Photovoltaics- and Battery-Based Power Network as Sustainable Source of Electric Power

Abstract

1. Introduction

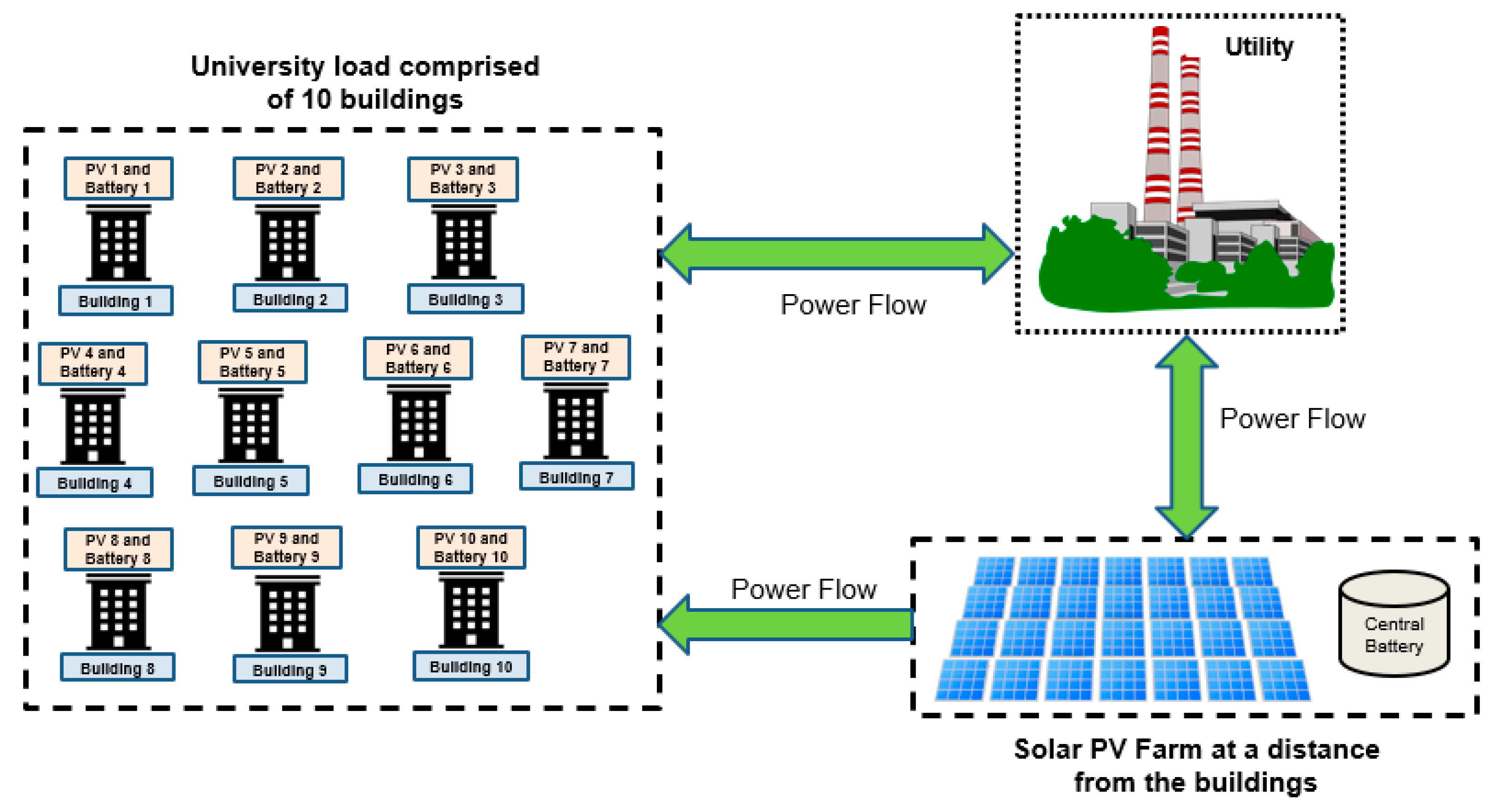

2. Transformation of the Electric Power Grid by a Photovoltaics- and Batteries-Based Power Network

2.1. Cost Trends in PV and Battery Systems

2.2. Environmental Benefits of Sustainable Power Generation with PV and Battery System

3. Maximum Utilization of Power Generated by PV System

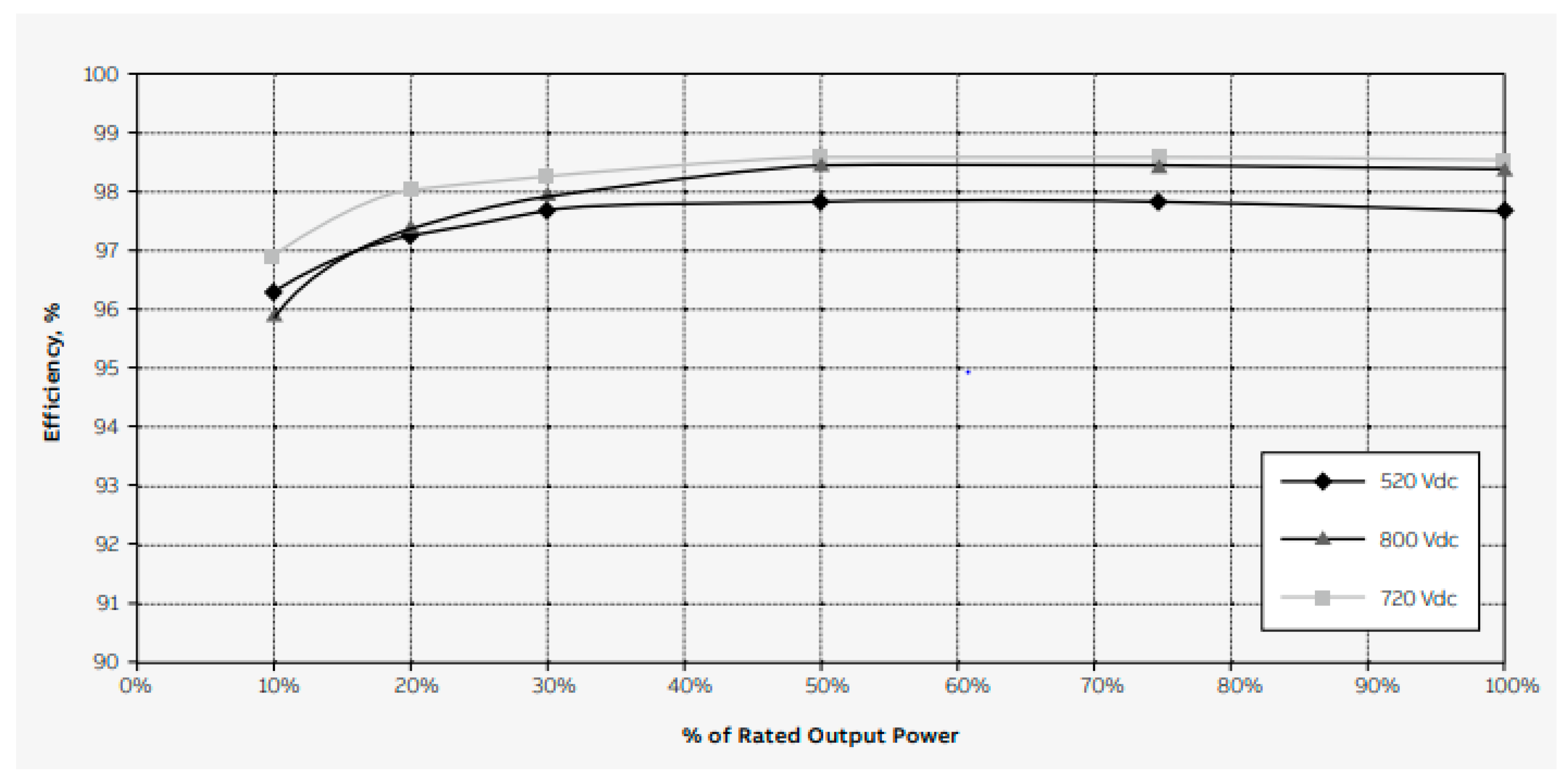

3.1. Inverter Sizing Considerations

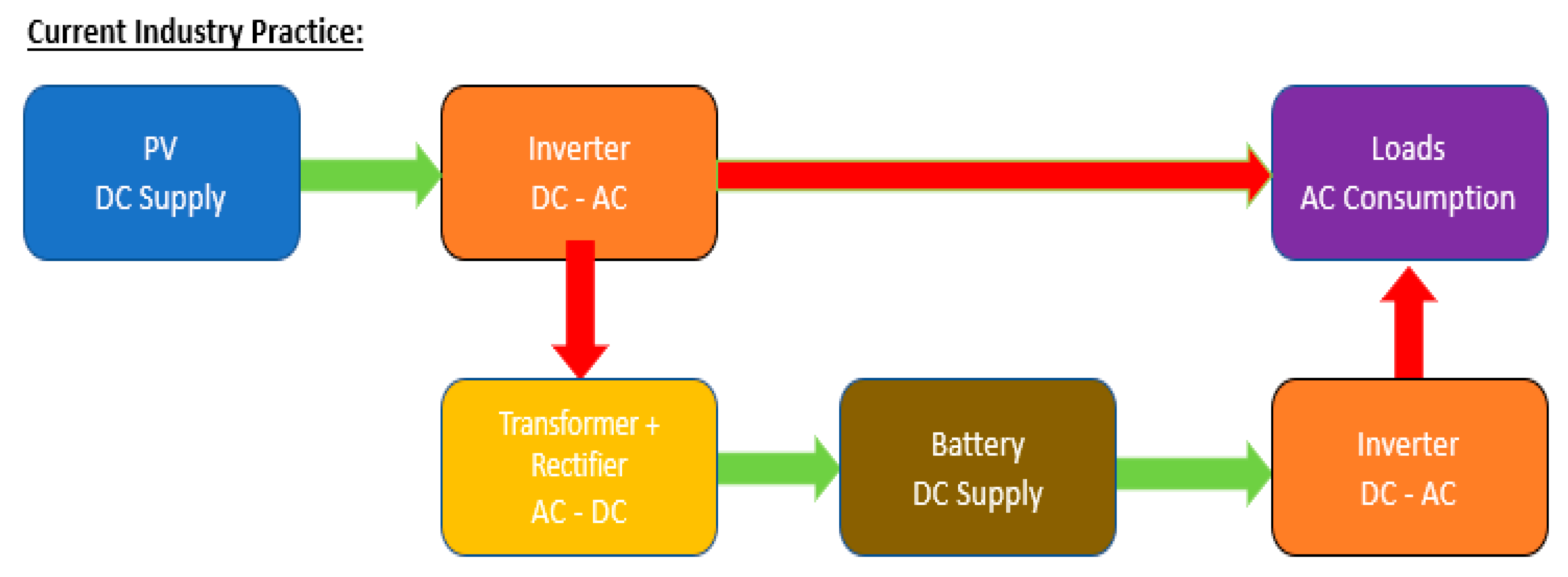

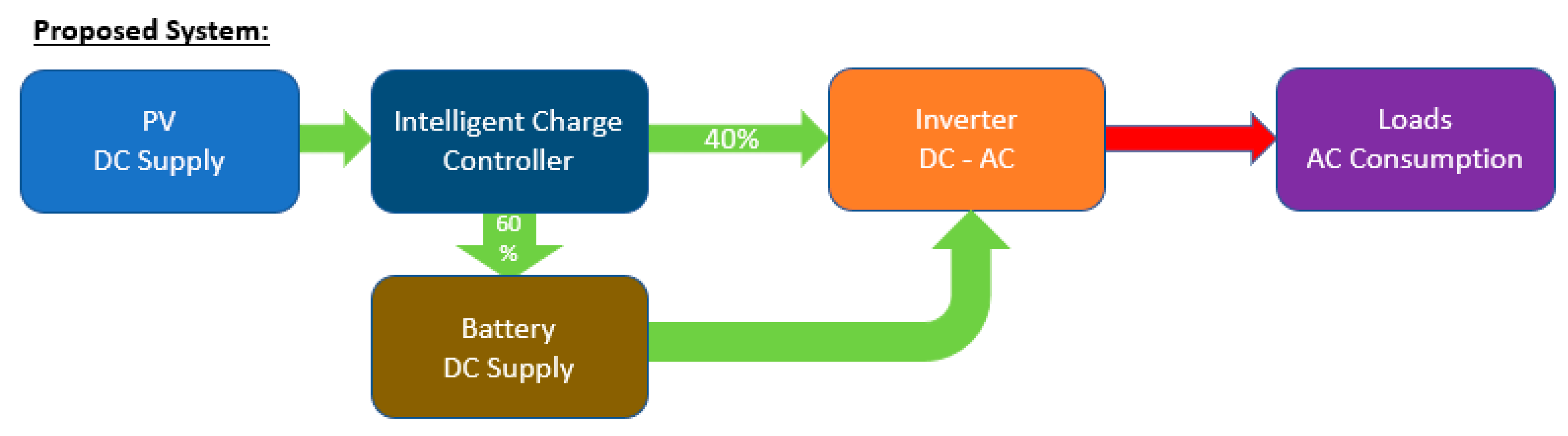

3.2. Proposed Inverter Architecture to Maximize DC Power Utilization

4. Design Considerations

4.1. Geographical Considerations

Altitude angle = 90 − L + Declination angle

Tilt = 90 − Altitude angle

where n = day number in a year;

L = latitude co-ordinate.

4.2. Ratings and Parameters for Equipment

4.3. Sizing Considerations

5. Economic and Feasibility Analysis

- According to a recent article of December 2019, the cost of a DC power PV system has gone as low as USD 0.7 per watt [52]. In our case, we have 12.2 MW DC power and the cost can be as low as USD 8.54 million. For an AC system, the cost of the inverter must be added. According to [53], the cost of an inverter in 2018 was USD 0.06153 per watt. Therefore, we can assume an inverter cost of USD 0.06 per watt in 2020. Thus, the PV system cost with AC power becomes USD 0.76 per watt. In addition to the PV system cost, one must consider the legal fees, project management cost, fencing, interconnection fee, construction, etc. On 20 November 2019, the El Paso Electric Company applied for