A Stacked Denoising Sparse Autoencoder Based Fault Early Warning Method for Feedwater Heater Performance Degradation

Abstract

:1. Introduction

2. Key Issues of FWH Fault Early Warning

2.1. Traditional Method Analysis

2.2. Presentation of Frequent Pattern Model

3. Stacked Denoising Sparse Autoencoder Based Frequent Pattern Modeling

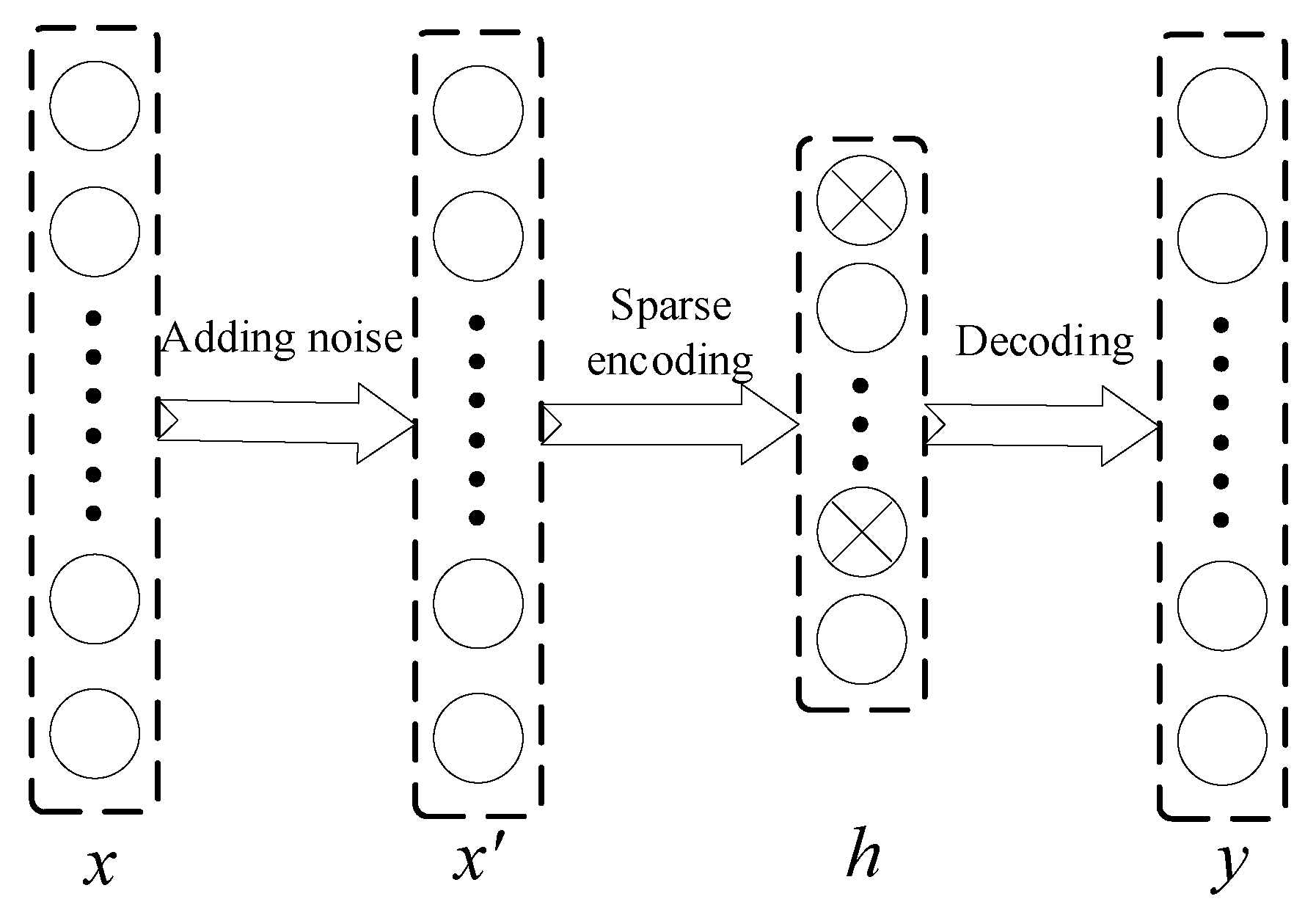

3.1. Feature Selection Based on Stacked Denoising Sparse Autoencoder

- First, train DSAE1 with the initial input x, and obtains weight, bias of hidden layer w11, b11 and the corresponding output h1;

