Effect of Color Coating of Cover Plate on Thermal Behavior of Flat Plate Solar Collector

Abstract

1. Introduction

2. Materials and Methods

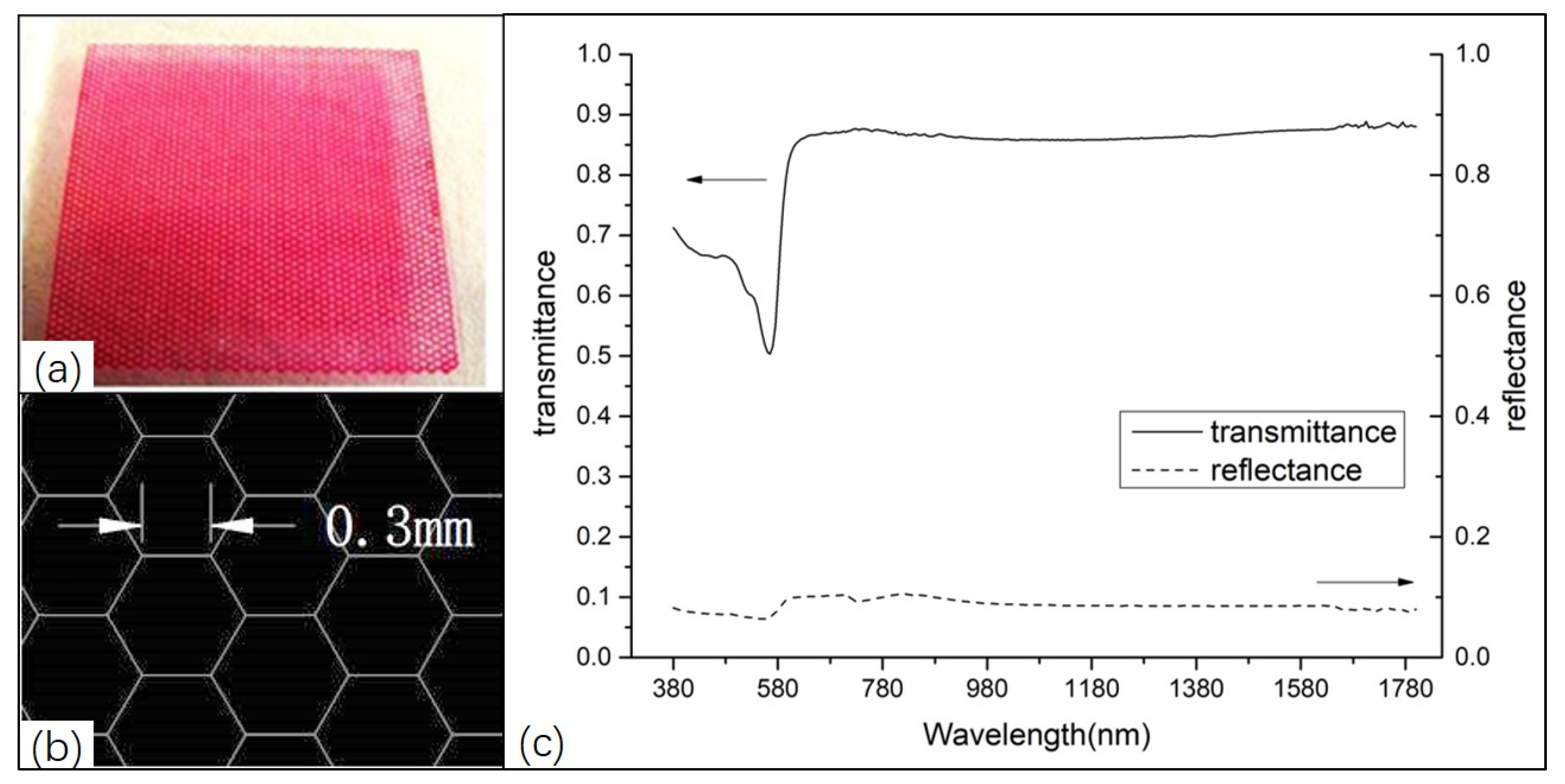

2.1. Halftone Coating

2.2. Design of Experimental Apparatus

2.2.1. The Structure of The Solar Collector

2.2.2. The Coated Cover Plate

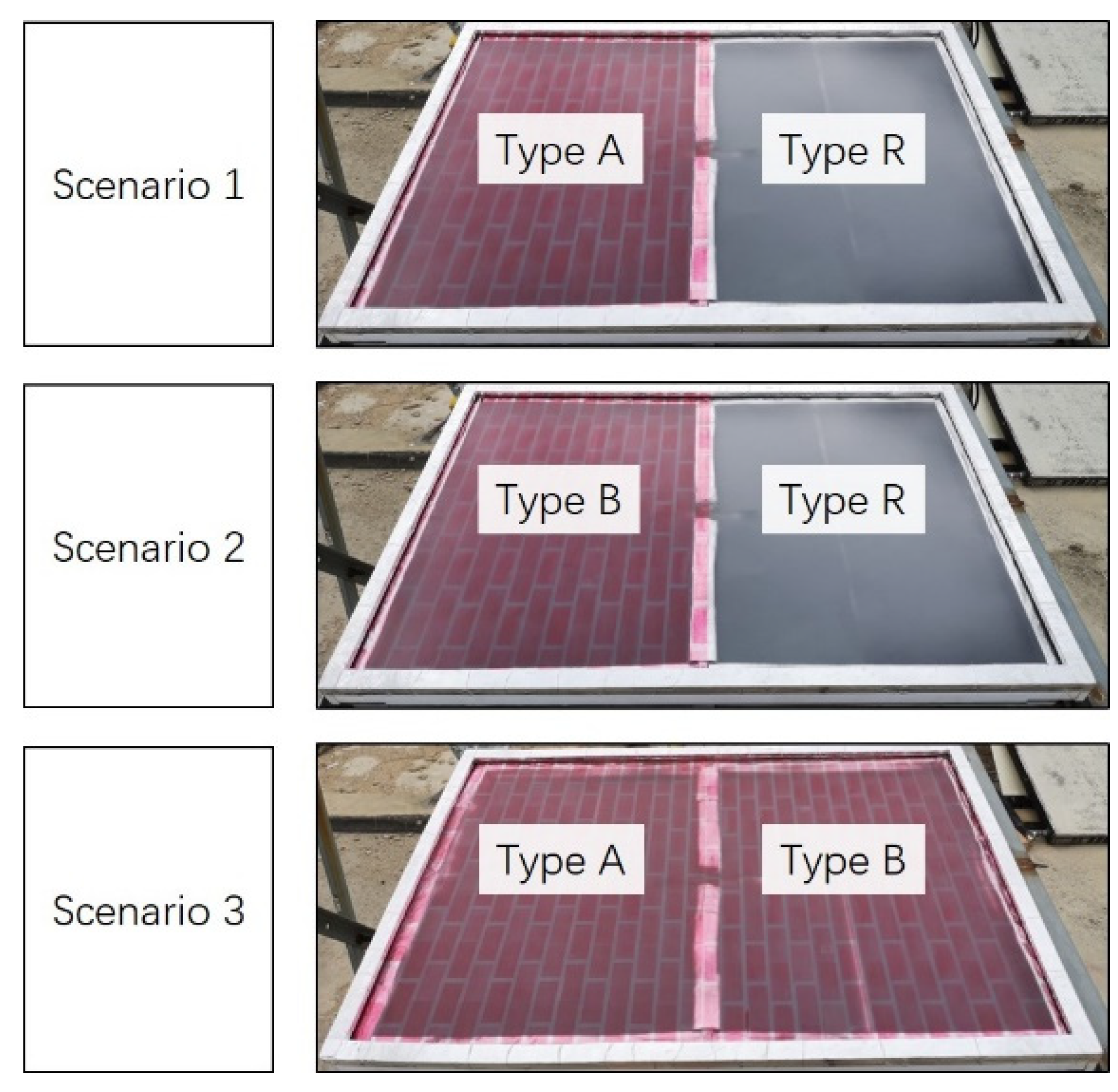

2.3. Experimental Scheme

2.4. Experimental System and Test Method

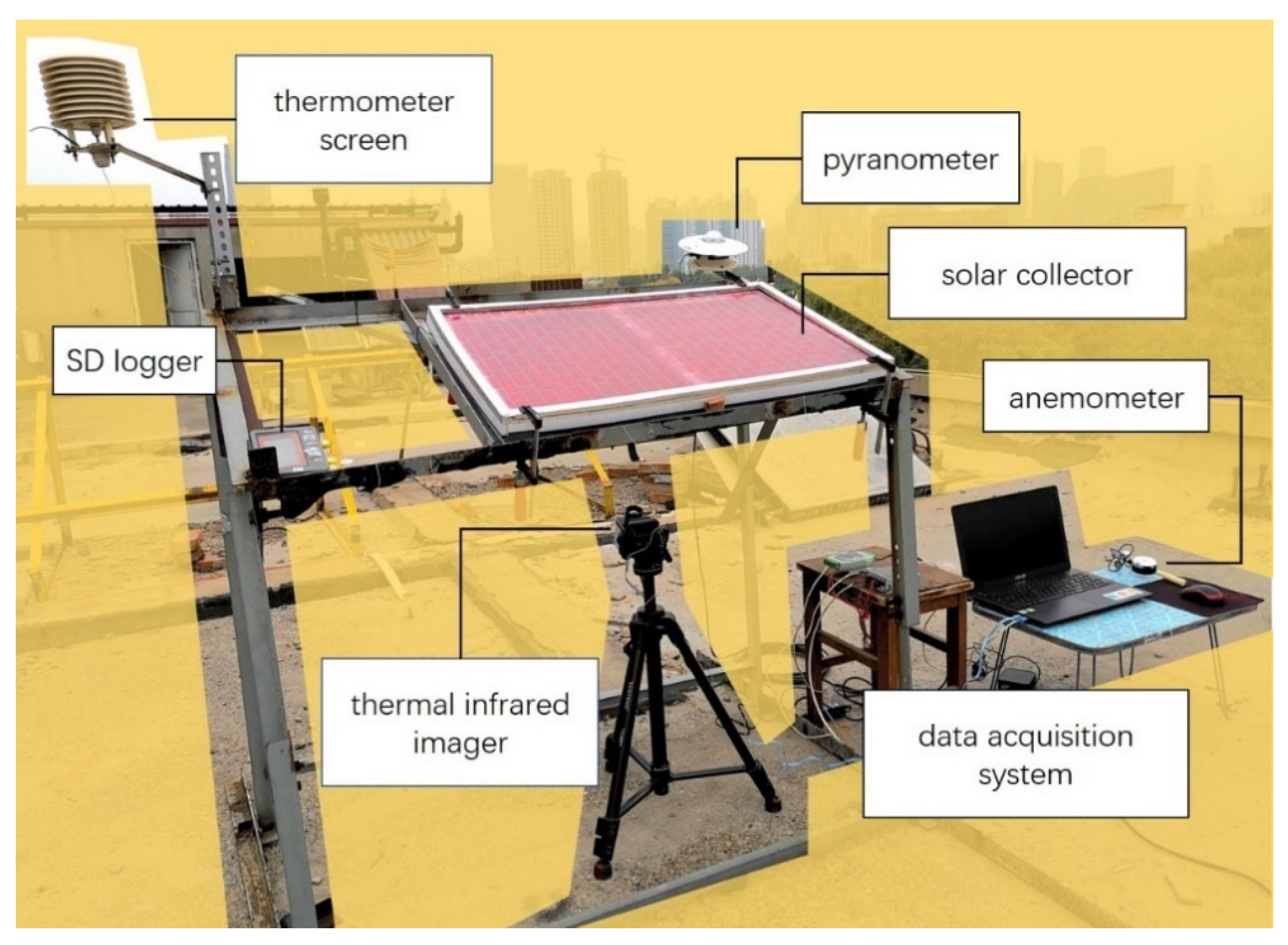

2.4.1. Experimental System

2.4.2. Test Method

3. Analysis of Thermal Network

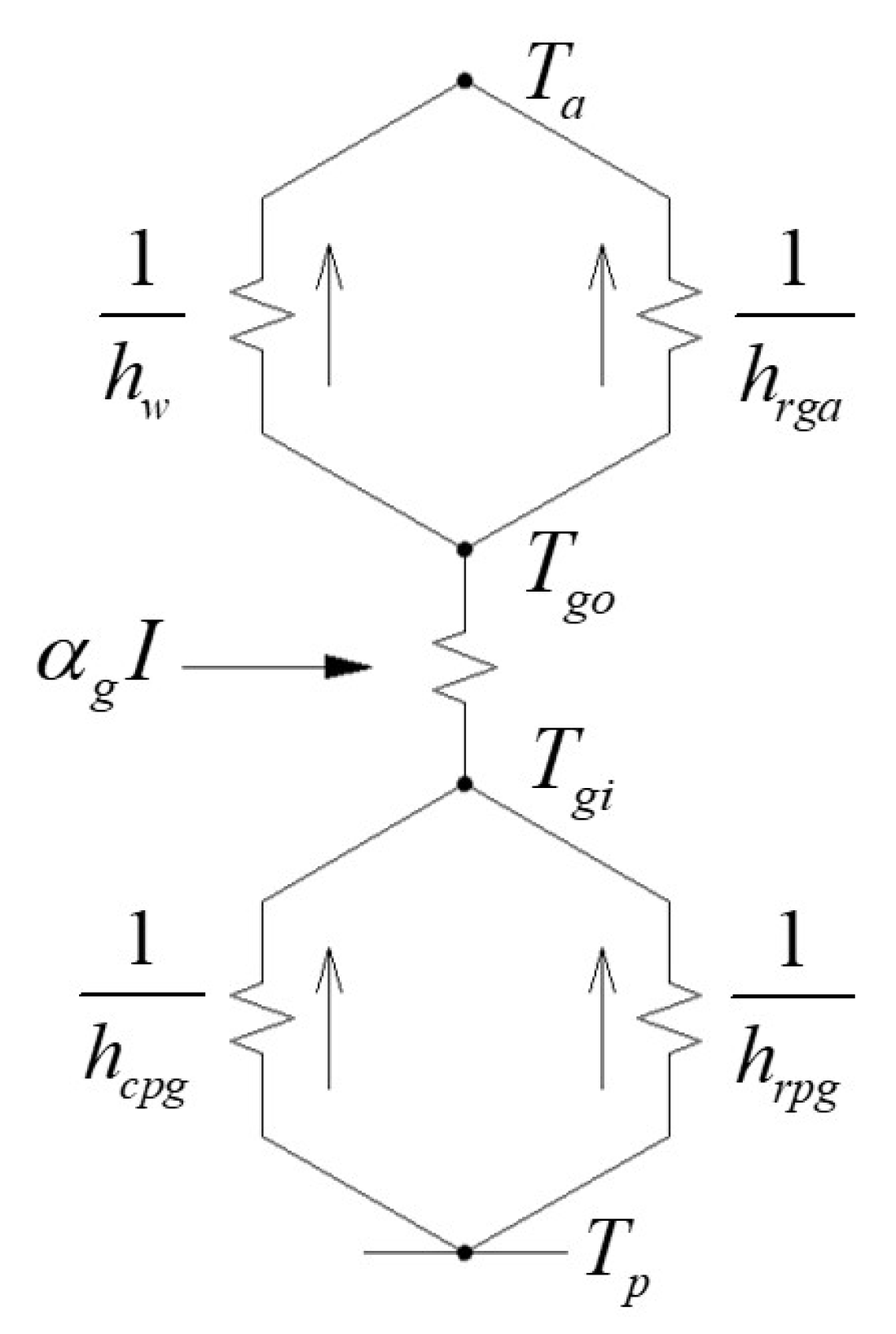

