Characteristic Analysis of Torrefied Pellets: Determining Optimal Torrefaction Conditions for Agri-Byproduct

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Torrefaction Experiments

2.3. Fuel Characteristic Evaluation

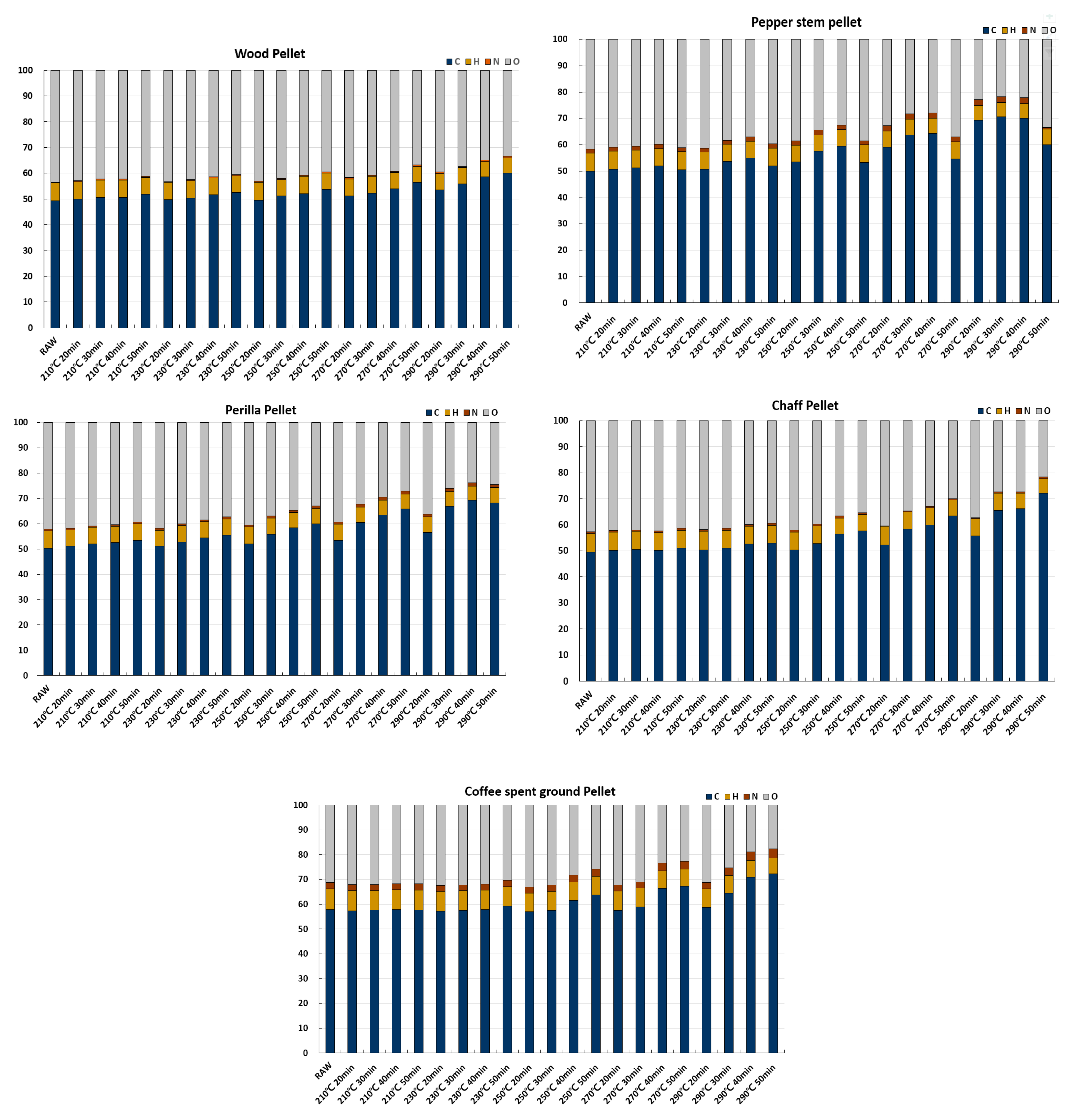

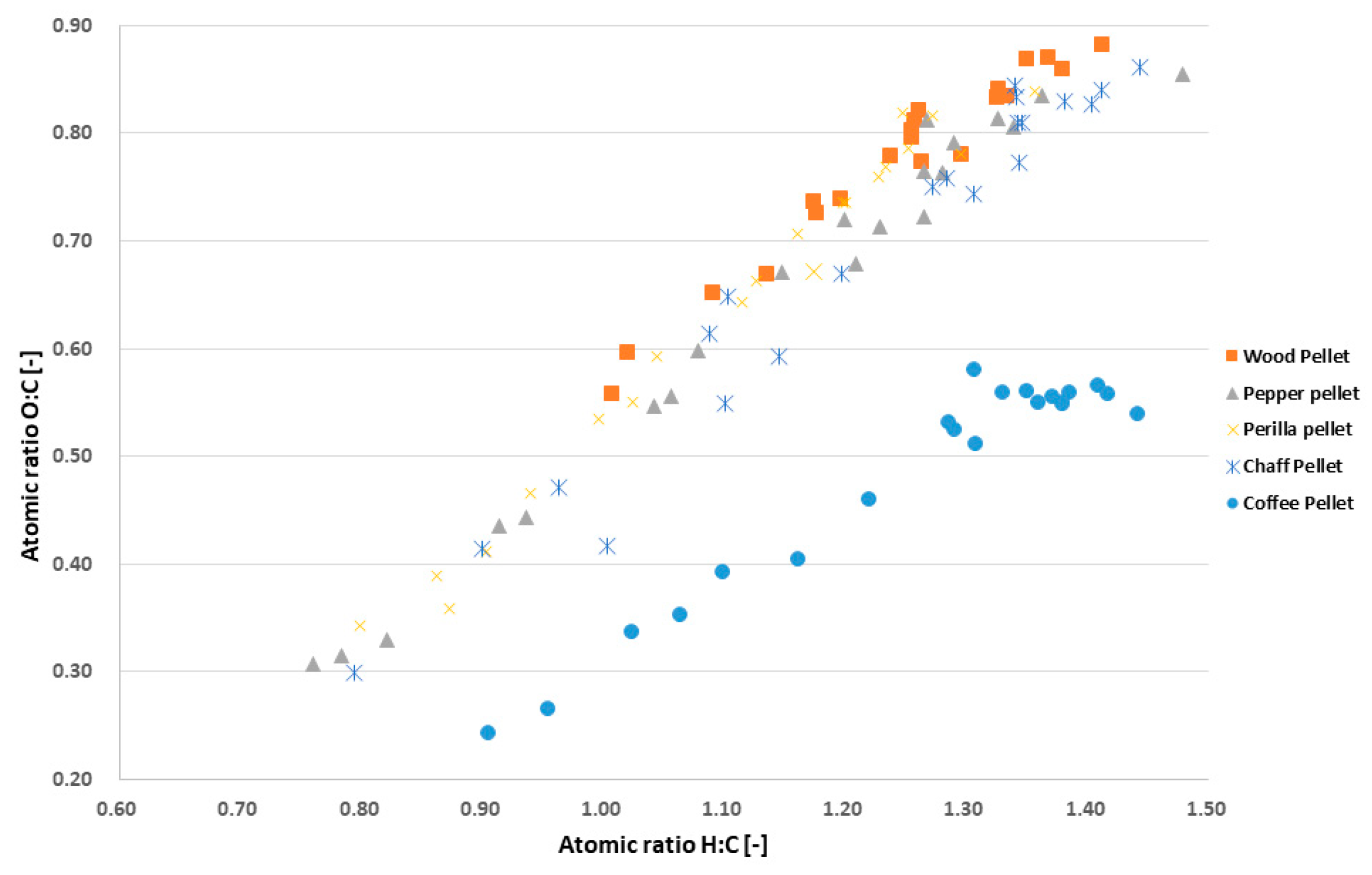

2.3.1. Ultimate Analysis and Van Krevelen Diagram

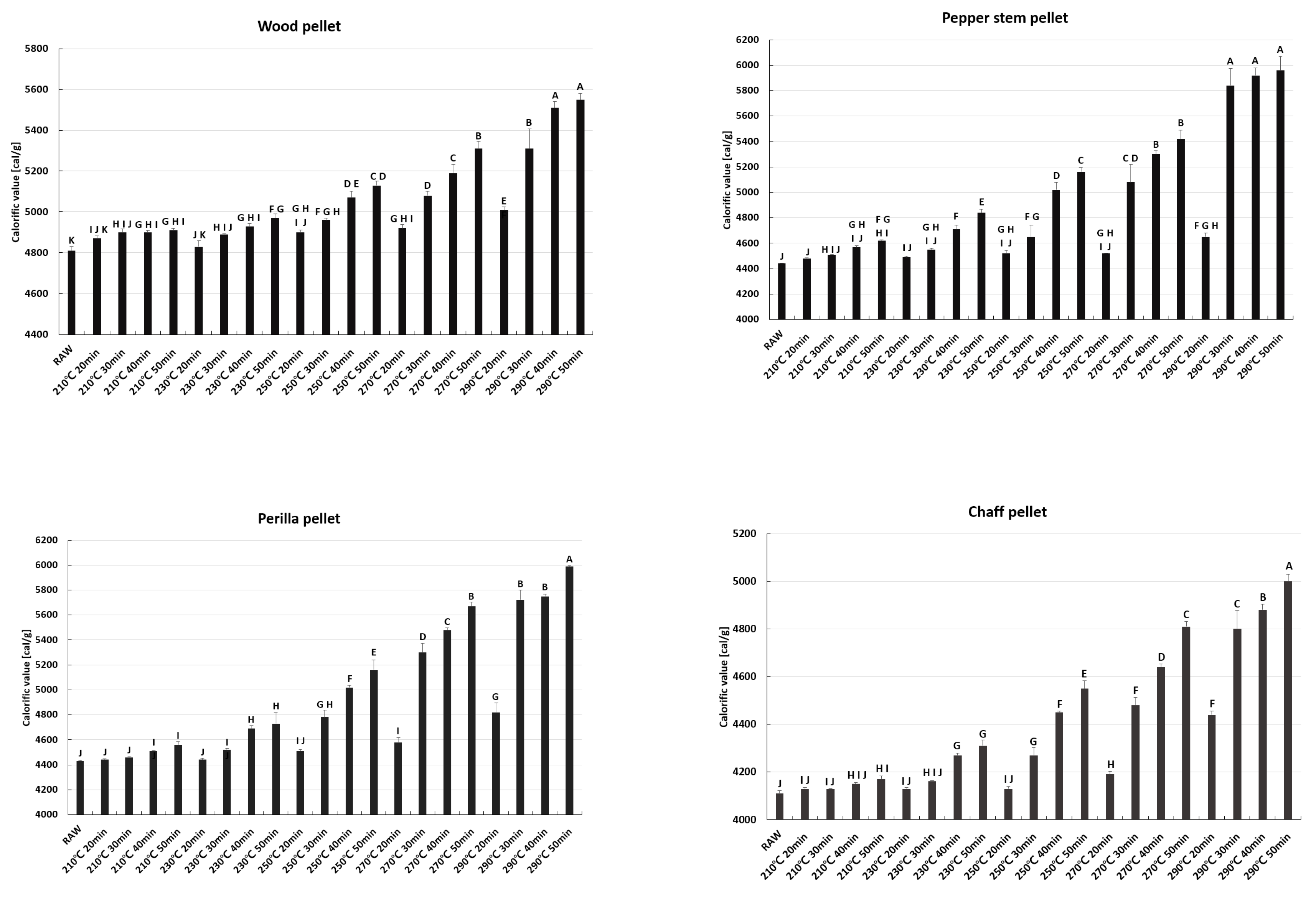

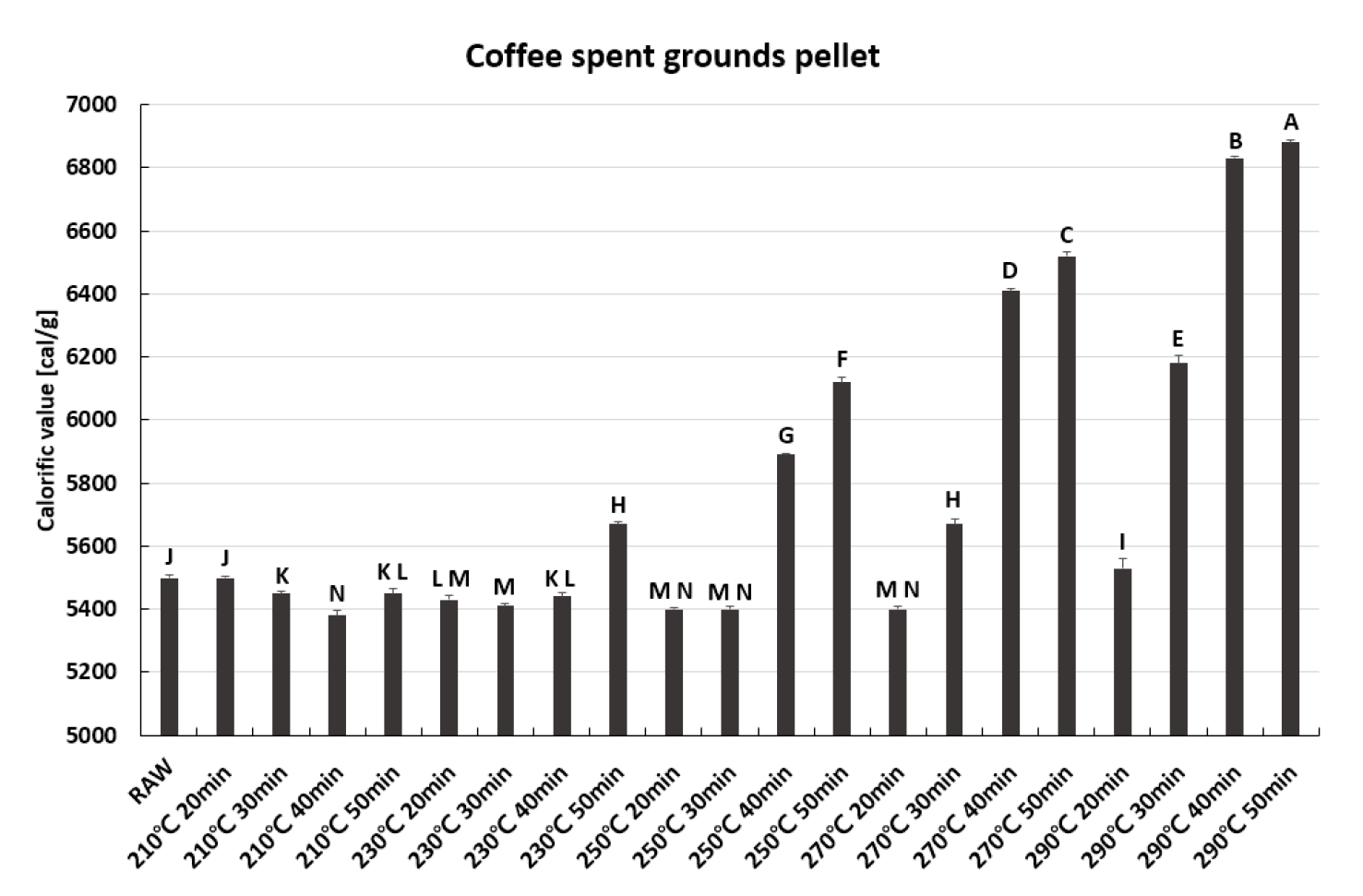

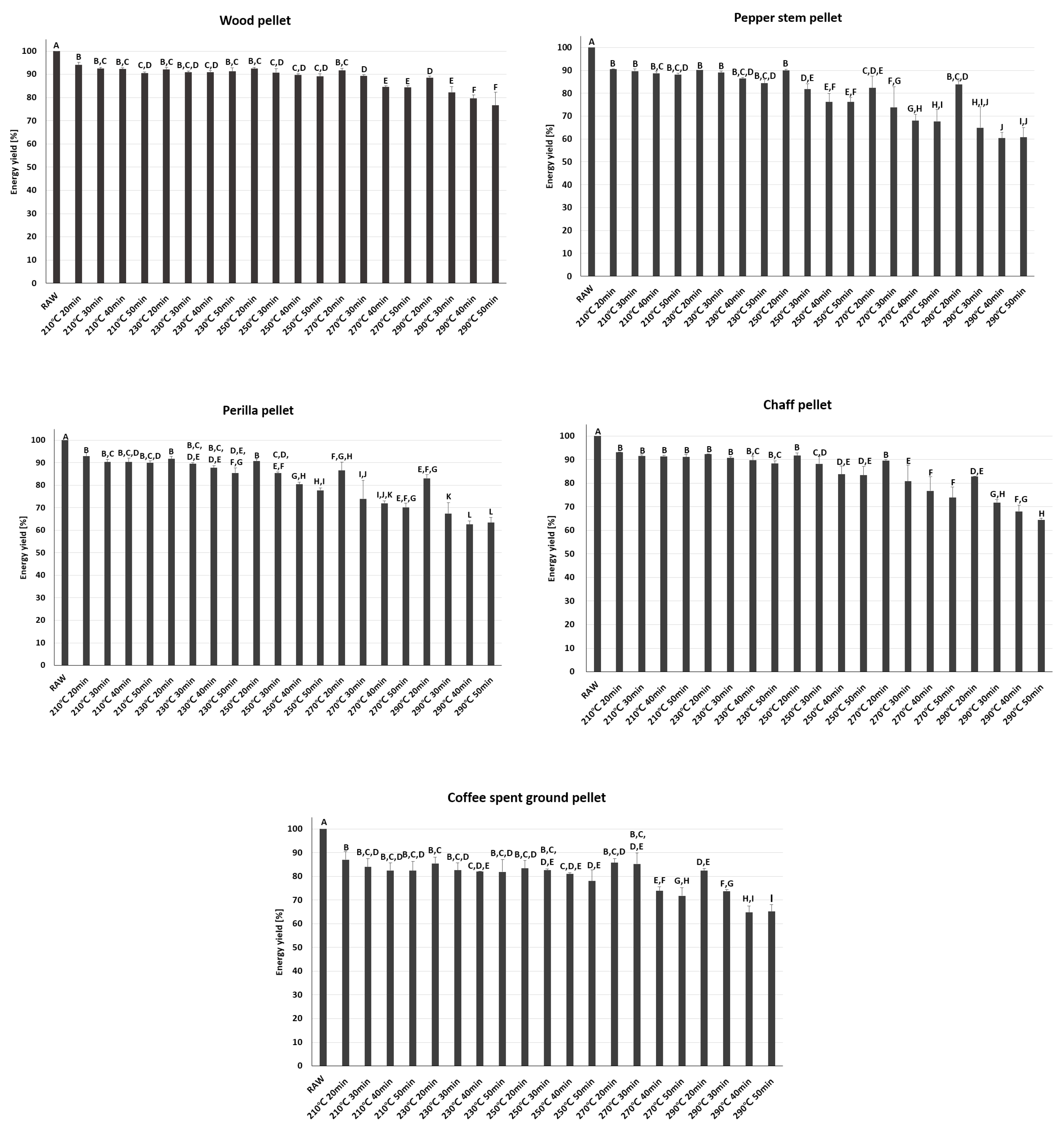

2.3.2. Calorific Value and Energy Yield

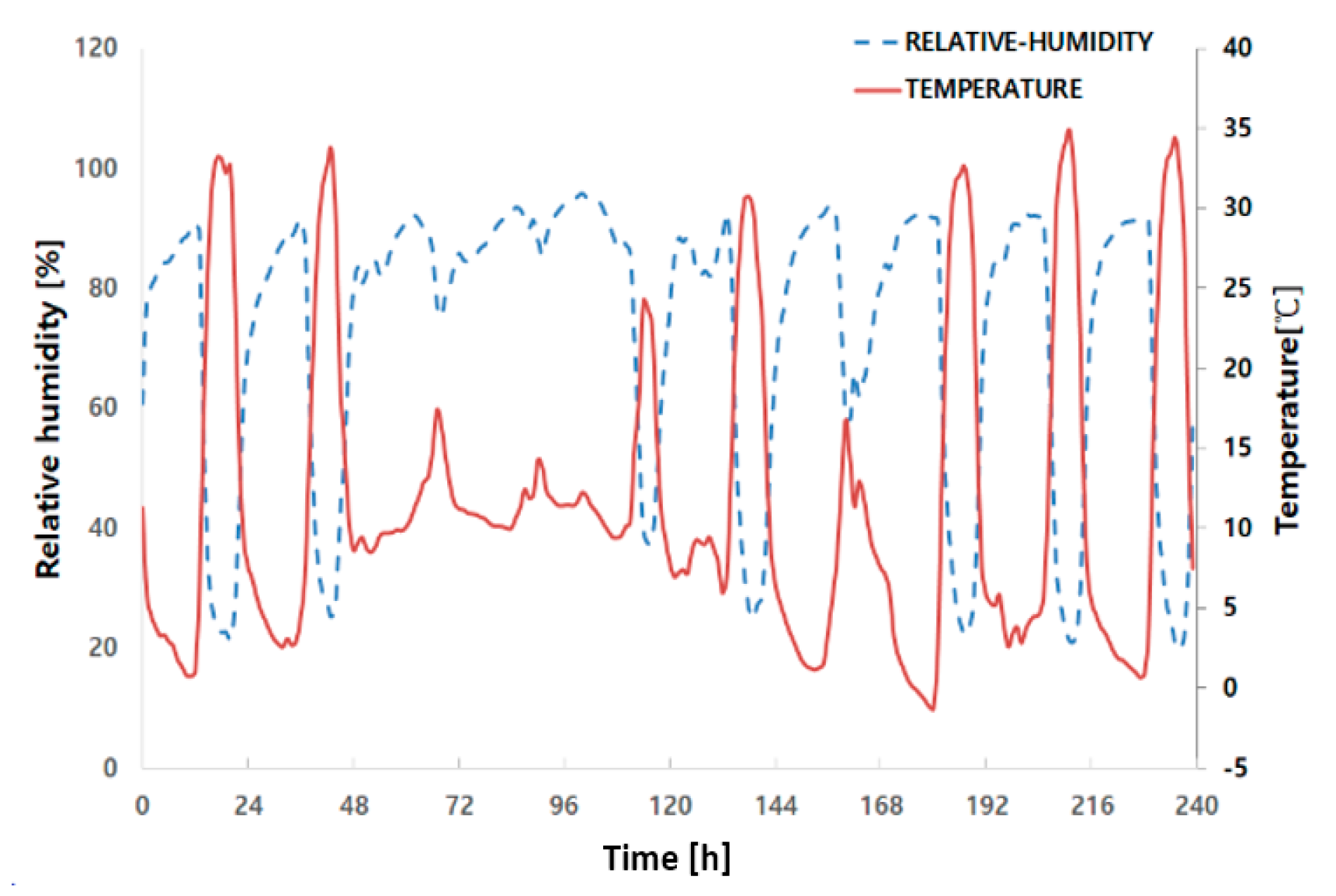