- Then, train DSAE2 with the input h1, and obtains weight, bias of hidden layer w21, b21;

- Finally, a three hidden layer neural network is constructed. The weight and bias of the first hidden layer and the second hidden layer are set to w11, b11 and w21, b21, and the parameters are not updated in the subsequent network training process. According to BP algorithm, the neural network parameters of the third hidden layer and output layer are trained.

3.2. Technical Process of the Proposed Method

4. Experiment

4.1. Data Preparation

4.2. Fault Early Warning Experiment

4.2.1. Frequent Pattern Modeling

4.2.2. Fault Early Warning Experiment

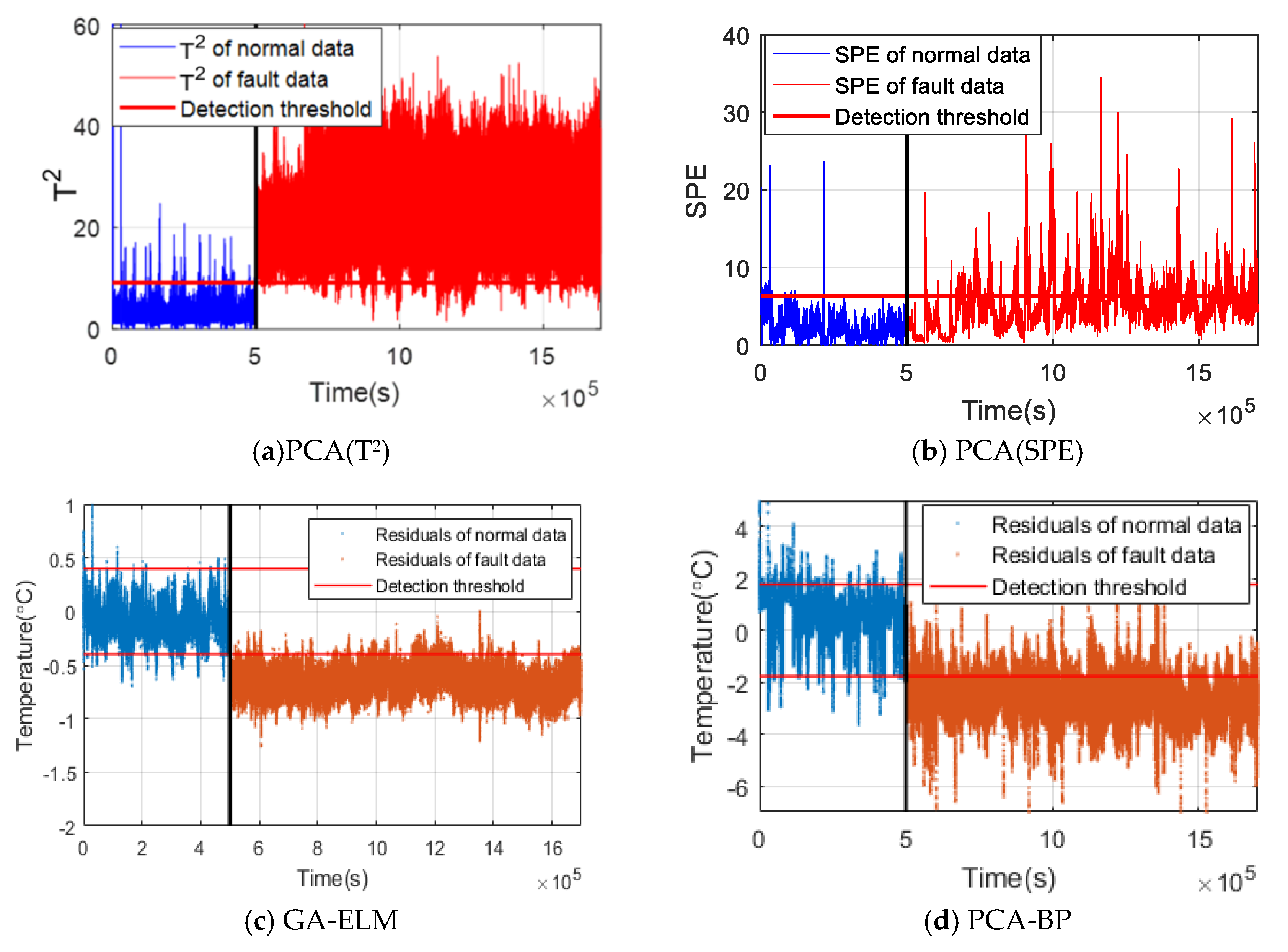

4.3. Comparison Experiment

4.3.1. The Necessity of Feature Reduction

4.3.2. Superiority of SDSAE based Feature Reduction Method

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baldwin, T.; Tawfik, M.; Bond, L. Report from the Light Water Reactor Sustainability Workshop on On-Line Monitoring Technologies; Technical Report No. INL/EXT-10-19500; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2010.

- Series, I.N.E. On-line Monitoring for Improving Performance of Nuclear Power Plants Part 2: Process and Component Condition Monitoring and Diagnostics; International Atomic Energy Agency (IAEA): Vienna, Austria, 2008. [Google Scholar]

- Akhtar, S.Z.; Phipps, M. Considerations for safe and effective design of feedwater heaters. Hydrocarb. Process. 2008, 87, 71–75. [Google Scholar]

- Vandani, A.M.K.; Joda, F.; Ahmadi, F.; Ahmadi, M.H. Exergoeconomic effect of adding a new feedwater heater to a steam power plant. Mech. Ind. 2017, 18, 224. [Google Scholar]

- Riesgo, A.; Folgueras, M.B. One feedwater heater taken out of service as a strategy to maintain full load and its effect on steam power cycle parameters and performance. Int. J. Energy Res. 2019, 43, 2296–2311. [Google Scholar]

