Online Rotor and Stator Resistance Estimation Based on Artificial Neural Network Applied in Sensorless Induction Motor Drive

Abstract

1. Introduction

- One article [19] concerns a sensorless control approach for a five-phase induction motor drive. The sensorless scheme uses the sliding mode theory, which applies a sliding mode observer to estimate rotor resistance. The operation methodology of the proposed control technique is formulated using the mathematical model of the machine and the two-time-scale approach.

- The author of [20] proposes the combination of parameter estimation-based observers with the dynamic regression extension and mixing parameter adaptation. The first framework is used to recast the flux observation task as a parameter estimation problem, for which the dynamic regressor extension and mixing method (DREM) technique is applied.

- One article [21] proposes using carrier signal injection with minimized torque ripple for rotor resistance estimation. The proposed approach is based on the injection of a relatively low-frequency carrier signal into the reference of the rotor flux linkage magnitude as well as extraction of the induction machine’s response to the carrier signal, which is then used in a model reference adaptive system.

- The author of [22] proposes the verification of rotor resistance identification in the field-oriented control-based drive system using the slip ring machine-based test bench. The paper proposes the torque calculations using the current stator and flux to propose the model reference adaptive system for online estimation of rotor resistance (without injection of the signal).

- Other articles [23,24] propose an online estimated rotor resistance method using a neural network. However, the proposed method is still limited by the learning rate that is pre-selected and does not change during the rotor resistance estimation process. Therefore, if the learning rate is selected inappropriately, it will lead to a slow network training process and large network output errors. The choice of appropriate learning rate is mainly based on the experience of the researchers.

- One article [35] proposes a novel Power Quality Model Reference Adaptive System (PQ-MRAS) concept for stator resistance. It uses the active and reactive power of the machine, which is calculated using measurable signals, (e.g., stator voltage and current). The paper includes a detailed description of the proposed estimator.

- The author of [36] proposes online identification of stator resistance based on the model reference adaptive system. In the article, the backpropagation is used to define the error between the measured and estimated value of stator current to adjust the weights of the neural network.

- The author of [37] presents the IM model that is transformable into the adaptive observer form. In this method, stator resistance estimation leads to the overparameterization problem. The proposed solution uses the first-order approximation of the error dynamics to the adaptive observer.

- The online stator resistance estimation methods using a neural network were studied and performed in [38]. However, in the proposed method, the learning rate must be selected and not changed during the estimation process. Consequently, this reduces its accuracy.

