Circuit-Based Electrothermal Simulation of Multicellular SiC Power MOSFETs Using FANTASTIC

Abstract

1. Introduction

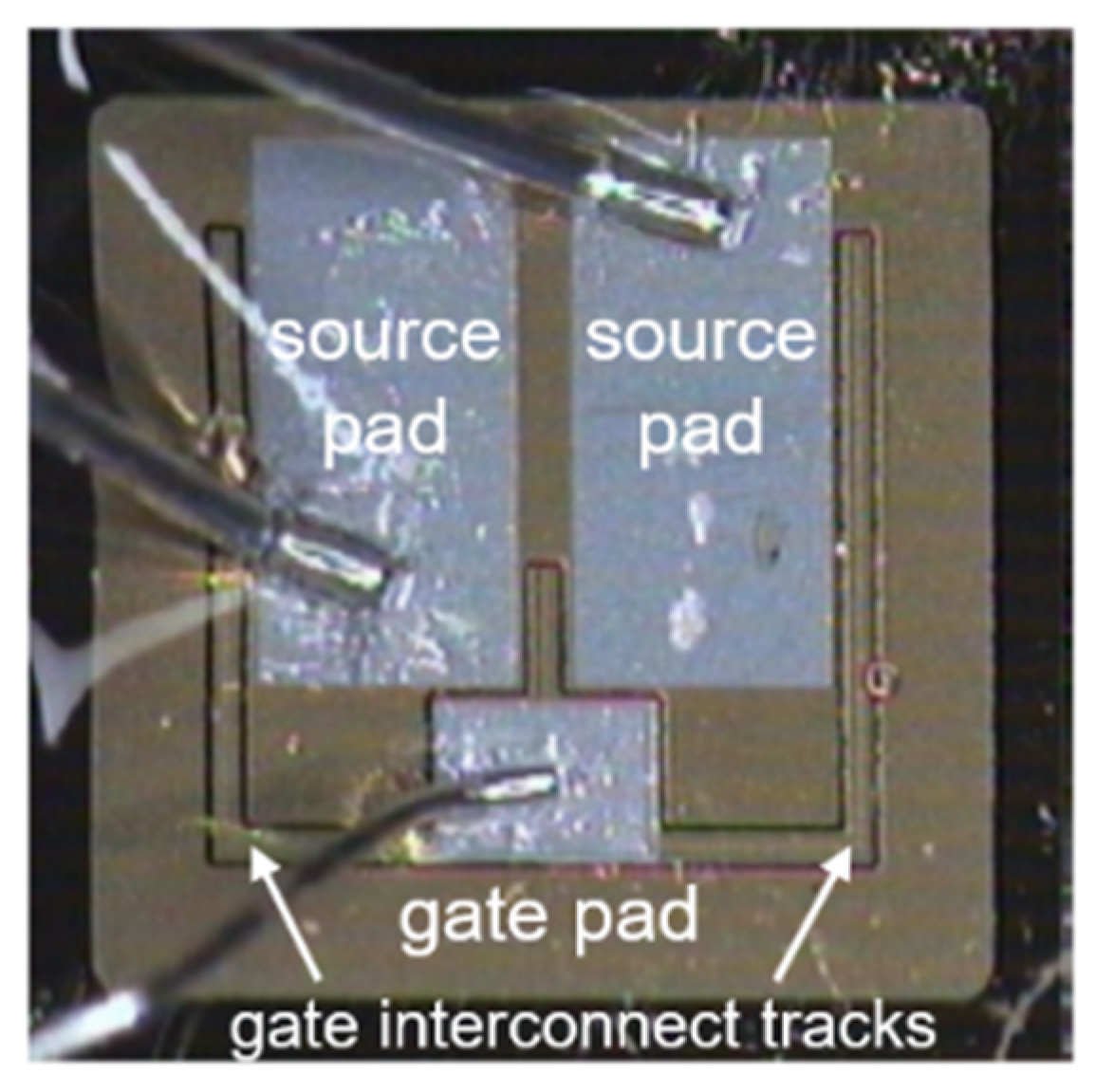

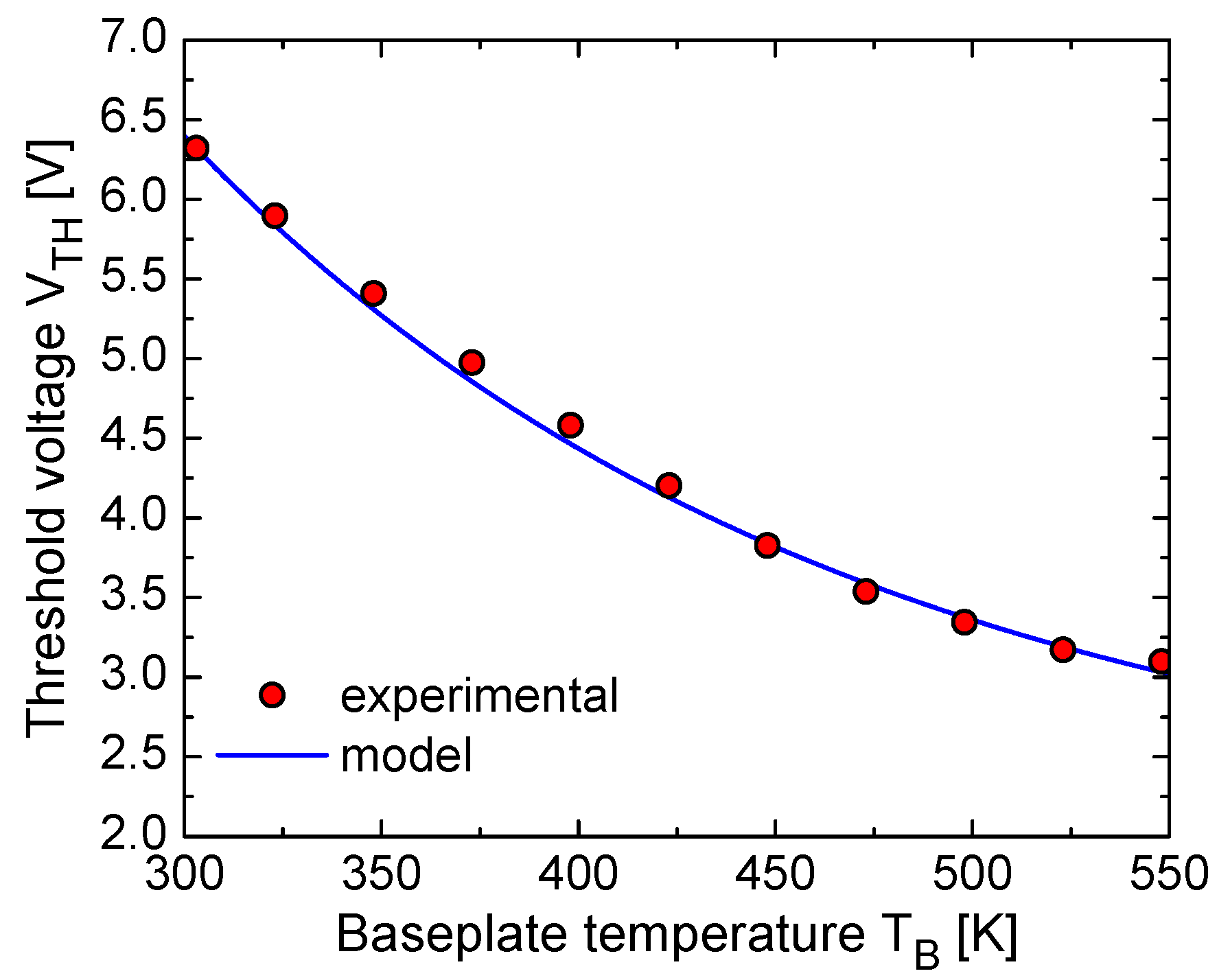

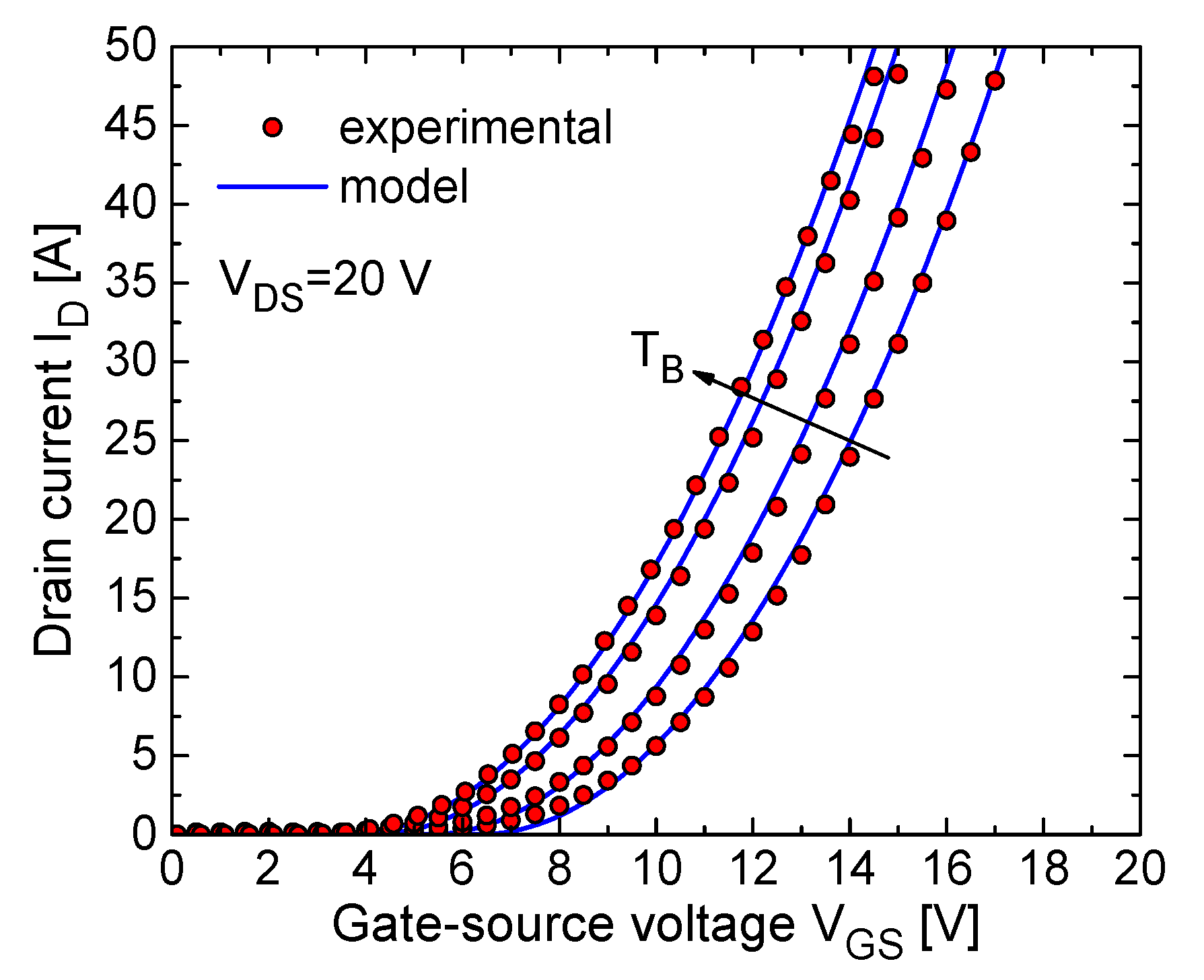

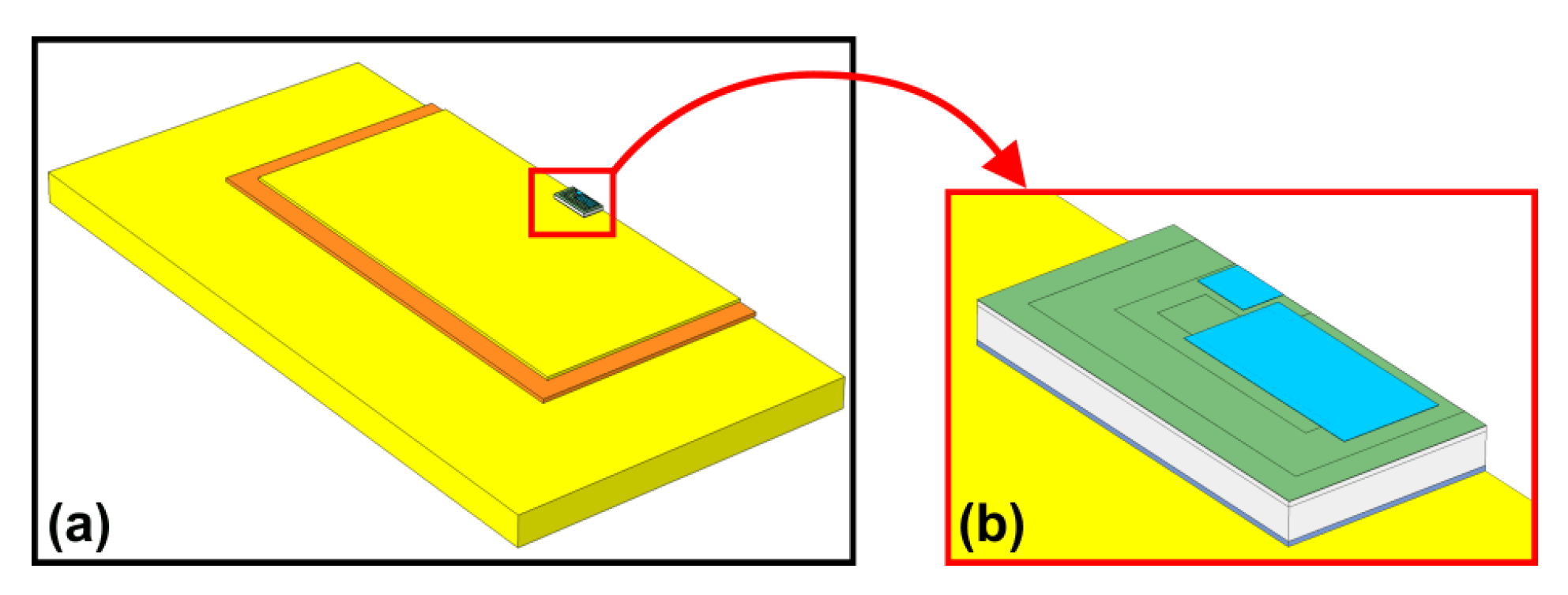

2. Device under Test and Experimental Setup

3. Transistor Model and Parameter Extraction Methodology

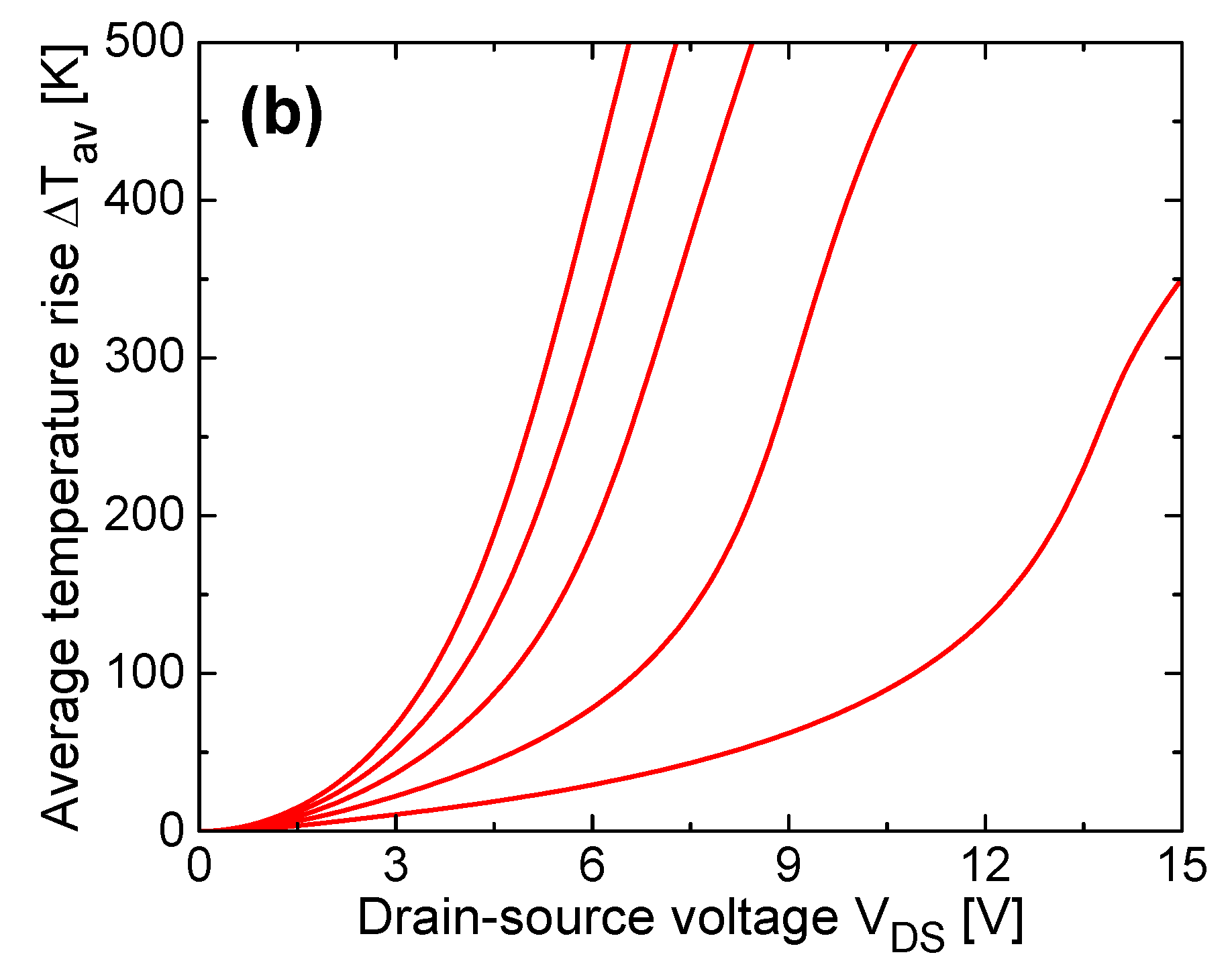

3.1. Transistor Model

- T [K] is the transistor temperature, assumed uniform in the regions impacting the device behavior.

- T0 = 300 K is the reference temperature.

- ΔT = T − T0 [K] is the temperature rise over T0.

- TB [K] the baseplate (and thermochuck) temperature.

- VGS [V] is the gate-source voltage.

- VDS [V] is the drain-source voltage.

- ID [A] is the drain current.

- Rdrift [Ω] is the bias- and temperature-dependent resistance of the N-type epitaxial drift region.