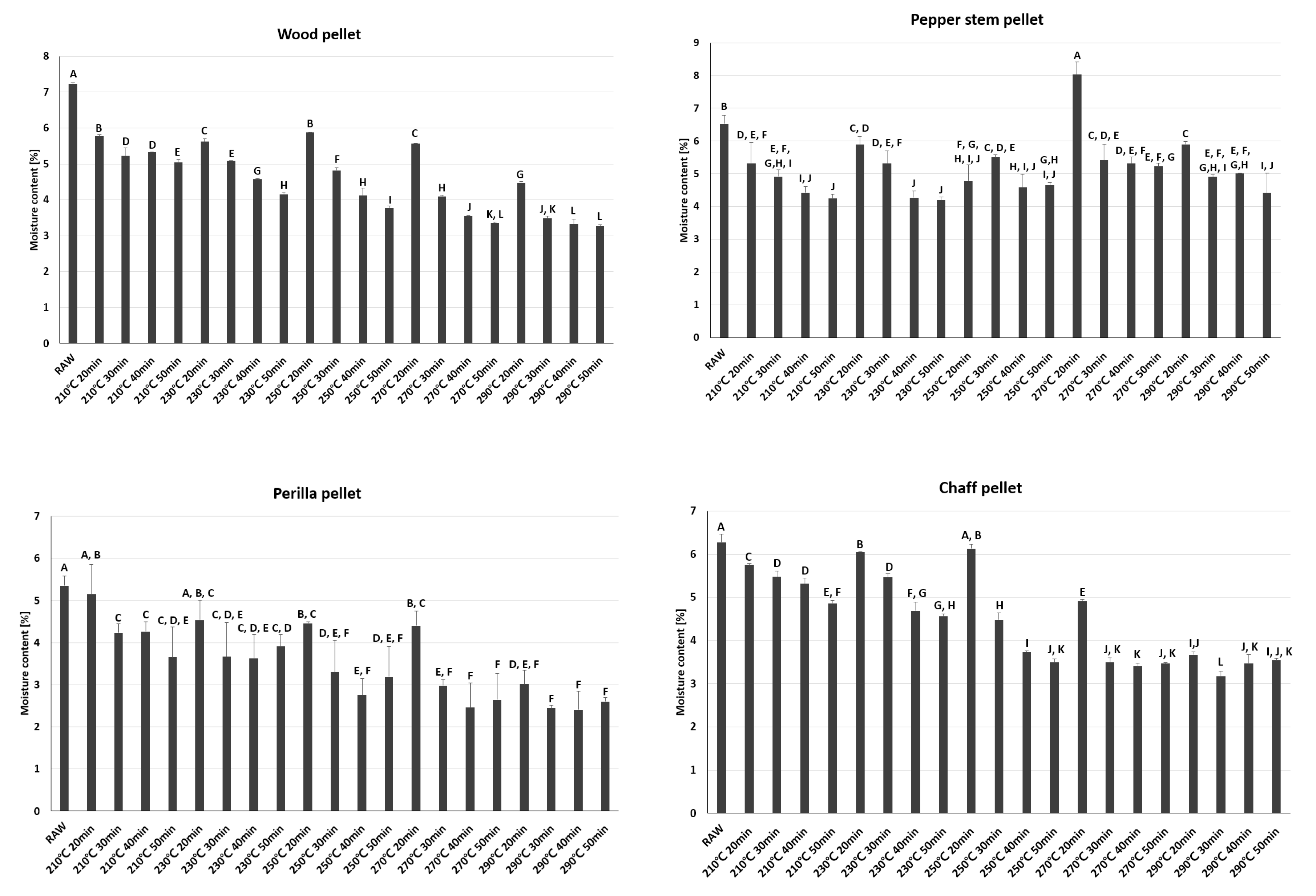

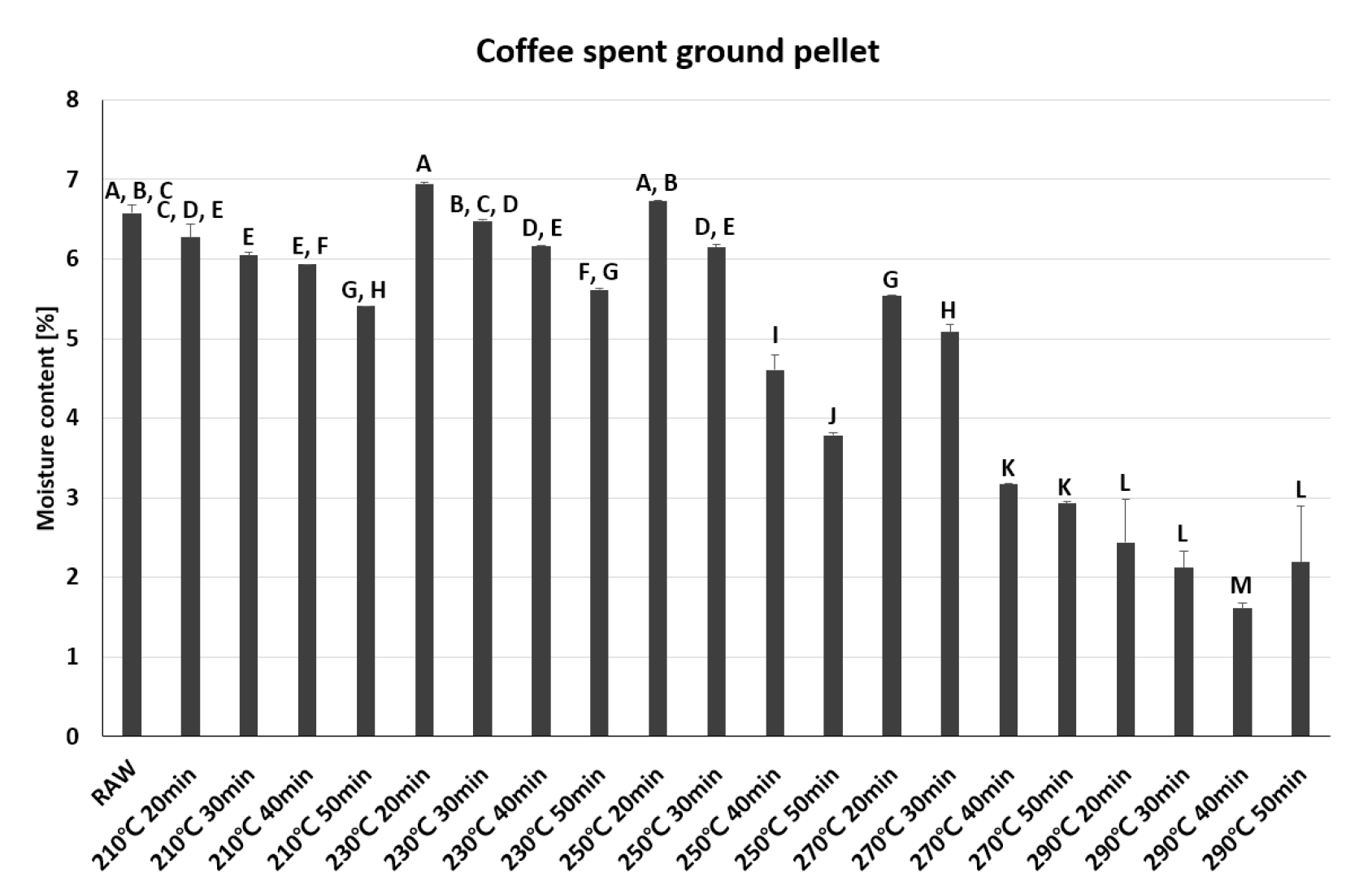

2.3.3. Hygroscopicity Evaluation

2.3.4. The Lower Heating Value (LHV) and Exergy Analysis

3. Results

3.1. Torrefied Pellets

3.2. Mass Yield

3.3. Ultimate Analysis and Van Krevelen Diagram

3.4. Calorific Value and Energy Yield

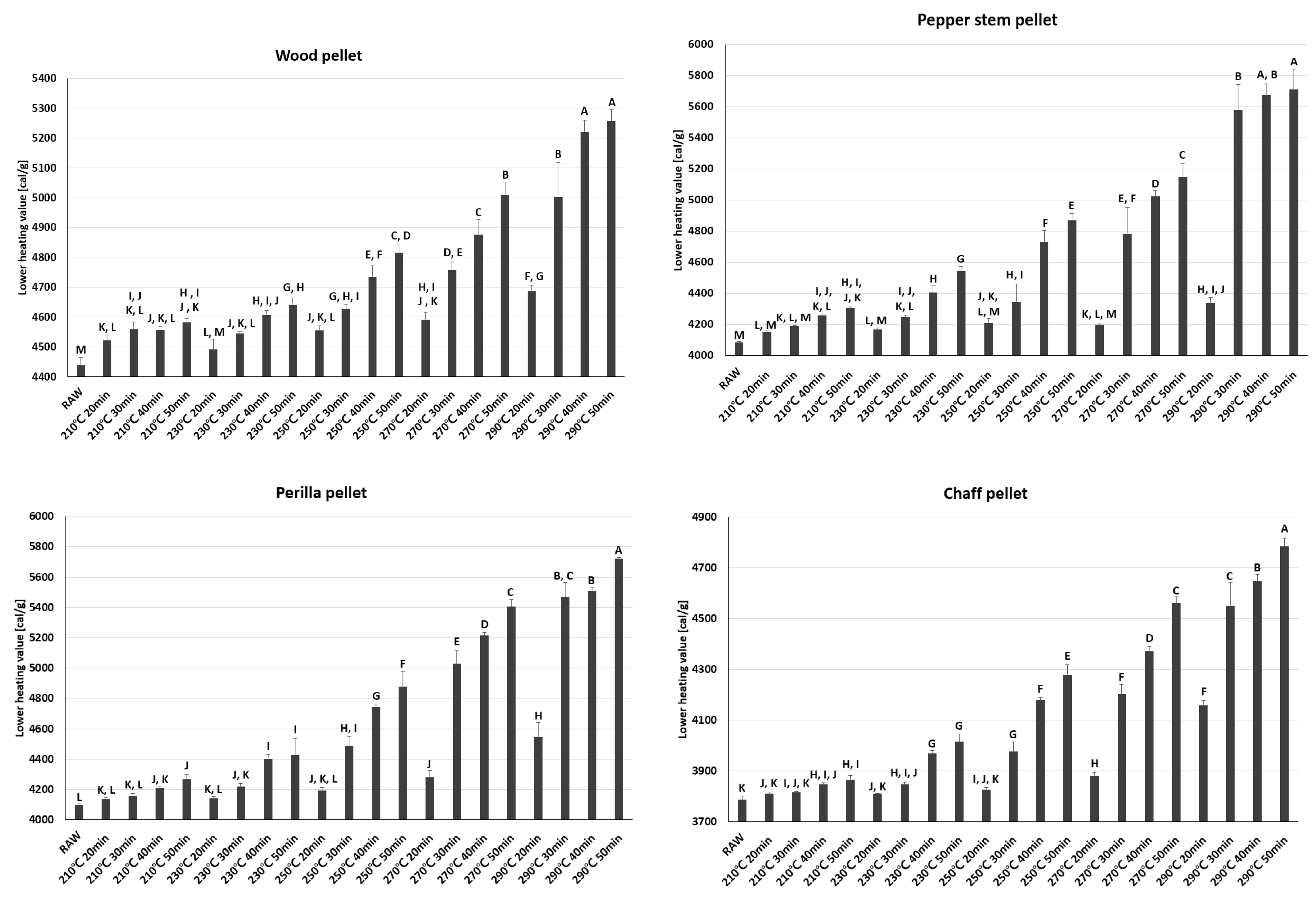

3.5. Hygroscopicity Evaluation and the Lower Heating Value

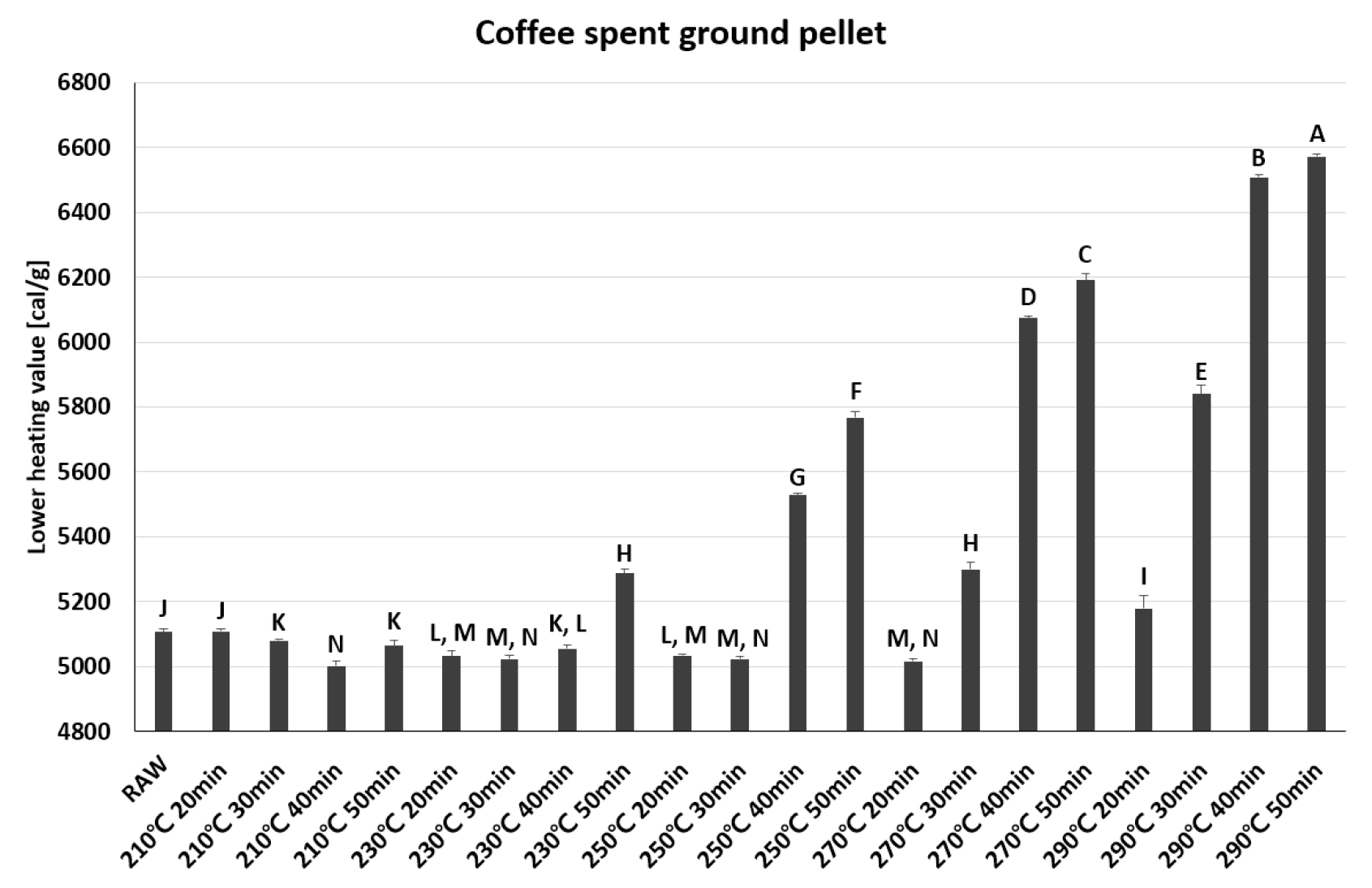

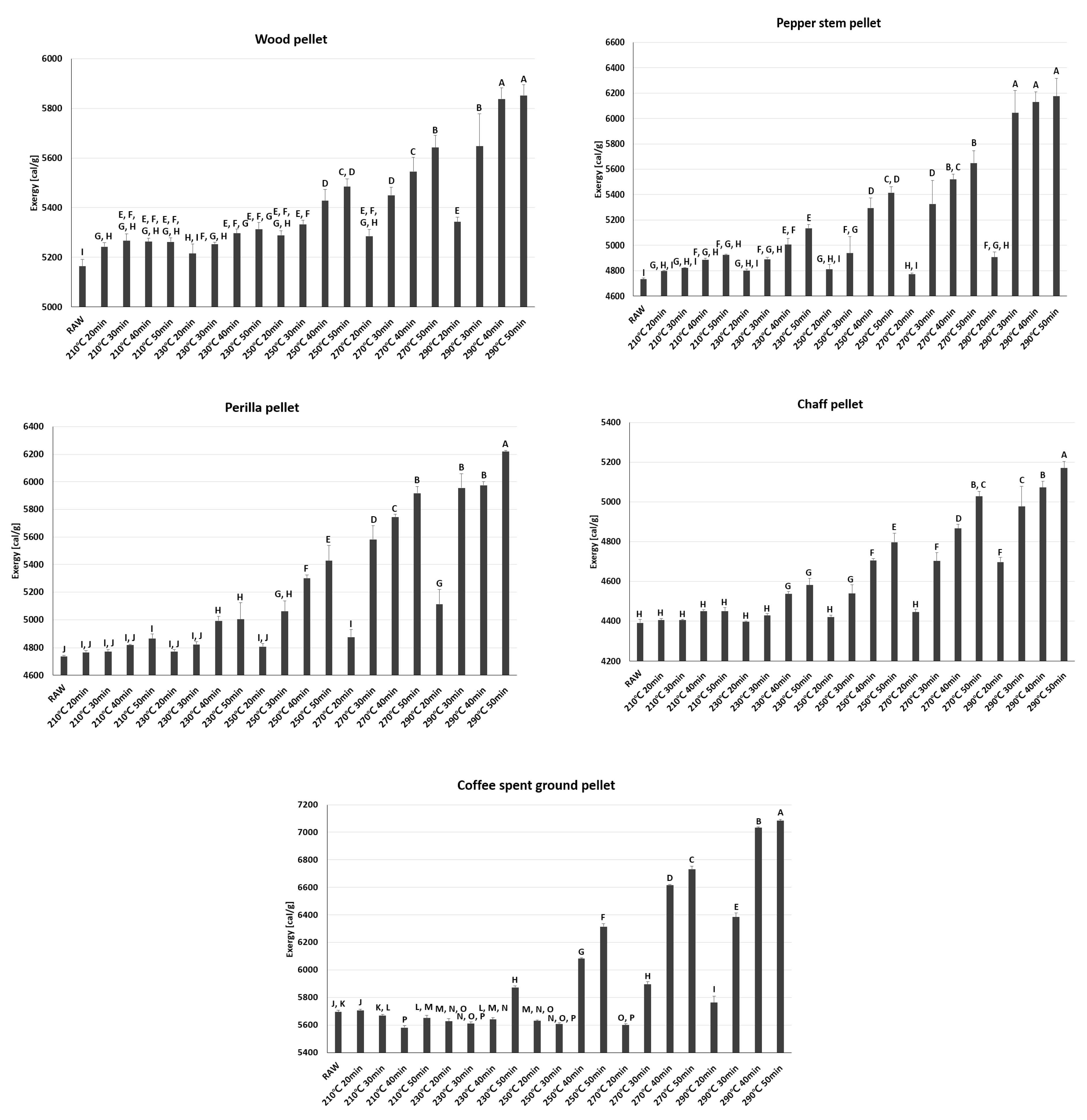

3.6. The Lower Heating Value and Exergy Analysis

