Method of Improving Lateral Stability by Using Additional Yaw Moment of Semi-Trailer

Abstract

1. Introduction

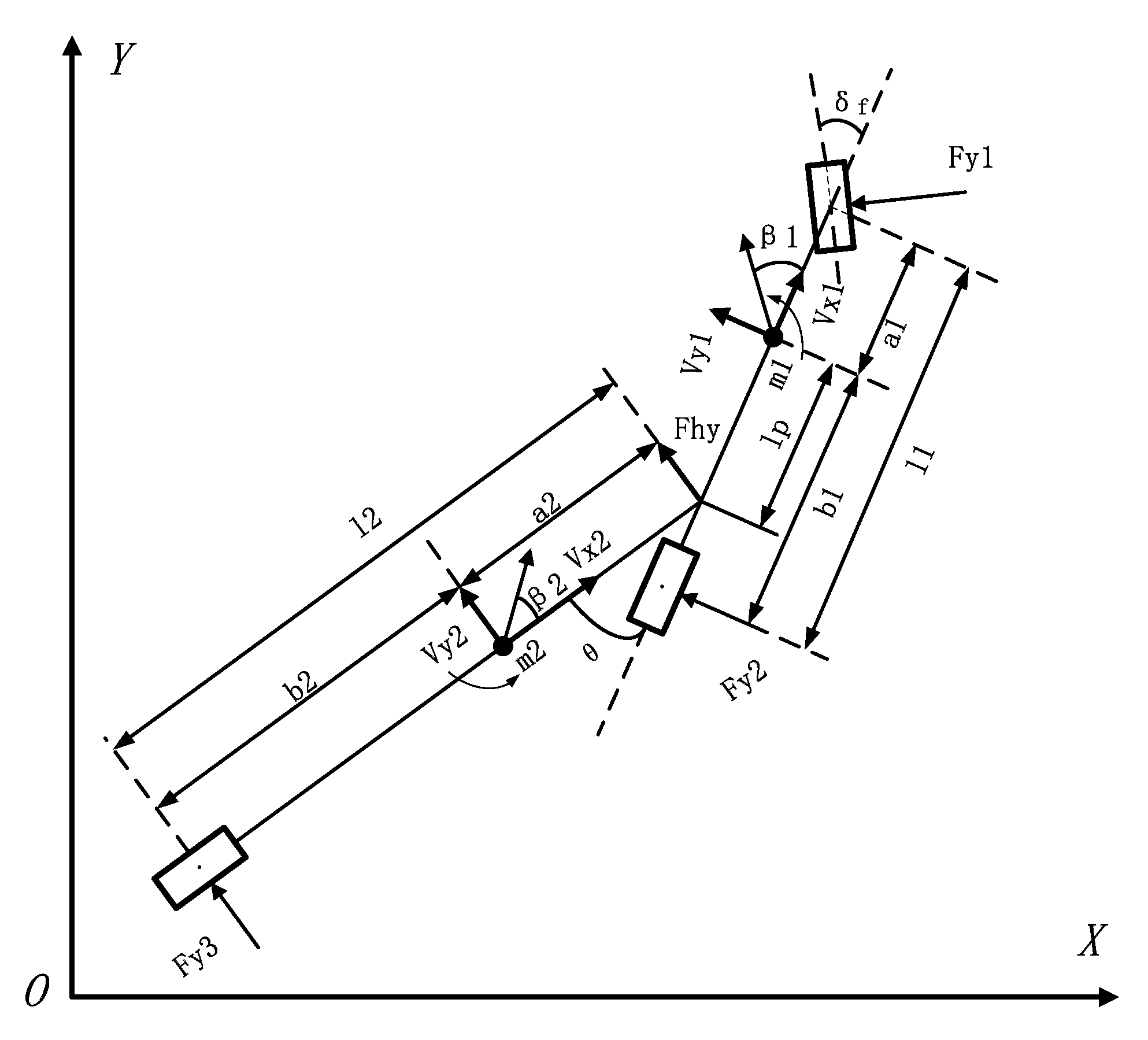

2. Dynamic Model

2.1. Nonlinear Tractor Semi-Trailer Model

2.2. Reference Model

2.3. Hub Motor Model

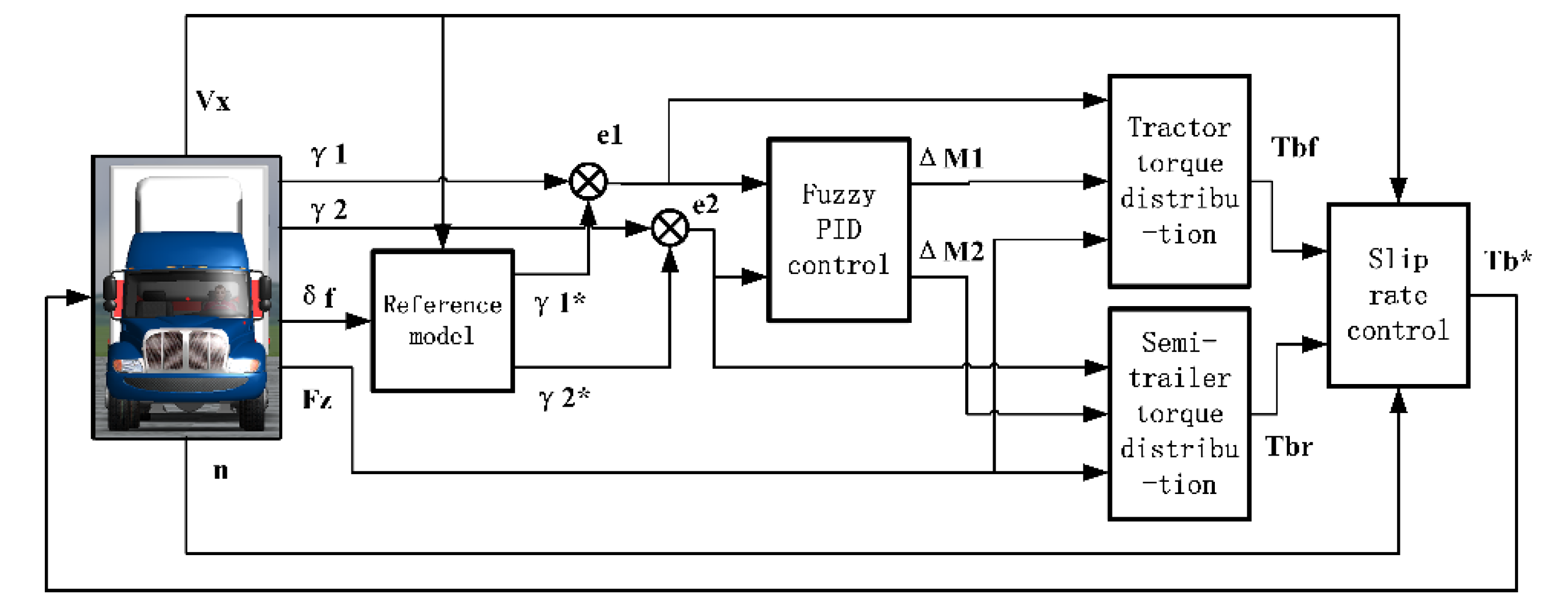

3. Design of Control System

3.1. The General Architecture of the Control System

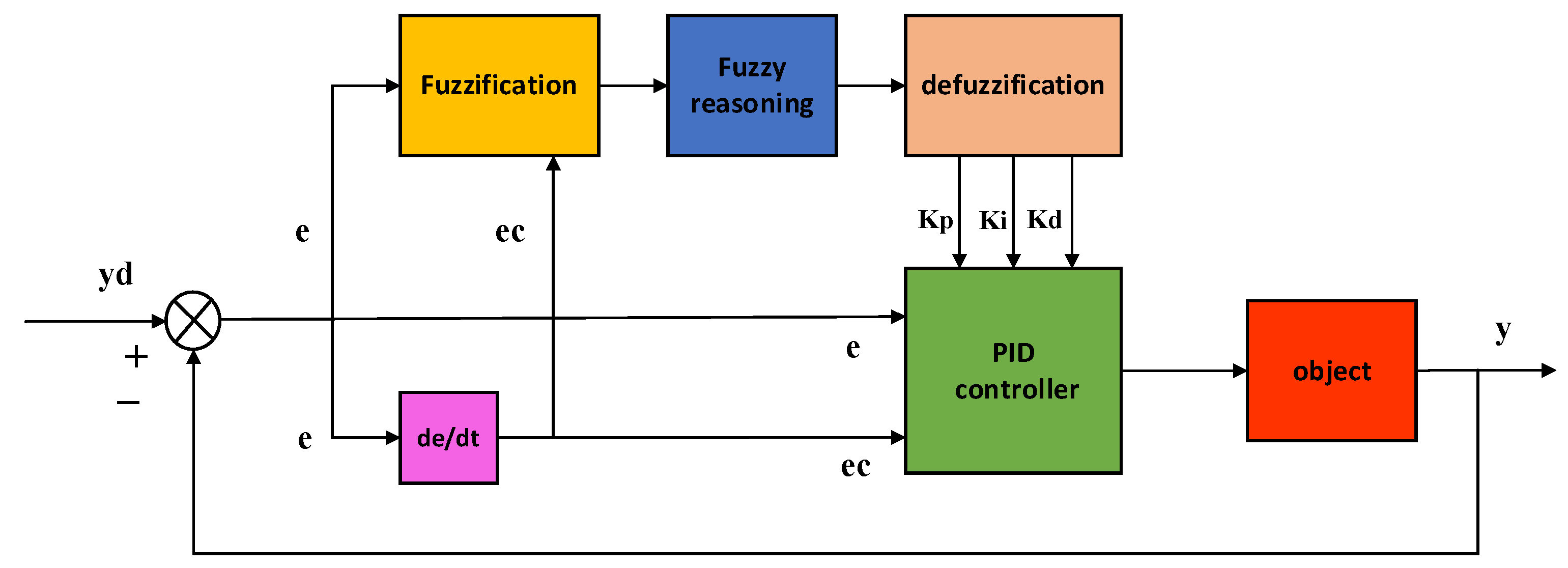

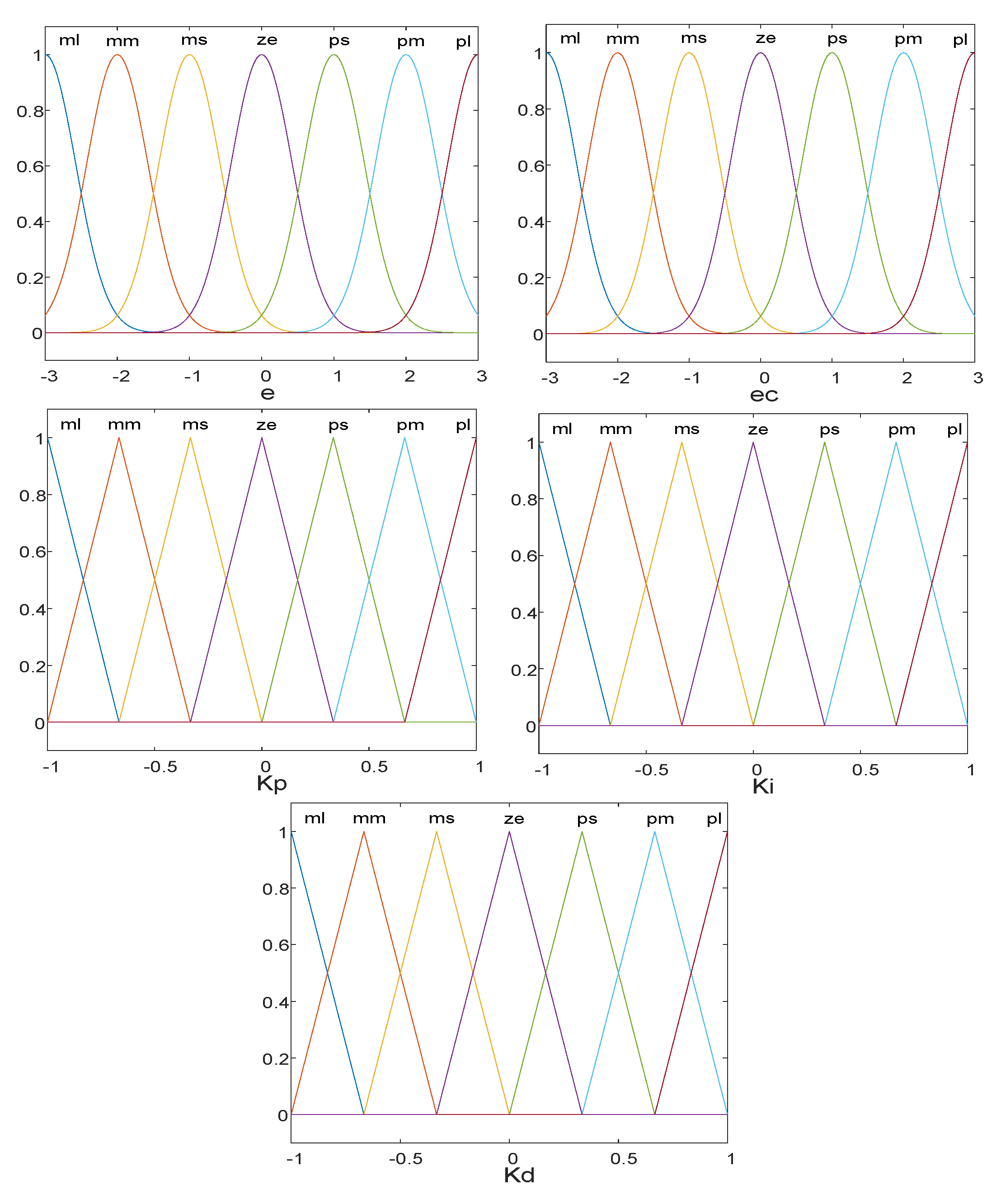

3.2. Upper Controller

3.3. Lower Controller

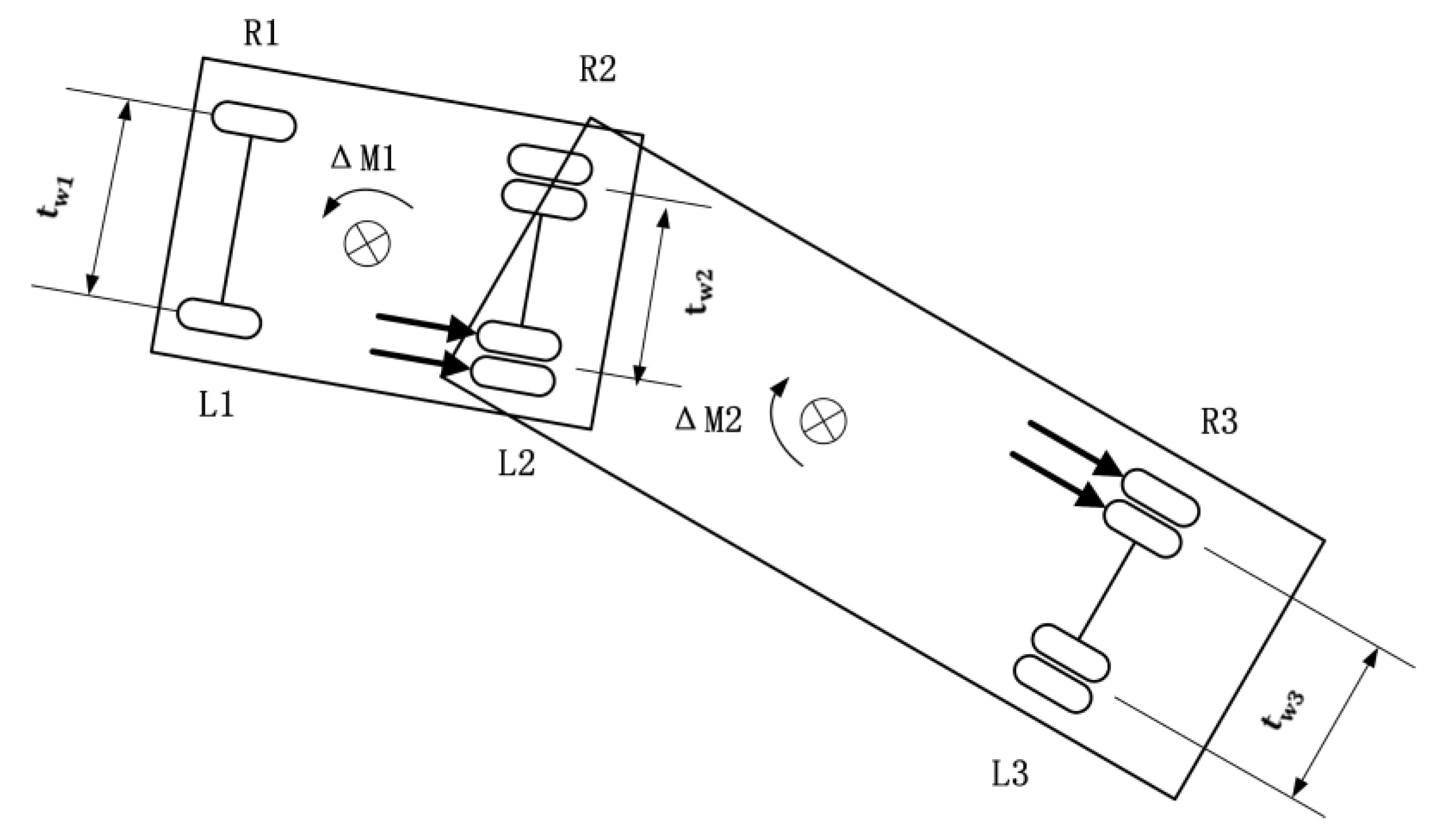

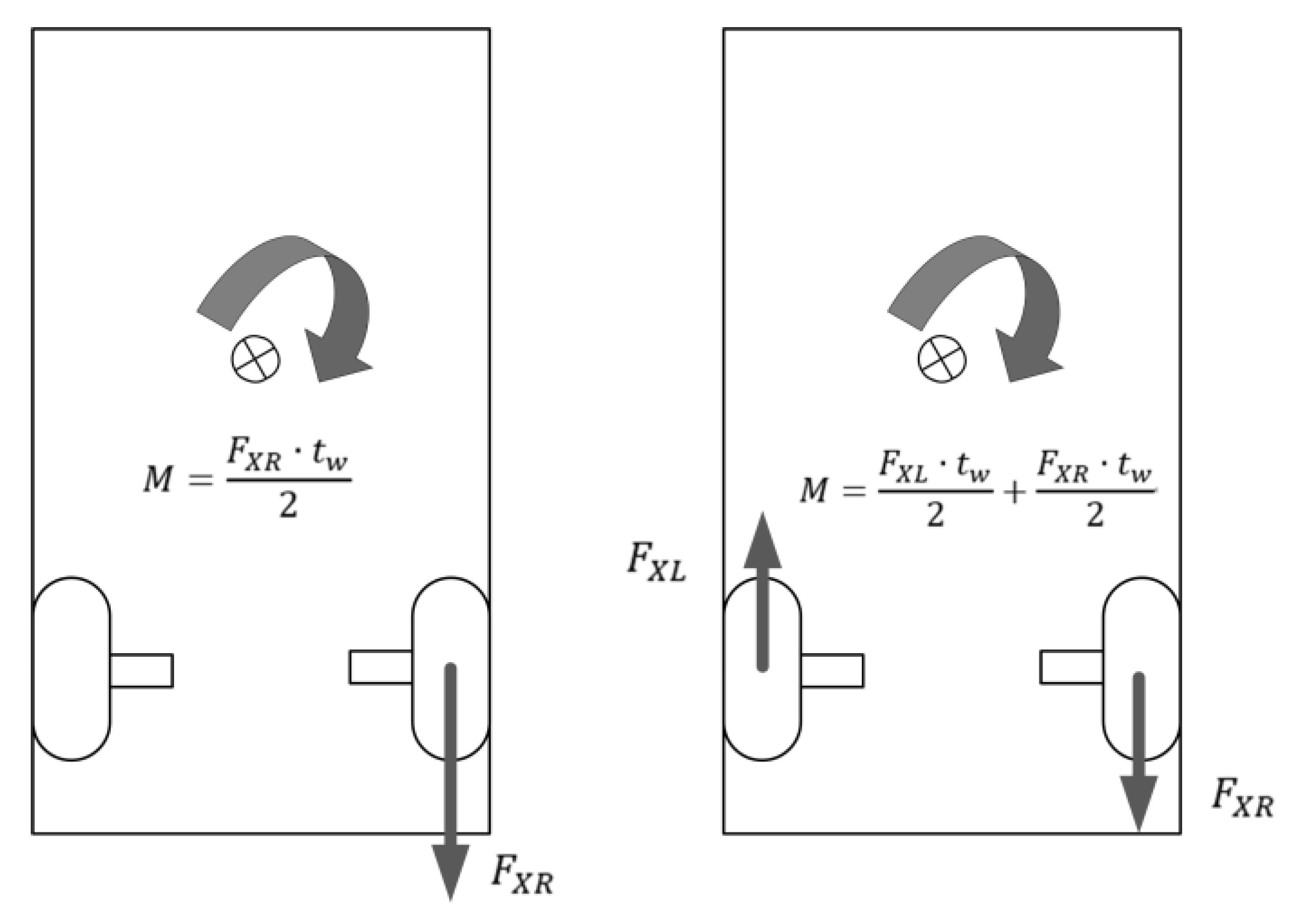

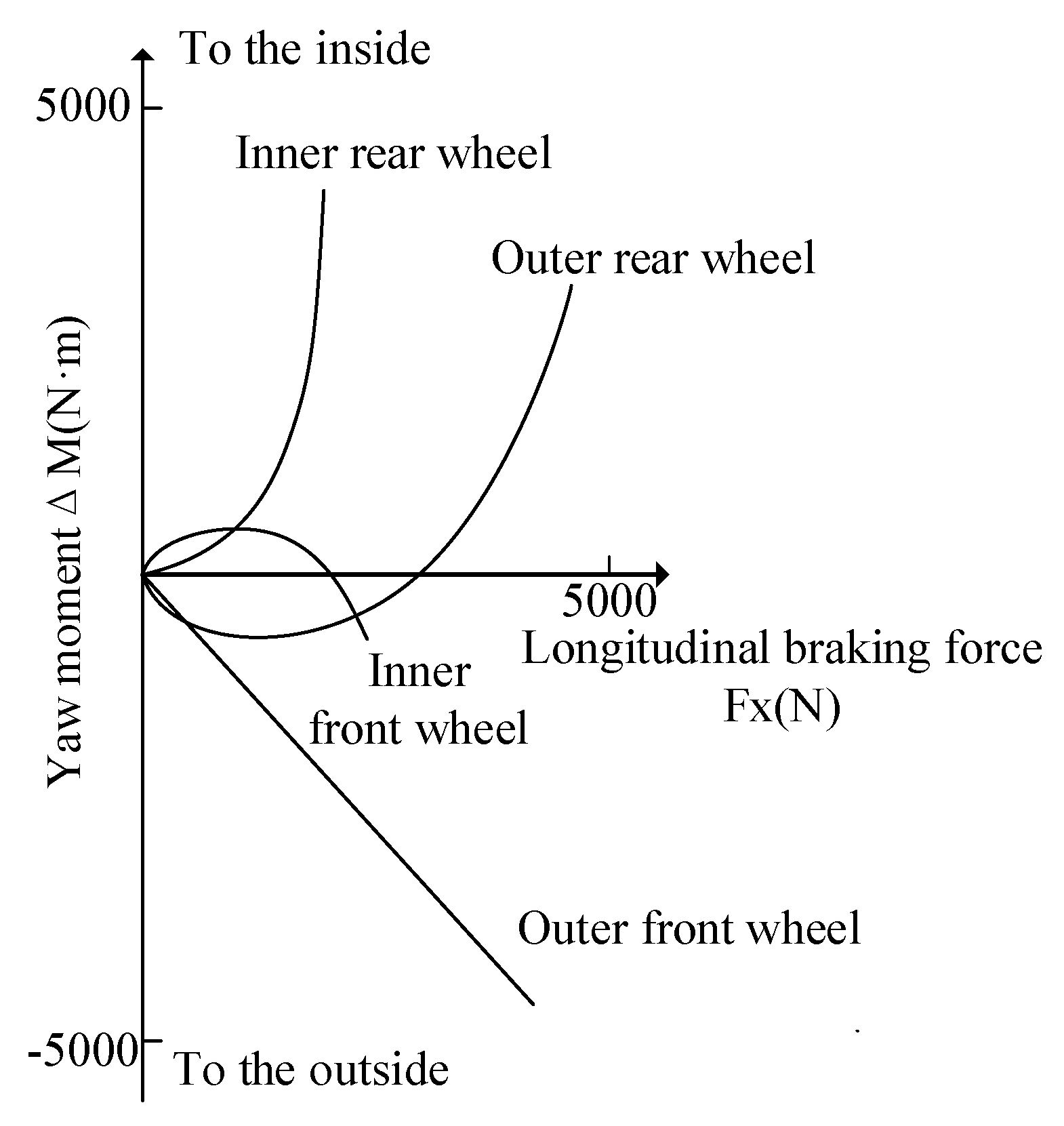

3.3.1. Determination of Braking Torque

3.3.2. Formulation of Target Wheel Braking (Driving) Rules

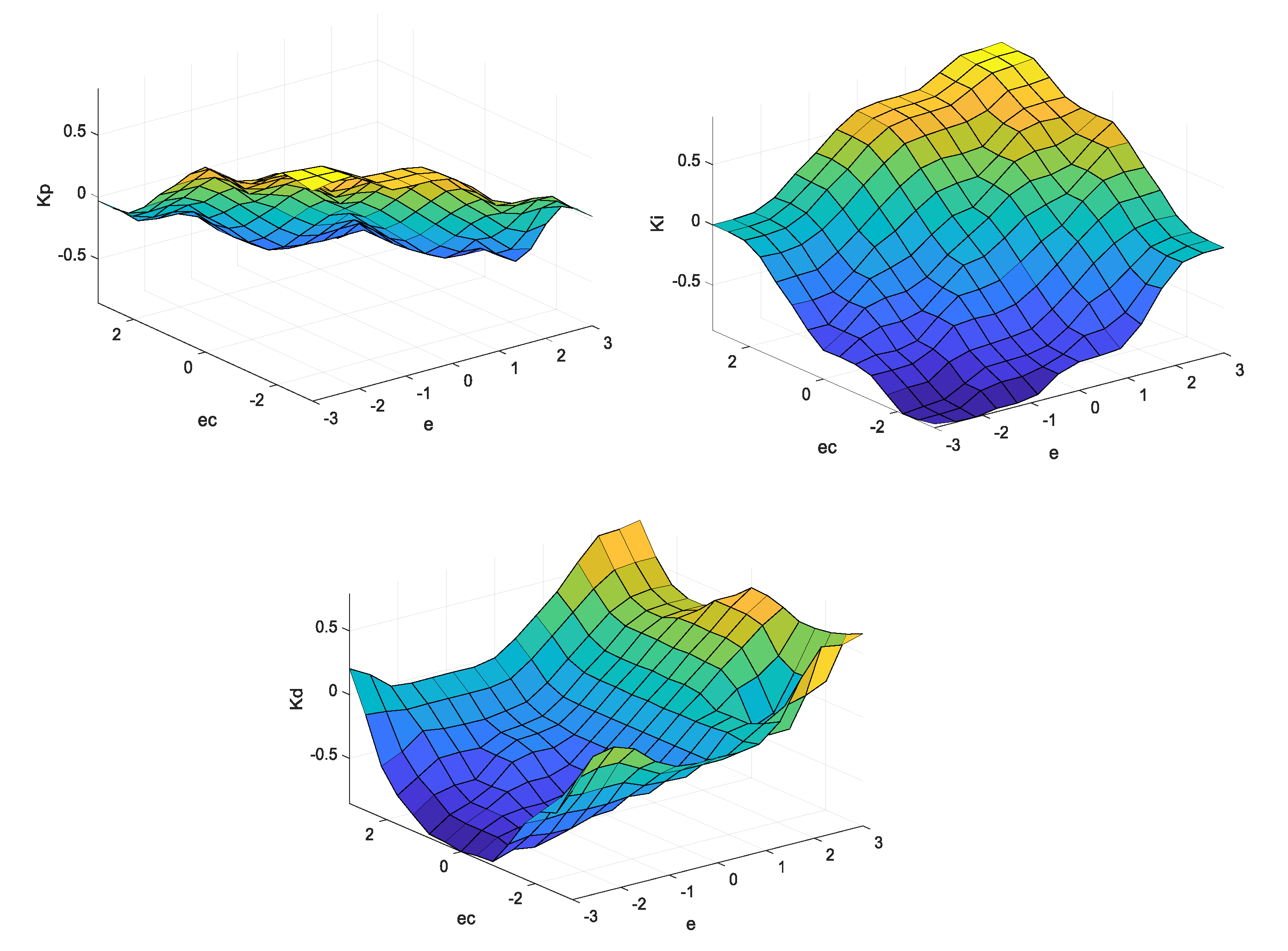

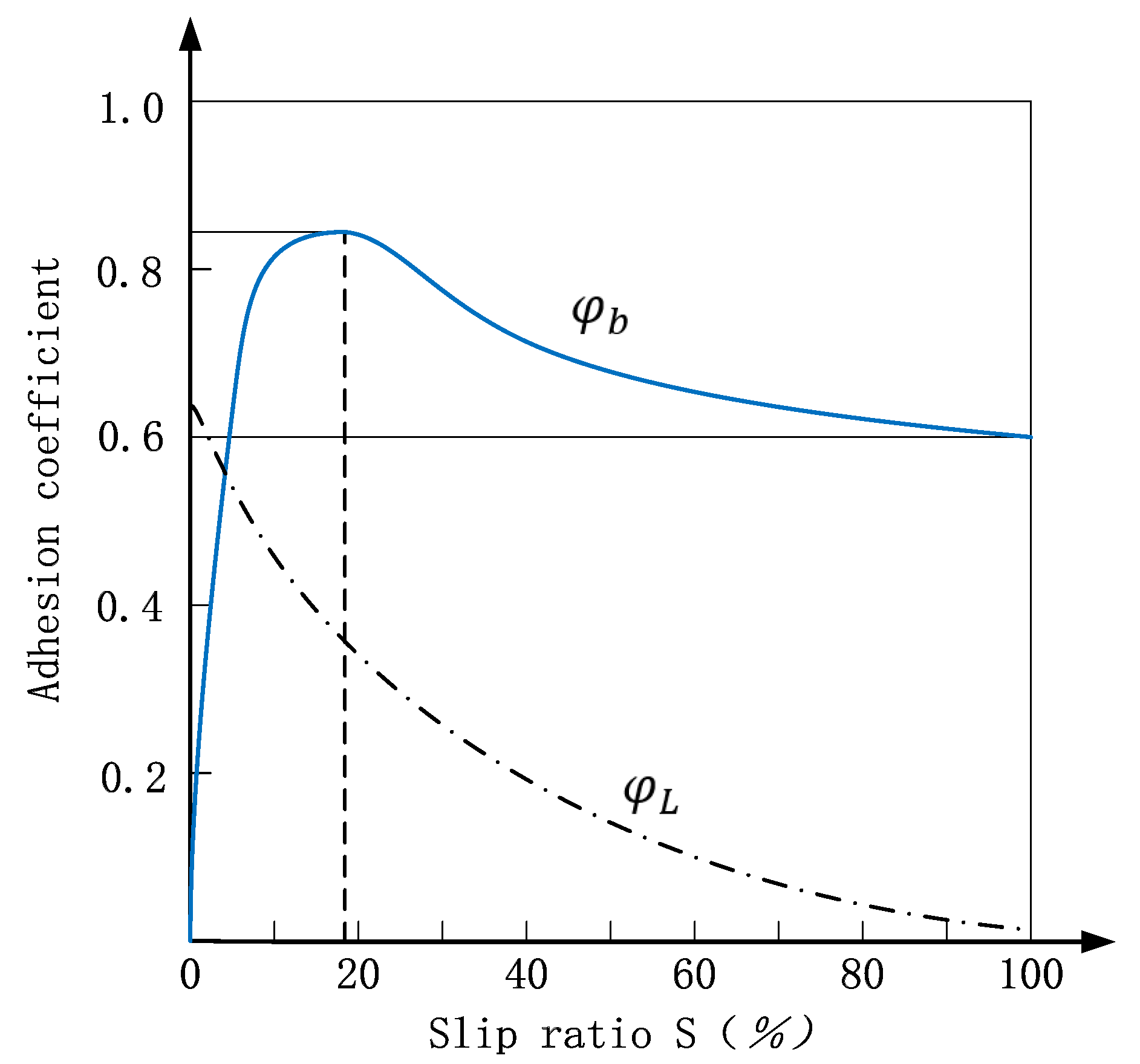

4. Slip Rate Controller

5. Simulation Analysis

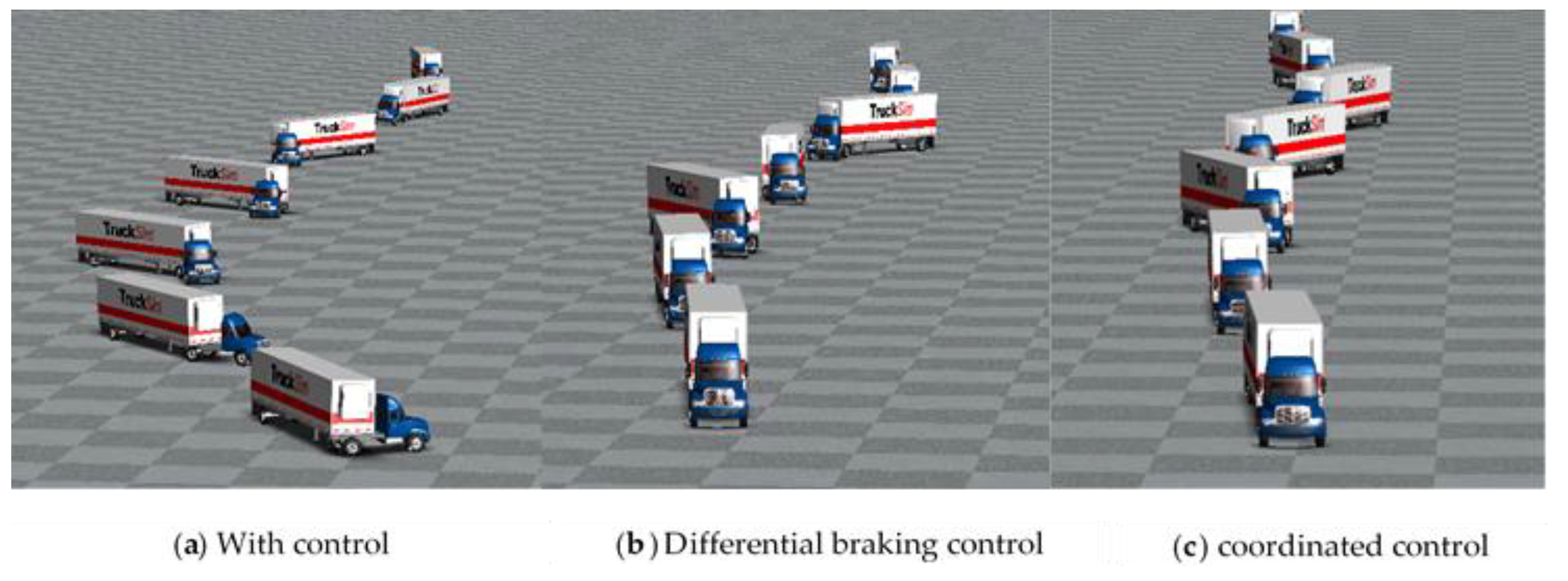

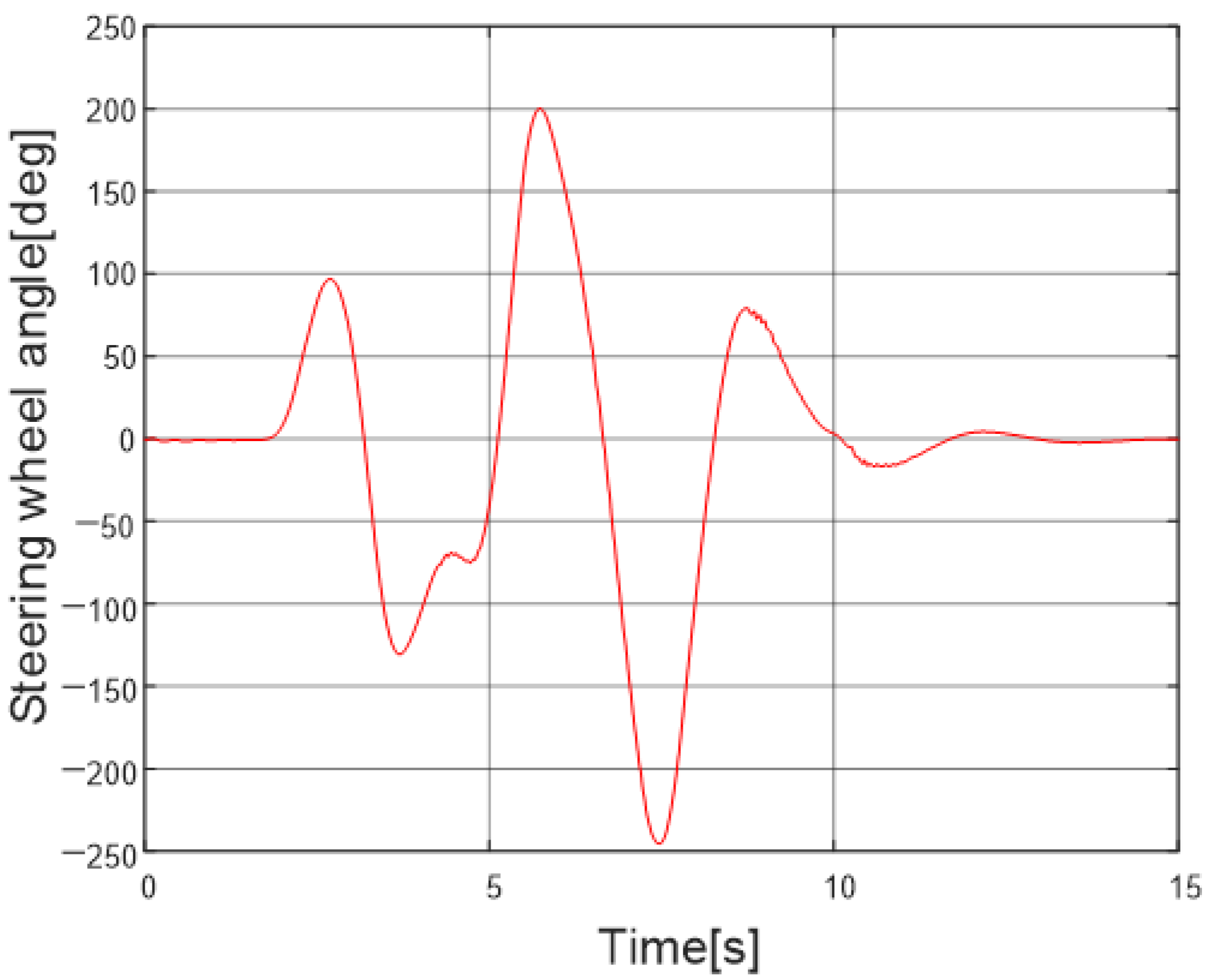

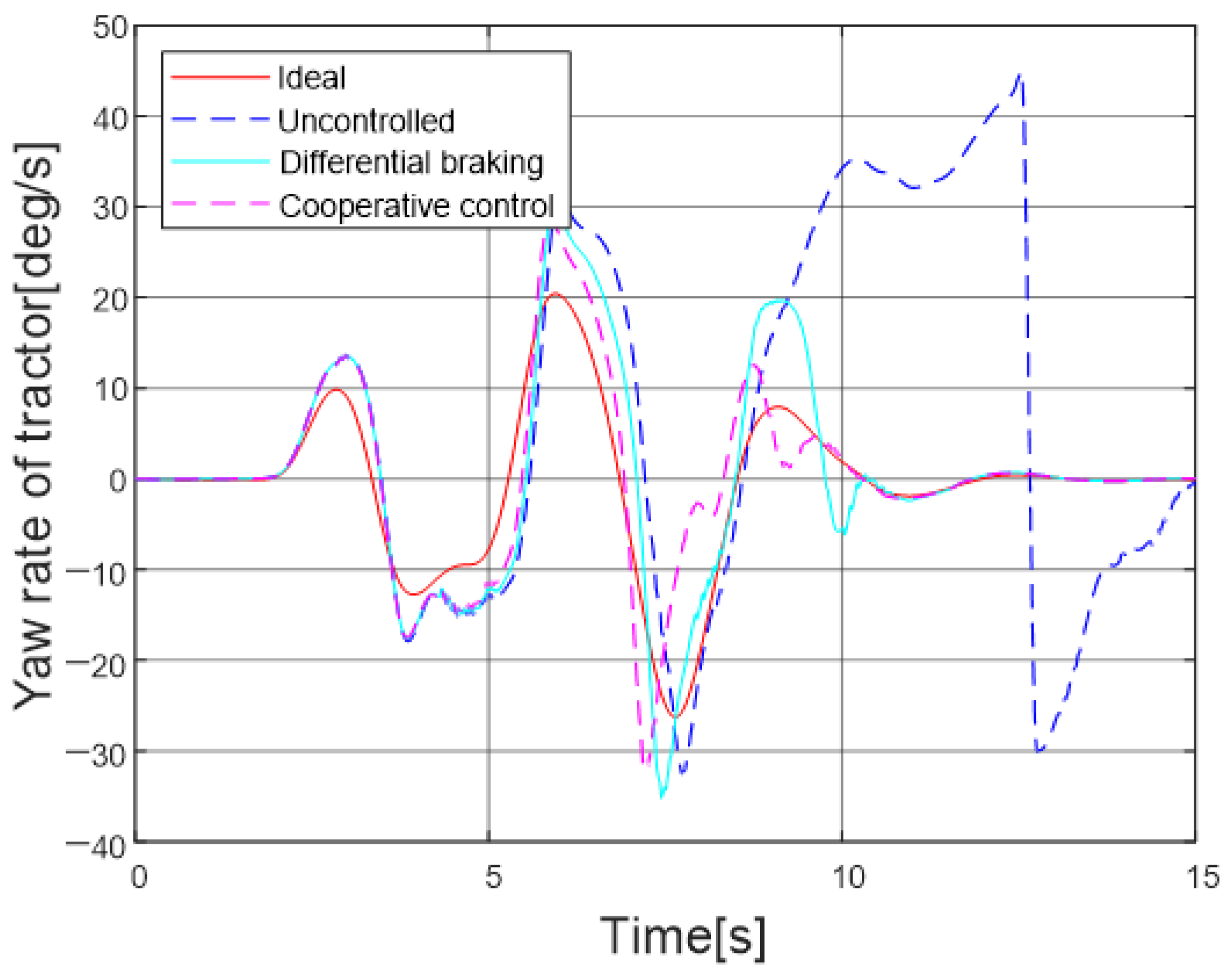

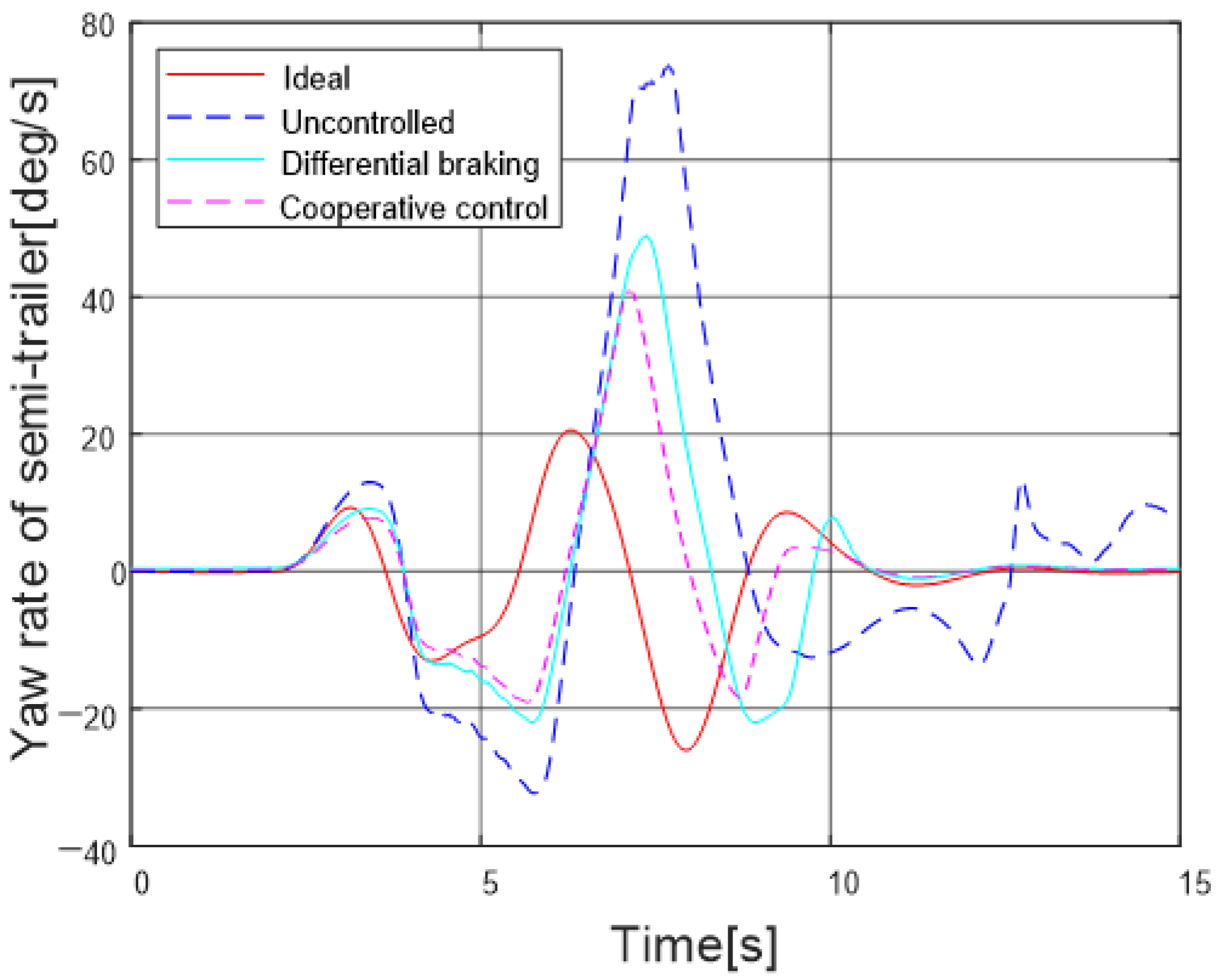

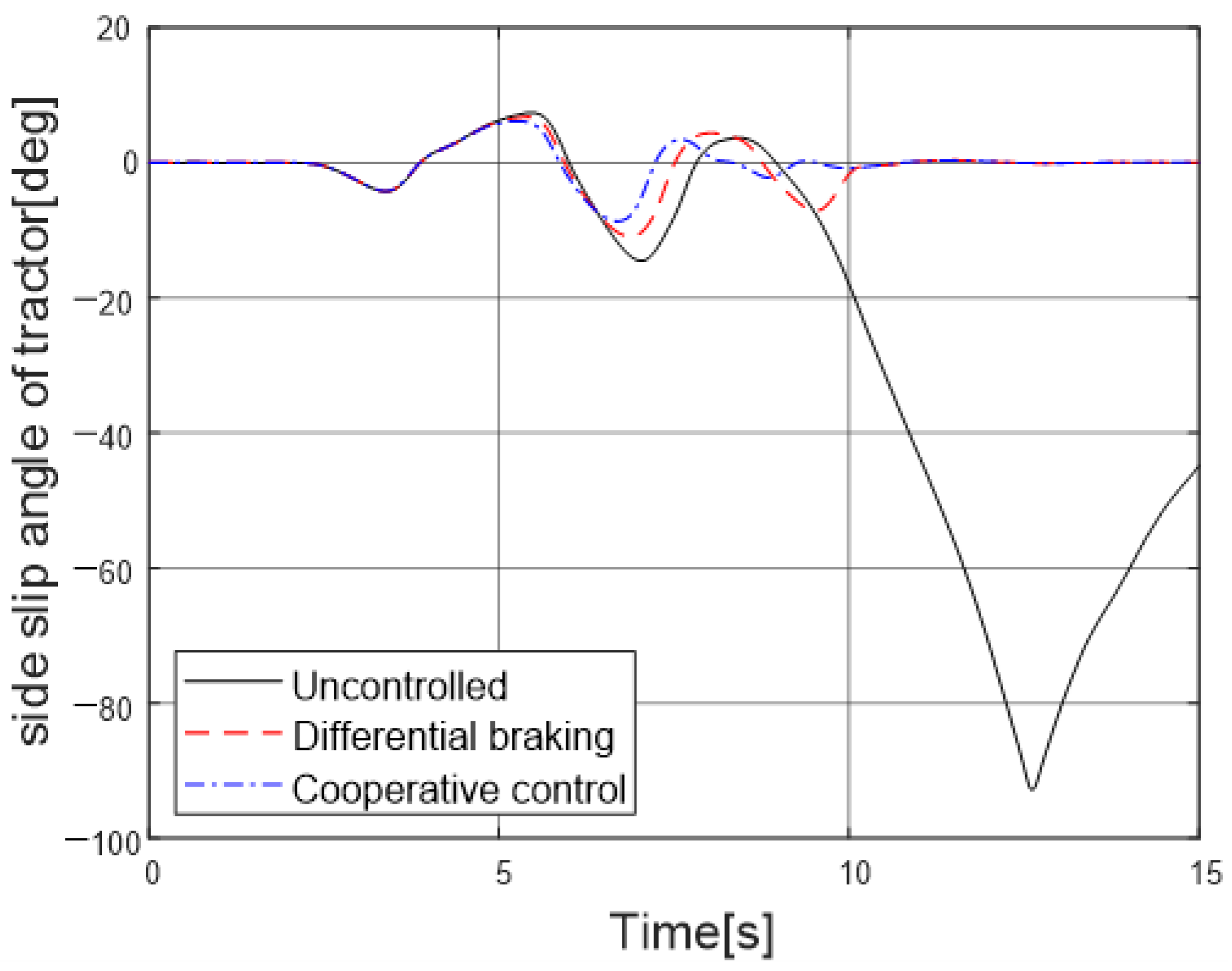

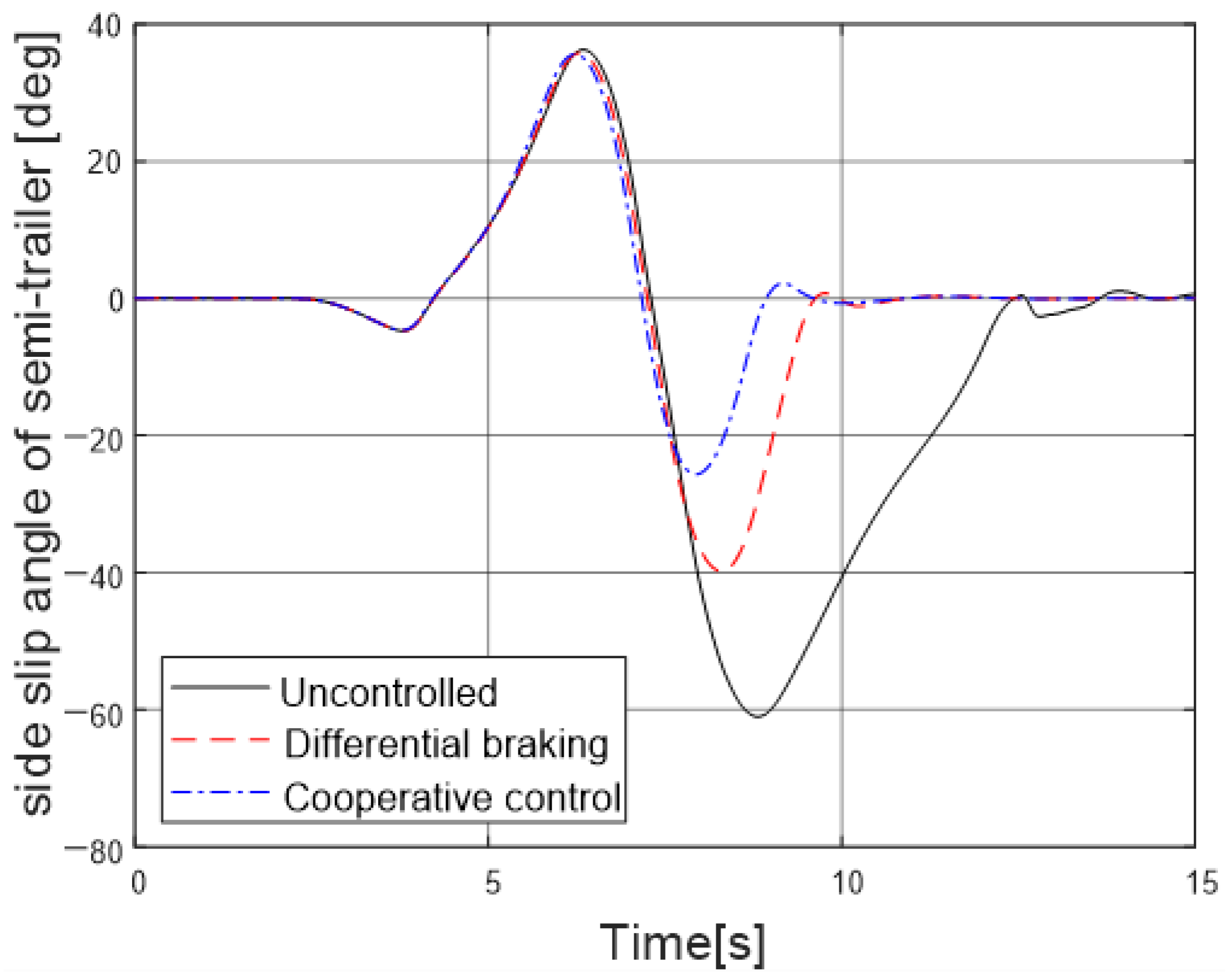

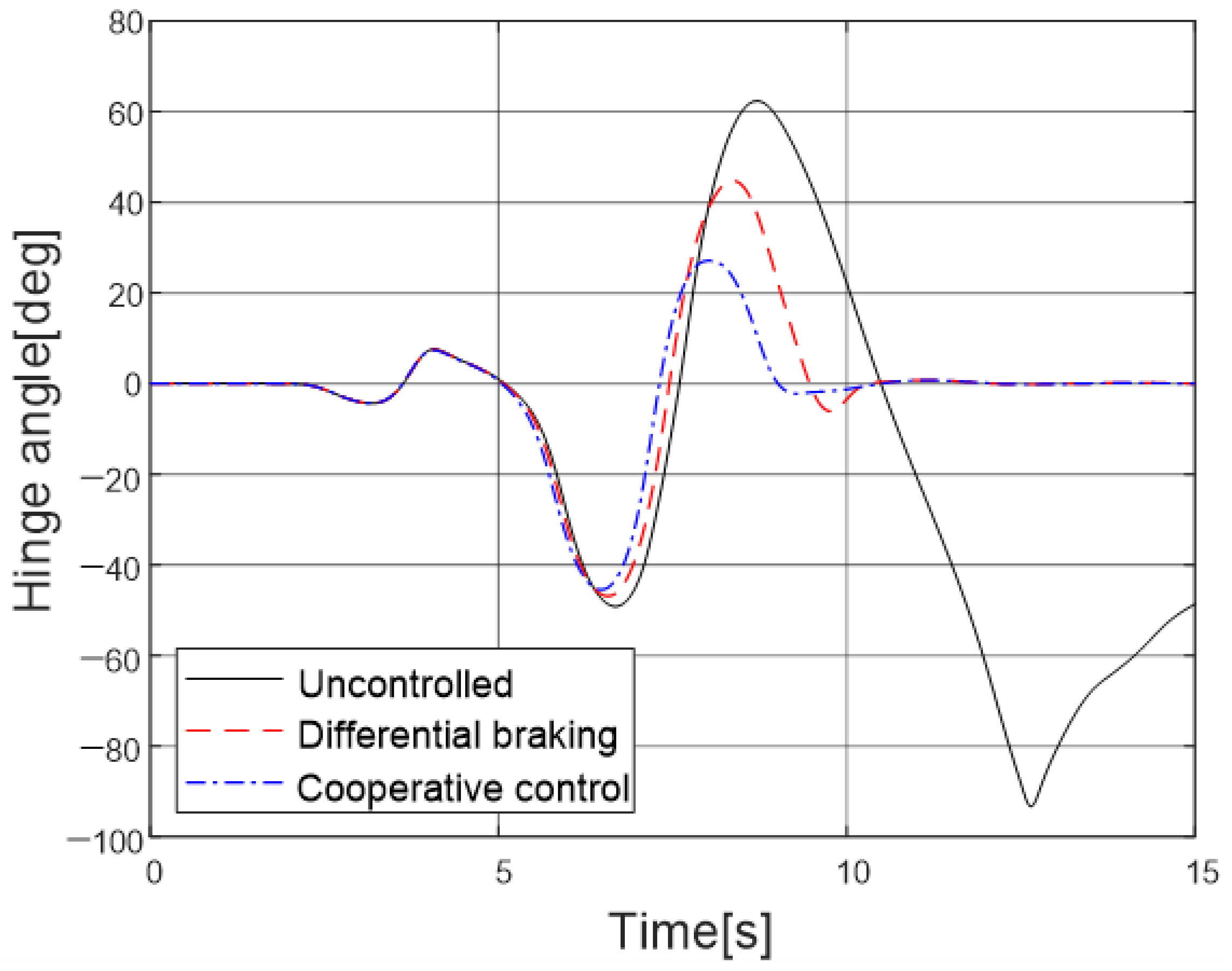

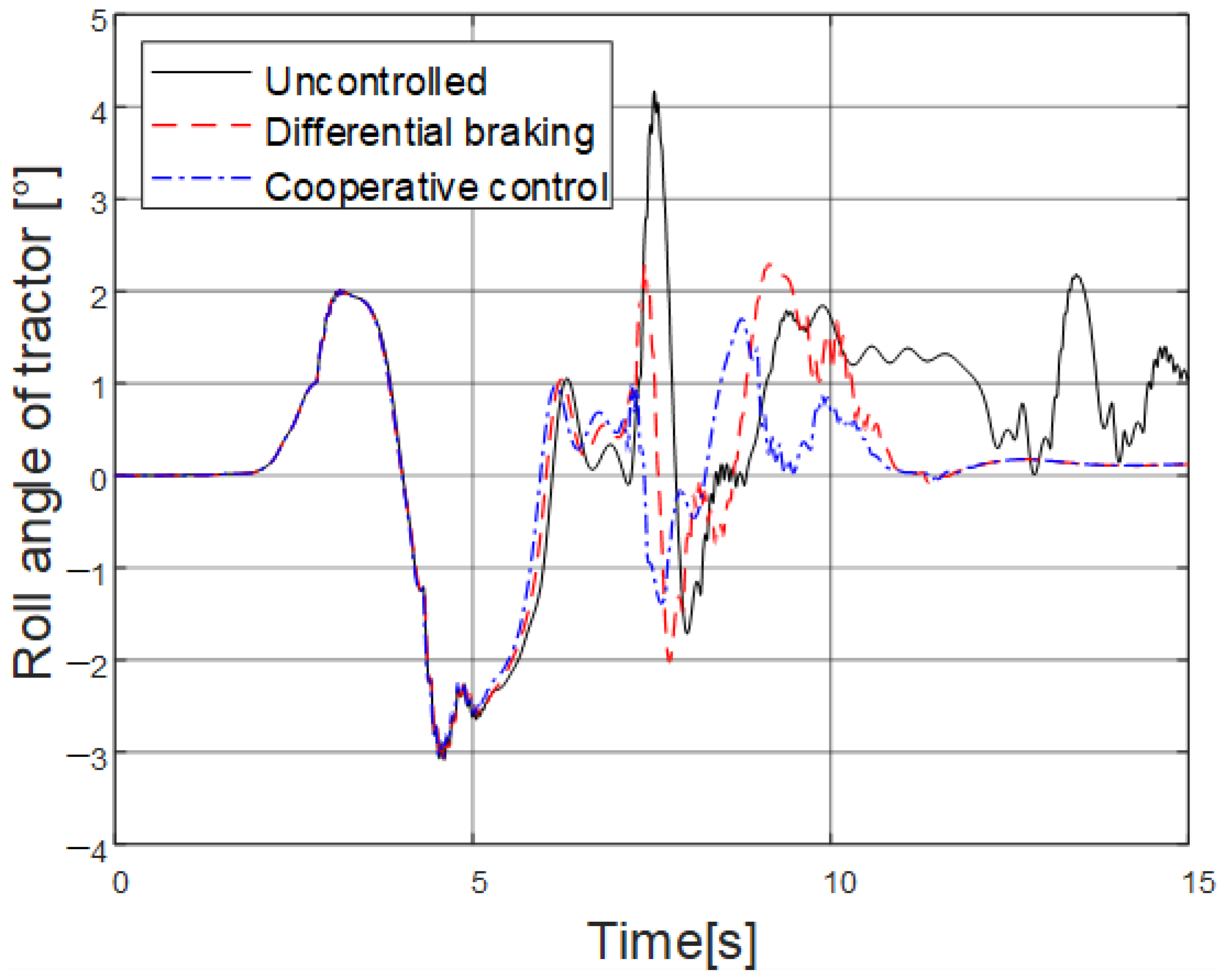

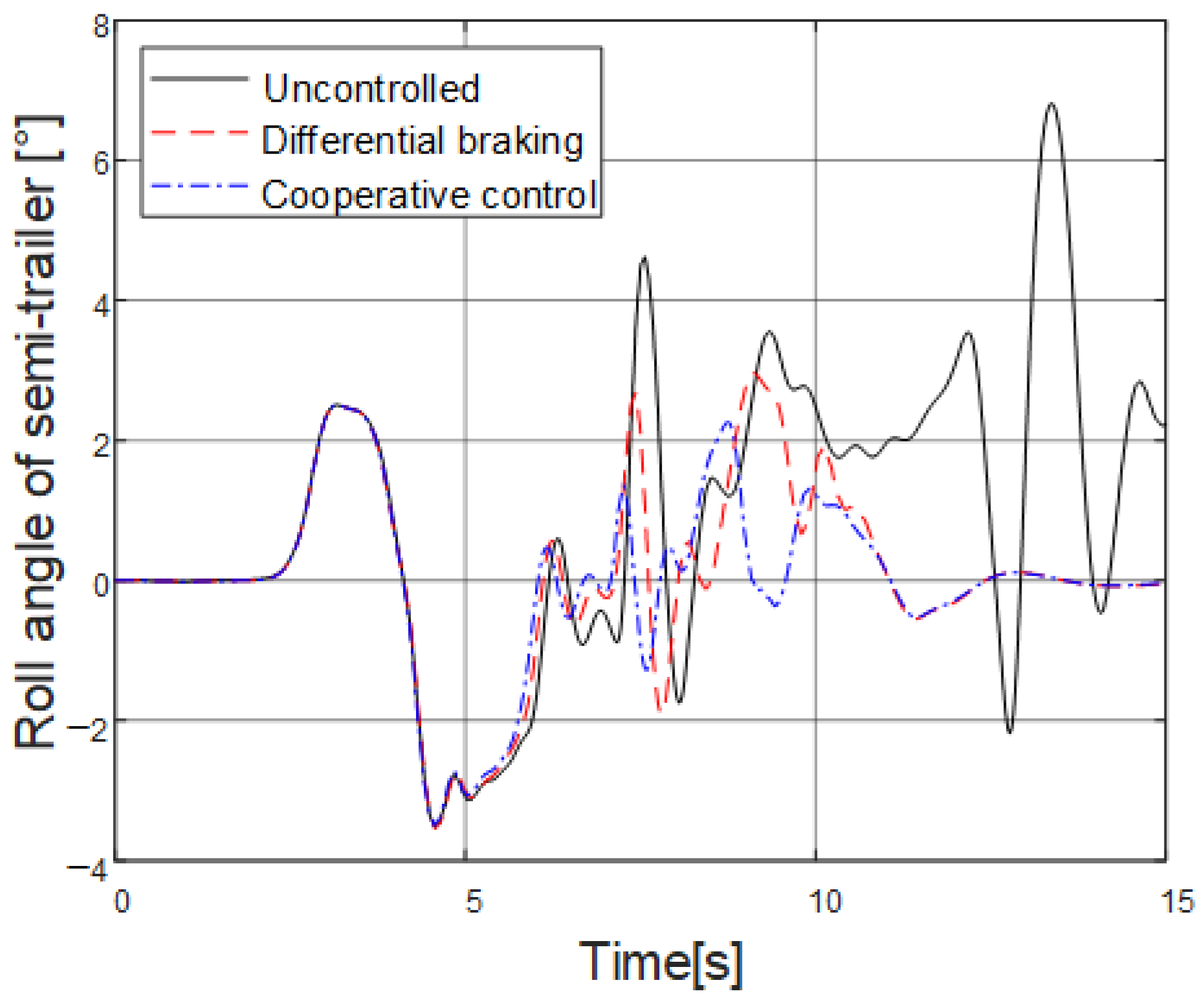

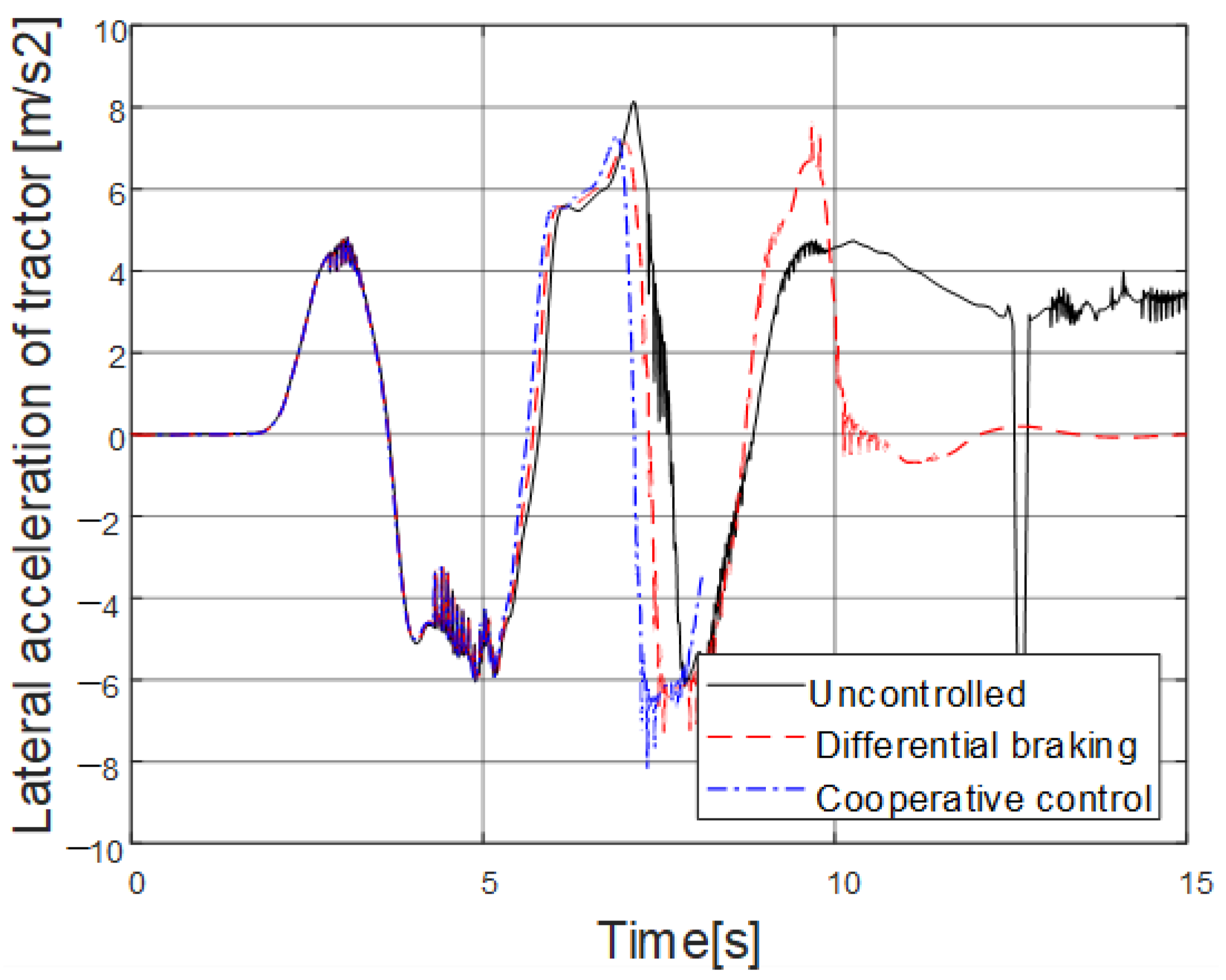

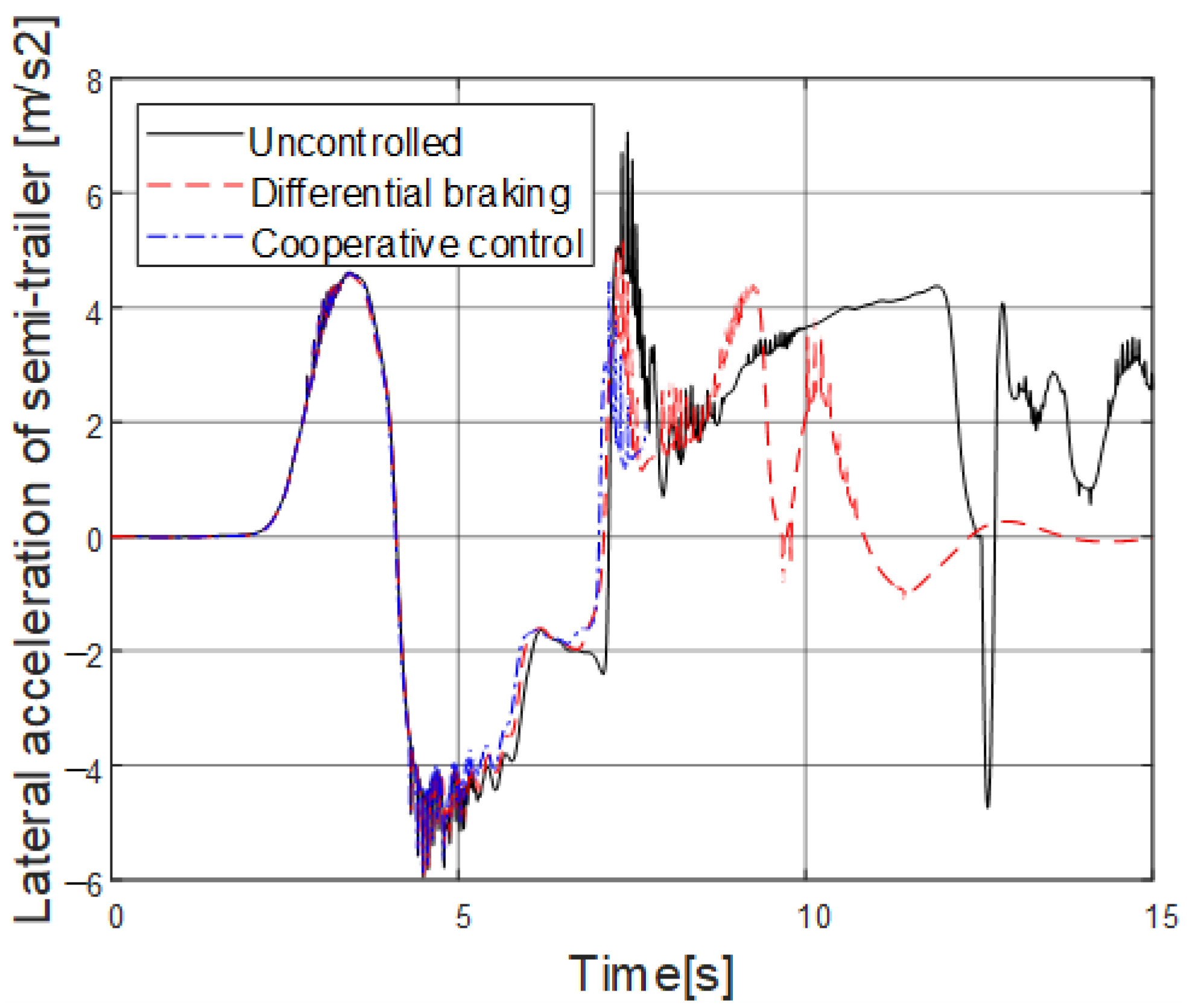

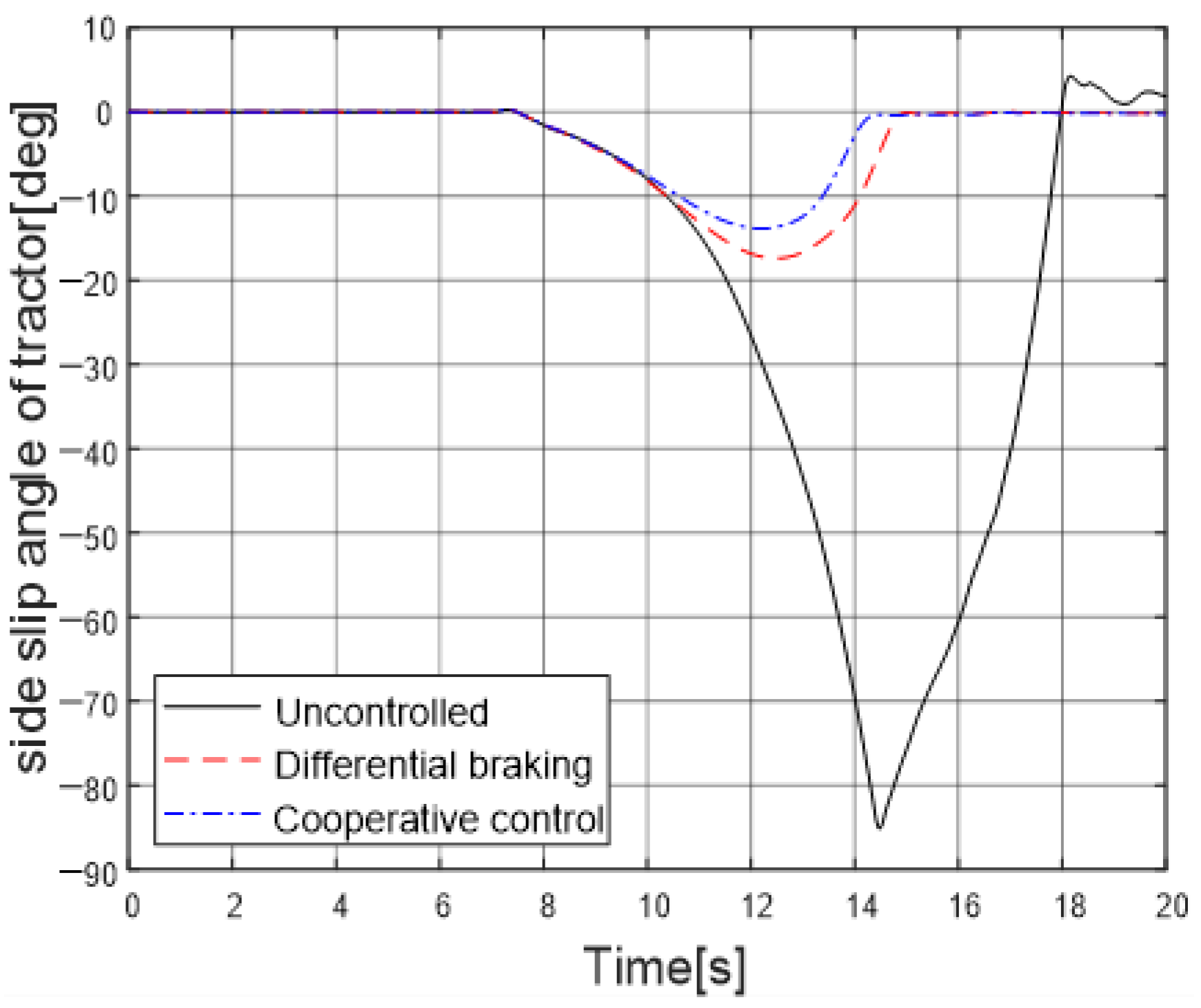

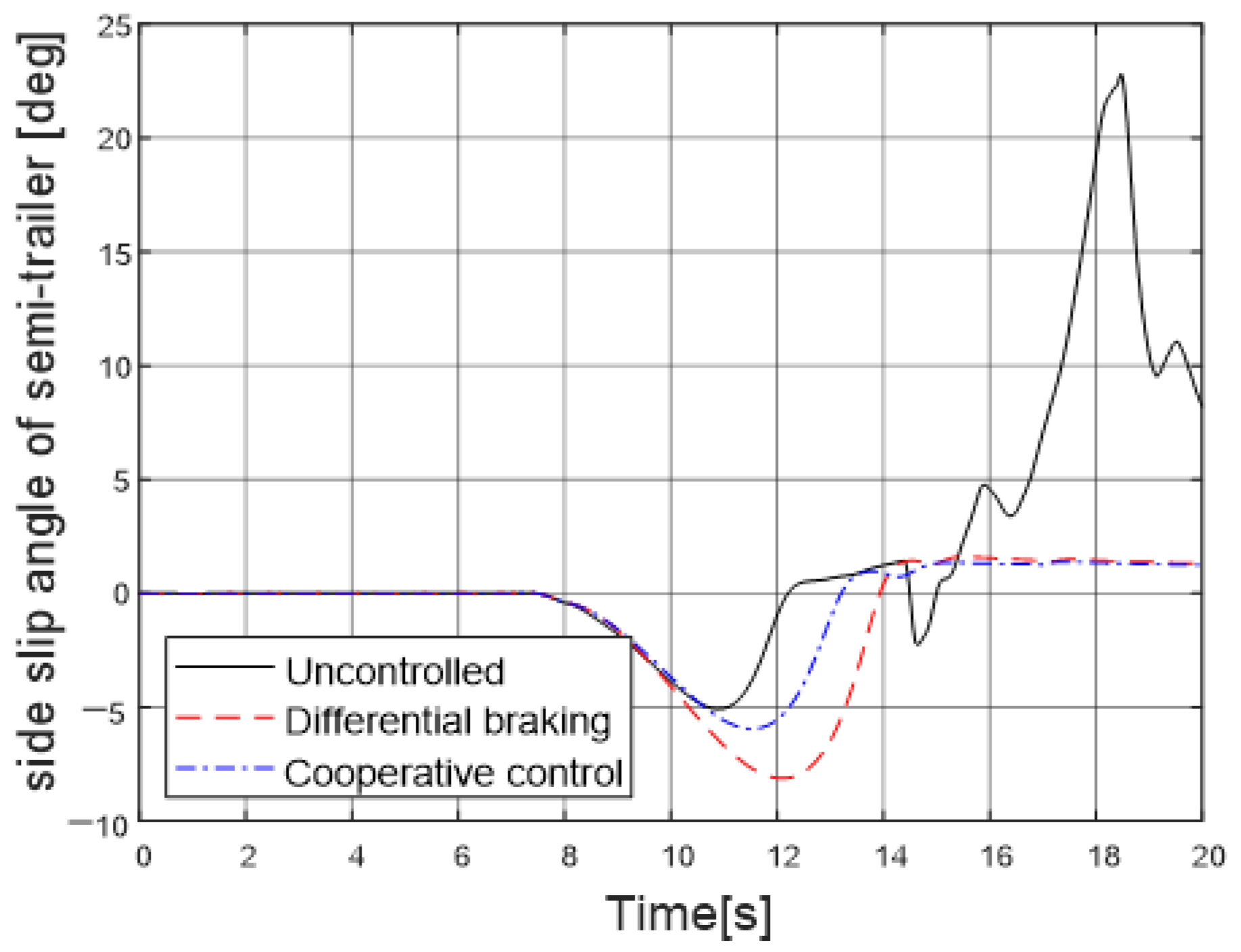

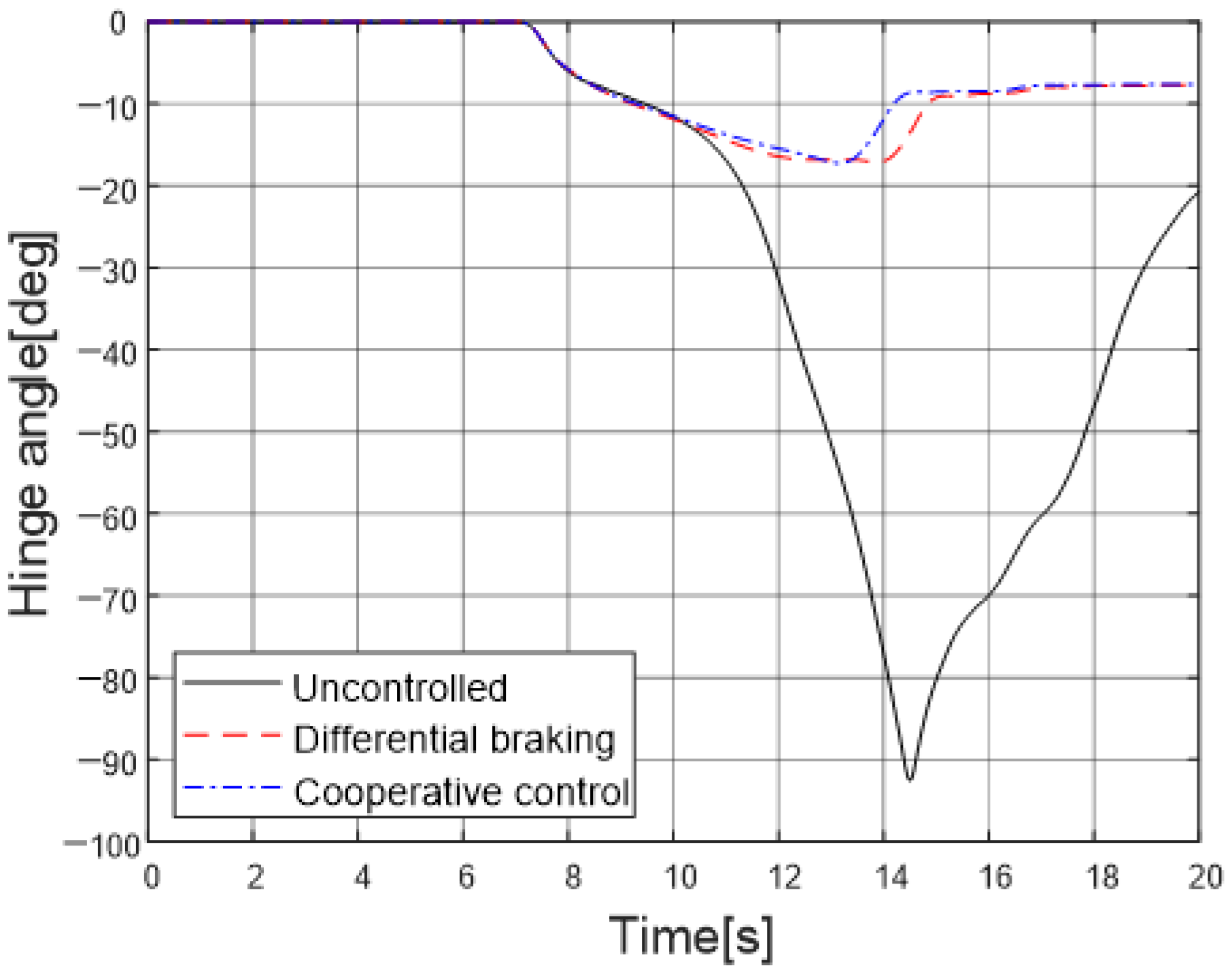

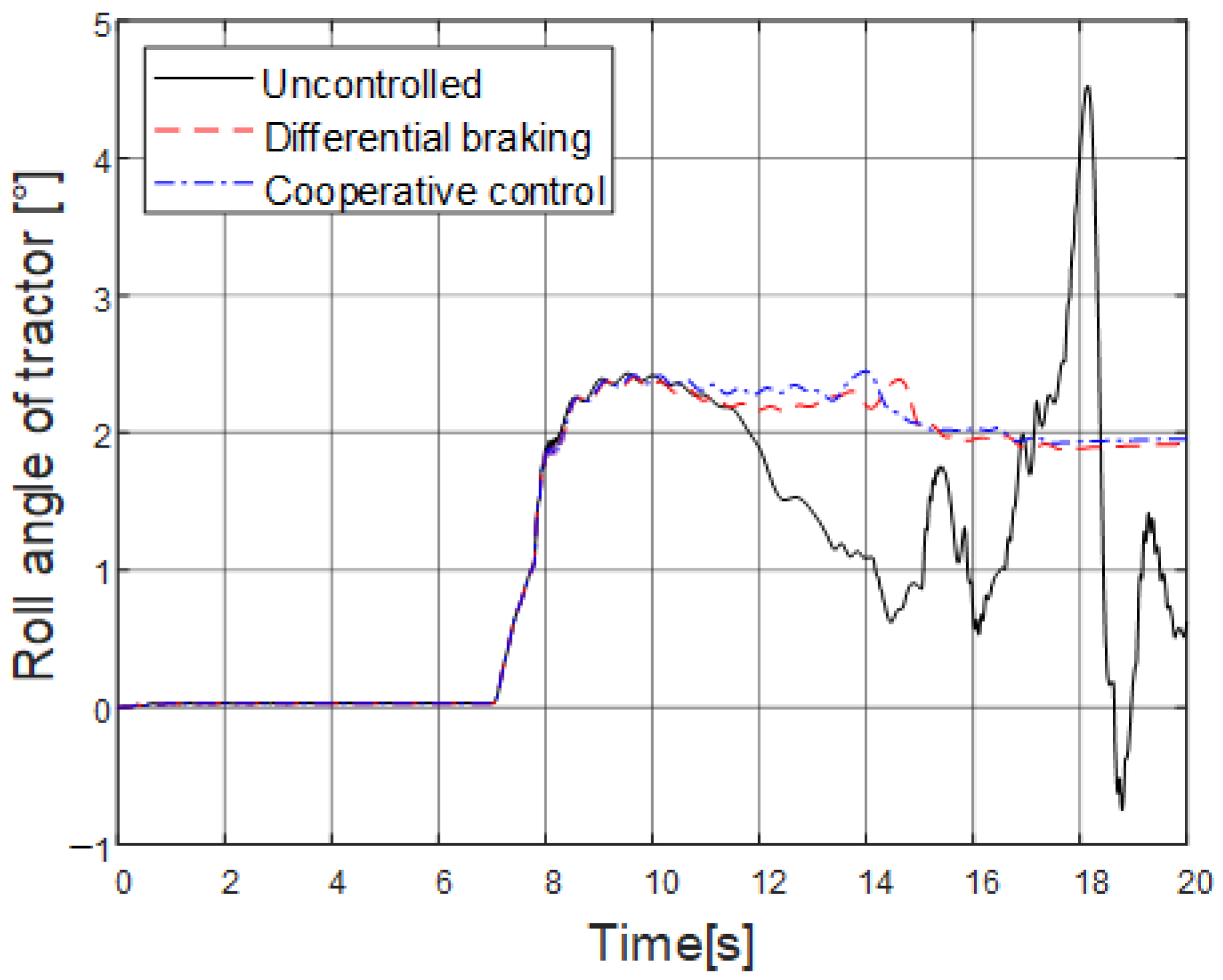

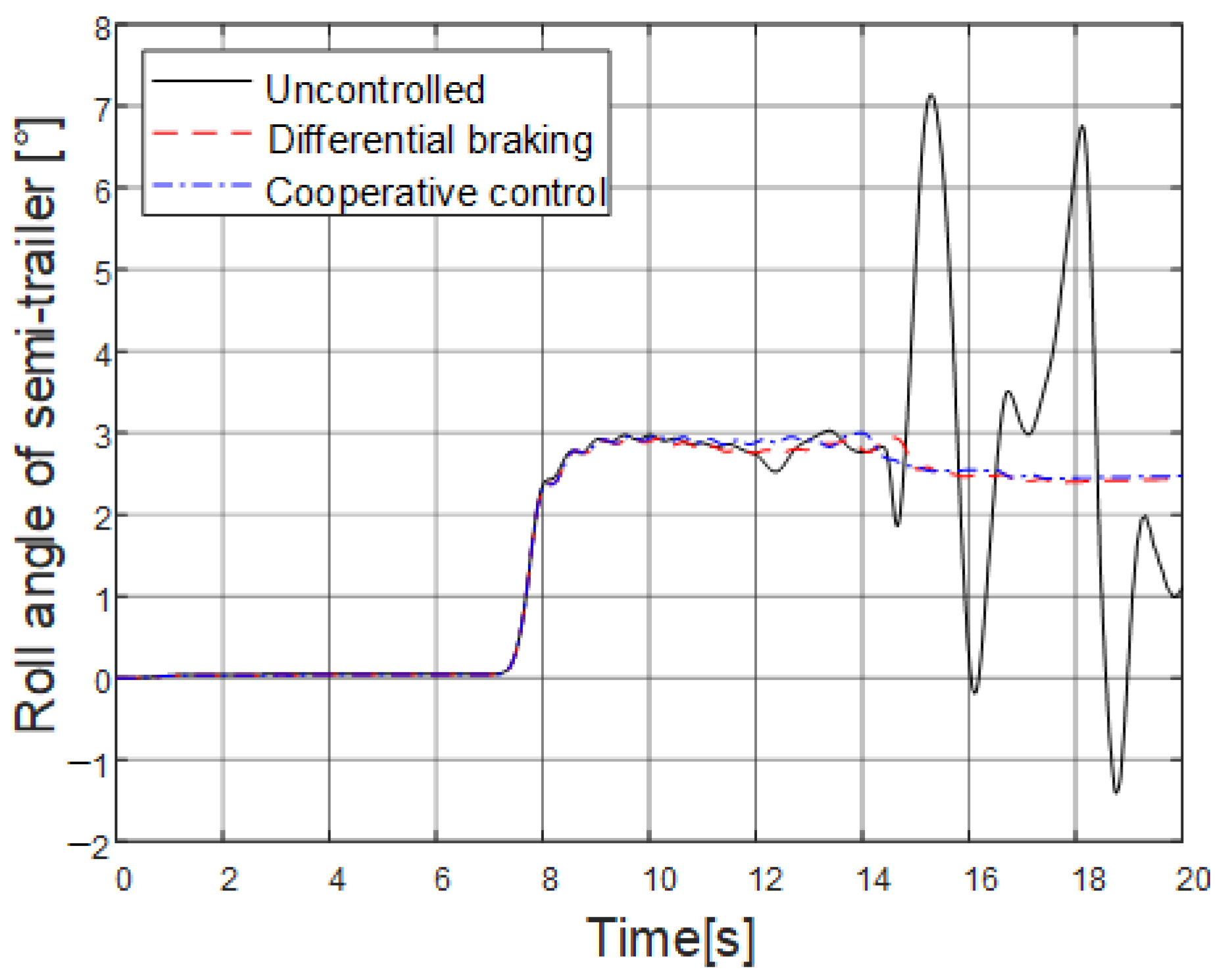

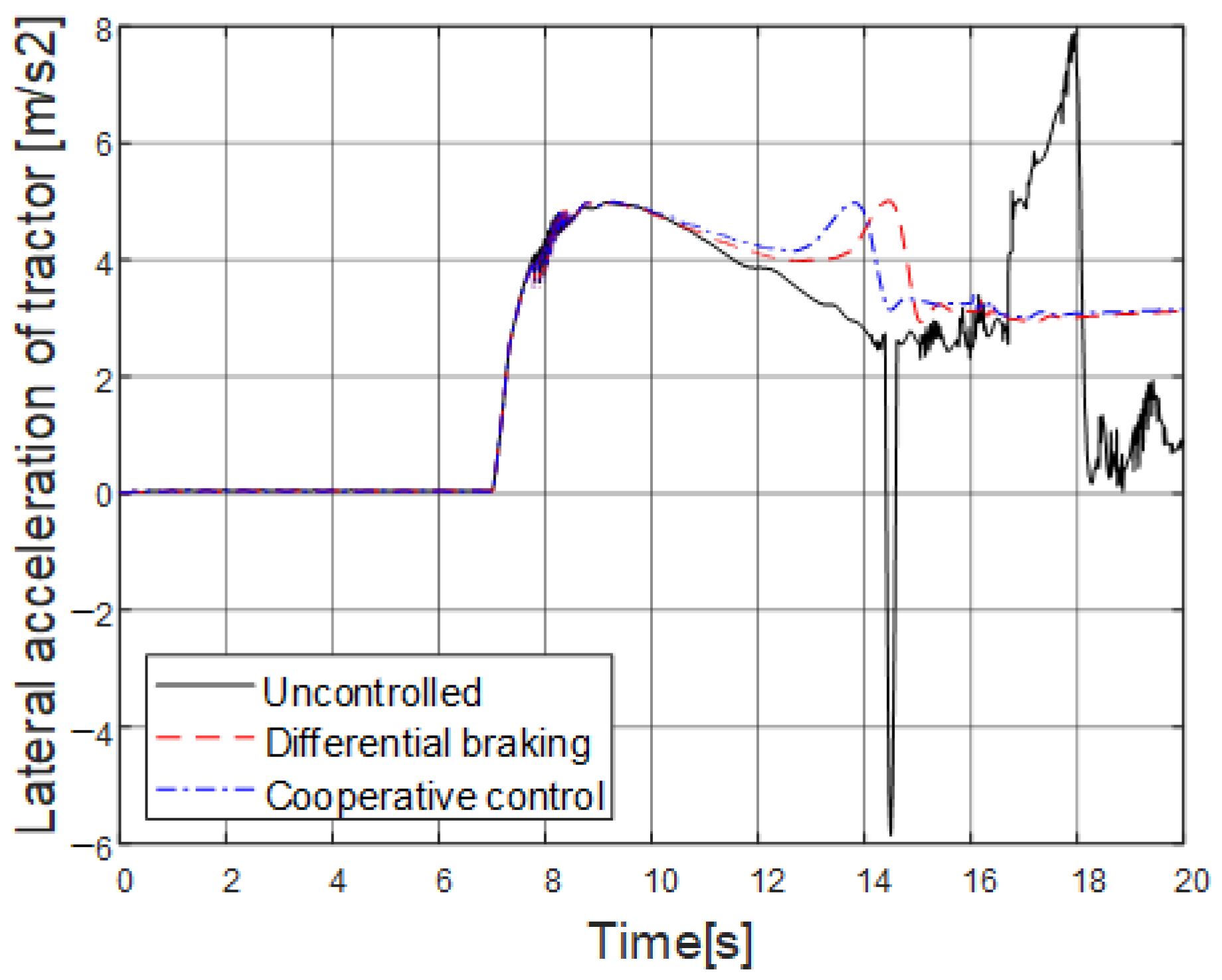

