Abstract

There has been intense debate over the depletion of fossil fuel reserves in recent decades as well as the greenhouse gas emissions that are causing climate change. At the same time, new legislation in Greece, national policies, European policies, and realistic needs, need effective waste management and the protection of national resources. As a result, it seems a necessity to exploit waste treatments, while expanding the use of renewable energy sources. In this study, an attempt is made to focus our interest and research on a specific biomass waste stream, namely the waste biomass from the agricultural-livestock sector. The possibility of processing these wastes through the technology of biomass biorefinery with anaerobic digestion as its central process will be studied. The technology of anaerobic digestion is a process widely used for the treatment of agricultural residues and livestock waste as well as for the exploitation of energy crops (energy development, soil enhancement) mainly in countries in Europe and globally. This study reviews the biorefinery biomass technology, the energy production technology, production of biofuels, and new materials from waste biomass at the behest of the circular economy and bioeconomy. Additionally, this research will be an introduction in maximizing the potential of the full utilization of agricultural and livestock waste, and the by-products that can be produced from these processes.

Keywords:

biogas; circular economy; bioeconomy; wastes; energy; R.E.S; biomass; anaerobic; digestion; agriculture; livestock; Greece; biorefinery 1. Introduction

Effective energy output and reduced consumption have been our primary objectives in achieving a secure global supply of energy. Today, many countries in Europe and around the world are encouraging the use of renewable energy sources with assured return prices or carbon trading schemes [1,2,3,4]. Biomass, which has great potential for exploitation, is a very important substrate for the supply of renewable energy. Anaerobic digestion is used as an effective method for converting biomass into energy [5].

Anaerobic digestion (AD) is a process of decomposing organic matter in an oxygen-free environment through a microbial composition. It is a cycle found in many inhospitable natural habitats such as aquifers, sediments, water-soluble soils, and in mammals’ intestines. It can also be used on a wide variety of raw materials including industrial, agricultural, municipal, food wastes, and bio-chemical wastes. Biogas is provided by the biodegradation of organic materials and the lack of oxygen. In nature, it is the result of anaerobic fermentation of biodegradable materials and is a form of biofuel [5]. Biogas technology is an option with major benefits, providing eco-friendly energy and at the same time addressing the waste management crisis. An estimation of 1,000,000 tons of waste will produce 1 MW of electrical energy (biogas) for around ten years annually [5]. Biogas is derived primarily from the anaerobic digestion of animal waste (wastewater produced from pig farms, dairy farms e.tc), industrial waste, wastewater, and municipal waste. Biogas is composed primarily of methane and carbon dioxide, which can be used for generating heat and electricity, but also as an internal combustion engine fuel [5]. Biogas production from a biological process was first recorded in the United Kingdom in 1895 [6]. The method has since been developed and widely implemented for the treatment of wastewater and also for the stabilization of sludges. The oil crisis of the 1970s brought about new ideas of using alternative energy sources including anaerobic digestion (AD). Global efforts have been made to displace fossil fuels for the production of energy and also to find environmentally sustainable alternatives for the management and recycling of organic wastes. Some of AD’s most significant applications today are treating agricultural substrates through biogas plants. The highest percentage of installed agricultural biogas plants are in Europe, and especially in North America [5,7,8].

Initially, the National Renewable Energy Action Plan (NREAP) targets for Greece are presented, showing that new installations of biomass projects are a necessity for Greece, and the country must move quickly to achieve these targets. Then, the definitions of biomass, bioeconomy, and circular economy are presented, focusing on the utilization of agricultural and livestock waste. The important problem of waste biomass management is presented and examined through the investigation of available technologies through the international literature. The central pillar in this work is the process of anaerobic digestion.

This study essentially presents the operation of an anaerobic biorefinery where the anaerobic digester is a central element for the biotransformation of raw materials into various intermediate and high-end products. Biorefinery seems to be the optimal technology for the utilization of agricultural and livestock waste, contributing to a triple benefit: (a) energy production; (b) environmental protection; and (c) production of new materials/products. A flow diagram of these contributing processes is shown schematically that can be used in the biogas plants and also in the biorefinery plant (laboratory, pilot, large scale). Finally, the advantages of an installation of a biorefinery plant are presented, and the benefits to the environment, the local community, and the country.

