The Integration of Hybrid Mini Thermal Power Plants into the Energy Complex of the Republic of Vietnam

Abstract

1. Introduction

2. Materials and Methods

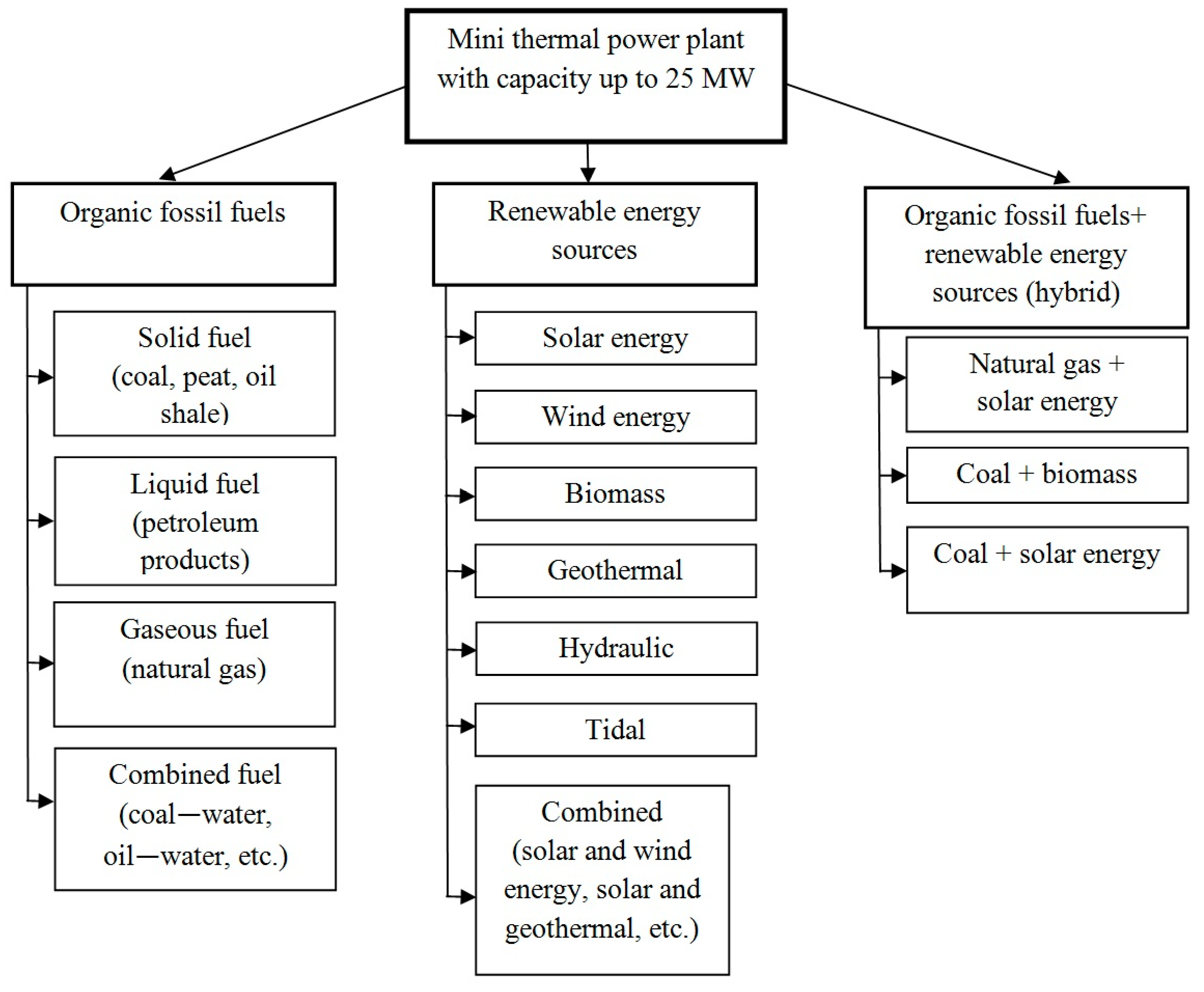

2.1. Mini Thermal Power Plant Classification

- By the number of resources. The number of energy resources is one of the factors that determine the complexity of HSRES, and its sustainability and efficiency; a large number of resources makes the system more complex, but at the same time, leads to increasing sustainability and energy efficiency;