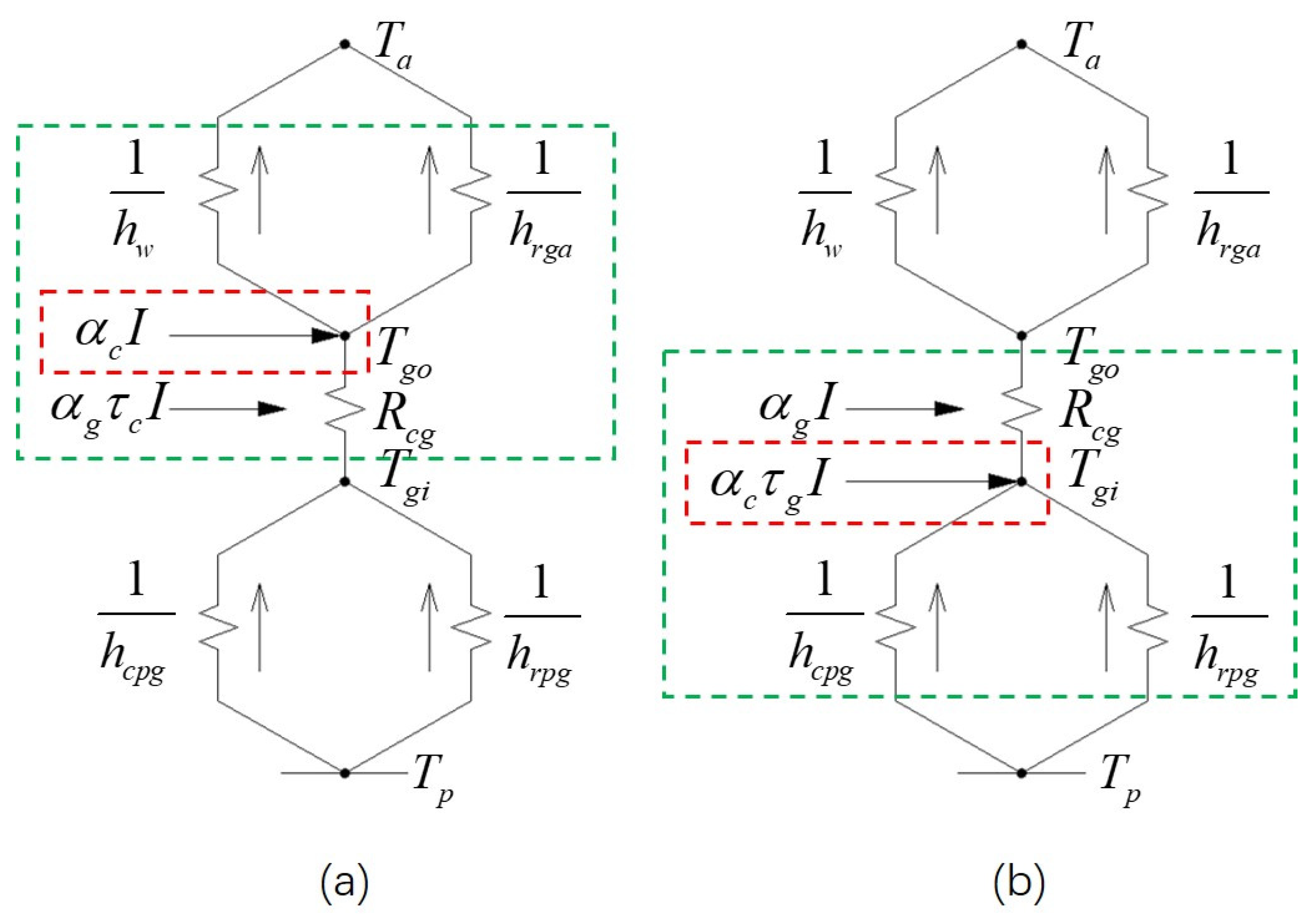

3.1. Thermal Network of Solar Collector without Coating

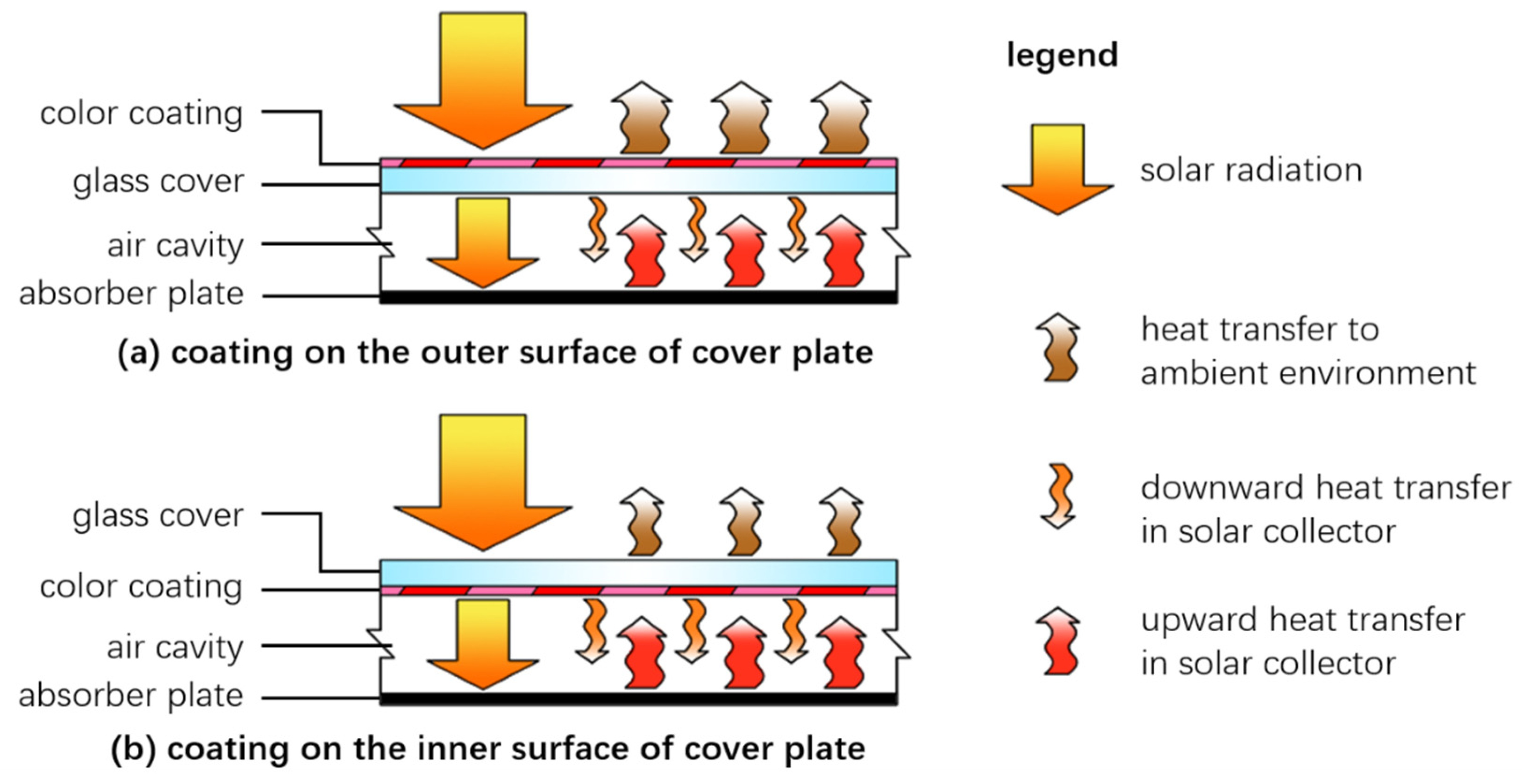

3.2. Thermal Network of Solar Collector with Coating

4. Results and Discussion

4.1. General Effect of Coating on Solar Collector

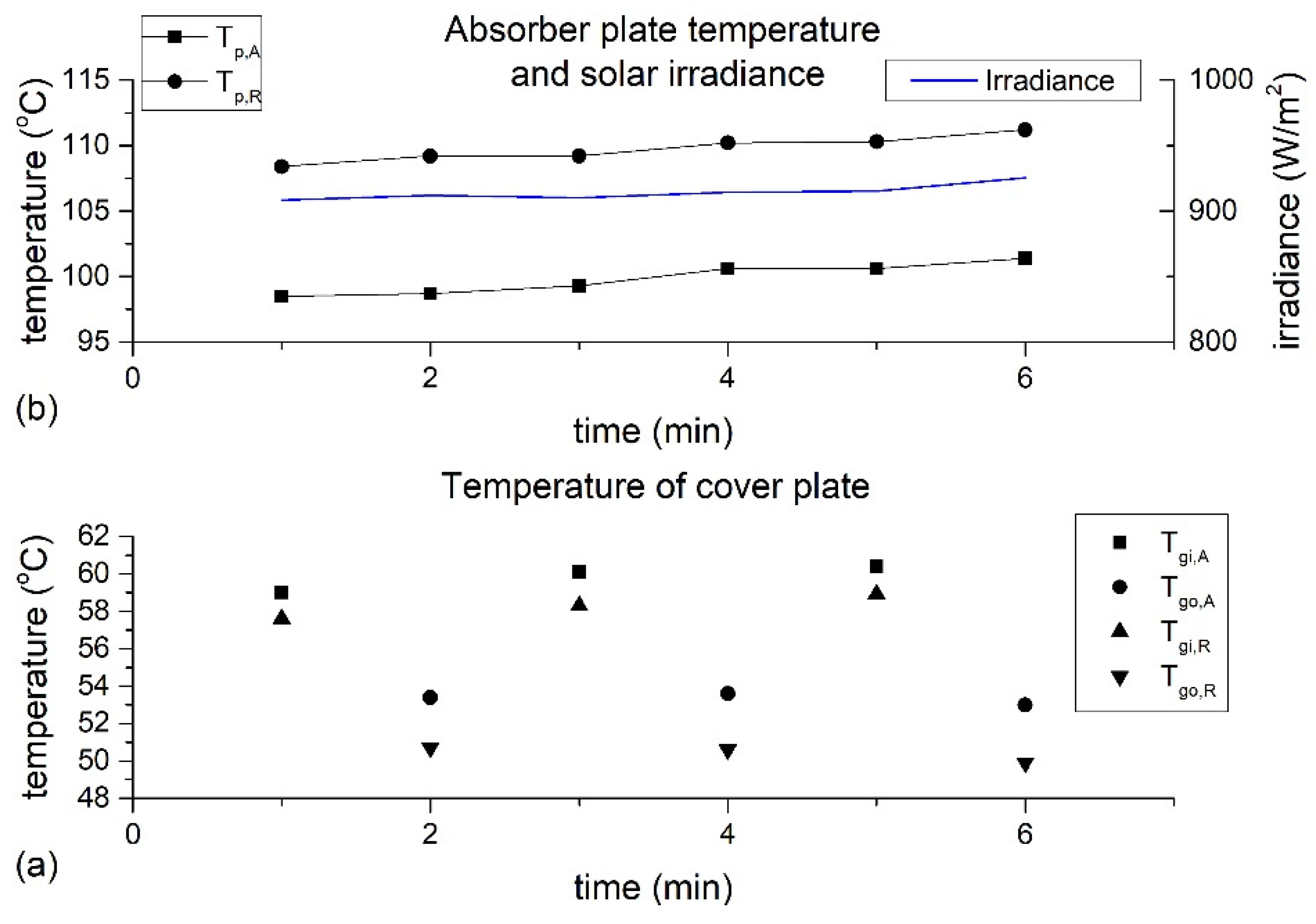

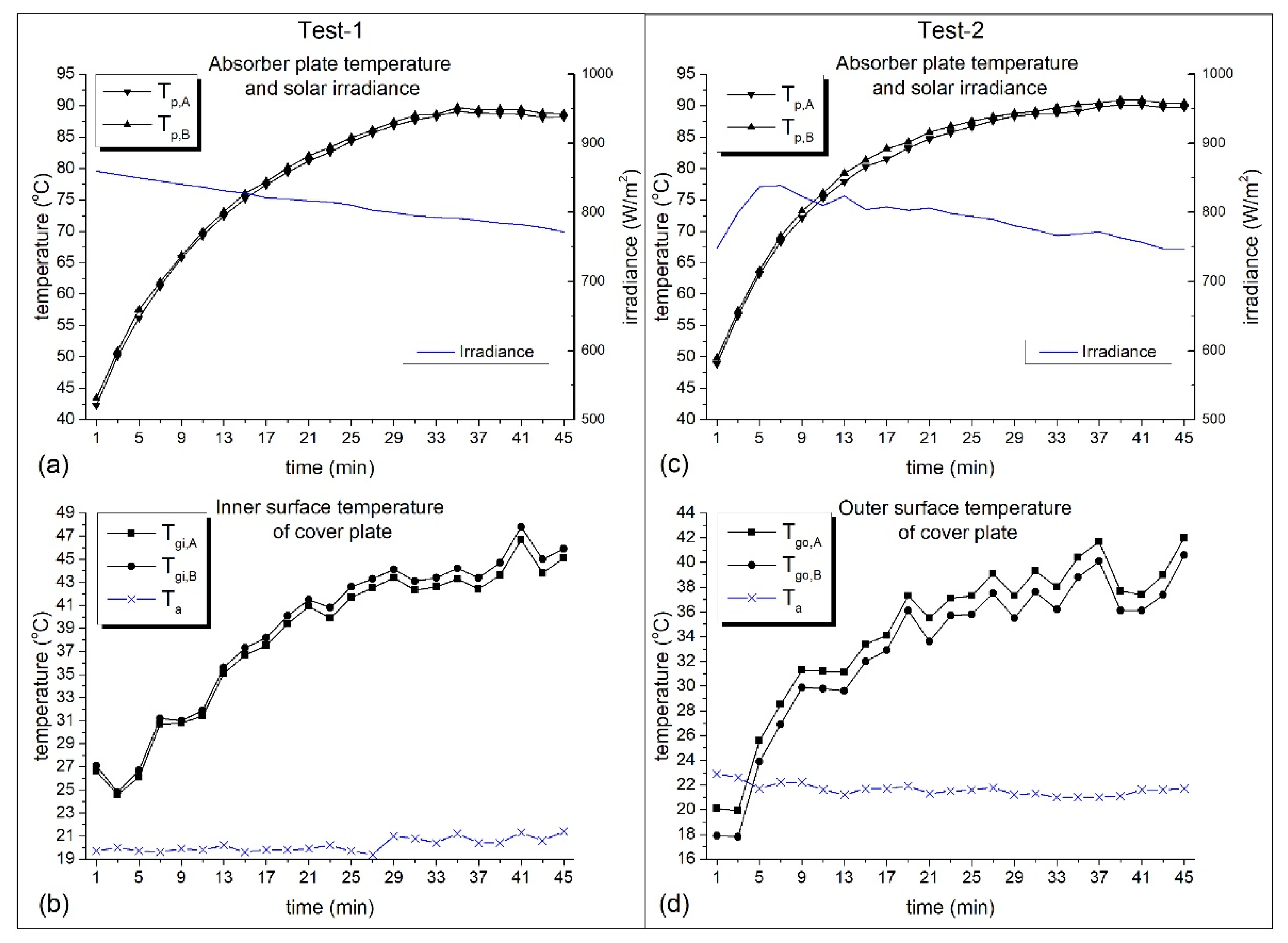

4.1.1. Increase in The Temperature of Cover Plate

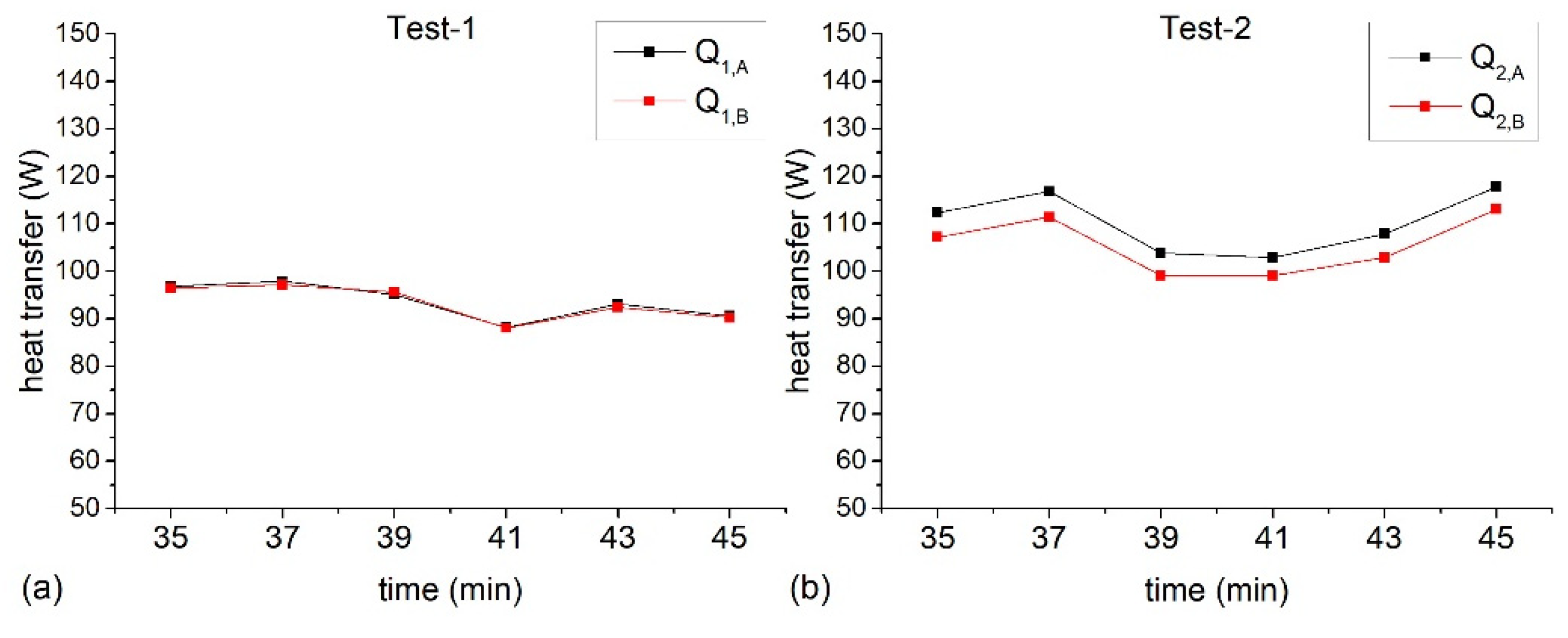

4.1.2. Effect on Energy Collection

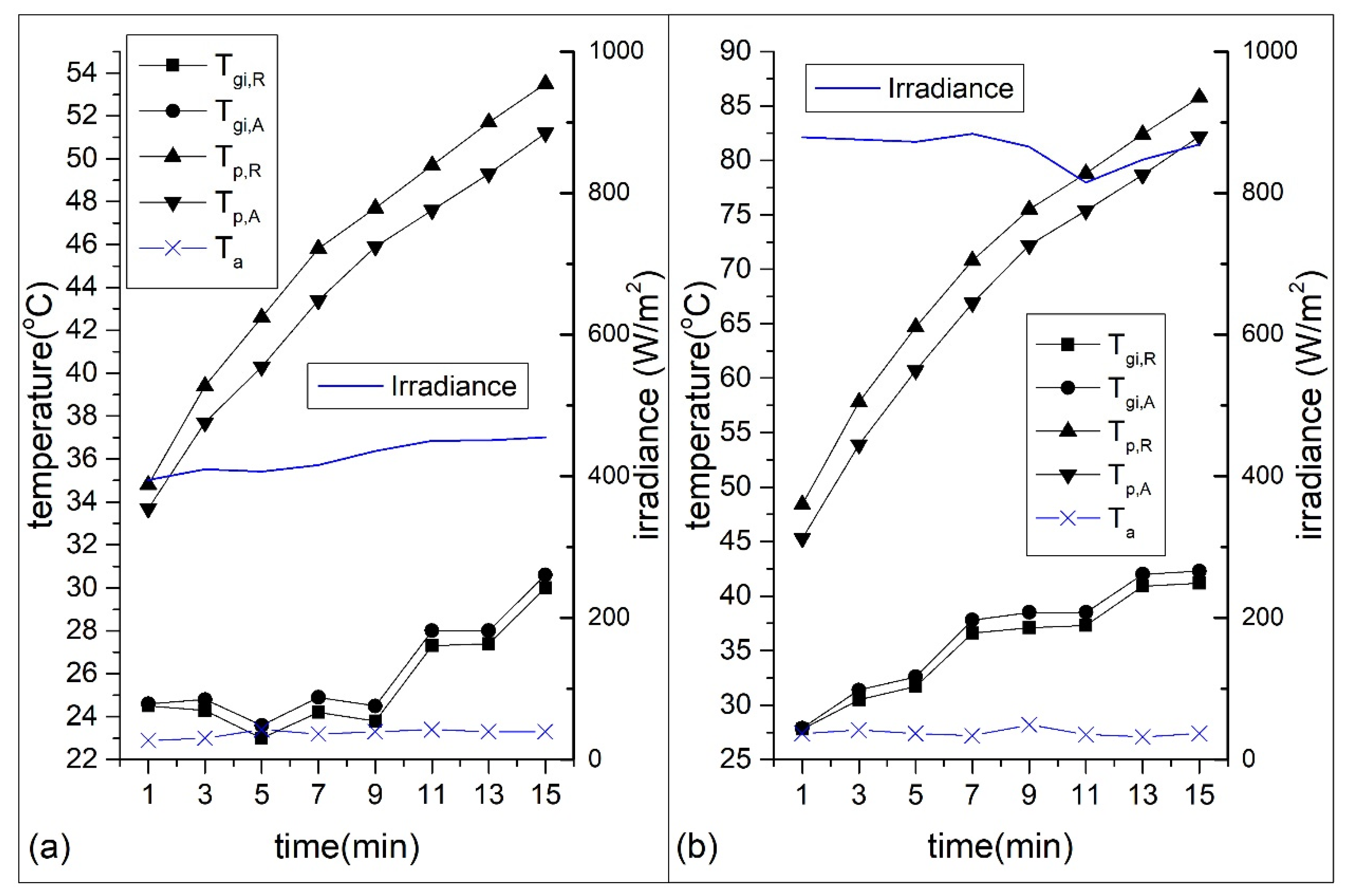

4.2. Effect of Solar Irradiance

