Impact of Liquefied Natural Gas Composition Changes on Methane Number as a Fuel Quality Requirement

Abstract

1. Introduction

2. Basics of Liquefied Natural Gas

Quality Criteria for Liquefied Natural Gas

- (1)

- Molar content of methane in LNG (see Table 1);

- (2)

- LNG higher heating value and Wobbe Index (usually min - max range) (Table 2);

- (3)

- Boiling temperature range (Table 2);

- (4)

- Relative density (the ratio of the average molecular weight of gas to that of air), (Table 2);

- (5)

- Maximum permitted levels of impurities (H2S, H2O, CO2, S) (Table 3);

- (6)

- Molar content of heavier hydrocarbons, in particular C4+ (Table 3);

3. Methane Number Criteria

3.1. Methane Number

3.2. Methane Number Calculation Methods

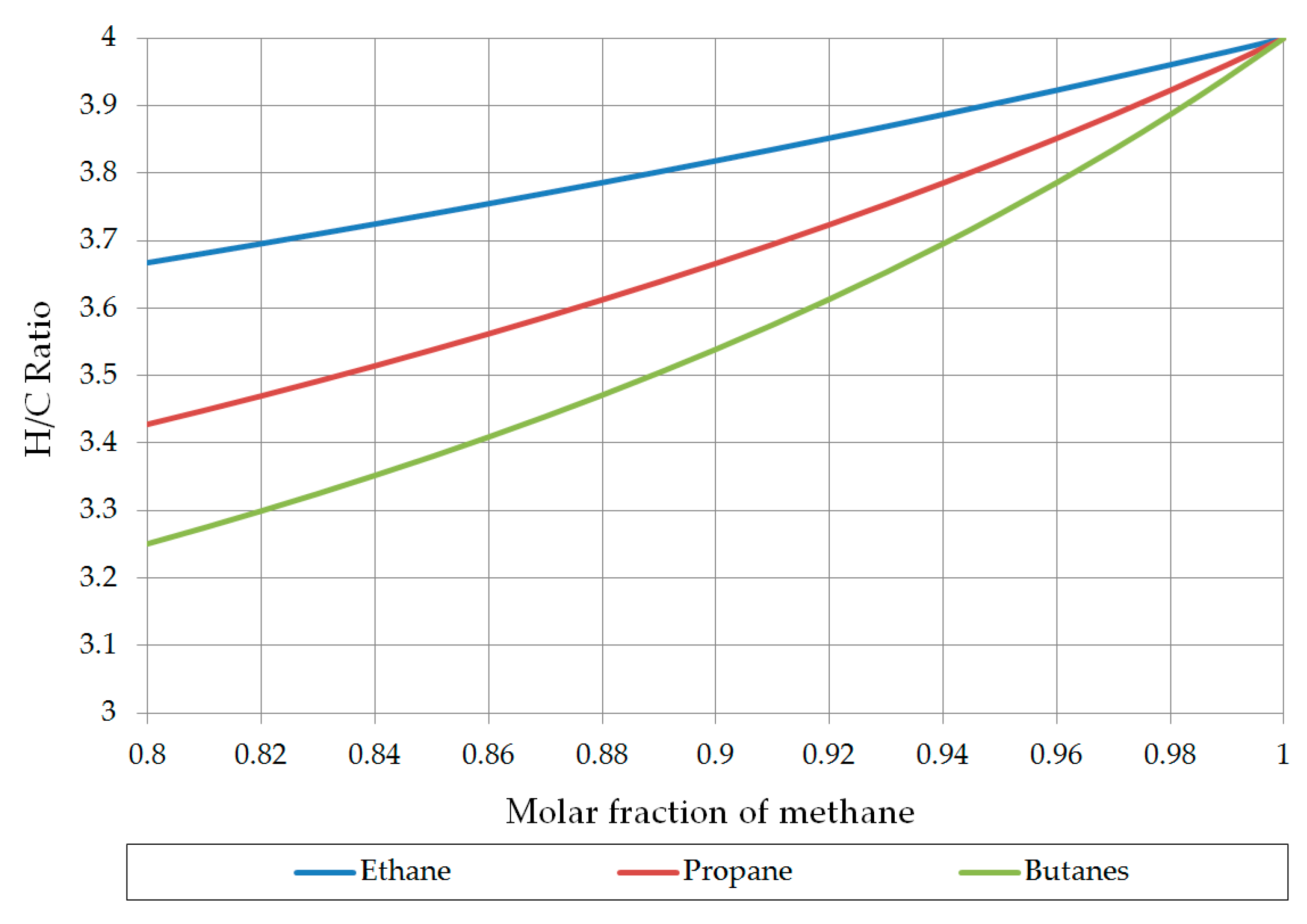

3.3. Hydrogen to Carbon (H/C) Ratio

3.4. Methane Number Criteria for Motor Engines

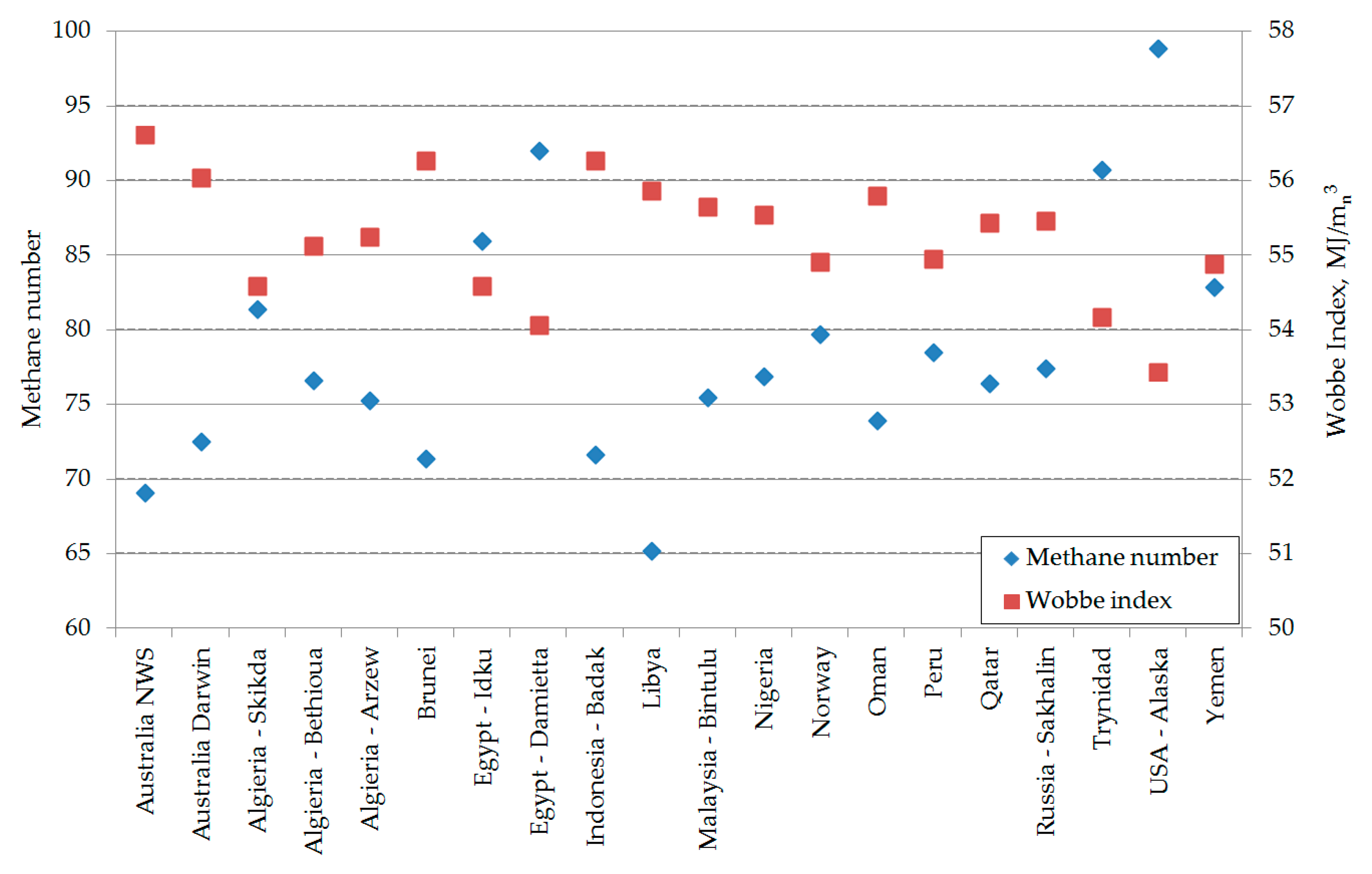

4. Methane Number Determination for Different LNG Compositions

