Factors Affecting the Performance of Membrane Osmotic Processes for Bioenergy Development

Abstract

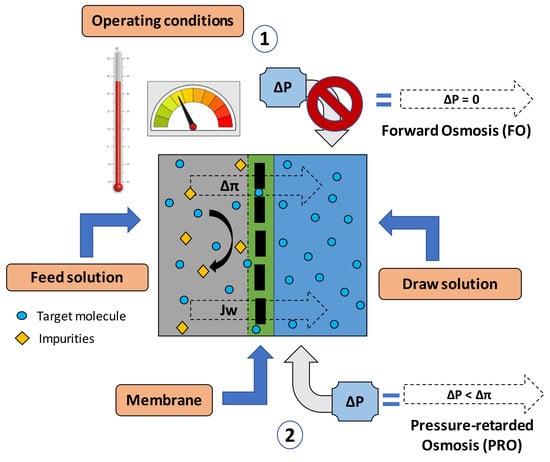

1. Introduction

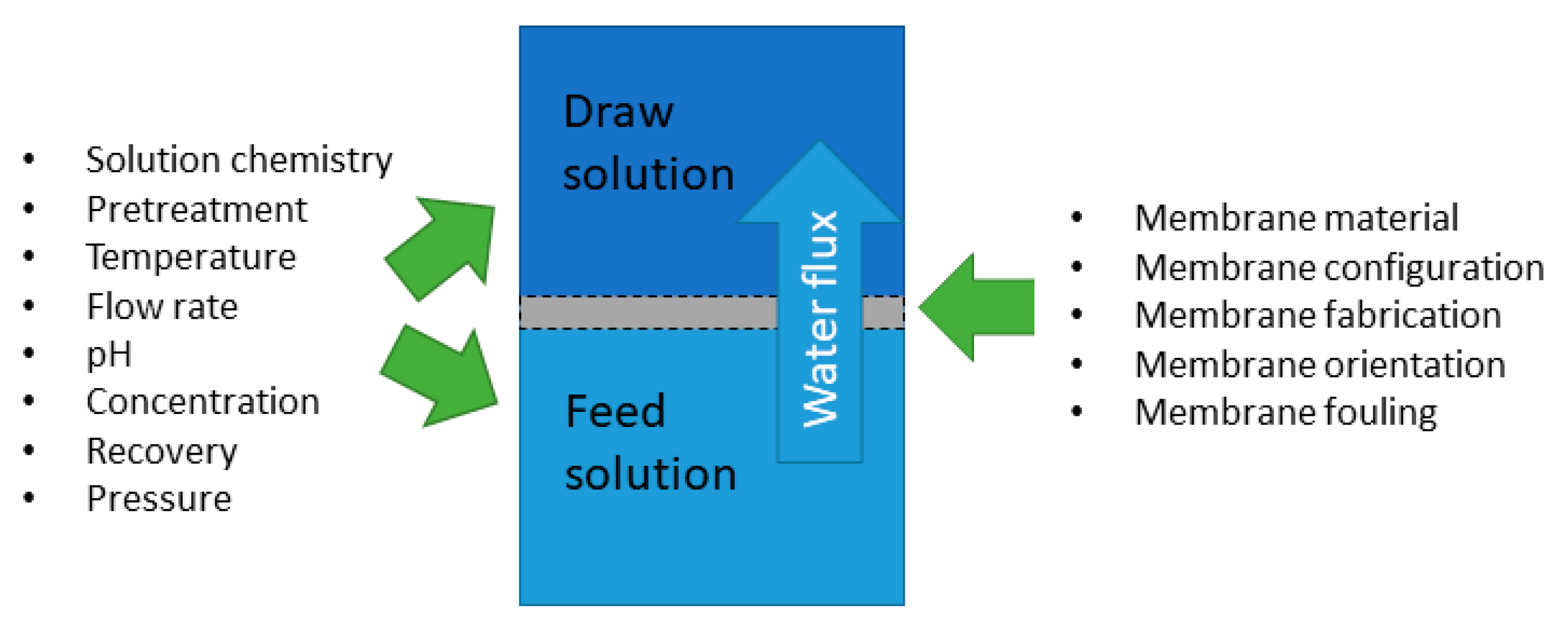

2. Osmotic Membrane

2.1. Concentration Polarization

2.2. Membrane Materials

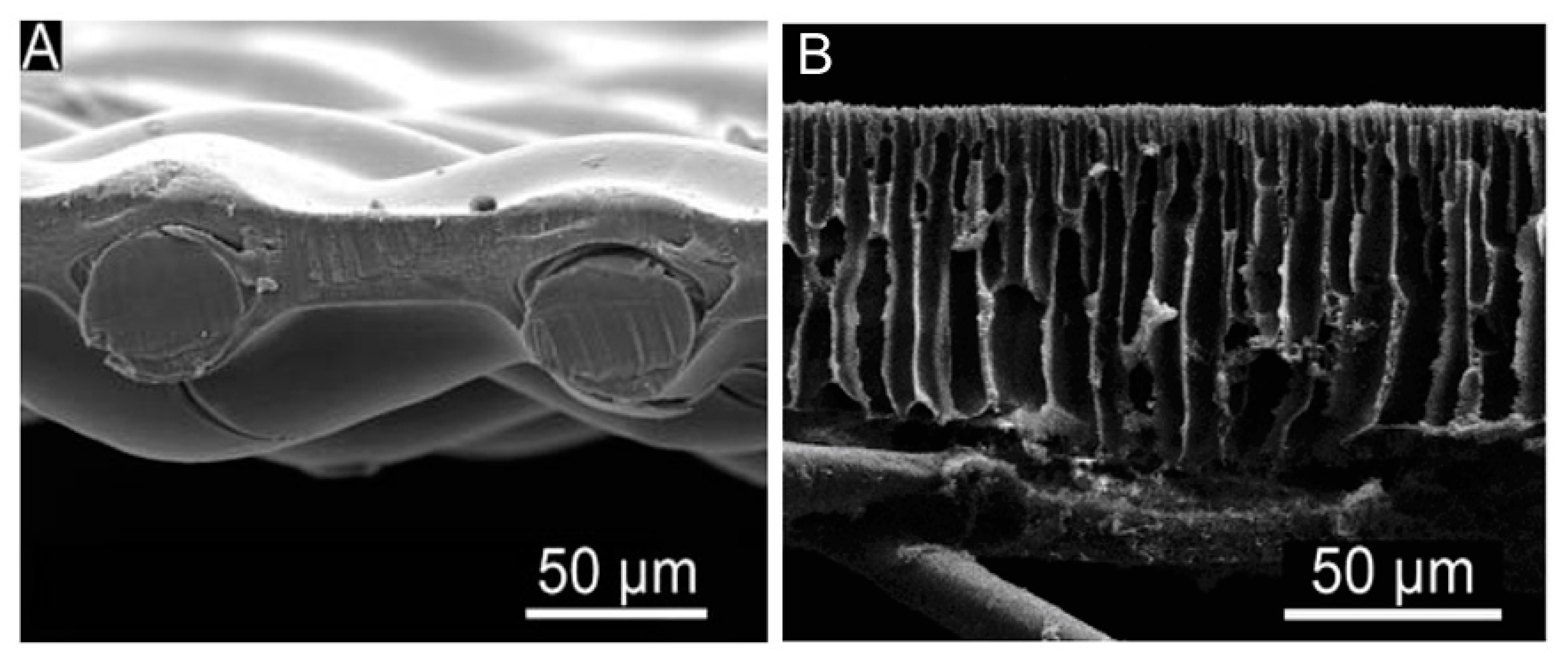

2.3. Membrane Configurations

2.4. Membrane Fouling

3. Feed Solutions

Pretreatments

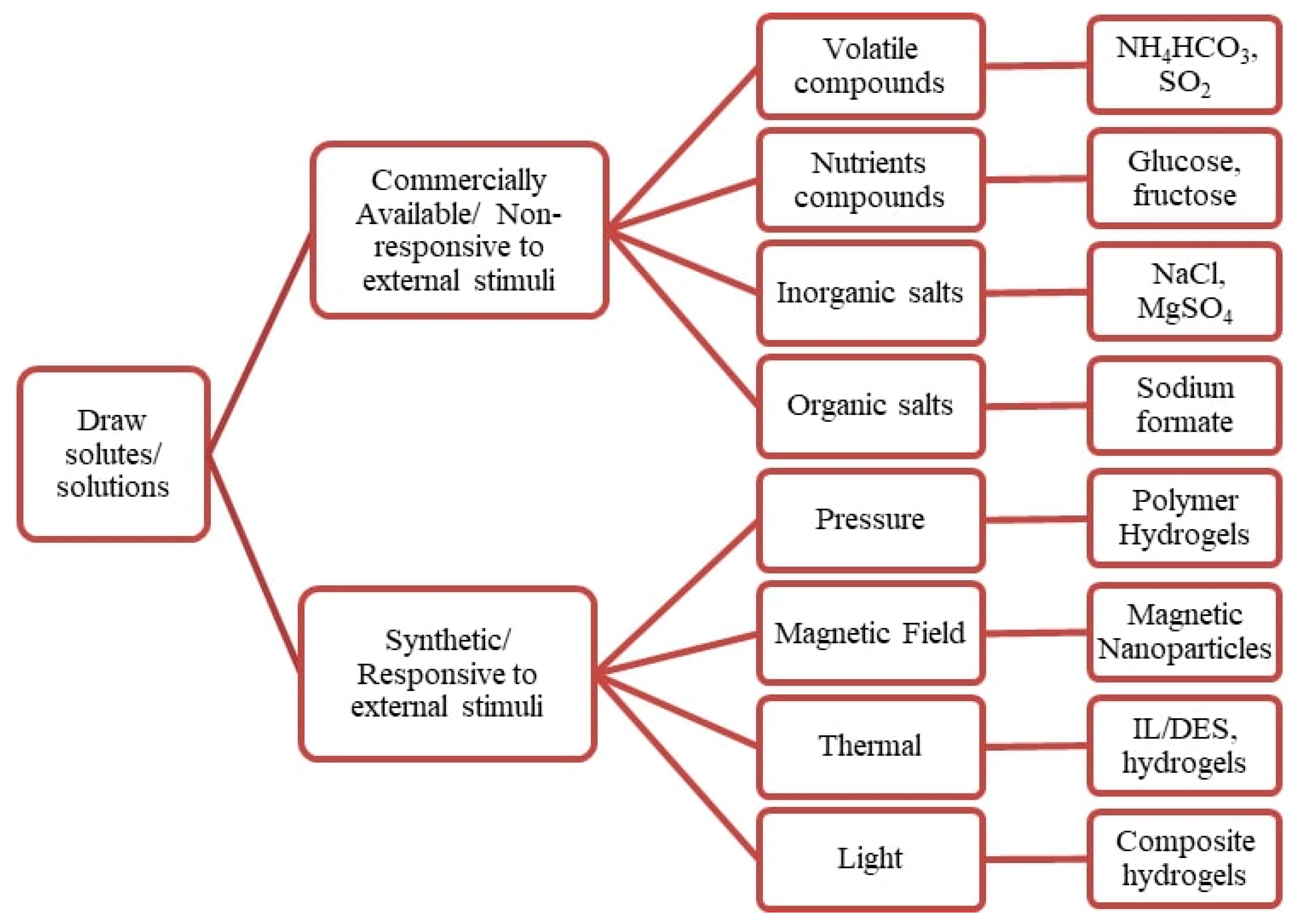

4. Draw Solutions

5. Operating Conditions

5.1. Cross-Flow Rate

5.2. Temperature

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chung, T.-S.; Luo, L.; Wan, C.F.; Cui, Y.; Amy, G. What is next for forward osmosis (FO) and pressure retarded osmosis (PRO). Sep. Purif. Technol. 2015, 156, 856–860. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, H.; Tong, X.; Liu, S.; Gan, L.; Chen, Y. Chapter 6—Pressure Retarded Osmosis and Reverse Electrodialysis as Power Generation Membrane Systems. In Current Trends and Future Developments on (Bio-) Membranes; Basile, A., Cassano, A., Figoli, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 133–152. [Google Scholar]

- Zhao, S.; Zou, L.; Tang, C.Y.; Mulcahy, D. Recent developments in forward osmosis: Opportunities and challenges. J. Membr. Sci. 2012, 396, 1–21. [Google Scholar] [CrossRef]

- Cath, T.Y.; Childress, A.E.; Elimelech, M. Forward osmosis: Principles, applications, and recent developments. J. Membr. Sci. 2006, 281, 70–87. [Google Scholar] [CrossRef]

- Helfer, F.; Lemckert, C.; Anissimov, Y.G. Osmotic power with Pressure Retarded Osmosis: Theory, performance and trends—A review. J. Membr. Sci. 2014, 453, 337–358. [Google Scholar] [CrossRef]