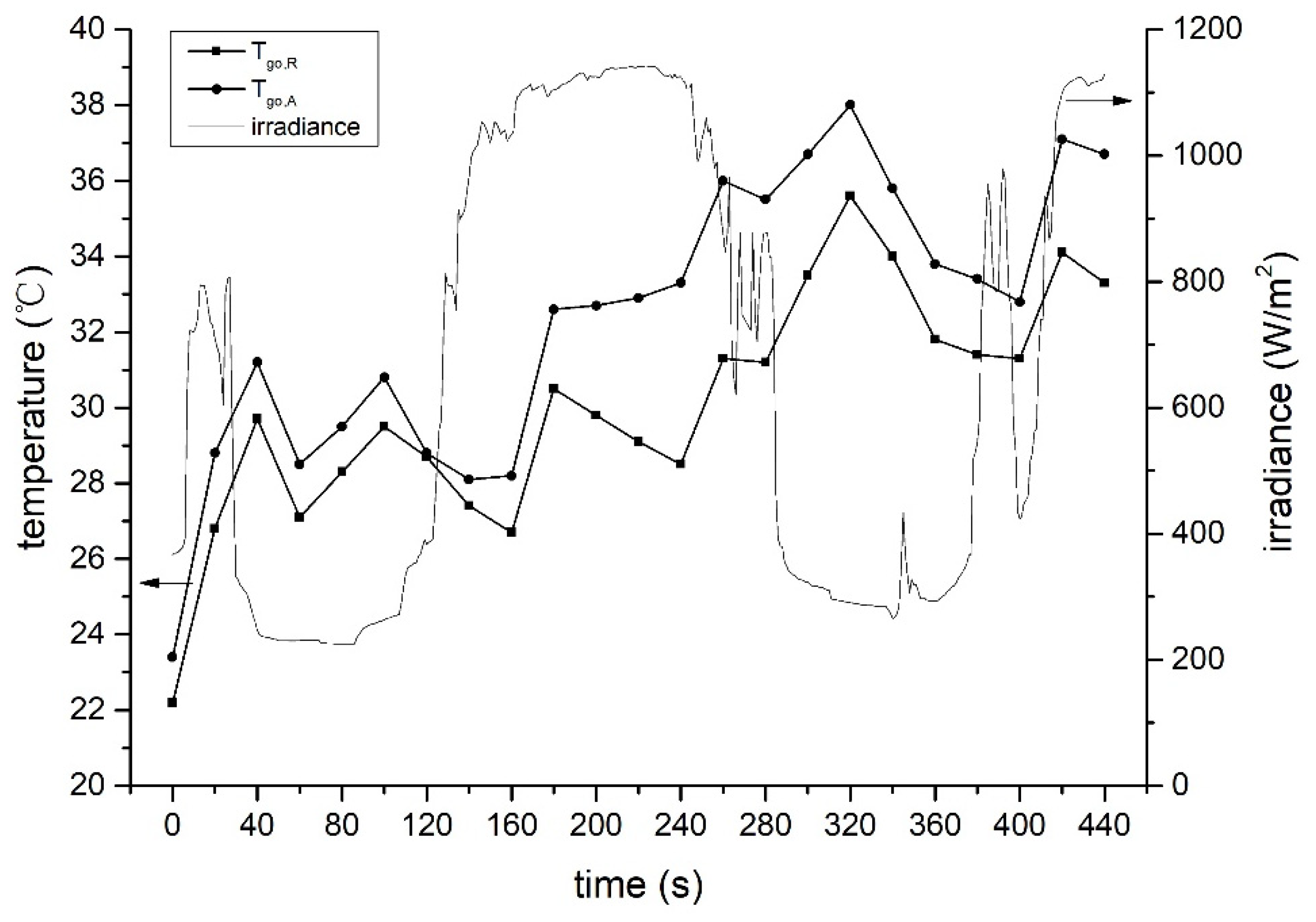

4.3. Effect of Different Coating Positions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| transmittance of glass plate | |

| transmittance of coating | |

| absorptance of glass plate | |

| absorptance of coating | |

| solar irradiance projected onto the collector | |

| radiative heat transfer coefficient between the heat absorber plate and the cover plate | |

| convective heat transfer coefficient between the heat absorber plate and the cover plate | |

| radiative heat transfer coefficient between the cover plate and atmosphere | |

