Abstract

Air handling units are usually used to maintain the thermal and humidity parameters in indoor swimming pools that are used for lap swimming and recreation. Their use throughout the year consumes much more energy than, for example, air conditioning in residential or office buildings. Their considerable energy consumption is due to the need for their continuous operation to remove moisture gains from the evaporation of water and to heat the air and cover the heat losses of the pool. It is possible to design ventilation devices in such a way that the operating costs will be reduced, and the environmental impact will be significantly reduced. In this article, six different ventilation units in which different heat sources are used to heat the ventilation air have been evaluated; the selection of which was based on the most commonly used solutions. The results of the analysis are aimed to show which of the available heat sources is the most advantageous in terms of global and operating costs, and in terms of low CO2 emissions. Indicators of both the final and primary energy consumption, as well as the operating and global costs, were determined. The recommended solution that was chosen was the one that had both the lowest cost index (18–20% lower than most ecological sources) and the low primary energy index (8–13% higher than most ecological sources). The results showed that a heat pump in the ventilation unit proved to be the most beneficial solution. Unfortunately, this solution is rarely used due to its high investment costs (20% higher). However, the results have shown that the investment cost of using an advanced air handling unit will be recouped in only two to three years. Also, the global cost for units with a heat pump proved to be the lowest, despite high investment cost.

1. Introduction

1.1. Energy-Saving Solutions for Swimming Pool Ventilation

Preparing ventilation air is a process that consumes large amounts of energy; this process is seen most in indoor swimming pools where the internal temperature is at least 30 °C, and the relative humidity is 55–60% [1,2]. Due to the significant moisture gains, the ventilation air stream in these facilities is considerable. Heat exchangers that can extract heat from exhaust air, heaters, and more often, heat pumps are used to heat the ventilation air. Air recirculation is also used, although this is mainly done to ensure adequate dehumidification potential [3,4,5,6,7,8].

Due to a high indoor temperature and relative humidity, indoor swimming pools are expensive to operate; [9,10] energy, which is becoming increasingly expensive, is used to provide the proper conditions for people using the swimming pool facilities [11,12]. In these facilities, energy in the form of heat and electricity is consumed to ensure the appropriate thermal and humidity parameters of the air, preparing the swimming pool’s water in terms of hygiene and temperature, as well as lighting, administration, and the service premises of the facility, such as heating shower water, drying hair, etc. All of these expenses make the costs of running swimming pool facilities very high.

Due to their high energy consumption, swimming pools also have a huge carbon footprint [11]. Numerous studies on energy consumption in swimming pool facilities and the energy-saving solutions used in these facilities can be found in the literature [13,14,15,16]. Reducing the energy consumption in these facilities is recommended as this will lead to a reduction in CO2 emissions [11].

One solution leading to a reduction in the energy consumption in heating the ventilation air and the pool water that has been proposed is active control of the water and air parameters as a function of pool loading and the time of day. This is affected by the variability of the evaporation of water from the swimming pool and any wet surfaces, as well as the impact of solar radiation on the heating of the swimming pool hall [17].

A good solution that can lead to a lower primary energy index is the use of renewable energy sources, including solar energy. However, such a solution can only be used in countries with a warm climate, where access to solar energy is better, and thus more profitable [18,19,20]. Using a solar-assisted heat pump for heating pool water is also recommended [21].

In the literature [1,3,4,6,18,22], the use of heat pumps to recover heat from ventilation air to heat the supply air and possibly the pool water has been proposed. A heat pump can operate in a ventilation unit alone or in cooperation with a heat recovery recuperator, thus creating a two-stage system for heat recovery from ventilation air. The heat pump in swimming pool ventilation units works with the same stable thermal parameters throughout the year, which means that high coefficient of performance COP heating coefficients can be obtained at a level of five to six. But is a heat pump an ecological source of heat?

1.2. Pool Air Handling Units

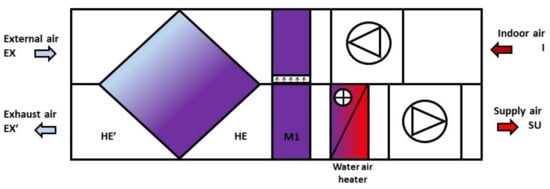

There are two main types of air handling units that are used in indoor swimming pools around the world. A simpler and, at the same time, cheaper solution is pool air handling units equipped with a crossflow heat exchanger for heat recovery and air recirculation. This two-stage heat recovery provides the potential for dehumidification, i.e., controlling the moisture content in the supply air; the control panel of such a system is shown in Figure 1.

Figure 1.

Swimming pool ventilation unit with heat recovery recuperator and water heater [23]: SU—supply air parameters, I—indoor air parameters, EX—external air parameters, M1—air parameters in the internal recirculation mixing chamber, HE—air parameters after the heat exchanger on the supply side, HE′—air parameters after the heat exchanger on the exhaust side.

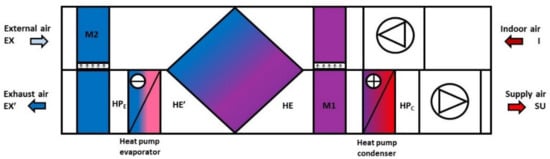

There is a more complicated device that is also recommended for swimming pool facilities [1,23], which is an air handling unit with three-stage heat recovery, i.e., a heat pump and a recuperator for heat recovery is used to recover heat and ensure the proper supply air parameters. The air condenser of the heat pump is placed in the air supply section of the unit and heats the air; this either replaces the heater or reduces its power requirements. The evaporator located in the exhaust section is a lesser source of heat and recovers the sensible and latent heat from the air that has been removed from the pool hall (Figure 2).

Figure 2.

Swimming pool ventilation unit with a heat pump and an air and water condenser [23] M2—air parameters in the external recirculation mixing chamber, HPE—air parameters after the heat pump’s evaporator, HPC—air parameters after the heat pump’s condenser (other points as in Figure 1).

1.3. Heat Sources for Heating Ventilation Air

Heat sources in swimming pool facilities are used to prepare hot water for various purposes in the pool facility; the hot water is used for:

- Heating the swimming pool water;

- The heating system—convection or floor heating installation;

- Ventilation air heating;

- Heating domestic hot water, including showers.

Heat sources for heating water may be different; their use is determined by access to the location of the pool and the technological capabilities of the facility. Popular heat sources in swimming pool facilities include:

- Substation supplied by the district heating network (with or without cogeneration);

- Gas boiler;

- Biomass boiler;

- Electrical energy (power supply for electric heaters or heat pumps);

- Solar energy.

In Poland, the source of heat for heating water in indoor swimming pools is usually district heating. It is a solution that is recommended for places where such a heating system is available; the Building Law also requires its use in Poland [24]. Such a recommendation can also be found in the literature [25,26]. A gas boiler can be another source of heat that is often used for heating water; this solution is used in places where it is not possible to connect the object to the heating network and where there is access to the gas network.