- Sarp, S. Chapter 11—Fundamentals of Pressure Retarded Osmosis. In Current Trends and Future Developments on (Bio-) Membranes; Basile, A., Curcio, E., Inamuddin, Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 271–283. [Google Scholar]

- Sarp, S.; Li, Z.; Saththasivam, J. Pressure Retarded Osmosis (PRO): Past experiences, current developments, and future prospects. Desalination 2016, 389, 2–14. [Google Scholar] [CrossRef]

- Yang, E.; Kim, K.-Y.; Chae, K.-J.; Lee, M.-Y.; Kim, I.S. Evaluation of energy and water recovery in forward osmosis–bioelectrochemical hybrid system with cellulose triacetate and polyamide asymmetric membrane in different orientations. Desalin. Water. Treat. 2016, 57, 7406–7413. [Google Scholar] [CrossRef]

- Zhang, F.; Brastad, K.S.; He, Z. Integrating Forward Osmosis into Microbial Fuel Cells for Wastewater Treatment, Water Extraction and Bioelectricity Generation. Environ. Sci. Technol. 2011, 45, 6690–6696. [Google Scholar] [CrossRef] [PubMed]

- Chia, S.R.; Chew, K.W.; Show, P.L.; Yap, Y.J.; Ong, H.C.; Ling, T.C.; Chang, J.-S. Analysis of Economic and Environmental Aspects of Microalgae Biorefinery for Biofuels Production: A Review. Biotechnol. J. 2018, 13, 1700618. [Google Scholar] [CrossRef] [PubMed]

- Phwan, C.K.; Chew, K.W.; Sebayang, A.H.; Ong, H.C.; Ling, T.C.; Malek, M.A.; Ho, Y.-C.; Show, P.L. Effects of acids pre-treatment on the microbial fermentation process for bioethanol production from microalgae. Biotechnol. Biofuels 2019, 12, 191. [Google Scholar] [CrossRef]

- Alsvik, L.I.; Hägg, M.-B. Pressure Retarded Osmosis and Forward Osmosis Membranes: Materials and Methods. Polymers 2013, 5, 303–327. [Google Scholar] [CrossRef]

- She, Q.; Wang, R.; Fane, A.G.; Tang, C.Y. Membrane fouling in osmotically driven membrane processes: A review. J. Membr. Sci. 2016, 499, 201–233. [Google Scholar] [CrossRef]

- Han, G.; Zhang, S.; Li, X.; Chung, T.-S. Progress in pressure retarded osmosis (PRO) membranes for osmotic power generation. Prog. Polym. Sci. 2015, 51, 1–27. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F.; Ng, B.C.; Abdullah, M.S. Recent Progresses of Forward Osmosis Membranes Formulation and Design for Wastewater Treatment. Water 2019, 11, 2043. [Google Scholar] [CrossRef]

- Yip, N.Y.; Tiraferri, A.; Phillip, W.A.; Schiffman, J.D.; Elimelech, M. High performance thin-film composite forward osmosis membrane. Environ. Sci. Technol. 2010, 44, 3812–3818. [Google Scholar] [CrossRef]

- McCutcheon, J.R.; Elimelech, M. Influence of concentrative and dilutive internal concentration polarization on flux behavior in forward osmosis. J. Membr. Sci. 2006, 284, 237–247. [Google Scholar] [CrossRef]

- Phuntsho, S.; Sahebi, S.; Majeed, T.; Lotfi, F.; Kim, J.E.; Shon, H.K. Assessing the major factors affecting the performances of forward osmosis and its implications on the desalination process. Chem. Eng. J. 2013, 231, 484–496. [Google Scholar] [CrossRef]

- McCutcheon, J.R.; Elimelech, M. Influence of membrane support layer hydrophobicity on water flux in osmotically driven membrane processes. J. Membr. Sci. 2008, 318, 458–466. [Google Scholar] [CrossRef]

- Population Distribution and Water Scarcity. Recent Developments in Forward Osmosis Processes; Linares, R.V., Li, Z., Elimelech, M., Amy, G., Vrouwenvelder, H., Eds.; IWA Publishing: London, UK, 2017. [Google Scholar]

- Klaysom, C.; Cath, T.Y.; Depuydt, T.; Vankelecom, I.F. Forward and pressure retarded osmosis: Potential solutions for global challenges in energy and water supply. Chem. Soc. Rev. 2013, 42, 6959–6989. [Google Scholar] [CrossRef]

- Majeed, T.; Lotfi, F.; Phuntsho, S.; Yoon, J.K.; Kim, K.; Shon, H.K. Performances of PA hollow fiber membrane with the CTA flat sheet membrane for forward osmosis process. Desalin. Water Treat. 2015, 53, 1744–1754. [Google Scholar] [CrossRef]

- Wong, M.C.Y.; Martinez, K.; Ramon, G.Z.; Hoek, E.M.V. Impacts of operating conditions and solution chemistry on osmotic membrane structure and performance. Desalination 2012, 287, 340–349. [Google Scholar] [CrossRef]

- Lee, K.L.; Baker, R.W.; Lonsdale, H.K. Membranes for power generation by pressure-retarded osmosis. J. Membr. Sci. 1981, 8, 141–171. [Google Scholar] [CrossRef]

- Sarp, S.; Hilal, N. Chapter 8—Membrane Modules for Large-Scale Salinity Gradient Process Applications. In Membrane-Based Salinity Gradient Processes for Water Treatment and Power Generation; Sarp, S., Hilal, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 223–242. [Google Scholar]

- Li, X.; Zhang, S.; Fu, F.; Chung, T.-S. Deformation and reinforcement of thin-film composite (TFC) polyamide-imide (PAI) membranes for osmotic power generation. J. Membr. Sci. 2013, 434, 204–217. [Google Scholar] [CrossRef]

- Qasim, M.; Darwish, N.A.; Sarp, S.; Hilal, N. Water desalination by forward (direct) osmosis phenomenon: A comprehensive review. Desalination 2015, 374, 47–69. [Google Scholar] [CrossRef]

- Wei, J.; Qiu, C.; Tang, C.Y.; Wang, R.; Fane, A.G. Synthesis and characterization of flat-sheet thin film composite forward osmosis membranes. J. Membr. Sci. 2011, 372, 292–302. [Google Scholar] [CrossRef]

- Lim, S.W.; Mah, S.-K.; Lee, Z.H.; Chai, S.-P. A study of water permeation using glycerol as the draw solution with thin film composite membranes in forward osmosis and pressure retarded osmosis configurations. AIP Conf. Proc. 2018, 2031, 020020. [Google Scholar]