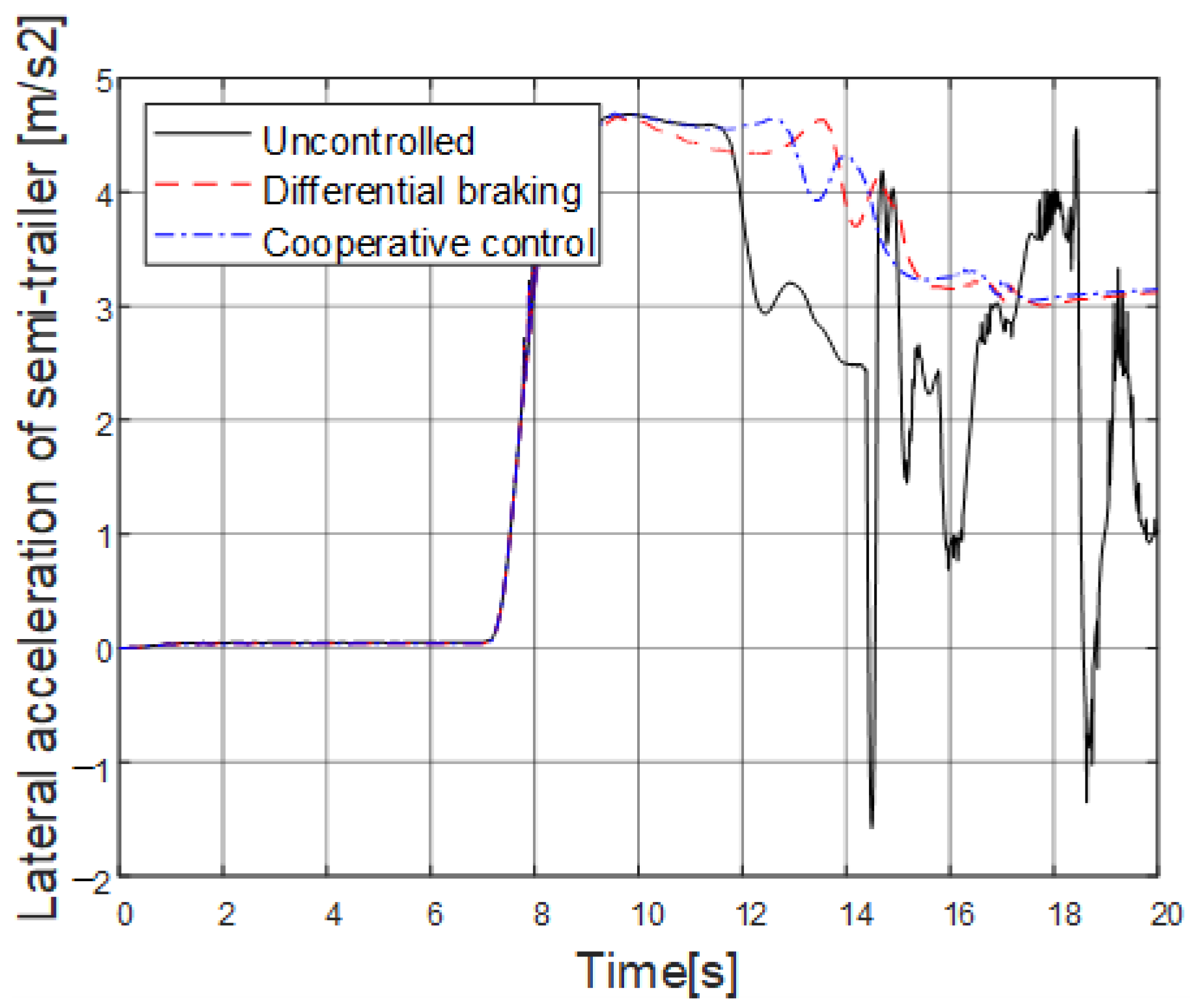

5.1. Double-Lane-Change Condition

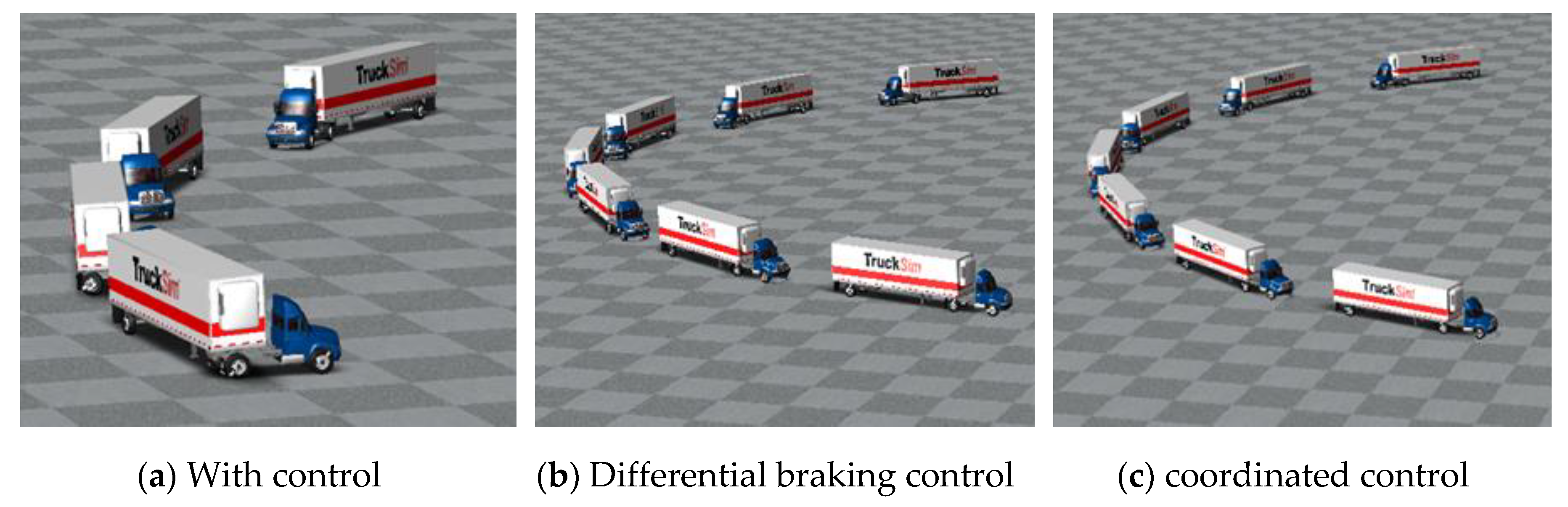

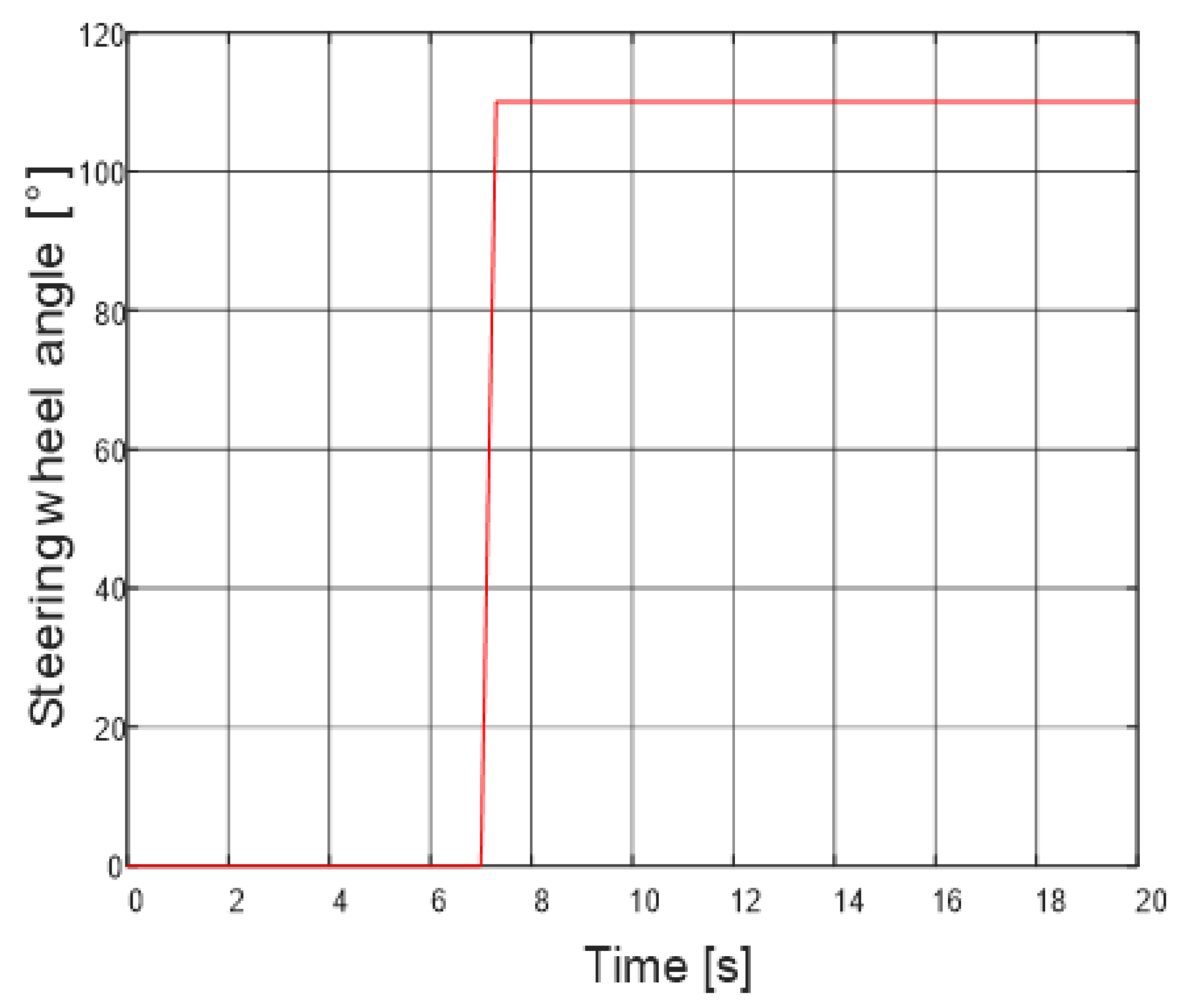

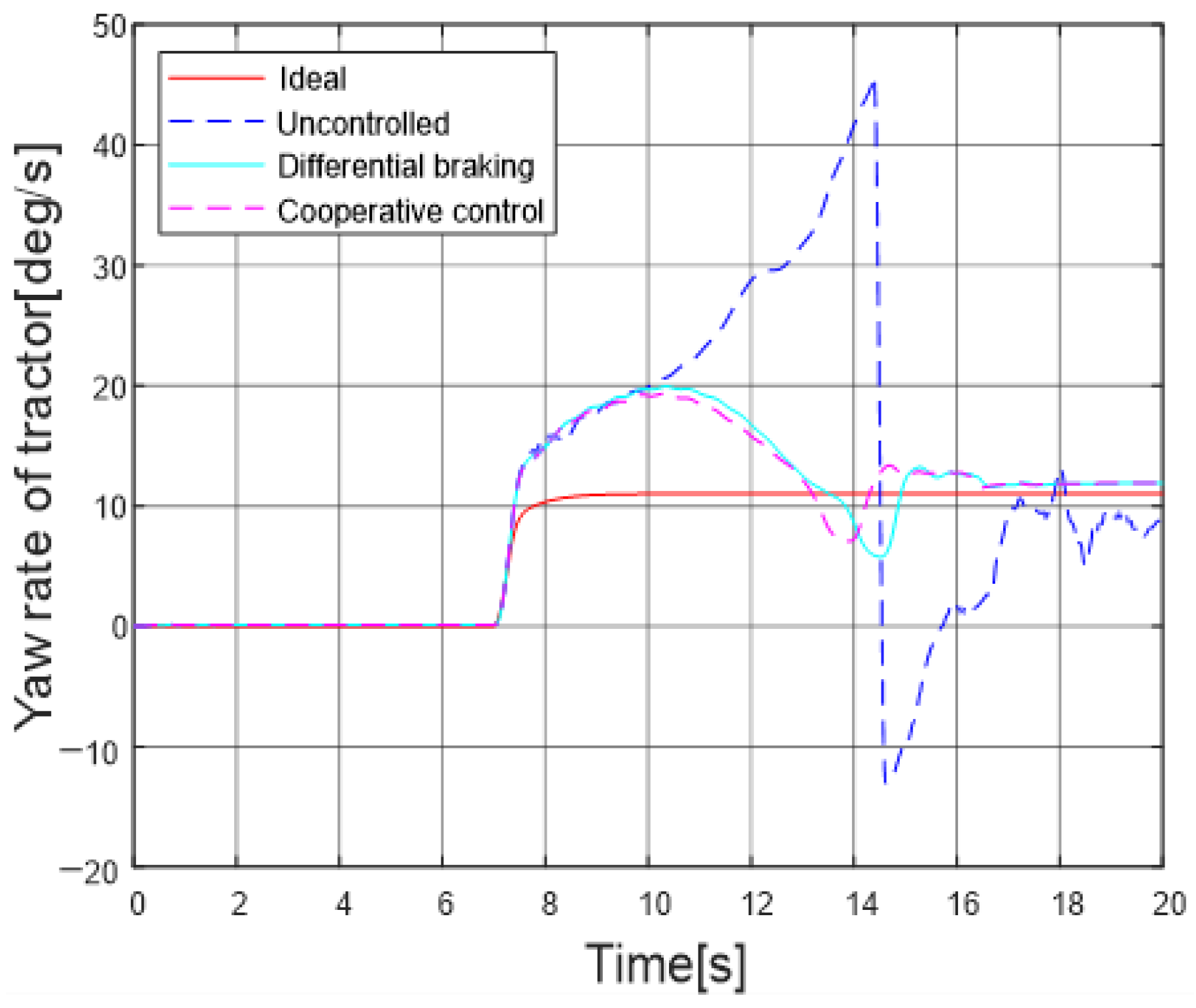

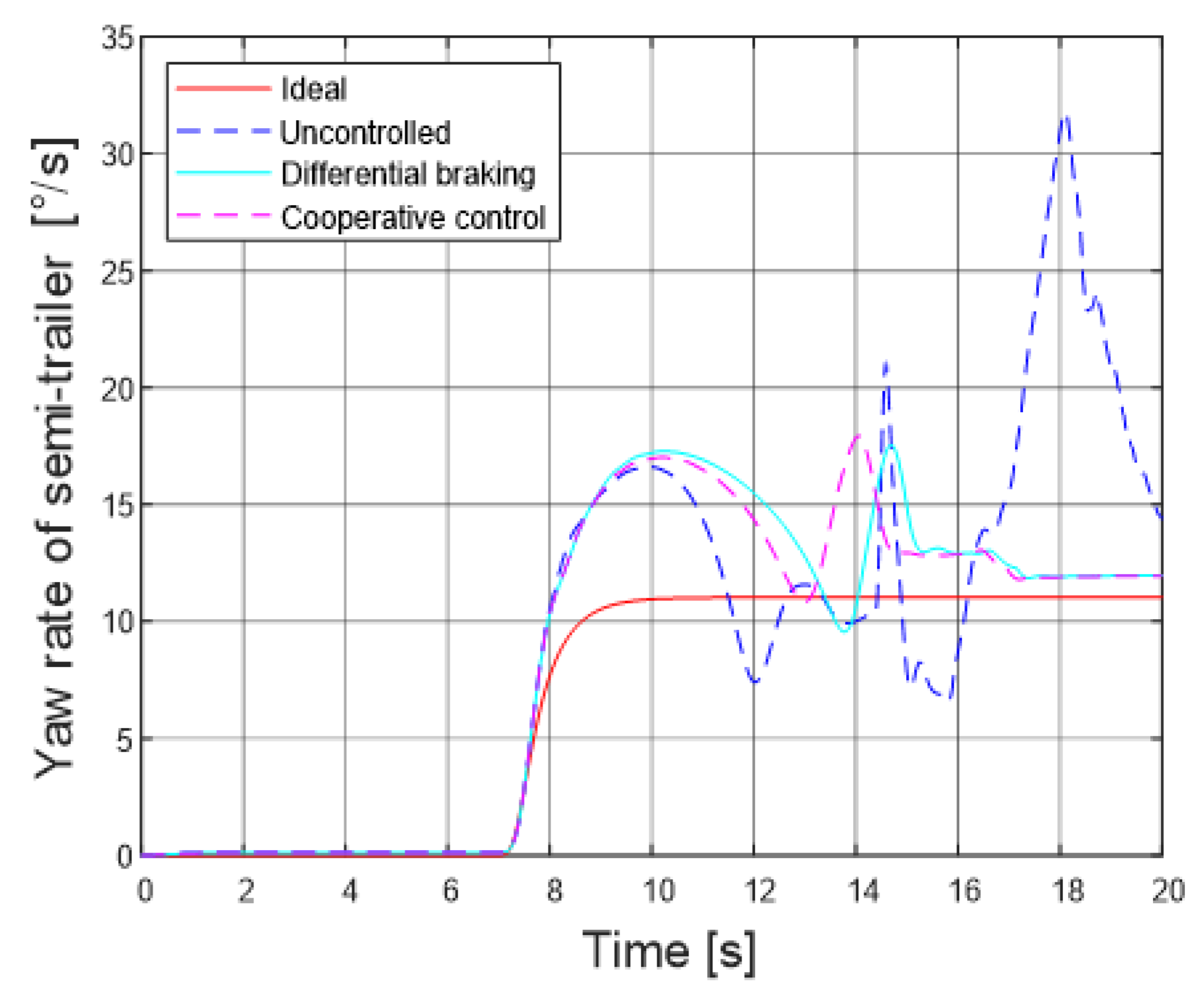

5.2. Step Steering Condition

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aripin, M.K.; Sam, Y.M.; Danapalasingam, K.A.; Peng, K.; Hamzah, N.; Ismail, M.F. A review of active yaw control system for vehicle handling and stability enhancement. Int. J. Veh. Technol. 2014, 6, 1–15. [Google Scholar] [CrossRef]

- Nie, Z.; Zong, C. Study on parameter identification of simplified model of heavy truck. Automot. Eng. 2015, 6, 622–630. [Google Scholar] [CrossRef]

- Yang, W.; Wei, L.; Liu, J. Joint simulation analysis of lateral stability optimization control of commercial vehicles. J. Mech. Eng. 2017, 2, 115–123. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, L.; Jiang, Y. Active control on path following and lateral stability for truck–trailer combinations. Arab. J. Sci. Eng. 2018, 44, 1365–1377. [Google Scholar] [CrossRef]

- National Highway Traffic Safety Administration. Traffic Safety Facts 2015; National Highway Traffic Safety Administration: Washington, DC, USA, 2016. [Google Scholar]

- Liu, C.; Guan, Z.; Du, F. Fuzzy PID control of lateral stability of four-wheel steering semitrailer. Mod. Manuf. Eng. 2016, 5, 47–50. [Google Scholar]

- Murata, S. Innovation by in-wheel-motor drive unit. Veh. Syst. Dyn. 2012, 50, 807–830. [Google Scholar] [CrossRef]