A heat pump can also be another source of air heating in a ventilation unit; the air is heated in an air condenser (upper heat source of the heat pump). The condenser can only be used as an air-heating condenser or a double condenser to heat air and the pool water. This solution in swimming pool units allows for optimal use of the heat pump throughout the year.

The type of fuel used in the heat source translates into the primary energy consumption for the needs of the given process. Depending on whether the energy is obtained from a renewable or non-renewable source and to what extent renewable components are used to produce it, the coefficient of non-renewable primary energy input will be different. A list of the coefficients of non-renewable primary energy input for fuels or energy used as heat sources for heating water and ventilation air is presented in Table 1 (according to the regulations in Poland [27] and data from heat suppliers).

Table 1.

Input coefficients of non-renewable primary energy (wi), conversion efficiency and the CO2 emissions for selected sources for heating ventilation air and pool water.

In order to analyze the primary energy consumption of the air handling unit, the electricity consumption of the supply and exhaust fans in the unit and the electricity consumed to drive the compressor of the heat pump in the ventilation unit and the pumps supplying the heater should be taken into account.

1.4. Research Gap and Scope of the Research

Heat pumps are recommended for use in swimming pool facilities. The heat pump as a source of air heating works most effectively when the lower and upper heat sources have a relatively constant temperature throughout the year. In swimming pools, the parameters of indoor air are constant and practically independent of the season, which guarantees that the heat pump can work effectively. This leads to low energy consumption of the air preparation system. Although heat pumps have advantages, they are not commonly used. Air handling units with heat pumps are more expensive investments, compared to units without heat pumps. That is why many investors, especially public ones, decide to buy cheaper devices. This article calculates the indicators of final energy, primary energy, and the operating costs in order to demonstrate the advantages of air handling units with heat pumps in both economic and ecological terms. Analyses of heat pump air handling units have been presented in various articles in the literature; however, there have been no analyses of primary energy consumption indicators and operating costs as well as CO2 emissions and the payback time of installing a more expensive device. Such analyses are necessary to show investors and pool operators that more investment-expensive solutions should be considered. Application of more expensive ventilation units may be more advantageous in terms of total global costs and operating costs. The comparative analysis includes a unit with both recirculation and a heat recovery exchanger with a water heater and a unit additionally equipped with a heat pump with an air condenser. The heat consumption necessary to heat the ventilation air will be calculated to ensure the correct temperature and humidity of the supply air and the consumption of final energy and primary energy, as well as the operating costs of all the solutions and the simple payback time for the heat pump solutions and global costs for different situations.

There are publications in the literature in which economic analyses have been described, but they concerned water heating [22] or the use of a heat pump for dehumidification of air and water heating only [8]. In both publications, the authors stated that the use of a heat pump is a good solution from an economic point of view; the analyses in this paper concern all of the processes needed for air preparation. There are also studies analyzing the energy and ecologic aspects of the use of a heat pump as a heat source, but the use of a heat pump for heating a single-family house was analyzed [31,32]. However, they did not analyze the air-to-air heat pump and its use in the swimming pool.

The article has also determined the CO2 emissions produced by the preparation of ventilation air; this has been done because analyses have shown that swimming pools have a high energy consumption which results in a huge carbon footprint [11].

Heat pumps are evaluated as the most advantageous in terms of energy [1,31,32]. When the ecological aspect is analyzed, heat pumps are indicated as definitely better than electric boilers, comparable to gas boilers, and sometimes even worse than coal boilers [32], but those analyzes were performed for a small single-family house. The comparison in the article includes a comparison of a non-renewable and a renewable source, to produce the designed parameters of ventilation air to have a better view of all available options. Economic analysis will be conducted to present an economic analysis, in order to decide which type of ventilation unit is optimal for a swimming pool facility.

1.5. Research Goal

The performed analyses are aimed at checking whether the air-to-air heat pump as a source of heat for the preparation of ventilation air is an economical and ecological heat source at the same time. The indicators adopted to compare the variants will be primary energy index EP, CO2 emission, simple payback time SPBT, as well as global costs. The selection of the recommended option will be based on the lowest primary energy consumption index and the lowest CO2 emissions (ecological factors) combined with the lowest operating costs and a short payback time and low global costs (economic factors).

The results of the analysis can be used by investors to decide if investing in a more expensive solution for their swimming pool may be profitable.

2. Materials and Methods

Usable energy demand calculations QH,nd were performed using an hourly time step. Calculations were based on using the air handling unit operation algorithm described in detail in the article [1]. Air parameters were calculated at each point of the air handling unit, and then the power of the devices and the amount of energy that should be supplied to the devices were determined to ensure proper parameters inside the swimming pool. Calculations made with the developed algorithm were validated in a real swimming pool facility. Final energy calculations, which are the basis for determining ecological and economic indicators, were made in accordance with the equations and relationships described in Section 2.

2.1. The Algorithm for Assessing Each Variant

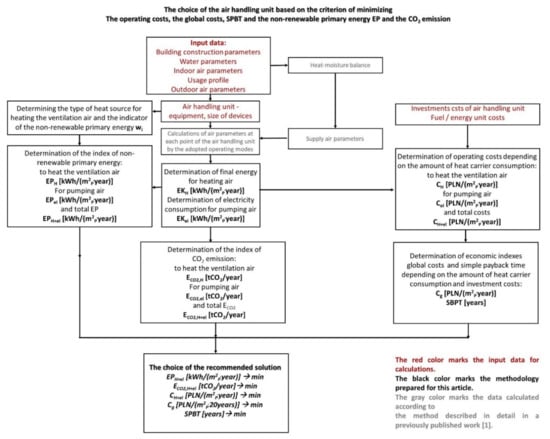

The selection of the recommended solution for each variant was implemented based on the minimization of the operating cost index CH+el and global cost index Cg and minimization of the primary energy index EPH+el. The scheme of the algorithm that was used to determine these indicators is shown in Figure 3.

Figure 3.

Selection of the ventilation unit based on the minimization of the operating costs, the global costs, simple payback time (SPBT), and the primary energy index and CO2 emissions.

The calculations of usable energy consumption were based on the methodology described in detail in the literature [1]. Ratajczak and Szczechowiak [1] described the equations of air state after it flows through successive devices in the air handling unit. Based on the equations described in [1], it is possible to determine the usable energy for heating the ventilation air (QH,nd). The same algorithm was used to calculate the usable energy in this article. The values calculated according to this methodology are shown in gray (Figure 3). The calculations marked in black were carried out according to the method prepared for this article.