4.1. Assumptions

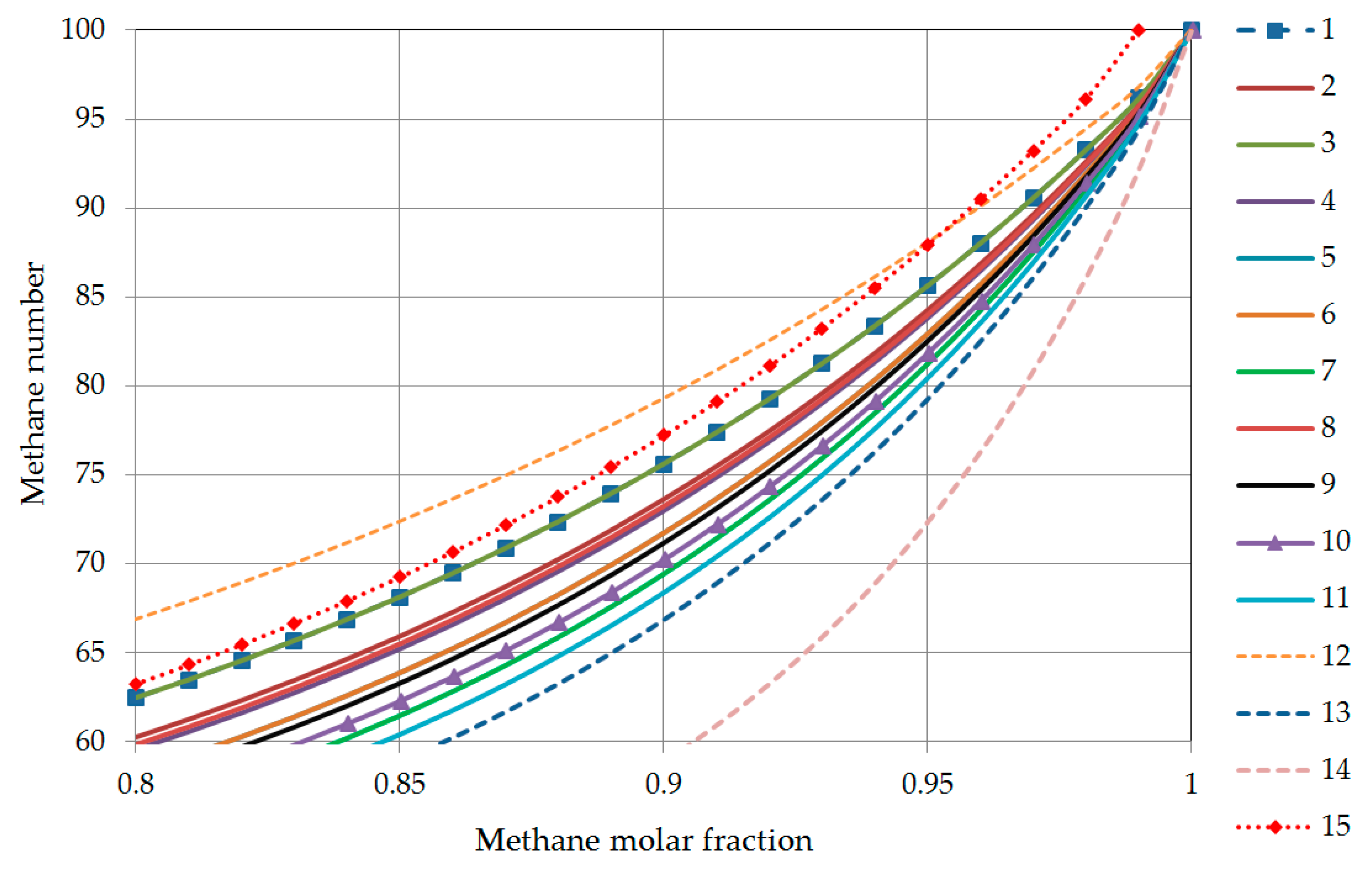

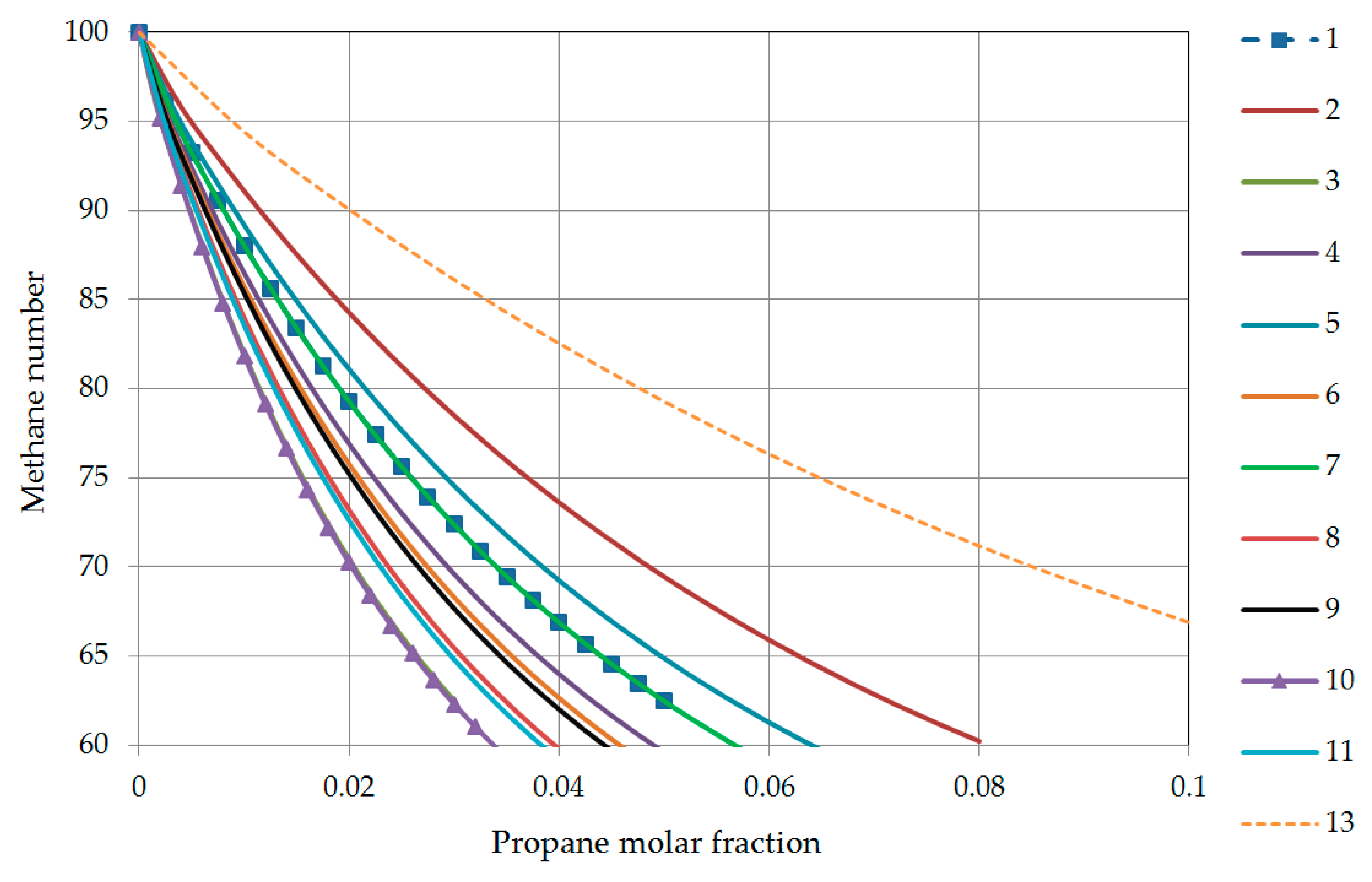

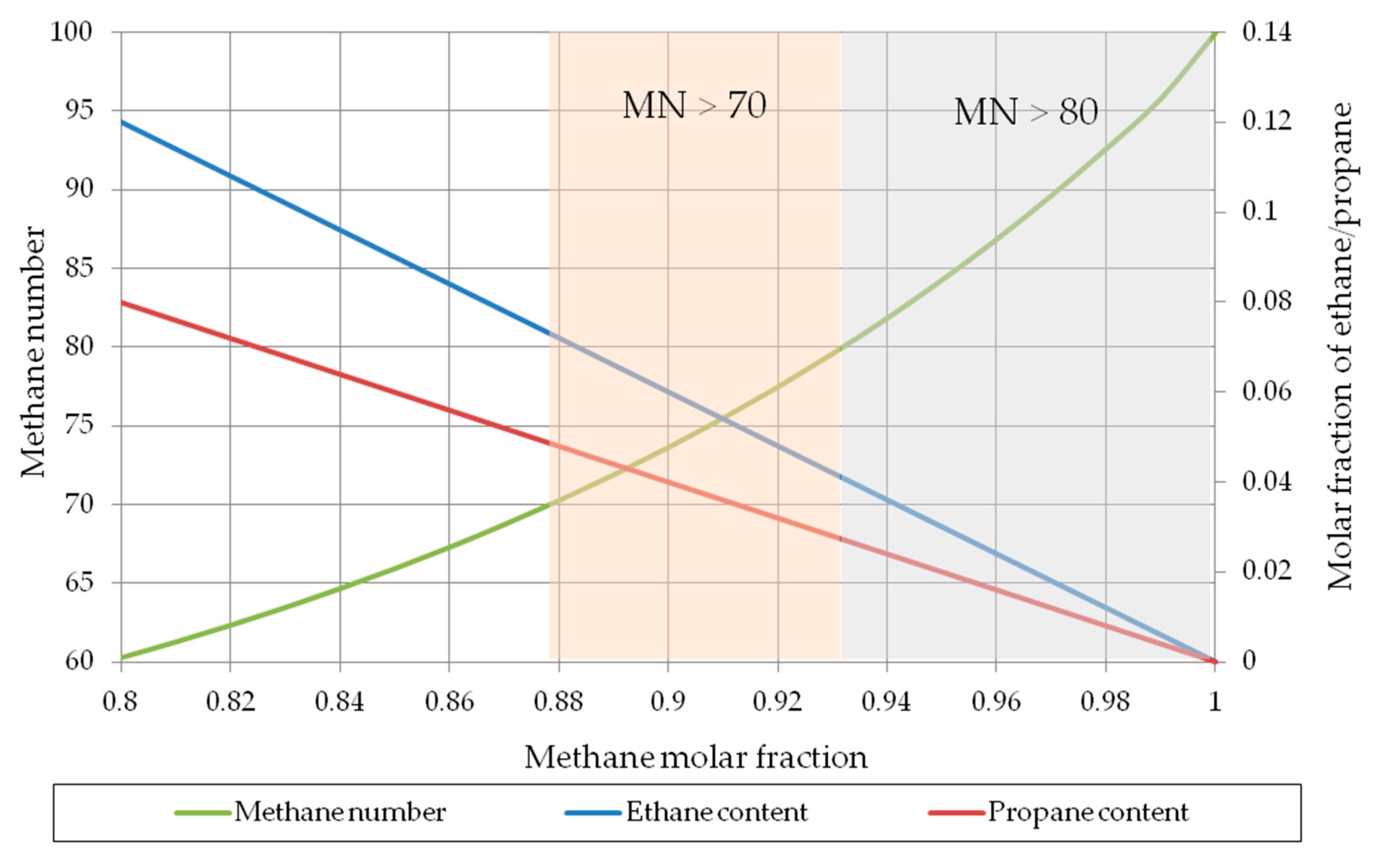

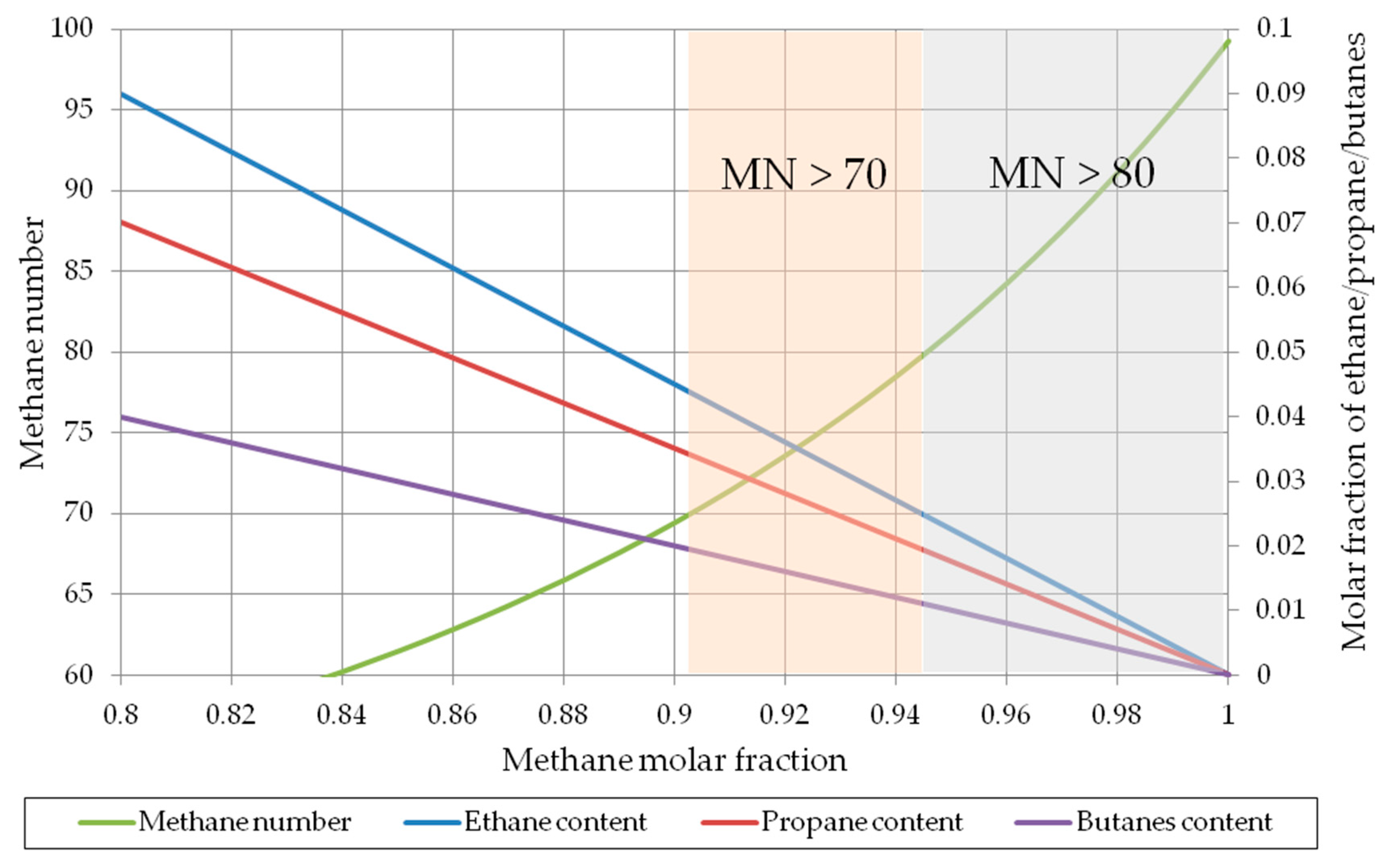

4.2. Methane Number and Component Content

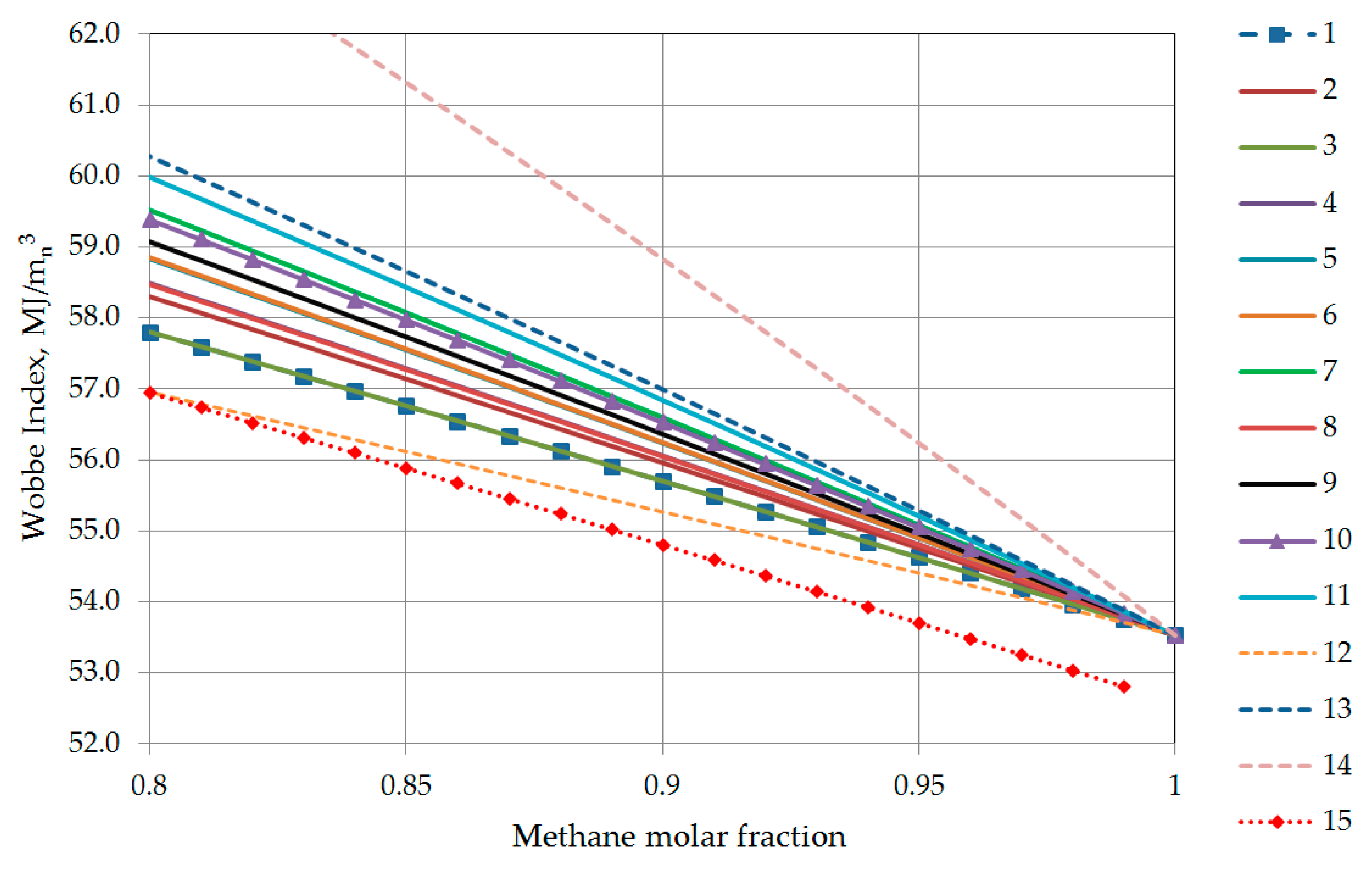

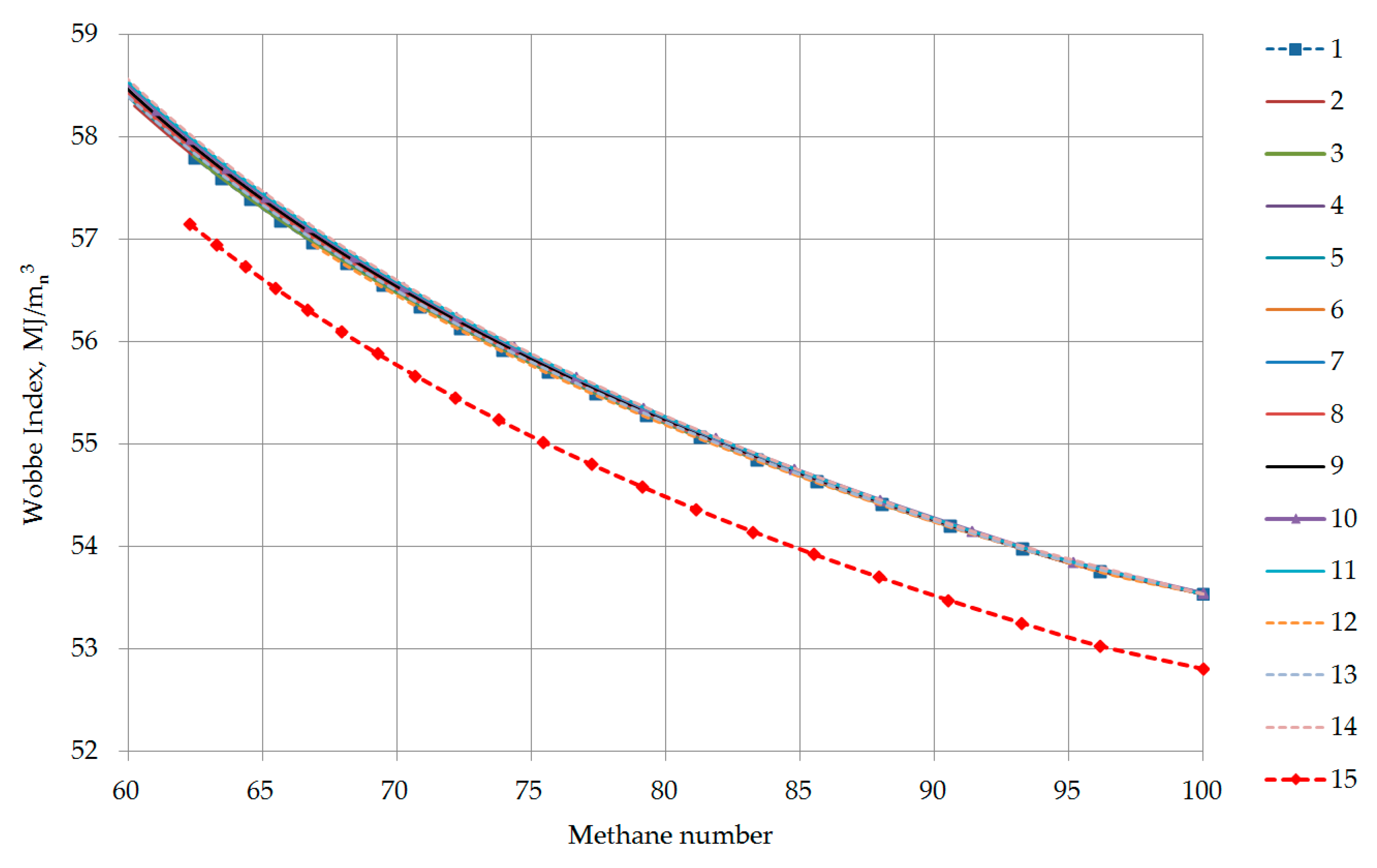

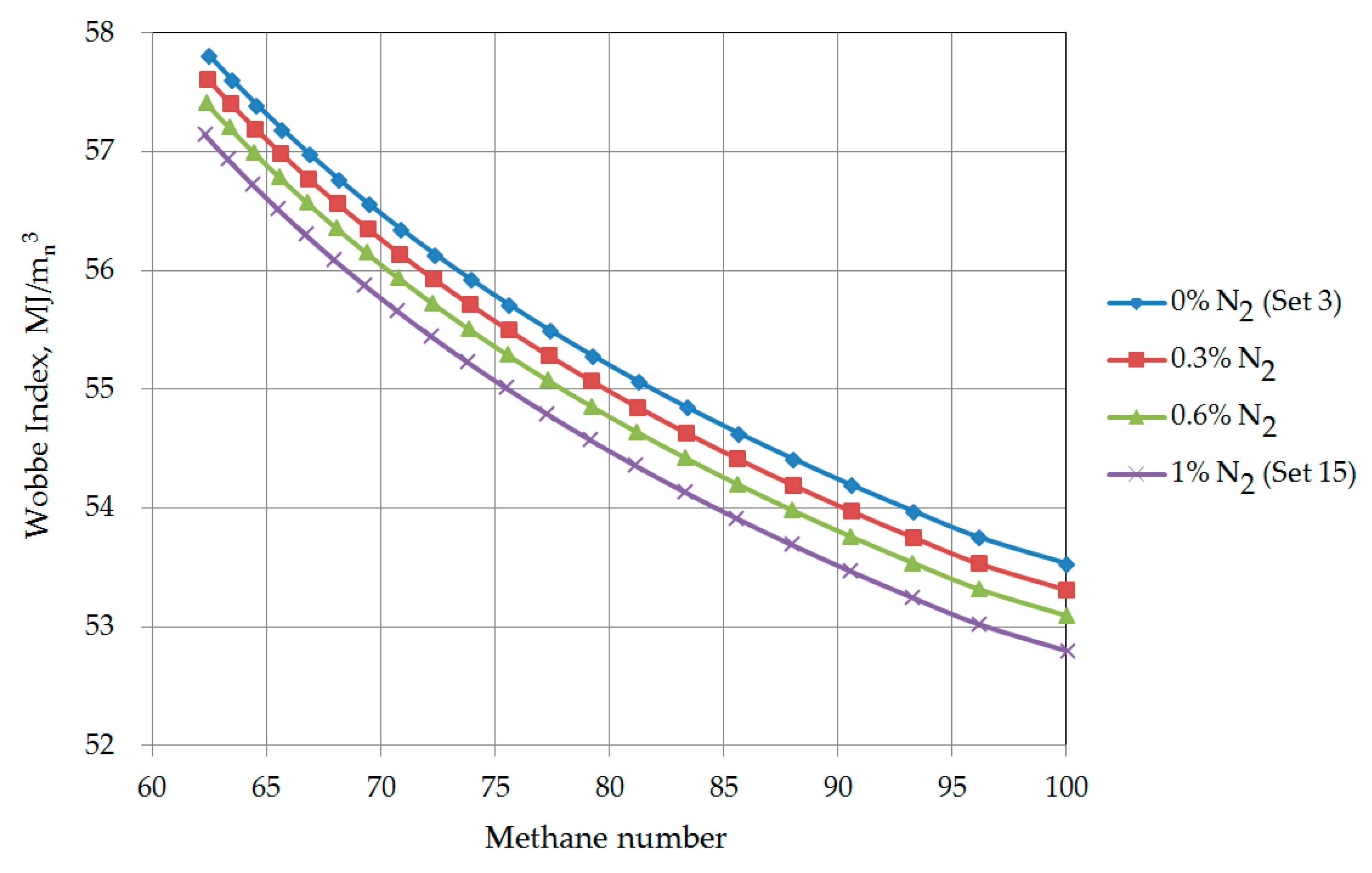

4.3. Wobbe Index and Methane Number

4.4. Nitrogen Content Impact on Methane Number

4.5. Composition Measurement Uncertainty Impact

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AVL | Anstalt für Verbrennungskraftmaschinen List, the world’s largest independent company for the development, simulation and testing of engine systems |

| HHV | gross heating value, MJ/mn3, |

| LHV | lower heating value, MJ/mn3, |

| LNG | liquefied natural gas |

| MON | motor octane number |

| MN | methane number |

| WI | Wobbe Index |

| WIU | upper Wobbe Index, MJ/mn3, |