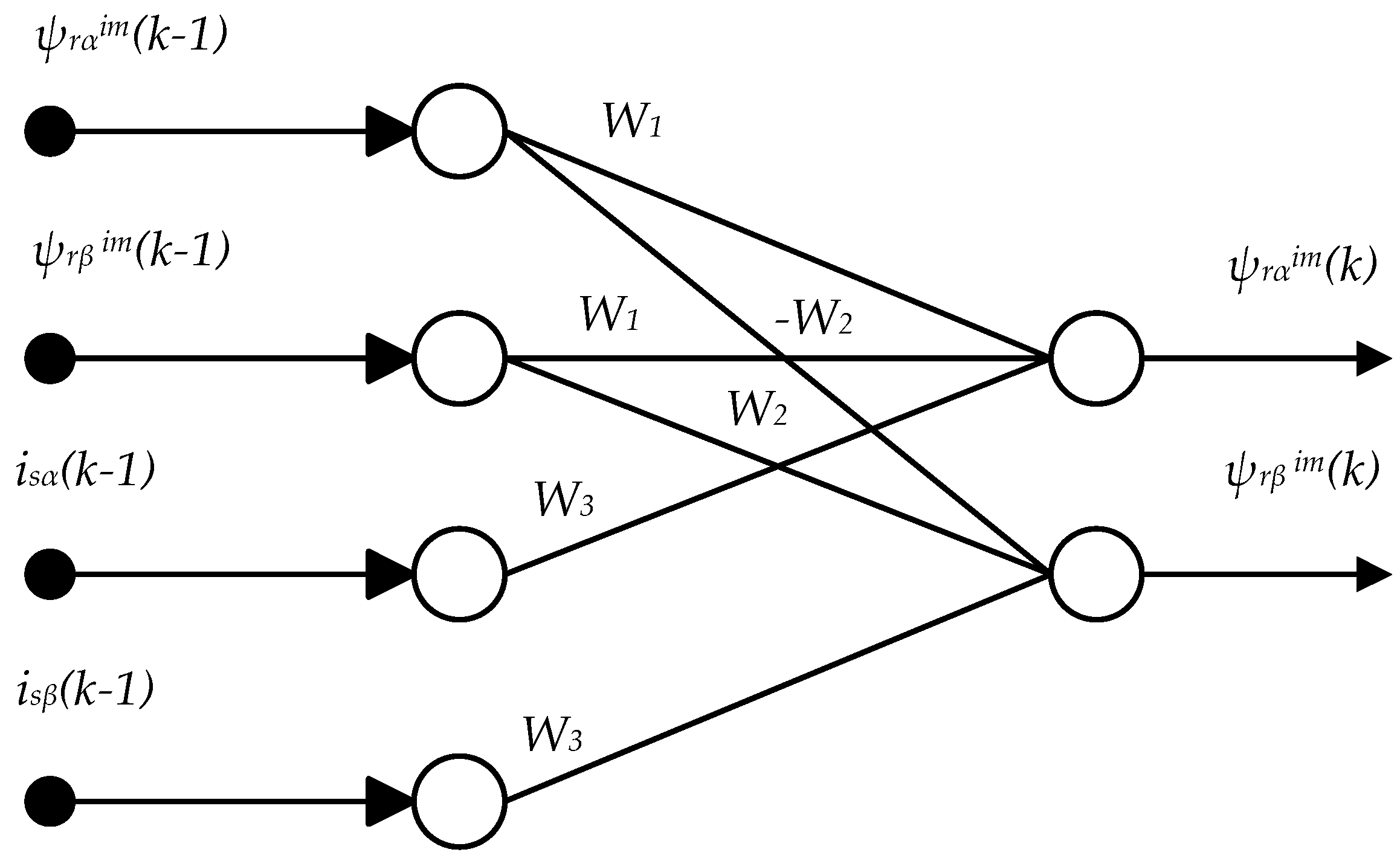

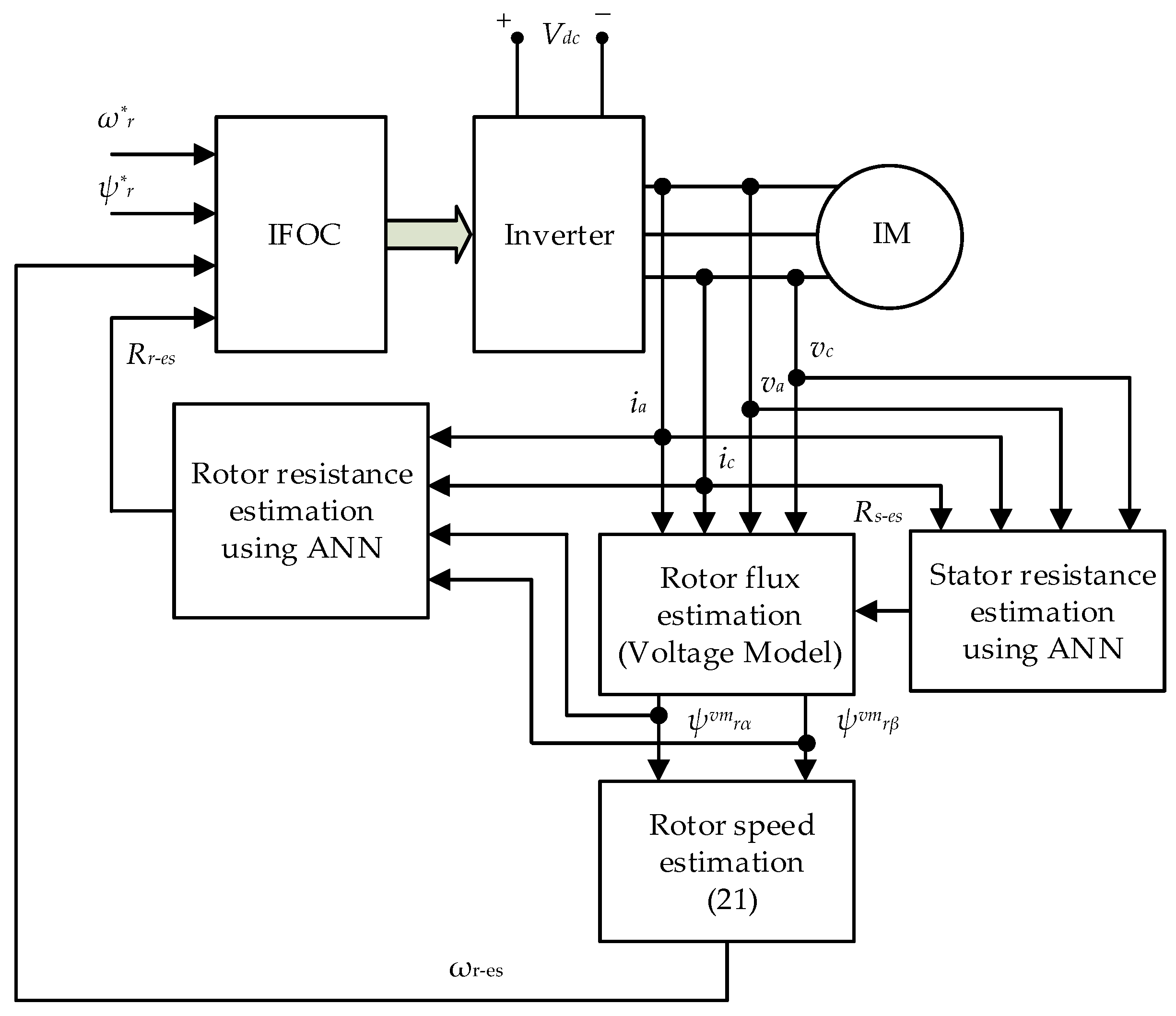

2. Rotor Resistance Estimation Using Artificial Neural Networks

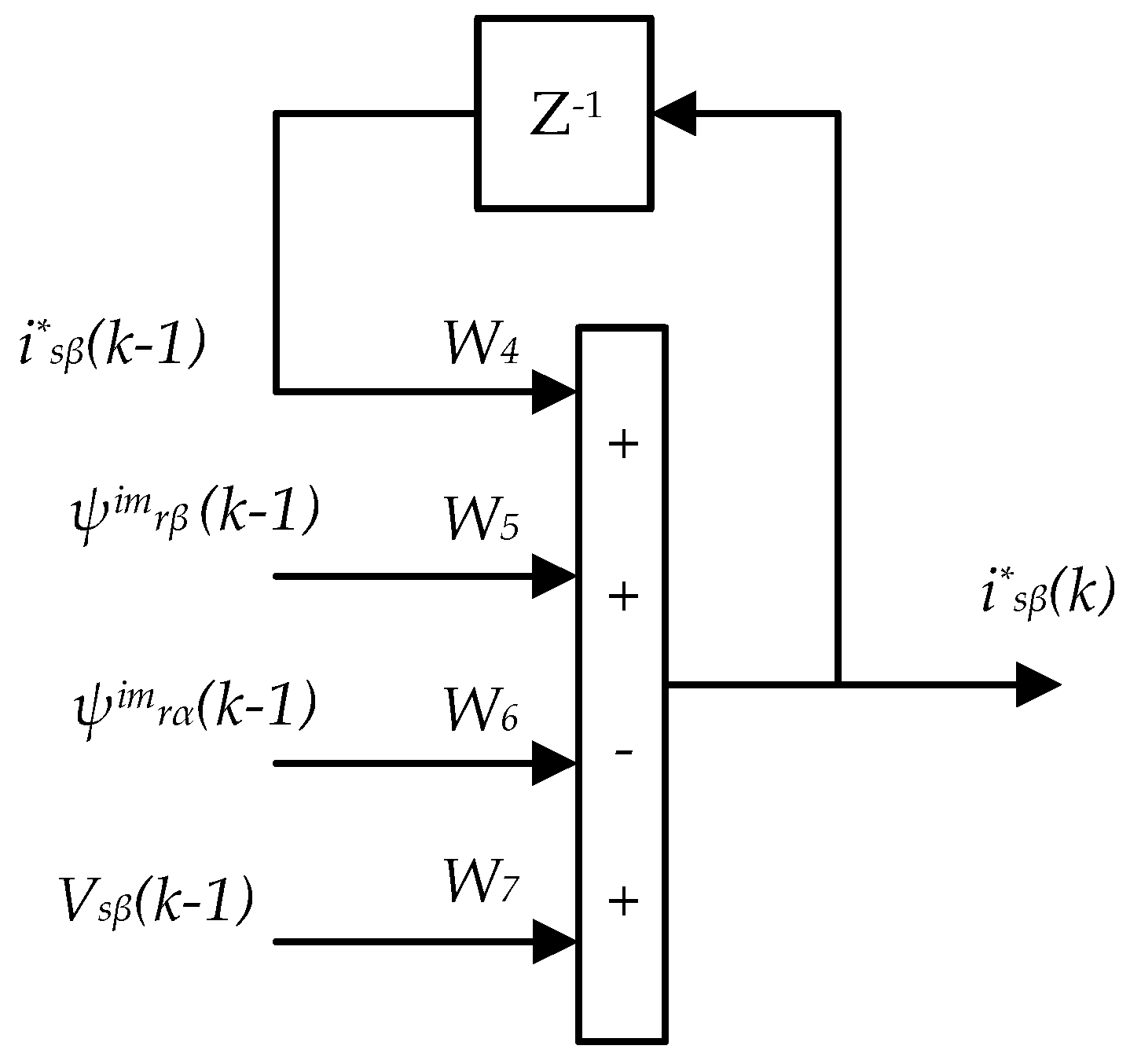

3. Stator Resistance Estimation Using Artificial Neural Networks

