Methodology for Predictive Assessment of Failures in Power Station Electric Bays Using the Load Current Frequency Spectrum

Abstract

1. Introduction

2. Related Works

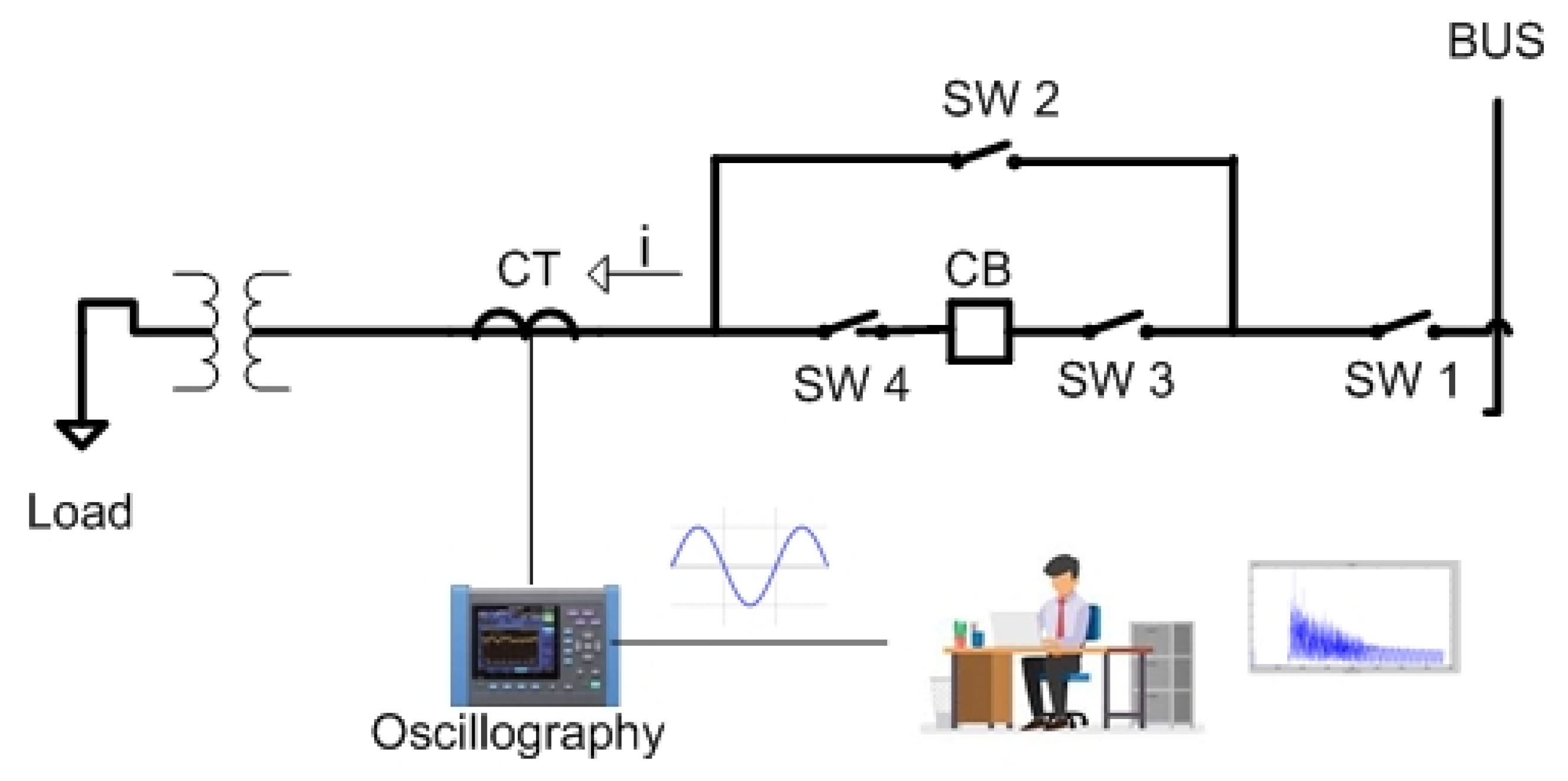

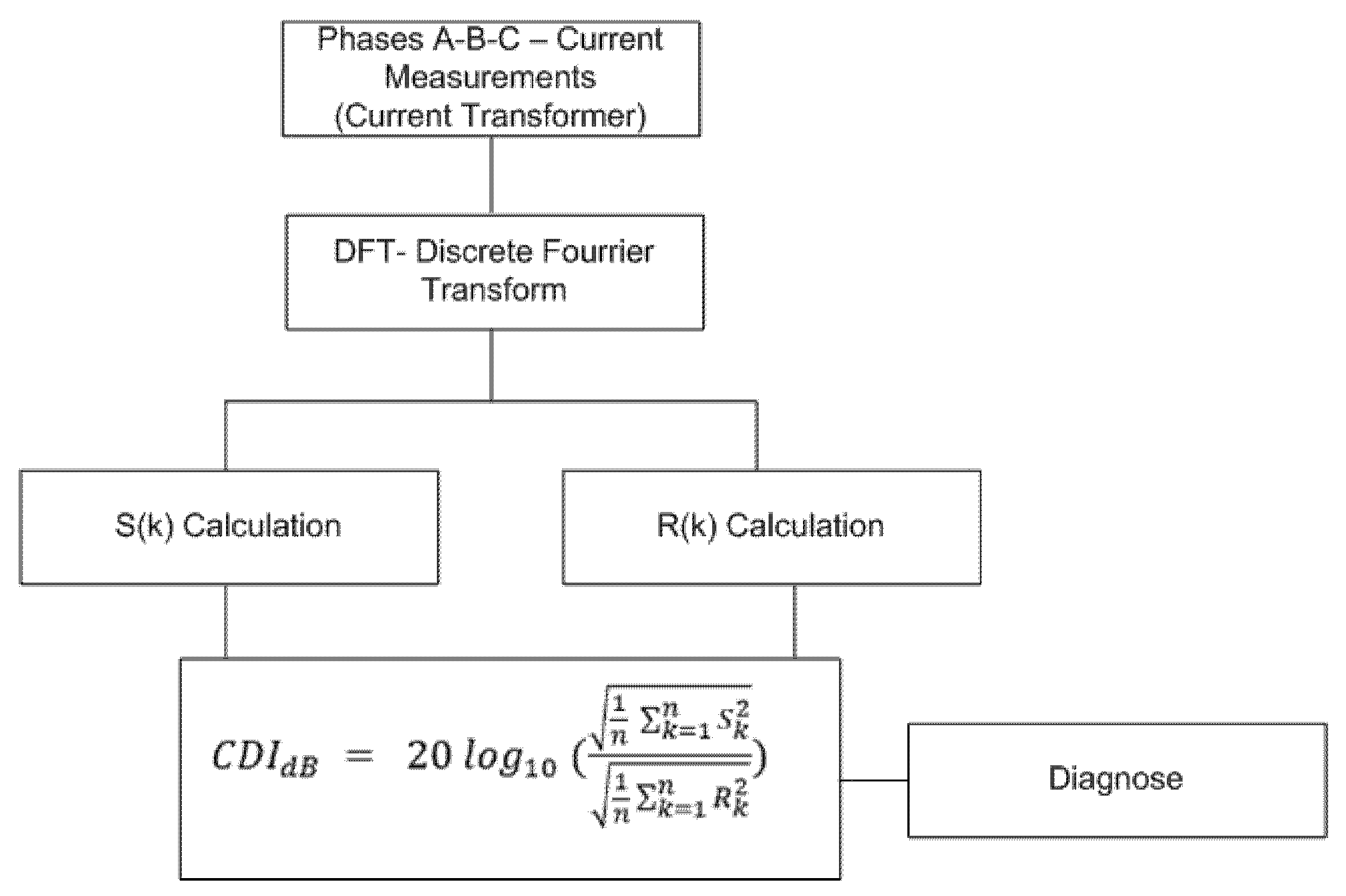

3. Proposed Methodology

3.1. Background for Establishing the Proposed Methodology

- N—number of samples per period (sampling rate);

- f(k)—magnitude of each sample;

- Fn—complex values (magnitude and phase angle) of the n sinusoids obtained by Fourier Discrete Transform (FDT).

- Sk—frequency spectra magnitudes obtained from the Fourier Discrete Transform (1) for the low-frequency region (f ≤ Fc) using a low-pass filter;

- Rk—frequency spectra magnitudes obtained from the Fourier Discrete Transform (1) for the high-frequency region (f > Fc) using a high-pass filter.