The article focuses on the calculation of final energy, i.e., taking into account the efficiency of the installation and the production of energy carriers. Analyses were performed on operating and global costs based on the final energy value. The method of determining these indicators as well as the SPBT index, the primary index, and the CO2 emission were given. As the calculation of usable energy is complicated, it was decided to be based on the previously described method (earlier article by the authors [1]), where a detailed method of determining the usable energy is described.

2.2. Variants

Annual analyses of an air-handling unit, based on climate data (temperature, relative humidity, solar radiation intensity) for the city of Poznań in Poland, were carried out for data from a typical meteorological year (TRY) [33]. The selected ventilation unit was for a separate pool basin zone in a facility where the pool has dimensions of 12 × 25 m = 300 m2, i.e., for a traditional sports pool (B1) and for a recreational pool (B2) also with an area of 300 m2. Detailed data for the analyzed pool hall are shown in Table 2 [1].

Table 2.

General data of the analyzed pool for the two variants B1 and B2.

Considering the recommendations that all analyses should be carried out by taking the appropriate thermal comfort parameters into account [11], it is worth noting that all of the analyses assume that comfortable conditions prevail in the analyzed pools.

The amount of heat required to heat the ventilation air was calculated on the basis of detailed calculations of the thermodynamic state of the air at each point of the air handling unit; detailed calculation formulas have been discussed in the literature [1]. The formula for calculating the amount of heat depends on the type of air handling unit and uses the calculated air enthalpy values: SU—supply, M1—in the mixing chamber, HP—after the heat pump condenser.

For units without a heat pump AHU1:

For units with a heat pump AHU2:

The formulas for the calculation of enthalpy, as well as for air parameters in accordance with the operating mode of the air handling unit are described in detail in [1]. Due to the range of the method, the descriptions of the formulas are not provided because this article focuses on the analysis of economic and ecological indicators, and not on usable energy.

2.2.1. Analyzed Air Handling Units

Two variants of ventilation units were analyzed for two pool variants: swimming pool (B1) and recreational pool (B2):

- (1)

- Air handling unit AHU1, with a crossflow heat exchanger with 73–83% total heat recovery efficiency (assumed average of 78%) as well as recirculation and a water heater (Figure 1).

- (2)

- Air handling unit AHU2, with a heat exchanger with 73–75% total heat recovery efficiency (assumed average of 74%), a heat pump (with an air condenser), and a heat exchanger (Figure 2).

According to the VDI 2089 guidelines [34,35], the supply airflow VSU is: for pool (B1)—50 m3/(h.m2P), for pool (B2)—70 m3/(h.m2P). For pools with a water surface area of 300 m2—the size of the ventilation units is as follows: pool B1—VSU = 15,000 m3/h; B2 pool—VSU = 21,000 m3/h.

An analysis of the AHUs that are commercially available determined the power of the supply (PSU) and exhaust (PEX) fans for variants without a heat pump and with a heat pump—with an available pressure of 300 Pa. The following equations are our elaboration based on a series of types of swimming pool ventilation units from DanTherm (Denmark) [36].

- (1)

- Air handling unit AHU1:

- PSU = 0.0242 V2SU + 1.0748 VSU + 0.02, [kW], where VSU [m3/s], PSU [kW];

- PEX = 0.0279 V2SU + 0.9794 VSU + 0.04, [kW].

- (2)

- Air handling unit AHU2:

- PSU = 0.0493 V2SU + 1.0036 VSU + 0.12, [kW];

- PEX = 0.0621 V2SU + 0.8686 VSU + 0.14, [kW].

In both cases, the airflow range is: 2.5–9.5 m3/s.

2.2.2. Devices for Heating the Ventilation Air

Due to the possibility of using different heat sources to heat the ventilation air, various possible heat sources will be compared. The following variants of air heating devices were adopted:

- (1)

- A water heater supplied with water heated by a gas boiler (AHU1);

- (2)

- A heater supplied with process water heated in the heat exchanger supplied (AHU1);

- Municipal District Heating MDH with cogeneration;

- Municipal District Heating MDH without cogeneration;

- From MDH Poznań 2016;

- From MDH Poznań 2018.

- (3)

- A heat pump condenser and a water heater (AHU2).

For comparison purposes, in relation to the heat pump, it was decided to compare the air heater powered by natural gas, district heating with three different rates of input coefficients of non-renewable primary energy. Different sources of district heat were taken for the calculation: when heat is generated with cooperation and without cogeneration, as well as when the heat is generated with a large share of biomass (MDH Poznan 2016) and with a small share of biomass (MDH Poznań 2018). It was decided to choose such solutions because the values of the MDH indicators in Poznań in 2016 differ significantly from the values of the indicators in Poznań in 2018.

It was decided to analyze the district heating as a heat source with the use of various indicators of non-renewable primary energy input and CO2 emission rates (Table 1) in order to present whether this heat source is the most beneficial and stable in terms of its ecological parameters. The above-mentioned indicators for the same heating network in 2016 and 2018 differ significantly, because in 2016 the share of biomass for heat generation in the plant was large, while in 2018 this share decreased due to the failure of the combustion unit.

2.2.3. Heat Pump in the Air Handling Units (AHU2)

The heat pump as a heat source for heating the ventilation air works in the following system: the evaporator is located in the exhaust part and is the lower heat source, and the condenser is located in the supply part and is the upper heat source. The evaporator dries and cools the air removed from the pool, which has a relatively constant temperature throughout the year (temperature 30–34 °C and relative humidity 55–60%). The condenser heats the supply air to a relatively constant temperature, which varies between 10–15 K in a moderate climate throughout the year. This phenomenon occurs because in the air handling units dedicated for the swimming pool there is recirculation and a heat exchanger. Thus, the air before the condenser is already preheated. Due to constant air parameters before the condenser and evaporator, the COP of the heat pump is quite stable and varies within a very narrow range. For DanTherm (Denmark) swimming pool air handling units with recuperator and heat pump with air condenser and double condenser (water and air)—COP is in the range of 6.2–6.4 under test conditions [36]. For the purposes of the analyses, SCOP (seasonal COP) = 5.1 was assumed.

2.2.4. Fans and Pumps in the Air Handling Units

The following parameters of the fans and the pumps supplying the heaters were adopted:

- (1)

- Supply air streams VSU of 50 m3/(h·m2P) and 70 m3/(h.m2P)—these are air streams that are able to receive moisture gains from evaporation in the swimming pool and the recreational pool, respectively;

- (2)

- Supply airflow during the day: B1 pool—15,000 m3/h; B2 pool—21,000 m3/h; at night between 10:00 p.m. and 6:00 a.m. the airflow was reduced by 20% for both pools;

- (3)

- Nominal powers of the fan motors and the devices for the B1 pool—15,000 m3/h:

- Air handling unit with recuperator and heater (without heat pump)—PSU = 4.0 kW; PEX = 3.7 kW; annual electricity consumption—188 kWh/(m2/year);

- Air handling unit with a recuperator, a heater, and a heat pump—PSU = 5.2 kW; PEX = 5.0 kW; annual electricity consumption—250 kWh/(m2/year);

- Heater circuit pump—75 W; annual electricity consumption 2.2 kWh/(m2/year).