4. Results

4.1. Analysis

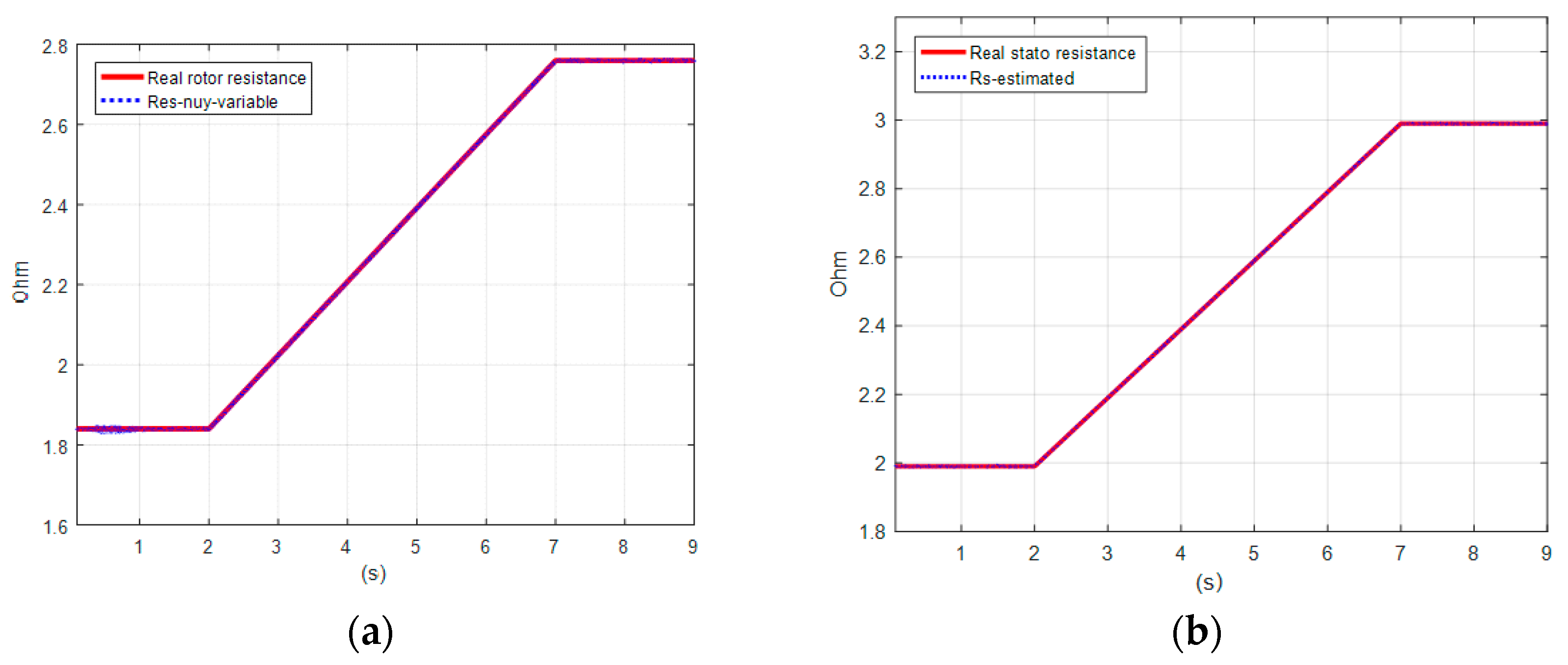

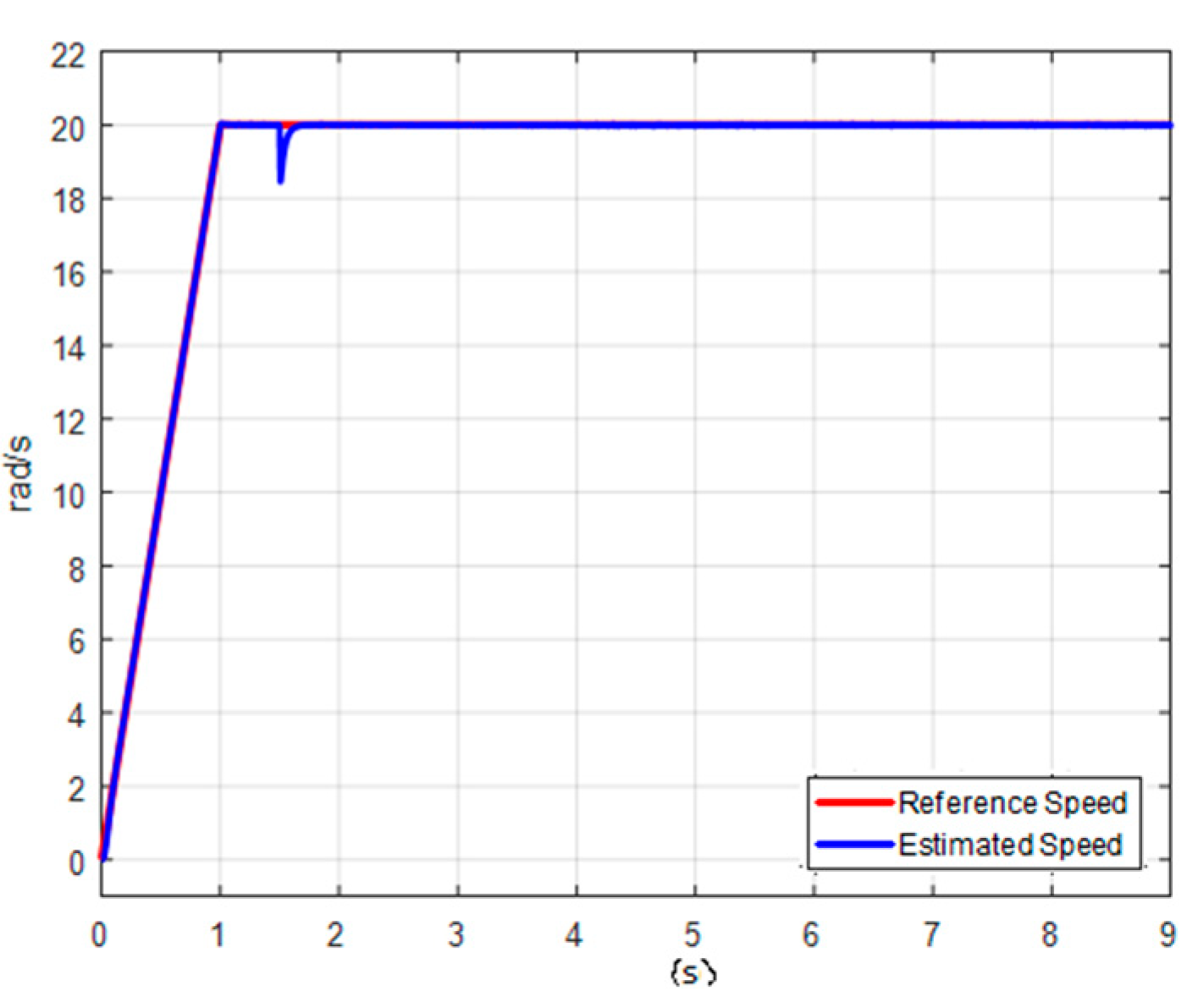

4.2. Results of the Simulation

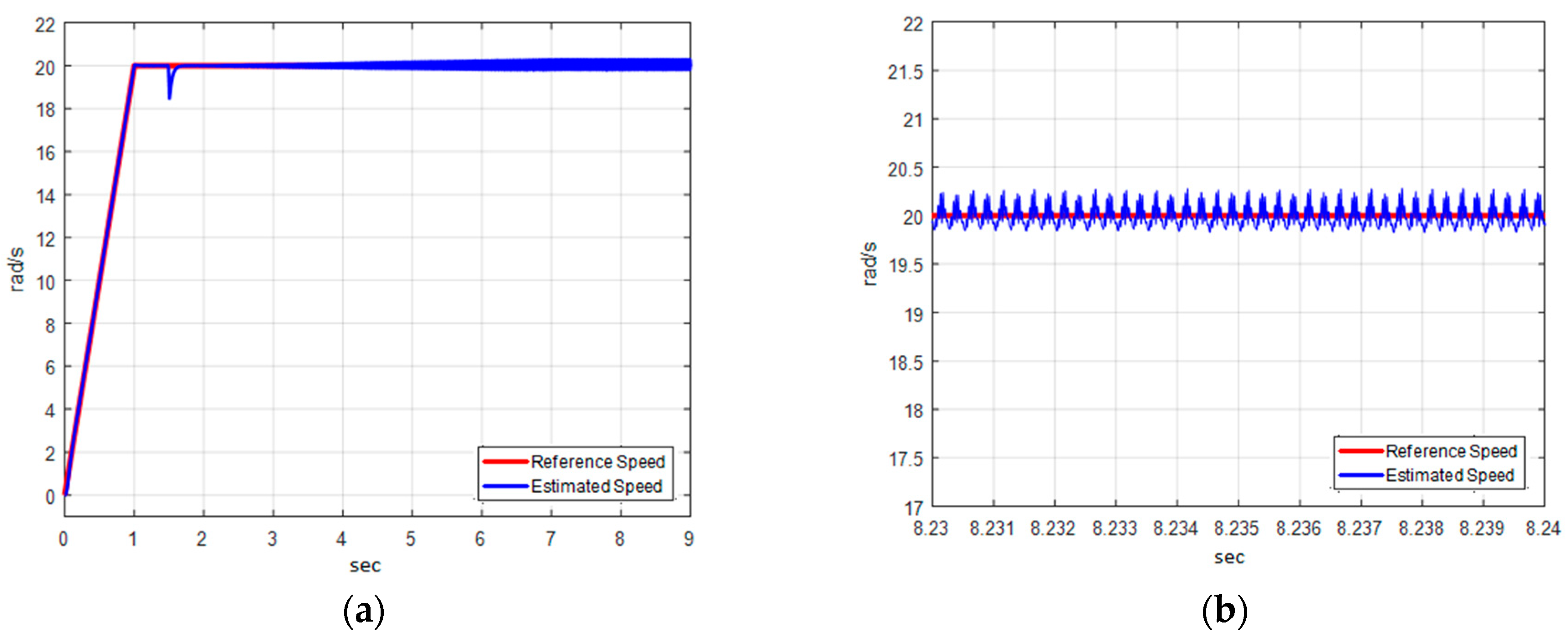

4.2.1. Speed of Induction Motor without Rotor and Stator Resistance Estimation