- Wang, Z.; Tang, J.; Zhu, C.; Dong, Y.; Wang, Q.; Wu, Z. Chemical cleaning protocols for thin film composite (TFC) polyamide forward osmosis membranes used for municipal wastewater treatment. J. Membr. Sci. 2015, 475, 184–192. [Google Scholar] [CrossRef]

- Fam, W.; Phuntsho, S.; Lee, J.H.; Shon, H.K. Performance comparison of thin-film composite forward osmosis membranes. Desalin. Water Treat. 2013, 51, 6274–6280. [Google Scholar] [CrossRef]

- Li, J.-Y.; Ni, Z.-Y.; Zhou, Z.-Y.; Hu, Y.-X.; Xu, X.-H.; Cheng, L.-H. Membrane fouling of forward osmosis in dewatering of soluble algal products: Comparison of TFC and CTA membranes. J. Membr. Sci. 2018, 552, 213–221. [Google Scholar] [CrossRef]

- Madsen, H.T.; Nissen, S.S.; Muff, J.; Søgaard, E.G. Pressure retarded osmosis from hypersaline solutions: Investigating commercial FO membranes at high pressures. Desalination 2017, 420, 183–190. [Google Scholar] [CrossRef]

- Wan, C.F.; Cui, Y.; Gai, W.X.; Cheng, Z.L.; Chung, T.-S. Chapter 14—Nanostructured Membranes for Enhanced Forward Osmosis and Pressure-Retarded Osmosis. In Sustainable Nanoscale Engineering; Szekely, G., Livingston, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 373–394. [Google Scholar]

- Sakai, M.; Seshimo, M.; Matsukata, M. Hydrophilic ZSM-5 membrane for forward osmosis operation. J. Water Process Eng. 2019, 32, 100864. [Google Scholar] [CrossRef]

- Chung, T.-S.; Zhao, D.; Gao, J.; Lu, K.; Wan, C.; Weber, M.; Maletzko, C. Emerging R&D on membranes and systems for water reuse and desalination. Chin. J. Chem. Eng. 2019, 27, 1578–1585. [Google Scholar]

- Sahebi, S.; Sheikhi, M.; Ramavandi, B. A new biomimetic aquaporin thin film composite membrane for forward osmosis: Characterization and performance assessment. Desalin. Water Treat. 2019, 148, 42–50. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Y.; Tian, E.; Ren, Y. Preparation and characterization of novel forward osmosis membrane incorporated with sulfonated carbon nanotubes. RSC Adv. 2018, 8, 41032–41039. [Google Scholar] [CrossRef]

- Salehi, T.M.; Peyravi, M.; Jahanshahi, M.; Lau, W.-J.; Rad, A.S. Impacts of zeolite nanoparticles on substrate properties of thin film nanocomposite membranes for engineered osmosis. J. Nanoparticle Res. 2018, 20, 113. [Google Scholar] [CrossRef]

- Lee, W.J.; Goh, P.S.; Lau, W.J.; Ong, C.S.; Ismail, A.F. Antifouling zwitterion embedded forward osmosis thin film composite membrane for highly concentrated oily wastewater treatment. Sep. Purif. Technol. 2019, 214, 40–50. [Google Scholar] [CrossRef]

- Shokrgozar Eslah, S.; Shokrollahzadeh, S.; Moini Jazani, O.; Samimi, A. Forward osmosis water desalination: Fabrication of graphene oxide-polyamide/polysulfone thin-film nanocomposite membrane with high water flux and low reverse salt diffusion. Sep. Sci. Technol. 2018, 53, 573–583. [Google Scholar] [CrossRef]

- Gai, W.; Zhao, D.L.; Chung, T.-S. Thin film nanocomposite hollow fiber membranes comprising Na+-functionalized carbon quantum dots for brackish water desalination. Water Res. 2019, 154, 54–61. [Google Scholar] [CrossRef]

- Amini, M.; Shekari, Z.; Hosseinifard, M.; Seidi, F. Preparation and Characterization of Thin-Film Nanocomposite Membrane Incorporated with MoO3 Nanoparticles with High Flux Performance for Forward Osmosis. ChemistrySelect 2019, 4, 7832–7837. [Google Scholar] [CrossRef]

- Gonzales, R.R.; Park, M.J.; Tijing, L.; Han, D.S.; Phuntsho, S.; Shon, H.K. Modification of Nanofiber Support Layer for Thin Film Composite Forward Osmosis Membranes via Layer-by-Layer Polyelectrolyte Deposition. Membranes 2018, 8, 70. [Google Scholar] [CrossRef]

- Dai, R.; Zhang, X.; Liu, M.; Wu, Z.; Wang, Z. Porous metal organic framework CuBDC nanosheet incorporated thin-film nanocomposite membrane for high-performance forward osmosis. J. Membr. Sci. 2019, 573, 46–54. [Google Scholar] [CrossRef]

- Subramani, A.; Jacangelo, J.G. Emerging desalination technologies for water treatment: A critical review. Water Res. 2015, 75, 164–187. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.; Wang, R.; Fane, A.G. Robust and High performance hollow fiber membranes for energy harvesting from salinity gradients by pressure retarded osmosis. J. Membr. Sci. 2013, 448, 44–54. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F. Chapter 5—Flat-Sheet Membrane for Power Generation and Desalination Based on Salinity Gradient. In Membrane-Based Salinity Gradient Processes for Water Treatment and Power Generation; Sarp, S., Hilal, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 155–174. [Google Scholar]

- Wang, Y.-N.; Goh, K.; Li, X.; Setiawan, L.; Wang, R. Membranes and processes for forward osmosis-based desalination: Recent advances and future prospects. Desalination 2018, 434, 81–99. [Google Scholar] [CrossRef]

- Crowder, M.L.; Gooding, C.H. Spiral wound, hollow fiber membrane modules: A new approach to higher mass transfer efficiency. J. Membr. Sci. 1997, 137, 17–29. [Google Scholar] [CrossRef]

- Wang, R.; Shi, L.; Tang, C.Y.; Chou, S.; Qiu, C.; Fane, A.G. Characterization of novel forward osmosis hollow fiber membranes. J. Membr. Sci. 2010, 355, 158–167. [Google Scholar] [CrossRef]

- Bajraktari, N.; Hélix-Nielsen, C.; Madsen, H.T. Pressure retarded osmosis from hypersaline sources—A review. Desalination 2017, 413, 65–85. [Google Scholar] [CrossRef]