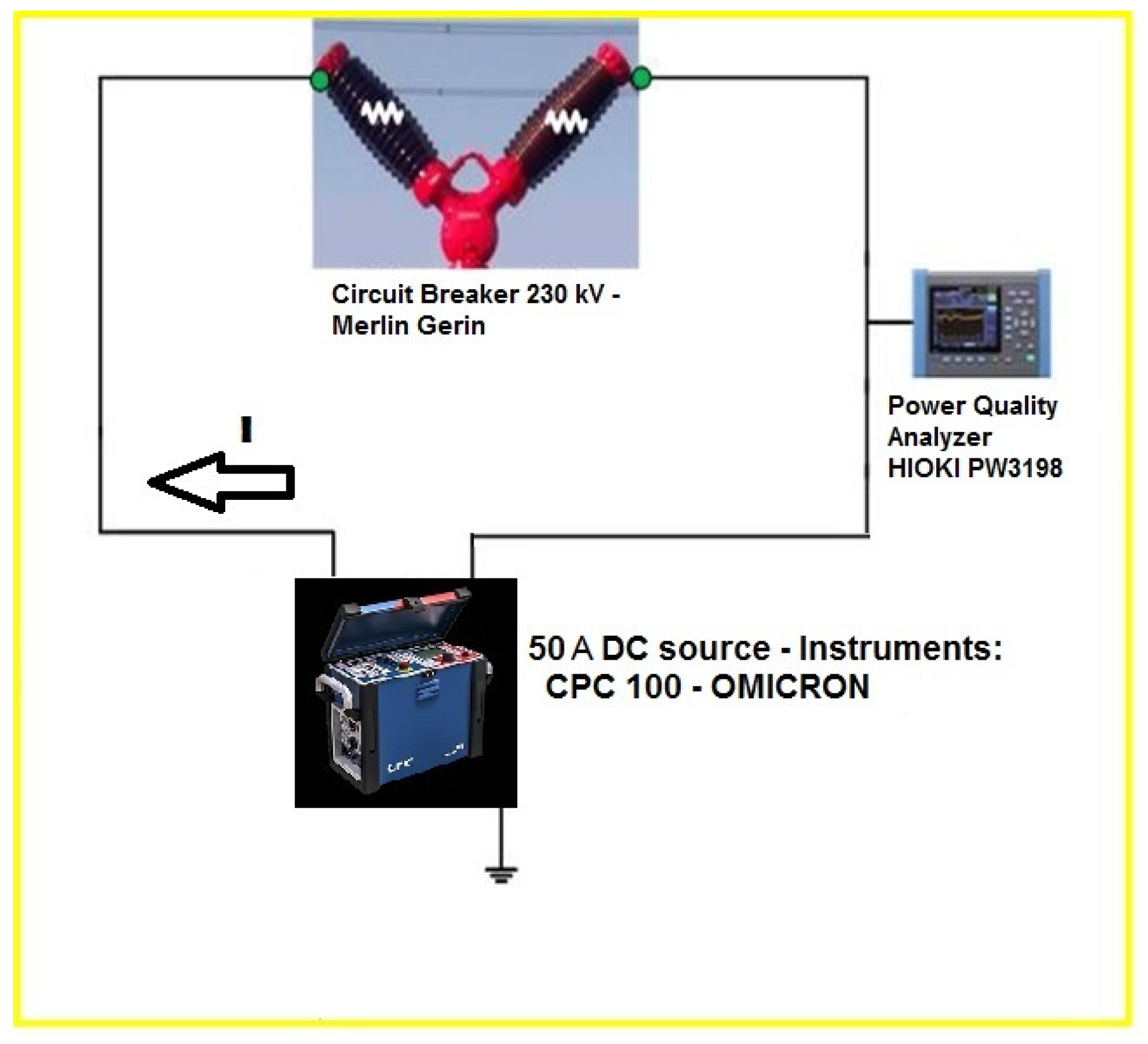

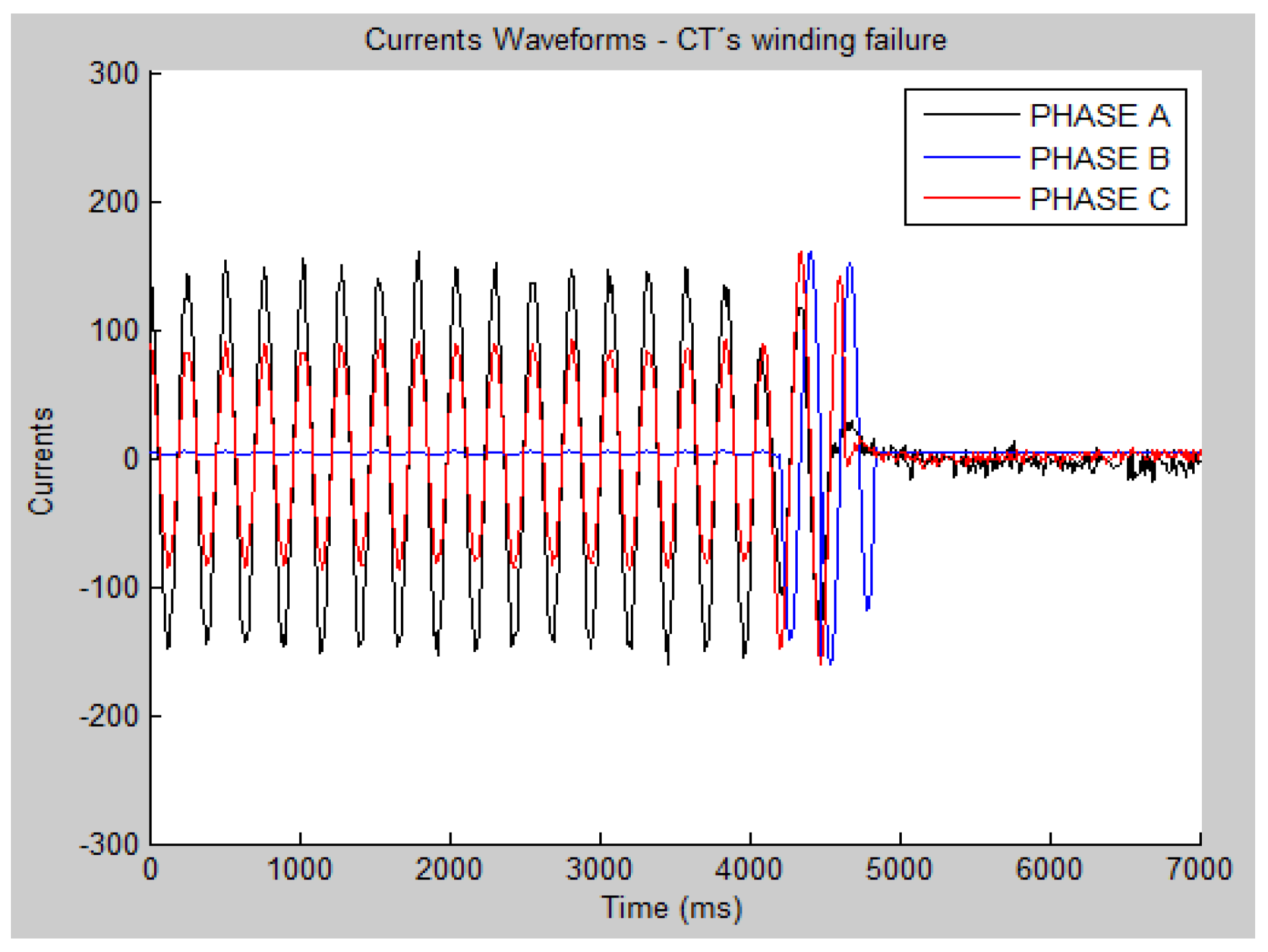