| WIU | lower Wobbe Index, MJ/mn3, |

| R | ratio of hydrogen atoms to carbon atoms in molecule (H/C) |

| d | specific density, |

| k | number of components |

| Ni | number of atoms of hydrogen or carbon in each component molecule, |

| xi | mole content of each component |

References

- Tjojudo, D.H.; Kartohardjono, S. Methane number improvement of gas from LNG regasification unit. E3s Web Conf. 2018, 67. [Google Scholar] [CrossRef]

- Palmer, G. Methane number. J. Nat. Gas Eng. 2019, 2, 134. [Google Scholar] [CrossRef]

- Gieseking, B.; Brown, A.S. Novel algorithm for calculating the methane number of liquefied natural gas with defined uncertainty. Fuel 2016, 185, 932–940. [Google Scholar] [CrossRef]

- Gupta, S.K.; Mittal, M. Predicting the methane number of gaseous fuels using an artificial neural network. Biofuels 2019. [Google Scholar] [CrossRef]

- Melenshek, M.; Olsen, D.B. Methane number testing of alternative gaseous fuels. Fuel 2009, 88, 650–656. [Google Scholar] [CrossRef]

- Ryan, T.W., III; Callahan, T.J.; King, S.R. Engine knock rating of natural gases—Methane number. J. Eng. Gas Turbines Power. 1993, 115, 769–776. [Google Scholar] [CrossRef]

- Heather, T.; James, J.C.; James, J.W. Natural gas as a marine fuel. Energy Policy 2015, 87, 153–167. [Google Scholar]

- Flynn, P.C. Commercializing an alternate vehicle fuel: Lessons learned from natural gas for vehicles. Energy Policy 2002, 30, 613–619. [Google Scholar] [CrossRef]

- Nijboer, M. The Contribution of Natural Gas Vehicles to Sustainable Transport; International Energy Agency: Paris, France, 2010.

- De Carvalho, A.V., Jr. Natural gas and other alternative fuels for transportation purposes. Energy 1985, 10, 187–215. [Google Scholar] [CrossRef]

- Pfoser, S.; Schauer, O.; Costa, Y. Acceptance of LNG as an alternative fuel: Determinants and policy implications. Energy Policy 2018, 120, 259–267. [Google Scholar] [CrossRef]