- (4)

- Nominal powers of the fan motors and devices for the B2 pool—21,000 m3/h:

- Air handling unit with recuperator and a heater (without a heat pump)—PSU = 8.8 kW; PEX = 9.4 kW; annual electricity consumption—467 kWh/(m2/year);

- Air handling unit with a recuperator, heater, and a heat pump—PSU = 9.7 kW; PEX = 5.0 kW; annual electricity consumption—250 kWh/(m2/year);

- Heater circuit pump—125 W; annual electricity consumption 3.7 kWh/(m2/year).

2.2.5. Efficiency of the Air Heating Installations

Production and transfer of heat from the source to the heater or pool heat exchanger are associated with losses; these losses can be included in the total efficiency value. The overall efficiency is influenced by the generation efficiency—, regulation efficiency—, distribution efficiency, and storage efficiency as follows:

The generation efficiency for each analyzed heat source is presented in Table 1. The regulation efficiency for each heat source was assumed to be 97%, the distribution efficiency for the system with a heat pump inside the unit and an electric heater, due to the lack of external wires was 100%; in comparison, this value was 96% for the other heat sources. Accumulation did not occur in the analyzed cases. The total efficiency value for each variant is presented in Table 3.

Table 3.

Analyzed variants.

2.2.6. Summary of All the Analyzed Variants

A summary of all the variants that were analyzed is presented in Table 3.

2.3. Determination of the Final Energy and Primary Energy Indicators

2.3.1. Final Energy Indicator

Final energy indicators are based on the calculation of the amount of heat necessary to heat the ventilation air during the year. For each variant, the amount of heat that must be transferred by the heater, regardless of its type, depends on the operational efficiency of the recuperator for heat recovery, the temperature of the air in the pool, the heat losses of the hall, and the control algorithm; final energy is denoted as QH,nd. However, the amount of final energy depends on the total efficiency of the air heating installation.

The final energy indicator for air heating of air handling units without a heat pump can be calculated according to the following Formula (4):

where,

- —final energy of the heating process (EKH), ;

- —amount of heat required to heat the air (QH,nd), ;

- —efficiency of the air heating system (Table 2), .

The final energy indicator for heating the air of the AHU with a heat pump can be calculated according to the following Formula (5):

where,

- —final energy of the heating process (EKH), ;

- —amount of heat required to heat the air (QH,nd), ;

- —seasonal coefficient of heating efficiency for heating air using a heat pump (Table 2), .

The final energy index for each solution for pumping air or water can be calculated according to the following Formula (6):

where,

- —final energy of the air circulation process,

2.3.2. Primary Energy Indicator

The primary energy consumption for the process of heating the ventilation air and pumping the air and water can be calculated according to the following Formula (7):

where,

- —primary energy of the heating process (EPH) or from pumping the air or water (EPel), ;

- —final energy of the heating (EKH) or from pumping the air or water (EKel), ;

- —coefficient of the non-renewable primary energy input for the process related to air heating and air or water pumping (Table 2), .

For variants of the air handling units equipped with an air heater, the primary energy consumption is determined by taking into account the following:

- The amount of heat necessary to heat the ventilation air and the efficiency of heat transfer, multiplied by the coefficient of the non-renewable primary energy input for the fuel from which the heat is generated (gas, district heat, electricity);

- The electricity required to drive all the devices producing the airflow and that necessary for the system’s operation (fans, heater circulation pump, etc.).

For variants of the air handling units equipped with a heat pump with a single condenser, the primary energy is determined by taking into account the following:

- The electricity required to drive all devices producing the airflow and that necessary for the system’s operation (fans, compressor, and heater circulation pump).

2.4. Determining the CO2 Emissions

The CO2 emissions for the process of heating the ventilation air and pumping the air and water can be calculated according to the following Formula (8):

where,

- —the final energy of the heating process (EKH) or from pumping air or water (EKel), ;

- —unit CO2 emissions for the fuel/Energy used to heat air (wCO2,H) or for pumping air or water (wCO2,el), (Table 1), .

The total CO2 emissions associated with the preparation of the ventilation air was then calculated for each variant as the sum of the CO2 emissions associated with the heating of the air in the heater or condenser as well as the electrical energy necessary for the operation of the ventilation unit and the heating system.

2.5. Determining the Operating Costs for Each Variant

The estimated annual heat demand for heating the ventilation air —the power required for the air heater or heat pump condenser and the specific electricity consumption for pumping air through the fans, pumps, or for the compressor drive in the heat pump system were the basis for the calculation index of the operating costs CH+el and the index of the non-renewable primary energy EPH+el.

The operating costs (energy) can be determined as follows:

where,

- —operating costs of the heating process (CH) or for pumping air or water (Cel), ;

- —final energy of the heating process (EKH) or for pumping air or water (EKel), ;

- —unit cost of the fuel or the energy consumed in the process of heating or pumping the air or water

For the variants of the air handling units equipped with a water heater, the operating costs consist of:

- The costs of the heat carrier that heats the air in the heater (final energy determined for the calculated amount of heat necessary to heat the ventilation air multiplied by the unit price of fuel—gas, network heat, electricity);

- The electricity-related costs for pumping the air or water (electricity supplied to fans and pumps multiplied by the unit price of electricity).

For the variants of the central units equipped with a heat pump, there are only electricity costs for:

- Pumping air through the fans (electricity supplied to the fans multiplied by the unit price of electricity);

- The power supply to the heat pump compressor for heating air in the air condenser in the unit;

- Potentially the costs of a heat carrier ensuring partial heating of the air in the heater;

- The cost of the electricity required to drive the heater pumps.

2.6. Simple Payback Time (SPBT)

The simple payback time (SPBT) can be used to evaluate the individual options as follows:

where,

- —the difference in the investment costs, i.e., purchasing the air handling unit in a given variant (AHU1) and purchasing an air handling unit with a heat pump (AHU2), [PLN];

- —the annual operating cost savings as a result of using the air handling unit in a given variant (variants 1–5) and the air handling unit with a heat pump (variant 6), [PLN/year].

In order to calculate the SPBT, it is necessary to determine the purchase price of the air handling unit. Table 4 summarizes the net costs of the ventilation units for the pools B1 and B2 in the version without a heat pump (AHU1) and for the variant with a heat pump (AHU2).

Table 4.

Investments costs for purchasing air handling units.