- VDSch = VDS − Vdrift [V] is the VDS portion falling over the channel (Vdrift = Rdrift·ID).

- VTH [V] is the temperature-dependent threshold voltage.

- K [A/V2] is the temperature-dependent current factor.

3.2. Parameter Extraction Procedure

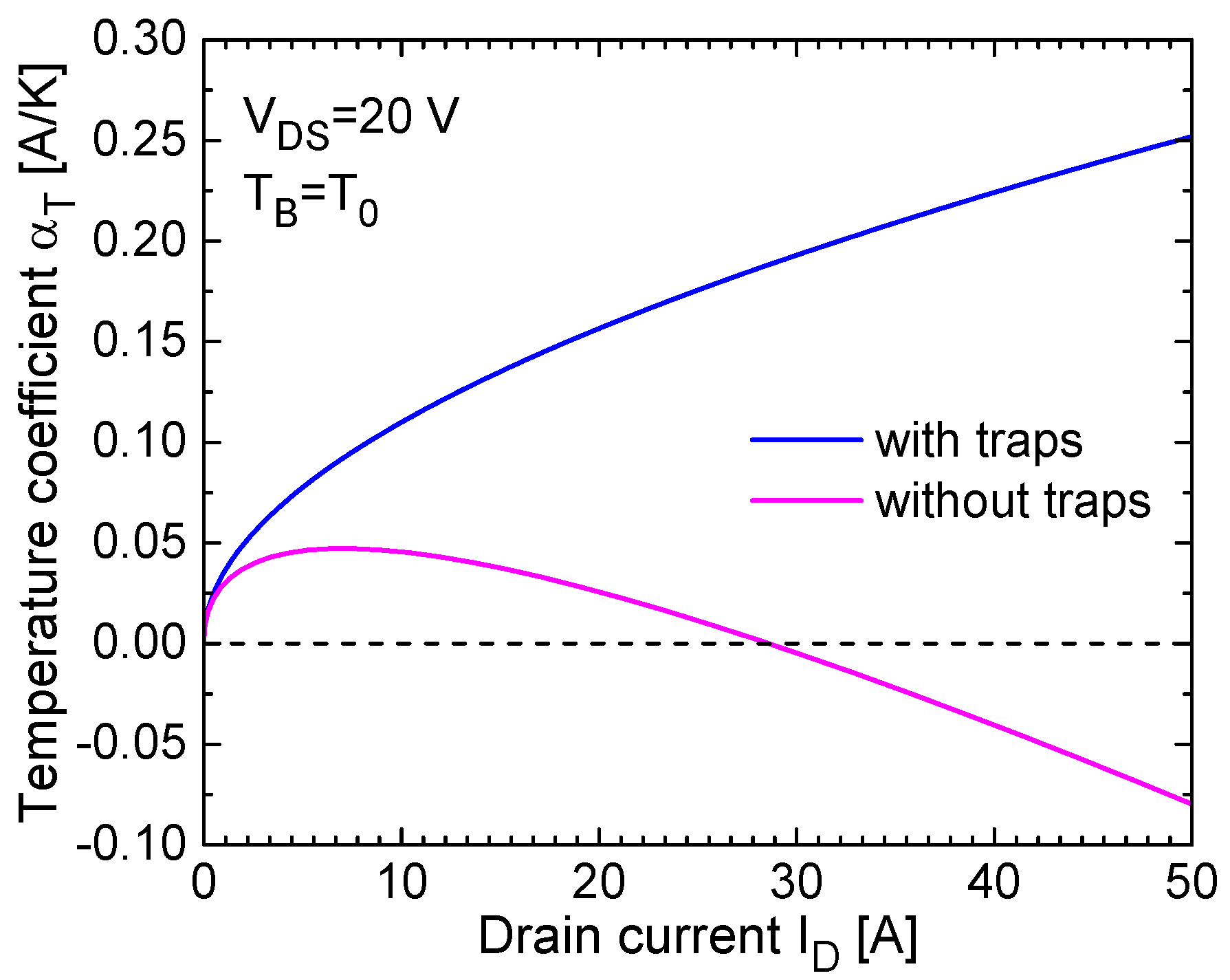

3.3. Impact of Interface Traps

- differently from the DUT, which suffers from a marked positive temperature coefficient over the entire current range, the traps-free device is subject to a slight positive coefficient only at low drain current ID (<20 A), where the negative temperature coefficient of VTH prevails over the negative coefficient of μn, while beyond a zero-temperature coefficient region (also referred to as compensation region), the negative coefficient of μn dominates, and ID reduces with temperature.

- the traps-free transistor benefits from a much higher current capability due to the lower VTH and the higher μn.