- By the type of energy produced: Mechanical energy—each turbine, independently of its type generates mechanical energy, which can be used directly, for example for pumping water or to be subsequently converted into electrical energy. Electrical energy can be easily distributed and converted to another type. Electricity can also be stored and consumed when it is needed. Thermal energy is used for heating and for many industrial, civil and technological processes. Thermal energy can be provided by combustion or recuperated as waste heat from thermal power plants or directly collected by means of solar thermal collectors and systems that use geothermal energy. Chemical energy, for example, the fuel production such as the hydrogen production by electrolysis. Mixed type—a typical example is a power system with a solar thermal collector combined with a wind turbine and photovoltaic cells.

- By the availability of energy storage devices: with and without storage devices;

- According to the presence of a connection to the distribution network: mini thermal power plants with a connection to the centralized power system must be synchronized with the distribution system. Autonomous mini thermal power plants are used to supply power to utilizers remote from the centralized power system.

2.2. Characteristics of Climatic and Economic Conditions of the Republic of Vietnam

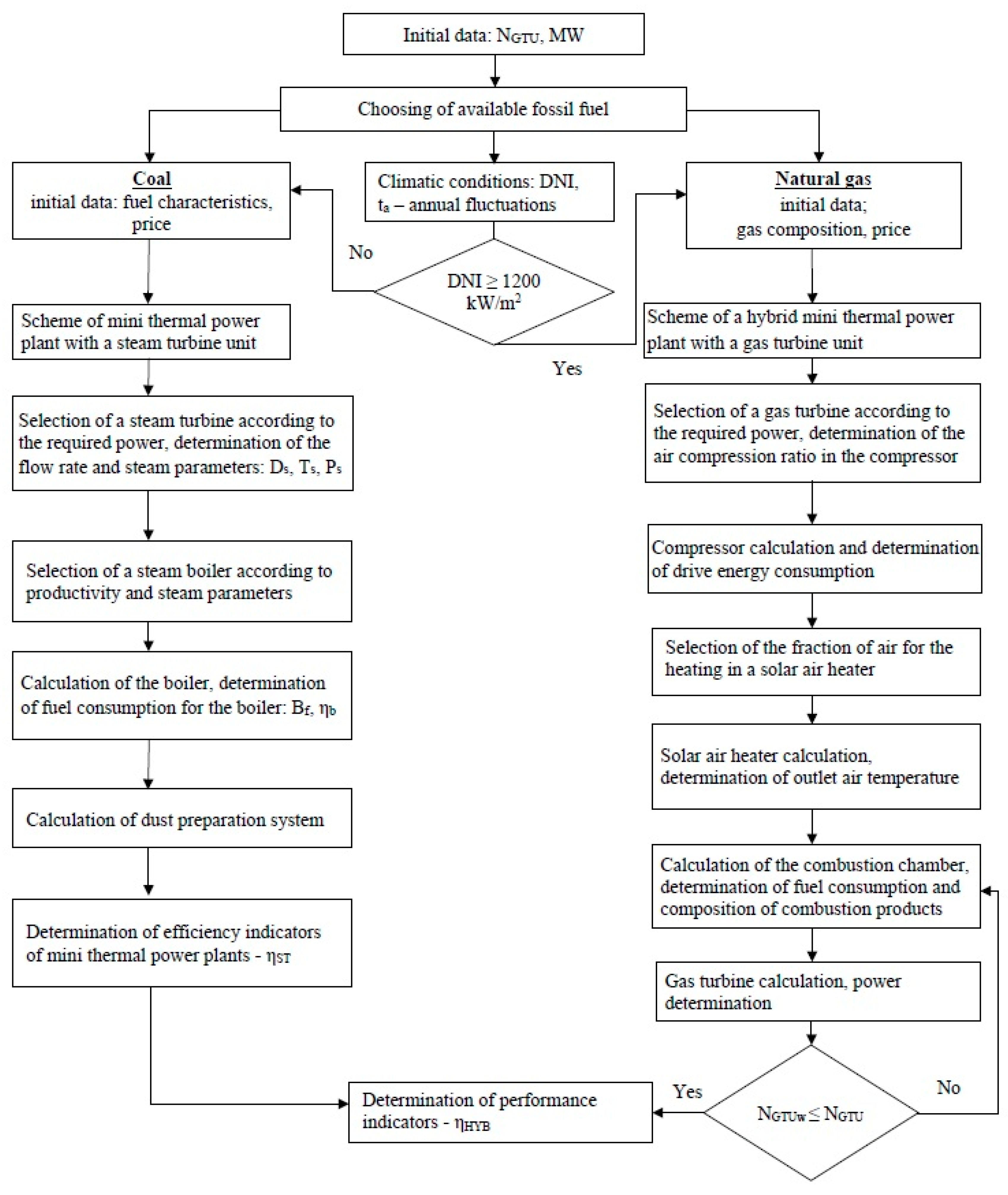

2.3. Used Algorithm for the Technological Scheme Selection of Mini Thermal Power Plant

2.4. Methodology of Calculating Mini Thermal Power Plants for Integration into the Energy System of the Republic of Vietnam

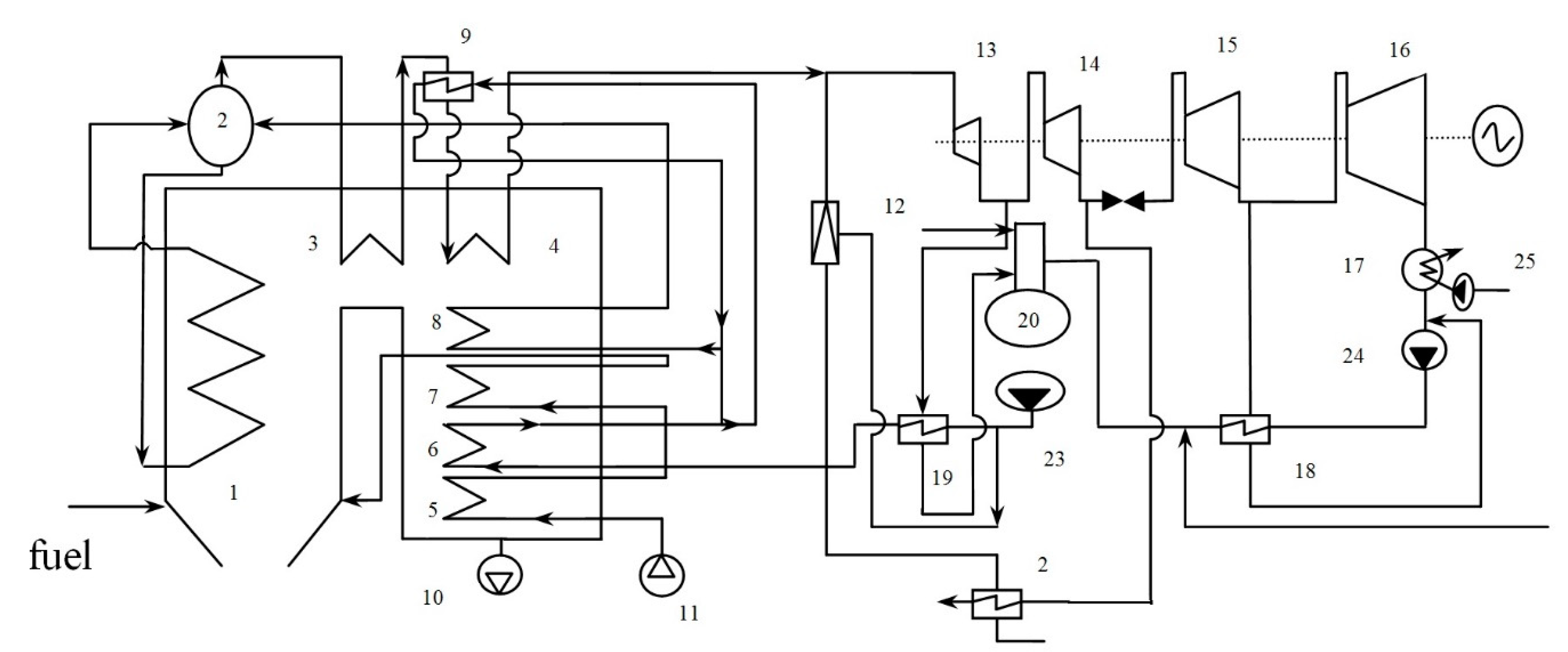

2.4.1. Exergy Efficiency Calculation Methodology Applied to a Steam-Turbine of a Mini Thermal Power Plant Operating with Coal

