Life Cycle Assessment of Tall Onshore Hybrid Steel Wind Turbine Towers

Abstract

1. Introduction

Life Cycle Assessment of Wind Turbine Towers

- (a)

- Definition of the analysis’ goal and scope, where the methodology, assumptions and limitations are established.

- (b)

- Inventory analysis, where the system’s inputs and outputs are assembled.

- (c)

- Impact assessment, where various indicators such as global warming, energy requirements etc. are determined.

- (d)

- Interpretation, where the system’s environmental impact is estimated and discussed.

2. Materials and Methods

2.1. Flowchart of Methodology

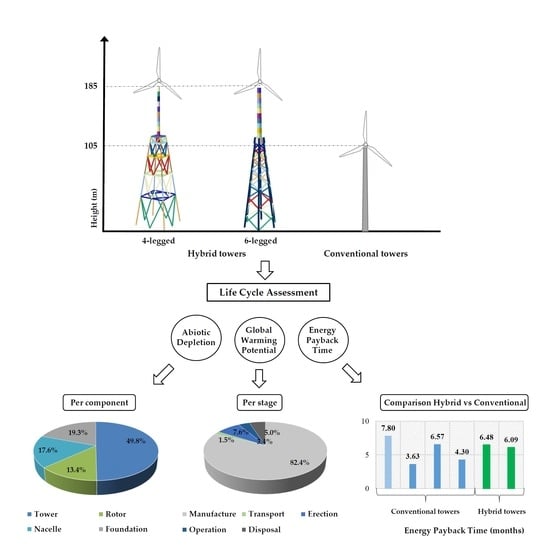

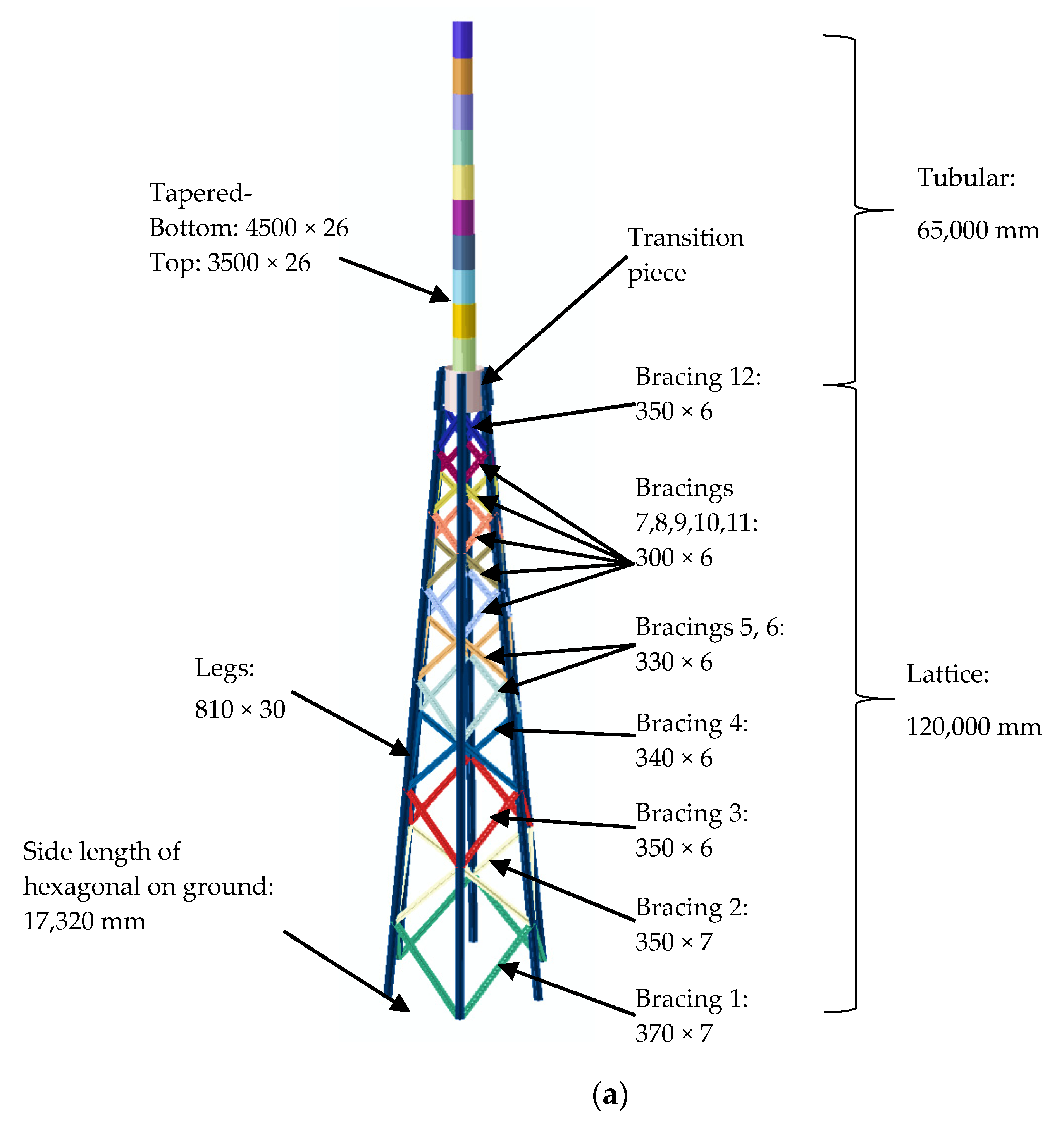

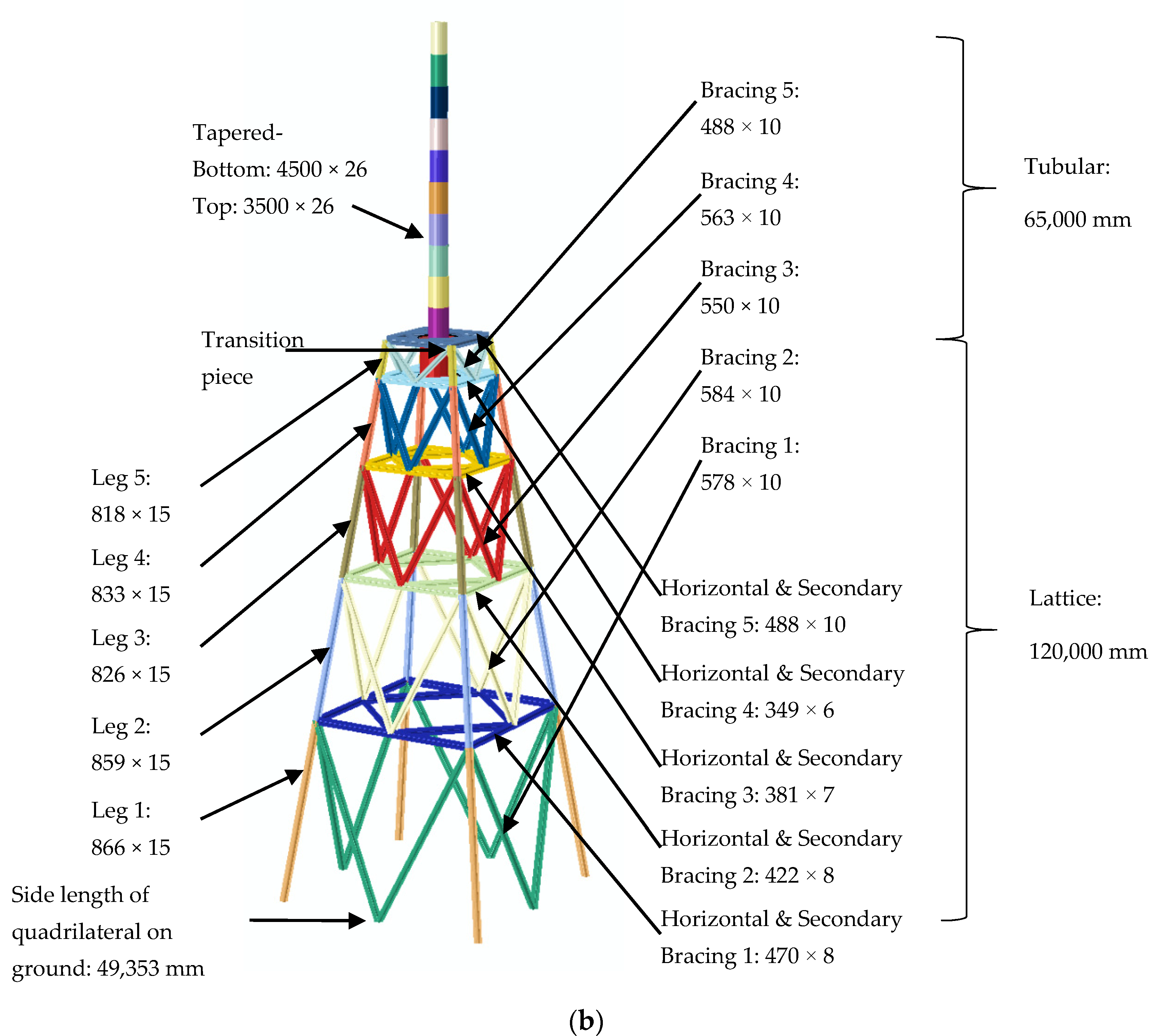