- Li, C. An optimal coordinated method for EVs participating in frequency regulation under different power system operation states. IEEE Access 2018, 6, 62756–62765. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- Li, Y.; Li, B.; Xu, X.; Sun, X. A nonlinear decoupling control approachusing RBFNNI-based robust pole placement for a permanent magnet in-wheel motor. IEEE Access 2017, 6, 1844–1854. [Google Scholar] [CrossRef]

- Najjari, B.; Mirzaei, M.; Tahouni, A. Constrained stability control with optimal power management strategy for in-wheel electric vehicles. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2019. [Google Scholar] [CrossRef]

- Asiabar, A.; Kazemi, R. A direct yaw moment controller for a four in-wheel motor drive electric vehicle using adaptive sliding mode control. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2019. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, W.; Wang, C.; Li, L. Stability control of in-wheel motor electric vehicles under extreme conditions. Trans. Inst. Meas. Control 2019, 41, 2838–2850. [Google Scholar] [CrossRef]

- Tamaddoni, S.; Taheri, S. Yaw Stability Control of Tractor Semi-Trailers; SAE Technical Paper 2008-01-2595; SAE: Warrendale, PA, USA, 2008. [Google Scholar] [CrossRef]

- Takenaga, H.; Konishi, M.; Imai, J. Route Tracking Control of Tractor-Trailer Vehicles based on Fuzzy Controller. In Proceedings of the Fifth International Workshop on Computational Intelligence & Applications, Hiroshima, Japan, 10–12 November 2009; pp. 105–110. [Google Scholar]

- Sogol, K.; Mathias, L.; Jonas, F. Robustness analysis of a steering-based control strategy for improved lateral performance of a truck-dolly-semitrailer. Int. J. Heavy Veh. Syst. 2015, 22, 1–20. [Google Scholar]