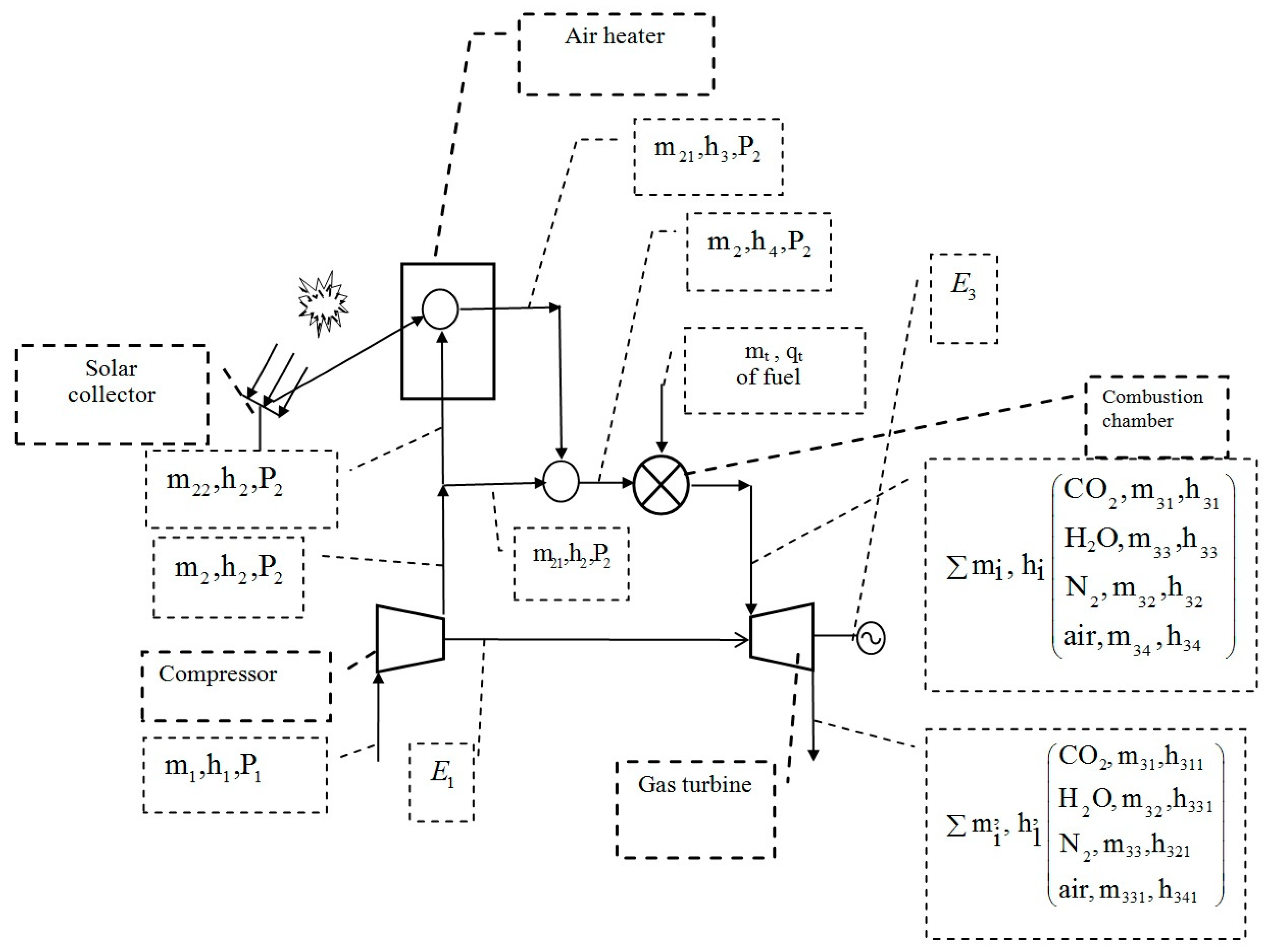

2.4.2. The Methodology for Calculating a Hybrid Mini Thermal Power Plant for Integration into the Power System of the Republic of Vietnam

2.4.3. Thermoeconomic Efficiency Calculation

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- World Seals Landmark Climate Accord, Marking Turn from Fossil Fuels. Reuters. Thomson Reuters (12 December 2015). Available online: http://www.reuters.com/article/us-climatechange-summit-idUSKBN0TV04L20151212#gVKudBATCD0EGdxL.97 (accessed on 24 September 2020).

