Coproduction of Furfural, Phenolated Lignin and Fermentable Sugars from Bamboo with One-Pot Fractionation Using Phenol-Acidic 1,4-Dioxane

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

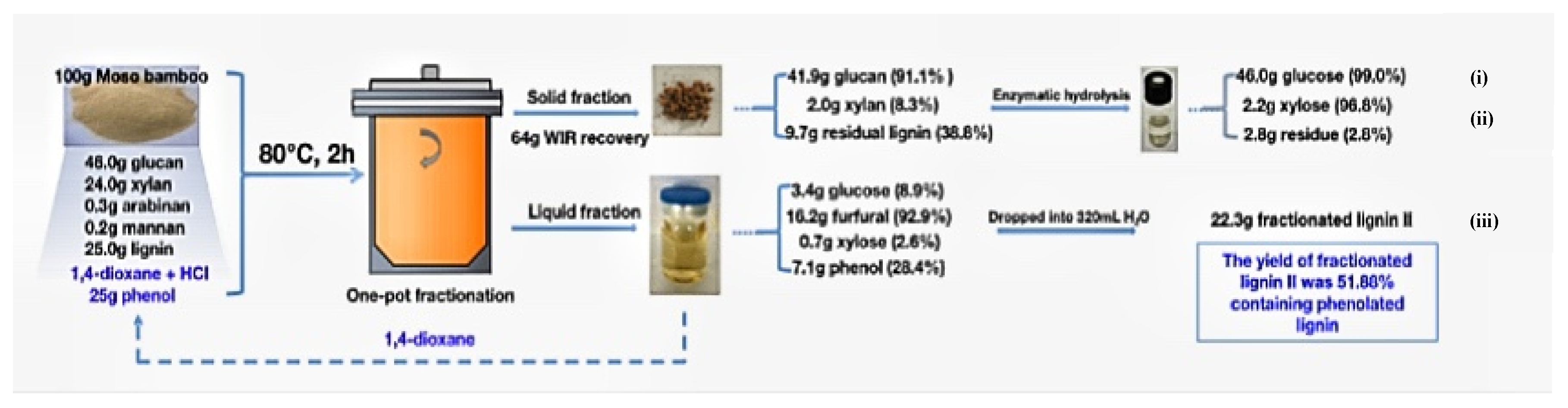

2.2. Standard Procedure for Lignocellulose Fractionation

2.3. Enzymatic Hydrolysis

2.4. Analysis Methods

2.5. Characterization of the Fractionated Lignin I and II

2.6. Statistical Analysis

2.7. Severity Factor

3. Results and Discussion