- Keith, D.R.; Struben, J.; Naumov, S. The diffusion of alternative fuel vehicles: A generalized model and future research agenda. J. Simul. 2020. [Google Scholar] [CrossRef]

- Khan, M.I. Policy options for the sustainable development of natural gas as transportation fuel. Energy Policy 2017, 110, 126–136. [Google Scholar] [CrossRef]

- Lopez Alvarez, J.A.; Buijs, P.; Kilic, O.A.; Vis, I.F.A. An inventory control policy for liquefied natural gas as a transportation fuel. Omega 2020, 90, 101985. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, F.; Xu, B.; Zhang, Q.; Liu, J. Influence of methane content on a LNG heavy-duty engine with high compression ratio. Energy 2017, 128, 329–336. [Google Scholar] [CrossRef]

- Karavalakis, G.; Hajbabaei, A.; Jiang, Y.; Yang, J.; Johnson, K.C.; Cocker, D.R.; Durbin, T.D. Regulated, greenhouse gas, and particulate emissions from lean-burn and stoichiometric natural gas heavy-duty vehicles on different fuel compositions. Fuel 2016, 175, 146–156. [Google Scholar] [CrossRef]

- Kakaee, A.-H.; Paykani, A.; Ghajar, M. The influence of fuel composition on the combustion and emission characteristics of natural gas fueled. Renew. Sustain. Energy Rev. 2014, 38, 64–78. [Google Scholar] [CrossRef]

- Vallabhunia, S.K.; Leleb, A.D.; Patela, V.; Lucassena, A.; Moshammera, K.; AlAbbadc, M.; Farooqc, A.; Fernandesa, R.X. Autoignition studies of liquefied natural gas (LNG) in a shock tube and a rapid compression machine. Fuel 2018, 232, 423–430. [Google Scholar] [CrossRef]

- Hwang, S.-K. Methane number control of fuel gas supply system using combined cascade/feed-forward control. J. Mar. Sci. Eng. 2020, 8, 307. [Google Scholar] [CrossRef]

- International Group of LNG Exporters (GIIGNL), Annual Report 2018, International Group of LNG Exporters. 2018. Available online: https://giignl.org/sites/default/files/PUBLIC_AREA/Publications/rapportannuel-2018pdf.pdf (accessed on 28 May 2020).