expedited approval of a certificate of public convenience and necessity (CNN) and for a special rate contract to construct a solar generation/storage project at New Mexico State University [54]. The cost of a ground-mounted single-axis 3 MW PV system is USD 4,301,797 and the 4 MWh battery system cost is USD 1,969,000, while the total PV and storage system cost is USD 6,284,580. The overall project cost is USD 7,838,226, which means that additional costs of legal fees, project management, fencing, interconnection fee, etc., for a project of the size of a 3 MW PV system and 4 MWh battery system is 24.7%. Since our project size is much larger than the case of reference [54], we will use 20% additional cost of the project. Thus, adding an additional 20% to the cost of USD 0.76 per AC watt provides the total cost of the AC system of USD 0.91 per watt. To be extremely conservative, we have used USD 1 per watt (AC power output) that covers all PV installed and operating system costs.

- The lithium-ion batteries cost also keeps falling in line with the cost reduction of PV modules [55]. Based on very recent (3 December 2019) cost data published by Bloomberg New Energy Finance [32], the average battery pack capital cost in the years 2020 and 2030 is expected to be USD 144 and USD 61 per kWh, respectively.

- Depending on the type of inverter (microinverter, central inverter or string inverter), the warranty can vary from 12 to 25 years [58]. We have chosen 15-years warranty in our calculations, since the quality of inverters is improving, and the cost of inverters is also constantly reducing. Based on 2017 data, the inverter cost is USD 0.06153 per watt [53]. In the year 2035, we expect that the cost will be reduced to USD 0.03 per watt. This is the cost we have used in our model to replace inverters in year 15.

- In line with the current debt rate for state universities in the United States, we have used a 4.00% debt rate.

- The investment tax credit (ITC), also known as the federal solar tax credit, allows one to deduct 26% of the cost of installing a solar energy system from their federal taxes. The ITC applies to both residential and commercial systems, and there is no cap on its value [59]. We have assumed that the utility or private investor pays enough federal taxes and all the 26% of the system cost can be deduced in year 1. After year 7 (no more equipment depreciation), the federal and state taxes are paid.

- In the estimation of the depreciation cost of the PV system, 70% is the hardware cost. For the battery system, the hardware cost is 90%.

- We have used the PPA cost of USD 0.04 per kWh in our analysis. The PPA cost is in line with large-scale utility projects in the United States. The main reason for the low cost is the falling cost of PV modules and batteries. As an example, Los Angeles Department of Water and Power has signed a groundbreaking 25-year PPA with 8Minute Solar [60]. The combined price for solar energy plus storage is just 3.3 cents per kWh, the lowest ever in the US and cheaper than electricity from a natural gas-powered generating plant [60].

- Utility rate enhancement of 2% per year is used in our financial model.

- As per the rules of the Solar District Cup, financial calculations are done for 20 years.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