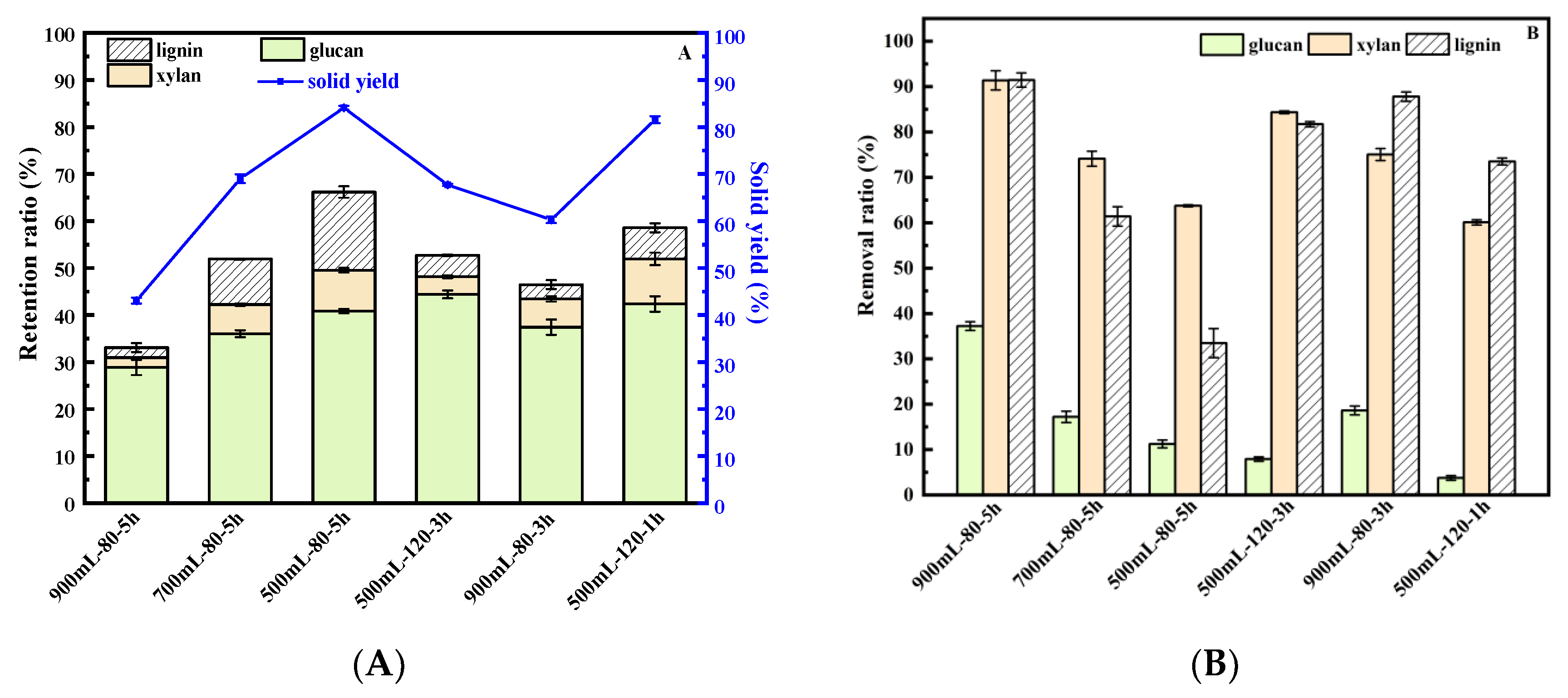

3.1. Influence of 1,4-Dioxane Dosage on Fractionation

3.2. Influence of Phenol Addition on Fractionation

3.3. Conversion of Hemicellulose to Furfural

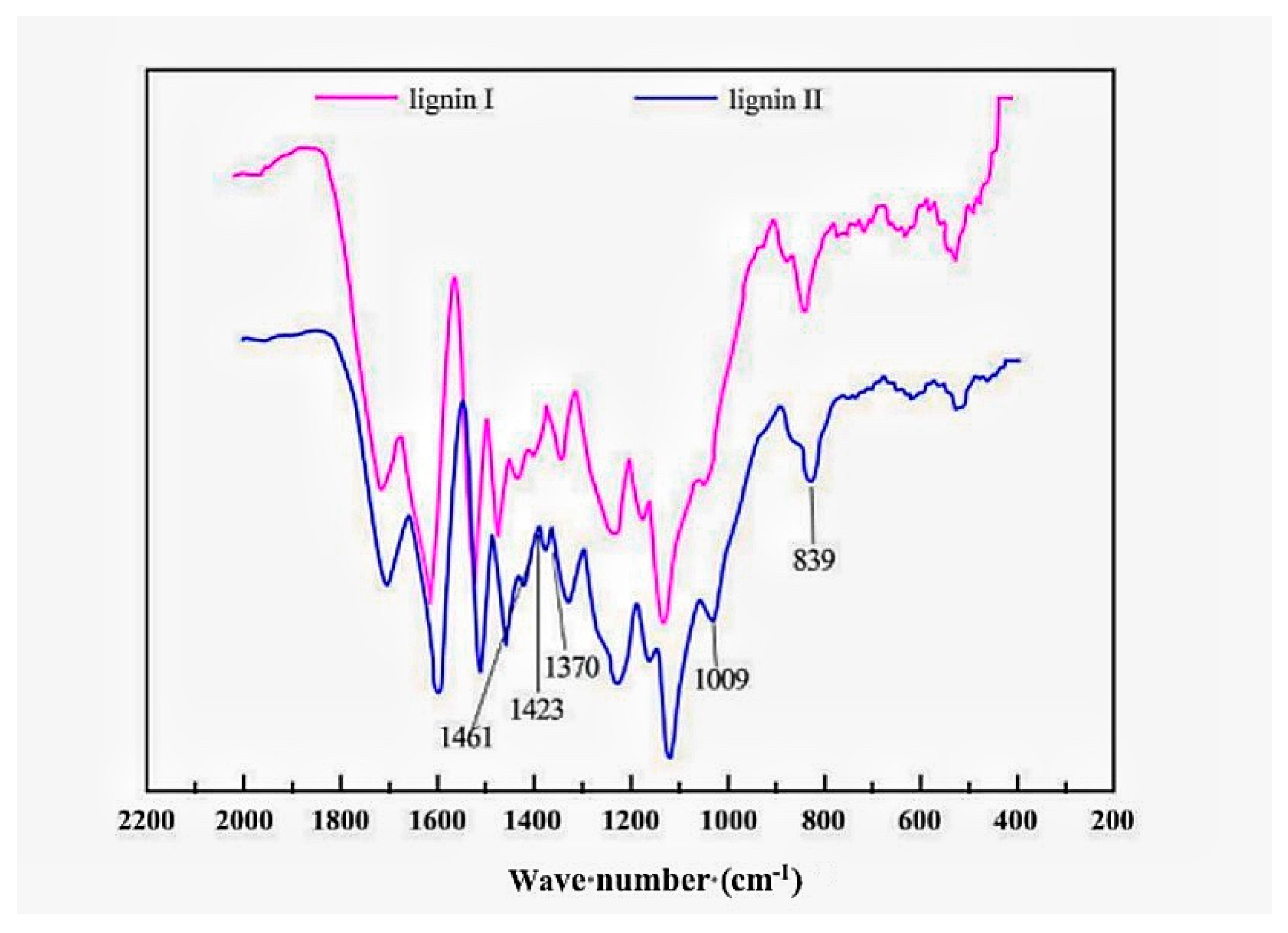

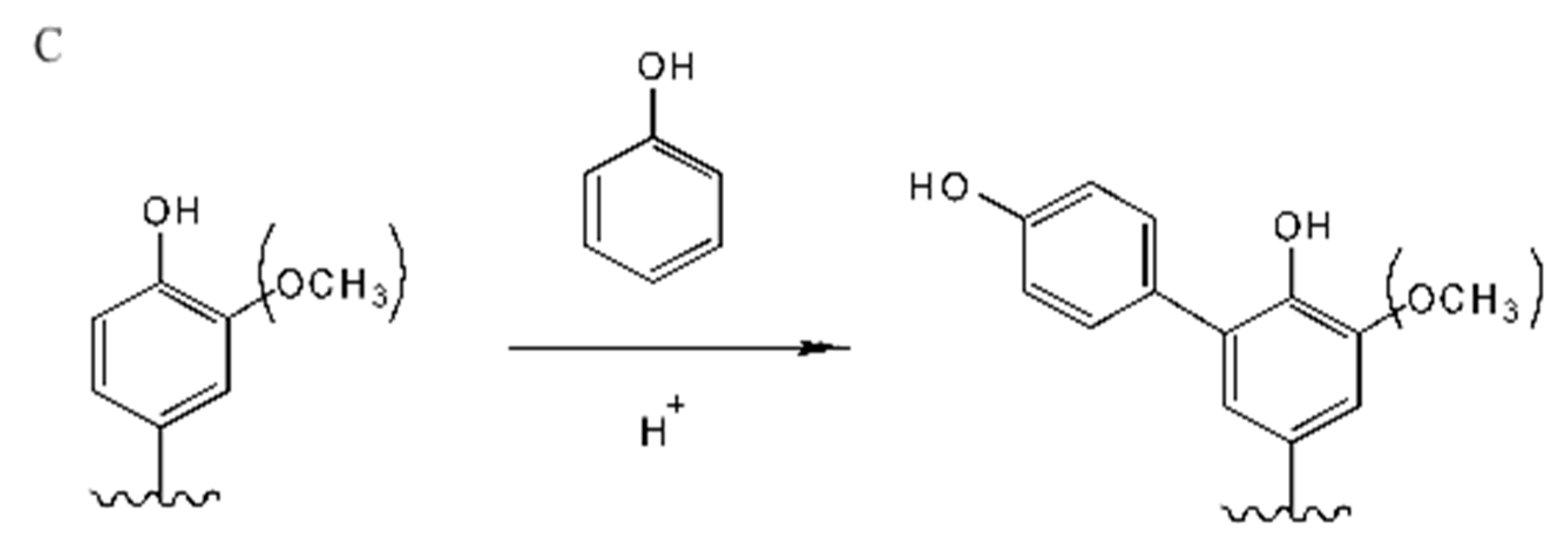

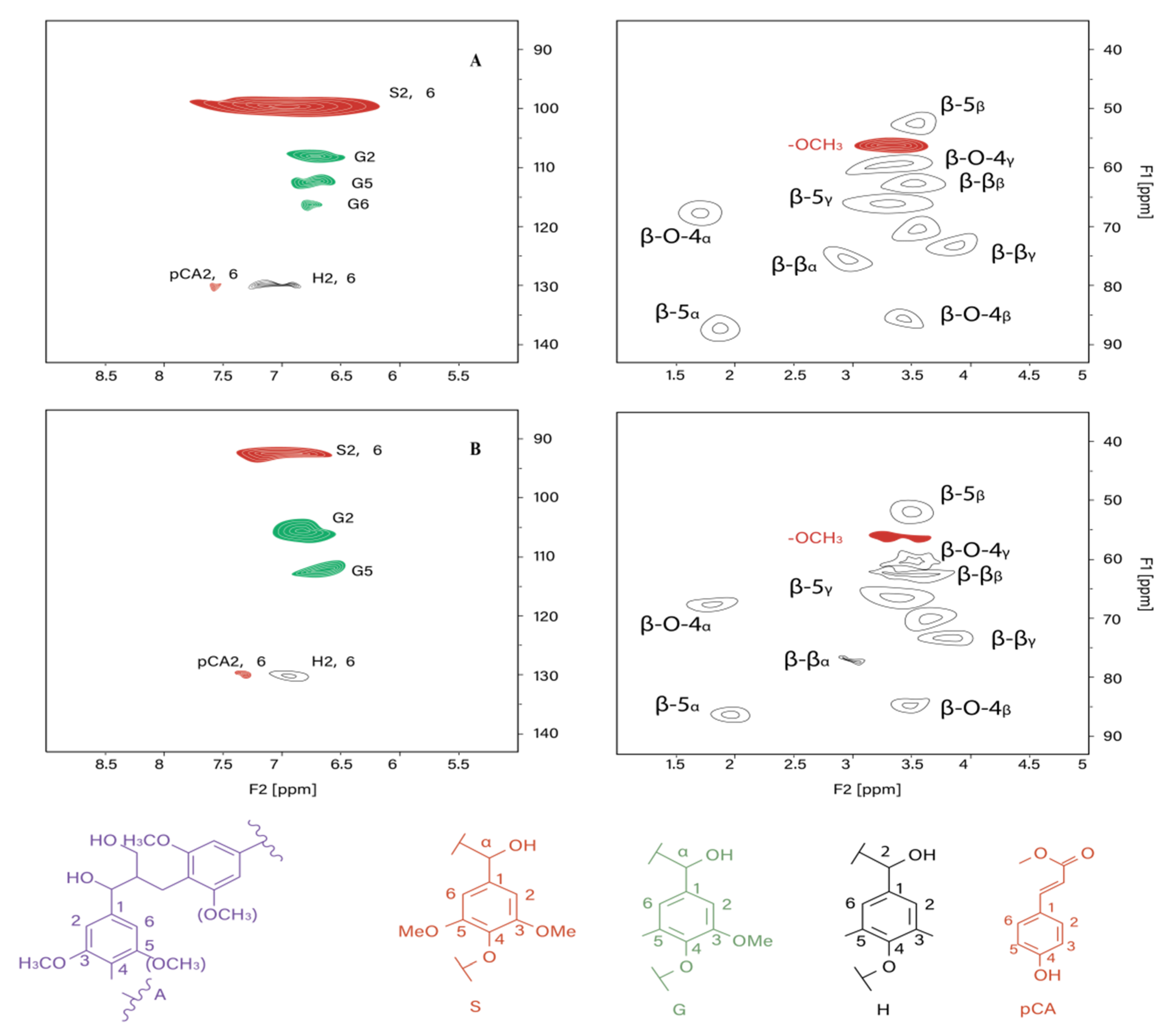

3.4. Conversion of Lignin to Phenolated Lignin

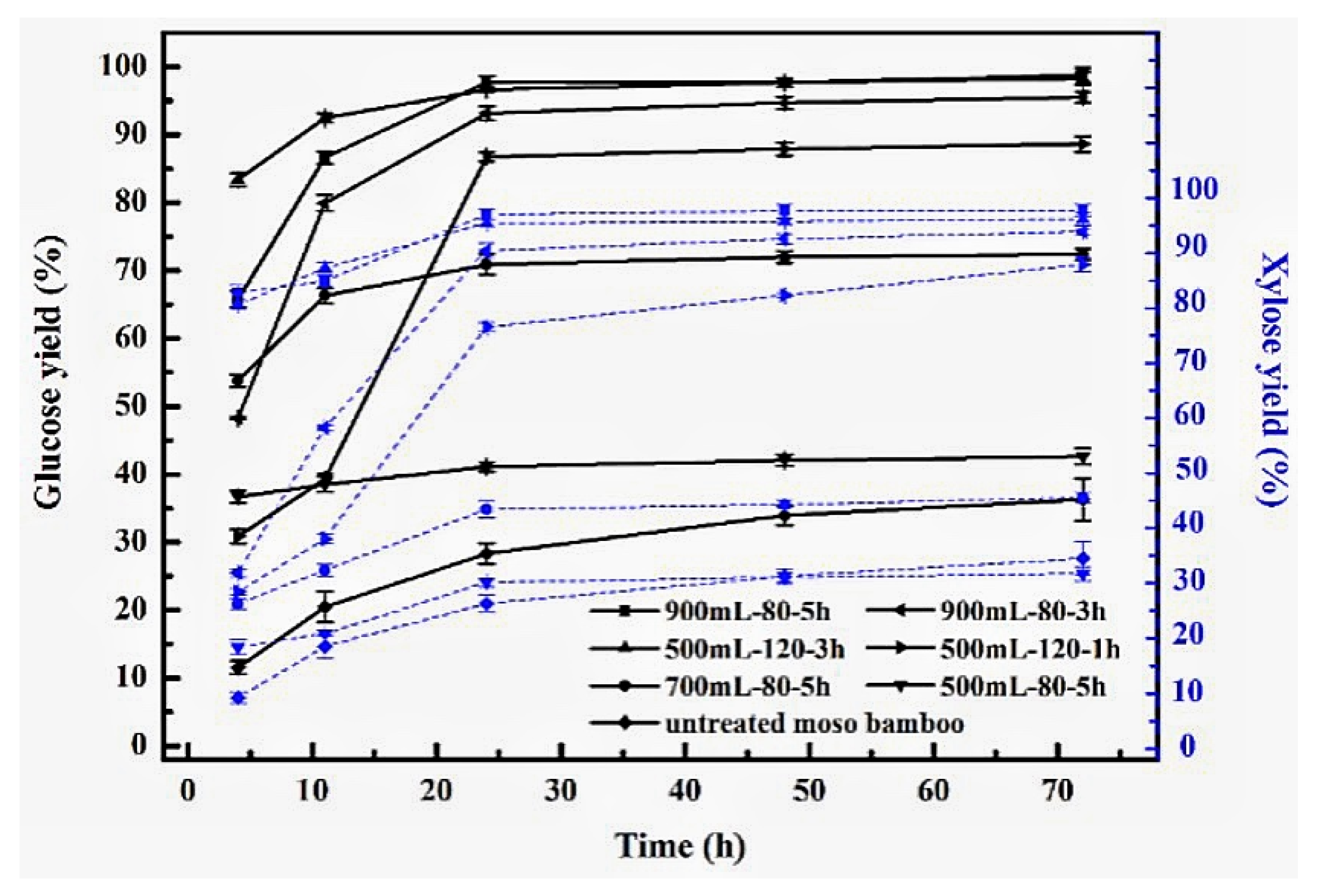

3.5. Conversion of Carbohydrate Pulps to Fermentable Sugars

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Welker, C.M.; Balasubramanian, V.K.; Petti, C.; Rai, K.M.; DeBolt, S.; Mendu, V. Engineering Plant Biomass Lignin Content and Composition for Biofuels and Bioproducts. Energies 2015, 8, 7654–7676. [Google Scholar] [CrossRef]

- Nitsos, C.K.; Choli, P.T.; Matis, K.A.; Triantafyllidis, K.S. Optimization of Hydrothermal Pretreatment of Hardwood and Softwood Lignocellulosic Residues for Selective Hemicellulose Recovery and Improved Cellulose Enzymatic Hydrolysis. ACS Sustain. Chem. Eng. 2016, 4, 4529–4544. [Google Scholar] [CrossRef]

- Kohli, K.; Prajapati, R.; Sharma, B.K. Bio-Based Chemicals from Renewable Biomass for Integrated Biorefineries. Energies 2019, 12, 233. [Google Scholar] [CrossRef]

- Sun, Z.; Fridrich, B.; De Santi, A.; Elangovan, S.; Barta, K. Bright Side of Lignin Depolymerization: Toward New Platform Chemicals. Chem. Rev. 2018, 118, 614–678. [Google Scholar] [CrossRef] [PubMed]