- Lau, W.-J.; Lai, G.-S.; Li, J.; Gray, S.; Hu, Y.; Misdan, N.; Goh, P.-S.; Matsuura, T.; Azelee, I.W.; Ismail, A.F. Development of microporous substrates of polyamide thin film composite membranes for pressure-driven and osmotically-driven membrane processes: A review. J. Ind. Eng. Chem. 2019, 77, 25–59. [Google Scholar] [CrossRef]

- Saito, K.; Irie, M.; Zaitsu, S.; Sakai, H.; Hayashi, H.; Tanioka, A. Power generation with salinity gradient by pressure retarded osmosis using concentrated brine from SWRO system and treated sewage as pure water. Desalin. Water Treat. 2012, 41, 114–121. [Google Scholar] [CrossRef]

- Sharma, M.; Mondal, P.; Chakraborty, A.; Kuttippurath, J.; Purkait, M. Effect of different molecular weight polyethylene glycol on flat sheet cellulose acetate membranes for evaluating power density performance in pressure retarded osmosis study. J. Water Process Eng. 2019, 30, 100632. [Google Scholar] [CrossRef]

- Wan, C.F.; Yang, T.; Gai, W.; Lee, Y.D.; Chung, T.-S. Thin-film composite hollow fiber membrane with inorganic salt additives for high mechanical strength and high power density for pressure-retarded osmosis. J. Membr. Sci. 2018, 555, 388–397. [Google Scholar] [CrossRef]

- Park, M.J.; Lim, S.; Gonzales, R.R.; Phuntsho, S.; Han, D.S.; Abdel-Wahab, A.; Adham, S.; Shon, H.K. Thin-film composite hollow fiber membranes incorporated with graphene oxide in polyethersulfone support layers for enhanced osmotic power density. Desalination 2019, 464, 63–75. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.L.; Cai, T.; Cheng, Z.L.; Li, X.; Chung, T.-S. Sulfonated hyperbranched polyglycerol grafted membranes with antifouling properties for sustainable osmotic power generation using municipal wastewater. J. Membr. Sci. 2018, 563, 521–530. [Google Scholar] [CrossRef]

- Gonzales, R.R.; Park, M.J.; Bae, T.-H.; Yang, Y.; Abdel-Wahab, A.; Phuntsho, S.; Shon, H.K. Melamine-based covalent organic framework-incorporated thin film nanocomposite membrane for enhanced osmotic power generation. Desalination 2019, 459, 10–19. [Google Scholar] [CrossRef]

- Lim, S.; Park, M.J.; Phuntsho, S.; Mai-Prochnow, A.; Murphy, A.B.; Seo, D.; Shon, H. Dual-layered nanocomposite membrane incorporating graphene oxide and halloysite nanotube for high osmotic power density and fouling resistance. J. Membr. Sci. 2018, 564, 382–393. [Google Scholar] [CrossRef]

- Wan, C.F.; Li, B.; Yang, T.; Chung, T.-S. Design and fabrication of inner-selective thin-film composite (TFC) hollow fiber modules for pressure retarded osmosis (PRO). Sep. Purif. Technol. 2017, 172, 32–42. [Google Scholar] [CrossRef]

- Wan, C.F.; Chung, T.-S. Osmotic power generation by pressure retarded osmosis using seawater brine as the draw solution and wastewater retentate as the feed. J. Membr. Sci. 2015, 479, 148–158. [Google Scholar] [CrossRef]

- Rana, D.; Matsuura, T. Surface Modifications for Antifouling Membranes. Chem. Rev. 2010, 110, 2448–2471. [Google Scholar] [CrossRef]

- Nagy, E.; Hegedüs, I.; Tow, E.W.; Lienhard, V.J.H. Effect of fouling on performance of pressure retarded osmosis (PRO) and forward osmosis (FO). J. Membr. Sci. 2018, 565, 450–462. [Google Scholar] [CrossRef]

- Le, N.L.; Nunes, S.P. Materials and membrane technologies for water and energy sustainability. Sustain. Mater. Technol. 2016, 7, 1–28. [Google Scholar] [CrossRef]

- Ibrar, I.; Naji, O.; Sharif, A.; Malekizadeh, A.; Alhawari, A.; Alanezi, A.A.; Altaee, A. A Review of Fouling Mechanisms, Control Strategies and Real-Time Fouling Monitoring Techniques in Forward Osmosis. Water 2019, 11, 695. [Google Scholar] [CrossRef]

- Mi, B.; Elimelech, M. Chemical and physical aspects of organic fouling of forward osmosis membranes. J. Membr. Sci. 2008, 320, 292–302. [Google Scholar] [CrossRef]

- Zhao, P.; Gao, B.; Yue, Q.; Liu, P.; Shon, H.K. Fatty acid fouling of forward osmosis membrane: Effects of pH, calcium, membrane orientation, initial permeate flux and foulant composition. J. Environ. Sci. 2016, 46, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Abbasi-Garravand, E.; Mulligan, C.N.; Laflamme, C.B.; Clairet, G. Investigation of the fouling effect on a commercial semi-permeable membrane in the pressure retarded osmosis (PRO) process. Sep. Purif. Technol. 2018, 193, 81–90. [Google Scholar] [CrossRef]

- Zhao, S.; Zou, L.; Mulcahy, D. Effects of membrane orientation on process performance in forward osmosis applications. J. Membr. Sci. 2011, 382, 308–315. [Google Scholar] [CrossRef]

- She, Q.; Jin, X.; Tang, C.Y. Osmotic power production from salinity gradient resource by pressure retarded osmosis: Effects of operating conditions and reverse solute diffusion. J. Membr. Sci. 2012, 401–402, 262–273. [Google Scholar] [CrossRef]

- Yip, N.Y.; Elimelech, M. Influence of natural organic matter fouling and osmotic backwash on pressure retarded osmosis energy production from natural salinity gradients. Environ. Sci. Technol. 2013, 47, 12607–12616. [Google Scholar] [CrossRef]

- Chun, Y.; Mulcahy, D.; Zou, L.; Kim, I.S. A Short Review of Membrane Fouling in Forward Osmosis Processes. Membranes 2017, 7, 30. [Google Scholar] [CrossRef]

- Jiang, S.; Li, Y.; Ladewig, B.P. A review of reverse osmosis membrane fouling and control strategies. Sci. Total Environ. 2017, 595, 567–583. [Google Scholar] [CrossRef]

- Singh, N.; Dhiman, S.; Basu, S.; Balakrishnan, M.; Petrinic, I.; Helix-Nielsen, C. Dewatering of sewage for nutrients and water recovery by Forward Osmosis (FO) using divalent draw solution. J. Water Process Eng. 2019, 31, 100853. [Google Scholar] [CrossRef]