4.2.2. Speed of Induction Motor with Online Rotor and Stator Resistance Estimation

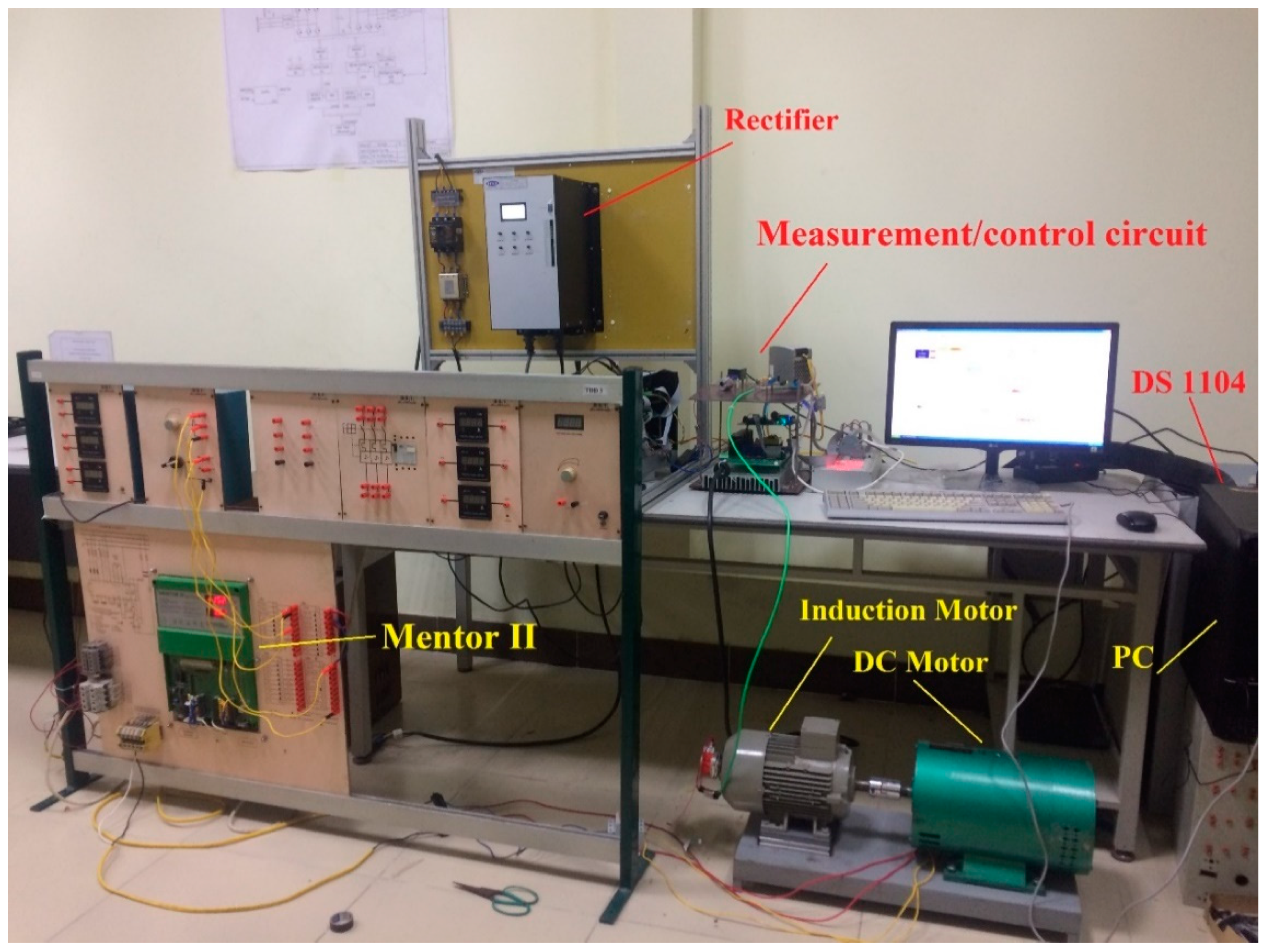

4.3. Results of the Experiment

- In Section 4.3.1, the comparison between estimation level with and without constant learning rate;

- In Section 4.3.2, the comparison between the speed of induction motor with and without online rotor and stator resistance estimators;

- In Section 4.3.3, the short discussion of obtained results is presented.