- Soto, L.R.; Byrne, E.; van Niel, E.W.; Sayed, M.; Villanueva, C.C.; Hatti-Kaul, R. Hydrogen and polyhydroxybutyrate production from wheat straw hydrolysate using Caldicellulosiruptor species and Ralstonia eutropha in a coupled process. Bioresour. Technol. 2019, 272, 259–266. [Google Scholar] [CrossRef]

- Silveira, L.; Morais, C.; da Costa Lopes, A.M.; Olekszyszen, D.N.; Bogel-Łukasik, R.; Andreaus, J.; Pereira, L. Current Pretreatment Technologies for the Development of Cellulosic Ethanol and Biorefineries. ChemSusChem 2015, 8, 3366–3390. [Google Scholar] [CrossRef]

- Cantero, D.A.; Martínez, C.; Bermejo, M.D.; Cocero, M.J. Simultaneous and selective recovery of cellulose and hemicellulose fractions from wheat bran by supercritical water hydrolysis. Green Chem. 2015, 17, 610–618. [Google Scholar] [CrossRef]

- Constant, S.; Wienk, H.L.J.; Frissen, A.E.; De Peinder, P.; Boelens, R.; Van Es, D.S.; Grisel, R.J.H.; Weckhuysen, B.M.; Huijgen, W.J.J.; Gosselink, R.; et al. New insights into the structure and composition of technical lignins: A comparative characterisation study. Green Chem. 2016, 18, 2651–2665. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Hou, J.; Ni, Y.; Liu, S.; Liu, Y.; Wu, C. Efficient Fractionation of Corn Stover for Biorefinery Using a Sustainable Pathway. ACS Sustain. Chem. Eng. 2020, 8, 3454–3464. [Google Scholar] [CrossRef]

- Renders, T.; van den Bosch, S.; Koelewijn, S.F.; Schutyser, W.; Sels, B.F. Lignin-first biomass fractionation: The advent of active stabilisation strategies. Energy Environ. Sci. 2017, 10, 1551–1557. [Google Scholar] [CrossRef]

- Galkin, M.V.; Samec, J.M. Lignin Valorization through Catalytic Lignocellulose Fractionation: A Fundamental Platform for the Future Biorefinery. ChemSusChem 2016, 9, 1544–1558. [Google Scholar] [CrossRef] [PubMed]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin Valorization: Improving Lignin Processing in the Biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- Liao, Y.; Koelewijn, S.F.; van den Bossche, G.; Van Aelst, J.; van den Bosch, S.; Renders, T.; Navare, K.; Nicolaï, T.; Van Aelst, K.; Maesen, M.; et al. A sustainable wood biorefinery for low–carbon footprint chemicals production. Science 2020, 367, 1385–1390. [Google Scholar] [CrossRef] [PubMed]

- You, X.; Koda, K.; Yamada, T.; Uraki, Y. Preparation of electrode for electric double layer capacitor from electrospun lignin fibers. Holzforschung 2015, 69, 1097–1106. [Google Scholar] [CrossRef]

- Balgis, R.; Sago, S.; Anilkumar, G.M.; Ogi, T.; Okuyama, K. Self-Organized Macroporous Carbon Structure Derived from Phenolic Resin via Spray Pyrolysis for High-Performance Electrocatalyst. ACS Appl. Mater. Interfaces 2013, 5, 11944–11950. [Google Scholar] [CrossRef] [PubMed]

- Alma, M.H.; Salan, T.; Zhao, G. Effect of different acid catalysts on the properties of activated carbon fiber precursors obtained from phenolated wheat straw. J. Nat. Fibers 2018, 16, 781–794. [Google Scholar] [CrossRef]

- Jiang, X.; Liu, J.; Du, X.; Hu, Z.; Chang, H.-M.; Jameel, H. Phenolation to Improve Lignin Reactivity toward Thermosets Application. ACS Sustain. Chem. Eng. 2018, 6, 5504–5512. [Google Scholar] [CrossRef]

- Renders, T.; Cooreman, E.; van den Bosch, S.; Schutyser, W.; Koelewijn, S.-F.; Vangeel, T.; Deneyer, A.; Bossche, G.V.D.; Courtin, C.M.; Sels, B.F. Catalytic lignocellulose biorefining in n-butanol/water: A one-pot approach toward phenolics, polyols, and cellulose. Green Chem. 2018, 20, 4607–4619. [Google Scholar] [CrossRef]

- Lopes, H.J.S.; Bonturi, N.; Miranda, E.A. Rhodotorula toruloides Single Cell Oil Production Using Eucalyptus urograndis Hemicellulose Hydrolysate as a Carbon Source. Energies 2020, 13, 795. [Google Scholar] [CrossRef]

- Shuai, L.; Amiri, M.T.; Questell-Santiago, Y.M.; Héroguel, F.; Li, Y.; Kim, H.; Meilan, R.; Chapple, C.; Ralph, J.; Luterbacher, J.S. Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science 2016, 354, 329–333. [Google Scholar] [CrossRef]

- Tang, Y.; Chandra, R.P.; Sokhansanj, S.; Saddler, J.N. Influence of steam explosion processes on the durability and enzymatic digestibility of wood pellets. Fuel 2018, 211, 87–94. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of structural carbohydrates and lignin in biomass. Lab. Anal. Proced. 2008, 1617, 1–16. [Google Scholar]

- Cao, Z.X.; Ye, Y.J.; Guo, Y.X. Determination of residual phenol in rigid phenolic foam by Gas Chromatography. Guangdong Chem. Indus. 2012, 8, 27–28. [Google Scholar]