2.7. Global Costs

The global cost index will also be used to assess the economic aspects of various heat sources to heat the ventilation air. Global costs are an indicator that takes into account the long life of buildings or installations, so they include the cost of replacing the equipment when it loses its useful life (durability), the cost of its disposal, and the cost of replacing this equipment with a new one. The method of calculation of global costs was described in [37,38,39]. Basińska et al. discuss the details of the global cost calculation method. Using the same methodology, Formula (11) and the data on economic indicators specified by the authors were adopted, as described below.

In the calculations of global costs (11), the analyzed period of time was assumed to be 20 years and the durability of the air handling unit was 15 years, according to the global cost calculation method. Costs of ventilation units were assumed according to Table 4, unit fuel prices according to Table 3, and final energy calculated for each of the six variants according to Formulas (4)–(6).

The following economic indicators were also adopted: inflation 2.5%, the Warsaw Interbank Offered Rate 4.7% and discount rate 2.15%, and VAT 23% in line with the values adopted for Poland according to [40].

The global cost calculations will concern only the air handling unit and its operation because this method can be applied to a single component, including an HVAC component [39]. The remaining building costs for all variants are the same. Global costs for the purposes of analyses in this paper are defined as costs that result from the use of various air handling units, in which the air is heated from various heat sources.

3. Results and Discussion

In accordance with the described methodology, the usable energy calculations were made with an hourly time step. The final energy, primary energy, CO2 emissions, and costs were calculated based on the value of the annual final energy consumption.

3.1. Presentation of the Results

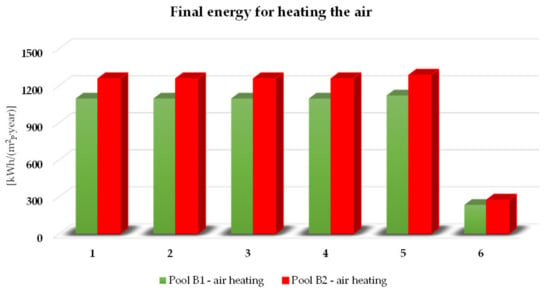

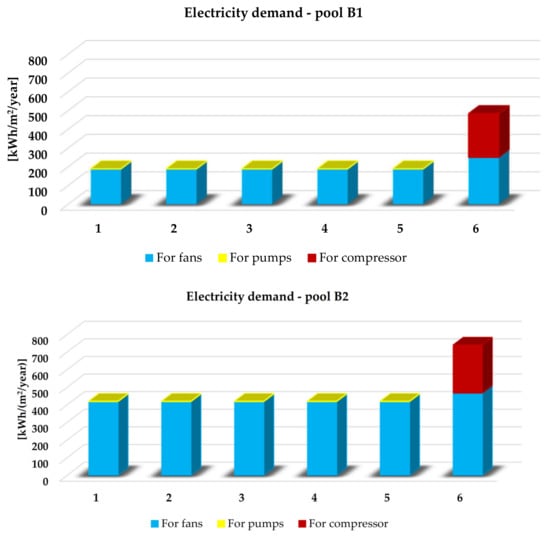

The results of the analyses regarding the heat consumption when heating the ventilation air and the electricity consumption by the devices (Section 2.2.3) are presented in Table 5 for pool B1 and in Table 6 for pool B2; the results are presented in the charts in Figure 4 and Figure 5.

Table 5.

Energy consumption calculation results—sports pool B1.

Table 6.

Energy consumption calculation results—recreation pool B2.

Figure 4.

Final energy consumption in the process of heating the ventilation air for the six variants for the sports pool B1 and the recreation pool B2.

Figure 5.

Electricity demand for pumping air, driving the compressor, and the water condenser pump for sports pool B1 and recreation pool B2.

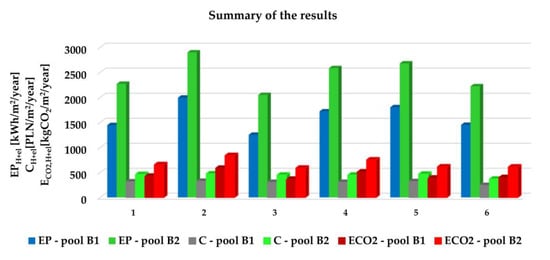

The primary energy index EPH+el was then calculated for each variant, taking into account the relevant primary energy input ratios and operating costs for unit fuel or heat prices CH+el. The ecological indicator for the assessment of a ventilation unit is also the CO2 emissions factor related to air heating and the operation of the ECO2 ventilation unit. The emissions were determined for each variant using Formula (8). The results of the calculations are presented in Table 7 (Pool B1) and Table 8 (Pool B2)—the highest values are marked in red, the lowest ones in green; the results are also shown in Figure 6.

Table 7.

Results of the calculations of the non-renewable primary energy ratio EP, CO2 emissions ECO2, and the operating costs C—sports pool B1.

Table 8.

Results of the calculations of the non-renewable primary energy ratio EP, CO2 emissions ECO2, and operating costs C—recreation pool B2.

Figure 6.

Calculated indicators of primary energy EPH+el, CO2 emissions ECO2,H+el, and operating costs CH+el—sports pool B1 and recreation pool B2.

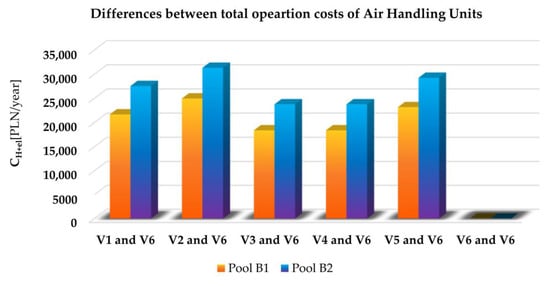

The differences in the total costs for each variant, compared to the cheapest variant—variant 6, are significant and are shown in Figure 7.

Figure 7.

The differences between the operating costs of the individual variants—compared to the cheapest option (variant 6)—for sports pool B1 and recreation pool B2.

Despite the low operating costs of the heat pump variant, investors rarely pick this solution. This is due to the higher costs of purchasing a ventilation unit with a heat pump, fear of their complicated operation, and a lack of knowledge about the operating costs. The average prices of AHUs with heat pumps and without heat pumps are presented in Table 4.

For the B1 pool, the difference in the purchase costs of the AHU2 AHU (with a heat pump) compared to the purchase of the AHU1 (without a heat pump) is: = 55,250 PLN.

For the B2 pool, the difference in the purchase costs of the AHU2 AHU (with a heat pump) compared to the purchase of the AHU1 (without a heat pump) is: = 72,250 PLN.

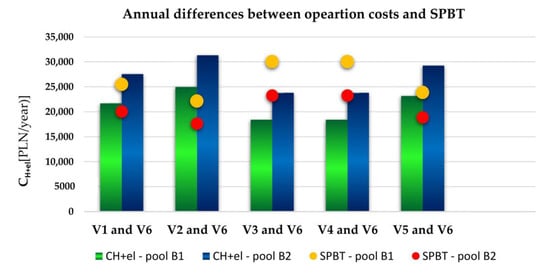

The SBPT index for basins B1 and B2 was calculated using Formula (10) and the results are shown in Figure 8.