- Yang, X.; Kang, N.; Li, X. Stability control of semitrailer train based on TruckSim Simulink joint simulation. Highw. Transp. Technol. 2013, 30, 141–148. [Google Scholar]

- Eunhyek, J.; Kwanwoo, P.; Youngil, K.; Kyongsu, Y.; Kilsoo, K. A tyre slip-based integrated chassis control of front/rear traction distribution and four-wheel independent brake from moderate driving to limit handling. Veh. Syst. Dyn. 2018, 56, 579–603. [Google Scholar]

- Chen, Y.; Chen, S.; Zhao, Y.; Gao, Z.; Li, C. Optimized handling stability control strategy for a four in-wheel motor independent-drive electric vehicle. IEEE Access 2019, 7, 17017–17032. [Google Scholar] [CrossRef]

- Chae, M.; Hyun, Y.; Yi, K.; Nam, K. Dynamic Handling Characteristics Control of an in-Wheel-Motor Driven Electric Vehicle Based on Multiple Sliding Mode Control Approach. IEEE Access 2019, 7, 132448–132458. [Google Scholar] [CrossRef]

- Huang, C.; Lei, F.; Hu, L. Lateral Stability Control Based on Regional Pole Placement of In-wheel-motored Electric Vehicle. Automot. Eng. 2019, 41, 905–914. [Google Scholar]

- Wang, Z.; Wang, Y.; Zhang, L.; Liu, M. Vehicle stability enhancement through hierarchical control for a four-wheel-independently-actuated electric vehicle. Energies 2017, 10, 947. [Google Scholar] [CrossRef]

- Zong, C.; Lin, F.; Hu, L. Control algorithm for braking force distribution of electric control braking system of motor train. In Proceedings of the 2011 Annual Meeting of Society of Automotive Engineering of China, Beijing, China, 26–28 October 2011. [Google Scholar]