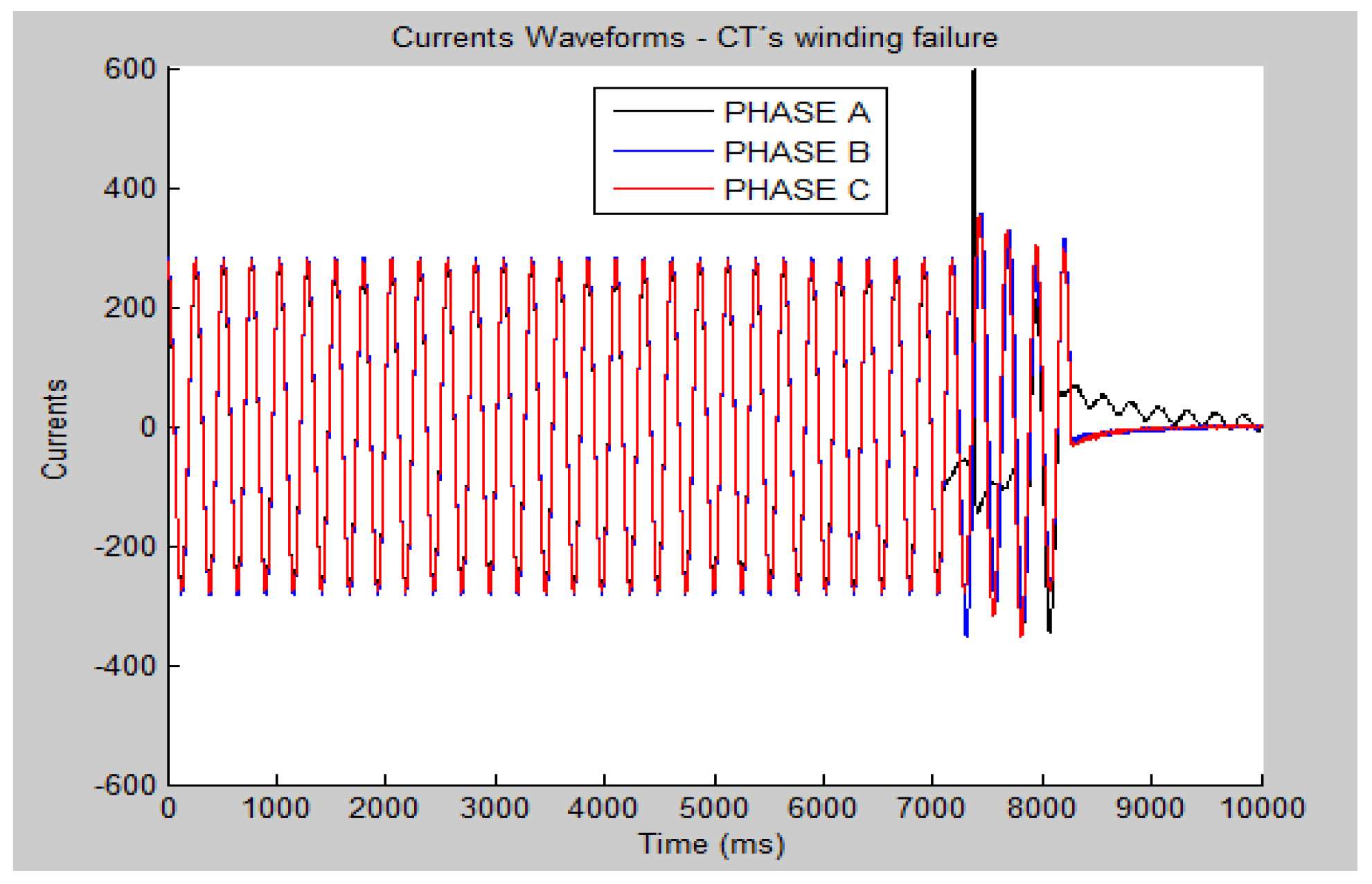

3.2. Laboratory Tests for Validating the Proposed Methodology