- Suntio, T.; Messo, T. Power Electron. Renew. Energy Sources. Energies 2019, 12, 1852. [Google Scholar] [CrossRef]

- Opportunities for Research and Development of Hybrid Power Plants. Technical Report NREL/TP-5000-75026 May 2020. Available online: https://www.nrel.gov/docs/fy20osti/75026.pdf (accessed on 24 September 2020).

- Minh, D.T.; Sharma, D. Vietnam’s energy sector: A review of current energy policies and strategies. Energy Police 2011, 39, 5770–5777. [Google Scholar] [CrossRef]

- Nguyen, K.Q. Alternatives to grid extension for rural electrification: Decentralized renewable energy technologies in Vietnam. Energy Police 2007, 35, 2579–2589. [Google Scholar] [CrossRef]

- Khanh, T.P.; Minh, B.N.; Ha, D.N. Energy supply, demand, and policy in Vietnam, with future projections. Energy Police 2011, 39, 6814–6826. [Google Scholar] [CrossRef]

- Thenepalli, T.; Ngoc, N.T.M.; Tuan, L.Q.; Son, T.H.; Hieu, H.H.; Thuy, D.T.N.; Thao, N.T.T.; Tam, D.T.T.; Huyen, D.T.N.; Van, T.T.; et al. Technological Solutions for Recycling Ash Slag from the Cao Ngan Coal Power Plant in Vietnam. Energies 2018, 11, 2018. [Google Scholar] [CrossRef]

- Polo, J.; Bernardos, A.; Navarro, A.A. Fernandez-Peruchena, C.M. Solar resources and power potential mapping in Vietnam using satellite-derived and GIS-based information. Energy Convers. Manag. 2015, 98, 98348–98358. [Google Scholar] [CrossRef]

- Seshie, Y.M.; N’Tsoukpoe, K.E.; Neveu, P.; Coulibaly, Y.; Azoumah, Y.K. Small scale concentrating solar plants for rural electrification. Renew. Sustain. Energy Rev. 2018, 90, 195–209. [Google Scholar] [CrossRef]

- Gambini, M.; Vellini, M.; Stilo, T.; Manno, M.; Bellocchi, S. High-Efficiency Cogeneration Systems: The Case of the Paper Industry in Italy. Energies 2019, 12, 335. [Google Scholar] [CrossRef]

- Calise, F.; d’Accadia, M.D.; Piacentino, A.; Vicidomini, M. Thermoeconomic Optimization of a Renewable Polygeneration System Serving a Small Isolated Community. Energies 2015, 8, 995–1024. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, H.; Chen, L. Comparative Study of Electric Energy Storages and Thermal Energy Auxiliaries for Improving Wind Power Integration in the Cogeneration System. Energies 2018, 11, 263. [Google Scholar] [CrossRef]

- Abagnale, C.; Cameretti, M.C.; De Robbio, R.; Tuccillo, R. Thermal Cycle and Combustion Analysis of a Solar-Assisted Micro Gas Turbine. Energies 2017, 10, 773. [Google Scholar] [CrossRef]

- Huang, S.; Li, C.; Tan, T.; Fu, P.; Wang, L.; Yang, Y. Comparative Evaluation of Integrated Waste Heat Utilization Systems for Coal-Fired Power Plants Based on In-Depth Boiler-Turbine Integration and Organic Rankine Cycle. Entropy 2018, 20, 89. [Google Scholar] [CrossRef]

- Stoltmann, A. Hybrid Multi-Criteria Method of Analyzing the Location of Distributed Renewable Energy Sources. Energies 2020, 13, 4109. [Google Scholar] [CrossRef]

- Afanasyeva, O.V.; Mingaleeva, G.R. Thermo-economic efficiency of low capacity coal-based power plants. Int. J. Exergy 2011, 8, 175–193. [Google Scholar] [CrossRef]

- Afanasyeva, O.V.; Mingaleeva, G.R. Comprehensive exergy analysis of the efficiency of a low-capacity power plant with coal gasification and obtaining sulfur. Energy Effic. 2015, 8, 255–265. [Google Scholar] [CrossRef]