Figure 8.

The differences between the operating costs of the individual variants in relation to the cheapest variant (V6) and the SPBT index—sports pool B1 and recreation pool B2.

The payback time for the additional investment outlays in the purchase of an air handling unit with a heat pump pays off very quickly. The obtained SBPT index was in the range of 2.5–3 years for the B1 pool and 1.5–2.5 years for the B2 pool and is very favorable. This indicates that the heat pump in a ventilation unit used to heat ventilation air is economically very beneficial, and at the same time is relatively good in ecological terms since the EP indicator for this solution was not the highest possible value included in the analyzed variants.

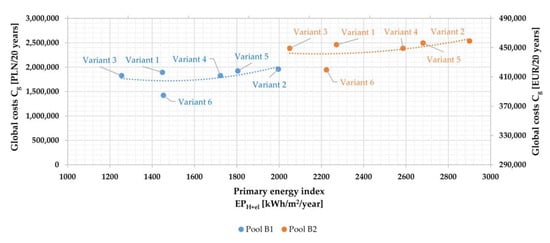

The results of calculations of global financial costs as a function of the method of using the swimming pool (sports swimming pool B1 and recreational swimming pool B2) are shown in Figure 9.

Figure 9.

Global costs in function of primary energy index for pools with different uses.

In both cases, the minimal value of global costs was achieved for variants with a heat pump (variant 6). This applied to both the use of the pool as a sports pool and as a recreational pool. The minimal value of the global costs for the B2 pool is higher than that for the B1 pool, due to the need to remove more moisture gains from evaporation as well as from a higher temperature of water and air.

3.2. Recommended Solution—Discussion

When choosing the recommended solution for heating ventilation air, four indicators were taken into account: the primary energy index EPH+el, the CO2 emissions ECO2,H+el, the index of the operating costs CH+el, and global cost Cg. The lowest values of EP and ECO2 should characterize the recommended solution and, at the same time, the lowest operating and global costs.

Striving for low operating costs is most beneficial for the pool operator; at the same time, it must be remembered that the energy sources with the smallest environmental impact should be used. This problem is determined by the primary energy index, which illustrates the consumption of rapidly depleting fossil fuels. At the same time, the use of fuels with a high level of non-renewable primary energy is associated with higher carbon dioxide emissions, which is also currently a consideration.

The variant with the lowest index of non-renewable primary energy is variant 3, which uses a water heater fed with technological heat heated in a heat exchanger fed from the district heating in Poznań in 2016; the primary energy index for 2016 was very low in Poznań—0.624. This is a very beneficial solution because such a low coefficient of non-renewable primary energy input is a result of the large share of biomass used to produce heat. In subsequent years, the value of this indicator increased to 1.05 due to a smaller percentage of biomass. Therefore, this variant can be rejected as it cannot be obtained at present. The low rate of primary energy and CO2 emissions in variant 3 was due to the fact that the plant used a large share of biomass. Due to failures of the biomass combustion unit in the following years, it was not possible to achieve such low environmental factors, and so far the index of non-renewable primary energy expenditure is still higher than one. Thus, if the plant does not use a large share of biomass for combustion, such favorable ecological indicators cannot be achieved. Another solution with the lowest primary energy indicator is powering the heater using district heat from cogeneration (indicator wi = 0.8)—variant 1. The variants that used a heat pump were in the middle range of the obtained results.

The primary energy index EP’s for all possible variants are ranked in ascending order as follows: 3; 1; 6; 4; 5; 2. The variants were in the same order for CO2 emissions, except for one variant. When natural gas is used as a heat source for heating the ventilation air (variant 5), its CO2 emissions factor is comparable with variants 1 and 6, even though its EP primary energy index is higher.

The value of the total CO2 emissions depends on the type of heat source that is used; the smallest value is for the variant in which the water to the heater was heated using a large amount of biomass (variant 3). This variant has a CO2 emissions rate up to 67% lower for the B1 pool and 37% lower for the B2 pool in comparison with variant 2 (heat source with no cogeneration—only coal combustion). The value of the CO2 emissions factor is linked to the value of the EP indicator; if the EP value is lower, then, as a rule, the CO2 emissions will also be low. The variants where the air was heated using district heating, as well as heat pumps, had a similar CO2 emissions level. This is an especially important consideration when choosing a heat pump. The CO2 emissions factor indicates that this is an option that is comparable to the other ones in ecological terms. Even though the heat pump is powered from electricity generated in Poland by the combustion of coal, the CO2 emissions for this variant are comparable with the use of district heating, which is indicated as being legally recommended. The low primary energy ratio and low CO2 emissions classify the variant with a heat pump as an ecological option.

The operating costs were also calculated for each of the variants: The most expensive systems to operate were the variants that used district heat and natural gas. The indicators of the operating costs of the variants in ascending order are: 6; 3; 4; 1; 5; 2. As for global costs index the order of variants is: 6; 3; 4; 1; 2; 5

Variant 6, i.e., the variant that used a heat pump to heat the air, was the cheapest solution to operate. The annual operating costs for these variants were 424 PLN/(m2/year)—for the B1 pool and 373 PLN/(m2/year) for the B2 pool. Such low operating costs could be achieved because the air was heated by the refrigerant circuit of the heat pump, which has a high COP. In the refrigerant circuit, the only element that draws energy from the outside is the compressor. As swimming pools have constant thermal and humidity parameters for the air that is removed from the pool hall throughout the year, the COP of the heat pump is high and remains almost constant throughout the year. For this reason, the demand for electricity during the year is relatively low. Also, variant 6 has the lowest global costs of operation.

Similar conclusions were reached by Peng Sun et al. [8] when they compared air dehumidification with and without a heat pump, and Lam and Chan [22] who compared the use of a heat pump for swimming pool water heating or Chow et al. [21] where a solar-assisted heat pump was used for water and space heating. The analyses in this work were carried out by taking all of the air preparation processes into account, not just some as in previous studies. The results have confirmed the results from the analyses in the literature indicating that a heat pump should be used in swimming pool facilities and extending them to the analysis of the overall air preparation.

3.3. Summary

Many publications in the literature have recommended solutions for use to ensure low energy consumption in pool technology. This article has examined two aspects related to the final energy consumption (operating costs), the primary energy consumption, and the CO2 emissions (ecological factor). It has been noted that the variants that are expensive to operate might be environmentally beneficial if technological heat that is generated using biomass is used to power the heat source. The difference in primary energy index EP value between the most advantageous variant (variant 3) and the variant with a heat pump (variant 6) was 13% and 8%, respectively, for the sports and recreation pool. However, the operating costs of the heat pump variant were 18–20% lower.