4. Electrothermal Simulation Approach

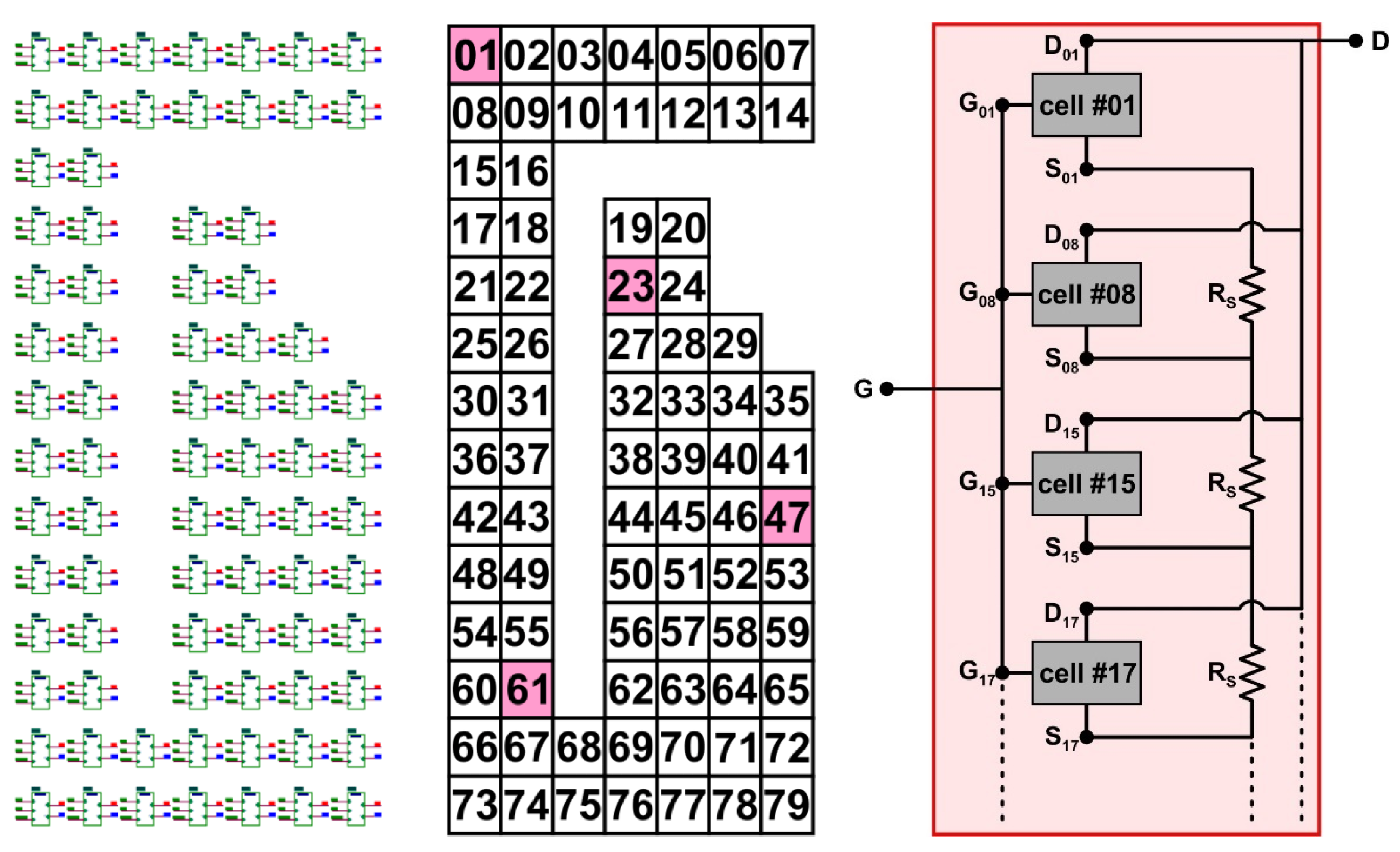

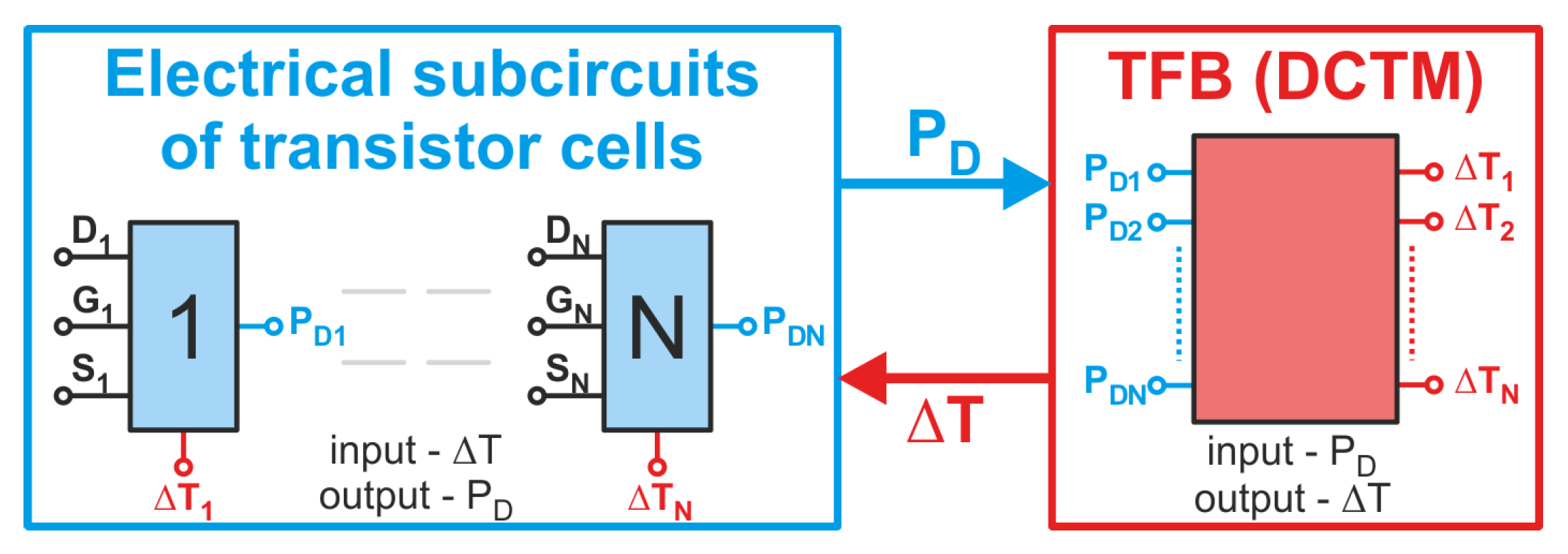

- The whole DUT is subdivided into an assigned number N of elementary cells, high enough to identify potentially-dangerous temperature gradients over the transistor active area, but not too high to prevent intolerably long CPU times or impossible memory storage. The individual cells are described with the model explained in Section 3, where the area-dependent parameters are properly scaled. For the simulation campaign reported in Section 5, all cells are assumed identical, although it is in principle possible to assign different parameter values to different cells to allow a statistical analysis of the influence of parameter fluctuations on the ET behavior of the component.