3.7. Estimation of Optimal Torrefaction Conditions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Forest Biomass Energy Association 2017 (Production+Import+Price+Stock). Available online: http://www.biomassenergy.kr/ (accessed on 1 November 2018).

- Lee, J.; Park, S. Estimation of Geographical & Technical Potential for Biomass Resources. New Renew. Energy 2016, 12, 53. [Google Scholar]

- Kanwal, S.; Chaudhry, N.; Munir, S.; Sana, H. Effect of torrefaction conditions on the physicochemical characterization of agricultural waste (sugarcane bagasse). Waste Manag. 2019, 88, 280–290. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; Protásio, T. Comparative energy properties of torrefied pellets in relation to pine and elephant grass pellets. BioResources 2018, 13, 2898–2906. [Google Scholar] [CrossRef]

- Azócar, L.; Hermosilla, N.; Gay, A.; Rocha, S.; Díaz, J.; Jara, P. Brown pellet production using wheat straw from southern cities in Chile. Fuel 2019, 237, 823–832. [Google Scholar] [CrossRef]

- Aurel, L.; Cosmin, S.; Tatiana, D. Effects and modeling of sawdust torrefaction for beech pellets. Bioresources 2015, 10, 4726–4739. [Google Scholar]

- Peng, J.; Wang, J.; Bi, X.T.; Lim, C.J.; Sokhansanj, S.; Peng, H.; Jia, D. Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process. Technol. 2015, 129, 168–173. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, M.; Zhang, M.; Zhang, K.; Wang, D.; Lei, C. A fundamental research on synchronized torrefaction and pelleting of biomass. Renew. Energy 2019, 142, 668–676. [Google Scholar] [CrossRef]

- Oh, K.C.; Park, S.Y.; Kim, S.J.; Choi, Y.S.; Lee, C.G.; Cho, L.H.; Kim, D.H. Development and validation of mass