- Yang, X.; Yang, C.; Zhang, X. Yaw stability control of tractor semi-trailer based on active braking. Automot. Eng. 2011, 33, 955–961. [Google Scholar]

- Gao, H. Research on Braking Direction Stability and Control Strategy of Semitrailer Train. Ph.D. Thesis, Jilin University, Changchun, China, 2014. [Google Scholar]

- Zhang, D.; Liu, G.; Zhou, H.; Zhao, W. Adaptive sliding mode fault-tolerant coordination control for four-wheel independently driven electric vehicles. IEEE Trans. Ind. Electron. 2018, 65, 9090–9100. [Google Scholar] [CrossRef]

- Ivanov, V.; Savitski, D. Systematization of integrated motion control of ground vehicles. IEEE Access 2015, 3, 2080–2099. [Google Scholar] [CrossRef]

- Mutoh, N.; Nakano, Y. Dynamics of front-and-rear-wheel-independent-drive-type electric vehicles at the time of failure. IEEE Trans. Ind. Electron. 2012, 20, 1488–1499. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J. Fast and global optimal energy-efficient control allocation with applications to over-actuated electric ground vehicles. IEEE Trans. Control. Syst. Technol. 2012, 20, 1202–1211. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J. Fault-tolerant control with active fault diagnosis for four-wheel independently driven electric ground vehicles. IEEE Trans. Veh. Technol. 2011, 60, 4276–4287. [Google Scholar] [CrossRef]

- Cheng, Z. Research on the PID control of the ESP system of tractor based on improved AFSA and improved SA. Comput. Electron. Agric. 2018, 148, 142–147. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Y.; Feng, Z. Research on control method based on Fuzzy PID controller. Mech. Sci. Technol. 2011, 30, 166–172. [Google Scholar]