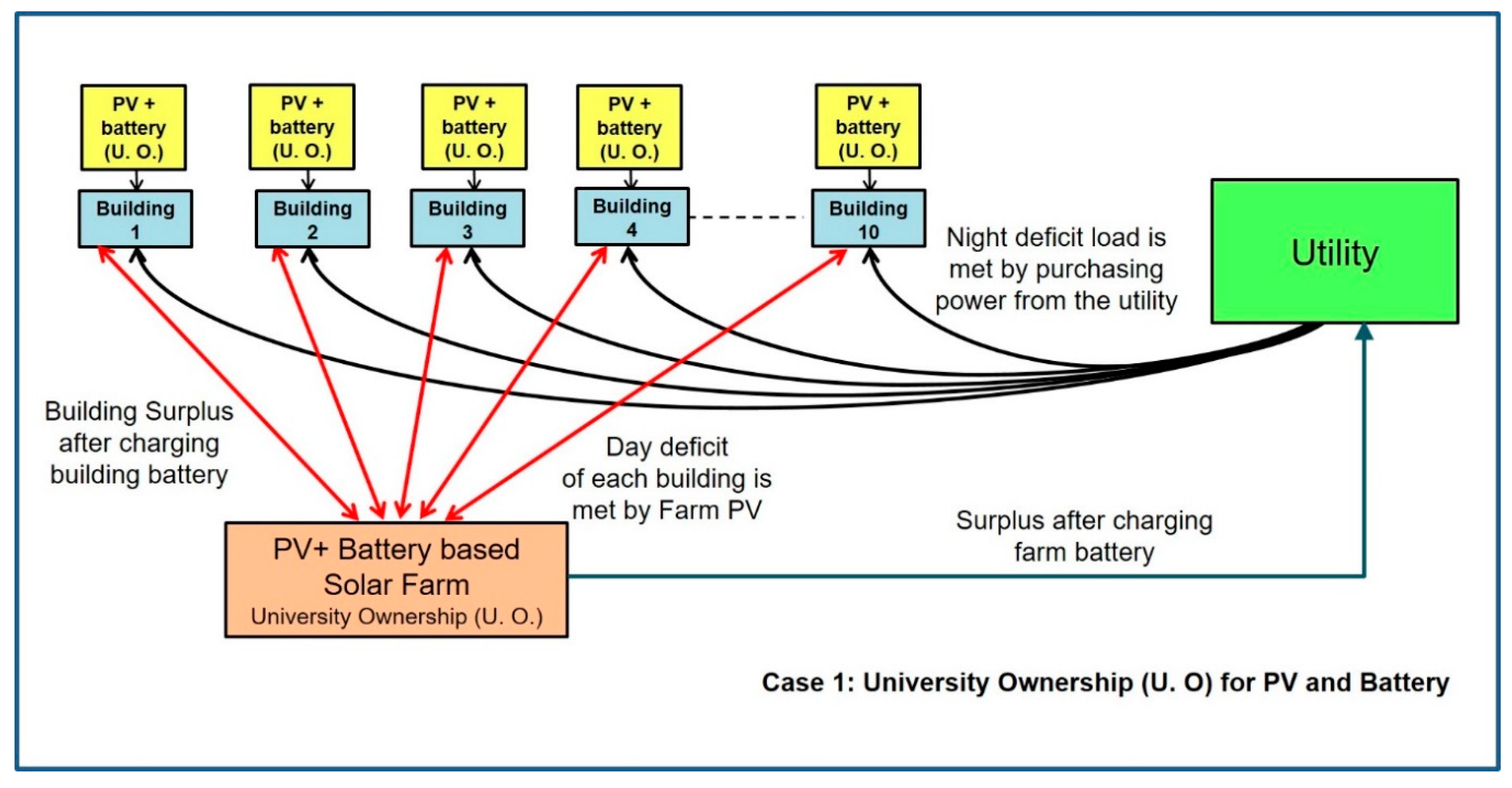

- The available rooftop area for PV panel installation on buildings is 80% of the provided area as justified in the text. The farm area is considered at 37,384 m2 to provide the sizing of an 8 MW system.

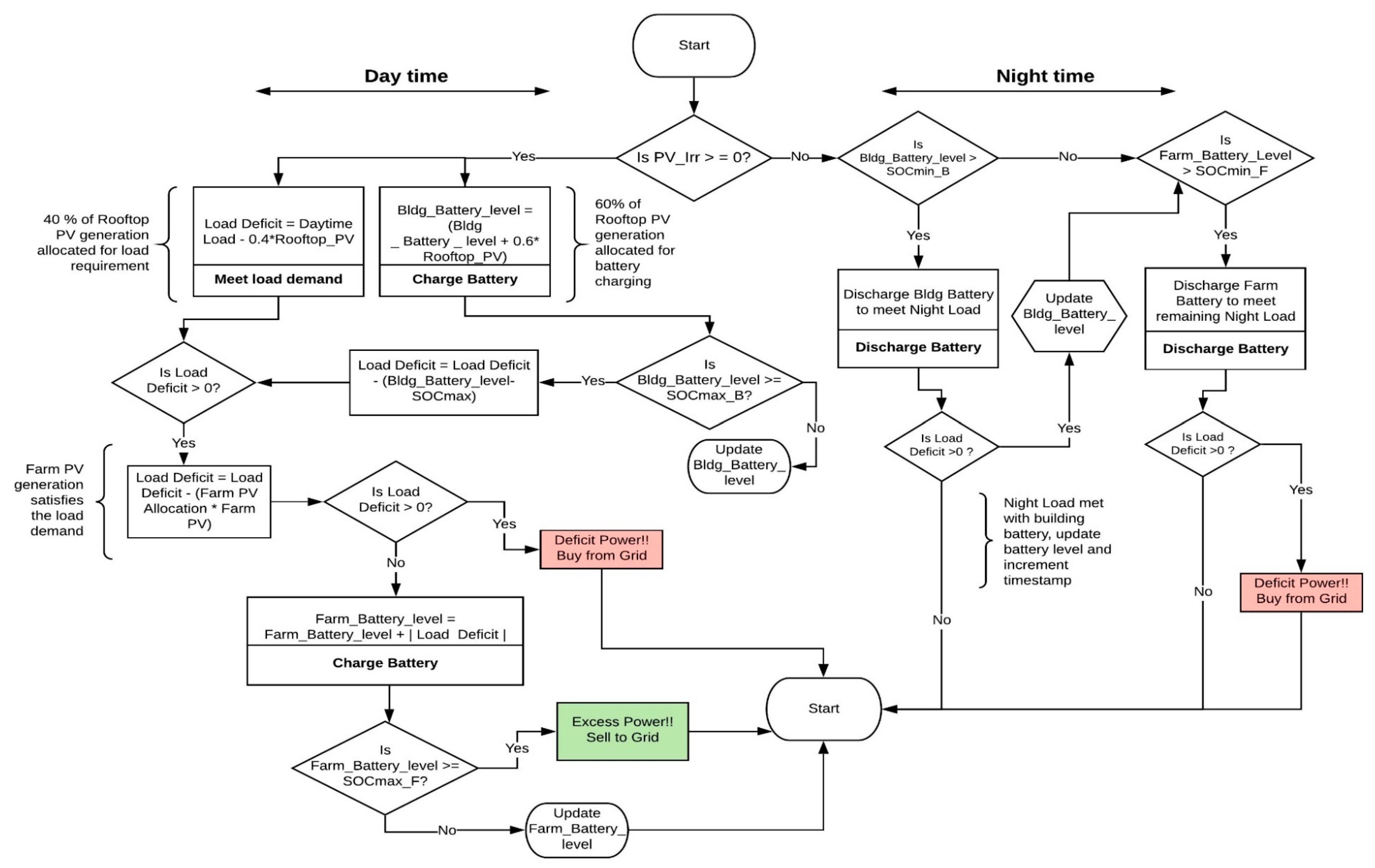

- The battery capacities chosen according to the sizing considerations are 12,000 kWh for the buildings and 35,000 kWh for the PV farm. These considerations are obtained through varying several values for the batteries in the given flowchart in Figure 8.