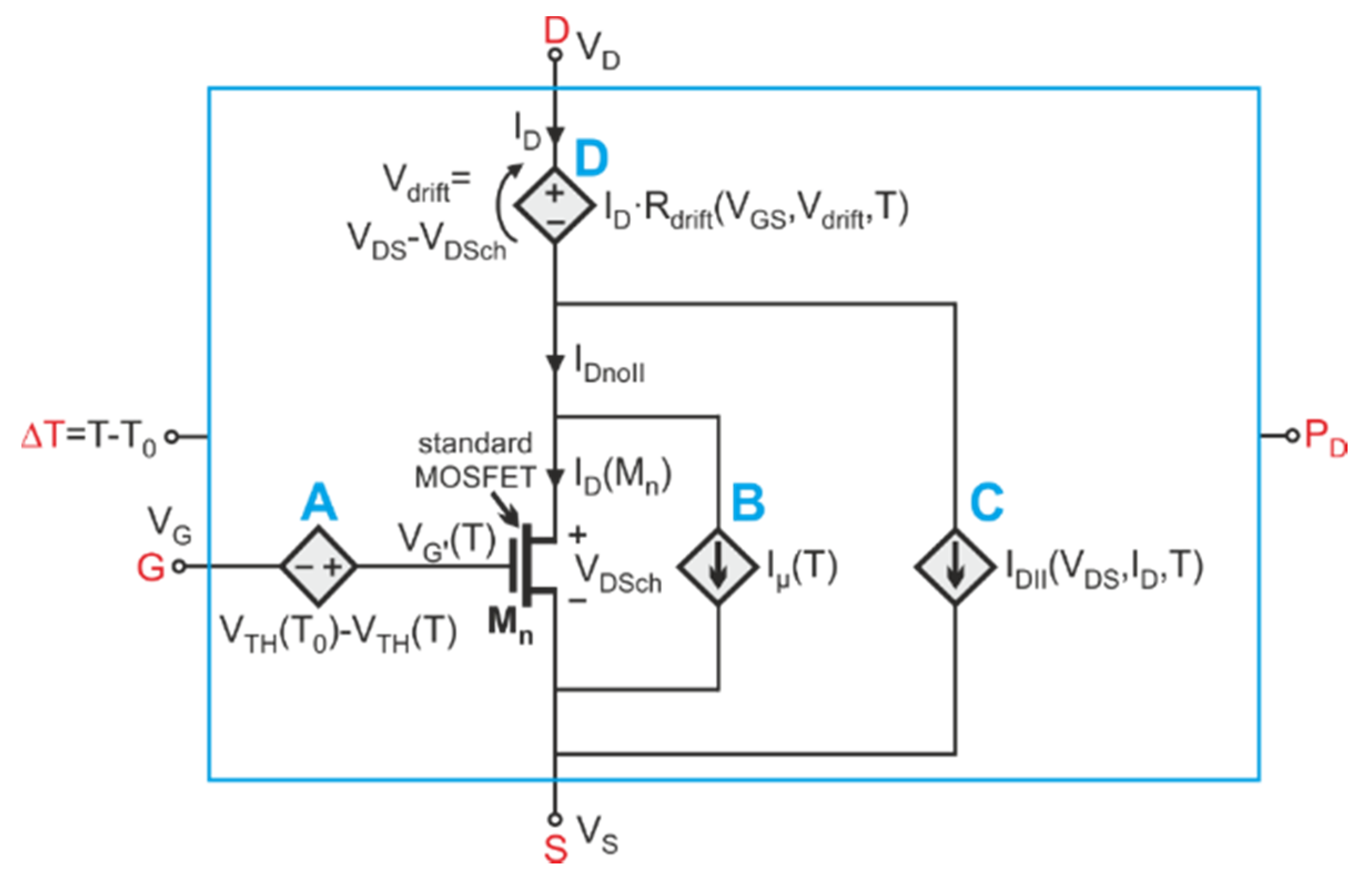

- Each cell is represented with a SPICE-compatible subcircuit implementing the above model through a macromodeling technique. The subcircuit makes use of (i) a standard MOSFET at reference temperature T0 = 300 K as a “main” component to describe the channel region, and (ii) linear and nonlinear controlled sources to include all the model features that cannot be accounted for with the basic MOSFET, i.e., the temperature dependence of the threshold voltage VTH and of the current factor K, the bias- and temperature-dependent drift resistance Rdrift, as well as the bias- and temperature-dependent II mechanism. The TEOL is adopted, namely, the temperature rise over ambient ΔT = T − T0 is actually a voltage, while the dissipated power PD is treated as a current; this allows (i) enabling the temperature sensitivity of the key physical parameters, and (ii) describing the power-temperature feedback with an electrical network. Besides the standard electrical terminals (gate, drain, source/body), the cell subcircuit is also equipped with an input node carrying the “voltage” ΔT (provided by the thermal feedback block introduced below) and with an output node offering the “current” PD (to be fed to the thermal feedback block).

- The power-temperature feedback (i.e., the dynamic heat propagation within the structure) is described with a TEOL-based SPICE-compatible thermal feedback block, which is composed by resistances, capacitances, and controlled sources. The inputs of this block are the powers PD dissipated by the transistor cells (represented with currents), and the outcomes are the individual (nonlinear) temperature rises ΔT (emulated with voltages).