- Wen, J.-L.; Sun, Z.; Sun, Y.-C.; Sun, R.; Xu, F.; Sun, R.C. Structural Characterization of Alkali-Extractable Lignin Fractions from Bamboo. J. Biobased Mater. Bioenergy 2010, 4, 408–425. [Google Scholar] [CrossRef]

- Peng, C.; Chen, Q.; Guo, H.; Hu, G.; Li, C.; Wen, J.-L.; Wang, H.; Zhang, T.; Zhao, Z.K.; Sun, R.; et al. Effects of Extraction Methods on Structure and Valorization of Corn Stover Lignin by a Pd/C Catalyst. ChemCatChem 2017, 9, 1135–1143. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y.; Yue, W.; Wang, W.; Wang, Y.-Y.; Yuan, T.-Q.; Sun, R. Valorization of lignin and cellulose in acid-steam-exploded corn stover by a moderate alkaline ethanol post-treatment based on an integrated biorefinery concept. Biotechnol. Biofuels 2016, 9, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; You, Y.; Lei, F.-H.; Li, P.; Jiang, J.; Zhu, L. Enhancement of enzymatic hydrolysis of sugarcane bagasse by pretreatment combined green liquor and sulfite. Fuel 2017, 203, 707–714. [Google Scholar] [CrossRef]

- Kosyakov, D.S.; Ul’Yanovskii, N.V.; Anikeenko, E.A.; Gorbova, N.S. Negative ion mode atmospheric pressure ionization methods in lignin mass spectrometry: A comparative study. Rapid Commun. Mass Spectrom. 2016, 30, 2099–2108. [Google Scholar] [CrossRef]

- Chen, R.; Liu, C.; Johnson, N.W.; Zhang, L.; Mahendra, S.; Liu, Y.; Dong, Y.; Chen, M. Removal of 1,4-dioxane by titanium silicalite-1: Separation mechanisms and bioregeneration of sorption sites. Chem. Eng. J. 2019, 371, 193–202. [Google Scholar] [CrossRef]

- Brown, W. Solution properties of lignin. Thermodynamic properties and molecular weight determinations. J. Appl. Polym. Sci. 1967, 11, 2381–2396. [Google Scholar] [CrossRef]

- He, M.-X.; Wang, J.-L.; Qin, H.; Shui, Z.-X.; Zhu, Q.-L.; Wu, B.; Tan, F.-R.; Pan, K.; Hu, Q.-C.; Dai, L.-C.; et al. Bamboo: A new source of carbohydrate for biorefinery. Carbohydr. Polym. 2014, 111, 645–654. [Google Scholar] [CrossRef] [PubMed]

- Stein, T.V.; Grande, P.M.; Kayser, H.; Sibilla, F.; Leitner, W.; De María, P.D. From biomass to feedstock: One-step fractionation of lignocellulose components by the selective organic acid-catalyzed depolymerization of hemicellulose in a biphasic system. Green Chem. 2011, 13, 1772. [Google Scholar] [CrossRef]

- Jafari, V.; Nieminen, K.; Sixta, H.; Van Heiningen, A. Delignification and cellulose degradation kinetics models for high lignin content softwood Kraft pulp during flow-through oxygen delignification. Cellulose 2015, 22, 2055–2066. [Google Scholar] [CrossRef]

- Tan, M.X.; Sum, Y.N.; Ying, J.Y.; Zhang, Y. A mesoporous poly-melamine-formaldehyde polymer as a solid sorbent for toxic metal removal. Energy Environ. Sci. 2013, 6, 3254–3259. [Google Scholar] [CrossRef]

- Shi, X.; Wu, Y.; Yi, H.; Rui, G.; Li, P.; Yang, M.; Wang, G. Selective Preparation of Furfural from Xylose over Sulfonic Acid Functionalized Mesoporous Sba-15 Materials. Energies 2011, 4, 669–684. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, H.; Wang, P.; Li, Y. Production of furfural from xylose, xylan and corncob in gamma-valerolactone using FeCl3·6H2O as catalyst. Bioresour. Technol. 2014, 151, 355–360. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, C.; Abu-Omar, M.M. Synthesis of Furfural from Xylose, Xylan, and Biomass Using AlCl3⋅6 H2O in Biphasic Media via Xylose Isomerization to Xylulose. ChemSusChem 2012, 5, 405–410. [Google Scholar] [CrossRef]

- Lin, Q.; Li, H.; Wang, X.; Jian, L.; Ren, J.; Liu, C.; Sun, R. SO42−/Sn-MMT Solid Acid Catalyst for Xylose and Xylan Conversion into Furfural in the Biphasic System. Catalusts 2017, 7, 118. [Google Scholar] [CrossRef]

- Bhaumik, P.; Dhepe, P.L. Efficient, Stable, and Reusable Silicoaluminophosphate for the One-Pot Production of Furfural from Hemicellulose. ACS Catal. 2013, 3, 2299–2303. [Google Scholar] [CrossRef]

- Dussan, K.; Girisuta, B.; Lopes, M.; Leahy, J.; Hayes, M.H.B. Effects of Soluble Lignin on the Formic Acid-Catalyzed Formation of Furfural: A Case Study for the Upgrading of Hemicellulose. ChemSusChem 2016, 9, 492–504. [Google Scholar] [CrossRef]