2. Renewable Energy Sources (RES) Production in Greece

The Greek power sector relies heavily on fossil fuels, the majority of which are imported. Approximately 54 percent of its energy needs are met by petroleum products, compared to an EU level average of 33.4 percent. In addition to being used in the transport sector, these petroleum products are often converted into energy in significant quantities. The non-connected Greek Islands, in particular, get their electricity primarily from expensive and inefficient diesel power stations. Nearly 61% of Greece’s primary energy needs are met through imports with the remaining 39% covered by domestic energy sources, mostly lignite 77 percent and RES 22 percent [9].

The EU criteria laid down in Directive 2009/28/EC (EEL 140/2009) (Promoting renewable energy use and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC) provide that the contribution of renewable energy sources (RES) to total final energy consumption for Greece by the end of 2020 must be 18% [10,11].

As provided from Greek Law 3851/2010 [12], the national RES goals are set as follows:

- Contribution of the RES produced energy to the total final gross energy consumption in 2020: 20%.

- Contribution of the electrical energy of RESs to total electrical consumption: at least 40%.

- Contribution of the energy generated by RES for the heating and cooling energy consumption: at least 20%.

- Contribution of electrical energy generated by RES to total consumption of electrical energy for transportation: at least 10%.

Table 1 shows the RES electricity installed capacity per technology, and the National Renewable Energy Action Plan targets for Greece.

Table 1.

RES electricity installed capacity per technology (September 2017) [10].

Biomass, which has great potential for exploitation, is an important raw material for the supply of renewable energy.

In Greece, only a few biomass energy projects have been developed, mainly for municipal solid waste management. The installed biomass power capacity currently stands at 58 MW for a total of 12 individual projects [9], while the biomass target for Greece for the year 2020 is 350 MW.

3. Biomass

3.1. General

Biomass is the organic matter of waste and residues from agriculture, livestock sector, forestry, and other industries including waste fisheries and the organic matter of industrial and municipal wastes.

Biomass, with proper treatment can be converted into fuel as well as energy. Below are briefly presented the methods of biomass conversion, the products that are being produced, and the types and applications of biofuels in Greece [5].

3.2. Biomass Conversion Methods

Biomass can be converted into energy and utilized products with the following conversion methods. Table 2 shows these biomass conversion methods [13,14,15].

Table 2.

Biomass conversion methods [13,14,15].

There is great interest from the international scientific community for further utilization of waste biomass through new innovative methods of conversion. Processing of biomass, with the conversion methods above-mentioned, can produce a number of products that have a high added value. Many of these products are presented in Table 3 [15,16,17,18,19,20,21,22].

Table 3.

High added value products [15,16,17,18,19,20,21,22].

3.3. Applications of Biofuels in Greece

Biofuels have a variety of applications in Greece and globally. Their main applications in brief, are presented as following [15,16,17,18]:

- Heating of buildings from biomass combustion in individual/central boilers.

- Energy production in agricultural industries.

- Energy production in wood industries.

- Energy production in wastewater treatment plants (mainly from biological treatment of sludges) and sanitary landfills (mainly from capture and combustion of gas).

- Liquid biofuels (e.g., biofuels for transportation).

4. Biomass, Bioeconomy, and Circular Economy

From the time of the Industrial Revolution onward, our planet has lived in a linear economy. Our modern society is based mainly on the consumer model. This model is based on the following process: “use of natural resources, produce, consume, dispose”. Natural resources provide inputs to factories, which are then used to create goods and eventually, will be disposed of in the environment. This linear model of economy of mass production and mass consumption is testing the natural limits of the planet and threatens the stability of our future.

Today, we consume our natural resources faster than we can replace them. By 2030, if we continue at the same pace, there will be a lack of natural resources [23]. At the same time, the global population will grow, which will increase the demand for advanced industrial products.

A circular economy is the answer to the ambition for sustainable development, taking into account the continuing concern about the ongoing reduction of environmental resources and the depletion of the natural environment. The circular economy is a centered economic model based mainly on reducing the resources used in the manufacturing process. A circular economy is also based on stressing the use of renewable energy sources, the full treatment of agricultural and livestock waste, the reuse of products and waste, and the generation of energy from waste. A circular economy is the answer to sustainable development, taking into account the growing concerns regarding natural resource constraints and environmental degradation.

4.1. Preserving a Sustainable Model Should Be a Top Policy Priority

Environmental initiatives of the United Nations (UN) embody those concerns and recommend effective measures to maximize the benefits of preserving a green planet. The Ellen MacArthur Foundation is a famous organization founded in 2010 that has made major contributions to form European policies for a sustainable environment. The organization stresses [24] that a viable circular economy will help Europe revitalize its competitiveness by three percentage points per year. This would offer a significant gain of up to 0.6 trillion EURO by 2030, increasing the gross domestic product (GDP) by seven percentage points at the EU level compared to current growth.