- The minimum state of charge (SOC) is rated at 20% of the battery charge level and the maximum SOC is rated at 100% of the battery capacity as modern batteries are equipped to operate at such ratings.

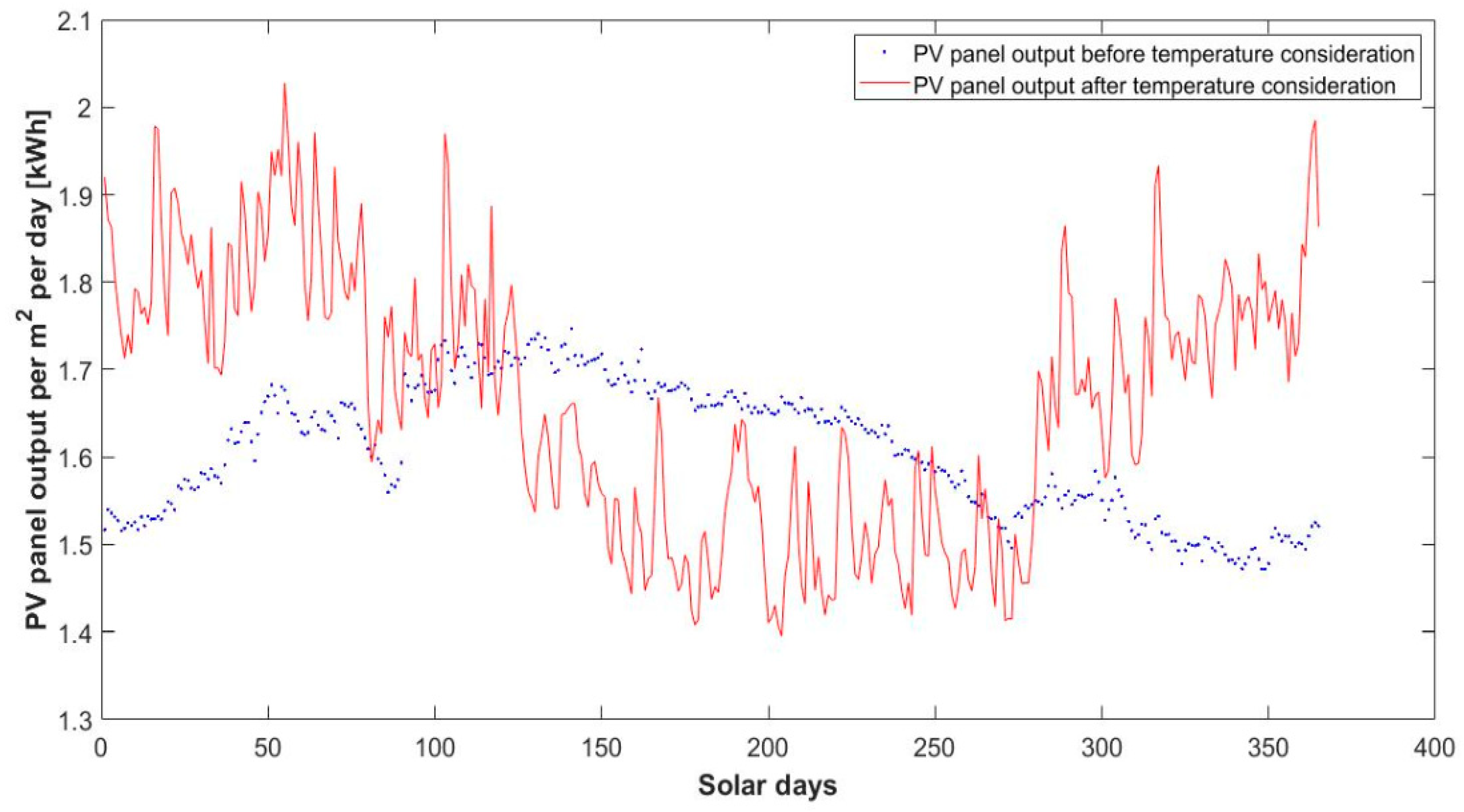

- The PV generation data are generated through the irradiance in the region. After temperature compensation is carried out for the panels, as described in Section 4.1, the panel output is obtained by multiplying the efficiency of the panel (22.1%, according to the data sheet in [24,25]). This obtained output is for per m2 of the panel. The final PV generation is obtained by multiplying the obtained per m2 value with the available rooftop area.

- The losses due to inverters, transmission lines and battery cycling efficiency are assumed after researching the most recent and state-of-the-art systems. These losses assumed are as follows:

- Inverter loss: 8%;

- Transmission loss: 7%;

- Battery cycling loss (round-trip efficiency consideration): 5%.

- The losses occur as follows:

- Building:From PV to battery charging: minimum DC-DC losses (neglected);From PV to load: inverter loss;From battery to load: inverter loss + battery cycling loss.

- PV Farm:From PV to battery charging: minimum DC-DC losses (neglected);From PV to load: inverter loss + transmission loss;From battery to load: inverter loss + battery cycling + transmission loss.

References

- The New York Times: Oil Companies Are Collapsing, but Wind and Solar Energy Keep Growing. Available online: https://www.nytimes.com/2020/04/07/business/energy-environment/coronavirus-oil-wind-solar-energy.html (accessed on 5 June 2020).

- Singh, R.; Alapatt, G.F.; Bedi, G. Why and How PV Will Provide the Cheapest Energy in the 21st Century. Facta Univ. Ser. Electron. Energ. 2014, 27, 275–298. [Google Scholar] [CrossRef]

- PV Magazine: The World Added. 115 Terawatts of Solar Power in 2019 for a Cumulative. 629 Terawatts. Available online: https://pv-magazine-usa.com/2020/04/30/the-world-added-115-terawatts-of-solar-power-in-2019-for-a-cumulative-629-terawatts/ (accessed on 5 June 2020).