2.2. Case Studies

2.3. System Boundary and Functional Unit

2.4. Life Cycle Stages

2.4.1. Manufacture Stage

2.4.2. Transportation Stage

2.4.3. Erection Stage

2.4.4. Operation Stage

2.4.5. Disposal Stage

2.5. Life Cycle Inventory (LCI)

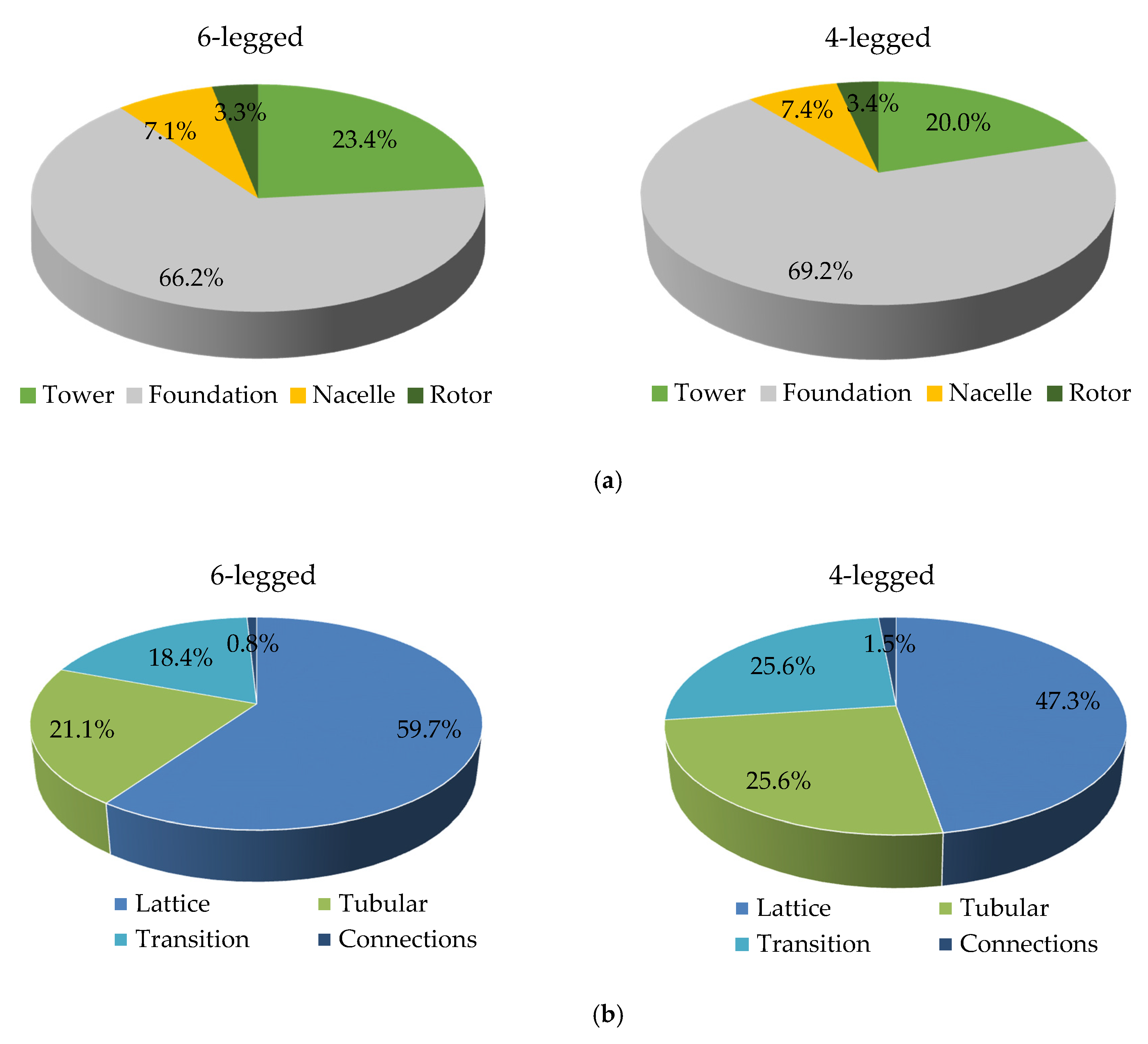

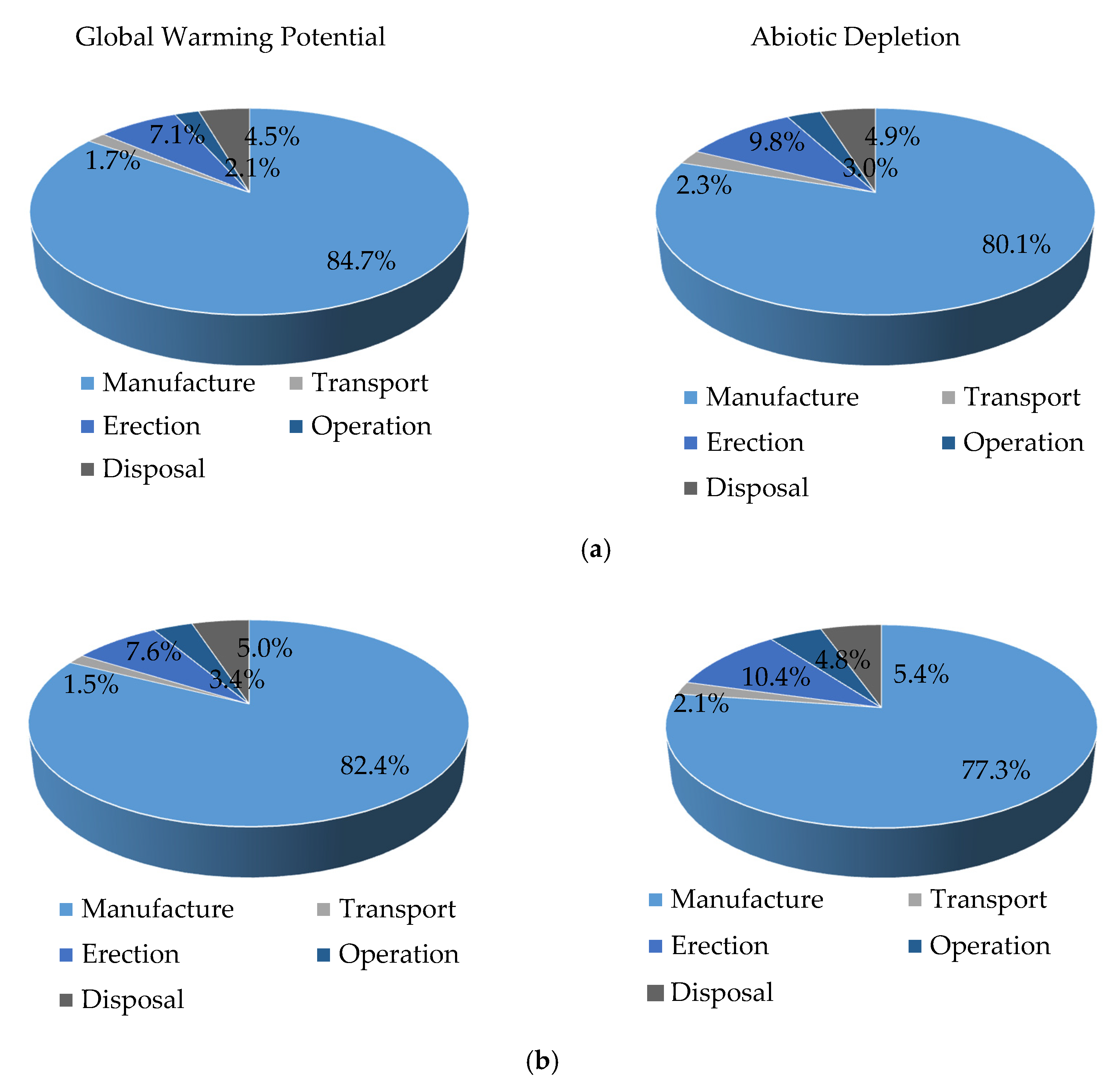

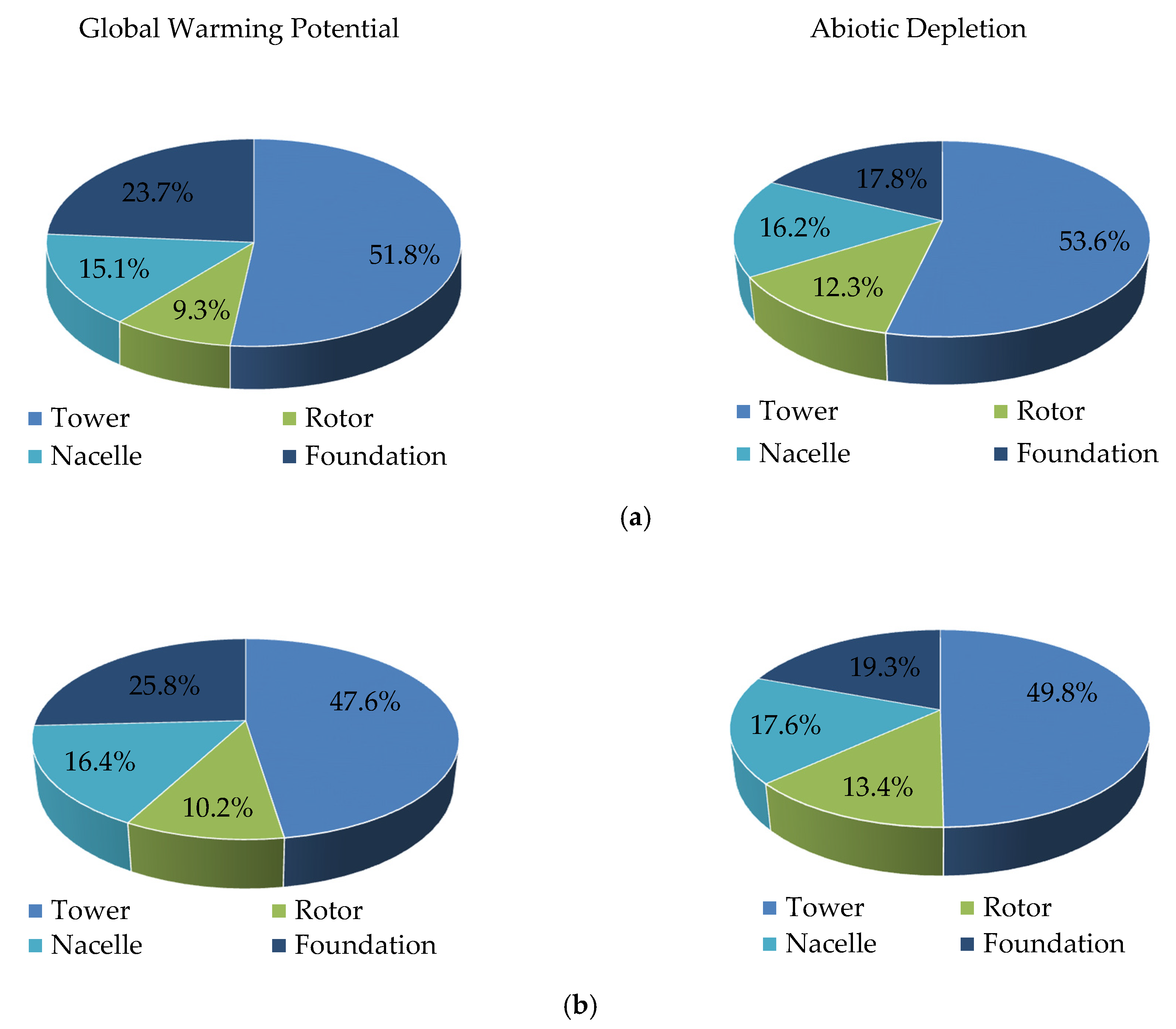

3. Results and Discussion

3.1. Life Cycle Indicators

3.2. Impact Assessment

4. Conclusions

- (1)