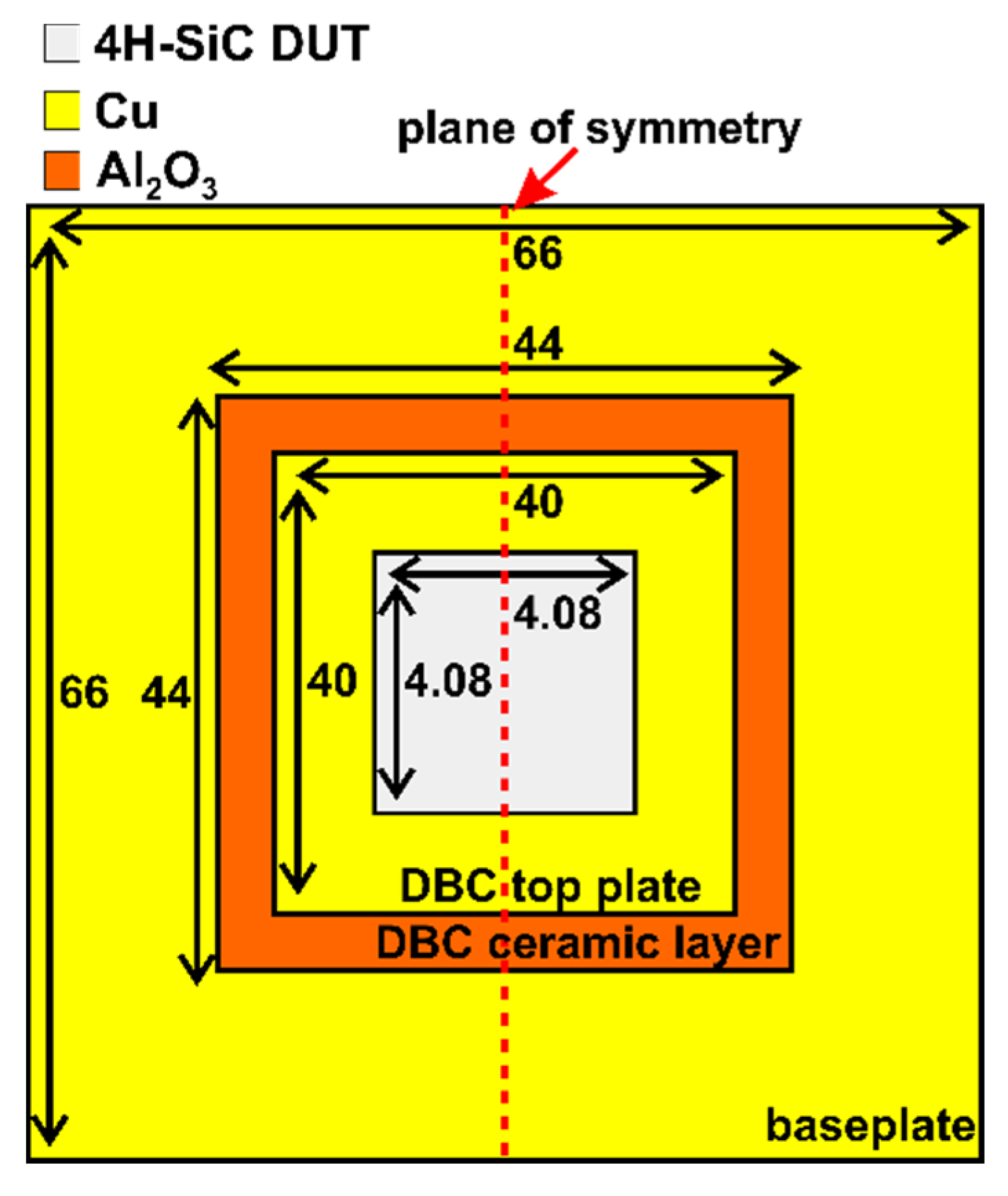

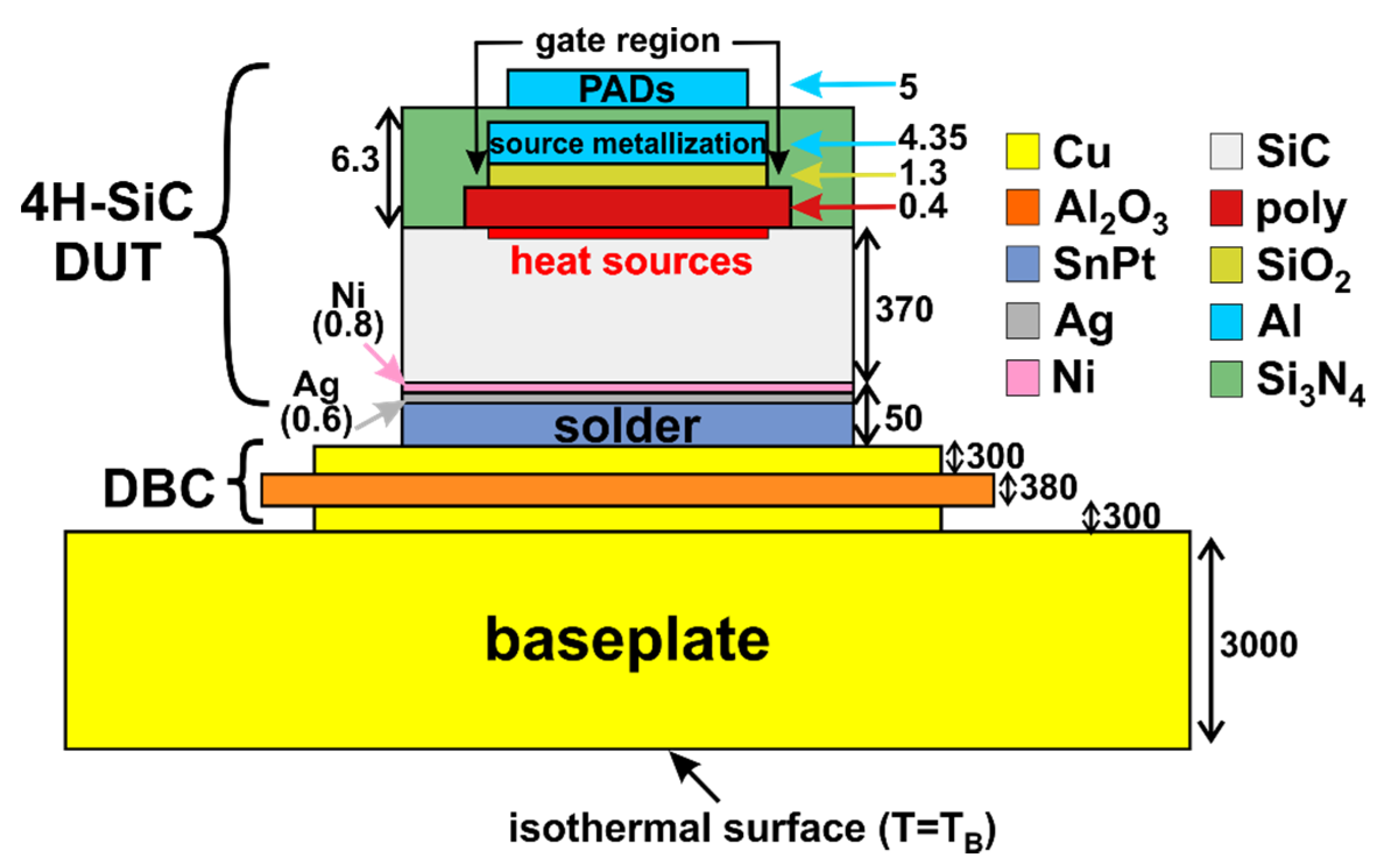

- The thermal feedback block contains an equivalent thermal network (i.e., a purely-electrical circuit relying on the TEOL). The main contribution of the proposed approach is that this network is automatically constructed in the pre-processing stage by invoking the FANTASTIC tool [6] (Section 4.3). FANTASTIC receives as an input an accurate 3D FEM representation of the domain, i.e., a mesh with information about (i) the discretization into elementary cells (each corresponding to an individual heat source), (ii) material parameters, and (iii) boundary conditions, and then extracts a reduced-order model and the associated network without the need of user’s expertise and COMSOL simulations; only 16 min were needed for the case study. The equivalent network accurately accounts for the self-heating of each cell and for the mutual interactions among all cells and describes the linear thermal problem. However, nonlinear thermal effects can be significant if the DUT is simulated under harsh conditions entailing high temperatures. In order to tackle this issue, a properly-tuned Kirchhoff’s transformation [28] is used, which converts the linear temperature rises (ΔTlin) into their nonlinear counterparts (ΔT) through [29]The calibration of the (positive) parameter mk will be detailed in Section 4.2. Nonlinear voltage-controlled voltage sources emulating (18) are applied to the N temperature rise nodes of the equivalent thermal network; the resulting circuit is referred to as a thermal feedback block. It is worth noting that the FANTASTIC-based approach improves the strategy exploited in [7,26], where the thermal feedback block was based on Foster networks extracted in a rather long pre-processing stage from N onerous transient COMSOL simulations of the DUT (performed by activating one heat source at a time), and the thermal coupling between horizontally-far heat sources was roughly described or even neglected.

- The cell subcircuits are then connected to the thermal feedback block in a commercial circuit simulation tool (like PSPICE, LTSPICE, Eldo, ADS, SIMetrix); as a result, the whole domain under test, composed by the DUT soldered on a DBC substrate, is transformed into a purely-electrical macrocircuit, which suitably accounts for ET effects: the temperature, and thus the temperature-sensitive parameters, are allowed to vary during the simulation run. The solution of this macrocircuit under both static and dynamic conditions is demanded to the powerful and robust engine of the circuit simulation tool, with very low computational effort and minimized occurrence of convergence issues compared to other numerical methods.

