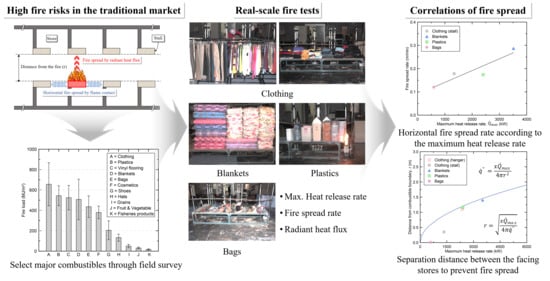

An Experimental Study on the Fire Spread Rate and Separation Distance between Facing Stores in Passage-Type Traditional Markets

Abstract

1. Introduction

2. Fire Characteristics of Traditional Market

2.1. Spreading Paths of the Fire

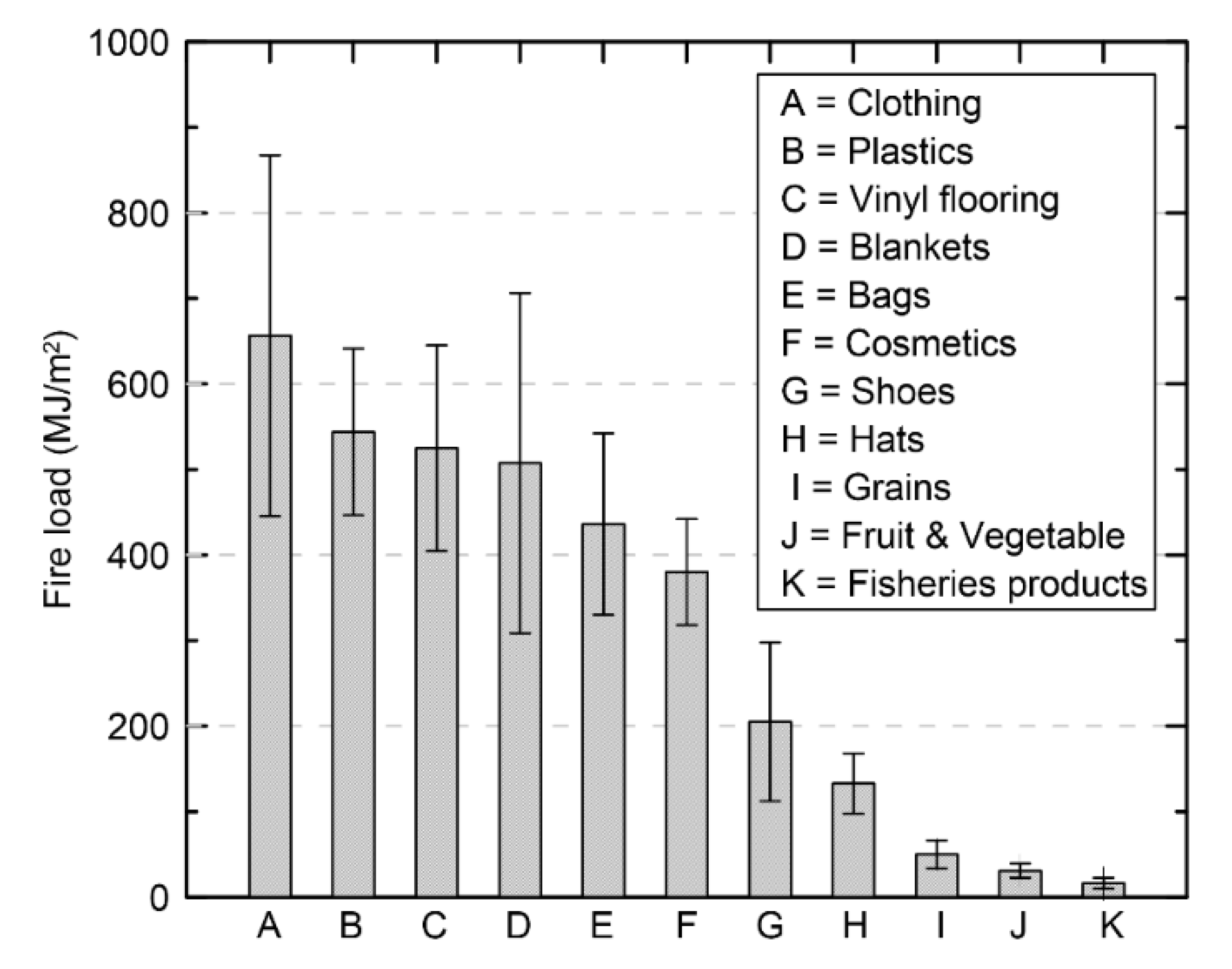

2.2. Field Survey to Select Major Combustibles

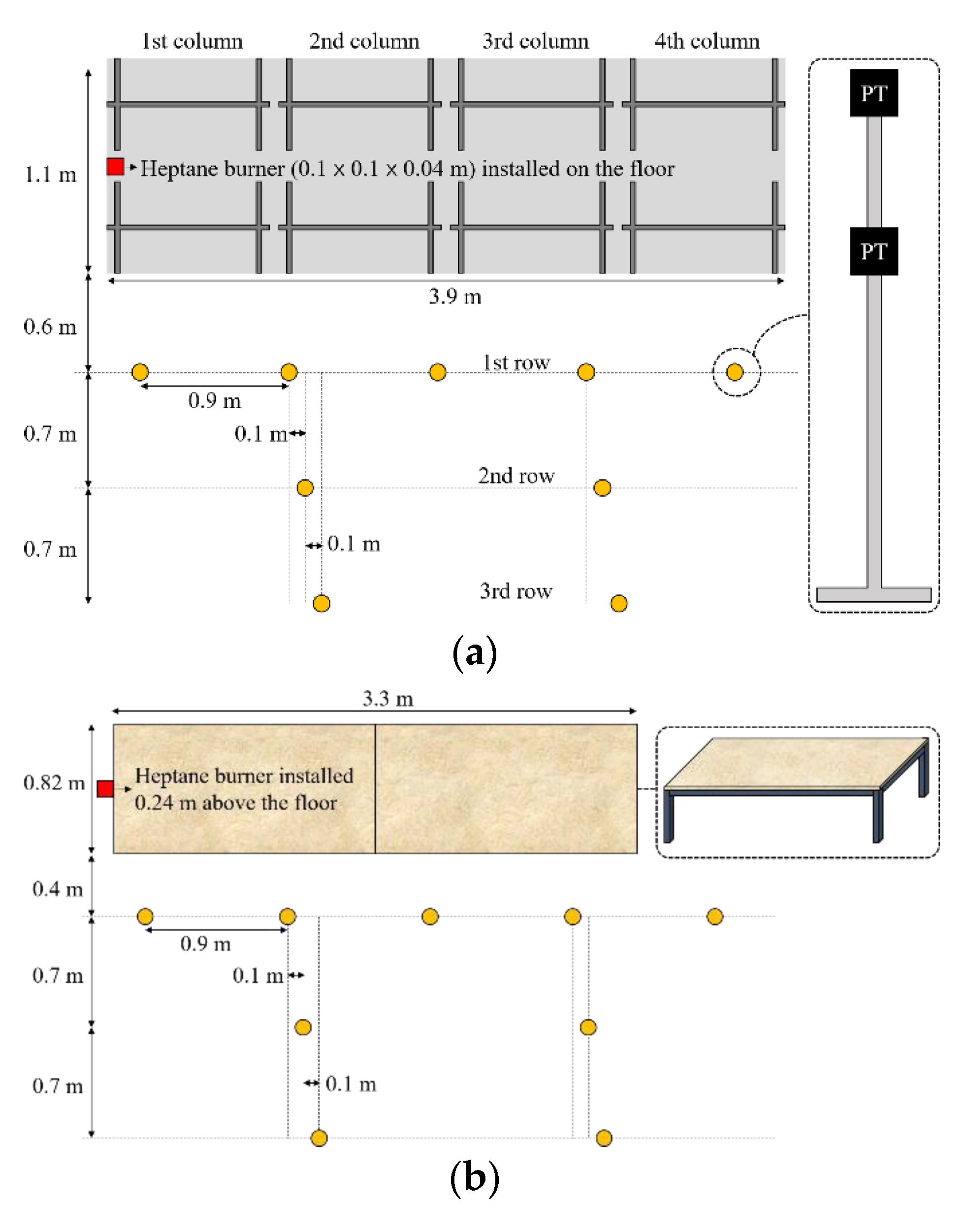

3. Experimental Details