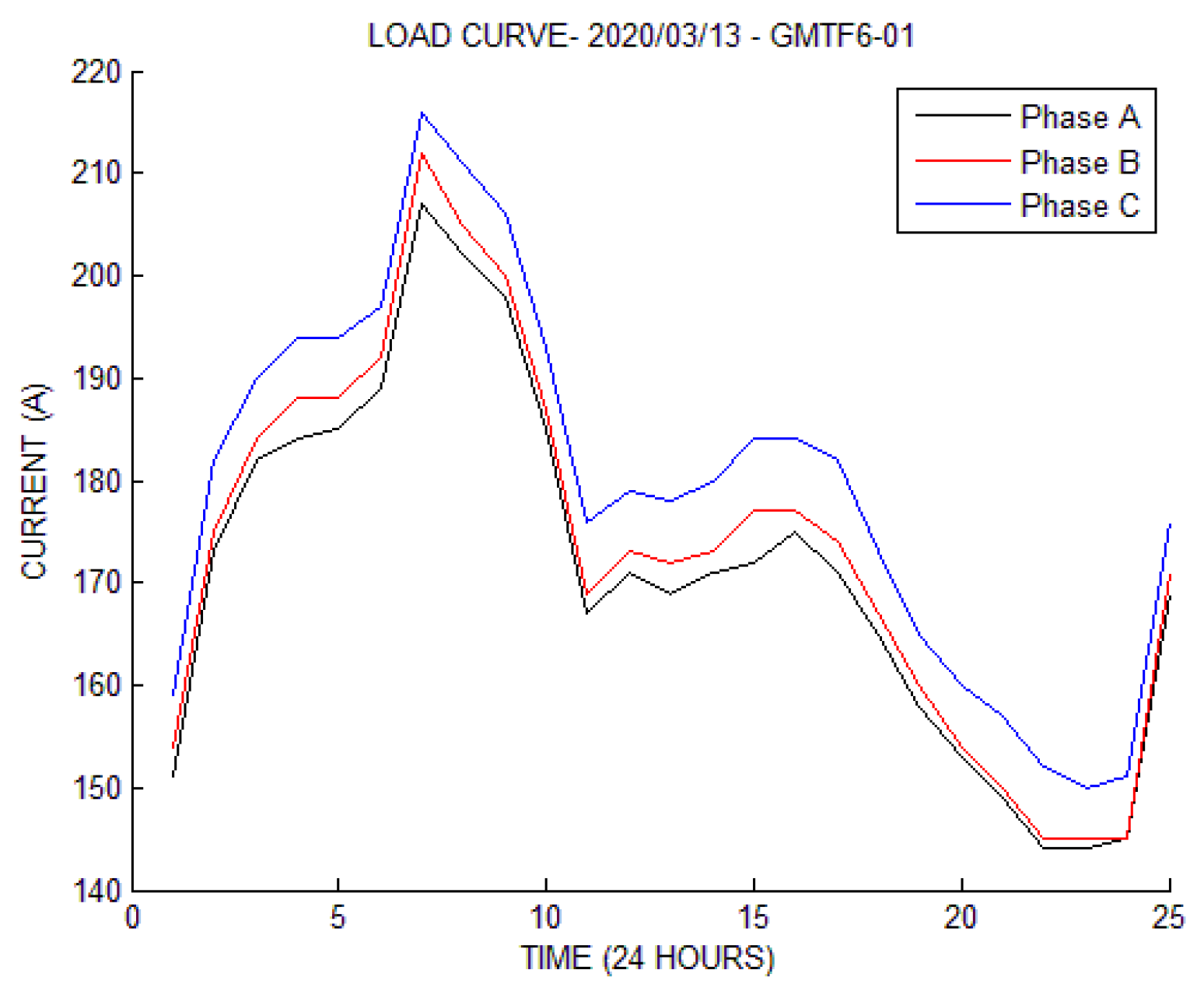

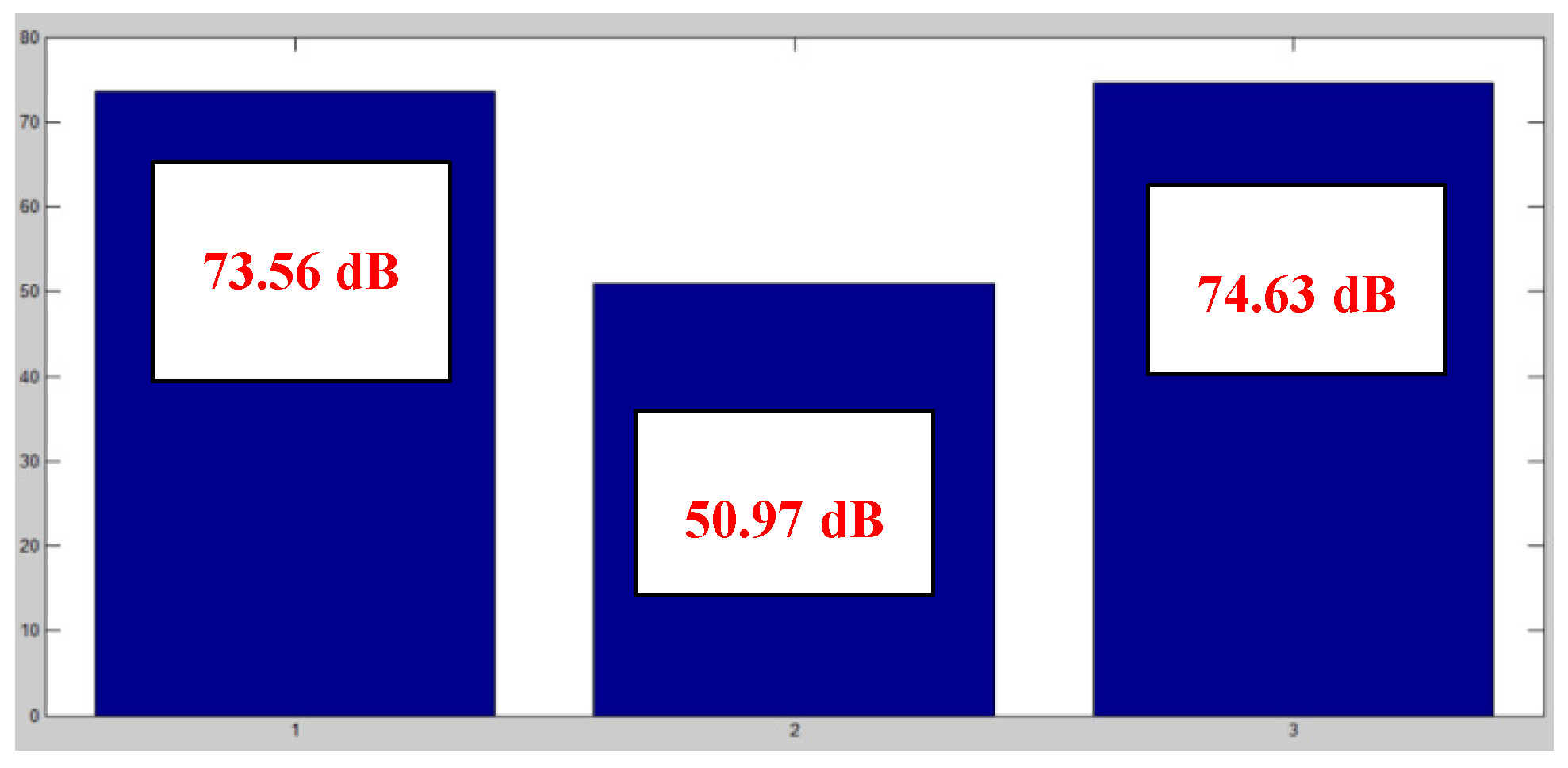