4.1. SPICE Subcircuit and DUT Discretization into Cells

4.2. FEM Representation of the Component under Test

4.3. FANTASTIC-Based Derivation of the Equivalent Thermal Network

4.4. Pre-Processing Evaluation of N and ε

4.5. Construction of the Macrocircuit

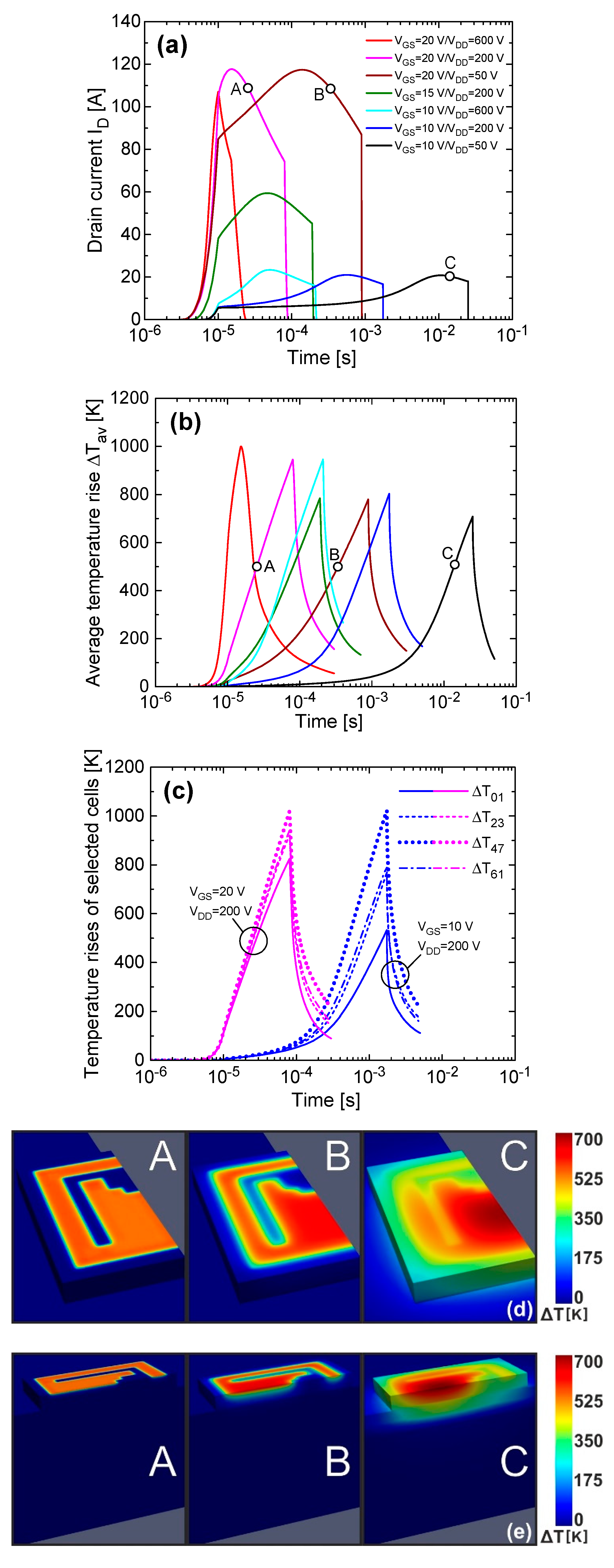

5. Static and Dynamic Electrothermal Simulations

- point A, which falls at a time instant close to the beginning of the test, is endowed with a uniform and superficial temperature field, since the heat is still confined in the top active region close to the generation area;

- the temperature distributions in B and C are increasingly uneven, which is again ascribable to the much longer stress times. In particular, C suffers from a severe temperature focusing over the innermost DUT area, and—as witnessed by the side view—the downward heat had enough time to reach and hit the DBC.

- case #1: VDD = 300 V, L = 4.6 mH, RGATE = 15 Ω

- case #2: VDD = 600 V, L = 12 mH, RGATE = 15 Ω

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| AlN | aluminum nitride |

| Al2O3 | alumina |

| Cu | copper |

| GaAs | gallium arsenide |

| Si | silicon |

| SiC | silicon carbide |

| SiO2 | silicon dioxide (or oxide) |

| Si3N4 | silicon nitride |

| SnPt | tin-platinum alloy |

| DBC | direct-bonded copper |

| DCTM | dynamic compact thermal model |

| DoF | degree of freedom |

| DUT | device under test |

| ET | electrothermal |

| FANTASTIC | FAst Novel Thermal Analysis Simulation Tool for Integrated Circuits |

| FEM | finite-element method |

| HBT | heterojunction bipolar transistor |

| II | impact ionization |

| ILS | inductive load switching |

| MM | moment matching |

| MOR | model-order reduction |

| MOSFET | metal oxide semiconductor field effect transistor |

| SC | short circuit |

| TEOL | thermal equivalent of the Ohm’s law |

| TRB | truncated balance |

| UIS | unclamped inductive switching |

| VDMOS | vertical double-diffused MOS |

References

- Östling, M.; Ghandi, R.; Zetterling, C.-M. SiC power devices—Present status, applications and future perspectives. In Proceedings of the IEEE International Symposium on Power Semiconductor Devices and IC’s (ISPSD), San Diego, CA, USA, 23–26 May 2011; pp. 10–15. [Google Scholar]

