Abstract

The broader use of cements with a higher content of the main non-clinker components in construction industry is one of the directions leading to the decarbonization in cement production. This contribution analyzes the properties of low-emission cements containing from 44% to 56% of Portland clinker in their composition and indicates the possibilities of wider use in the construction. The obtained results confirmed that following the appropriate technological regimes, low-emission cements can be implemented into the production of concrete exposed to carbonation-induced corrosion (exposure class XC4 according to EN 206), frost-resistant concrete (exposure class XF4 according to EN 206), self-compacting concrete (SCC) and high-performance concrete (HPC). An analysis of the level of CO2 emissions in the production of specific types of concrete using low-emission cements was also made.

1. Introduction

In recent years, a lot of emphasis has been put on the use of low-carbon and energy-saving products. Concrete, as one of the most commonly used materials, is the subject to continuous improvement, not only to reduce the negative impact on the environment, but also to increase its positive properties in practical use.

The properties of concrete are determined by cement, which production is associated with carbon dioxide (CO2) emission and the consumption of non-renewable natural resources [1]. CO2 emission comes from the production of main cement component, which is Portland clinker, with about 2/3 of the emissions coming from the thermal decomposition of calcium carbonate, the main component of raw material for the production of Portland clinker, while the remaining 30–40% of CO2 emissions are the result of fuel combustion (mainly coal) in order to obtain the necessary temperature for the synthesis of cement clinker. The heat energy consumption to produce one ton of cement clinker is about 3.4 GJ [2]. Therefore, numerous technological measures are taken to reduce greenhouse gas emissions in the cement production process, as well as in the effective use of cement in concrete composition. These include the wider application of alternative fuels substituting the primary energy carrier used in the cement industry, which is hard coal, affected by combustion with the emissions of 84.6–94.6 kg CO2/ GJ [2]. The second important factor is the reduction of Portland clinker content in the cement composition. This is due to the wider practical implementation of multicomponent cements CEM II–CEM V, in accordance with EN 197-1 [3,4]. The main components in this type of cements are basically industrial by-products from various industries, such as granulated blast furnace slag (S) from the pig iron smelting process in a blast furnace, or fly ash from coal combustion in heat and power plants (siliceous V, calcareous W). These components successfully replace Portland cement clinker in cement, reducing cement and concrete emissions. Moreover, they affect the properties of cement, concrete mix, and hardened concrete [5,6,7]. Unfortunately, the availability of these valuable raw materials is limited in the world. Granulated blast furnace slag is practically completely utilized, while fly ash has variable properties associated with several coal combustion techniques [8,9]. Europe is also moving away from the energy obtained from coal in favor of the energy obtained from renewable sources (solar, wind, and water energy), which significantly limits the possibility of obtaining fly ash for the cement (concrete) production. Therefore, standardization works have been started to introduce new types of cements, such as CEM II/C-M multicomponent Portland cements and a group of multicomponent cements CEM VI [10]. These binders are considered as so-called ternary cements, with low content of Portland clinker, which composition mainly consist of siliceous fly ash (V) with granulated blast furnace slag (S) and limestone (LL) with fly ash (V) or limestone (LL) with slag (S). The properties of such cements are the effect of activity and synergistic interaction of individual non-clinker components [11,12,13,14]. A special emphasis should be put on the presence of limestone (LL) in the composition of this type of cements. It is a raw material widely available in the world, and importantly, practically at the disposal of every cement producer.

The wider use of low-emission cements in the construction industry very often encounters great difficulties from contracting entities and construction supervision concerned about obtaining adequate strength and durability properties. The argument relating to the lack of concrete tests carried with these application-oriented cements is very often raised. Hence, the purpose of this work was to show the possibility of making concrete, commonly used in construction, produced from low-emission cements. The attention was focused on concrete exposed to environmental corrosion caused by carbonation (exposure class XC4 according to EN 206 [15]), concrete subjected to aggression caused by freezing/thawing with the use of de-icing agents, self-compacting concrete (SCC) and high-strength concrete (HPC). Increased need for implementation of low-emission concretes, determined by the constantly growing environmental requirements, force the cement industry to strive to reduce greenhouse gas and dust emissions. The European Union places particular emphasis on reducing emissions, which has introduced a comprehensive decarbonization strategy, the so-called ‘The European Green Deal’. It assumes that by 2050, Europe will be a net-zero emitter of greenhouse gases [16].

2. Materials and Methods

2.1. Characteristic of Components and Composition of Tested Cements

The cements applied in the research were manufactured on an industrial scale in cement plant. They contained ground granulated blast furnace slag (S), silica fly ash (V), and limestone (LL). Table 1 shows the methods used to determine cement and main cement constituents’ properties.