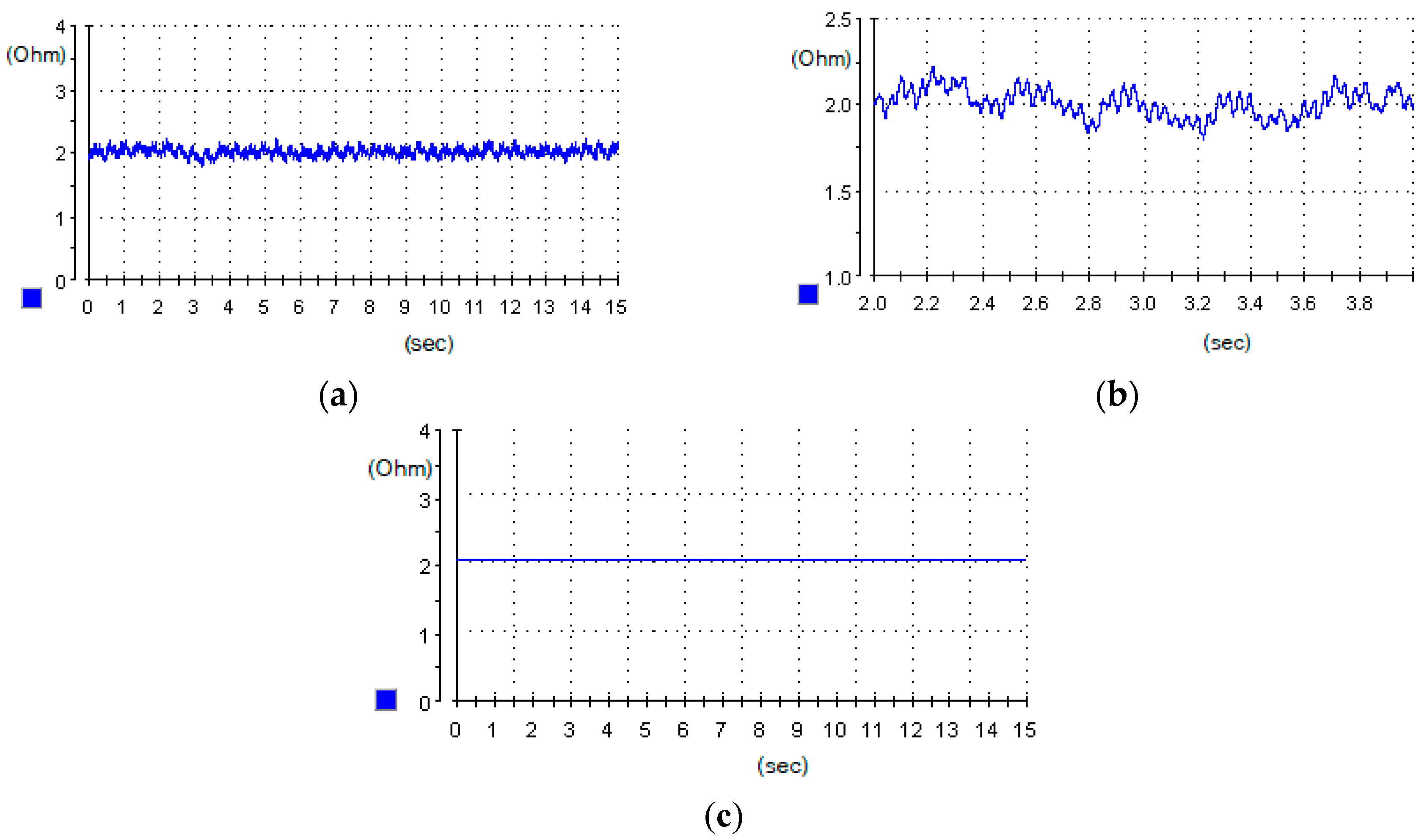

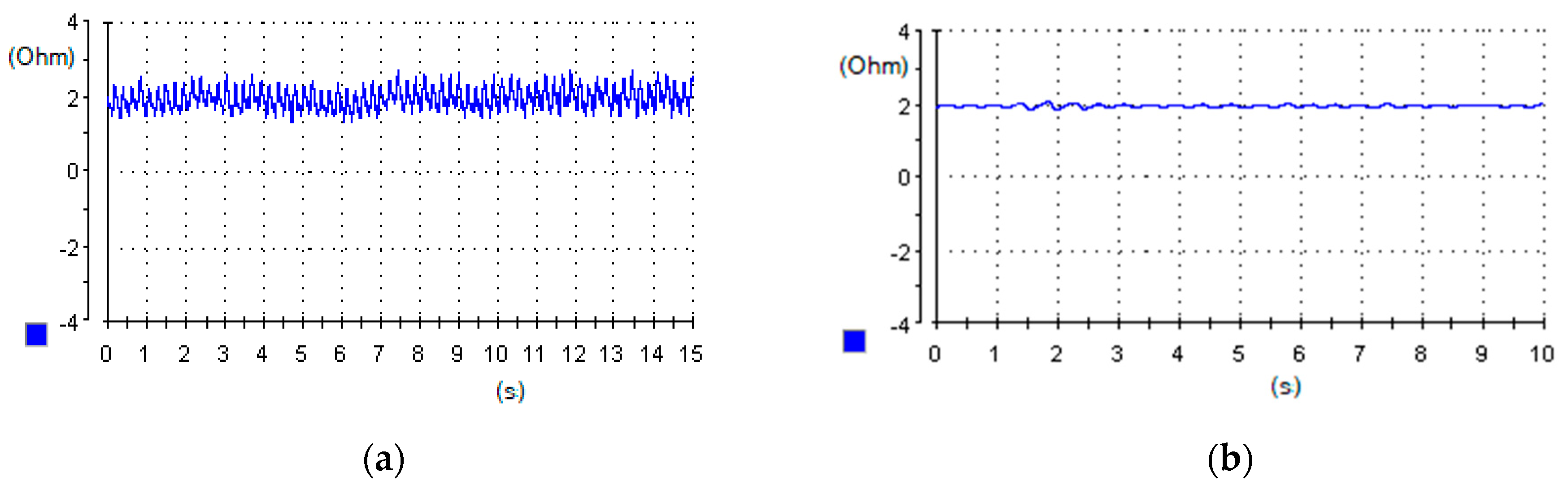

4.3.1. Results of Rotor and Stator Resistance Estimation

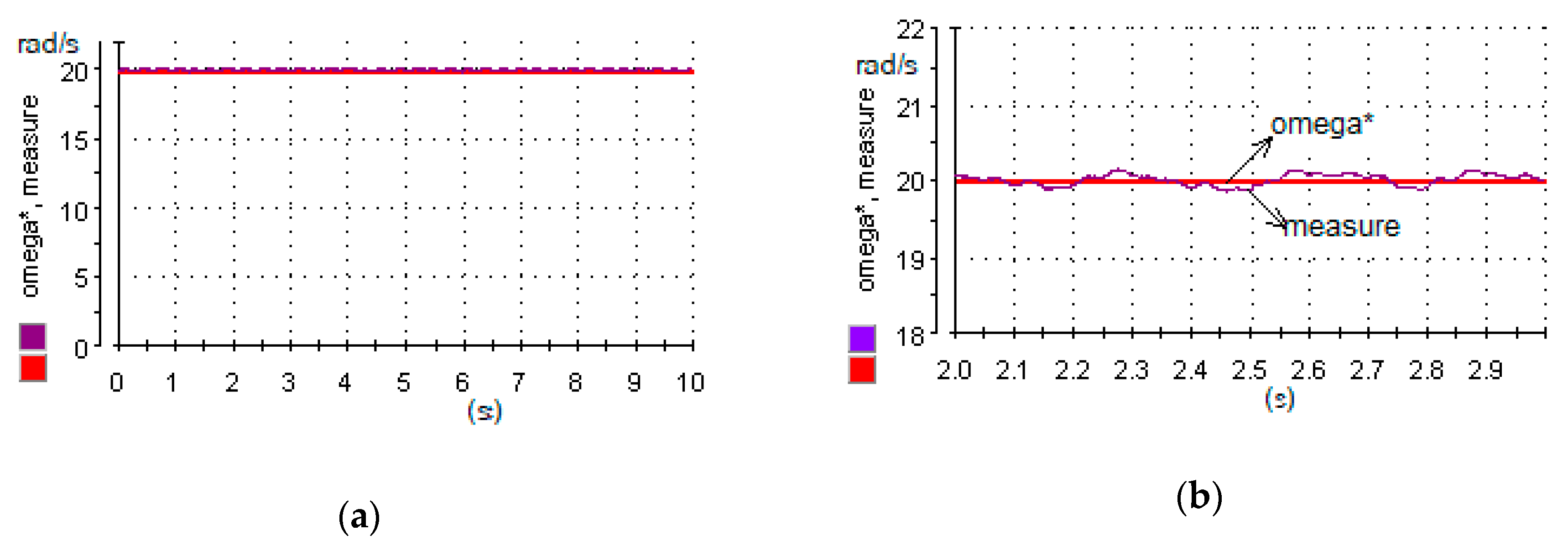

4.3.2. Impact of Online Rotor and Stator Resistance Estimation

4.3.3. Discussion

- Estimated rotor resistance obtained from the proposed methodology ensures that the pulsation is 20% lower than with constant learning rate. Additionally, the level of pulsation of the proposed method is less than 1%, which is better than results obtained in, e.g., [16] (up to 5%);

- Estimated stator resistance obtained from the proposed methodology ensures that the pulsation is 22% lower than with constant learning rate. Additionally, the level of pulsation of the proposed method is less than 3%, which is better than results obtained in, e.g., [35] (not exceeding 10%);

- Application of the proposed online rotor and stator resistance estimation ensured a decrease in the value of pulsation of over 4% than with constant learning rate.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

List of Symbols

| α-axis rotor flux linkages estimated by voltage model in the stator reference frame | |

| β-axis rotor flux linkages estimated by voltage model in the stator reference frame | |

| α-axis stator flux linkages in the stator reference frame | |

| β-axis stator flux linkages in the stator reference frame | |

| α-axis rotor flux linkages estimated by current model in the stator reference frame | |

| β-axis rotor flux linkages estimated by current model in the stator reference frame | |

| α-axis stator voltage in the stator reference frame | |

| β-axis stator voltage in the stator reference frame | |

| α-axis stator current in the stator reference frame | |

| β-axis stator current in the stator reference frame | |

| Lm | magnetizing inductance |

| Lr | rotor self-inductance |

| Ls | stator self-inductance |

| Rs | stator resistance |

| Rr | rotor resistance |

References

- Lascu, C.; Argeseanu, A.; Blaabjerg, F. Supertwisting Sliding-Mode Direct Torque and Flux Control of Induction Machine Drives. IEEE Trans. Power Electron. 2020, 35, 5057–5065. [Google Scholar] [CrossRef]