| wind heat transfer coefficient | |

| heat conductivity of glass plate | |

| thickness of glass plate | |

| thermal resistance of coated glass plate | |

| inner surface temperature of cover plate | |

| outer surface temperature of cover plate | |

| heat absorber plate temperature | |

| ambient temperature | |

| Subscript | |

| A | Type A |

| B | Type B |

| R | Type R |

References

- Liu, G.; Tan, Y.; Li, X. China’s Policies of Building Green Retrofit: A State-Of-The-Art Overview. Build Environ. 2020, 169, 106554.1–106544.8. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Li, Z. A Rapid Evaluation Method of Existing Building Applied Photovoltaic (BAPV) Potential. Energy Build. 2017, 135, 39–49. [Google Scholar] [CrossRef]

- Jung, S.; Huh, J.H. Demand Response Resource Energy Optimization System for Residential Buildings: Smart Grid Approach: MUE/FutureTech 2018. In Advanced Multimedia and Ubiquitous Engineering; James, J., Park, J.H., Chen, S.-C., Eds.; Springer: Singapore, 2018; pp. 517–522. [Google Scholar]

- Ko, J.S.; Huh, J.H.; Kim, J.C. Overview of Maximum Power Point Tracking Methods for PV System in Micro Grid. Electronics 2020, 9, 816. [Google Scholar] [CrossRef]