Table 1.

Procedures applied to determine the properties of cement and main cement constituents.

Table 2 concludes the chemical composition of cement components. The ingredients exploited in the tests met the requirements of EN-197-1 [3]. The composition of tested low-emission cements is given in Table 3. The names of cements were adopted, taking into account the provisions of the draft standard prEN 197-5 [10]. The percentage of Portland clinker in cement composition ranged from 56% (cement C1) to 44% (cement C4). Assuming the emission from clinker production at the level of 840 kg CO2 from 1 Mg of clinker [23], the level of CO2 emission from the production of tested cements was calculated (Table 3).

Table 2.

Chemical composition and physical properties of main cement components.

Table 3.

Composition of low-emission cements and CO2 emission level.

2.2. Concrete Compositions and Properties’ Test Methods

In order to assess the properties of concrete mixtures and hardened concrete, the test methods given in Table 4 were used.

Table 4.

Research methods used to determine the properties.

In order to check the applicability of low-emission cements in construction industry, concretes for various applications were designed: concrete exposed to carbonation corrosion (XC4), frost-resistant concrete (XF4), self-compacting concrete (SCC), and high-performance concrete (HPC). The depth of water penetration under pressure [32], frost resistance [34], and carbonation depth [33] were assessed after two curing periods: after 28 and after 90 days. This is due to the significant increase in the compressive strength and insulating of the microstructure of concrete made of low-emission cements containing fly ash and slag after a longer curing [4,5,8]. The compositions of designed concrete mixtures are shown in Table 5. Concrete designations were adopted as a combination of the concrete usage and the type of cement used from C1 to C4.

Table 5.

Concrete mixture compositions.

The aggregate adopted in concretes was compliant with the standard EN 12620:2002 + A1:2008 [35]. Sand with a fraction of 0/2 mm was used as a fine aggregate in concrete. For concrete in exposure class XC4 (carbonation) [34] and SCC concrete, gravel aggregate of 2/8 and 8/16 mm fraction was applied. Crushed basalt aggregate of 2/8 and 8/16 mm was used for frost-resistant concretes in the XF4 exposure class as well as for HPC concretes. In order to achieve adequate solidity of the SCC concrete mixture, the content of fine fraction (below 0.125 mm) was increased by using the type II additive, in the form of FA silica fume, as per standard EN 450-1:2012 [36]. The composition of HPC concrete included the type II additive in the form of SF silica fume, complying to EN 13263-1:2005 + A1:2009 [37]. To obtain the right consistency of concrete mixtures, a superplasticizer based on polycarboxylate ether and plasticizer based on lignosulfonates (for SCC and HPC concretes requiring high flowability and delay in drop in consistency) were added. In order to provide adequate frost resistance air entraining agent based on turpentine resin was used for XF4 concretes. As an alternative aeration method, polymer microspheres were added, which are tiny, prefabricated air pores in flexible plastic capsules.

3. Results and Discussion

3.1. Properties of Cements’ Constituents and Cements

Specified standard properties of cements are shown in Table 6. Figure 1 illustrates the amount of heat released in the process of cement hydration [20]. The process of hydration of C1 multi-component cement (56% clinker) released the highest amount of heat, while the least when hydrating C4 (44% clinker).

Table 6.

Standard properties of cements.

Figure 1.

Heat released during low-emission cement hydration process. (Semi-adiabatic method consistent with EN-196-9 [20]).

In accordance with EN 197-1 [3], cements C2-C4 can be classified as binders with low hydration heat (LH), while the amount of heat released from hydration of multicomponent cement C1 is slightly higher than 270 J/g.

Low-emission cements were characterized by relatively low strength properties in the initial setting time (two days) and a significant increase in strength between 28 and 90 days of curing. After 90 days, the levels of cement compressive strength prove to be similar and amount to over 70 MPa, except for slag cement CEM III/A C3, for which it was 66.6 MPa (Table 6).

Curing temperature has a significant impact on the dynamics of cement compressive strength development. The results of compressive strength of standard mortars under reduced (+8 °C) and higher (+38 °C) temperatures, after two and seven days of curing, are shown in Figure 2.

Figure 2.

The influence of temperature on mortars compressive strength after: (a) two days of curing, (b) seven days of curing.

Rising the curing temperature from 20 °C to 38 °C caused a nearly 100% increase in early compression strength after two days and a nearly 50% increase in strength after seven days of the process. Lowering the curing temperature to 8 °C resulted in more than two-fold reduction in strength after two days compared to curing at 20 °C, while for multicomponent cement C4 more than three times. After seven days of curing, the differences reduced. It is clear that there is a visible reduction of strength with a decrease in temperature, which significantly limits the application of this type of cements in the autumn and winter season.