- U.S. Energy Information Administration, EIA Report, Annual Energy Outlook 2020, U.S. Energy Information Administration. 2020. Available online: https://www.eia.gov/outlooks/aeo/pdf/AEO2020%20Full%20Report.pdf (accessed on 29 May 2020).

- International Energy Agency. World Energy Outlook: Are We Entering a Golden Age of Gas? International Energy Agency: Paris, France, 2011.

- BP. Statistical Review of World Energy; BP: London, UK, 2016. [Google Scholar]

- International Gas Union: World LNG Report-2019 Edition, International Gas Union. 2019. Available online: https://www.igu.org/app/uploads-wp/2019/06/IGU-Annual-Report-2019_23.pdf (accessed on 3 June 2020).

- Liu, J.; Dumitresu, C.E. Numerical investigation of methane number and Wobbe index effects in lean-burn natural gas spark-ignition combustion energy. Fuels 2019, 33, 4564–4574. [Google Scholar] [CrossRef]

- Mozgovoy, A.; Burmeister, F.; Albus, R. Contribution of LNG use for the low calorific natural gas network’s safe and sustainable operation. Energy Procedia 2015, 64, 83–90. [Google Scholar] [CrossRef][Green Version]

- Klinkenbijl, J.; Grootjans, H.; Rajani, J. Best practice for deep treating sour natural gases (to LNG and GTL). In Proceedings of the GasTech 2005 Conference & Exhibition, Bilbao, Spain, 14–17 March 2005. [Google Scholar]

- Mokhatab, S.; Mak, J.Y.; Valappil, J.V.; Wood, D.A. Handbook of Liquefied Natural Gas; Gulf Professional Publishing (Elsevier Inc.): Houston, TX, USA, 2014. [Google Scholar]

- GIE Position Paper on Impact of Including Methane Number in the European Standard for Natural Gas, November 2012, Gas Infrastructure Europe. Available online: https://giignl.org/system/files/mn-position-paper-giignl.pdf (accessed on 3 June 2020).

- ISO-TR-22302: 2014 Natural Gas-Calculation of Methane Number. Available online: https://www.iso.org/standard/63772.html (accessed on 24 April 2020).

- Kubesh, J.; King, S.R.; Liss, W.E. Effect of Gas Composition on Octane Number of Natural Gas Fuels; 922359; SAE: Troy, MI, USA, 1992. [Google Scholar]

- Partho, S.R.; Christopher, R.; Sang Keun, D.; Chan Seung, P. Development of a natural gas methane number prediction model. Fuel 2019, 246, 204–211. [Google Scholar]

- Algorithm for Methane Number Determination for Natural Gasses; Dansk Gasteknisk Center: Hørsholm, Denmark, 1999.

- Euromot, Position Paper: Methane number as a Parameter for Gas Quality Specifications. 2012. Available online: https://www.euromot.eu/wp-content/uploads/2017/03/GAS_QUALITY_methane_number_calculation_2012-04-04.pdf (accessed on 8 May 2020).

- Graham, E.; Kenbar, A. LNG energy transfer uncertainty-sensitivity to composition and temperature changes. Flow Meas. Instrum. 2015, 44, 79–88. [Google Scholar] [CrossRef]

| Component | Minimum Molar Content | Maximum Molar Content |

|---|---|---|

| Methane | 87% | >99% |

| Ethane | <1% | 10% |

| Propane | <1% | 5% |

| Butanes | <1% | 1.5% |

| Nitrogen | <0.1% | 1% |

| Component | Min | Max |

|---|---|---|

| Higher (Gross) Heating Value, MJ/mn3 | 39.4 | 46.0 |

| Wobbe Index, MJ/mn3 | 52.7 | 56.9 |

| Relative density, - | 0.55 | 0.66 |

| Boiling temperature (p = 1 atm), K | 108.7 | 115.5 |

| Impurity/Component | Maximum Content | |

|---|---|---|

| Vapor water H2O | 0.1 ppmv | 0.8 mg/mn3 |

| Hydrogen Sulphide H2S | 4 ppmv | 6.07 mg/mn3 |

| Sulphur S | 28 ppmv | 40 mg/mn3 |

| Carbon dioxide CO2 | 50 ppmv | 98.21 mg/mn3 |

| Mercury Hg | 0.01 μg/mn3 | |

| Butanes and heavier hydrocarbons C4+ | 2% | |

| Pentanes and heavier hydrocarbons C5+ | 0.1% | |

| Nitrogen N2 | 1% | |

| Composition | Methane C1 | Ethane C2 | Propane C3 | C4+ | Nitrogen N2 | |

|---|---|---|---|---|---|---|

| Source | ||||||

| Australia NWS | 87.33 | 8.33 | 3.33 | 0.97 | 0.04 | |

| Australia Darwin | 87.64 | 9.97 | 1.96 | 0.33 | 0.1 | |

| Algieria–Skikda | 91.4 | 7.35 | 0.57 | 0.05 | 0.63 | |

| Algieria–Bethioua | 89.55 | 8.2 | 1.3 | 0.31 | 0.64 | |

| Algieria–Arzew | 88.92 | 8.42 | 1.58 | 0.37 | 0.71 | |

| Brunei | 90.12 | 5.34 | 3.02 | 1.48 | 0.04 | |

| Egypt–Idku | 95.31 | 3.58 | 0.74 | 0.35 | 0.02 | |

| Egypt–Damietta | 97.25 | 2.49 | 0.12 | 0.12 | 0.02 | |

| Indonesia–Badak | 90.14 | 5.46 | 2.98 | 1.41 | 0.01 | |

| Libya | 81.39 | 12.44 | 3.51 | 0.64 | 2.02 | |

| Malaysia–Bintulu | 91.69 | 4.64 | 2.6 | 0.93 | 0.14 | |

| Nigeria | 91.7 | 5.52 | 2.17 | 0.58 | 0.03 | |

| Norway | 92.03 | 5.75 | 1.31 | 0.45 | 0.46 | |

| Oman | 90.68 | 5.75 | 2.12 | 1.25 | 0.2 | |

| Peru | 89.06 | 10.26 | 0.1 | 0.01 | 0.57 | |

| Qatar | 90.91 | 6.43 | 1.66 | 0.73 | 0.27 | |

| Russia–Sakhalin | 92.54 | 4.47 | 1.97 | 0.95 | 0.07 | |

| Trynidad | 96.78 | 2.78 | 0.37 | 0.06 | 0.01 | |

| USA–Alaska | 99.7 | 0.09 | 0.03 | 0.01 | 0.17 | |

| Yemen | 93.17 | 5.92 | 0.77 | 0.12 | 0.02 | |

| Set No. | Methane C1 | Ethane C2 | Propane C3 | Butanes C4 | Pentanes C5 | Nitrogen N2 |