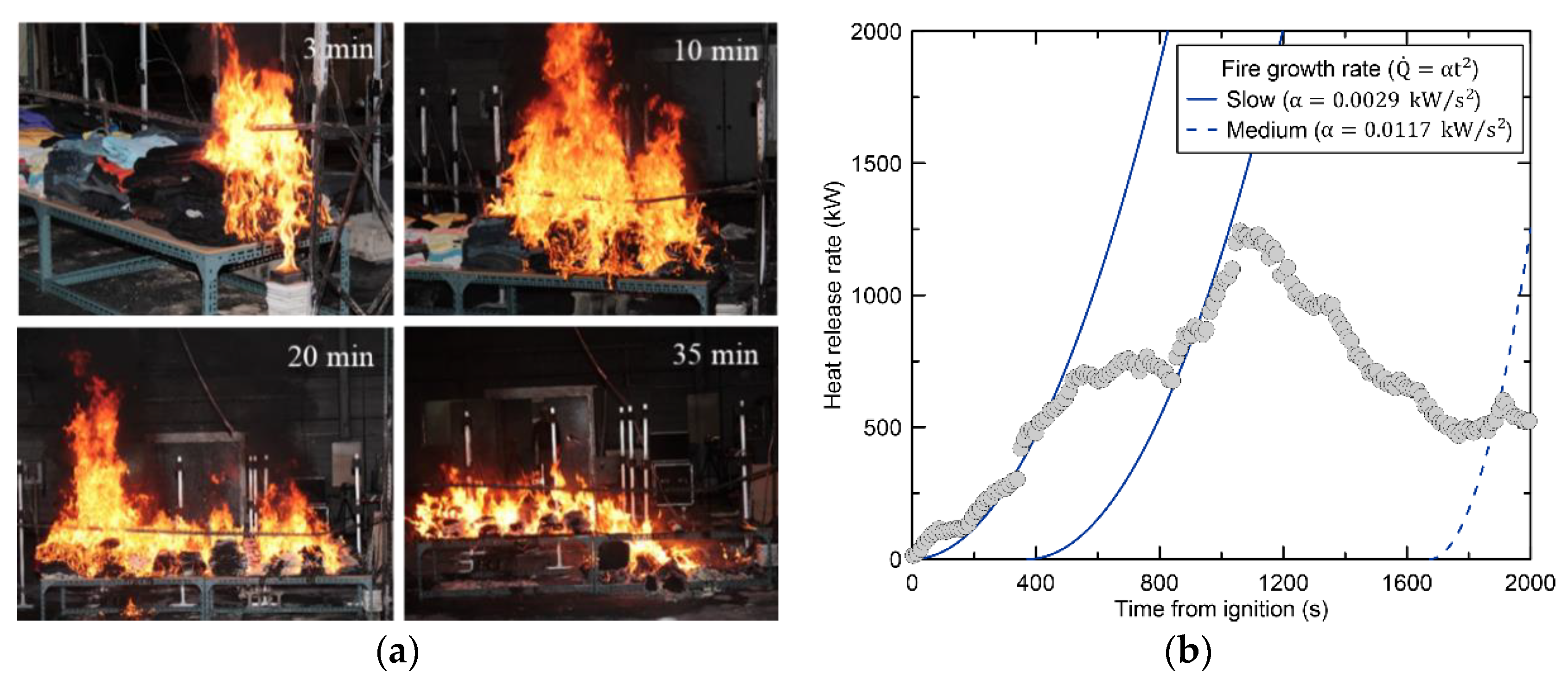

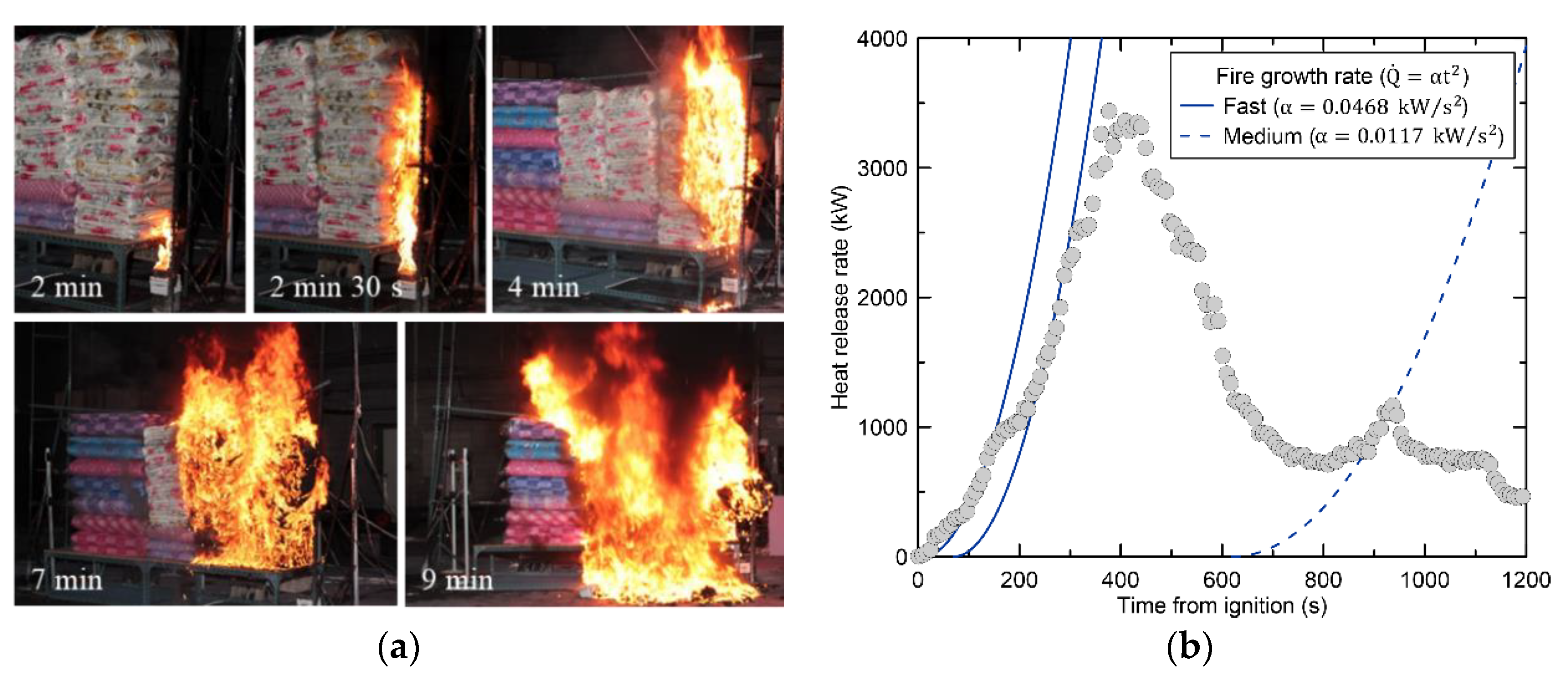

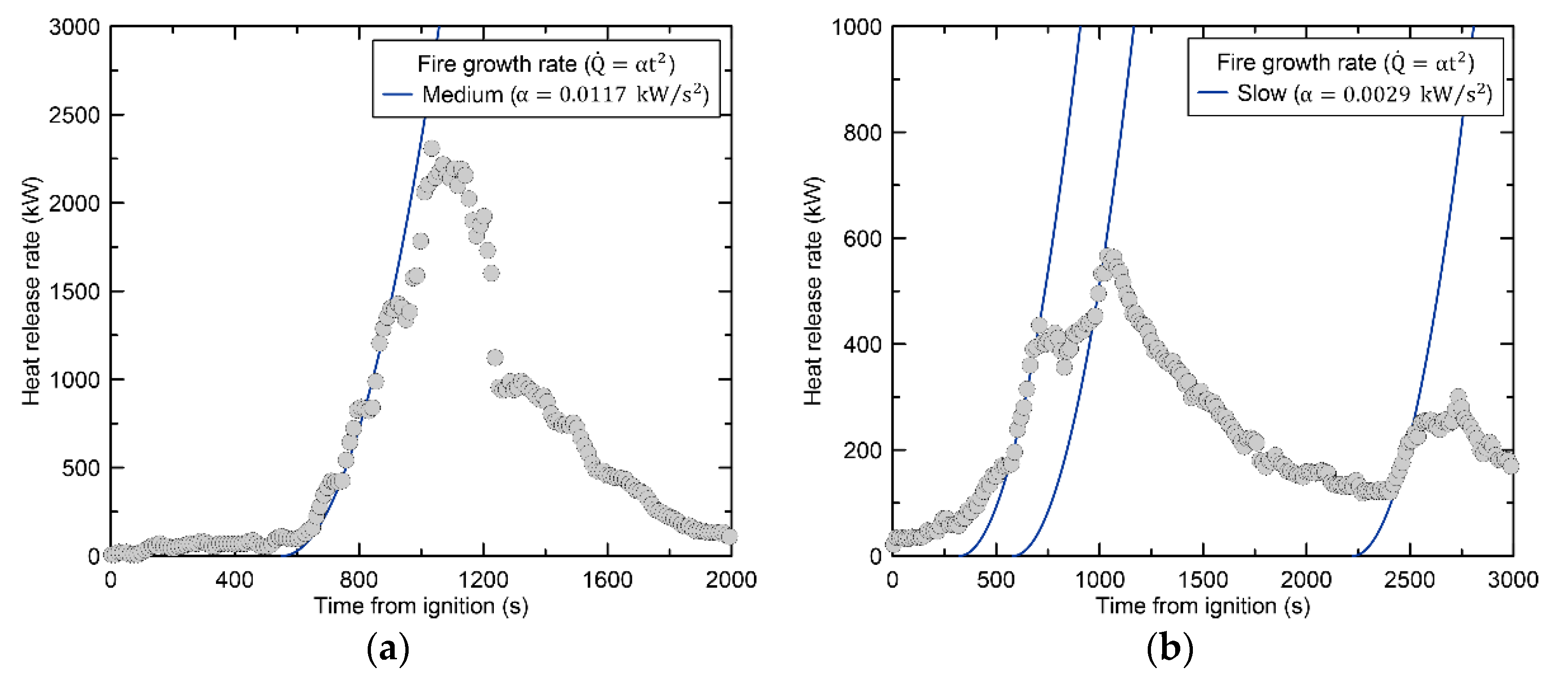

4. Results and Discussion

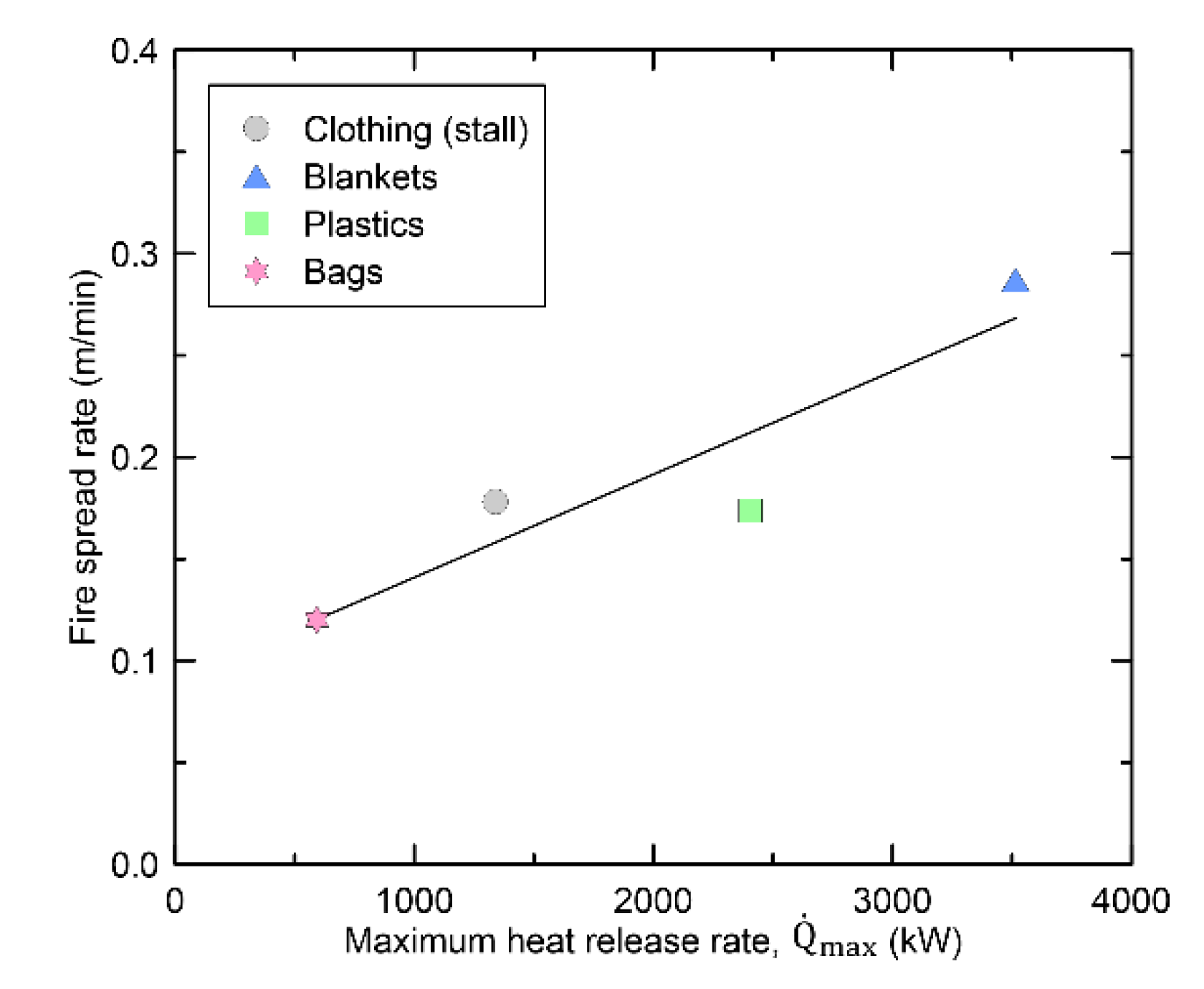

4.1. Relationship between the Maximum Heat Release Rate and Fire Spread Rate