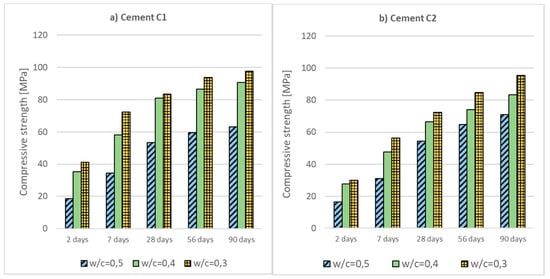

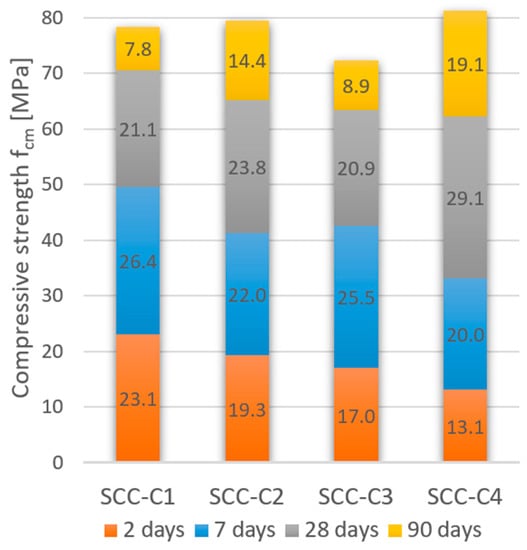

The effect of the water-cement (w/c) ratio on the compressive strength of mortars was also investigated. The results are shown in Figure 3. The mortars were made with a mortar flow similar to the one made with a standard w/c ratio 0.5. A superplasticizer based on polycarboxylic ethers was used to improve the rheological properties of mortars.

Figure 3.

Compressive strength of cements with different w/c ratio: (a) Cement C1; (b) Cement C2; (c) Cement C3; (d) Cement C4.

Lowering the w/c ratio from 0.5 to 0.4 and 0.3 resulted in a significant increase in compressive strength. This effect was most visible in the case of early strength, i.e., after two and seven days of curing. It should be emphasized that with a reduced w/c ratio, slag cements C1 (CEM III/A) and C3 (CEM II/C-M (S-LL)) are characterized by a much higher increase in strength than slag-fly ash cements (C2 and C4).

Concluding this part of the research, it should be stated that both the reduction of the w/c ratio and the increase in the temperature of concrete curing are technological methods that allow to obtain higher early strengths when using low-emission cements with a low content of Portland clinker.

3.2. Properties of Concretes

3.2.1. Concrete Exposed to Corrosion Due to Carbonation

Carbonation (reaction of calcium hydroxide and other hydrated phases of hydrated cement with CO2 contained in atmospheric air) is one of the basic environmental factors, which concrete elements and structures are subjected to [38,39,40]. This process leads to a decrease in the pH of the pore liquid in concrete, thus, negatively affects the durability of concrete and, in particular, the passivating properties of reinforcing steel [41,42]. Most concrete structures are exposed to this type of corrosion, therefore, concrete elements such as walls, columns, ceilings, and foundations that are common constructions ought to be resistant to the destructive effects of carbonation. The composition of concrete for the XC4 exposure class (Table 5) was designed based on the Polish national supplement to the EN 206 standard contained in the PN-B-06265: 2018-10 standard [34].

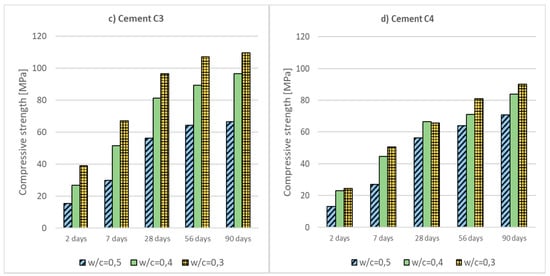

The analyzed concrete mixtures performed S3 consistency class [26], lasting for 90 min (Figure 4).

Figure 4.

Consistency of concrete mixtures XC4 in time.

Concretes produced with low-emission C2–C4 cements in the amount of 300 kg/m3, after 90 days of curing, achieved compressive strength fcm 50 MPa (Figure 5), which corresponded to the compressive strength class C35/45 (required standard strength in exposure class XC4 is C 25/30 [34]).

Figure 5.

Compressive strength fcm—concretes XC4.

The results of the depth of water penetration under pressure (Table 7) prove that concrete tightness improves with longer ageing period (from 28 days to 90 days).

Table 7.

Properties of XC4 concretes with CO2 emission level.