|---|---|---|---|---|---|---|

| 1 | (100 − n)% | 0.75 n% | 0.25 n% | - | - | - |

| 2 | (100 − n)% | 0.6 n% | 0.4 n% | - | - | - |

| 3 | (100 − n)% | 0.8 n% | 0.15 n% | 0.05 n% | - | - |

| 4 | (100 − n)% | 0.65 n% | 0.25 n% | 0.1 n% | - | - |

| 5 | (100 − n)% | 0.55 n% | 0.35 n% | 0.1 n% | - | - |

| 6 | (100 − n)% | 0.6 n% | 0.25 n% | 0.15 n% | - | - |

| 7 | (100 − n)% | 0.45 n% | 0.35 n% | 0.2 n% | - | - |

| 8 | (100 − n)% | 0.7 n% | 0.2 n% | 0.07 n% | 0.03 n% | - |

| 9 | (100 − n)% | 0.6 n% | 0.25 n% | 0.1 n% | 0.05 n% | - |

| 10 | (100 − n)% | 0.6 n% | 0.2 n% | 0.12 n% | 0.08 n% | - |

| 11 | (100 − n)% | 0.5 n% | 0.25 n% | 0.15 n% | 0.1 n% | - |

| 12 | (100 − n)% | n% | - | - | - | - |

| 13 | (100 − n)% | - | n% | - | - | - |

| 14 | (100 − n)% | - | - | n% | - | - |

| 15 | (99 − n)% | 0.8 n% | 0.15 n% | 0.05 n% | - | 1% |

| Set No. | Methane C1 | Ethane C2 | Propane C3 | Butanes C4 | Pentanes C5 | Nitrogen N2 |

|---|---|---|---|---|---|---|

| Min %mol | Max %mol | Max %mol | Max %mol | Max %mol | %mol | |

| 1 | 92.5 | 5.6 | 1.9 | - | - | - |

| 2 | 93.2 | 4.1 | 2.7 | - | - | - |

| 3 | 92.3 | 6.2 | 1.2 | 0.3 | - | - |

| 4 | 93.5 | 4.2 | 1.7 | 0.6 | - | - |

| 5 | 94.0 | 3.3 | 2.1 | 0.6 | - | - |

| 6 | 94.0 | 3.6 | 1.5 | 0.9 | - | - |

| 7 | 94.5 | 2.5 | 1.9 | 1.1 | - | - |

| 8 | 93.3 | 4.7 | 1.3 | 0.5 | 0.2 | - |

| 9 | 94.0 | 3.6 | 1.5 | 0.6 | 0.3 | - |

| 10 | 94.3 | 3.4 | 1.1 | 0.7 | 0.5 | - |

| 11 | 95.0 | 2.5 | 1.3 | 0.7 | 0.5 | - |

| 12 | 90.5 | 9.5 | - | - | - | - |

| 13 | 95.2 | - | 4.8 | - | - | - |

| 14 | 96.8 | - | - | 3.2 | - | - |

| 15 | 91.5 | 6.1 | 1.1 | 0.3 | - | 1.0 |

| Set No. | Methane C1 | Ethane C2 | Propane C3 | Butanes C4 | Pentanes C5 | Nitrogen N2 |

|---|---|---|---|---|---|---|

| Min %mol | Max %mol | Max %mol | Max %mol | Max %mol | %mol | |

| 1 | 86.5 | 10.2 | 3.3 | - | - | - |

| 2 | 87.8 | 7.4 | 4.8 | - | - | - |

| 3 | 86.4 | 10.8 | 2.0 | 0.8 | - | - |

| 4 | 88.2 | 7.7 | 3.0 | 1.1 | - | - |

| 5 | 89.0 | 6.1 | 3.8 | 1.1 | - | - |

| 6 | 89.0 | 6.6 | 2.8 | 1.6 | - | - |

| 7 | 90.5 | 4.3 | 3.3 | 1.9 | - | - |

| 8 | 88.0 | 8.4 | 2.4 | 0.8 | 0.4 | - |

| 9 | 89.5 | 6.3 | 2.6 | 1.1 | 0.5 | - |

| 10 | 90.0 | 6.0 | 2.0 | 1.2 | 0.8 | - |

| 11 | 91.0 | 4.5 | 2.3 | 1.3 | 0.9 | - |

| 12 | 83.0 | 17.0 | - | - | - | - |

| 13 | 91.5 | - | 8.5 | - | - | - |

| 14 | 94.3 | - | - | 5.7 | - | - |

| 15 | 85.5 | 10.8 | 2.0 | 0.7 | - | 1.0 |

| Component | MN > 70 | MN > 80 |

|---|---|---|

| %mol | %mol | |

| Methane | >88.7 | >93.65 |

| Ethane | <7.55 | <4.35 |

| Propane | <3.4 | <1.9 |

| Butanes | <0.8 | <0.4 |

| Pentanes | <0.45 | <0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuczyński, S.; Łaciak, M.; Szurlej, A.; Włodek, T. Impact of Liquefied Natural Gas Composition Changes on Methane Number as a Fuel Quality Requirement. Energies 2020, 13, 5060. https://doi.org/10.3390/en13195060

Kuczyński S, Łaciak M, Szurlej A, Włodek T. Impact of Liquefied Natural Gas Composition Changes on Methane Number as a Fuel Quality Requirement. Energies. 2020; 13(19):5060. https://doi.org/10.3390/en13195060

Chicago/Turabian StyleKuczyński, Szymon, Mariusz Łaciak, Adam Szurlej, and Tomasz Włodek. 2020. "Impact of Liquefied Natural Gas Composition Changes on Methane Number as a Fuel Quality Requirement" Energies 13, no. 19: 5060. https://doi.org/10.3390/en13195060

APA StyleKuczyński, S., Łaciak, M., Szurlej, A., & Włodek, T. (2020). Impact of Liquefied Natural Gas Composition Changes on Methane Number as a Fuel Quality Requirement. Energies, 13(19), 5060. https://doi.org/10.3390/en13195060