- Sathikumar, S.; Vithayathil, J. Digital Simulation of Field-Oriented Control of Induction Motor. IEEE Trans. Ind. Electron. 1984, IE-31, 141–148. [Google Scholar] [CrossRef]

- Gabriel, R.; Leonhard, W.; Nordby, C.J. Field-Oriented Control of a Standard AC Motor Using Microprocessors. IEEE Trans. Ind. Appl. 1980, IA-16, 186–192. [Google Scholar] [CrossRef]

- Takahashi, I.; Noguchi, T. A New Quick-Response and High-Efficiency Control Strategy of an Induction Motor. IEEE Trans. Ind. Appl. 1986, IA-22, 820–827. [Google Scholar] [CrossRef]

- Murata, T.; Tsuchiya, T.; Takeda, I. Vector control for induction machine on the application of optimal control theory. IEEE Trans. Ind. Electron. 1990, 37, 283–290. [Google Scholar] [CrossRef]

- Krishnan, R.; Doran, F.C. Study of Parameter Sensitivity in High-Performance Inverter-Fed Induction Motor Drive Systems. IEEE Trans. Ind. Appl. 1987, IA-23, 623–635. [Google Scholar] [CrossRef]

- Pal, A.; Das, S. Development of energy efficient scheme for speed sensorless induction motor drive. Int. Trans. Electr. Energy Syst. 2020, 30, e12448. [Google Scholar] [CrossRef]

- Chitra, A.; Himavathi, S. Investigation and analysis of high performance green energy induction motor drive with intelligent estimator. Renew. Energy 2016, 87, 965–976. [Google Scholar] [CrossRef]

- Mapelli, F.L.; Bezzolato, A.; Tarsitano, D. A Rotor Resistance MRAS Estimator for Induction Motor Traction Drive for Electrical Vehicles. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 823–829. [Google Scholar]

- Basnet, B.; Lee, H.-H. Rotor Flux Estimation for Low Speed Induction Motor Sensorless Drives with MRAS. In Lecture Notes in Electrical Engineering; Springer: Singapore, 2018; pp. 509–518. [Google Scholar]

- Orlowska-Kowalska, T.; Korzonek, M.; Tarchala, G. Performance Analysis of Speed-Sensorless Induction Motor Drive Using Discrete Current-Error Based MRAS Estimators. Energies 2020, 13, 2595. [Google Scholar] [CrossRef]

- Ouhrouche, M.A. Estimation of speed, rotor flux, and rotor resistance in cage induction motor using the EKF algorithm. Int. J. Power Energy Syst. 2002, 22, 103–109. [Google Scholar]

- Lin, G.; Wan, Q. Estimation of rotor resistance of induction motor based on extended kalman filter. In Part of the Advances in Intelligent and Soft Computing Book Series; Springer: Berlin, Germany, 2012; pp. 193–198. [Google Scholar]

- Demir, R.; Barut, M.; Yildiz, R.; Inan, R.; Zerdali, E. EKF based rotor and stator resistance estimations for direct torque control of Induction Motors. In Proceedings of the 2017 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM) & 2017 Intl Aegean Conference on Electrical Machines and Power Electronics (ACEMP), Fundata, Romania, 25–27 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 376–381. [Google Scholar]

- Tak, R.; Kumar, S.Y.; Rajpurohit, B.S. Estimation of Rotor and Stator Resistance for Induction Motor Drives using Second order of Sliding Mode Controller. J. Eng. Sci. Technol. Rev. 2017, 10, 9–15. [Google Scholar] [CrossRef]

- Yang, S.; Sun, R.; Cao, P.; Xie, Z.; Zhang, X. Sliding-mode observer based rotor resistance updating method for indirect vector controlled induction motor. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–5. [Google Scholar]

- Karanayil, B.; Rahman, M.F.; Grantham, C. Stator and Rotor Resistance Observers for Induction Motor Drive Using Fuzzy Logic and Artificial Neural Networks. IEEE Trans. Energy Convers. 2005, 20, 771–780. [Google Scholar] [CrossRef]

- Miloud, Y.; Draou, A. Fuzzy Logic Based Rotor Resistance Estimator of an Indirect Vector Controlled Induction Motor Drive. In Proceedings of the IEEE 2002 28th Annual Conference of the Industrial Electronics Society, Sevilla, Spain, 5–8 November 2002; IECON 02. IEEE: Piscataway, NJ, USA; Volume 2, pp. 961–966. [Google Scholar]

- Mossa, M.A.; Echeikh, H.; Iqbal, A.; Duc Do, T.; Al-Sumaiti, A.S. A Novel Sensorless Control for Multiphase Induction Motor Drives Based on Singularly Perturbed Sliding Mode Observer-Experimental Validation. Appl. Sci. 2020, 10, 2776. [Google Scholar] [CrossRef]

- Bazylev, D.N.; Doria-Cerezo, A.; Pyrkin, A.A.; Bobtsov, A.A.; Ortega, R. A New Approach for Flux and Rotor Resistance Estimation of Induction Motors. IFAC PapersOnLine 2017, 50, 1885–1890. [Google Scholar] [CrossRef]

- Hasanzadeh, A.; Reed, D.M.; Hofmann, H.F. Rotor Resistance Estimation for Induction Machines Using Carrier Signal Injection With Minimized Torque Ripple. IEEE Trans. Energy Convers. 2019, 34, 942–951. [Google Scholar] [CrossRef]

- Égető, T.; Farkas, B. Model Reference Adaptive System for the Online Rotor Resistance Estimation in the Slip-Ring Machine Based Test-bench. Period. Polytech. Electr. Eng. Comput. Sci. 2018, 62, 149–154. [Google Scholar] [CrossRef]

- Chitra, A.; Himavathi, S. A modified neural learning algorithm for online rotor resistance estimation in vector controlled induction motor drives. Front. Energy 2015, 9, 22–30. [Google Scholar] [CrossRef]

- Venkadesan, A.; Himavathi, S.; Muthuramalingam, A.; Sedhuraman, K. ANN based Flux Estimator for Rotor Resistance Estimation in Vector Controlled IM Drives. In Proceedings of the 2018 IEEE International Conference on System, Computation, Automation and Networking (ICSCA), Pondicherry, India, 6–7 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Bensalem, Y.; Abdelkrim, M.N. A Sensorless Neural Model Reference Adaptive Control for Induction Motor Drives. In Proceedings of the 2009 3rd International Conference on Signals, Circuits and Systems (SCS), New York, NY, USA, 6–8 November 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–6. [Google Scholar]