Figure 6 presents the results of measuring the depth of concrete carbonation realized by the accelerated method (CO2 concentration was 4%) [33] after 28 and 90 days of curing. Samples for carbonation tests were cured in two variants: variant N—in water for seven days and in air-dry conditions for the remaining curing period until the test date (designations 28 N and 90 N), variant P—in water throughout the entire ageing period (designations 28 P and 90 P). The carbonation depth was measured by applying a phenolphthalein indicator to the surface of the fresh fracture of the sample (color has changed to purple at pH ≥ 8.3) [43]. The cross-section of samples after the determination is shown in Figure 7.

Figure 6.

Carbonation depth—concretes XC4.

Figure 7.

Carbonation depth of concretes XC4-C2 (a) variant 28 N; (b) variant 28 P; (c) variant 90 N; (d) variant 90 P.

The obtained results prove the beneficial impact of extended curing process in water on the carbonation depth. The carbonation depth was the smallest for samples treated in water for a period of 90 days.

3.2.2. Frost-Resistant Concrete

In the temperate climate zone, one of the factors determining the durability of concrete is its resistance to freeze-thaw cycles [44]. It is influenced by high daily temperature amplitudes associated with frequent passages through 0 °C (over 100 passes each winter) [45]. The use of de-icing salts on road communication facilities (mainly NaCl) is another essential aspect in the winter, accelerating frost destruction, causing above all scaling of the surface layers of concrete [46]. The most effective methods to increase concrete resistance to cyclic freezing and thawing processes are the proper aeration of concrete, reduction of water-cement ratio and adequate curing [47].

Properties of concrete were designed (Table 5) and determined in order to meet the requirements for exposure classes XF4 according to EN 206 [15]. Exposure class XF4 assumes corrosive effects due to freeze/thaw cycles in the presence of de-icing salts or sea water. The test subjected non-aerated concrete (additional designation N), aerated to the air content in the concrete mix of 5% vol. and concrete containing microspheres (additional designation M) in the amount of 2.1 kg/m3 of concrete.

Cements C1–C3 were used in the tests. The properties of concrete mixtures are presented in Table 8. For XF4, XF4-M, and XF4-N concretes, the consistency of the concrete mix was established by slump test after 5, 30, and 60 min after the first contact of cement with water. Achieving similar slump values after 5 min (about 150 mm) for concretes without the addition of air-entraining agent (XF4-M and XF4-N) required an increase in the superplasticizer dosage by 0.9 kg/m3. It was observed, that despite the increased dosage of superplasticizer and similar initial consistencies, non-aerated concrete mixtures and mixtures using polymer microspheres were characterized by a faster decrease in consistency over the examined period of 60 min. The results of consistency tests are shown in Figure 8.

Table 8.

XF4 concrete mixtures test results.

Figure 8.

Consistency of concrete mixtures XF4 in time.

The dynamics of strength increase of concretes is illustrated in Figure 9. The properties of hardened concrete and decarbonization factor are demonstrated in Table 9. After 28 days of curing, the concretes reached average fcm strength above 60 MPa, and after 90 days, the fcm strength increased to approximately 70 MPa. Obtained level of strength met the requirements for class XF4 (minimum C 30/37).

Figure 9.

Compressive strength fcm—concretes XF4.

Table 9.

Properties of XF4 concretes with CO2 emission level.

Frost resistance of concrete was determined by two methods. The concretes were tested for F150 frost resistance [34], which means that the concrete samples were subjected to 150 cycles of alternating freezing and thawing in a special chamber. Samples were weighed before and after the freezing (−18 °C) and thawing (+18 °C) cycles. The drop-in sample weight stands for a measure of concrete frost destruction. A visual assessment was also carried out. In order to assess the destructive effect of frost on the concrete microstructure, the compressive strength of samples subjected to freeze/thaw cycles was provided, then compared to the strength of test specimens. This included samples that were not subjected to freeze/thaw cycles and matured in laboratory conditions. The decrease in strength should be ≤20%. Concretes were also submitted for resistance to freeze-thaw cycles in the presence of de-icing salts in accordance with PN-B-06265:2018-10 [34]. The determination was made after 90 days of curing. The test consisted of subjecting the surface obtained from the intersection of the concrete sample to freeze/thaw cycles under a 3 mm thick 3% sodium chloride (NaCl) solution. The result of the test was the mass of material exfoliated from the test surface after 56 freeze/thaw cycles. Frost resistance test results on the F150 degree, as well as the resistance of concrete to cyclic freeze-thaw process in the presence of de-icing salts are shown in Table 9 and Figure 10.

Figure 10.

De-icing salt resistance test results (90 days of curing).