- Zangeneh, S.; Bakhtiari, R. Failure investigation of a deaerating feed-water heater in a power plant. Eng. Fail. Anal. 2019, 101, 145–156. [Google Scholar]

- Karg, D.C.; Henderson, T.N.; Svensen, L.M., III. Analysis of feedwater heater performance data to detect and monitor pass partition plate leakage. In Proceedings of the 1996 International Joint Power Generation Conference, American Society of Mechanical Engineers, New York, NY, USA, 13–17 October 1996. [Google Scholar]

- Shabani, G.A.S.; Ameri, M.; Akbari, O.; Seifi, A. Performance assessment and leakage analysis of feed water pre-heaters in natural gas–fired steam power plants. J. Power Technol. 2018, 98, 352–364. [Google Scholar]

- Barszcz, T.; Czop, P. Estimation of feedwater heater parameters based on a grey-box approach. International J. Appl. Math. Comput. Sci. 2011, 21, 703–715. [Google Scholar]

- Barszcz, T.; Czop, P. A feedwater heater model intended for model-based diagnostics of power plant installations. Appl. Therm. Eng. 2011, 31, 1357–1367. [Google Scholar]

- Zhao, Y.; Wang, C.; Liu, M.; Chong, D.; Yan, J. Improving operational flexibility by regulating extraction steam of high-pressure heaters on a 660 MW supercritical coal-fired power plant: A dynamic simulation. Appl. Energy 2018, 212, 1295–1309. [Google Scholar]

- Chen, C.; Zhong, X.; Xiao, J.; Zhu, Y.; Jiang, J. Performance monitoring of regenerative system based on dominant factor method. In Proceedings of the ASME 2017 Power Conference Joint With ICOPE-17 collocated with the ASME 2017 11th International Conference on Energy Sustainability, the ASME 2017 15th International Conference on Fuel Cell Science, Engineering and Technology, and the ASME 2017 Nuclear Forum, Charlotte, NC, USA, 26–30 June 2017; American Society of Mechanical Engineers Digital Collection, 2017. [Google Scholar]