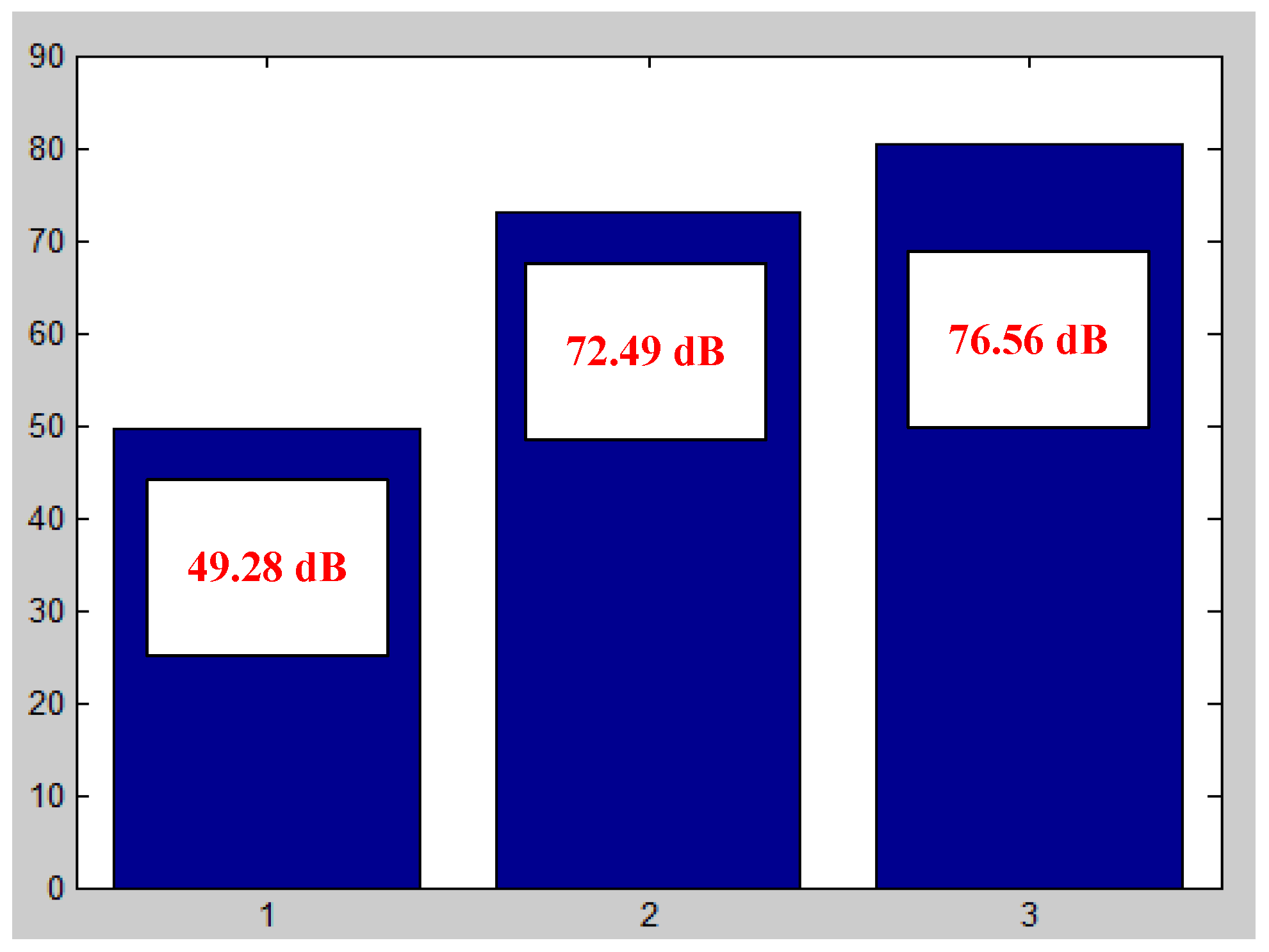

4. Results and Discussion