The results of frost resistance tests (Table 10) revealed that concretes made of low-emission C1-C3 cements did not prove adequate frost resistance without the additional aeration process. Non-aerated concretes on cements C1-C3 after 150 of freeze/thaw cycles showed strength drops well above 20% and could not be considered as a frost-resistant. Frost resistance improves after the aeration of concrete, both, through the use of traditional aeration agents and the addition of polymer microspheres, however, the application of microspheres led to much greater decrease of strength. This requires an increase in the number of microspheres in concrete composition—corresponding studies are on-going. The results of concrete surface test on frost resistance in the presence of de-icing agents confirmed a significant amount of scaling in non-aerated concretes. It has been observed, that both aeration by means of an air-entrained admixture and polymer microspheres significantly reduced the mass of scaling of the surface of concrete subjected to freezing/thawing cycles in the presence of deicing salts for all cements used.

Table 10.

Tests results of F150 frost resistance of concretes XF4.

3.2.3. Self-Compacting Concrete (SCC)

Self-compacting concrete is a product with special properties of concrete mixture that demonstrates the ability to flow easily, tightly, and evenly filling the formwork, bypassing the vibration process, without segregating the ingredients. This allows one to eliminate the nuisance associated with noise and vibration when concreting and reduce the labor and energy consumption of concrete works. Self-compacting concrete mixture is required to obtain specific rheological properties, i.e., flowability and stability, as well as the ability to flow through reinforcement without loss of homogeneity. Self-compacting concrete is currently widely used both in prefabrication plants and in the implementation of monolithic elements with a complex reinforcement system [48,49].

Mixtures of self-compacting concrete were designed according to the composition presented in Table 6. The following properties of concrete mixture were determined:

- Consistency by concrete slump test acc. to EN 12350-8:2019-08 [27],

- Viscosity by V-funnel method acc. to EN 12350-9:2012 [28],

- Flow ratio by L-box method acc. to EN 12350-10:2012 [29].

The test results of self-compacting concrete mixtures are presented in Table 11. No signs of segregation of components were observed (Figure 11). The consistency, viscosity and flow rates were obtained in accordance with the requirements for self-compacting concrete mixtures.

Table 11.

SCC concrete mixture test results.

Figure 11.

Concrete mixture SCC-C1.

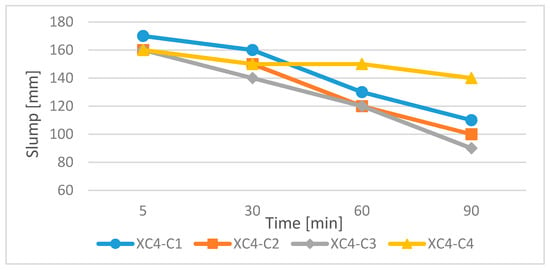

The properties of hardened concrete and the emissivity of concrete are shown in Table 12. Concrete was characterized by high tightness, which increased with the curing period. This was visible in the measurements of the depth of water penetration under pressure after 28 and 90 days of curing. A similar trend was noted for the level of strength increase. The highest dynamics of strength increase between 7 and 90 days of curing period was performed by concrete made of C4 cement containing 53% of the slag S and fly ash V mixture (Figure 12).

Table 12.

Properties of SCC concretes with CO2 emission level.

Figure 12.

Compressive strength fcm—concretes SCC.

3.2.4. High-Performance Concrete (HPC)

HPC high-performance concrete stands for concrete obtained by modifying the composition in terms of quality and quantity. Typically, such concretes are produced with high-quality cement, maintaining a low water-cement ratio (water-binder), resulting from the use of highly effective chemical admixtures (plasticizers and superplasticizers) and active additives of type II (most frequently silica fume SF) [50,51]. The application of high-strength concrete in construction allows for a reduction in cross-sections of structural elements, less wear of reinforcing steel and the reduction of the structure’s own weight while ensuring that the load capacity of the element and durability are preserved at the right level [52,53].

Table 5 present the compositions of HPC concretes. The consistency of the tested concrete mixtures remained in S3 consistency class for 90 min (Figure 13). Hardened concrete showed high tightness and average compressive strength fcm, approximately 100 MPa after 28 days of curing (Table 13). The increase in strength between 28 and 90 days of curing time ranged from 5% in case of C3 cement (slag cement CEM III/A) to about 15% in case of cement C2 and C4 (Figure 14). Noteworthy is also the low emissivity level—below 2 kg of CO2 per 1 MPa after 90 days of curing (Table 13).

Figure 13.

Consistency of SCC concrete mixtures in time.

Table 13.

Properties of HPC with CO2 emission level.

Figure 14.

Compressive strength fcm—HPC concretes.