4.2. Circular Economy and Waste

Research by the Ellen MacArthur Foundation focuses on planning based on circular economic principles and is trying to help businesses turn a linear production line into a circular economy model as circular economists cite waste as a useful commodity. The Ellen MacArthur Foundation [24] defines and classifies waste into four different categories:

- Exhausted resources: materials and energy that cannot be constantly regenerated (e.g., fuel).

- Products with recurring life cycles: products that have an artificially short lifespan (e.g., smartphones).

- Products that become useless when their lifespan is ended, (e.g., cars that remain unused for 90% of their lifespan).

- Waste with built-in value: these are materials and energy that are not recovered from discarded products and can be reused (e.g., non-reusable fabrics).

4.3. Biomass and Bioeconomy

The key aim of a bioeconomy is to manage various agricultural, industrial, and forestry activities in a sustainable manner. Therefore, the main effort to ensure a successful transition to bioeconomics is to achieve a sustainable design that combines sustainability and profitability. This is the big challenge for bioeconomics for the next few decades. Science and technology play a key role in the transition to sustainable bioeconomics.

Defining bioeconomics is a critical step. The concept of bioeconomics is to deal with the global population growth, the depletion of resources, climate change, and other environmental concerns. The concept itself is very basic. In fact, it is about satisfying the needs of the present generation without undermining the potential of the next generation to fulfill their own needs.

In terms of bioeconomics, many international institutions, governments, and scientific communities have put forward their own interpretations in terms of bioeconomics. The problem here is that bioeconomics is a multidimensional concept and its meaning depends largely on who defines the term. Economists, industrialists, economists, governments, scientists, and so on can use various concepts of bioeconomy.

We present here the well-known definition (which is still widely accepted) regarding bioeconomics. The bio-economy, according to the European Union, “includes the production and conversion of renewable biological resources into food, feed, organic products and bioenergy. It also includes food, forestry, agriculture, fisheries, pulp and paper production” [25].

4.4. Bioeconomics, Sustainability, and Agriculture

Agriculture is the foundation of any economic model. Agriculture is the key-role to the concept of bioeconomics and has a privileged position in bioeconomics. As an economic model, bioeconomics focuses primarily on meeting the food needs due to the human population growth. Agricultural sustainability means meeting people’s needs for feed, food, crops, fuel, and energy, while at the same time protecting and enhancing the quality of the environment and preserving natural resources for the needs of future generations. The goal of a bioeconomy is very simple when compared with previous and existing economic systems, which is to use all available resources (water, land and energy) to feed the human population growth.

4.5. Bioeconomy in Greece

Agricultural sector in Greece contributed with 27 billion euros in 2017, almost 4.1 percent to gross domestic product (GDP) of Greece. Seventy percent of this contribution comes from agricultural products, and the remaining 30 percent from animal products. In addition, there is a lot of unexploited waste in the agricultural and livestock sector in Greece. Through research [26], the annual waste generation in Greece from the agricultural and livestock sector has been calculated to be around 57,983,751 tn/y. A total of 53 percent of these wastes comes from the agricultural sector and 47 percent from the livestock sector.

5. Biogas Plant from Anaerobic Digestion of Agricultural and Livestock Wastes

Biogas production technology from waste biomass is an effective solution with many major advantages. Biogas delivers environmentally sustainable energy and also contributes to a comprehensive and integrated treatment of agricultural and livestock waste, reducing pollution discharge to the atmosphere by more than 55 per cent [5,7]. The production of biogas consists mainly of carbon dioxide and methane. Anaerobic digestion is the decomposition of organic matter without oxygen and is an effective method for converting biomass into energy. It can also be used on a wide variety of raw materials including industrial, urban waste, agricultural, municipal, food waste, and biochemical waste.

5.1. Agricultural and Livestock Waste Biomass

Biomass is the necessary raw material for the anaerobic digestion process. Agricultural waste (such as residues from wheat, sorghum, rice, etc.), livestock wastes (such as animal manures, animal bedding straw) and waste from the food industries are an abundant and often unlimited source of biomass. The amount of methane produced from these materials is usually very high, although pretreatment methods are usually required for maximum methanogenic efficiency [20].