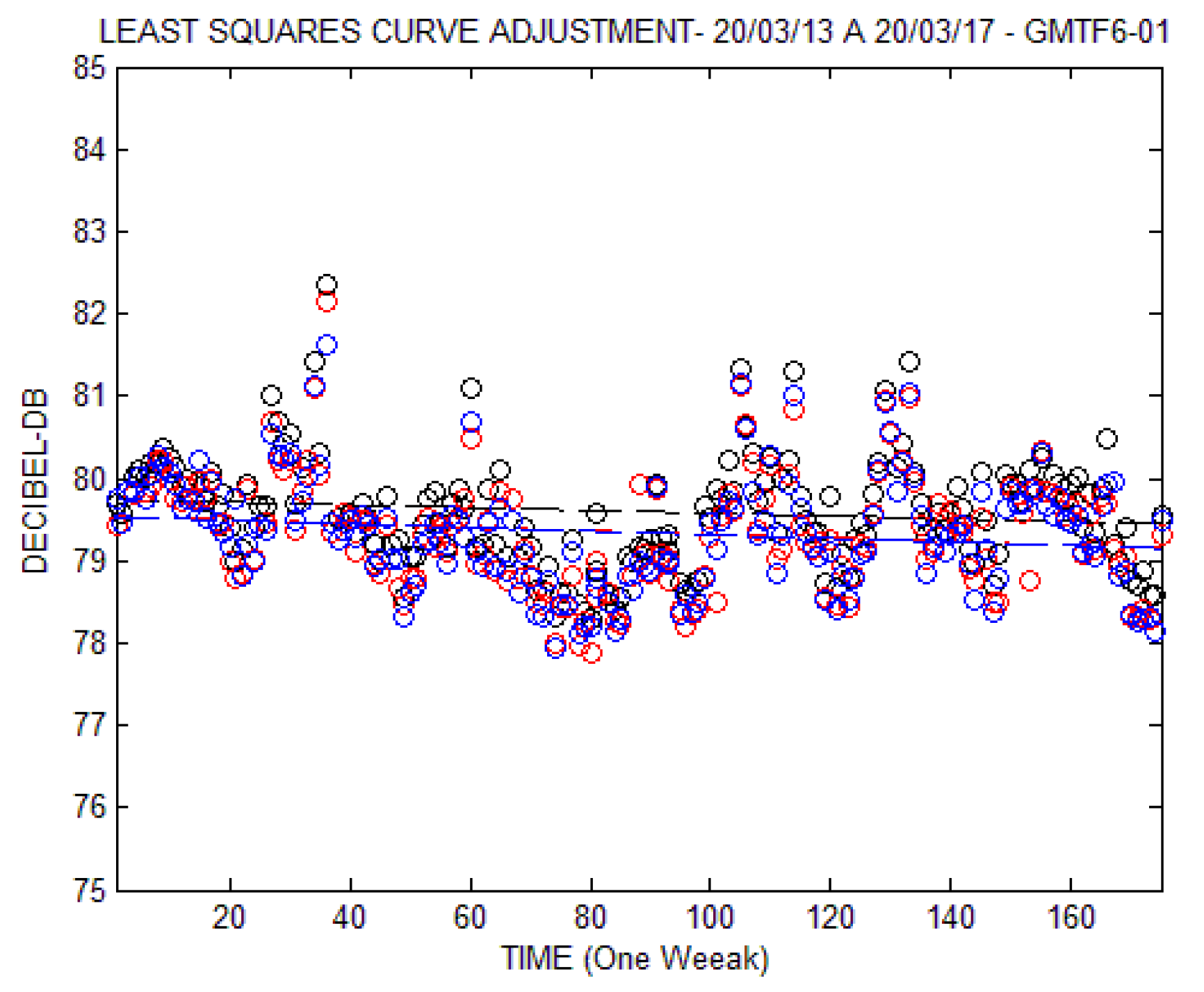

- YA,B,C—are the CDIs in dB for phases A, B, and C, respectively;