- For the transportation stage of a 20 year life cycle of a hybrid tower, it was estimated that there would be required 90 concrete mixers, 65 normal 15 ton trucks and 16 special trucks.

- (2)

- With the current technology available in Portugal, the erection process of the hybrid wind turbine is estimated to last 10 weeks.

- (3)

- LCA of two different hybrid towers, one 4-legged and one 6-legged, was evaluated by means of GEMIS software. The results between the two towers were similar with energy payback time ~6 months and CO2-eq ~10 g CO2-eq/kWh.

- (4)

- The component with most significant LCA footprints is the tower (~50%) followed by the foundation (~20%), whilst the stage with the highest environmental impact is the manufacture (~80%) followed by the erection (~10%).

- (5)

- The LCA footprints related to the tower and the erection stage can be further reduced, as the erection process of the hybrid towers gets more established in the industry.

- (6)

- The LCA results of the 185 m hybrid towers were compared to that of conventional towers, resulting in similar carbon footprints and energy payback times.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Global Wind Energy Council (GWEC). Wind in Numbers. Available online: http://gwec.net/ (accessed on 6 July 2020).

- Wind in Europe. European Statistical Data Support. Available online: https://windeurope.org/ (accessed on 6 July 2020).

- Ahmed, N.A.; Cameron, M. The challenges and possible solutions of horizontal axis wind turbines as a clean energy solution for the future. Renew. Sustain. Energy Rev. 2014, 38, 439–460. [Google Scholar] [CrossRef]

- Saad, M.M.M.; Mohd, S.B.; Zulkafli, M.F. Power generation of small wind turbine: Under high-speed operation. Sustain. Energy Technol. 2018, 26, 1–5. [Google Scholar] [CrossRef]

- Hand, B.; Cashman, A. A review on the historical development of the lift-type vertical axis wind turbine: From onshore to offshore floating application. Sustain. Energy Technol. 2020, 38, 100646. [Google Scholar] [CrossRef]

- Tziavos, N.I.; Hemida, H.; Metje, N.; Baniotopoulos, C. Non-linear finite element analysis of grouted connections for offshore monopile wind turbines. Ocean Eng. 2019, 171, 633–645. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, J.; Baniotopoulos, C. Repowering Steel Tubular Wind Turbine Towers Enhancing them by Internal Stiffening Rings. Energies 2020, 13, 1538. [Google Scholar] [CrossRef]

- Martinez-Vazquez, P.; Gkantou, M.; Baniotopoulos, C. Strength and ductility demands on wind turbine towers due to earthquake and wind load. Proc. Inst. Civ. Eng.-Struct. Build. 2019, 172, 556–563. [Google Scholar] [CrossRef]

- Konstandakopoulou, D.; Papagiannopoulos, G.A.; Pnevmatikos, N.; Hatzigeorgiou, G.D. Seismic Hazard Assessment of Offshore Platforms. Int. J. Civ. Environ. Eng. 2019, 13, 272–276. [Google Scholar] [CrossRef]

- Konstandakopoulou, F.; Konstantinidou, M.; Pnevmatikos, N.; Hatzigeorgiou, G.D. Safety and performance of offshore platforms subjected to repeated earthquakes. Infrastructures 2020, 5, 38. [Google Scholar] [CrossRef]

- Moeini, R.; Tricoli, P.; Hemida, H.; Baniotopoulos, C. Increasing the reliability of wind turbines using condition monitoring of semiconductor devices: A review. IET Renew. Power Gener. 2017, 12, 182–189. [Google Scholar] [CrossRef]