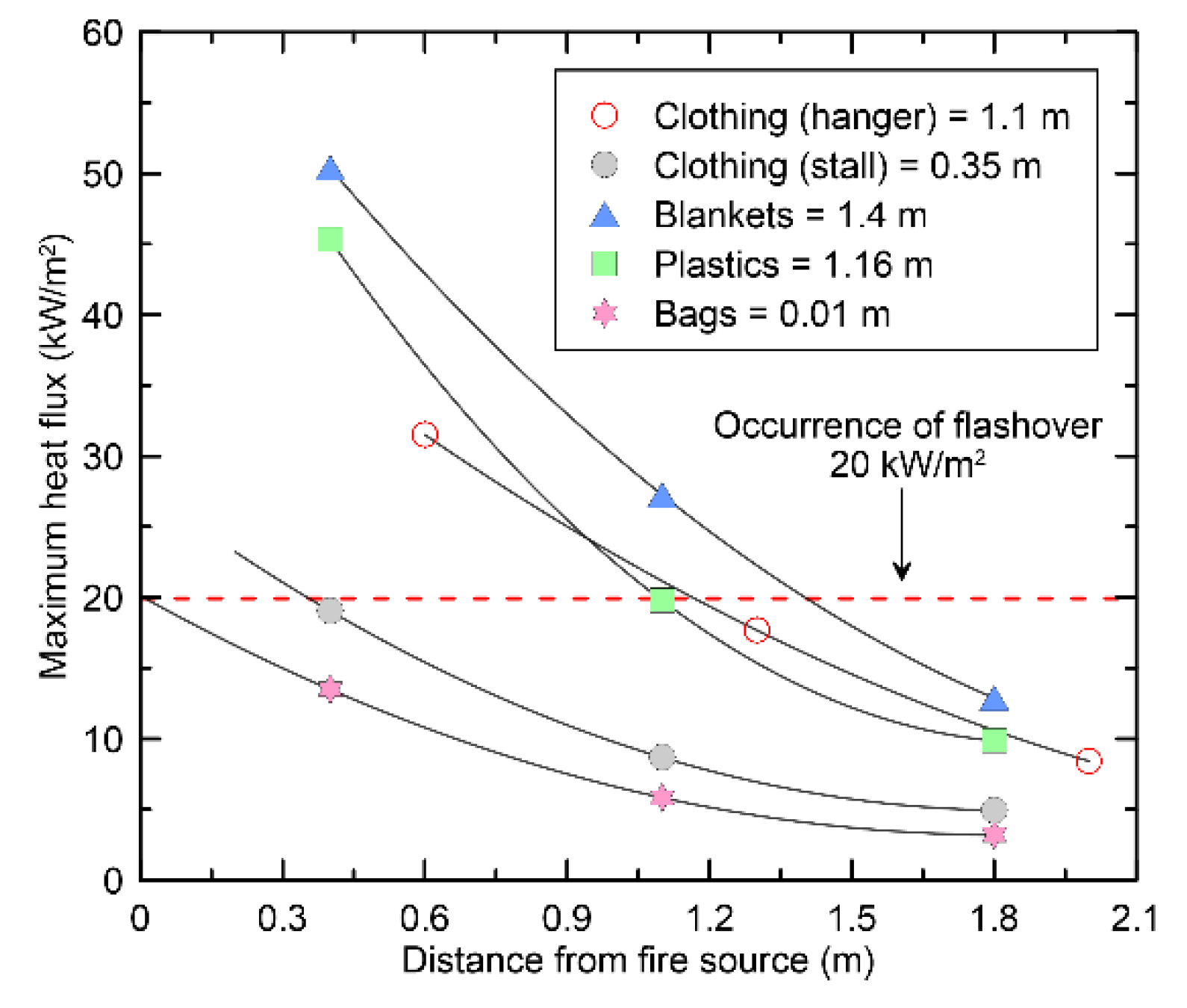

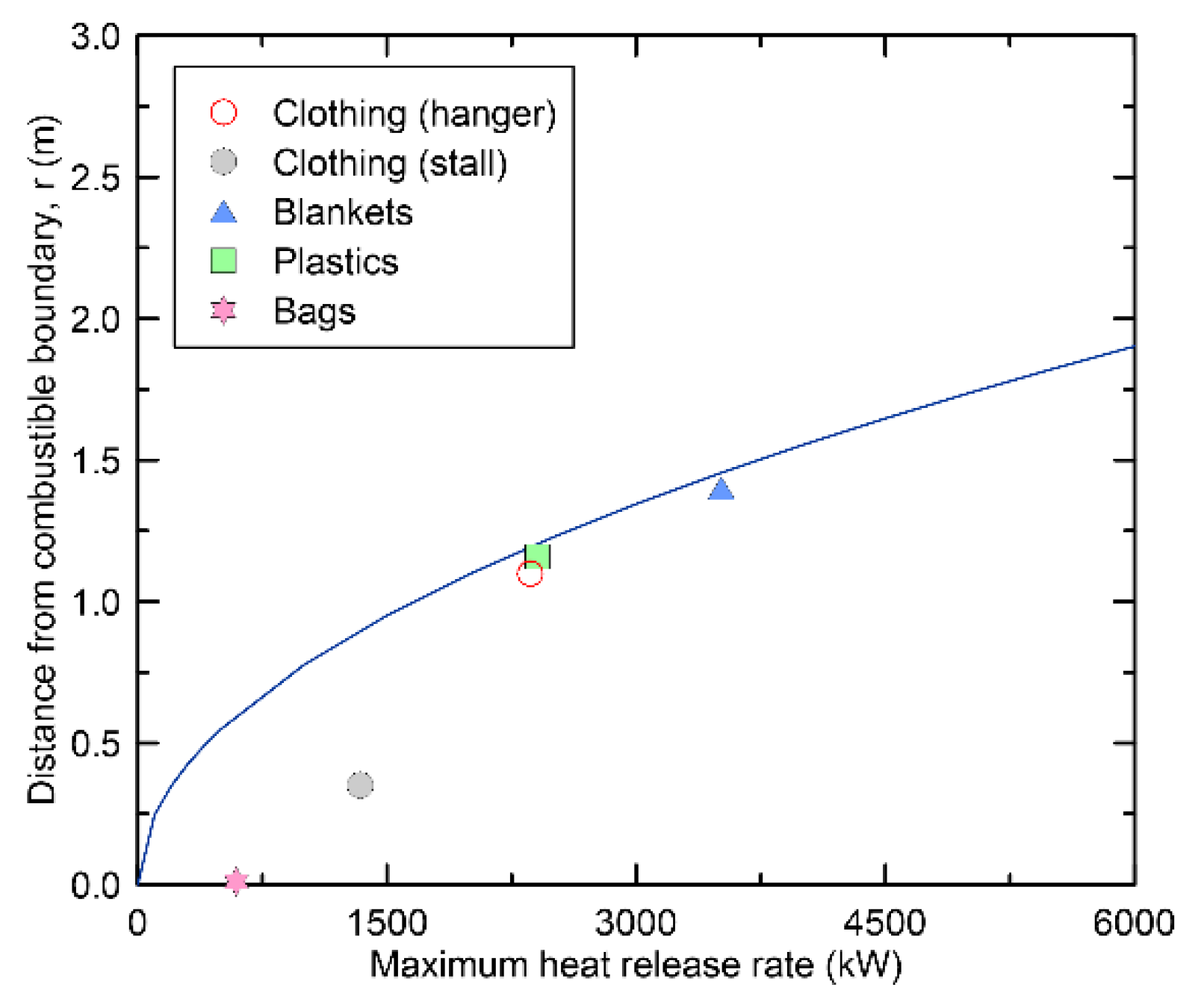

4.2. Separation Distance to Prevent Fire Spread by Radiant Heat Flux

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Vanella, M.; Weinschenk, C.; Overholt, K. FDS User’s Guide, 6th ed.; NIST Special Publication 1019; National Institute of Standard and Technology: Gaithersburg, MD, USA, 2017. [Google Scholar]

- Madrzykowski, D. Impact of a Residential Sprinkler on the Heat Release Rate of a Christmas Tree Fire. USA, 2008. NIST Interagency/Internal Report 7506. Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=861535 (accessed on 20 January 2017).