- Wang, T.; Li, K.; Liu, Q.; Zhang, Q.; Qiu, S.; Long, J.; Chen, L.; Ma, L.; Zhang, Q. Aviation fuel synthesis by catalytic conversion of biomass hydrolysate in aqueous phase. Appl. Energy 2014, 136, 775–780. [Google Scholar] [CrossRef]

- Luo, Y.; Li, Z.; Li, X.; Liu, X.; Fan, J.; Clark, J.H.; Hu, C. The production of furfural directly from hemicellulose in lignocellulosic biomass: A review. Catal. Today 2019, 319, 14–24. [Google Scholar] [CrossRef]

- Lu, J.; Wang, M.; Zhang, X.; Heyden, A.; Wang, F. β-O-4 Bond Cleavage Mechanism for Lignin Model Compounds over Pd Catalysts Identified by Combination of First-Principles Calculations and Experiments. ACS Catal. 2016, 6, 5589–5598. [Google Scholar] [CrossRef]

- Jiang, W.; Chu, J.; Wu, S.; Lucia, L.A. Secondary pyrolysis pathway of monomeric aromatics resulting from oxidized β-O-4 lignin dimeric model compounds. Fuel Process. Technol. 2017, 168, 11–19. [Google Scholar] [CrossRef]

- Nonaka, H.; Kobayashi, A.; Funaoka, M. Lignin isolated from steam-exploded eucalyptus wood chips by phase separation and its affinity to Trichoderma reesei cellulase. Bioresour. Technol. 2013, 140, 431–434. [Google Scholar] [CrossRef]

- Funaoka, M.; Matsubara, M.; Seki, N.; Fukatsu, S. Conversion of native lignin to a highly phenolic functional polymer and its separation from lignocellulosics. Biotechnol. Bioeng. 1995, 46, 545–552. [Google Scholar] [CrossRef]

- Wen, J.-L.; Sun, R.; Xue, B.-L.; Sun, R.-C. Quantitative structural characterization of the lignins from the stem and pith of bamboo (Phyllostachys pubescens). Holzforschung 2013, 67, 613–627. [Google Scholar] [CrossRef]

- Serrano, L.; Esakkimuthu, E.S.; Marlin, N.; Brochier-Salon, M.-C.; Mortha, G.; Bertaud, F.; Serrano, L. Fast, Easy, and Economical Quantification of Lignin Phenolic Hydroxyl Groups: Comparison with Classical Techniques. Energy Fuels 2018, 32, 5969–5977. [Google Scholar] [CrossRef]

- Zhang, F.-D.; Jiang, X.; Lin, J.; Zhao, G.J.; Chang, H.-M.; Jameel, H. Reactivity improvement by phenolation of wheat straw lignin isolated from a biorefinery process. New J. Chem. 2019, 43, 2238–2246. [Google Scholar] [CrossRef]

- Chen, H.; Liu, N.; Qu, X.; Joshee, N.; Liu, S. The effect of hot water pretreatment on the heavy metal adsorption capacity of acid insoluble lignin from Paulownia elongata. J. Chem. Technol. Biotechnol. 2017, 93, 1105–1112. [Google Scholar] [CrossRef]

- Lin, J.; Shang, J.; Zhao, G. Effect of the size of spinneret on the thermal stability of chemically liquefied wood. Wood Res.-Slovak. 2014, 59, 731–738. [Google Scholar]

- Aro, T.; Fatehi, P. Production and Application of Lignosulfonates and Sulfonated Lignin. ChemSusChem 2017, 10, 1861–1877. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, E.; Pataki, H.; Domján, J.; Farkas, A.; Vass, P.; Fehér, C.; Barta, Z.; Nagy, Z.K.; Marosi, G.J.; Csontos, I.; et al. Inline noninvasive Raman monitoring and feedback control of glucose concentration during ethanol fermentation. Biotechnol. Prog. 2019, 35, e2848. [Google Scholar] [CrossRef] [PubMed]

- Qu, H.; Liu, B.; Li, L.; Zhou, Y. A bifunctional recoverable catalyst based on phosphotungstic acid for cellulose hydrolysis to fermentable sugars. Fuel Process. Technol. 2020, 199, 106272. [Google Scholar] [CrossRef]

- Zhai, R.; Hu, J.; Saddler, J.N. What Are the Major Components in Steam Pretreated Lignocellulosic Biomass That Inhibit the Efficacy of Cellulase Enzyme Mixtures? ACS Sustain. Chem. Eng. 2016, 4, 3429–3436. [Google Scholar] [CrossRef]

- Rodríguez, F.; Sánchez, A.; Parra, C. Role of Steam Explosion on Enzymatic Digestibility, Xylan Extraction, and Lignin Release of Lignocellulosic Biomass. ACS Sustain. Chem. Eng. 2017, 5, 5234–5240. [Google Scholar] [CrossRef]

- Ramírez, I.M.; Román, M.G.; Arteaga, A.F. Rhamnolipids: Highly Compatible Surfactants for the Enzymatic Hydrolysis of Waste Frying Oils in Microemulsion Systems. ACS Sustain. Chem. Eng. 2017, 5, 6768–6775. [Google Scholar] [CrossRef]