- GWEC: Over 60 GW of Wind Energy Capacity Installed in 2019, the Second-Biggest Year in History. Available online: https://gwec.net/gwec-over-60gw-of-wind-energy-capacity-installed-in-2019-the-second-biggest-year-in-history/ (accessed on 5 June 2020).

- The Wall Street Journal: Green Energy Won’t Slip on Cheap Oil. Available online: https://www.wsj.com/amp/articles/green-energy-wont-slip-on-cheap-oil-11587975878 (accessed on 5 June 2020).

- Renewable Energy World: Champions of Photovoltaics Technology. Available online: https://www.renewableenergyworld.com/2010/10/01/champions-of-photovoltaics/#gref (accessed on 5 June 2020).

- GTM: World’s Largest Solar Project Will Also Be Its Cheapest. Available online: https://www.greentechmedia.com/amp/article/worlds-largest-solar-project-will-also-be-worlds-cheapest (accessed on 5 June 2020).

- Paniyil, P.; Singh, R.; Asif, A.; Powar, V.; Bedi, G.; Kimsey, J. Transformative and Disruptive Roles of Durect Current Power Networks in Power and Transportation Sectors. Facta Univ. Ser. Electron. Energ. 2019, 32, 387–402. [Google Scholar] [CrossRef]

- Energy Storage: Battery Storage at US $20/MWh? Breaking Down Low-Cost Solar-Plus-Storage PPAs in the USA. Available online: https://www.energy-storage.news/blogs/battery-storage-at-us20-mwh-breaking-down-low-cost-solar-plus-storage-ppas (accessed on 5 June 2020).

- Singh, R.; Shenai, K. DC Microgrids and the Virtues of Local Electricity. IEEE Spectrum 2014. Available online: https://spectrum.ieee.org/green-tech/buildings/dc-microgrids-and-the-virtues-of-local-electricity (accessed on 5 June 2020).

- Ertugrul, N.; Abbott, D. DC Is the Future. Proc. IEEE 2020, 108, 615–624. [Google Scholar] [CrossRef]

- Almasalma, H.; Deconinck, G. Simultaneous Provision of Voltage and Frequency Control by PV-Battery System. IEEE Access 2020, 8, 152820–152836. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, B.; Mishra, S. Multifunctional Control for PV Integrated Battery Energy Storage System with Improved Power Quality. IEEE Trans. Ind. Appl. 2020. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, D.; Choi, D.; Park, E. Exploring public perceptions of renewable energy: Evidence from a word network model in social network services. Energy Strategy 2020, 32, 100552. [Google Scholar] [CrossRef]

- Sun, L.; Li, G.; You, F. Combined internal resistance and state-of-charge estimation of lithium-ion battery based on extended state observer. Renew. Sustain. Energy Rev. 2020, 131, 109994. [Google Scholar] [CrossRef]

- Sun, L.; Sun, W.; You, F. Core temperature modelling and monitoring of lithium-ion battery in the presence of sensor bias. Appl. Energy 2020, 271, 115243. [Google Scholar] [CrossRef]

- EIA: Use of Energy Explained, Energy Use in Commercial Buildings. Available online: https://www.eia.gov/energyexplained/use-of-energy/commercial-buildings.php (accessed on 8 August 2020).

- Environment America: America’s Top Colleges for Renewable Energy. Available online: https://environmentamerica.org/reports/ame/americas-top-colleges-renewable-energy (accessed on 8 August 2020).

- Office of Energy Efficiency & Renewable Energy: U.S. Department of Energy Solar District Cup Collegiate Design Competition. Available online: https://www.energy.gov/eere/solar/solar-district-cup (accessed on 5 June 2020).

- Bedi, G.; Venayagamoorthy, G.K.; Singh, R.; Brooks, R.; Wang, K.C. Review of Internet of Things (IoT) in Electric Power and Energy Systems. IEEE Internet Things J. 2018, 5, 847–870. [Google Scholar] [CrossRef]

- CHM: 13 Sextillion & Counting: The Long & Winding Road to The Most Frequently Manufactured Human Artifact in History. Available online: https://computerhistory.org/blog/13-sextillion-counting-the-long-winding-road-to-the-most-frequently-manufactured-human-artifact-in-history/ (accessed on 5 June 2020).

- CISION: Global Consumer Electronics Market to Reach US $2.9 Trillion by 2020–Persistence Market Research. Available online: https://www.prnewswire.com/news-releases/global-consumer-electronics-market-to-reach-us-29-trillion-by-2020---persistence-market-research-609486755.html (accessed on 5 June 2020).

- IRENA: Future of Solar Photovoltaic. Available online: https://www.irena.org//media/Files/IRENA/Agency/Publication/2019/Nov/IRENA_Future_of_Solar_PV_2019.pdf (accessed on 5 June 2020).

- Electrek: Tesla’s Secret Roadrunner Project: New Battery Production at $100 per kWh on a Massive Scale. Available online: https://electrek.co/2020/02/26/tesla-secret-roadrunner-project-battery-production-massive-scale/amp/ (accessed on 5 June 2020).

- CIF: Global Solar Investment Report. Available online: https://www.climateinvestmentfunds.org/sites/cif_enc/files/knowledge-documents/bnef_2019-10-30_isa-cif_report-final_002.pdf (accessed on 5 June 2020).

- SunPower: SunPower Module 40-Year Useful Life. Available online: https://us.sunpower.com/sites/default/files/media-library/white-papers/wp-sunpower-module-40-year-useful-life.pdf (accessed on 5 June 2020).

- BNEF: Lithium-ion Battery Costs and Market. Available online: https://data.bloomberglp.com/bnef/sites/14/2017/07/BNEF-Lithium-ion-battery-costs-and-market.pdf (accessed on 5 June 2020).

- Barron’s: Tesla and California Are Making Nice. The Next Factories Will Be Somewhere Else. Available online: https://www.barrons.com/articles/tesla-stock-california-factories-geographic-diversification-texas-shanghai-china-germany-51590075949 (accessed on 5 June 2020).

- The Guardian: UK’s First Car Battery ‘Gigafactory’ to be Built by Two Startups. Available online: https://www.theguardian.com/business/2020/may/20/uk-first-car-battery-gigafactory-amte-power-britishvolt (accessed on 5 June 2020).