A heat pump is an alternative that allows for low operating costs, as well as low primary energy indicators and low CO2 emissions (these indicators can be further reduced—by using renewable energy) compared to the other analyzed cases.

Unfortunately, air handling units with heat pumps are more expensive, approximately by 20%, hence the decision to use cheaper devices in swimming and recreational pools. However, taking into account the lower operating costs and the relatively short payback time for an air handling unit with a heat pump, these solutions should be recommended. The payback time for the more expensive solution of the air handling unit with a heat pump—up to three years for the B1 pool and even less than 2.5 years for the B2 recreation pool—justifies recommending this solution.

The analyses were carried out for pools located in Poland, but the results may refer to locations in different countries with a similar (temperate) climate. In the case of swimming pools, the indoor parameters are important, which define the amount of heat that should be supplied to the ventilation air, and these parameters are similar in many countries. The indicators of non-renewable primary energy inputs, which result from the type of fuels used in Poland, were also taken into account. Fuel prices were adopted for Poland. However, by using simple assessment indicators, it is possible to compare the situation in different countries. Based on the value of the final energy for heating the ventilation air for different variants and knowing the unit price of fuel and the input index of non-renewable primary energy, it is possible to easily convert the results for other countries. Similar analyses could be interesting based on other economic and ecological values existing in other countries, as well as analysis with a combination of different heat sources, including the use of additional renewable sources, such as photovoltaic cells.

The following indicators were analyzed: primary energy, global costs, SPBT, operating costs, and CO2 emissions. Solutions with the lowest values of all indicators were sought. A heat pump as a heat source to heat the air for a swimming pool is the cheapest solution in terms of operating costs and global costs, and at the same time, the payback time for this more expensive solution is only two to three years. The economic aspect is the most important for the investor and pool operator. At the same time, in terms of CO2 emissions, the indicator for the heat pump is only 3–7% higher than the variant with district heating using a large share of biomass. However, since the most favorable option in terms of CO2 emissions can be rejected due to the fact that such low CO2 emissions occurred only for two years, the heat pump is also at the same time the cheapest and the most ecological heat source for ventilation of swimming pools.

4. Conclusions

As a result of the conducted analyses, which are supplementing the literature with research on economic and ecological indicators for heat pumps for heating ventilation air for swimming pools, it was shown that a heat pump can be a good source of heat.

It was found that:

- The way the swimming pool is used affects the investment and operating costs of the ventilation system. It has been shown that regardless of the way the swimming pool is used (sports or recreational), a heat pump is a good source of heat for the ventilation air;

- Air handling units with a heat pump are more expensive in terms of investment (by about 20%), but their advantage is lower operating costs by about 18–20% compared to the use of water heaters;

- Global costs calculated for a period of 20 years showed that heat pump unit has lower global costs, which means that that unit is more economically advantageous;

- There are more ecological heat sources for heating ventilation air than a heat pump, but the difference in the primary energy index for a heat pump compared to more environmentally friendly sources was higher by only 8–13%. It should be taking into account that the heat pump can be installed anywhere because the heat source is supplied with electricity, and in some places, there may not be access to district heating using biomass;

- The most ecological heat sources for heating the ventilation air for the swimming pool are even twice as expensive in operation. As the investment in a more expensive air handling unit with a heat pump can pay off after about two to three years, it is a solution worth investing in.

Author Contributions

Conceptualization, K.R.; methodology, K.R. and E.S.; formal analysis, K.R. and E.S.; investigation, K.R.; writing—original draft preparation, K.R.; writing—review and editing, K.R. and E.S.; visualization, K.R.; supervision, E.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Polish Ministry of Science and Higher Education, grant number 504101/0713/SBAD/0940.

Conflicts of Interest

The authors declare no conflict of interests.

References

- Ratajczak, K.; Szczechowiak, E. Energy consumption decreasing strategy for indoor swimming pools—Decentralized Ventilation system with a heat pump. Energy Build. 2020, 206, 109574. [Google Scholar] [CrossRef]

- Trianti-Stourna, E.; Spyropoulou, K.; Theofylaktos, C.; Droutsa, K.; Balaras, C.; Santamouris, M.; Asimakopoulos, D.; Lazaropoulou, G.; Papanikolaou, N. Energy conservation strategies for sports centers: Part B. Swimming pools. Energy Build. 1998, 27, 123–135. [Google Scholar] [CrossRef]

- Westerlund, L.; Dahl, J. Use of an open absorption heat-pump for energy conservation in a public swimming-pool. Appl. Energy 1994, 49, 275–300. [Google Scholar] [CrossRef]

- Lazzarin, R.M.; Longo, G.A. Comparison of heat recovery systems in public in-door swimming pools. Appl. Therm. Eng. 1996, 16, 561–570. [Google Scholar] [CrossRef]

- Johansson, L.; Westerlund, L. Energy savings in indoor swimming-pools: Comparison between different heat-recovery systems. Appl. Energy 2001, 70, 281–303. [Google Scholar] [CrossRef]

- Lee, W.-S.; Kung, C.-K. Optimization of heat pump system in indoor swimming pool using particle swarm algorithm. Appl. Therm. Eng. 2008, 28, 1647–1653. [Google Scholar] [CrossRef]

- Panaras, G.; Markogiannaki, M.; Tolis, E.; Sakellaris, Y.; Bartzis, J. Experimental and theoretical investigation of air exchange rate of an indoor aquatic center. Sustain. Cities Soc. 2018, 39, 126–134. [Google Scholar] [CrossRef]

- Sun, P.; Wu, J.Y.; Wang, R.Z.; Xu, Y.X. Analysis of indoor environmental conditions and heat pump energy supply systems in indoor swimming pools. Energy Build. 2011, 43, 1071–1080. [Google Scholar] [CrossRef]

- Kampel, W.; Carlucci, S.; Aas, B.; Bruland, A. A proposal of energy performance indicators for a reliable benchmark of swimming facilities. Energy Build. 2016, 129, 186–198. [Google Scholar] [CrossRef]

- Kampel, W.; Aas, B.; Bruland, A. Energy-use in Norwegian swimming halls. Energy Build. 2013, 59, 181–186. [Google Scholar] [CrossRef]

- Rajagopalan, P.; Jamei, P. Thermal comfort of multiple user group in indoor aquatic centers. Energy Build. 2015, 105, 129–138. [Google Scholar] [CrossRef]

- Revel, G.M.; Arnesano, M. Perception of the thermal environment in sports facilities through subjective approach. Build. Environ. 2014, 77, 12–19. [Google Scholar] [CrossRef]

- Kampel, W.; Aas, B.; Bruland, A. Characteristics of energy-efficient swimming facilities—A case study. Energy 2014, 75, 508–512. [Google Scholar] [CrossRef]