reduction model to optimize torrefaction for agricultural byproduct biomass. Renew. Energy 2019, 139, 988–999. [Google Scholar] [CrossRef]

- Cruz Ceballos, D.C.; Hawboldt, K.; Hellleur, R. Effect of production conditions on self-heating propensity of torrefied sawmill residues. Fuel 2015, 160, 227–237. [Google Scholar] [CrossRef]

- Rodrigues, T.O.; Rousset, P.L.A. Effects of Torrefaction on Energy Properties of Eucalyptus Grandis Wood. Cern. Lavras 2009, 15, 446–452. [Google Scholar]

- Chen, W.H.; Lin, B.J.; Colin, B.; Chang, J.S.; Pétrissans, A.; Bi, X.; Pétrissans, M. Hygroscopic transformation of woody biomass torrefaction for carbon storage. Appl. Energy 2018, 231, 768–776. [Google Scholar] [CrossRef]

- Felfli, F.F.; Luengo, C.A.; Suárez, J.A.; Beatón, P.A. Wood briquette torrefaction. Energy Sustain. Dev. 2005, 9, 19–22. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory; Academic Press: Cambridge, MA, USA, 2013; ISBN 9780123964885. [Google Scholar]

- Morris, D.R.; Steward, F.R. Exergy analysis of a chemical metallurgical process. Metall. Trans. B 1984, 15, 645–654. [Google Scholar] [CrossRef]