- Jiang, X.; Liu, P.; Li, Z. A data reconciliation based approach to accuracy enhancement of operational data in power plants. Chem. Eng. 2013, 35, 1213–1218. [Google Scholar]

- Wang, X.; Ma, L.; Wang, T. An optimized nearest prototype classifier for power plant fault diagnosis using hybrid particle swarm optimization algorithm. Int. J. Electr. Power Energy Syst. 2014, 58, 257–265. [Google Scholar]

- Li, F.; Upadhyaya, B.R.; Coffey, L.A. Model-based monitoring and fault diagnosis of fossil power plant process units using group method of data handling. ISA Trans. 2009, 48, 213–219. [Google Scholar] [PubMed]

- Kang, Y.K.; Kim, H.; Heo, G.; Song, S.Y. Diagnosis of feedwater heater performance degradation using fuzzy inference system. Expert Syst. With Appl. 2017, 69, 239–246. [Google Scholar]

- Ma, L.; Ma, Y.; Lee, K.Y. An intelligent power plant fault diagnostics for varying degree of severity and loading conditions. IEEE Trans. Energy Convers. 2010, 25, 546–554. [Google Scholar]

- Ma, L.; Wang, X.; Cao, X. Feedwater heater system fault diagnosis during dynamic transient process based on two-stage neural networks. In Proceedings of the 32nd IEEE Chinese Control Conference, Xi’an, China, 26–28 July 2013; pp. 6148–6153. [Google Scholar]

- Ma, L.; Ma, Y.; Ma, J. Fault diagnosis for the feedwater heater system of a 300mw coal-fired power generating unit based on RBF neural network. In Advances in Machine Learning and Cybernetics; Springer: Berlin/Heidelberg, Germany, 2006; pp. 832–841. [Google Scholar]

- Heo, G.; Lee, S.K. Internal leakage detection for feedwater heaters in power plants using neural networks. Expert Syst. Appl. 2012, 39, 5078–5086. [Google Scholar]

- Garcia, R.F. Improving heat exchanger supervision using neural networks and rule based techniques. Expert Syst. Appl. 2012, 39, 3012–3021. [Google Scholar]

- Radhakrishnan, V.R.; Ramasamy, M.; Zabiri, H.; Do Thanh, V.; Tahir, N.M.; Mukhtar, H.; Hamdi, M.R.; Ramli, N. Heat exchanger fouling model and preventive maintenance scheduling tool. Appl. Therm. Eng. 2007, 27, 2791–2802. [Google Scholar]

- Bengio, Y.; Courville, A.; Vincent, P. Representation learning: A review and new perspectives. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 1798–1828. [Google Scholar] [PubMed]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; Cambridge MIT Press: Cambridge, MA, USA, 2016; Chapter 14; Volume 1, pp. 499–507. [Google Scholar]

- Vincent, P.; Larochelle, H.; Bengio, Y.; Manzagol, P.A. Extracting and composing robust features with denoising autoencoders. In Proceedings of the International Conference on Machine Learning, Helsinki, Finland, 5–9 June 2008; pp. 1096–1103. [Google Scholar]

- Xu, J.; Xiang, L.; Liu, Q.; Gilmore, H.; Wu, J.; Tang, J.; Madabhushi, A. Stacked Sparse Autoencoder (SSAE) for Nuclei Detection on Breast Cancer Histopathology Images. IEEE Trans. Med Imaging 2016, 35, 119–130. [Google Scholar] [PubMed] [Green Version]