- Jung, S.; Huh, J.H.; Park, J. A Study on Acer Mono Sap Integration Management System Based on Energy Harvesting Electric Device and Sap Big Data Analysis Model. Electronics 2020, 9, 1979. [Google Scholar] [CrossRef]

- Cristofari, C.; Notton, G.; Canaletti, J.L. Thermal behavior of a copolymer PV/Th solar system in low flow rate conditions. Sol. Energy 2009, 83, 1123–1138. [Google Scholar] [CrossRef]

- Maurer, C.; Cappel, C.; Kuhn, T.E. Progress in Building-Integrated Solar Thermal Systems. Sol. Energy 2017, 154, 158–186. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Building Integration of Solar Renewable Energy Systems towards Zero or Nearly Zero Energy Buildings. Int. J. Low-Carbon Technol. 2015, 10, 379–385. [Google Scholar] [CrossRef]

- Quesada, G.; Rousse, D.; Dutil, Y. A Comprehensive Review of Solar Facades. Opaque Solar Facades. Renew. Sustain. Energy Rev. 2012, 16, 2820–2832. [Google Scholar] [CrossRef]

- Quesada, G.; Rousse, D.; Dutil, Y. A Comprehensive Review of Solar Facades. Transparent and Translucent Solar Facades. Renew. Sustain. Energy Rev. 2012, 16, 2643–2651. [Google Scholar] [CrossRef]