5.2. Operation of a Biogas Plant

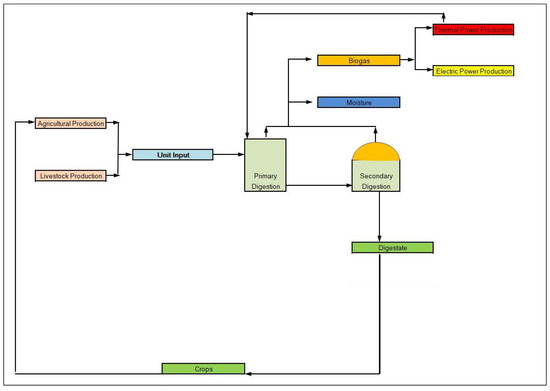

The following flowchart (Figure 1) shows how a biogas plant operates:

Figure 1.

Process flowchart of a typical biogas plant from agricultural and livestock production.

The process flow below examines the various steps taken at a biogas facility. Originally, the first stage in the unit input is the collection and storage of raw materials for anaerobic digestion. This is followed by the improvement of the substrate material, consisting of the stages of chopping, filtering, preparation mixing, pasteurization, etc. for the following anaerobic digestion cycle. In the stage of anaerobic digestion, the already formed substrate is led to primary (primary digestion) and then secondary digesters (secondary digestion) to conduct and complete the anaerobic digestion cycle. Biogas is derived from the anaerobic digestion process and is subjected to a series of treatments (desulfurization, drying, etc.) to make it suitable for use. Finally, the processed biogas is burnt in an ICE (internal combustion engine) unit for electrical and thermal energy production. The residue from the anaerobic digestion process (digestate) is processed and then available for the fields as liquid fertilizer (agriculture production). The general structure and technique of the biogas plant process is intended for the digestion and anaerobic treatment of a complete mix of farms and residues such as cow manure, pig manure (livestock production), and agricultural residues.

Through the scientific literature, a flowchart can be created that shows the processes that take place in a biogas plant and how the energy is produced [5,7,8].

5.3. Digestate as a Fertilizer

Digestate, which originates from the anaerobic digestion of agricultural and livestock organic waste, contains nutrients such as phosphorus, nitrogen, and potassium that may be beneficial as fertilizer for application to soil [27,28]. Therefore, the ammonia in the digested product may differ according to the substrate.

Parameters such as salinity, pH, heavy metals, and nutrients in digested products are important chemical properties to consider. The common residual pH is on a scale of 6.7 to 8.4 [29,30] and is generally slightly alkaline due to the degradation in the production of volatile fatty acids (VFA) and ammonia during the anaerobic digestion process.

5.4. Advantages of a Biogas Plant

A major advantage of biogas plants is that these systems can be easily extended with the installation of modern internal combustion engines (ICE) and can be easily transported without much difficulty or modification.

Additionally, a significant advantage of this technology is that the lifespan of these plants can exceed 25 years with low maintenance and operating costs.

Furthermore, these systems are ideal for central and distributed energy production as they can make a major contribution to the ‘distributed power generation’ of the area that they are being installed.

Biogas plants offer diversification of energy output provided by internal combustion engines and can create conditions for economic growth in the area that they are being installed.

Finally, the anaerobic digestion of agricultural and livestock waste in biogas plants has significant environmental and agricultural benefits such as [31]:

- Low emissions of greenhouse gases (CO2, CH4).

- Cost savings by the farmer.

- Improved soil fertility.

- Economic and ecological recycling of waste and wastewater.

- Reduced discomfort related to odor removal and insects (e.g., bugs, mosquitoes).

- Reduction of pathogens in the digestate.

In addition, and in terms of fertility production, the environmental benefits of applying anaerobic digestion technologies to both agricultural and livestock waste are shown below.

- Advantages for Farmers [5,7]:

- Improving the quality of organic fertilizers/reducing inorganic fertilizers.

- Reduction of phytotoxic substances and odors.

- Reduction of weeds, etc.

- Stabilization and improvement of soil fertility.

- Advantages for Local Community [5,7]:

- Reducing pollutants and odors.

- Positive effect on the protection of water resources.

- Positive effect on climate protection.

- Compared to other fuels, biogas shows positive behavior.

5.5. Biogas Potential in Greece

In Greece, in most cases, the local authorities and the regional and national bodies are responsible for policy-making, but also for the collection, treatment, and final disposal of municipal waste. In these cases, the availability of waste is stable (with the exception of small seasonal fluctuations due to tourism). In contrast, the management of agricultural-livestock waste is a major problem that needs to be solved due to the high potential, but also because of its spatial dispersion throughout the country. In some cases, there is a lack of knowledge about the potential of waste and the method of treatment of these wastes [32].