The investigated high-performance concretes HPC, despite the lack of the aeration admixtures in composition, met the requirements for the degree of frost resistance F150 after 28 days of curing (Table 14). Strength drop after the frost resistance test was several percent (permitted value is up to 20%). This was the result of the formation of a tight structure in the binder matrix of concrete, the fact confirmed by the results of the depth of water penetration under pressure. The high compressive strength fcm around 100 MPa after 28 days of curing was not without significance (Table 13, Figure 14).

Table 14.

Frost resistance F150 test results of HPC concretes.

4. Summary

The prospects of reducing carbon dioxide emissions through various methods at the cement (concrete) production stage are one of the key factors determining their increasingly neutral environmental impact. It is important to make the most of concrete’s capacity and capture its value already at the design stage of the concrete structure (object).

Table 15 presents CO2 emissivity calculated for obtaining strength at 1 MPa. Attention ought to be paid to its reduction after 90 days of concrete curing.

Table 15.

The emissivity of concretes calculated per 1MPa.

The selection of an appropriate type of cement, considering its quantity and emissivity, moreover, the choice of a low water-cement ratio (using effective superplasticizers) and a properly designed aggregate skeleton in the mixture, ensure the production of good quality concrete that plays a key role in reducing CO2 emissions generated by cement industry and the entire construction industry.

The test results of low-emission cements and concretes made with their use, presented in the article, testify to the wide range of possible applications of low-emission cements in construction (concrete for the construction of foundations, foundation walls, columns and floors, prefabrication, high performance concrete), and under the provision of the additional technological conditions associated with confirming concrete frost resistance (aeration of the concrete mix) also in infrastructural elements. The properties of the similar ternary cements have been also tested by other researchers [54,55]. Achieved results were similar, but in this article the authors focused on presenting the application possibilities of concretes made of low-emission cements, where Portland and slag cements are currently used. In the future, the researchers intend to focus on testing the concretes made of CEM II/C-M and CEM VI multi-component cements built into real structures on an industrial scale.

5. Conclusions

Based on the results obtained, the following conclusions were drawn:

- Portland multicomponent cements CEM II/C-M (S-LL) and CEM II/C-M (S-V), slag cement CEM III/A, as well as multicomponent cement CEM VI (S-V) perform low emission per Mg of produced cement, ranging from 369.6 (CEM VI) to 470.4 (CEM II/C-M (S-LL) kg CO2.

- Low-emission cements CEM II/C-M, CEM III/A and CEM VI with a high content of non-clinker main components (ground granulated blast furnace slag (S), siliceous fly ash (V) and limestone (LL)) are characterized by a moderate increase in compressive strength at the beginning of curing (2 and 7 days) and a significant increase in strength over a longer period of time.

- Reducing the w/c ratio or rising the temperature results in a significant increase in concrete strength, both early and after a longer period of curing. Lowering the temperature has the opposite effect, which can lead to complications with the use of low-emission concretes at low temperatures in the autumn and winter weather.

- Longer curing period and concrete humidity care improve the tightness of cement matrix, which results in an increase in compressive strength and durability. Appropriate selection of concrete mixture composition (w/c = 0.45, adequate aeration of concrete mixture, the use of frost-resistant aggregate, proper care) allows to obtain concrete with a high frost resistance both in the presence of de-icing salts and without them.

- Self-compacting concrete mixtures SCC produced with the use of low-emission cements CEM II/C-M, CEM III/A, CEM VI and the addition of FA fly ash were characterized by adequate flow, stability and viscosity of the concrete mixture in the assumed time of 90 min.

- Low-emission cements can be successfully applied into the production of HPC high-performance concretes (using SF silica fume an additive type II). After 90 days of curing, all analyzed concretes reached compressive strength above 100 MPa.

- Significant increase in strength in the later period of curing (between 28 and 90 days) is a key feature of the tested concretes with low-emission cements, leading to a decrease in the level of emissions associated with obtaining 1 MPa of concretes’ compressive strength.

Author Contributions

Conceptualization: Z.G.; investigation: M.T. and K.W.; methodology: Z.G. and A.K.; supervision: Z.G.; writing—original draft: Z.G., A.K., M.T. and K.W.; writing—review and editing: Z.G., A.K., M.T. and K.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Silesian University of Technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Neville, A.M. Properties of Concrete; Polish Cement: Cracow, Poland, 2012. (In Polish) [Google Scholar]

- Chatterjee, A.; Sui, T. Alternative fuels—Effects on clinker process and properties. Cem. Conr. Res. 2019, 123, 105777. [Google Scholar] [CrossRef]

- EN 197-1:2011. Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements; British Standards Institution: London, UK, 2011. [Google Scholar]