- De Falco, G.; Riccio, M.; Romano, G.; Maresca, L.; Irace, A.; Breglio, G. ELDO-COMSOL based 3D electro-thermal simulations of power semiconductor devices. In Proceedings of the IEEE Annual SEMIconductor THERMal measurement, modeling, and management symposium (SEMI-THERM), San Jose, CA, USA, 9–13 March 2014; pp. 35–40. [Google Scholar]

- Chvála, A.; Donoval, D.; Marek, J.; Príbytný, P.; Molnár, M.; Mikolášek, M. Fast 3-D electrothermal device/circuit simulation of power superjunction MOSFET based on SDevice and HSPICE interaction. IEEE Trans. Electron Devices 2014, 61, 1116–1122. [Google Scholar] [CrossRef]

- Košel, V.; de Filippis, S.; Chen, L.; Decker, S.; Irace, A. FEM simulation approach to investigate electro-thermal behavior of power transistors in 3-D. Microelectron. Reliab. 2013, 53, 356–362. [Google Scholar] [CrossRef]

- Pfost, M.; Boianceanu, C.; Lohmeyer, H.; Stecher, M. Electrothermal simulation of self-heating in DMOS transistors up to thermal runaway. IEEE Trans. Electron Devices 2013, 60, 699–707. [Google Scholar] [CrossRef]

- Codecasa, L.; d’Alessandro, V.; Magnani, A.; Rinaldi, N.; Zampardi, P.J. FAst Novel Thermal Analysis Simulation Tool for Integrated Circuits (FANTASTIC). In Proceedings of the IEEE international workshop on THERMal INvestigations of ICs and systems (THERMINIC), Greenwich, London, UK, 24–26 September 2014. [Google Scholar]

- d’Alessandro, V.; Magnani, A.; Riccio, M.; Breglio, G.; Irace, A.; Rinaldi, N.; Castellazzi, A. SPICE modeling and dynamic electrothermal simulation of SiC power MOSFETs. In Proceedings of the IEEE International Symposium of Power Semiconductor Devices and IC’s (ISPSD), Waikoloa, HI, USA, 15–19 June 2014. [Google Scholar]

- Fayyaz, A.; Romano, G.; Urresti, J.; Riccio, M.; Castellazzi, A.; Irace, A.; Wright, N. A comprehensive study of the avalanche breakdown robustness of silicon carbide power MOSFETs. Energies 2017, 10, 452. [Google Scholar] [CrossRef]

- Riccio, M.; d’Alessandro, V.; Romano, G.; Maresca, L.; Breglio, G.; Irace, A. A temperature-dependent SPICE model of SiC power MOSFETs for within and out-of-SOA simulations. IEEE Trans. Power Electron. 2018, 33, 8020–8029. [Google Scholar] [CrossRef]

- Mantooth, H.A.; Peng, K.; Santi, E.; Hudgins, J.L. Modeling of wide bandgap semiconductor devices–Part I. IEEE Trans. Electron Devices 2015, 62, 423–433. [Google Scholar] [CrossRef]

- Codecasa, L.; d’Alessandro, V.; Magnani, A.; Irace, A. Circuit-based electrothermal simulation of power devices by an ultrafast nonlinear MOS approach. IEEE Trans. Power Electron. 2016, 31, 5906–5916. [Google Scholar] [CrossRef]

- Rinaldi, N.; d’Alessandro, V. Theory of electrothermal behavior of bipolar transistors: Part III–Impact ionization. IEEE Trans. Electron Devices 2006, 53, 1683–1697. [Google Scholar] [CrossRef]

- Ren, Y.; Xu, M.; Zhou, J.; Lee, F.C. Analytical loss model of power MOSFET. IEEE Trans. Power Electron. 2006, 21, 310–319. [Google Scholar]

- Baliga, B.J. Modern Power Devices; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Arora, N. MOSFET Modeling for VLSI Simulation: Theory and Practice; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2007. [Google Scholar]

- Ólafsson, H.Ö.; Gudjónsson, G.; Allerstam, F.; Sveinbjörnsson, E.Ö.; Rödle, T.; Jos, R. Stable operation of high mobility 4H-SiC MOSFETs at elevated temperatures. Electron. Lett. 2005, 41, 825–826. [Google Scholar]

- Wang, J.; Zhao, T.; Li, J.; Huang, A.Q.; Callanan, R.; Husna, F.; Agarwal, A. Characterization, modeling, and application of 10-kV SiC MOSFETs. IEEE Trans. Electron Devices 2008, 55, 1798–1806. [Google Scholar] [CrossRef]

- Chen, S.; Cai, C.; Wang, T.; Guo, Q.; Sheng, K. Cryogenic and high temperature performance of 4H-SiC power MOSFETs. In Proceedings of the Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 207–210. [Google Scholar]

- Spirito, P.; Breglio, G.; d’Alessandro, V.; Rinaldi, N. Thermal instabilities in high current power MOS devices: Experimental evidence, electro-thermal simulations and analytical modeling. In Proceedings of the IEEE International Conference on MIcroELectronics (MIEL), Niš, Yugoslavia, 12–15 May 2002; pp. 23–30. [Google Scholar]

- Spirito, P.; Breglio, G.; d’Alessandro, V.; Rinaldi, N. Analytical model for thermal instability of low voltage power MOS and S.O.A. in pulse operation. In Proceedings of the IEEE International Symposium on Power Semiconductor Devices and IC’s (ISPSD), Santa Fe, NM, USA, 3–7 June 2002; pp. 269–272. [Google Scholar]

- Pérez-Tomás, A.; Brosselard, P.; Godignon, P.; Millán, J.; Mestres, N.; Jennings, M.R.; Covington, J.A.; Mawby, P.A. Field-effect mobility temperature modeling of 4H-SiC metal-oxide-semiconductor transistors. J. Appl. Phys. 2006, 100, 114508. [Google Scholar] [CrossRef]

- Cheng, L.; Agarwal, A.K.; Dhar, S.; Ryu, S.-H.; Palmour, J.W. Static performance of 20 A, 1200 V 4H-SiC power MOSFETs at temperatures of −187 °C to 200 °C. J. Electron. Mater. 2012, 41, 910–914. [Google Scholar] [CrossRef]

- Huang, X.; Wang, G.; Li, Y.; Huang, A.Q.; Baliga, B.J. Short-circuit capability of 1200V SiC MOSFET and JFET for fault protection. In Proceedings of the Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 197–200. [Google Scholar]

- TCAD Sentaurus User’s Manual, Synopsis, 2015. Available online: https://www.synopsys.com/silicon/tcad/device-simulation/sentaurus-device.html (accessed on 25 May 2020).

- Castellazzi, A.; Funaki, T.; Kimoto, T.; Hikihara, T. Thermal instability effects in SiC power MOSFETs. Microelectron. Reliab. 2012, 52, 2414–2419. [Google Scholar] [CrossRef]

- d’Alessandro, V.; Magnani, A.; Riccio, M.; Iwahashi, Y.; Breglio, G.; Rinaldi, N.; Irace, A. Analysis of the UIS behavior of power devices by means of SPICE-based electrothermal simulations. Microelectron. Reliab. 2013, 53, 1713–1718. [Google Scholar] [CrossRef]

- Bazzano, G.; Cavallaro, D.G.; Greco, G.; Grimaldi, A.; Rinaudo, S. Stress and reliability of power devices: An innovative thermal analysis approach to predict a device’s lifetime. In Proceedings of the International Exhibition & Conference for Power Electronics, Intelligent Motion, Power Quality (PCIM Europe), Nuremberg, Germany, 17–19 May 2011; pp. 117–123. [Google Scholar]

- Joyce, W.B. Thermal resistance of heat sinks with temperature-dependent conductivity. Solid State Electron. 1975, 18, 321–322. [Google Scholar] [CrossRef]

- Poulton, K.; Knudsen, K.L.; Corcoran, J.J.; Wang, K.-C.; Pierson, R.L.; Nubling, R.B.; Chang, M.-C.F. Thermal design and simulation of bipolar integrated circuits. IEEE J. Solid State Circuits 1992, 27, 1379–1387. [Google Scholar] [CrossRef]

- PSPICE User’s Manual, Cadence OrCAD 16.5, 2011. Available online: https://www.orcad.com/ (accessed on 25 May 2020).