- Jin, X.; Chen, K.; Zhao, Y.; Ji, J.; Jing, P. Simulation of hydraulic transplanting robot control system based on fuzzy PID controller. Measurement 2020, 164, 108023. [Google Scholar] [CrossRef]

- Shi, Q.; Lam, H.; Xuan, C.; Chen, M. Adaptive Neuro-Fuzzy PID Controller based on Twin Delayed Deep Deterministic Policy Gradient Algorithm. Neurocomputing 2020, 402, 183–194. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, M.; Chen, X.; Chen, L.; Du, S. A Fuzzy PID Controller with Nonlinear Compensation Term for Mold Level of Continuous Casting Process. Inf. Sci. 2020, 539, 487–503. [Google Scholar] [CrossRef]

- Liu, Y. Study on Stability of Hydraulic Hybrid Semitrailer Train. Ph.D. Thesis, Qilu University of Technology, Jinan, China, 2019. [Google Scholar]

- Guo, K.; Wang, D. Preliminary study on anti slip control theory of automobile drive. J. Jilin Univ. Technol. 1997, 27, 1–5. [Google Scholar]

| Category | Value | Unit | |

|---|---|---|---|

| Tractor | Semi-Trailer | ||

| No-load mass | 4457 | 6000 | kg |

| Yaw inertia | 34,823 | 54,000 | Kg m2 |

| Roll inertia | 2287 | 10,140 | Kg m2 |

| Wheelbase | 3500 | 6700 (to hinge point) | m |

| Wheel distance | 2030/1863 | 1863 | mm |

| Wheel radius | 510/510 | 510 | mm |

| Centroid height | 1173 | 1935 | mm |

| Maximum brake pressure | 0.7 | 0.7 | mpa |

| Engine power | 225 | - | kw |

| Transmission | 7-speed MT | - | - |

| ec | ||||||||

|---|---|---|---|---|---|---|---|---|