- Xue, W.; Tobino, T.; Nakajima, F.; Yamamoto, K. Seawater-driven forward osmosis for enriching nitrogen and phosphorous in treated municipal wastewater: Effect of membrane properties and feed solution chemistry. Water Res. 2015, 69, 120–130. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, T.; Bao, R.; Li, T.; Wang, Y.; Li, D.; Li, X.; He, T. Zwitterionic surface modification of forward osmosis membranes using N-aminoethyl piperazine propane sulfonate for grey water treatment. Process Saf. Environ. Prot. 2018, 116, 632–639. [Google Scholar] [CrossRef]

- Son, J.; Sung, M.; Ryu, H.; Oh, Y.-K.; Han, J.-I. Microalgae dewatering based on forward osmosis employing proton exchange membrane. Bioresour. Technol. 2017, 244, 57–62. [Google Scholar] [CrossRef]

- Yun, T.; Kim, Y.-J.; Lee, S.; Hong, S.; Kim, G.I. Flux behavior and membrane fouling in pressure-assisted forward osmosis. Desalin. Water Treat. 2014, 52, 564–569. [Google Scholar] [CrossRef]

- Nave, F.; Kommalapati, R.; Thompson, A. Introductory Chapter: Osmotically Driven Membrane Processes. In Osmotically Driven Membrane Processes—Approach, Development and Current Status; IntechOpen: London, UK, 2018. [Google Scholar]

- Yang, T.; Wan, C.F.; Xiong, J.Y.; Chung, T.-S. Pre-treatment of wastewater retentate to mitigate fouling on the pressure retarded osmosis (PRO) process. Sep. Purif. Technol. 2019, 215, 390–397. [Google Scholar] [CrossRef]

- Choi, Y.; Vigneswaran, S.; Lee, S. Evaluation of fouling potential and power density in pressure retarded osmosis (PRO) by fouling index. Desalination 2016, 389, 215–223. [Google Scholar] [CrossRef]

- Yang, S.; Gao, B.; Jang, A.; Shon, H.K.; Yue, Q. Municipal wastewater treatment by forward osmosis using seawater concentrate as draw solution. Chemosphere 2019, 237, 124485. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Liu, C.; Setiawan, L.; Wang, Y.-N.; Hu, X.; Wang, R. Enhancing pressure retarded osmosis performance with low-pressure nanofiltration pretreatment: Membrane fouling analysis and mitigation. J. Membr. Sci. 2017, 543, 114–122. [Google Scholar] [CrossRef]

- Wan, C.F.; Jin, S.; Chung, T.-S. Mitigation of inorganic fouling on pressure retarded osmosis (PRO) membranes by coagulation pretreatment of the wastewater concentrate feed. J. Membr. Sci. 2019, 572, 658–667. [Google Scholar] [CrossRef]

- Seker, M.; Buyuksari, E.; Topcu, S.; Babaoglu, D.S.; Celebi, D.; Keskinler, B.; Aydiner, C. Effect of pretreatment and membrane orientation on fluxes for concentration of whey with high foulants by using NH3/CO2 in forward osmosis. Bioresour. Technol. 2017, 243, 237–246. [Google Scholar] [CrossRef]

- Kim, M.; Kim, S. Practical limit of energy production from seawater by full-scale pressure retarded osmosis. Energy 2018, 158, 373–382. [Google Scholar] [CrossRef]

- Chekli, L.; Phuntsho, S.; Shon, H.K.; Vigneswaran, S.; Kandasamy, J.; Chanan, A. A review of draw solutes in forward osmosis process and their use in modern applications. Desalin. Water Treat. 2012, 43, 167–184. [Google Scholar] [CrossRef]

- Gwak, G.; Hong, S. Chapter 3—Draw Solute Selection. In Membrane-Based Salinity Gradient Processes for Water Treatment and Power Generation; Sarp, S., Hilal, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 87–122. [Google Scholar]

- Cai, Y.; Hu, X.M. A critical review on draw solutes development for forward osmosis. Desalination 2016, 391, 16–29. [Google Scholar] [CrossRef]

- Alejo, T.; Arruebo, M.; Carcelen, V.; Monsalvo, V.M.; Sebastian, V. Advances in draw solutes for forward osmosis: Hybrid organic-inorganic nanoparticles and conventional solutes. Chem. Eng. J. 2017, 309, 738–752. [Google Scholar] [CrossRef]

- Johnson, D.J.; Suwaileh, W.A.; Mohammed, A.W.; Hilal, N. Osmotic’s potential: An overview of draw solutes for forward osmosis. Desalination 2018, 434, 100–120. [Google Scholar] [CrossRef]

- Dutta, S.; Nath, K. Prospect of ionic liquids and deep eutectic solvents as new generation draw solution in forward osmosis process. J. Water Process Eng. 2018, 21, 163–176. [Google Scholar] [CrossRef]

- Ge, Q.; Ling, M.; Chung, T.-S. Draw solutions for forward osmosis processes: Developments, challenges, and prospects for the future. J. Membr. Sci. 2013, 442, 225–237. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, W.; Ge, Q. Synthetic draw solutes for forward osmosis: Status and future. Rev. Chem. Eng. 2018, 34, 767. [Google Scholar] [CrossRef]

- Xu, Y.; Peng, X.; Tang, C.Y.; Fu, Q.S.; Nie, S. Effect of draw solution concentration and operating conditions on forward osmosis and pressure retarded osmosis performance in a spiral wound module. J. Membr. Sci. 2010, 348, 298–309. [Google Scholar] [CrossRef]

- Sivertsen, E.; Holt, T.; Thelin, W.R. Concentration and Temperature Effects on Water and Salt Permeabilities in Osmosis and Implications in Pressure-Retarded Osmosis. Membranes 2018, 8, 39. [Google Scholar] [CrossRef]

- Hawari, A.H.; Kamal, N.; Altaee, A. Combined influence of temperature and flow rate of feeds on the performance of forward osmosis. Desalination 2016, 398, 98–105. [Google Scholar] [CrossRef]

- Maisonneuve, J.; Pillay, P.; Laflamme, C.B. Pressure-retarded osmotic power system model considering non-ideal effects. Renew. Energy 2015, 75, 416–424. [Google Scholar] [CrossRef]

- He, W.; Luo, X.; Kiselychnyk, O.; Wang, J.; Shaheed, M.H. Maximum power point tracking (MPPT) control of pressure retarded osmosis (PRO) salinity power plant: Development and comparison of different techniques. Desalination 2016, 389, 187–196. [Google Scholar] [CrossRef]