- FPL: FPL Announces Plan to Build the World’s Largest Solar-Powered Battery and Drive Accelerated Retirement of Fossil Fuel Generation. Available online: http://newsroom.fpl.com/2019-03-28-FPL-announces-plan-to-build-the-worlds-largest-solar-powered-battery-and-drive-accelerated-retirement-of-fossil-fuel-generation (accessed on 5 June 2020).

- Wood Mackenzie: Solar Technology Got Cheaper and Better in the 2010s. Now What? Available online: https://www.woodmac.com/news/opinion/solar-technology-got-cheaper-and-better-in-the-2010s.-now-what/ (accessed on 5 June 2020).

- BloombergNEF: Battery Pack Prices Fall as Market Ramps up with Market Average at $156/kWh in 2019. Available online: https://about.bnef.com/blog/battery-pack-prices-fall-as-market-ramps-up-with-market-average-at-156-kwh-in-2019/ (accessed on 5 June 2020).

- Solar Industry: JinkoSolar Launches Its Tiger Pro Series of PV Modules. Available online: https://solarindustrymag.com/jinkosolar-launches-its-tiger-pro-series-of-pv-modules (accessed on 5 June 2020).

- Singh, R.; Alapatt, G.F.; Lakhtakia, A. Making Solar Cells a Reality in Every Home: Opportunities and Challenges for Photovoltaic Device Design. IEEE J. Electron Devices Soc. 2013, 1, 129–144. [Google Scholar] [CrossRef]

- Singh, R. Why Silicon is and will Remain the Dominant Photovoltaic Material. J. Nanophotonics 2009, 3, 032503. [Google Scholar] [CrossRef]

- Asif, A.; Singh, R. Further Cost Reduction of Battery Manufacturing. Batteries 2017, 3, 17. [Google Scholar] [CrossRef]

- Aljazeera: Tesla Is Working on Making Electric Cars Less Expensive. Available online: https://www.aljazeera.com/amp/ajimpact/tesla-working-making-electric-cars-expensive-200514181336609.html (accessed on 5 June 2020).

- Popular Mechanics: Tesla’s Battery Cell Patent Is ‘Way More Important than It Sounds’. Available online: https://www.popularmechanics.com/science/a32433420/elon-musk-tesla-battery-cell-patent/ (accessed on 5 June 2020).

- Bloomberg: These Countries Are the Most at Risk from a Water Crisis. Available online: https://www.bloomberg.com/graphics/2019-countries-facing-water-crisis/ (accessed on 5 June 2020).

- The Wall Street Journal: Power Plants Aim to Curb Their Thirst. Available online: https://www.wsj.com/articles/SB10000872396390444433504577649914114390298 (accessed on 5 June 2020).

- Solar Power World: How to Maximize Solar Project Value Using Inverter Clipping. Available online: https://www.solarpowerworldonline.com/2019/12/how-to-maximize-solar-installation-value-using-inverter-clipping/ (accessed on 5 June 2020).

- Sunny Tripower Core1 33-US Datasheet. Available online: https://documents.wholesalesolar.com/media/specs-20190530215325.2950183-4.pdf?_ga=2.46336487.1967707496.1600033514-1216853251.1574280990 (accessed on 14 September 2020).

- ABB: Solar String Inverters (TRIO-50.0-TL-OUTD-US-480-50 kW) Datasheet. Available online: https://library.e.abb.com/public/4d8140daa2b24c7c9ca4a37638e153bc/TRIO-50.0-TL-OUTD-US-480_Rev.G.pdf (accessed on 14 September 2020).

- Solar Power World: Too much of a Good Thing: Inverter Hyper-Clipping. Available online: https://www.solarpowerworldonline.com/2018/06/too-much-of-a-good-thing-inverter-hyper-clipping/ (accessed on 5 June 2020).

- Solar Power World: Hybrid Inverters Can Future-Proof Solar+Storage Installations. Available online: https://www.solarpowerworldonline.com/2018/09/hybrid-inverters-future-proof-solar-storage-installation/ (accessed on 5 June 2020).

- University of Oregon–Solar Radiation Monitoring Laboratory: Sun Path Chart Program. Available online: http://solardat.uoregon.edu/SunChartProgram.html (accessed on 14 September 2020).

- NMSU: Solar Time, Angles, and Irradiance Calculator: User Manual. Available online: https://aces.nmsu.edu/pubs/_circulars/CR674/welcome.html (accessed on 5 June 2020).

- SunPower: SunPower Residential AC Module. Available online: https://us.sunpower.com/sites/default/files/sp-x22-370-360-d-ac-datasheet-527025-revb.pdf (accessed on 5 June 2020).

- SunPower: SunPower X-Series Commercial Solar Panels. Available online: https://us.sunpower.com/sites/default/files/sunpower-x-series-commercial-solar-panels-x21-470-com-datasheet-524935-revb.pdf (accessed on 5 June 2020).

- Simpliphipower: Phi 3.8 Battery. Available online: https://simpliphipower.com/wp-content/uploads/documentation/phi-3-8/simpliphi-power-phi-3-8-kwh-60-amp-specification-sheet.pdf (accessed on 5 June 2020).

- Renewable Energy World: Levelized Cost of Electricity Models: The Good, The Bad and the Potential for Bias. Available online: https://www.renewableenergyworld.com/2014/11/14/levelized-cost-of-electricity-models-the-good-the-bad-and-the-potential-for-bias/#gref (accessed on 5 June 2020).

- PV Magazine: Utility Scale Solar Power as Cheap as 70 Cents Per Watt and Still Falling. Available online: https://pv-magazine-usa.com/2019/12/20/utility-scale-solar-power-as-cheap-as-75%C2%A2-per-watt-says-government-researchers/ (accessed on 5 June 2020).

- NREL: 2018 U.S. Utility-Scale Photovoltaics-Plus-Energy Storage System Costs Benchmark. Available online: https://www.nrel.gov/docs/fy19osti/71714.pdf (accessed on 5 June 2020).

- The Electric Company: El Paso Electric. Available online: https://www.transmissionhub.com/wp-content/uploads/2019/11/EPEappNov202019.pdf (accessed on 5 June 2020).

- GTM: Why Moore’s Law Doesn’t Apply to Clean Energy Technologies. Available online: https://www.greentechmedia.com/articles/read/why-moores-law-doesnt-apply-to-clean-technologies (accessed on 5 June 2020).