- XA,B,C—are the time in hours for phases A, B, and C, respectively.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kwong, R.H.; Yonge-Mallo, D.L. Fault Diagnosis in Discrete-Event Systems: Incomplete Models and Learning. IEEE Trans. Syst. Man Cybern. Part B 2011, 41, 118–130. [Google Scholar] [CrossRef] [PubMed]

- Langarica, S.; Ruffelmacher, C.; Nunez, F. An Industrial Internet Application for Real-Time Fault Diagnosis in Industrial Motors. IEEE Trans. Autom. Sci. Eng. 2020, 17, 284–295. [Google Scholar] [CrossRef]

- Ballal, M.S.; Jaiswal, G.C.; Tutkane, D.R.; Vanikar, P.A.; Mishra, M.K.; Suryawanshi, H.M. Online Condition Monitoring System for Substation and Service Transformer. IET Electr. Power Appl. 2017, 11, 1187–1195. [Google Scholar] [CrossRef]

- Saponara, S.; Fanucci, L.; Bernardo, F.; Falciani, A. Predictive Diagnosis of High-Power Transformer Faults by Networking Vibration Measuring Nodes with Integrated Signal Processing. IEEE Trans. Instrum. Meas. 2016, 65, 1749–1760. [Google Scholar] [CrossRef]

- Carneiro, J.C. Substation Power Transformer Risk Management: Predictive Methodology Based on Reliability Centered Maintenance Data. In Proceedings of the 4th International Conference on Power Engineering, Energy and Electrical Drives, Istanbul, Turkey, 13–17 May 2013. [Google Scholar]

- Firoozi, H.; Mahmoodi, N.; Kharezi, M.; Ghiyasi, M.I. Frequency Response Analysis—Low Frequency Characteristics and Fault Diagnosis on Power Transformers. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010. [Google Scholar]

- Hong, K.; Huang, H.; Zhou, J. Winding Condition Assessment of Power Transformers Based on Vibration Correlation. IEEE Trans. Power Deliv. 2015, 30, 1735–1742. [Google Scholar] [CrossRef]

- Rinaldi, I.; Smit, J.; Munir, B. Diagnosing Winding on Core Condition of Power Transformer by Vibration Signal Analysis. In Proceedings of the IEEE International Conference on Condition Monitoring and Diagnosis, Bali, Indonesia, 23–27 September 2012. [Google Scholar]

- Dubey, A.K.; Jaffery, Z. Design of Early Fault Detection Technique for Electrical Assets Using Infrared Thermograms. Int. J. Electr. Power Energy Syst. 2014, 63, 753–759. [Google Scholar]

- Chottopadhyay, P.; Sil, J.; Dutta, T. Condition Monitoring of Electrical Equipment Using Thermal Image Processing. In Proceedings of the IEEE First International Conference on Control, Measurement and Instrumentation, Kolkata, India, 8–10 January 2016. [Google Scholar]

- Sampaio, D.J.B.S.; Sousa, V.G.S.; Glatt, R.; Rubbo, D.; Costa, A.F. Thermography Inspection Using a Microcontroller-based Camera Positioning System. In Proceedings of the 3rd International Conference on Applied Robotics for the Power Industry, Foz do Iguassu, Brazil, 14–16 October 2014. [Google Scholar]

- Sisman, G.R.; Oproescu, M. Monitoring the Parameters of the Electronics Devices to Assure the Predictive Maintenance of Equipment. In Proceedings of the 10th International Symposium on Advanced Topics in Electrical Engineering, Bucharest, Romania, 23–25 March 2017. [Google Scholar]

- Razi-Kazemi, A.A.; Abdollah, M. Novel High-Frequency-Based Diagnostic Approach for Main Contact Assessment of High-Voltage Circuit Breakers. IET J. Inst. Eng. Technol. 2018, 12, 1121–1126. [Google Scholar] [CrossRef]

- Kadechhar, A.; Riba, J.R.; Eguilaz, M.M.; Capelli, F.; Gonzalez, D. On-line Resistance Measurement of Substation Connectors Focused on Predictive Maintenance. In Proceedings of the 18th International Power Eletronics and Motion Control Conference (PEMC), Budapest, Hungary, 26–30 August 2018. [Google Scholar]

- Kadechhar, A.; Riba, J.-R.; Moreno-Eguilaz, M.; Perez, J. SmartConnector: A Self-Powered IoT Solution to Ease Predictive Maintenance in Substation. IEEE Sens. J. 2020, 20, 11632–11641. [Google Scholar] [CrossRef]

- Braunovic, M.; Konchits, V.V.; Myshkin, K.N. Electrical Contacts—Fundamentals Applications and Tecnology; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Khoddam, M.; Sadeh, J. Pourmohamadiyan-Performance Evaluation of Circuit Breaker Electrical Contact Based on Dynamic Resistance Signature and Using Health Index. Trans. Compon. Packag. Manuf. Technol. 2016, 6, 1505–1512. [Google Scholar] [CrossRef]

- Tingling, C.; Wenjun, Z.; Guangyao, J.; Zhiyong, Y.; Gao, W. Influence of the Injected Current on Dynamic Contact Resistance Measurements of HV Circuit Breakers. In Proceedings of the China International Conference on Electricity Distribution (CICED 2014), Shenzhen, China, 23–26 September 2014. [Google Scholar]

