]

- Zhang, C.; Shang, Y.; Li, Z.; Cui, N. An Interleaved Equalization Architecture with Self-Learning Fuzzy Logic Control for Series-Connected Battery Strings. IEEE Trans. Veh. Technol. 2017, 66, 10923–10934. [Google Scholar] [CrossRef]

- Gallardo-Lozano, J.; Romero-Cadaval, E.; Milanes-Montero, M.I.; Guerrero-Martinez, M.A. A novel active battery equalization control with on-line unhealthy cell detection and cell change decision. J. Power Sourcesces 2015, 299, 356–370. [Google Scholar] [CrossRef]

- Liu, X.; Wan, Z.; He, Y.; Zheng, X.; Zeng, G.; Zhang, J. A Unified Control Strategy for Inductor-Based Active Battery Equalisation Schemes. Energies 2018, 11, 405. [Google Scholar] [CrossRef]

- Gallardo-Lozano, J.; Romero-Cadaval, E.; Milanes-Montero, M.I.; Guerrero-Martinez, M.A. Battery equalization active methods. J. Power Sourcesces 2014, 246, 934–949. [Google Scholar] [CrossRef]

- Bouchhima, N.; Schnierle, M.; Schulte, S.; Birke, K.P. Active model-based balancing strategy for self-reconfigurable batteries. J. Power Sourcesces 2016, 322, 129–137. [Google Scholar] [CrossRef]

- Daowd, M.; Antoine, M.; Omar, N.; van den Bossche, P.; van Mierlo, J. Single Switched Capacitor Battery Balancing System Enhancements. Energies 2013, 6, 2149–2174. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, X.; Cui, Y.; Zou, J.; Yang, S. A Multi-Winding Transformer Cell-to-Cell Active Equalization Method for Lithium-Ion Batteries with Reduced Number of Driving Circuits. IEEE Trans. Power Electron. 2016, 31, 4916–4929. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Chen, Z.; Xie, J.; Zhang, X. A novel active equalization method for lithium-ion batteries in electric vehicles. Appl. Energy 2015, 145, 36–42. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Peng, S.E.; Uddin, M.N. Lithium-Ion Battery Charge Equalization Algorithm for Electric Vehicle Applications. IEEE Trans. Ind. Appl. 2017, 53, 2541–2549. [Google Scholar] [CrossRef]

- Dai, H.; Wei, X.; Sun, Z.; Wang, D. A novel dual-inductor based charge equalizer for traction battery cells of electric vehicles. Int. J. Electr. Power Energy Syst. 2015, 67, 627–638. [Google Scholar] [CrossRef]

- Cui, X.; Shen, W.; Zhang, Y.; Hu, C. A Fast Multi-Switched Inductor Balancing System Based on a Fuzzy Logic Controller for Lithium-Ion Battery Packs in Electric Vehicles. Energies 2017, 10, 1034. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, X.; Yao, H.; Zeng, G. Active vehicle battery balancing scheme in the condition of constant-voltage/current charging and discharging. IEEE Trans. Veh. Technol. 2017, 66, 3714–3723. [Google Scholar] [CrossRef]

- Wu, Z.; Ling, R.; Tang, R. Dynamic battery equalization with energy and time efficiency for electric vehicles. Energy 2017, 141, 937–948. [Google Scholar] [CrossRef]

- Zhang, Z.; Gui, H.; Gu, D.; Yang, Y.; Ren, X. A Hierarchical Active Balancing Architecture for Lithium-Ion Batteries. IEEE Trans. Power Electron. 2017, 32, 2757–2768. [Google Scholar] [CrossRef]

- Ouyang, Q.; Chen, J.; Zheng, J.; Hong, Y. SOC Estimation-Based Quasi-Sliding Mode Control for Cell Balancing in Lithium-Ion Battery Packs. IEEE Trans. Ind. Electron. 2018, 65, 3427–3436. [Google Scholar] [CrossRef]

- Ma, Y.; Duan, P.; Sun, Y.; Chen, H. Equalization of Lithium-Ion Battery Pack Based on Fuzzy Logic Control in Electric Vehicle. IEEE Trans. Ind. Electron. 2018, 65, 6762–6771. [Google Scholar] [CrossRef]

- Diao, W.; Xue, N.; Bhattacharjee, V.; Jiang, J.; Karabasoglu, O.; Pecht, M. Active battery cell equalization based on residual available energy maximization. Appl. Energy 2018, 210, 690–698. [Google Scholar] [CrossRef]

- Zeng, M.; Zhang, P.; Yang, Y.; Xie, C.; Shi, Y. SOC and SOH Joint Estimation of the Power Batteries Based on Fuzzy Unscented Kalman Filtering Algorithm. Energies 2019, 12, 3122. [Google Scholar] [CrossRef]

| Number | 16 | 9 | 30 | 19 | 17 | 29 | 4 | 22 | 20 | 25 | 18 | 3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cell | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 | B10 | B11 | B12 |

| Capacity (Ah) | 33.4 | 32.4 | 32.3 | 31.6 | 31.2 | 31.1 | 30.9 | 30.7 | 30.7 | 30.6 | 30.5 | 29.8 |

| Groups | P1 | P2 | P3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cells | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 | B10 | B11 | B12 |

| SOC (%) | 80.9 | 80.6 | 78.5 | 78.7 | 77.3 | 74.9 | 73.6 | 75.4 | 73.5 | 71.2 | 70.3 | 70.6 |

| Groups | P1 | P2 | P3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cells | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 | B10 | B11 | B12 |

| SOC (%) | 50.2 | 48.1 | 48.3 | 48.8 | 47.6 | 42.5 | 44.9 | 41 | 40.2 | 38.7 | 36.3 | 38.5 |

| SOC Range (%) | SOCavg (%) | Maximum Deviation from Average (%) | Standard Deviation (%) | Equalization Time (s) | Charge Transfer Efficiency (%) | |

|---|---|---|---|---|---|---|

| Static equalization | 6060 | 63.83 | ||||

| Before equalization | 10.6 | 75.458 | 5.442 | 3.596 | ||

| After equalization | 1.6 | 74.841 | 0.92 | 0.531 | ||

| Charging equalization | 4925 | 63.18 | ||||

| Before equalization | 13.9 | 43.77 | 7.47 | 4.6 | ||

| After equalization | 1.41 | 86.91 | 0.87 | 0.42 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Zhu, W.; Xie, C.; Shi, Y.; Liu, F.; Li, W.; Tang, Z. A Layered Bidirectional Active Equalization Method for Retired Power Lithium-Ion Batteries for Energy Storage Applications. Energies 2020, 13, 832. https://doi.org/10.3390/en13040832

Yang Y, Zhu W, Xie C, Shi Y, Liu F, Li W, Tang Z. A Layered Bidirectional Active Equalization Method for Retired Power Lithium-Ion Batteries for Energy Storage Applications. Energies. 2020; 13(4):832. https://doi.org/10.3390/en13040832

Chicago/Turabian StyleYang, Yang, Wenchao Zhu, Changjun Xie, Ying Shi, Furong Liu, Weibo Li, and Zebo Tang. 2020. "A Layered Bidirectional Active Equalization Method for Retired Power Lithium-Ion Batteries for Energy Storage Applications" Energies 13, no. 4: 832. https://doi.org/10.3390/en13040832

APA StyleYang, Y., Zhu, W., Xie, C., Shi, Y., Liu, F., Li, W., & Tang, Z. (2020). A Layered Bidirectional Active Equalization Method for Retired Power Lithium-Ion Batteries for Energy Storage Applications. Energies, 13(4), 832. https://doi.org/10.3390/en13040832