In areas such as Greece, the seasonal production of waste (e.g., waste from fruits, potato processing, etc.) is an important factor for the successful implementation of a biogas project. Biogas can be produced from almost all organic wastes. Today in Europe, there are relatively limited volumes of biogas coming from wastewater plants, sanitary landfills, and industrial facilities. The large volume of biogas in 2030 is projected to be produced from large central combustion plants, livestock facilities, and food processing industries [32].

In Greece, biogas is produced mainly from wastewater plants, sanitary landfills, and industrial facilities. According to estimates of the Center for Renewable Energy Sources and Saving of Greece (CRES) based on conservative scenarios, it is estimated that anaerobic digestion from only livestock waste could supply cogeneration biogas units with a total capacity of 350 MW of installed power [32].

6. Biorefinery

6.1. Definition of Biorefinery

There are many different definitions that explain the term “biorefinery”. Some examples are:

- A biorefinery is an installation that incorporates biomass conversion processes and equipment.

- A biorefinery produces fuels, energy, and high-added value chemicals. The concept is similar to that of an oil refinery, which produces multiple fuels and petroleum products [33].

- A biorefinery is a complex of industries based on organic raw materials and produce chemicals, fuels, energy, and other products and materials [34].

- A biorefinery is a promising plant, where biomass is converted to a range of valuable products [35].

- A biorefinery is the integrated bio-industry that uses various technologies to produce chemicals, biofuels, food, biomaterials (including fiber), and electricity [36].

- A biorefinery is a comprehensive bio-industry complex, using various technologies for the production of chemicals, food ingredients, biofuels, and biomass energy [37].

6.2. Biocellulose Biorefinery Biomass Plants, the Future of the Chemical Industry

An essential component of society is the sustainable development of the energy and chemical industries. Chemical and energy industries, however, are heavily dependent on non-renewable resources like oil, coal, and natural gas. The shortages of raw materials and the effects of climate change pose a great threat to any type of sustainable development.

At this point, lignocellulosic biomass is one of the most abundant renewable raw material. A lignocellulosic biorefinery (lignocellulosic feedstock biorefinery) is a promising model for the full utilization of lignocellulosic biomass, with a major role in the development of the energy and chemical industries [20].

Lignocellulosic biomass is a suitable raw material for the chemical and energy industries and is extremely necessary for the sustainable development of the energy and chemical industries. This choice is always influenced by many factors such as the availability of raw materials, the technical/technological level required, various economic criteria, and environmental and ecological implications.

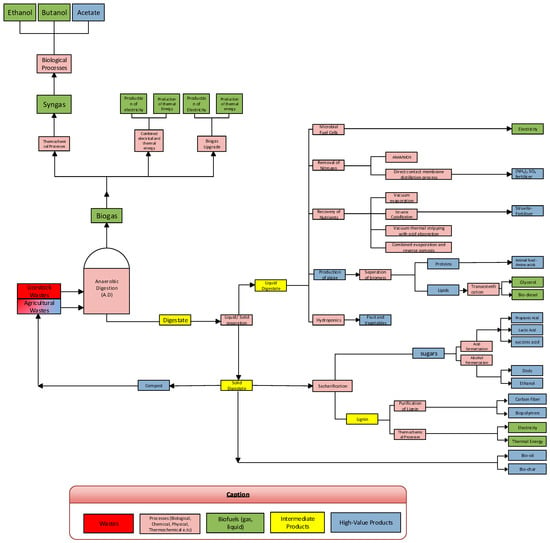

6.3. Flowchart of Biorefinery Plant

Through the scientific literature [38,39,40,41,42], a flowchart (Figure 2) was created that shows the processes that take place in a biorefinery plant and also the energy, intermediate products, and high value products that are produced.

Figure 2.

Process flowchart of a biorefinery plant [39,40,41,42,43].

6.4. Energy, Biofuels, and High Value Products

Figure 2 shows the processes that take place inside a biorefinery plant, with anaerobic digestion as its central process. Table 4 shows the incoming agricultural and livestock waste and the intermediate products, biofuels, and high value products that can be produced through the treatment of these wastes [38,39,40,41,42].

Table 4.

Waste, intermediate products, biofuels, and high value products in a biorefinery [38,39,40,41,42].