- Bwalya, A.; Gibbs, E.; Lougheed, G.; Kashef, A. Heat release rate of modern residential furnishings during combustion in a room calorimeter. Fire Mater. 2015, 39, 685–716. [Google Scholar] [CrossRef]

- Bennetts, I.D.; Moinuddin, K.A.; Thomas, I.R.; Proe, D.J. Sprinklered office fire tests. Fire Mater. 2008, 32, 159–198. [Google Scholar] [CrossRef]

- Zalok, E.; Hadjisophocleous, G.V.; Mehaffey, J.R. Fire loads in commercial premises. Fire Mater. 2009, 33, 63–78. [Google Scholar] [CrossRef]

- Hadjisophocleous, G.V.; Zalok, E. Development of Design Fires for Performance-Based Fire Safety Designs. Fire Saf. Sci. 2008, 9, 63–78. [Google Scholar] [CrossRef]

- Gross, D. Measurement of Fire Loads and Calculations of Fire Severity. Wood Fiber Sci. 1977, 9, 72–85. [Google Scholar]

- National Fire Data System. Available online: http://nfds.go.kr/stat/general.do (accessed on 7 May 2020).

- Oh, J.H.; Kim, D.Y. Fire-Resistant Green-Wall System for Traditional Markets. J. Archit. Inst. Korea Struct. Constr. 2017, 33, 27–33. [Google Scholar] [CrossRef]

- Park, J.W.; Jeon, G.Y.; Na, W.J.; Hong, W.H. A Study on Features of Fire and Change of Extinguishing Capacity of Sprinkler Equipment against Fire at a Traditional Market. Fire Sci. Eng. 2008, 22, 128–138. Available online: http://kifsejournal.or.kr/upload/pdf/HJSBCY_2008_v22n1_128.pdf (accessed on 11 April 2018).

- Lee, S.C.; Kim, B.J.; Lee, J.O.; Park, C.H.; Hwang, C.H. An Experimental Study on the Effects of the Shape of a Drencher Head on the Characteristics of a Water Curtain. Fire Sci. Eng. 2016, 30, 86–93. [Google Scholar] [CrossRef]

- Rothermel, R.C.; Anderson, H.E. Fire Spread Characteristics Determined in the Laboratory; United States Forest Serviece: Ogden, UT, USA, 1966.

- Zhang, Y.; Huang, X.; Wang, Q.; Ji, J.; Sun, J.; Yin, Y. Experimental study on the characteristics of horizontal flame spread over XPS surface on plateau. J. Hazard. Mater. 2011, 189, 34–39. [Google Scholar] [CrossRef]

- Zhao, K.; Zhou, X.; Peng, F.; Ju, X.; Yang, L. Experimental Study on Flame Spread over Inclined PMMA and PE Slabs. Key Eng. Mater. 2018, 775, 390–394. [Google Scholar] [CrossRef]

- Chaos, M.; Khan, M.M.; Krishnamoorthy, N.; De Ris, J.L.; DoroFeev, S.B. Evaluation of optimization schemes and determination of solid fuel properties for CFD fire models using bench-scale pyrolysis tests. Proc. Combust. Inst 2011, 33, 2599–2606. [Google Scholar] [CrossRef]

- Park, W.H. Optimization of fire-related properties in layered structures. J. Mech. Sci. Technol. 2019, 33, 3031–3840. [Google Scholar] [CrossRef]

- Tang, F.; Hu, L.H.; Qui, Z.W.; Zhang, X.C.; Lu, K.H. Window ejected flame height and heat flux along façade with air entrainment constraint by sloping facing wall. Fire Saf. J. 2015, 71, 248–256. [Google Scholar] [CrossRef]

- Hu, L.; Hu, K.; Ren, F.; Sun, X. Façade flame height ejected from an opening of fire compartment under external wind. Fire Saf. J. 2017, 92, 151–158. [Google Scholar] [CrossRef]

- Maranghides, A.; Johnsson, E.L. Residential Structure Separation Fire Experiment, USA, 2008. NIST Technical Note 1600. Available online: https://www.govinfo.gov/content/pkg/GOVPUB-C13-61ebeb4a9065a1584c3a9b0561bbb525/pdf/GOVPUB-C13-61ebeb4a9065a1584c3a9b0561bbb525.pdf (accessed on 10 May 2020).