- He, W.; Wang, Y.; Shaheed, M.H. Maximum power point tracking (MPPT) of a scale-up pressure retarded osmosis (PRO) osmotic power plant. Appl. Energy 2015, 158, 584–596. [Google Scholar] [CrossRef]

- Chen, Y.; Vepa, R.; Shaheed, M.H. Enhanced and speedy energy extraction from a scaled-up pressure retarded osmosis process with a whale optimization based maximum power point tracking. Energy 2018, 153, 618–627. [Google Scholar] [CrossRef]

- Maisonneuve, J.; Chintalacheruvu, S. Increasing osmotic power and energy with maximum power point tracking. Appl. Energy 2019, 238, 683–695. [Google Scholar] [CrossRef]

- Manzoor, H.; Selam, M.A.; Abdur Rahman, F.B.; Adham, S.; Castier, M.; Abdel-Wahab, A. A tool for assessing the scalability of pressure-retarded osmosis (PRO) membranes. Renew. Energy 2019. [Google Scholar] [CrossRef]

- Ettouney, H.; Al-Hajri, K. Modeling and performance analysis of forward and pressure-retarded osmosis. Desalin. Water Treat. 2019, 154, 1–13. [Google Scholar] [CrossRef]

- Chen, Y.; Alanezi, A.A.; Zhou, J.; Altaee, A.; Shaheed, M.H. Optimization of module pressure retarded osmosis membrane for maximum energy extraction. J. Water Process Eng. 2019, 32, 100935. [Google Scholar] [CrossRef]

- Touati, K.; Tadeo, F. Study of the Reverse Salt Diffusion in pressure retarded osmosis: Influence on concentration polarization and effect of the operating conditions. Desalination 2016, 389, 171–186. [Google Scholar] [CrossRef]

- Jung, D.H.; Lee, J.; Kim, D.Y.; Lee, Y.G.; Park, M.; Lee, S.; Yang, D.R.; Kim, J.H. Simulation of forward osmosis membrane process: Effect of membrane orientation and flow direction of feed and draw solutions. Desalination 2011, 277, 83–91. [Google Scholar] [CrossRef]

- Bui, N.-N.; Arena, J.T.; McCutcheon, J.R. Proper accounting of mass transfer resistances in forward osmosis: Improving the accuracy of model predictions of structural parameter. J. Membr. Sci. 2015, 492, 289–302. [Google Scholar] [CrossRef]

- Tang, C.Y.; Chong, T.H.; Fane, A.G. Colloidal interactions and fouling of NF and RO membranes: A review. Adv. Colloid Interface Sci. 2011, 164, 126–143. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.T.D.; Park, K.; Smith, A.D. Performance Analysis for Pressure Retarded Osmosis: Experimentation With High Pressure Difference and Varying Flow Rate, Considering Exposed Membrane Area. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition IMECE, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar]

- Seker, M.; Buyuksari, E.; Topcu, S.; Sesli, D.; Celebi, D.; Keskinler, B.; Aydiner, C. Effect of process parameters on flux for whey concentration with NH3/CO2 in forward osmosis. Food Bioprod. Process. 2017, 105, 64–76. [Google Scholar] [CrossRef]

- Gulied, M.; Al Momani, F.; Khraisheh, M.; Bhosale, R.; AlNouss, A. Influence of draw solution type and properties on the performance of forward osmosis process: Energy consumption and sustainable water reuse. Chemosphere 2019, 233, 234–244. [Google Scholar] [CrossRef] [PubMed]

- Hickenbottom, K.L.; Vanneste, J.; Elimelech, M.; Cath, T.Y. Assessing the current state of commercially available membranes and spacers for energy production with pressure retarded osmosis. Desalination 2016, 389, 108–118. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Wang, Y. Treatment of greywater by forward osmosis technology: Role of the operating temperature. Environ. Technol. 2019, 40, 3434–3443. [Google Scholar] [CrossRef] [PubMed]

- Touati, K.; Tadeo, F.; Hänel, C.; Schiestel, T. Effect of the operating temperature on hydrodynamics and membrane parameters in pressure retarded osmosis. Desalin. Water Treat. 2015, 57, 10477–10489. [Google Scholar] [CrossRef]

- Shin, S.; Kim, A.S. Temperature Effect on Forward Osmosis. In Osmotically Driven Membrane Processes—Approach, Development and Current Status; IntechOpen: London, UK, 2018. [Google Scholar]

- Touati, K.; Tadeo, F. Chapter Three—Effects of the Temperatures on PRO. In Pressure Retarded Osmosis; Touati, K., Tadeo, F., Chae, S.H., Kim, J.H., Alvarez-Silva, O., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 97–128. [Google Scholar]

- Anastasio, D.D.; Arena, J.T.; Cole, E.A.; McCutcheon, J.R. Impact of temperature on power density in closed-loop pressure retarded osmosis for grid storage. J. Membr. Sci. 2015, 479, 240–245. [Google Scholar] [CrossRef]

- Zhao, S.; Zou, L. Effects of working temperature on separation performance, membrane scaling and cleaning in forward osmosis desalination. Desalination 2011, 278, 157–164. [Google Scholar] [CrossRef]

- Phuntsho, S.; Vigneswaran, S.; Kandasamy, J.; Hong, S.; Lee, S.; Shon, H.K. Influence of temperature and temperature difference in the performance of forward osmosis desalination process. J. Membr. Sci. 2012, 415–416, 734–744. [Google Scholar] [CrossRef]

- Kim, Y.C.; Elimelech, M. Potential of osmotic power generation by pressure retarded osmosis using seawater as feed solution: Analysis and experiments. J. Membr. Sci. 2013, 429, 330–337. [Google Scholar] [CrossRef]