- Prasada Rao, D.V.; Lakshmi Narayana, N. Properties of multi component composite cement concrete. Int. J. Eng. Res. Gen. Sci. 2017, 5, 1. [Google Scholar]

- Yuksel, I. Blast-Furnace Slag. In Waste and Supplementary Cementitious Materials in Concrete; Woodhead Publishing: Cambridge, UK, 2018; pp. 361–415. [Google Scholar]

- Department of Structural Engineering. Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials: State-of-the-Art Report of the RILEM Technical Committee 238-SCM Working Group 4; Soutsos, M., De Belie, N., Gruyaert, E., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 55–98. [Google Scholar]

- Alberici, S.; de Beer, J.; van der Hoorn, I. Fly Ash and Blast Furnace Slag for Cement Manufacturing, BEIS Research Paper No. 19; Department for Business, Energy & Industrial Strategy: London, UK, 2017; p. 19. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/660888/fly-ash-blast-furnace-slag-cement-manufacturing.pdf (accessed on 7 April 2020).

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- prEN 197-5-Working Document. Available online: https://www.cen.eu/news/brochures/brochures/cen-cenelec_wp_2019.pdf (accessed on 20 April 2020).

- Król, A.; Giergiczny, Z.; Kuterasińska-Warwas, J. Properties of Concrete Made with Low-Emission Cements CEM II/C-M and CEM VI. Materials 2020, 13, 2257. [Google Scholar] [CrossRef]

- Schöler, A.; Lothenbach, B.; Winnefeld, F.; Zajac, M. Hydration of quaternary Portland cement blends containing blast-furnace slag, siliceous fly ash and limestone powder. Cem. Concr. Compos. 2014, 55, 374–382. [Google Scholar] [CrossRef]

- Adu-Amankwah, S.; Black, L.; Skocek, J.; Ben Haha, M.; Zajac, M. Effect of sulfate additions on hydration and performance of ternary slag-limestone composite cements. Constr. Build. Mater. 2018, 164, 451–462. [Google Scholar] [CrossRef]

- De Weerdt, K.; Ostnor, T.; Justnes, H.; Ben Haha, M.; Kjellsen, K. Fly-ash limestone synergy in triple cement. In Proceedings of the 1st International Conference on Concrete Sustainability, Tokyo, Japan, 27–29 May 2013; pp. 510–515. [Google Scholar]

- EN 206. Concrete—Specification, Performance, Production and Conformity; CEN: Brussels, Belgium, 2013. [Google Scholar]

- The European Green Deal. Available online: https://eur-lex.europa.eu (accessed on 17 May 2020).

- EN 196-2. Methods of Testing Cement—Part 2: Chemical Analysis of Cement; CEN: Brussels, Belgium, 2013. [Google Scholar]

- EN 196-3. Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness; British Standards Institution: London, UK, 2016. [Google Scholar]

- EN 196-6. Methods of Testing Cement—Part 6: Determination of Fineness; British Standards Institution: London, UK, 2011. [Google Scholar]

- EN 196-9. Methods of Testing Cement—Part 9: Heat of Hydration—Semi-Adiabatic Method; British Standards Institution: London, UK, 2010. [Google Scholar]

- EN 1097-7. Tests for Mechanical and Physical Properties of Aggregates—Part 7: Determination of the Particle Density of Filler-Pyknometer Method; British Standards Institution: London, UK, 2008. [Google Scholar]

- EN 196-1. Methods of Testing Cement—Part 1: Determination of Strength; British Standards Institution: London, UK, 2016. [Google Scholar]

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon dioxide uptake by cement-based materials. A Spanish case study. Appl. Sci. 2020, 10, 339. [Google Scholar] [CrossRef]

- EN 12350-6. Testing Fresh Concrete-Part 6: Density; CEN: Brussels, Belgium, 2019. [Google Scholar]

- EN 12350-7. Testing Fresh Concrete-Part 7: Air Content. Pressure Methods; CEN: Brussels, Belgium, 2019. [Google Scholar]

- EN 12350-2. Testing Fresh Concrete-Part 2: Slump-Test; CEN: Brussels, Belgium, 2019. [Google Scholar]

- EN 12350-8. Testing Fresh Concrete-Part 8: Self-Compacting Concrete—Slump-Flow Test; CEN: Brussels, Belgium, 2019. [Google Scholar]

- EN 12350-9. Testing Fresh Concrete-Part 9: Self-Compacting Concrete—V-Funnel Test; CEN: Brussels, Belgium, 2012. [Google Scholar]

- EN 12350-10. Testing Fresh Concrete-Part 10: Self-Compacting Concrete—L Box Test; CEN: Brussels, Belgium, 2012. [Google Scholar]