| ml | mm | ms | ze | ps | pm | pl | ||

| ml | pl | pl | pl | pm | ps | ze | ze | |

| mm | pl | pl | pm | ps | ps | ze | ms | |

| ms | pm | pl | ps | ps | ze | ms | ms | |

| e | ze | pm | pm | ps | ze | ms | mm | mm |

| ps | ps | ps | ze | ms | ms | mm | mm | |

| pm | ps | ze | ms | mm | mm | mm | ml | |

| pl | ps | ze | mm | mm | mm | ml | ml | |

| ec | ||||||||

|---|---|---|---|---|---|---|---|---|

| ml | mm | ms | ze | ps | pm | pl | ||

| ml | pl | pl | pl | pm | ps | ze | ze | |

| mm | pl | pl | pm | ps | ps | ze | ms | |

| ms | pm | pl | ps | ps | ze | ms | ms | |

| e | ze | pm | pm | ps | ze | ms | mm | mm |

| ps | ps | ps | ze | ms | ms | mm | mm | |

| pm | ps | ze | ms | mm | mm | mm | ml | |

| pl | ps | ze | mm | mm | mm | ml | ml | |

| ec | ||||||||

|---|---|---|---|---|---|---|---|---|

| ml | mm | ms | ze | ps | pm | pl | ||

| ml | ms | ms | ml | ml | ml | mm | ps | |

| mm | ps | ms | ml | mm | mm | ms | ze | |

| ms | ze | ms | mm | mm | ms | ms | ze | |

| e | ze | ze | ms | ms | ms | ms | ms | ze |

| ps | ze | ze | ze | ze | ze | ze | ps | |

| pm | pl | ms | ps | ps | ps | ps | pl | |

| pl | pl | pm | pm | pm | ps | ps | pl | |

| Reference Yaw Rate | Actual Yaw Rate | Yaw Rate Deviation | Steering Characteristics | Target Brake Wheel |

|---|---|---|---|---|

| + | + | + | understeer | L2 |

| + | + | − | oversteer | R1 |

| + | + | 0 | neutral steer | \ |

| + | 0 | + | understeer | L2 |

| + | − | + | understeer | L1 |

| 0 | − | + | oversteer | L1 |

| 0 | + | − | oversteer | R1 |

| 0 | 0 | 0 | neutral steer | \ |