- Heo, J.; Chu, K.H.; Her, N.; Im, J.; Park, Y.-G.; Cho, J.; Sarp, S.; Jang, A.; Jang, M.; Yoon, Y. Organic fouling and reverse solute selectivity in forward osmosis: Role of working temperature and inorganic draw solutions. Desalination 2016, 389, 162–170. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, Z.; Li, J.; Tang, Q.; Hu, Y. Investigation of the reduced specific energy consumption of the RO-PRO hybrid system based on temperature-enhanced pressure retarded osmosis. J. Membr. Sci. 2019, 581, 439–452. [Google Scholar] [CrossRef]

| Parameters | Cellulose Triacetate | Thin-Film Composite |

|---|---|---|

| Thickness of active layer (µm) | 6.1 ± 2.0 | 4.9 ± 1.1 |

| Thickness of support layer (µm) | 51.4 ± 6.7 | 47.8 ± 2.5 |

| Pore size of SL (µm) | 5.3 ± 1.0 | 3.9 ± 2.0 |

| Contact angle of active layer (°) | 86.0 ± 4.5 | 79.2 ± 6.3 |

| Contact angle of support layer (°) | 72.8 ± 1.9 | 73.8 ± 6.0 |

| Water permeability (A) (L/(m2 h bar)) | 0.70 ± 0.07 | 1.24 ± 0.04 |

| Salt permeability (B) (L/(m2 h)) | 0.53 ± 0.03 | 0.37 ± 0.08 |

| Salt rejection rate (%) | 94.7 ± 0.1 | 97.7 ± 0.5 |

| Water flux | Lower | Higher |

| Reverse solute flux | Lower | Higher |

| Type of Nanomaterials | Nanoparticles Incorporated | Effects | Water Flux (Jw, L/m2 h) | Ref. | |

|---|---|---|---|---|---|

| Unmodified | Incorporated | ||||

| Carbon nanotubes | 400 ppm sulfonated carbon nanotubes |

| 21.3 ± 2.1 | 29.9 ± 1.6 | Li, et al. [38] |

| Zeolites | 0.4 wt % modified clinoptilolite |

| 16.3 | 24.61 | Salehi, et al. [39] |

| Zwitterions | Poly [3-(N-2-methacryloylxyethyl-N,N-dimethyl)-ammonatopropanesulfonate] (PMAPS) |

| 12.54 | 15.79 | Lee, et al. [40] |

| Graphene oxide | 0.1% graphene oxide nanosheets |

| 7.9 | 14.5 | Shokrgozar Eslah, et al. [41] |

| Carbon quantum dots | Na+-functionalized carbon quantum dots |

| 24.25 ± 2.8 | 34.86 ± 1.41 | Gai, et al. [42] |

| Metal and metal oxide nanoparticles | 0.5 wt % molybdenum oxide NPs (MoO3) |

| ~21 | 67 | Amini, et al. [43] |

| Polyelectrolytes | Layer-by-layer polyvinylidenefluoride (PVDF) |

| 5.4 | 24.1 | Gonzales, et al. [44] |

| Metal–organic frameworks | 0.12 w/v % copper 1,4-benzenedicarboxylate nanosheets, CuBDC-NS |

| 18 | 28 | Dai, et al. [45] |

| Membrane | Feed Solution | Draw Solution | Hydraulic Pressure (Bar) | Power Density (W/m2) | Ref. |

|---|---|---|---|---|---|

| TFC | DI water | 1.2 M NaCl | 30 | 38 | Wan, et al. [56] |

| TFC | DI water | 1 M NaCl | 16.5 | 14.6 | Park, et al. [57] |

| TFC | DI water | 0.81 M NaCl | 20 | 18.8 | Zhang, et al. [58] |

| TFC | DI water | 1.0 M NaCl | 20 | 12.1 | Gonzales, et al. [59] |

| TFC | DI water | 1 M NaCl | 21 | 16.7 | Lim, et al. [60] |

| TFC | DI water | 1 M NaCl | 20 | 20 | Wan, et al. [61] |

| TFC | DI water | 1 M NaCl | 20 | 27 | Wan and Chung [62] |

| Type of Fouling | Model Foulants |

|---|---|

| Organic | Alginate, humic acid (HA), and bovine serum albumin (BSA) |

| Inorganic | Calcium salts and silica |

| Colloidal | Colloidal silica particles |

| Biological | Escherichia coli bacteria suspensions |

| Membrane | FS | DS | Temperature (°C) | Increase in Water Flux Per °C (%) | Increase in Specific Power Per °C (%) | Ref. |

|---|---|---|---|---|---|---|

| CTA-HTI | Brackish water | 1.5 M Na2SO4 | 25–35 | 3.1 | - | Zhao and Zou [120] |

| 35–45 | 1.2 | |||||

| CTA-HTI | 10 mM NaCl | 1 M NaCl | 25–35 | 4.1 | 3.4 | She, Jin and Tang [71] |

| CTA-HTI | Brackish water | 0.5 M KCl | 25–35 | 1.7 | - | Phuntsho, et al. [121] |

| 25–45 | 3.2 | |||||

| CTA-HTI | 0.5 M NaCl | 1 M NaCl | 20–30 | 7.1 | 6.5 | Kim and Elimelech [122] |

| 1.5 M NaCl | 3.9 | 3.3 | ||||

| 2 M NaCl | 5.0 | 4.7 | ||||

| CA-HTI | DI water | 1.5 M NaCl | 20–40 | - | 5.2 | Anastasio, Arena, Cole and McCutcheon [119] |

| CTA-HTI | DI water | 2 M NaCl | 5–20 | 2.9 | - | Heo, et al. [123] |

| 20–45 | 3.3 | |||||

| TFC-TCK | 0.01 M NaCl | 0.6 M NaCl | 25–50 | 2.9 | 3.2 | Wang, et al. [124] |

| 1.2 M NaCl | 3.0 | 3.1 | ||||

| TFC | Municipal wastewater | Synthetic seawater concentrate | 15–25 | 4.0 | - | Yang, Gao, Jang, Shon and Yue [83] |

| 25–35 | 1.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chia, W.Y.; Khoo, K.S.; Chia, S.R.; Chew, K.W.; Yew, G.Y.; Ho, Y.-C.; Show, P.L.; Chen, W.-H. Factors Affecting the Performance of Membrane Osmotic Processes for Bioenergy Development. Energies 2020, 13, 481. https://doi.org/10.3390/en13020481

Chia WY, Khoo KS, Chia SR, Chew KW, Yew GY, Ho Y-C, Show PL, Chen W-H. Factors Affecting the Performance of Membrane Osmotic Processes for Bioenergy Development. Energies. 2020; 13(2):481. https://doi.org/10.3390/en13020481

Chicago/Turabian StyleChia, Wen Yi, Kuan Shiong Khoo, Shir Reen Chia, Kit Wayne Chew, Guo Yong Yew, Yeek-Chia Ho, Pau Loke Show, and Wei-Hsin Chen. 2020. "Factors Affecting the Performance of Membrane Osmotic Processes for Bioenergy Development" Energies 13, no. 2: 481. https://doi.org/10.3390/en13020481

APA StyleChia, W. Y., Khoo, K. S., Chia, S. R., Chew, K. W., Yew, G. Y., Ho, Y.-C., Show, P. L., & Chen, W.-H. (2020). Factors Affecting the Performance of Membrane Osmotic Processes for Bioenergy Development. Energies, 13(2), 481. https://doi.org/10.3390/en13020481