- Martín, C.; Volkov, P.V.; Rozhkova, A.M.; Puls, J.; Sinitsyn, A.P. Comparative study of the enzymatic convertibility of glycerol- and dilute acid-pretreated sugarcane bagasse using Penicillium and Trichoderma-based cellulase preparations. Ind. Crop. Prod. 2015, 77, 382–390. [Google Scholar] [CrossRef]

| Entry | 1,4-Dioxane Addition (mL/100 g Bamboo) | T (°C) | Time (h) | Fractionated Lignin I Yield (%) |

|---|---|---|---|---|

| 1 | 900 | 80 | 5 | 54.00 ± 0.88 |

| 2 | 700 | 80 | 5 | 42.24 ± 0.93 |

| 3 | 500 | 80 | 5 | 23.95 ± 0.91 |

| Entry | Phenol Addition (%, w/v) | T (°C) | Time (h) | Removal Ratio of Lignin (%) | Yield of Fractionated Lignin II (%) | Weight Loss of Glucan (%) | Enzymatic Hydrolysis (%) | Furfural Conversion (% of Theoretical Yield) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 80 | 2 | 78.62 ± 1.21 | 43.36 ± 1.39 | 3.32 ± 0.07 | 93.52 ± 1.13 | 89.78 ± 1.48 |

| 2 | 2.0 | 80 | 2 | 81.65 ± 0.76 | 46.54 ± 0.88 | 4.59 ± 0.11 | 95.14 ± 1.16 | 91.06 ± 1.26 |

| 3 | 2.5 | 80 | 2 | 84.83 ± 1.43 | 51.88 ± 0.75 | 8.92 ± 0.13 | 99.03 ± 0.97 | 92.92 ± 1.23 |

| 4 | 1.0 | 100 | 2 | 81.71 ± 1.28 | 37.92 ± 0.54 | 11.80 ± 0.42 | 96.25 ± 1.63 | 87.57 ± 0.79 |

| 5 | 1.5 | 100 | 2 | 85.22 ± 0.99 | 40.56 ± 0.92 | 15.50 ± 0.56 | 99.22 ± 0.86 | 88.94 ± 0.53 |

| 6 | 2.5 | 100 | 2 | 86.98 ± 0.23 | 42.79 ± 1.03 | 16.74 ± 1.01 | 99.26 ± 1.31 | 90.78 ± 1.09 |

| Entry | 1,4-Dioxane Solvent Addition (mL/100 g Bamboo) | T (°C) | Time (h) | Furfural Conversion Yield (% of Theoretical Yield) |

|---|---|---|---|---|

| 1 | 900 | 80 | 5 | 93.81 ± 1.05 |

| 2 | 700 | 80 | 5 | 69.03 ± 0.89 |

| 3 | 500 | 80 | 5 | 57.43 ± 1.01 |

| 4 | 500 | 120 | 3 | 80.42 ± 1.23 |

| 5 | 900 | 80 | 3 | 91.43 ± 0.77 |

| 6 | 500 | 120 | 1 | 72.46 ± 0.69 |

| Starting Materials | Solvent | Catalyst | Conditions | Yield a | Reference |

|---|---|---|---|---|---|

| xylan | GVL-10% H2O | FeCl3·6H2O | 170 °C, 100 min | 68.6% a | Zhang et al. [36] |

| xylan | H2O-THF | AlCl3·6H2O-NaCl | 140 °C, 45 min | 64% a | Yang et al. [37] |

| xylan | 2-MTHF-H2O | NaCl-SO42−/Sn-MMT | 160 °C, 90 min | 77.35% a | Lin et al. [38] |

| bagasse | H2O/toluene | SAPO | 170 °C, 8 h | 63% b | Bhaumik et al. [39] |

| wheat straw | [bmim][HSO4] | - | 160 °C, 120 min | 36.2% b | Dussan et al. [40] |

| corncob | H2O | 0.9 mmol H2SO4 | 160 °C, 5 h | 71% b | Wang et al. [41] |

| Moso bamboo | H2O/1,4-dioxane | HCl | 80 °C, 3 h | 91.47% | In this study |

| Moso bamboo | H2O/phenol-acidic1,4-dioxane | HCl | 80 °C, 2 h | 92.92% | In this study |

| Lignin-Derived Products | Mn (g/mol) | Mw (g/mol) | PDI |

|---|---|---|---|

| lignin I | 6.515 × 102 (±2.467%) | 8.237 × 102 (±2.241%) | 1.264 (±1.895%) |

| lignin II | 5.611 × 102 (±3.048%) | 6.936 × 102 (±2.924%) | 1.236 (±4.224%) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, L.; Li, P.; Lei, F.; Song, X.; Jiang, J.; Wang, K. Coproduction of Furfural, Phenolated Lignin and Fermentable Sugars from Bamboo with One-Pot Fractionation Using Phenol-Acidic 1,4-Dioxane. Energies 2020, 13, 5294. https://doi.org/10.3390/en13205294

Ji L, Li P, Lei F, Song X, Jiang J, Wang K. Coproduction of Furfural, Phenolated Lignin and Fermentable Sugars from Bamboo with One-Pot Fractionation Using Phenol-Acidic 1,4-Dioxane. Energies. 2020; 13(20):5294. https://doi.org/10.3390/en13205294

Chicago/Turabian StyleJi, Li, Pengfei Li, Fuhou Lei, Xianliang Song, Jianxin Jiang, and Kun Wang. 2020. "Coproduction of Furfural, Phenolated Lignin and Fermentable Sugars from Bamboo with One-Pot Fractionation Using Phenol-Acidic 1,4-Dioxane" Energies 13, no. 20: 5294. https://doi.org/10.3390/en13205294

APA StyleJi, L., Li, P., Lei, F., Song, X., Jiang, J., & Wang, K. (2020). Coproduction of Furfural, Phenolated Lignin and Fermentable Sugars from Bamboo with One-Pot Fractionation Using Phenol-Acidic 1,4-Dioxane. Energies, 13(20), 5294. https://doi.org/10.3390/en13205294