| Properties | Units | WP | PEP | PRP | CHP | CFP |

|---|---|---|---|---|---|---|

| Moisture content | % | 9.0 | 10.6 | 9.7 | 9.3 | 11.1 |

| Ash content | % | 0.4 | 5.6 | 5.8 | 12.6 | 1.8 |

| Gross calorific value | kcal kg−1 | 4810 | 4440 | 4430 | 4110 | 5500 |

| Chlorine | % | 0.01 | 0.67 | 0.19 | 0.19 | <0.01 |

| Sulfur | % | 0.02 | 0.12 | 0.12 | 0.06 | 0.05 |

| As | mg kg−1 | N.D. | N.D. | N.D. | N.D. | N.D. |

| Cd | mg kg−1 | 0.2 | N.D. | N.D. | N.D. | N.D. |

| Cr | mg kg−1 | 1 | 2 | 3 | 9 | <1 |

| Cu | mg kg−1 | 4 | 20 | 15 | 5 | 31 |

| Pb | mg kg−1 | 1 | 1 | 2 | <1 | <1 |

| Hg | mg kg−1 | N.D. | 0.01 | 0.01 | <0.01 | <0.01 |

| Ni | mg kg−1 | 1 | 2 | 2 | 2 | 1 |

| Zn | mg kg−1 | 6 | 25 | 56 | 36 | 16 |

| Temp [°C] | Time [min] | PEP [%] | PRP [%] | CHP [%] | CFP [%] | WP [%] |

|---|---|---|---|---|---|---|

| 210 | 20 | 90 (0.75) | 93 (0.75) | 93 (0.11) | 87 (0.24) | 93 (0.26) |

| 30 | 88 (0.85) | 90 (0.85) | 91 (0.02) | 85 (0.17) | 91 (0.32) | |

| 40 | 86 (0.19) | 89 (0.19) | 91 (0.52) | 84 (0.21) | 91 (0.25) | |

| 50 | 85 (0.48) | 87 (0.48) | 90 (0.15) | 83 (0.35) | 89 (0.52) | |

| 230 | 20 | 89 (0.22) | 92 (0.22) | 92 (0.55) | 86 (0.25) | 92 (0.31) |

| 30 | 87 (0.54) | 88 (0.54) | 90 (0.07) | 84 (0.15) | 89 (1.38) | |

| 40 | 81 (1.10) | 83 (1.10) | 87 (1.04) | 83 (0.58) | 89 (0.74) | |

| 50 | 77 (1.41) | 80 (1.41) | 84 (1.41) | 79 (0.39) | 88 (1.14) | |

| 250 | 20 | 88 (0.94) | 89 (0.94) | 91 (0.52) | 85 (0.61) | 91 (0.45) |

| 30 | 78 (0.35) | 79 (0.35) | 85 (1.48) | 84 (0.63) | 88 (0.57) | |

| 40 | 67 (2.61) | 71 (2.61) | 77 (0.29) | 75 (2.31) | 85 (0.63) | |

| 50 | 65 (1.66) | 67 (1.66) | 75 (2.20) | 71(1.65) | 84 (1.86) | |

| 270 | 20 | 81 (5.68) | 84 (5.68) | 88 (1.83) | 87 (0.60) | 90 (0.67) |

| 30 | 65 (5.07) | 62 (5.07) | 74 (2.74) | 83 (0.79) | 85 (1.53) | |

| 40 | 57 (2.66) | 58 (2.66) | 68 (0.19) | 63 (2.73) | 78 (1.99) | |

| 50 | 55 (2.94) | 55 (2.94) | 63 (1.51) | 61 (2.26) | 76 (1.51) | |

| 290 | 20 | 80 (0.98) | 76 (0.98) | 77 (2.77) | 82 (1.57) | 85 (0.46) |

| 30 | 49 (6.60) | 52 (6.60) | 62 (4.04) | 65 (1.99) | 74 (2.87) | |

| 40 | 45(1.63) | 49 (1.63) | 57 (1.52) | 52 (0.78) | 69 (0.96) | |

| 50 | 45 (2.60) | 47 (2.60) | 53 (1.02) | 52 (1.70) | 66 (5.38) |

| Process | PEP | PRP | CHP | CFP | |||||

|---|---|---|---|---|---|---|---|---|---|

| LHV | UEx | LHV | UEx | LHV | UEx | LHV | UEx | ||

| Raw | 4085 (7.13) | 4733 | 4099 (4.85) | 4737 | 3786 (15.64) | 4391 | 5106 (10.82) | 5696 | |

| 210 °C | 20 min | 4152 (7.25) | 4306 | 4137 (12.04) | 4420 | 3810 (6.06) | 4092 | 5109 (7.02) | 4969 |

| 30 min | 4192 (1.07) | 4251 | 4159 (13.68) | 4281 | 3816 (3.16) | 4018 | 5079 (5.86) | 4805 | |

| 40 min | 4258 (10.17) | 4208 | 4211 (5.27) | 4276 | 3848 (5.99) | 4032 | 5002 (14.63) | 4698 | |

| 50 min | 4306 (5.44) | 4172 | 4269 (31.24) | 4247 | 3866 (3.72) | 3998 | 5065 (17.15) | 4708 | |

| 230 °C | 20 min | 4168 (10.82) | 4272 | 4142 (12.03) | 4372 | 3810 (3.72) | 4051 | 5032 (17.29) | 4864 |

| 30 min | 4248 (13.04) | 4248 | 4220 (16.89) | 4237 | 3847 (8.01) | 3977 | 5025 (11.37) | 4710 | |

| 40 min | 4407 (42.09) | 4072 | 4401 (28.30) | 4141 | 3970 (10.65) | 3927 | 5056 (12.43) | 4662 | |

| 50 min | 4546 (27.77) | 3972 | 4428 (107.65) | 4008 | 4016 (29.31) | 3860 | 5288 (10.97) | 4669 | |

| 250 °C | 20 min | 4209 (30.50) | 4251 | 4194 (19.33) | 4289 | 3827 (8.80) | 4035 | 5033 (4.04) | 4790 |

| 30 min | 4345 (114.49) | 3853 | 4487 (65.19) | 4013 | 3976 (38.66) | 3859 | 5024 (8.14) | 4716 | |

| 40 min | 4731 (72.40) | 3561 | 4742 (21.47) | 3769 | 4179 (9.10) | 3646 | 5527 (6.02) | 4561 | |

| 50 min | 4869 (43.98) | 3546 | 4879 (100.45) | 3629 | 4278 (39.99) | 3615 | 5768 (17.59) | 4474 | |

| 270 °C | 20 min | 4208 (5.10) | 3866 | 4280 (47.60) | 4088 | 3882 (12.50) | 3906 | 5015 (7.09) | 4895 |

| 30 min | 4784 (166.20) | 3439 | 5028 (89.07) | 3458 | 4203 (38.26) | 3490 | 5300 (19.69) | 4880 | |

| 40 min | 5023 (37.81) | 3141 | 5216 (18.65) | 3349 | 4372 (18.90) | 3313 | 6075 (4.96) | 4156 | |

| 50 min | 5147 (86.36) | 3129 | 5404 (44.46) | 3252 | 4562 (23.72) | 3178 | 6192 (19.98) | 4107 | |

| 290 °C | 20 min | 4338 (36.68) | 3930 | 4544 (95.78) | 3904 | 4158 (93.13) | 3608 | 5180 (40.93) | 4749 |

| 30 min | 5578 (162.83) | 2983 | 5468 (95.83) | 3121 | 4552 (93.13) | 3071 | 5841 (26.98) | 4157 | |

| 40 min | 5672 (75.22) | 2777 | 5509 (23.04) | 2912 | 4648 (28.44) | 2924 | 6508 (6.17) | 3684 | |

| 50 min | 5709 (130.79) | 2794 | 5722 (7.18) | 2925 | 4785 (31.81) | 2745 | 6571 (9.67) | 3705 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Kim, S.J.; Oh, K.C.; Cho, L.H.; Kim, M.J.; Jeong, I.S.; Lee, C.G.; Kim, D.H. Characteristic Analysis of Torrefied Pellets: Determining Optimal Torrefaction Conditions for Agri-Byproduct. Energies 2020, 13, 423. https://doi.org/10.3390/en13020423

Park S, Kim SJ, Oh KC, Cho LH, Kim MJ, Jeong IS, Lee CG, Kim DH. Characteristic Analysis of Torrefied Pellets: Determining Optimal Torrefaction Conditions for Agri-Byproduct. Energies. 2020; 13(2):423. https://doi.org/10.3390/en13020423

Chicago/Turabian StylePark, Sunyong, Seok Jun Kim, Kwang Cheol Oh, La Hoon Cho, Min Jun Kim, In Seon Jeong, Chung Geon Lee, and Dae Hyun Kim. 2020. "Characteristic Analysis of Torrefied Pellets: Determining Optimal Torrefaction Conditions for Agri-Byproduct" Energies 13, no. 2: 423. https://doi.org/10.3390/en13020423

APA StylePark, S., Kim, S. J., Oh, K. C., Cho, L. H., Kim, M. J., Jeong, I. S., Lee, C. G., & Kim, D. H. (2020). Characteristic Analysis of Torrefied Pellets: Determining Optimal Torrefaction Conditions for Agri-Byproduct. Energies, 13(2), 423. https://doi.org/10.3390/en13020423