- Pirkandi, J.; Jahromi, M.; Sajadi, S.Z.; Ommian, M. Thermodynamic performance analysis of three solid oxide fuel cell and gas microturbine hybrid systems for application in auxiliary power units. Clean Technol. Environ. Policy 2018, 20, 1047–1060. [Google Scholar] [CrossRef]

- Mantripragada, H.C.; Rubin, E.S. Techno-economic evaluation of coal-to-liquids (CTL) plants with carbon capture and sequestration. Energy Policy 2011, 39, 2808–2816. [Google Scholar] [CrossRef]

- Raj, N.T.; Iniyan, S.; Goic, R. A review of renewable energy based cogeneration technologies. Renew. Sustain. Energy Rev. 2011, 15, 3640–3648. [Google Scholar] [CrossRef]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen-Geiger climate classification. Hydrol. Earth Syst. Sci. Discuss. 2007, 4, 439–473. [Google Scholar] [CrossRef]

- Valero, A.; Serra, L. Fundamentals of exergy cost accounting and thermoeconomics. Trans. ASME. J. Energy Resour. Technol. Pt. 1 Theory Cent. Energy Resour. Consum. 2006, 1, 1–8. [Google Scholar]

- Ozgur, B. Exergoeconomic analysis of a combined heat and power (CHP) system. Int. J. Energy 2008, 32, 273–289. [Google Scholar]

- Essackjee, I.A.; Ah King, R.T.F. Impact of Introducing Small Scale Distributed Generation on Technical Losses in a Secondary Distribution Network. LNNE 2006, 416, 71–80. [Google Scholar]

- Hooshmand, R.; Ataei, M. Optimal capacitor placement inactual configuration and operational conditions of distribution system using RCGA. J. Electr. Eng. 2007, 58, 189–199. [Google Scholar]

- Dlfanti, M.; Granelli, G.P.; Maranninio, P. Optimal capacitor placement using deterministic and genetic algorithm. IEEE Trans. Power Syst. 2000, 15, 1041–1046. [Google Scholar] [CrossRef]

- Reddy, M.D.; Reddy, V.C. Optimal capacitor placement using fuzzy and real coded genetic algorithm for maximum savings. J. Theor. Appl. Inf. Technol. 2008, 4, 219–226. [Google Scholar]

- Huang, T.; Hsiao, Y.; Jiang, C.J. Optimal placement of capacitors in distribution systems using an immune multi–objective algorithm. Int. J. Electr. Power Energy Syst. 2008, 30, 184–192. [Google Scholar] [CrossRef]

- Hattacharya, S.K.; Goswami, S.K. A new fuzzy based solution of the capacitor placement problem in radial distribution system. Expert Syst. Appl. 2009, 36, 4207–4212. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Z.; Sharma, S.; Mian, A.; Lin, T.-E.; Tsatsaronis, G.; Maréchal, F.; Yang, Y.A. Review of Evaluation, Optimization and Synthesis of Energy Systems: Methodology and Application to Thermal Power Plants. Energies 2019, 12, 73. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Yang, Z.; Wei, Q.; Wang, N.; Wang, L. The Application of Cyber Physical System for Thermal Power Plants: Data-Driven Modeling. Energies 2018, 11, 690. [Google Scholar] [CrossRef]

- Martynovsky, V. Analysis of Actual Thermodynamic Cycles; Energiya: Moscow, Russia, 1972; p. 206. [Google Scholar]

- Kuznetsov, N.; Mitor, V.; Dubovskiy, I.; Karasina, E. Thermal Calculation of Boiler Units. Standard Method; EKOLIT: Moscow, Russia, 2011; p. 296. [Google Scholar]

- Szargut, J.; Petela, R. Egzergia; Wydawnictwo naukowo-techniczne: Warszawa, Poland, 1965; p. 411. [Google Scholar]

- Stepanov, V. The Chemical Energy and Exergy of Substances, 2nd ed.; Nauka: Novosibirsk, Russia, 1990; p. 164. [Google Scholar]

- Nguen, D.T.; Pham, D.N.; Mingaleeva, G.R.; Afanaseva, O.V.; Zunino, P. Assessment of efficiency and prospects for the use of hybrid thermal low-capacity power plants in the Republic of Vietnam. E3S Web Conf. 2019, 124, 01040. [Google Scholar] [CrossRef]