- Beltran, H.; Ayuso, P.; Perez, E. Lifetime Expectancy of Li-Ion Batteries used for Residential Solar Storage. Energies 2020, 13, 568. [Google Scholar] [CrossRef]

- Limited Warranty for Panasonic’s Lithium-Ion Battery Module for Pika Harbor Smart Battery/Flex and Plus System. Available online: https://d3g1qce46u5dao.cloudfront.net/warranty/dcb105_warranty.pdf (accessed on 5 June 2020).

- Wholesale Solar: Solar Panel Warranty Guide: How Long Will My System Last? Available online: https://www.wholesalesolar.com/blog/solar-panel-warranty-guide (accessed on 5 June 2020).

- Energysage: Investment Tax Credit for Solar Power. Available online: https://www.energysage.com/solar/cost-benefit/solar-investment-tax-credit/ (accessed on 5 June 2020).

- CleanTechnica: LA & 8Minute Solar Ink Lowest Cost Solar-Plus-Storage Deal in US History. Available online: https://cleantechnica.com/2019/09/11/la-8minute-solar-ink-lowest-cost-solar-plus-storage-deal-in-us-history/ (accessed on 5 June 2020).

- UtilityDive: El Paso Electric Sees Record Low Solar Prices as It Secures New Mexico Project Approvals. Available online: https://www.utilitydive.com/news/el-paso-electric-sees-record-low-solar-prices-as-it-secures-new-mexico-proj/578113/ (accessed on 14 September 2020).

- PV Magazine: Portuguese Government Confirms World Record Solar Price of $0.01316/kWh. Available online: https://www.pv-magazine.com/2020/08/27/portuguese-government-confirms-world-record-solar-price-of-0-01316-kwh/ (accessed on 14 September 2020).

- The Motley Fool: This Renewable Energy Juggernaut Wants to Supercharge America’s Battery Storage Capacity. Available online: https://www.fool.com/investing/2020/09/05/this-renewable-energy-juggernaut-wants-to-supercha/ (accessed on 14 September 2020).

- Renewable Energy World: Weighing the Advantages of Distributed and Centralized Energy Storage. Available online: https://www.renewableenergyworld.com/2015/04/01/weighing-the-advantages-of-distributed-energy-storage-and-centralized-energy-storage/#gref (accessed on 14 September 2020).

| Technology | Sector | Remarks |

|---|---|---|

| CMOS | Information Technology | CMOS accounts for 99.9% of all transistors used in USD 2.9 trillion consumer electronics [21,22] |

| Crystalline silicon PV | Power Generation | About 93–95% of global PV production by the end of 2018 accounted for about 470–480 GW, leading towards a TW scale [23] |

| Lithium-ion battery | Energy Storage | Plummeting costs of about USD 100/kWh [24], nearing cost of pumped hydro storage at about USD 75–100/kWh |

| Metric | Value |

|---|---|

| Maximum array power | 50,000 Wp STC |

| Maximum system voltage | 1000 V |

| Rated MPP voltage range | 330 V–800 V |

| MPPT operating voltage range | 150 V–1000 V |

| Maximum operating input current/per MPP tracker | 120 A/20 A |

| AC nominal Power | 33,300 W |

| Maximum Apparent Power | 33,300 VA |

| Maximum output current | 40 A |

| Nominal AC Voltage | 480 V/277 V WYE |

| AC voltage range | 244 V–305 V |

| CEC Efficiency (preliminary) | 97.5% |

| Calculated Metric | Rooftop Demand [kWh/year] | Total DC Rooftop PV Power [MW] | Number of Rooftop Panels | PV Farm Demand [kWh/year] | Total DC Farm PV Power [MW] | Number of Ground-Mounted Panels | Number of Panels per String | Number of Strings | Number of Inverters |

|---|---|---|---|---|---|---|---|---|---|

| Value | 10,967,356 | 4.294 | 11,606 | 20,890,202 | 8.18 | 17,403 | 10 | 1688 | 140 |

| Building | Rooftop PV Value [kW] |

|---|---|

| Building 1 | 820 |

| Building 2 | 317 |

| Building 3 | 371 |

| Building 4 | 631 |

| Building 5 | 715 |

| Building 6 | 127 |

| Building 7 | 524 |

| Building 8 | 86 |

| Building 9 | 231 |

| Building 10 | 316 |

| Total | 4200 |

| Model | Total Bills Paid by the University to the Utility under Existing Agreements | University’s Savings over 20 Years by Using PV- and Battery-Based Power Network | Profit of Utility or Investor |

|---|---|---|---|

| University is the owner of power network | USD 28,572,525 | USD 7,380,148 | Not Applicable |

| Power network is owned by the utility or investor | USD 28,572,525 | USD 4,163,022 | USD 1,652,379 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paniyil, P.; Powar, V.; Singh, R.; Hennigan, B.; Lule, P.; Allison, M.; Kimsey, J.; Carambia, A.; Patel, D.; Carrillo, D.; et al. Photovoltaics- and Battery-Based Power Network as Sustainable Source of Electric Power. Energies 2020, 13, 5048. https://doi.org/10.3390/en13195048

Paniyil P, Powar V, Singh R, Hennigan B, Lule P, Allison M, Kimsey J, Carambia A, Patel D, Carrillo D, et al. Photovoltaics- and Battery-Based Power Network as Sustainable Source of Electric Power. Energies. 2020; 13(19):5048. https://doi.org/10.3390/en13195048

Chicago/Turabian StylePaniyil, Prahaladh, Vishwas Powar, Rajendra Singh, Benjamin Hennigan, Pamela Lule, Matthew Allison, John Kimsey, Anthony Carambia, Dhruval Patel, Daniel Carrillo, and et al. 2020. "Photovoltaics- and Battery-Based Power Network as Sustainable Source of Electric Power" Energies 13, no. 19: 5048. https://doi.org/10.3390/en13195048

APA StylePaniyil, P., Powar, V., Singh, R., Hennigan, B., Lule, P., Allison, M., Kimsey, J., Carambia, A., Patel, D., Carrillo, D., Shriber, Z., Bazer, T., Farnum, J., Jadhav, K., & Pumputis, D. (2020). Photovoltaics- and Battery-Based Power Network as Sustainable Source of Electric Power. Energies, 13(19), 5048. https://doi.org/10.3390/en13195048