- Franko, J.; Du, S.; Kallweit, S.; Duelberg, E.; Engemann, H. Design of a Multi-Robot System for Wind Turbine Maintenance. Energies 2020, 13, 2552. [Google Scholar] [CrossRef]

- Lagaros, N.D.; Karlaftis, M.G.; Paida, M.K. Stochastic life-cycle cost analysis of wind parks. Reliab. Eng. Syst. Saf. 2015, 144, 117–127. [Google Scholar] [CrossRef]

- Karpat, F. A virtual tool for minimum cost design of a wind turbine tower with ring stiffeners. Energies 2013, 6, 3822–3840. [Google Scholar] [CrossRef]

- Lerch, M.; De-Prada-Gil, M.; Molins, C.; Benveniste, G. Sensitivity analysis on the levelized cost of energy for floating offshore wind farms. Sustain. Energy Technol. 2018, 30, 77–90. [Google Scholar] [CrossRef]

- Jovašević, S.; Mohammadi, M.R.S.; Rebelo, C.; Pavlović, M.; Veljković, M. New Lattice-Tubular Tower for Onshore WEC–Part 1: Structural Optimization. Procedia Eng. 2017, 199, 3236–3241. [Google Scholar] [CrossRef]

- Jovasevic, S.; Correia, J.; Pavlovic, M.; Dantas, R.; Rebelo, C.; Veljkovic, M.; de Jesus, A.M. Alternative steel lattice structures for wind energy converters. Int. J. Struct. Integr. 2019. [Google Scholar] [CrossRef]

- Gkantou, M.; Martinez-Vazquez, P.; Baniotopoulos, C. On the structural response of a tall hybrid onshore wind turbine tower. Procedia Eng. 2017, 199, 3200–3205. [Google Scholar] [CrossRef]