- Delichatsios, M.A.; Ryan, J.; Tian, N.; Zhang, J. Vertical safe separation distance between openings in multi-storey buildings having a fire resistant spandrel. MATEC Web Conf. 2016, 46, 04003. [Google Scholar] [CrossRef]

- Barnett, C.R. Fire Separation between External Walls of Buildings. Fire Saf. Sci. 1989, 2, 841–850. [Google Scholar] [CrossRef]

- Cicione, A.; Walls, R.; Sander, Z.; Flores, N.; Narayanan, V.; Stevens, S.; Rush, D. The Effect of Separation Distance between Informal Dwellings on Fire Spread Rates Based on Experimental Data and Analytical Equations. Fire Technol. 2020. [Google Scholar] [CrossRef]

- Modak, A.T. Thermal Radiation from Pool Fires. Combust. Flame. 1977, 29, 177–192. [Google Scholar] [CrossRef]

- Hwang, C.H. Development of Water Curtain System Based on the Design of Optimized Fire Prevention Block in the Conventional Markets, Korea Fire Institute: Seoul, South Korea, 2016. Available online: https://www.ndsl.kr/ndsl/search/detail/report/reportSearchResultDetail.do?cn=TRKO201600011230 (accessed on 30 June 2016).

- Cote, A.E.; Hall, J.R.; Powell, P.; Grant, C.C.; Solomon, R.E. Fire Protection Handbook, 20th ed.; National Fire Protection Association (NFPA): Quincy, MA, USA, 2008; Section 6; pp. 6–274. ISBN 978-087-765-758-3. [Google Scholar]

- Wickström, U. The plate thermometer—A simple instrument for reaching harmonized fire resistance tests. Fire Technol. 1994, 30, 195–208. [Google Scholar] [CrossRef]

- ISO 834-1:1999. Fire Resistance Tests—Elements of Building Construction—Part 1: General Requirements. 1999. Available online: https://www.iso.org/obp/ui/#iso:std:iso:834:-1:ed-1:v1:en (accessed on 3 March 2016).

- Ingason, H.; Wickström, U. Measuring incident radiant heat flux using the plate thermometer. Fire Saf. J. 2007, 42, 161–166. [Google Scholar] [CrossRef]

- Häggkvist, A. The Plate Thermometer as a Mean of Calculating Incident Heat Radiation. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2009. [Google Scholar]

- Ditch, B. Evaluating pool fire severity and the cooling effect of local water spray using a continuous plate thermometer. Fire Saf. Sci. 2011, 109, 133–143. [Google Scholar] [CrossRef]

- Han, H.S.; Yun, H.S.; Hwang, C.H. Calibration of the Plate Thermometer for measuring Heat Flux using a Conical Heater. J. Mech. Sci. Technol. 2019, 33, 3563–3569. [Google Scholar] [CrossRef]

- NFPA 92B. Standard for Smoke Management Systems in Malls, Atria, and Large Spaces. National Fire Protection Association (NFPA). 2009. Available online: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=92B (accessed on 11 August 2015).

- Poon, L.S. Predicting Time of Flashover. 1991. Available online: Iafss.org/publications/aofst/3/283/view/aofst_3-283.pdf (accessed on 2 July 2020).

| Combustibles | Total Mass (kg) | Average Mass Per Unit Area (kg/m2) | Heat of Combustion (MJ/kg) | Fire Load (MJ/m2) | |

|---|---|---|---|---|---|

| Experiment | Field Survey | ||||

| Clothing (hanger) | 79.19 | 18.45 | 23.30 | 430.09 | 656.39 ± 211.0 |

| Clothing (stall) | 63.56 | 23.49 | 547.28 | ||

| Blankets | 68.00 | 25.13 | 17.41 | 437.50 | 507.48 ± 198.9 |

| Plastics | 22.29 | 16.47 | 34.33 | 565.57 | 543.90 ± 97.5 |

| Bags | 30.01 | 11.09 | 30.73 | 340.80 | 436.16 ± 106.0 |

| Combustibles | Maximum Heat Release Rate (kW) | Horizontal Fire Spread Rate (m/min) | |

|---|---|---|---|

| Clothing (hanger) | Ultra-fast | 2360 | 0.325 |

| Clothing (stall) | Slow | 1340 | 0.178 |

| Blankets | Fast | 3514 | 0.287 |

| Plastics | Medium | 2405 | 0.174 |

| Bags | Slow | 592 | 0.120 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, H.-S.; Nam, D.-G.; Hwang, C.-H. An Experimental Study on the Fire Spread Rate and Separation Distance between Facing Stores in Passage-Type Traditional Markets. Energies 2020, 13, 4458. https://doi.org/10.3390/en13174458

Yun H-S, Nam D-G, Hwang C-H. An Experimental Study on the Fire Spread Rate and Separation Distance between Facing Stores in Passage-Type Traditional Markets. Energies. 2020; 13(17):4458. https://doi.org/10.3390/en13174458

Chicago/Turabian StyleYun, Hong-Seok, Dong-Gun Nam, and Cheol-Hong Hwang. 2020. "An Experimental Study on the Fire Spread Rate and Separation Distance between Facing Stores in Passage-Type Traditional Markets" Energies 13, no. 17: 4458. https://doi.org/10.3390/en13174458

APA StyleYun, H.-S., Nam, D.-G., & Hwang, C.-H. (2020). An Experimental Study on the Fire Spread Rate and Separation Distance between Facing Stores in Passage-Type Traditional Markets. Energies, 13(17), 4458. https://doi.org/10.3390/en13174458