7. Conclusions

This research aims to study, investigate, and evaluate the feasibility of the full utilization of organic waste, particularly waste from agricultural and livestock units. In this work, we showed that the implementation of biorefinery has several great benefits as it provides environmental-friendly energy and, at same time, exploits energy efficiency and contributes to the comprehensive and holistic waste management of livestock and agricultural wastes.

Additionally, this study is an introduction to an anaerobic biorefinery as promising technology where anaerobic digestion serves as a hub for the conversion of waste to energy, intermediate products, and many high value products.

The installation of a biorefinery plant in a region where agricultural and livestock wastes are produced will have the following benefits:

- A high biomass capacity that can be extracted from agricultural waste will lead to a triple benefit: (a) energy production, (b) production of high-value products, and (c) environmental protection.

- The development of a central biorefinery plant from livestock and agricultural wastes will help to centralize organic waste management and protect vulnerable habitats in a broader region [21].

- The operation of a biorefinery plant will contribute to Greece’s target goals for RES installations [10].

- The anaerobic digestion process is extremely beneficial for organic farming, particularly for soils that require nutrients. The organic matter in the digested soil can create humus in the soil and this is a unique advantage for low-carbon content soils [5,7,29].

- It will improve the energy autonomy and energy security of the wider installation area by improving the flexibility of Greece’s energy network, and with the result of leading to the self-sufficiency of electricity imports during peak times [10].

- It will help to centralize the treatment of organic waste and to protect fragile habitats in the installation region [8,9].

- Large amounts of nitrogen, ammonia, hydrogen sulfide, oxides, and volatile compounds will not be emitted into the air [43].

- Large amounts of methane will not be released into the atmosphere, which is the main greenhouse gas that induces climate change [43].

- Chemical fertilizers that cause ongoing regional soil, surface water, and underground water pressures will be replaced with organic fertilizer from biorefineries at the behest of the circular economy [44,45,46].

- This will lead to an increase in the productivity of agricultural products as organic fertilizers will improve annual production quantitatively and qualitatively [44,45,46].

- It will help create new jobs [5].

- It will effectively deal with and eliminate the waste produced [5,7,8].

- It will be a central lever of research and innovation with an emphasis on environmental protection technologies [5].

- It will be a model of sustainable development, bioeconomy, and circular economy [24].

- It will provide significant economic benefits to the local community [5,7,8].

In this work, a biorefinery plant has a special position as one of the largest facilities for the processing of biomass into high value products in the circular economy. This design presents a dynamic culture of innovation, where new materials that have significantly higher value or energy content than biogas or the digestate material can be produced.

Author Contributions

Conceptualization, G.R., K.-J.H., M.L. and K.A.; Supervision, K.-J.H.; Writing—review & editing, G.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Climate Adaptation Platform Climate-ADAPT. Climate-ADAPT Strategy 2019-2021; European Climate Adaptation Platform Climate-ADAPT: Luxembourg, January 2019. [Google Scholar]

- Brussels European Council Conclusions of 8/9 March 2007 (Document Reference: 7224/1/07 REV 1 dated 2 May 2007), European Council. Available online: http://www.consilium.europa.eu/uedocs/cms_data/docs/pressdata/en/ec/93135.pdf (accessed on 14 August 2020).

- European Climate Summit 2014, Chair’s Summary: “Leaders Committed to Limit Global Temperature Rise to Less than 2 Degrees Celsius from Pre-Industrial Levels.”, European Council. Available online: http://www.un.org/climatechange/summit/2014/09/2014-climate-change-summary-chairs-summary/ (accessed on 14 August 2020).

- Intended Nationally Determined Contribution of the EU and Its Member States Submission by Latvia and the European Commission on Behalf of the European Union and Its Member States, Dated 6 March 2015, European Council. Available online: http://ec.europa.eu/clima/news/docs/2015030601_eu_indc_en.pdf (accessed on 14 August 2020).

- Al Seadi, T.; Rutz, D.; Prassl, H.; Köttner, M.; Finsterwalder, T.; Volk, S.; Janssen, R. Biogas Handbook; Niels Bohrs, V., Ed.; University of Southern Denmark: Esbjerg, Denmark, 2003; pp. 9–10. ISBN 9788799296200. [Google Scholar]

- Metcalf, L.; Eddy, H.P. Wastewater Engineering: Treatment Disposal Reuse, 3rd ed.; Revised by George Tchobanoglous, Frank Burton; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Al Seadi, T. Good Practice in Quality Management of AD Residues from Biogas Production, Report Made for the International Energy Agency, Task 24-Energy from Biological Conversion of Organic Waste; IEA Bioenergy and AEA Technology Environment: Oxfordshire, UK, 2001. [Google Scholar]

- Al Seadi, T.; Holm Nielsen, J. Utilisation of Waste from Food and Agriculture: Solid Waste: Assesment, Monitoring and Remediation; 2004 Waste Management Series 4; Elsevier: Amsterdam, The Netherlands, 2004; pp. 735–754. ISBN 0080443214. [Google Scholar]

- Greece Energy Situation. Available online: https://energypedia.info/wiki/Main_Page (accessed on 17 April 2020).