- Mohan Krishna, S.; Febin Daya, J.L. An Improved Stator Resistance Adaptation Mechanism in MRAS Estimator for Sensorless Induction Motor Drives. In Proceedings of the First International Conference on Intelligent Computing and Communication. Advances in Intelligent Systems and Computing, West Bengal, India, 18–19 February 2016; Volume 458, pp. 371–385. [Google Scholar]

- Karthikeyan, A.; Prabhakaran, K.K.; Nagamani, C. Stator flux based MRAS speed and stator resistance estimator for sensorless PMSM drive. In Proceedings of the 2017 14th IEEE India Council International Conference (INDICON), Roorkee, India, 15–17 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar]

- Jouili, M.; Agrebi, Y.; Koubaa, Y.; Boussak, M. A Luenberger State Observer for Simultaneous Estimation of Speed and Stator Resistance in Sensorless IRFOC Induction Motor Drives. In Proceedings of the 2015 16th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Monastir, Tunisia, 21–23 December 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 898–904. [Google Scholar]

- Djamila, C.; Yahia, M.; Ali, T. Simultaneous estimation of rotor speed and stator resistance in sensorless indirect vector control of induction motor drives using a Luenberger observer. Int. J. Comput. Sci. Issues 2012, 9, 325. [Google Scholar]

- Boulghasoul, Z.; Kandoussi, Z.; Elbacha, A.; Tajer, A. Fuzzy Improvement on Luenberger Observer Based Induction Motor Parameters Estimation for High Performances Sensorless Drive. J. Electr. Eng. Technol. 2020. [Google Scholar] [CrossRef]

- Ameur, A.; Kious, M.; Ameur, F.; Ameur, I.; Hadjadj, A. Speed sensorless direct torque control of a PMSM drive based type-2 fuzzy logic stator resistance estimator and luenberger observer. In Proceedings of the 2016 8th International Conference on Modelling, Identification and Control (ICMIC), Algiers, Algeria, 15–17 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 219–224. [Google Scholar]

- Reza, C.M.F.S.; Islam, D.; Mekhilef, S. Stator resistance estimation scheme using fuzzy logic system for direct torque controlled induction motor drive. J. Intell. Fuzzy Syst. 2014, 27, 1631–1638. [Google Scholar] [CrossRef]

- Khadar, S.; Kouzou, A.; Benguesmia, H. Fuzzy Stator Resistance Estimator of Induction Motor fed by a Three Levels NPC Inverter Controlled by Direct Torque Control. In Proceedings of the 2018 International Conference on Applied Smart Systems (ICASS), Medea, Algeria, 24–25 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–7. [Google Scholar]

- Karunathilake, K.R.R.D.K.; Ranathunga, D.S.; Kaushalya, K.L.S.; Abeyratne, S.G. Fuzzy logic based stator resistance compensation technique for PWM-VSI drives. In Proceedings of the 2015 IEEE 10th International Conference on Industrial and Information Systems (ICIIS), Sri Lanka, Sri Lanka, 17–20 December 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 452–457. [Google Scholar]

- Bednarz. Dybkowski Estimation of the Induction Motor Stator and Rotor Resistance Using Active and Reactive Power Based Model Reference Adaptive System Estimator. Appl. Sci. 2019, 9, 5145. [Google Scholar] [CrossRef]

- Youlin, Y. A Speed Estimation Method with Stator Resistance Online Identification based on MRAS. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 3697–3700. [Google Scholar]

- Chen, J.; Huang, J.; Sun, Y. Resistances and Speed Estimation in Sensorless Induction Motor Drives Using a Model With Known Regressors. IEEE Trans. Ind. Electron. 2019, 66, 2659–2667. [Google Scholar] [CrossRef]

- Karanayil, B.; Rahman, M.F.; Grantham, C. Online Stator and Rotor Resistance Estimation Scheme Using Artificial Neural Networks for Vector Controlled Speed Sensorless Induction Motor Drive. IEEE Trans. Ind. Electron. 2007, 54, 167–176. [Google Scholar] [CrossRef]

- Isen, E.; Bakan, A.F. Development of 10 kW Three-Phase Grid Connected Inverter. Automatika 2016, 57, 319–328. [Google Scholar] [CrossRef]

- Zarkov, Z. Application of dSPACE Platform in the Study of Electric Generators with RES. In Proceedings of the 2018 20th International Symposium on Electrical Apparatus and Technologies (SIELA), Bourgas, Bulgaria, 3–6 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

| No | Parameters | Values |

|---|---|---|

| 1 | Rated power | 2.2 kW |

| 2 | Rated voltage | 400 V |

| 3 | Rated frequency | 50 Hz |

| 4 | Stator resistance | 1.99 Ohm |

| 5 | Rotor resistance | 1.84 Ohm |

| 6 | Magnetizing inductance | 0.37 H |

| 7 | Poles | 2 |

| 8 | Rated speed | 2880 Rpm |

| 9 | Rotor moment of inertia | 0.002159 kgm2 |

| No | Parameters | Values |

|---|---|---|

| 1 | Rated power | 1.5 kW |

| 2 | Rated frequency | 50 Hz |

| 3 | Rated armature voltage | 200 V |

| 4 | Rated field voltage | 200 V |

| 5 | Rated field current | 1.5 A |

| 6 | Rated speed | 1500 Rpm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham Van, T.; Vo Tien, D.; Leonowicz, Z.; Jasinski, M.; Sikorski, T.; Chakrabarti, P. Online Rotor and Stator Resistance Estimation Based on Artificial Neural Network Applied in Sensorless Induction Motor Drive. Energies 2020, 13, 4946. https://doi.org/10.3390/en13184946

Pham Van T, Vo Tien D, Leonowicz Z, Jasinski M, Sikorski T, Chakrabarti P. Online Rotor and Stator Resistance Estimation Based on Artificial Neural Network Applied in Sensorless Induction Motor Drive. Energies. 2020; 13(18):4946. https://doi.org/10.3390/en13184946

Chicago/Turabian StylePham Van, Tuan, Dung Vo Tien, Zbigniew Leonowicz, Michal Jasinski, Tomasz Sikorski, and Prasun Chakrabarti. 2020. "Online Rotor and Stator Resistance Estimation Based on Artificial Neural Network Applied in Sensorless Induction Motor Drive" Energies 13, no. 18: 4946. https://doi.org/10.3390/en13184946

APA StylePham Van, T., Vo Tien, D., Leonowicz, Z., Jasinski, M., Sikorski, T., & Chakrabarti, P. (2020). Online Rotor and Stator Resistance Estimation Based on Artificial Neural Network Applied in Sensorless Induction Motor Drive. Energies, 13(18), 4946. https://doi.org/10.3390/en13184946