- Li, H.; Munk-Nielsen, S.; Bęczkowski, S.; Wang, X. A novel DBC layout for current imbalance mitigation in SiC MOSFET multichip power modules. IEEE Trans. Power Electron. 2016, 31, 8042–8045. [Google Scholar] [CrossRef]

- Suganuma, K.; Kim, S. Ultra heat-shock resistant die attachment for silicon carbide with pure zinc. IEEE Electron Device Lett. 2010, 31, 1467–1469. [Google Scholar] [CrossRef]

- Catalano, A.P.; Scognamillo, C.; Castellazzi, A.; d’Alessandro, V. Optimum thermal design of high-voltage double-sided cooled multi-chip SiC power modules. In Proceedings of the IEEE International Workshop on THERMal INvestigations of ICs and Systems (THERMINIC), Lecco, Italy, 25–27 September 2019. [Google Scholar]

- COMSOL Multiphysics User’s Guide, Release 5.2A, 2016. Available online: https://www.comsol.it/ (accessed on 25 May 2020).

- d’Alessandro, V.; Catalano, A.P.; Codecasa, L.; Zampardi, P.J.; Moser, B. Accurate and efficient analysis of the upward heat flow in InGaP/GaAs HBTs through an automated FEM-based tool and Design of Experiments. Int. J. Numer. Model. Electron. Netw. Devices Fields 2019, 32. [Google Scholar]

- Harris, G.L. Properties of Silicon Carbide; INSPEC, the Institution of Electrical Engineers: London, UK, 1995. [Google Scholar]

- Goldberg, Y.; Levinshtein, M.E.; Rumyantsev, S.L. Silicon Carbide. In Properties of Advanced Semiconductor Materials: GaN, AlN, InN, BN, SiC, SiGe; Levinshtein, M.E., Rumyantsev, S.L., Shur, M.S., Eds.; John Wiley & Sons, Inc.: New York, NY, USA, 2001; Volume 5, pp. 93–148. [Google Scholar]

- Gomes de Mesquita, A.H. Refinement of the crystal structure of SiC type 6H. Acta Crystallogr. 1967, 23, 610–617. [Google Scholar] [CrossRef]

- Palankovski, W.; Quay, R. Analysis and Simulation of Heterostructure Devices; Springer: New York, NY, USA, 2004. [Google Scholar]

- Joshi, R.P.; Neudeck, P.G.; Fazi, C. Analysis of the temperature dependent thermal conductivity of silicon carbide for high temperature applications. J. Appl. Phys. 2000, 88, 265–269. [Google Scholar] [CrossRef]

- Lienhard, I.V.; Lienhard, H. A Heat Transfer Textbook; Phlogiston Press: Cambridge, MA, USA, 2008. [Google Scholar]

- Codecasa, L.; D’Amore, D.; Maffezzoni, P. Compact modeling of electrical devices for electrothermal analysis. IEEE Trans. Circuits Syst. I Fundam. Theory Appl. 2003, 50, 465–476. [Google Scholar] [CrossRef]

- Codecasa, L.; Catalano, A.P.; d’Alessandro, V. A Priori error bound for moment matching approximants of thermal models. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 2383–2392. [Google Scholar] [CrossRef]

- Fayyaz, A.; Yang, L.; Castellazzi, A. Transient robustness testing of silicon carbide (SiC) power MOSFETs. In Proceedings of the European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013. [Google Scholar]

- Nguyen, T.-T.; Ahmed, A.; Thang, T.V.; Park, J.-H. Gate oxide reliability issues of SiC MOSFETs under short-circuit operation. IEEE Trans. Power Electron. 2015, 30, 2445–2455. [Google Scholar] [CrossRef]

- Romano, G.; Maresca, L.; Riccio, M.; d’Alessandro, V.; Breglio, G.; Irace, A.; Fayyaz, A.; Castellazzi, A. Short-circuit failure mechanism of SiC power MOSFETs. In Proceedings of the IEEE International Symposium on Power Semiconductor Devices and IC’s (ISPSD), Hong Kong, China, 10–14 May 2015; pp. 345–348. [Google Scholar]

- Cavallaro, D.; Pulvirenti, M.; Zanetti, E.; Saggio, M. Capability of SiC MOSFETs under short-circuit tests and development of a thermal model by finite element analysis. Mater. Sci. Forum 2019, 963, 788–791. [Google Scholar] [CrossRef]

| Parameter | Definition | Value |

|---|---|---|

| VTH(T0) | threshold voltage at reference temperature T0 | 6.398 V |

| VTH∞ | parameter of the threshold voltage model | 2.05 V |

| aVTH | temperature coefficient of the threshold voltage | 6 mK−1 |

| K(T0) | current factor at reference temperature T0 | 0.422 A/V2 |

| am | parameter of the exponent m accounting for the mobility temperature dependence | 0.24 |

| bm | parameter of the exponent m accounting for the mobility temperature dependence | 2 |

| cm | parameter of the exponent m accounting for the mobility temperature dependence | 1.02 |

| dm | parameter of the exponent m accounting for the mobility temperature dependence | 0.09 |

| RJFET(T0) | resistance of the accumulation and JFET regions at reference temperature T0, Vdrift » V1, and VGS = V2 | 0.235 Ω |

| mRJFET | exponent for the temperature dependence of the resistance RJFET | −1.3 |

| V1 | parameter to account for the RJFET dependence on Vdrift | 13 V |

| V2 | parameter to account for the RJFET dependence on VGS | 20 V |

| η | exponent to account for the RJFET dependence on VGS | 3.45 |

| Repi(T0) | resistance of the deep epilayer region at reference temperature T0 | 10 mΩ |

| mRepi | exponent to account for the potential temperature dependence of the resistance Repi | 0 |

| BVDS(T0) | drain-source breakdown voltage at reference temperature T0 | 1750 V |

| mII | parameter of the avalanche multiplication factor M | 1.8 |

| nII | parameter of the avalanche multiplication factor M | 2.9 |

| αII | temperature coefficient of the breakdown voltage BV | 0.18 mK-1 |

| βII | coefficient to account for the ID dependence of factor M | 0 A−1 |

| RII | resistance to account for the ID dependence of factor M | 10 Ω |

| CGD0 | zero-bias gate-drain capacitance | 0.85 nF |

| CGDMIN | minimum gate-drain reverse-biased capacitance | 0.01 nF |

| V * | gate-drain capacitance parameter | 2 V |

| CDS0 | zero-bias drain-source capacitance | 2.8 nF |

| CDSMIN | minimum drain-source reverse-biased capacitance | 0.06 nF |

| V ** | drain-source capacitance parameter | 10 V |

| Material | k(T0) (W/mK) | cp (J/KgK) | ρ (Kg/m3) | α | β (W/mK2) |

|---|---|---|---|---|---|

| 4H-SiC | 370 [36,37] | 690 [37] | 3211 [38,39] (value common to 4H-SiC and 6H-SiC) | 1.29 [40] | |

| Al | 240 [41] | 905 [41] | 2707 [41] | 0.04 [41] | |

| SnPt | 68.8 [41] | 228 [41] | 7310 [41] | 0.02 [41] | |

| Ni | 89.5 [41] | 445 [41] | 8906 [41] | 0.08 [41] | |

| Ag | 427 [41] | 236 [41] | 10,524 [41] | 0.07 [41] | |

| poly-Si | 40 [39] | 920 [39] | 2330 [39] | ||

| SiO2 | 1.38 [39] | 709 [39] | 2203 [39] | −0.33 [39] | |

| Al2O3 | 28 [39] | 796 [39] | 3900 [39] | 1 [39] | |

| Cu | 396.8 [41] | 384 [41] | 8954 [41] | 0.05 [41] | |

| Si3N4 | 18.5 [39] | 787 [39] | 3100 [39] | −0.33 [39] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

d’Alessandro, V.; Codecasa, L.; Catalano, A.P.; Scognamillo, C. Circuit-Based Electrothermal Simulation of Multicellular SiC Power MOSFETs Using FANTASTIC. Energies 2020, 13, 4563. https://doi.org/10.3390/en13174563

d’Alessandro V, Codecasa L, Catalano AP, Scognamillo C. Circuit-Based Electrothermal Simulation of Multicellular SiC Power MOSFETs Using FANTASTIC. Energies. 2020; 13(17):4563. https://doi.org/10.3390/en13174563

Chicago/Turabian Styled’Alessandro, Vincenzo, Lorenzo Codecasa, Antonio Pio Catalano, and Ciro Scognamillo. 2020. "Circuit-Based Electrothermal Simulation of Multicellular SiC Power MOSFETs Using FANTASTIC" Energies 13, no. 17: 4563. https://doi.org/10.3390/en13174563

APA Styled’Alessandro, V., Codecasa, L., Catalano, A. P., & Scognamillo, C. (2020). Circuit-Based Electrothermal Simulation of Multicellular SiC Power MOSFETs Using FANTASTIC. Energies, 13(17), 4563. https://doi.org/10.3390/en13174563