- European Parliament. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 ‘on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC’; European Council: Brussels, Belgium, 2009. [Google Scholar]

- Ministry of Development, Greece (2020). Available online: http://www.mindev.gov.gr/ (accessed on 17 April 2020).

- Greek Law. Nr.3851/2010: Accelerating the Development of Renewable Energy Sources to Deal with Climate Change and other Regulations Addressing Issues under the Authority of the Ministry of Environment; Energy and Climate Change: Athens, Greece, 2010. [Google Scholar]

- U.S Department of Energy (DOE)—Energy Efficiency and Renewable Energy: Biomass Conversion, DOE/EE-1436 June 2016. Available online: https://www.energy.gov/sites/prod/files/2016/07/f33/conversion_factsheet.pdf (accessed on 14 August 2020).

- Nautiyal, O.P.; Dugesh, P. Biomass to Fuel: Conversion Techniques. Energy Resources: Development, Harvesting and Management, 1st ed.; Uttarakhand Science Education and Research Centre (USERC), Government of Uttrakhand: Dehradun, Uttarakhand, India, 2016; pp. 155–194.

- Grassi, G.; Collina, A.; Zibetta, H. Biomass for Energy, Industry and Environment 6th E.C Conference, Athens, Greece, 22–26 April 1991; Taylor & Francis: Boca Raton, FL, USA, 1992; ISBN 185166730X. [Google Scholar]

- Mousdale, D.M. Biofuels-Biotechnology, Chemistry and Sustainable Development; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Drapcho, C.M.; Nhuan, N.P.; Walker, T.H. Biofuels Engineering Process Technology; McGraw-Hill Education: New York, NY, USA, 2008. [Google Scholar]

- Demirbas, A. Biofuels-Securing the Planet’s Future Energy Needs; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 9781848820111. [Google Scholar]

- Scragg, A.H. Biofuels: Production, Application and Development; CABI Publishing: Wallingford, UK, 2009; pp. 1–237. [Google Scholar]

- Petersson, A.; Thomsen, M.H.; Hauggaard-Nielsen, H.; Thomsen, A.B. Potential bioethanol and biogas production using lignocellulosic biomass from winter rye, oilseed rape and faba bean. Biomass Bioenerg. 2007, 31, 812–819. [Google Scholar] [CrossRef]

- Sawatdeenarunat, C.; Surendra, K.C.; Takara, D.; Oechsner, H.; Kumar Khanal, S. Anaerobic digestion of lignocellulosic biomass: Challenges and opportunities. Bioresour. Technol. 2014, 178, 178–186. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Xu, F.; Ge, X.; Li, Y. Challenges and strategies for solid-state anaerobic digestion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2015, 44, 824–834. [Google Scholar] [CrossRef]

- Hult International Business School, Cambridge, MA, USA. Available online: https://www.hult.edu/blog/tag/sustainability/ (accessed on 17 April 2020).

- Mac Arthur, E. Towards a Circular Economy. J. Ind. Ecol. 2013, 1, 23–44. Available online: https://mvonederland.nl/system/files/media/towards-the-circular-economy.pdf (accessed on 15 June 2020).

- European Association for Chemicals. Biotechnology and Energy; European Association for Bioindustries (EuropaBio): Brussels, Belgium, 2011. [Google Scholar]

- EUBIONETIII Project Partners. Available online: https://www.researchgate.net/figure/257547972_fig8_Fig-8-Amounts-of-unexploited-agro-industrial-residues-in-selected-EU-member-countries (accessed on 15 June 2020).