- Hecht-Nielsen, R. Theory of the backpropagation neural network. In Neural Networks for Perception; Academic Press: Cambridge, MA, USA, 1992; pp. 65–93. [Google Scholar]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1–32. [Google Scholar]

| No. | Parameter | No. | Parameter |

|---|---|---|---|

| 1 | #2 FWH inlet feedwater temperature | 7 | #2 FWH drain water temperature |

| 2 | #2 FWH U-tube metal temperature | 8 | #2 FWH water level |

| 3 | Feedwater mass flow | 9 | #2 FWH extraction steam pressure |

| 4 | Feedwater pressure | 10 | #2 FWH extraction steam temperature |

| 5 | #1 FWH extraction steam pressure | 11 | OFT |

| 6 | #1 FWH drain water temperature |

| Hyperparameters | DSAE1 | DSAE2 | BPNN |

|---|---|---|---|

| Degradation rate | 0.1 | 0.1 | - |

| Hidden layer neurons | 7 | 4 | 7 |

| Epochs | 1000 | 500 | 500 |

| L2 Regularization coefficient | 0.001 | 0.001 | - |

| Sparse regularization coefficient | 4 | 4 | - |

| Sparse parameter | 0.05 | 0.05 | - |

| Decoder transfer function | Purelin | Purelin | - |

| Training RMSE | Validation RMSE | Detection Threshold | Accuracy of Training Set | Accuracy of Validation Set | Fault Early Warning Set | |

|---|---|---|---|---|---|---|

| Accnormal | Accfault | |||||

| 0.0922 | 0.1006 | 0.2763 | 0.9967 | 0.9863 | 0.9958 | 1.0000 |

| No. | Modeling Method | Hidden Layer Neurons | Detection Threshold | Accuracy of Training Set | Accuracy of Validation Set | Fault Early Warning Set | |

|---|---|---|---|---|---|---|---|

| Accnormal | Accfault | ||||||

| 1 | ELM | (35) | 0.3512 | 0.9925 | 0.9151 | 0.8958 | 0.9316 |

| 2 | BPNN | (30) | 0.2349 | 0.9949 | 0.9190 | 0.9513 | 0.9267 |

| 3 | BPNN | (7-4-7) | 0.2462 | 0.9945 | 0.9117 | 0.9537 | 0.9716 |

| 4 | LSTM | (30) | 0.3908 | 0.9958 | 0.9924 | 0.9957 | 0.9927 |

| 5 | SDSAE-BP | (7-4-7) | 0.2763 | 0.9967 | 0.9863 | 0.9958 | 1.0000 |

| No. | Modeling Method | Detection Threshold | Accuracy of Training Set | Accuracy of Validation Set | Fault Early Warning Set | |

|---|---|---|---|---|---|---|

| Accnormal | Accfault | |||||

| 1 | PCA(T2) | 9.2104 | 0.9958 | 0.9820 | 0.9925 | 0.9506 |

| 2 | PCA(SPE) | 6.2763 | 0.9777 | 0.9492 | 0.9883 | 0.3097 |

| 3 | GA-ELM | 0.3981 | 0.9911 | 0.9833 | 0.9860 | 0.9888 |

| 4 | PCA-BP | 1.7658 | 0.9869 | 0.9576 | 0.9856 | 0.9248 |

| 5 | SDSAE-BP | 0.2763 | 0.9967 | 0.9863 | 0.9958 | 1.0000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, J.; Li, J.; Li, X.; Yan, P.; Yu, D. A Stacked Denoising Sparse Autoencoder Based Fault Early Warning Method for Feedwater Heater Performance Degradation. Energies 2020, 13, 6061. https://doi.org/10.3390/en13226061

Li X, Liu J, Li J, Li X, Yan P, Yu D. A Stacked Denoising Sparse Autoencoder Based Fault Early Warning Method for Feedwater Heater Performance Degradation. Energies. 2020; 13(22):6061. https://doi.org/10.3390/en13226061

Chicago/Turabian StyleLi, Xingshuo, Jinfu Liu, Jiajia Li, Xianling Li, Peigang Yan, and Daren Yu. 2020. "A Stacked Denoising Sparse Autoencoder Based Fault Early Warning Method for Feedwater Heater Performance Degradation" Energies 13, no. 22: 6061. https://doi.org/10.3390/en13226061

APA StyleLi, X., Liu, J., Li, J., Li, X., Yan, P., & Yu, D. (2020). A Stacked Denoising Sparse Autoencoder Based Fault Early Warning Method for Feedwater Heater Performance Degradation. Energies, 13(22), 6061. https://doi.org/10.3390/en13226061