- Yantovsky, E. Energy and Exergy Currents; Nauka: Moscow, Russia, 1988; p. 144. [Google Scholar]

| № | Province or City Name | GDP per Capita (thousand USD/person/year) | Population, People | Solar Radiation Intensity DNI, kW/m2 |

|---|---|---|---|---|

| Coal-fired steam turbine mini thermal power plants | ||||

| 1 | Hai Fong | 4.217 | 1,837,173 | 700 |

| 2 | Quang Ninh | 5.11 | 1,320,324 | 675 |

| Hybrid gas turbine mini thermal power plants | ||||

| 3 | Binh Duong | 5.681 | 2,426,561 | 1285 |

| 4 | Da Nang | 3.612 | 1,134,310 | 1293 |

| 5 | Heng Hoa | 2.698 | 1,231,107 | 1620 |

| 6 | Ninh Thuan | 1.724 | 590,467 | 1764 |

| 7 | Ho Chi Minh | 6.725 | 8,993,082 | 1443 |

| Option: 20% Coal-Fired Steam Turbine (Coal Type 4b) and 80% Hybrid Gas Turbine Mini Thermal Power Plants | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Name of Province/City | Capacity of Mini Thermal Power Plant, MW | Amount of Mini Thermal Power Plants | Fuel Consumption for one Mini Thermal Power Plant, kg/s | Initial Investment, US $ Million | Cost of Operation and Maintenance per year, US $ Million | Fuel Costs per year, US $ million | Exergy Efficiency, ηex, % | Thermo-economic Efficiency, φ, % |

| Coal Steam Turbine | Hai Phong + Quang Ninh | 25 | 4 | 2.85 | 150 | 3.33 | 29.75 | 34.67 | 4.85 |

| Hybrid Mini Thermal Power Plants | Binh Duong | 4.6 | 14 | 0.24 | 190 | 0.71 | 61.19 | 36.3 | 7.02 |

| 11.86 | 2 | 0.685 | 71.16 | 0.26 | 24.95 | 32.8 | 6.75 | ||

| Da Nang | 4.6 | 5 | 0.239 | 69 | 0.26 | 21.76 | 36.4 | 7.02 | |

| 11.86 | 0 | 0.679 | 0 | 0 | 0 | 33.0 | 0 | ||

| Heng Hoa | 4.6 | 14 | 0.235 | 193 | 0.71 | 59.92 | 37.0 | 7.07 | |

| 11.86 | 2 | 0.671 | 71.16 | 0.26 | 24.44 | 33.5 | 6.81 | ||

| Ninh Thuan | 4.6 | 24 | 0.233 | 331 | 1.23 | 102 | 37.3 | 7.09 | |

| 11.86 | 8 | 0.667 | 285 | 1.05 | 97.18 | 33.7 | 6.82 | ||

| Ho Chi Minh | 4.6 | 14 | 0.238 | 193 | 0.71 | 60.68 | 36.6 | 7.04 | |

| 11.86 | 0 | 0.678 | 0 | 0 | 0 | 33.1 | 0 | ||

| Total (average) values | 568.9 | 1560 | 8.54 | 482 | 35.57 | 6.77 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mingaleeva, G.; Afanaseva, O.; Nguen, D.T.; Pham, D.N.; Zunino, P. The Integration of Hybrid Mini Thermal Power Plants into the Energy Complex of the Republic of Vietnam. Energies 2020, 13, 5848. https://doi.org/10.3390/en13215848

Mingaleeva G, Afanaseva O, Nguen DT, Pham DN, Zunino P. The Integration of Hybrid Mini Thermal Power Plants into the Energy Complex of the Republic of Vietnam. Energies. 2020; 13(21):5848. https://doi.org/10.3390/en13215848

Chicago/Turabian StyleMingaleeva, Guzel, Olga Afanaseva, Duc Toan Nguen, Dang Nayt Pham, and Pietro Zunino. 2020. "The Integration of Hybrid Mini Thermal Power Plants into the Energy Complex of the Republic of Vietnam" Energies 13, no. 21: 5848. https://doi.org/10.3390/en13215848

APA StyleMingaleeva, G., Afanaseva, O., Nguen, D. T., Pham, D. N., & Zunino, P. (2020). The Integration of Hybrid Mini Thermal Power Plants into the Energy Complex of the Republic of Vietnam. Energies, 13(21), 5848. https://doi.org/10.3390/en13215848