- Mishima, D.; Tateda, M.; Ike, M.; Fujita, M. Comparative study on chemical pretreatments to accelerate enzymatic hydrolysis of aquatic macrophyte biomass used in water purification processes. Bioresour. Technol. 2006, 97, 2166–2172. [Google Scholar] [CrossRef] [PubMed]

- Lissens, G.; Thomsen, A.B.; De Baere, L.; Verstraete, W.; Ahring, B.K. Thermal wet oxidation improves anaerobic biodegradability of raw and digested biowaste. Environ. Sci. Technol. 2004, 38, 3418–3424. [Google Scholar] [CrossRef] [PubMed]

- Madsen, M.; Holm-Nielsen, J.B.; Esbensen, K.H. Monitoring of anaerobic digestion processes: A review perspective. Renew. Sustain. Energy Rev. 2011, 15, 3141–3155. [Google Scholar] [CrossRef]

- Tampio, E.; Ervasti, S.; Rintala, J. Characteristics and agronomic usability of digestates from laboratory digesters treating food waste and autoclaved food waste. J. Clean. Prod. 2015, 94, 86–92. [Google Scholar] [CrossRef]

- IEA Bioenergy. Task 37. In The Role of Anaerobic Digestion and Biogas in the Circular Economy; IEA Bioenergy: Paris, France, 2018. [Google Scholar]

- Centre for Renewable Energy Sources and Saving of Greece (CRES). Energy Policy & Planning Directorate; Database: Athens, Greece, 2017. [Google Scholar]

- National Renewable Energy Laboratory. Available online: www.nrel.gov (accessed on 15 June 2020).

- Kamm, B.; Hüttl, R.; Grünewald, H. Lignocellulosic Feedstock Biorefinery—Combination of technologies of agroforestry and a biobased substance and energy economy. Forum Forsch. 2006, 19, 53–62. [Google Scholar]

- U.S. Department of Energy (DOE). Available online: https://www.energy.gov/ (accessed on 15 June 2020).

- European Commission Current Situation and Potential of the Bio-Refinery Concept in the EU: Strategic Framework and Guidelines for Its Development. Available online: https://cordis.europa.eu/project/id/44275/reporting (accessed on 15 June 2020).

- European Association for Bioindustries (EuropaBio). Building a Bio-based Economy for Europe in 2020; European Association for Bioindustries: Brussels, Belgium, 2011. [Google Scholar]

- Choi, S.; Song, C.W.; Shin, J.H.; Lee, S.Y. Biorefineries for the production of top building block chemicals and their derivatives. Metab. Eng. 2015, 28, 223–239. [Google Scholar] [CrossRef] [PubMed]

- Elbersen, H.W.; Bindraban, P.S.; Blaauw, R.; Jongman, R. Biodiesel from Brazil. In The Biobased Economy—Biofuels, Materials and Chemicals in the Post-Oil Era; Langeveld, H., Sanders, J., Meeusen, M., Eds.; Earthscan: London, UK, 2010; pp. 283–301. [Google Scholar]

- Bozell, J.J.; Petersen, G.R. Technology Development for the Production of Biobased Products from Biorefinery Carbohydrates—The US Department of Energy’s “Top 10” Revisited. Green Chem. 2010, 12, 539–554. [Google Scholar] [CrossRef]

- Sheets, J.P.; Yang, L.; Ge, X.; Wang, Z.; Li, Y. Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. Waste Manag. 2015, 44, 94–115. [Google Scholar] [CrossRef] [PubMed]

- Vaneeckhaute, C. Nutrient Recovery from Bio-Digestion Waste: From Field Experimentation to Model-based Optimization. Ph.D. Thesis, Ghent University, Ghent, Belgium, Faculte’ des Sciences et deGe´nie, Universite´, Laval, QC, Canada, 2015. [Google Scholar]

- Balde, H.; VanderZaag, A.C.; Burtt, S.D.; Wagner-Riddle, C.; Crolla, A.; Desjardins, R.L.; MacDonald, D.J. Methane emissions from digestate at an agricultural biogas plant. Bioresour. Technol. 2016, 216, 914–922. [Google Scholar] [CrossRef] [PubMed]

- Mateo-Sagasta, J.; Burke, J. Agriculture and Water Quality Interactions: A Global Overview; Executive Summary; SOLAW Background Thematic Report-TR08; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2010. [Google Scholar]

- World Water Assessment Programme (WWAP). The United Nations World Water Development Report 2015: Water for a Sustainable World; United Nations World Water Assessment Programme (WWAP); United Nations Educational, Scientific and Cultural Organization: Paris, France, 2015. [Google Scholar]

- World Water Assessment Programme (WWAP). The United Nations World Water Development Report 2017: Wastewater, the Untapped Resource; United Nations World Water Assessment Programme (WWAP); United Nations Educational, Scientific and Cultural Organization: Paris, France, 2017. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).