| − | − | − | understeer | R2 |

| − | − | + | oversteer | L1 |

| − | − | 0 | neutral steer | \ |

| − | + | − | understeer | R1 |

| − | 0 | − | understeer | R2 |

| Reference Yaw Rate | Actual Yaw Rate | Yaw Rate Deviation | Steering Characteristics | Target Wheel | |

|---|---|---|---|---|---|

| Drive | Brake | ||||

| + | + | + | understeer | R3 | L3 |

| + | + | − | oversteer | L3 | R3 |

| + | + | 0 | neutral steer | \ | \ |

| + | 0 | + | understeer | R3 | L3 |

| + | - | + | understeer | R3 | L3 |

| 0 | - | + | oversteer | R3 | L3 |

| 0 | + | − | oversteer | L3 | R3 |

| 0 | 0 | 0 | neutral steer | \ | \ |

| − | − | − | understeer | L3 | R3 |

| − | − | + | oversteer | R3 | L3 |

| − | − | 0 | neutral steer | \ | \ |

| − | + | − | understeer | L3 | R3 |

| − | 0 | − | understeer | L3 | R3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Z.; Lu, Y.; Li, Y. Method of Improving Lateral Stability by Using Additional Yaw Moment of Semi-Trailer. Energies 2020, 13, 6317. https://doi.org/10.3390/en13236317

Bai Z, Lu Y, Li Y. Method of Improving Lateral Stability by Using Additional Yaw Moment of Semi-Trailer. Energies. 2020; 13(23):6317. https://doi.org/10.3390/en13236317

Chicago/Turabian StyleBai, Zhenyuan, Yufeng Lu, and Yunxia Li. 2020. "Method of Improving Lateral Stability by Using Additional Yaw Moment of Semi-Trailer" Energies 13, no. 23: 6317. https://doi.org/10.3390/en13236317

APA StyleBai, Z., Lu, Y., & Li, Y. (2020). Method of Improving Lateral Stability by Using Additional Yaw Moment of Semi-Trailer. Energies, 13(23), 6317. https://doi.org/10.3390/en13236317