- EN 12390-7. Testing Hardened Concrete-Part 7: Density of Hardened Concrete; CEN: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-3. Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens; CEN: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-8. Testing Hardened Concrete-Part 8: Depth of Penetration of Water Under Pressure; CEN: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-12. Testing Hardened Concrete-Part 12: Determination of the Carbonation Resistance of Concrete-Accelerated Carbonation Method; CEN: Brussels, Belgium, 2020. [Google Scholar]

- PN-B-06265. Concrete-Specification, Performance, Production and Conformity—National Annex to PN-EN 206+A1:2016-12; PKN: Warsaw, Poland, 2018. [Google Scholar]

- EN 12620. Aggregates for Concrete; British Standards Institution: London, UK, 2002. [Google Scholar]

- EN 450-1. Fly Ash for Concrete—Part 1: Definition, Specifications and, Conformity Criteria; British Standards Institution: London, UK, 2012. [Google Scholar]

- EN 13263-1. Silica Fume for Concrete—Part 1: Definitions, Requirements and Conformity Criteria; CEN: Brussels, Belgium, 2019. [Google Scholar]

- Chi, J.M.; Huang, R.; Yang, C.C. Effects of carbonation on mechanical properties and durability of concrete using accelerated testing method. J. Mar. Sci. Technol. 2002, 10, 14–22. [Google Scholar]

- Balayssac, J.P.; Grandet, J.; Detriche, H. Effects of curing upon carbonation of concrete. Constr. Build. Mater. 1995, 9, 91–95. [Google Scholar] [CrossRef]

- Czarnecki, L.; Woyciechowski, P.; Adamczewski, G. Risk of Concrete Carbonation with Mineral Industrial By-Products. J. Civ. Eng. 2018, 22, 755–764. [Google Scholar] [CrossRef]

- Angst, U.M. Challenges and opportunities in corrosion of steel in concrete. Mater. Struct. 2018, 51, 1–20. [Google Scholar] [CrossRef]

- Poursaee, A. Corrosion of Steel in Concrete Structures; Woodhead Publishing: Sawston, Cambridge, UK, 2016; pp. 19–33. [Google Scholar]

- Jackiewicz-Rek, W.; Wojciechowski, P. Carbonation rate of air-entrained fly ash concretes. Cement Wapno Beton 2011, 5, 249–256. (In Polish) [Google Scholar]

- Boss, P.; Giergiczny, Z. Testing the Frost resistance of concrete with different cement types- experience from laboratory and practice. Archit. Civ. Eng. Environ. 2010, 2, 41–51. [Google Scholar]

- Rusin, Z. Frost Resistant Concrete Technology; Polish Cement: Cracow, Poland, 2002. (In Polish) [Google Scholar]

- Yuan, J.; Lu, H.; Yang, Q.; Ling, J. Mechanisms on the salt-frost scaling of concrete. J. Mater. Civ. Eng. 2015. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Jaskulski, R.; Dąbrowski, M. Design principles and testing of internal frost resistance of concrete for road structures—Critical review. Roads Bridges 2016, 15, 21–43. [Google Scholar]

- Siva, A.; Ravindiran, G. Review on Self Compacting Concrete. Int. J. ChemTech Res. 2018, 10, 62–68. [Google Scholar]

- Khayat, K.H.; De Schutter, G. Mechanical Properties of Self-Compacting Concrete, State-of-the-Art Report of the RILEM Technical Committee 228-MPS; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Zain, M.F.M.; Safiuddin, M.; Mahmud, H. Development of high performance concrete using silica fume at relatively high water–binder ratios. Cem. Concr. Res. 2000, 30, 1501–1505. [Google Scholar] [CrossRef]

- Khaloo, A.; Mobini, M.H.; Hosseini, P. Influence of different types of nano-SiO2 particles on properties of high-performance concrete. Constr. Build. Mater. 2016, 113, 188–201. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, 197. [Google Scholar] [CrossRef]

- Sidodikromo, E.P.; Chen, Z.; Habib, M. Review of the cement-based composite ultra-high-performance concrete (UHPC). Open Civ. Eng. J. 2019, 13, 147–162. [Google Scholar]

- Matsuka, T.; Suzuki, Y.; Sakai, K. Low-Carbon Concrete Using Ground Granulated Blast-Furnace Slag and Fly Ash. Cem. Sci. Concr. Technol. 2010, 64, 295–302. [Google Scholar] [CrossRef][Green Version]

- Adu-Amankwah, S.; Zając, M.; Stabler, C.; Lothenbach, B.; Black, L. Influence of limestone on the hydration of ternary slag cements. Cem. Concr. Res. 2017, 100, 96–109. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).