- Munari, P.M.; Roecker, C. Towards an Improved Architectural Quality of Building Integrated Solar Thermal Systems (BIST). Sol. Energy 2007, 81, 1104–1116. [Google Scholar] [CrossRef]

- Cappel, C.; Streicher, W.; Lichtblau, F. Barriers to the Market Penetration of Façade-Integrated Solar Thermal Systems. Energy Procedia 2014, 48, 1336–1344. [Google Scholar] [CrossRef]

- Crnjakorel, Z. Spectrally Selective Solar Absorbers in Different Non-Black Colours. Sol. Energy Mater. Sol. Cells 2004, 85, 41–50. [Google Scholar] [CrossRef]

- Anderson, T.N.; Duke, M.; Carson, J.K. The Effect of Colour on the Thermal Performance of Building Integrated Solar Collectors. Sol. Energy Mater. Sol. Cells 2010, 94, 350–354. [Google Scholar] [CrossRef]

- Kalogirou, S.; Tripanagnostopoulos, Y.; Souliotis, M. Performance of Solar Systems Employing Collectors with Colored Absorber. Energy Build. 2005, 37, 824–835. [Google Scholar] [CrossRef]

- Bonhôte, P.; Eperon, Y.; Renaud, P. Unglazed Coloured Solar Absorbers on Façade: Modelling and Performance Evaluation. Sol. Energy 2009, 83, 799–811. [Google Scholar] [CrossRef]

- Fekete, I.; Farkas, I. Numerical and Experimental Study of Building Integrated Solar Tile Collectors. Renew. Energy 2019, 137, 45–55. [Google Scholar] [CrossRef]

- Bingqing, L.; Zhongting, H.; Xiaoqiang, H. Experimental study of the water heating performance of a novel tile-shaped dual-function solar collector. Energy Procedia 2015, 70, 87–94. [Google Scholar]

- Zhongting, H.; Bingqing, L.; Wei, H. Performance study of a dual-function roof solar collector for Chinese traditional buildings application. Appl. Therm. Eng. 2018, 128, 179–188. [Google Scholar]

- Schüler, A.; Roecker, C.; Scartezzini, J.L. On the Feasibility of Colored Glazed Thermal Solar Collectors Based On Thin Film Interference Filters. Sol. Energy Mater. Sol. Cells 2004, 84, 241–254. [Google Scholar] [CrossRef]

- Schuler, A.; Boudaden, J.; Oelhafen, P. Thin Film Multilayer Design Types for Colored Glazed Thermal Solar Collectors. Sol. Energy Mater. Sol. Cells 2005, 89, 219–231. [Google Scholar] [CrossRef]

- Boudaden, J.; Ho, S.C.; Oelhafen, P. Towards coloured glazed thermal solar collectors. Sol. Energy Mater. Sol. Cells 2004, 84, 225–239. [Google Scholar] [CrossRef]

- Mertin, S.; Hody-Le, C.V.; Joly, M. Reactively Sputtered Coatings on Architectural Glazing for Coloured Active Solar Thermal Façades. Energy Build. 2014, 68, 764–770. [Google Scholar] [CrossRef]

- Jolissaint, N.; Hanbali, R.; Hadorn, J. Colored Solar Façades for Buildings. Energy Procedia 2017, 122, 175–180. [Google Scholar] [CrossRef]

- Alvarez, A.; Cabeza, O.; Muniz, M.C. Experimental and numerical investigation of a flat-plate solar collector. Energy 2010, 35, 3707–3716. [Google Scholar] [CrossRef]

- Fan, J.; Furbo, S. Buoyancy Effects on Thermal Behavior of a Flat-Plate Solar Collector. J. Sol. Energy Eng. 2008, 130, 247–266. [Google Scholar] [CrossRef]

- Said, Z.; Sajid, M.H.; Alim, M.A. Experimental investigation of the thermophysical properties of AL2O3-nanofluid and its effect on a flat plate solar collector. Int. Commun. Heat Mass Transf. 2013, 48, 99–107. [Google Scholar] [CrossRef]

- Yang, L.; Lenz, R.; Kruse, B. Light scattering and ink penetration effects on tone reproduction. J. Opt. Soc. Am. A Opt. Image Sci. Vis. 2001, 18, 360–366. [Google Scholar] [CrossRef][Green Version]

- Clapper, F.R.; Yule, A.C. The Effect of Multiple Internal Reflections on the Densities of Half-tone Prints on Paper. J. Opt. Soc. Am. 1953, 43, 600–603. [Google Scholar] [CrossRef]

- Tianhong, D.; Zhu, Z. The Calculations of The Effective Transmittance-absorptance Product of Flat Plate Solar Air Collectors. Acta Energ. Sol. Sin. 1996, 17, 303–307. [Google Scholar]

- Akhtar, N.; Mullick, S.C. Effect of Absorption of Solar Radiation in Glass-Cover(S) On Heat Transfer Coefficients in Upward Heat Flow in Single and Double Glazed Flat-Plate Collectors. Int. J. Heat Mass Transf. 2012, 55, 125–132. [Google Scholar] [CrossRef]

- Hollands, K.G.T.; Unny, T.E.; Raithby, G.D. Free convective heat transfer across inclined air layers. ASME J. Heat Transf. 1976, 98, 89–192. [Google Scholar] [CrossRef]

- Buchberg, H.; Catton, I.; Ewards, D.K. Natural convection in enclosed spaces–a review of application to solar energy collection. ASME J. Heat Transf. 1976, 98, 182–188. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Huang, Q.; Wang, Y. Effect of Color Coating of Cover Plate on Thermal Behavior of Flat Plate Solar Collector. Energies 2020, 13, 6696. https://doi.org/10.3390/en13246696

Li C, Huang Q, Wang Y. Effect of Color Coating of Cover Plate on Thermal Behavior of Flat Plate Solar Collector. Energies. 2020; 13(24):6696. https://doi.org/10.3390/en13246696

Chicago/Turabian StyleLi, Chengyi, Qunwu Huang, and Yiping Wang. 2020. "Effect of Color Coating of Cover Plate on Thermal Behavior of Flat Plate Solar Collector" Energies 13, no. 24: 6696. https://doi.org/10.3390/en13246696

APA StyleLi, C., Huang, Q., & Wang, Y. (2020). Effect of Color Coating of Cover Plate on Thermal Behavior of Flat Plate Solar Collector. Energies, 13(24), 6696. https://doi.org/10.3390/en13246696