- Mousia, A.; Dimoudi, A. Energy performance of open air swimming pools in Greece. Energy Build. 2015, 90, 166–172. [Google Scholar] [CrossRef]

- Zuccari, F.; Santiangeli, A.; Orecchini, F. Energy analysis of swimming pools for sports activities: Cost effective solutions for efficiency improvement. Energy Procedia 2017, 126, 123–130. [Google Scholar] [CrossRef]

- Saari, A.; Sekki, T. Energy Consumption of a Public Swimming Bath. Open Constr. Build. Technol. J. 2008, 2, 202–206. [Google Scholar] [CrossRef]

- Delgado, J.P.M.; Garcia, F.V.; Garcia Gascales, J.R. Use of a predictive control to improve the Energy efficiency in indor swimming pools using solar thermal Energy. Solar Energy 2019, 179, 380–390. [Google Scholar] [CrossRef]

- Tagliafico, L.A.; Scarpa, F.; Tagliafico, G.; Valsuani, F. An approach to energy saving assessment of solar assisted heat pumps for swimming pool water heating. Energy Build. 2012, 55, 833–840. [Google Scholar] [CrossRef]

- Marinopoulos, I.; Katsifarakis, K. Optimization of Energy and Water Management of Swimming Pools. A Case Study in Thessaloniki, Greece. Procedia Environ. Sci. 2017, 38, 773–780. [Google Scholar] [CrossRef]

- Katsaprakakis, D.A. Comparison of swimming pools alternative passive and active heating systems based on renewable energy sources in Southern Europe. Energy 2015, 81, 738–753. [Google Scholar] [CrossRef]

- Chow, T.; Bai, Y.; Fong, K.; Lin, Z. Analysis of a solar assisted heat pump system for indoor swimming pool water and space heating. Appl. Energy 2012, 100, 309–317. [Google Scholar] [CrossRef]

- Lam, J.C.; Chan, W.W. Life cycle energy cost analysis of a heat pump application for a hotel swimming pools. Energy Conserv. Manag. 2001, 42, 1299–1306. [Google Scholar] [CrossRef]

- Ratajczak, K.; Szczechowiak, E. Efektywność pomp ciepła w centralach klimatyzacyjnych basenowych. Chłod. Klimatyzacja 2017, 4, 58–61. (In Polish) [Google Scholar]

- Internet System of Legal Acts. Journal Of Laws of 1994 No. 89, item 414 Act of 7 July 1994. Construction Law. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU19940890414 (accessed on 17 December 2020).

- Lund, H.; Möller, B.; Mathiesen, B.V.; Dyrelund, A. The role of district heating in future renewable energy systems. Energy 2010, 35, 1381–1390. [Google Scholar] [CrossRef]

- Nielsen, S.; Hansen, K.; Lund, R.; Moreno, D. Unconventional Excess Heat Sources for District Heating in a National Energy System Context. Energies 2020, 13, 5068. [Google Scholar] [CrossRef]

- Internet System of Legal Acts. Regulation of the Minister of Infrastructure of 6th November [2008] Concerning Energy Characteristic Methodology for Building or its Part. [Rozporządzenie Ministra Infrastruktury z Dnia 6 Listopada 2008 r. w Sprawie Metodologii Obliczania Charakterystyki Energetycznej Budynku i Lokalu Mieszkalnego lub Części Budynku Stanowiącej Samodzielną Całość Techniczno-użytkową Oraz Sposobu Sporządzania i Wzorów świadectw ich Charakterystyki Energetycznej. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20082011240 (accessed on 17 December 2020).

- Data on Non-Renewable Primary Energy Inputs: Energy for Poznań. Available online: http://www.energiadlapoznania.pl/cieplo-systemowe/zielone-cieplo (accessed on 18 February 2018).

- Eur-Lex Access to European Union Law. Commission Regulation (EU) No 601/2012 of 21 June 2012 on monitoring and reporting of greenhouse gas emissions in accordance with Directive 2003/87/EC of the European Parliament and of the Council (Official Journal EU L 181 of 12.07.2012, p. 30, as amended). Available online: http://data.europa.eu/eli/reg/2012/601/oj (accessed on 17 December 2020).

- Port, P.C. Emisja CO2 z energii elektrycznej w Polsce. Rynek Instalacyjny 2019, 7-8. (in polish). Available online: http://www.rynekinstalacyjny.pl/artykul/id3856,emisja-co2-z-energii-elektrycznej-w-polsce (accessed on 17 December 2020).

- Sewastianik, S.; Gajewski, A. Energetic and Ecologic Heat Pumps Evaluation in Poland. Energies 2020, 13, 4980. [Google Scholar] [CrossRef]

- Grygierek, K.; Ferdyn-Grygierek, J.; Gumińska, A.; Baran, L.; Barwa, M.; Czerw, K.; Gowik, P.; Makselan, K.; Potyka, K.; Psikuta, A. Energy and environmental analysis of single-family houses located in Poland. Energies 2020, 13, 2740. [Google Scholar] [CrossRef]

- Data for Energy Calculations of Buildings. Available online: https://www.gov.pl/web/archiwum-inwestycje-rozwoj/dane-do-obliczen-energetycznych-budynkow (accessed on 8 May 2020).

- VDI-Fachbereich Technische Gebäudeausrüstung. VDI 2089 Blatt 1. Technische Gebaeudeausruestung von Schwimmbaedern. Hallenbaeder; VDI-Fachbereich Technische Gebäudeausrüstung: München, Germany, 2008. [Google Scholar]

- VDI-Fachbereich Technische Gebäudeausrüstung. VDI 2089 Blatt 2. Technische Gebaeudeausruestung von Schwimmbaedern. Energie- und Wassereffizienz in Schwimmbaedern; VDI-Fachbereich Technische Gebäudeausrüstung: München, Germany, 2008. [Google Scholar]

- Data of Air Handling Units DanX. Available online: https://www.dantherm.com/pl/wentylacja/wentylacja-basenow/centrale-basenowe-danx/ (accessed on 7 December 2020).

- Basińska, M.; Koczyk, H.; Szczechowiak, E. Sensivity analysis in determining the optimum energy for residential buildings in Poland conditions. Energy Build. 2015, 107, 307–318. [Google Scholar] [CrossRef]

- Basińska, M.; Koczyk, H. Analysis of the possibilities to achieve the low energy residential buildings standards. Technol. Econ. Dev. Econ. 2016, 22, 830–849. [Google Scholar] [CrossRef]

- Basińska, M.; Kaczorek, D.; Koczyk, H. Building Thermo-Modernisation Solution Based on the Multi-Objective Optimisation Method. Energies 2020, 13, 1433. [Google Scholar] [CrossRef]

- Basińska, M. The use of multi-criteria optimization to choose solutions for energy-efficient buildings. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 815–826. [Google Scholar] [CrossRef][Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).