- Stanisic, Z. Method for Static and Dynamic Resistance Measurements of HV Circuit Breaker. In Proceedings of the IEEE PES International Conference and Exhibition on Innovative Smart Grid Technologies, Manchester, UK, 5–7 December 2011. [Google Scholar]

- Souza, T.R.; Costa, G.E.; Oliveira, C.A.; Sousa, V.W. Characterization of Contacts Degradation in Circuit Breakers through the Dynamic Contact Resistance. In Proceedings of the PES Transmission & Distribution Conference and Exposition—Latin America, Medellin, DC, USA, 10–13 September 2014. [Google Scholar]

- Lezama, J.; Schweitzer, P.; Weber, S.; Tisserand, E.; Joyeux, P.; Rabla, M. Frequency Analysis to Arcing Detection and Prototyping FPGA Approach. In Proceedings of the IEEE 59th Conference on Electrical Contacts (HOLM), Newport, RI, USA, 22–25 September 2013. [Google Scholar]

- Ziemer, R.E.; Tranter, W.H.; Fannin, D.R. Signals and Systems. Continuous and Discrete, 4th ed.; Prentice Hall: London, UK, 1998. [Google Scholar]

- Arrilaga, J. Power Systems Harmonics; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 1985. [Google Scholar]

- IEEE Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems: IEEE Standard 519. 2014. Available online: https://ieeexplore.ieee.org/document/6826459 (accessed on 14 July 2020).

- Dugan, R.; Kennedy, B.J. Electrical Power System Quality; McGraw-Hill, Inc.: New York, NY, USA, 1996. [Google Scholar]

- ANEEL. Electric Energy Distribution Procedures Guide—PRODIST, Module 8—Power Quality; Electric Energy Brazilian Agency, ANEEL: Brasilia, Brazil, 2017.

- Meyer, J.; Khokhlov, V.; Klatt, M.; Blum, J.; Warniek, C.; Wohlfahrt, T.; Myrzik, T. Overview and classification of interferences in the frequency range 2–150 kHz (Supraharmonics). In Proceedings of the 2018 International Symposiumon on Power Eletronics, Electrical Devices, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018. [Google Scholar]

- Bhole, A.A.; Gandhare, W.Z. An Overview of Dynamic Contact Resistance Measurement of HV Circuit Breakers. J. Inst. Eng. Ser. B 2016, 97, 219–226. [Google Scholar] [CrossRef]

- IEC 62271—High-Voltage Switchgear and Controlgear—Part 1: Common Specifications. 2007. Available online: http://www.abnt.org.br/pesquisas/?searchword=60694&x=6&y=18 (accessed on 14 July 2020).

- Mariscotti, A. Analysis of the DC-link Current Spectrum in Voltage Source Inverters. IEEE Trans. Circuits Syst. I Fundam. Theory Appl. 2002, 49, 484–491. [Google Scholar] [CrossRef]

- Abramovitz, A.; Bem-Yaakov, S. Current Spectra Translation in Single Phase Rectifiers: Implications to Active Power Factor Corrections. IEEE Trans.Circuits Syst. I Fundam. Theory Appl. 1997, 2, 1342–1347. [Google Scholar] [CrossRef]

- Karris, S.T. Signals and Systems with MATLAB and Simulink, 3rd ed.; Orchard publications: London, UK, 2007. [Google Scholar]

| Measurement | CDI (dB)—CB’s Resistance 30 μΩ | CDI (dB)—CB’s Resistance 50 μΩ |

|---|---|---|

| 1 | 70.44 | 66.12 |

| 2 | 70.56 | 66.69 |

| 3 | 70.61 | 66.71 |

| Measurement | Temperature °C | CB Res μΩ | CDI (dB) | ||||

| Bay 1 | SW1 | SW3 | SW4 | CT | CB | ||

| Phase A | 47.3 | 42.0 | 42.0 | 44.0 | 39.5 | 70.3 | 78.6 |

| Phase B | 45.1 | 42.0 | 41.0 | 39.0 | 40.0 | 75.7 | 74.01 |

| Phase C | 38.4 | 39.6 | 41.2 | 38.9 | 39.8 | 66.2 | 87.07 |

| Bay 2 | |||||||

| Phase A | 46.3 | 37.9 | 42.7 | 39.0 | 39.9 | 62.4 | 79.37 |

| Phase B | 54.0 | 40.9 | 54.7 | 39.2 | 40.0 | 62.0 | 74.02 |

| Phase C | 39.8 | 40.9 | 44.0 | 39.1 | 39.9 | 61.9 | 86.95 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bezerra, F.V.V.; Cavalcante, G.P.S.; Barros, F.J.B.; Tostes, M.E.L.; Bezerra, U.H. Methodology for Predictive Assessment of Failures in Power Station Electric Bays Using the Load Current Frequency Spectrum. Energies 2020, 13, 5123. https://doi.org/10.3390/en13195123

Bezerra FVV, Cavalcante GPS, Barros FJB, Tostes MEL, Bezerra UH. Methodology for Predictive Assessment of Failures in Power Station Electric Bays Using the Load Current Frequency Spectrum. Energies. 2020; 13(19):5123. https://doi.org/10.3390/en13195123

Chicago/Turabian StyleBezerra, Fábio Vinicius Vieira, Gervásio Protásio Santos Cavalcante, Fabrício Jose Brito Barros, Maria Emília Lima Tostes, and Ubiratan Holanda Bezerra. 2020. "Methodology for Predictive Assessment of Failures in Power Station Electric Bays Using the Load Current Frequency Spectrum" Energies 13, no. 19: 5123. https://doi.org/10.3390/en13195123

APA StyleBezerra, F. V. V., Cavalcante, G. P. S., Barros, F. J. B., Tostes, M. E. L., & Bezerra, U. H. (2020). Methodology for Predictive Assessment of Failures in Power Station Electric Bays Using the Load Current Frequency Spectrum. Energies, 13(19), 5123. https://doi.org/10.3390/en13195123