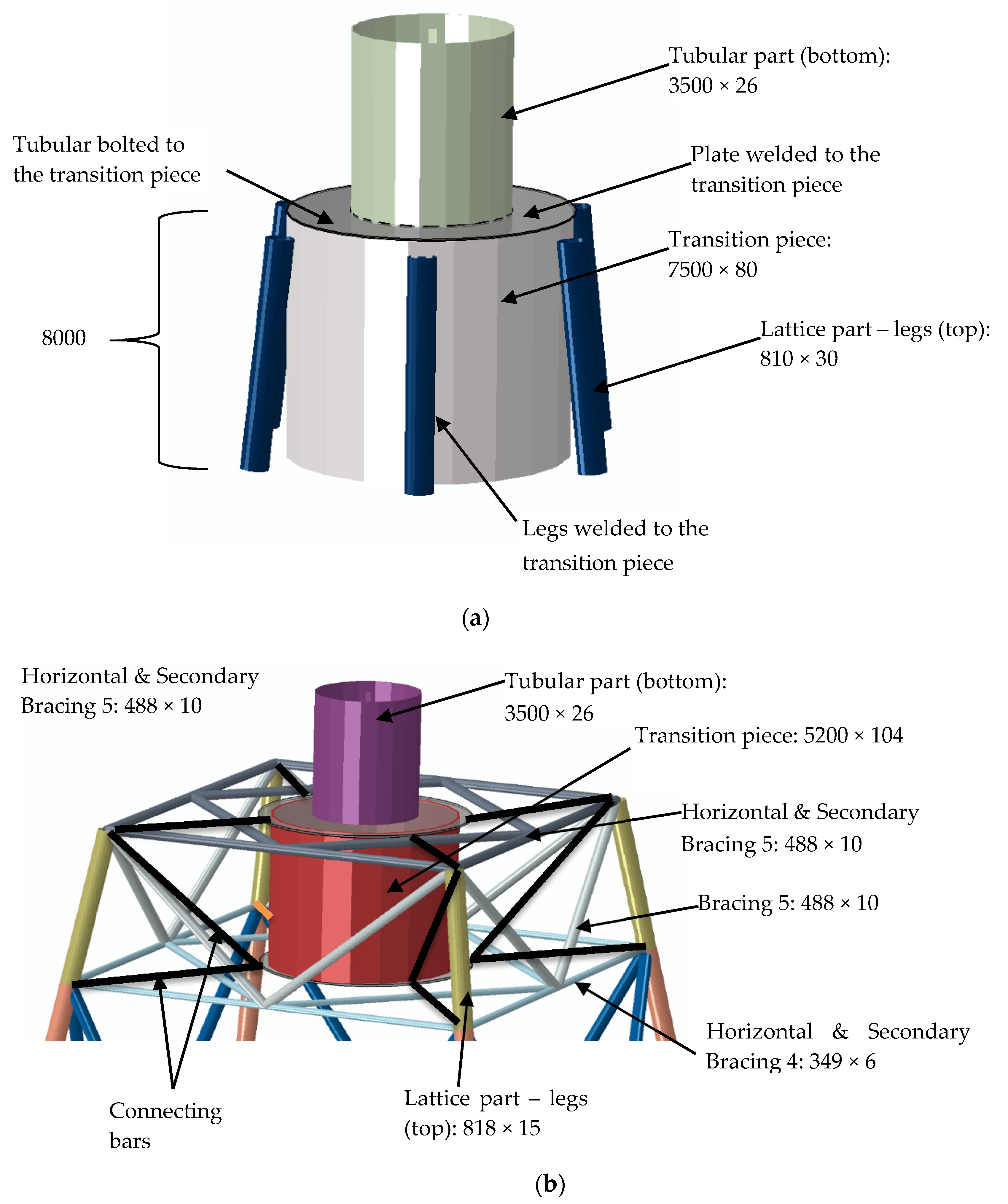

- Farhan, M.; Mohammadi, M.R.S.; Correia, J.A.; Rebelo, C. Transition piece design for an onshore hybrid wind turbine with multiaxial fatigue life estimation. Wind Eng. 2018, 42, 286–303. [Google Scholar] [CrossRef]

- Mohammadi, M.R.S.; Richter, C.; Pak, D.; Rebelo, C.; Feldmann, M. Steel hybrid onshore wind towers installed with minimal effort: Development of lifting process. Wind Eng. 2018, 42, 335–352. [Google Scholar] [CrossRef]

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044. Environmental Management-Life Cycle Assessment-Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Góralczyk, M. Life-cycle assessment in the renewable energy sector. Appl. Energy 2003, 75, 205–211. [Google Scholar] [CrossRef]

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef]

- Fleck, B.; Huot, M. Comparative life-cycle assessment of a small wind turbine for residential off-grid use. Renew. Energy 2009, 34, 2688–2696. [Google Scholar] [CrossRef]

- Garrett, P.; Rønde, K. Life cycle assessment of wind power: Comprehensive results from a state-of-the-art approach. Int. J. Life Cycle Assess. 2013, 18, 37–48. [Google Scholar] [CrossRef]

- Lee, Y.M.; Tzeng, Y.E. Development and life-cycle inventory analysis of wind energy in Taiwan. J. Energy Eng. 2008, 134, 53–57. [Google Scholar] [CrossRef]

- Schleisner, L. Life cycle assessment of a wind farm and related externalities. Renew. Energy 2000, 20, 279–288. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, M.; Cellura, M.; Brano, V.L. Energy performances and life cycle assessment of an Italian wind farm. Renew. Sustain. Energy Rev. 2008, 12, 200–217. [Google Scholar] [CrossRef]

- Guezuraga, B.; Zauner, R.; Pölz, W. Life cycle assessment of two different 2 MW class wind turbines. Renew. Energy 2012, 37, 37–44. [Google Scholar] [CrossRef]

- Chipindula, J.; Botlaguduru, V.; Du, H.; Kommalapati, R.; Huque, Z. Life cycle environmental impact of onshore and offshore wind farms in Texas. Sustainability 2018, 10, 2022. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life-cycle assessment of a 2-MW rated power wind turbine: CML method. Int. J. Life Cycle Assess. 2009, 14, 52. [Google Scholar] [CrossRef]

- Razdan, P.; Garrett, P. Life Cycle Assessment of Electricity Production from an Onshore V110-2.0 MW Wind Plant; Vestas Wind Systems: Aarhus, Denmark, 2015. [Google Scholar]

- Yang, J.; Chang, Y.; Zhang, L.; Hao, Y.; Yan, Q.; Wang, C. The life-cycle energy and environmental emissions of a typical offshore wind farm in China. J. Clean. Prod. 2018, 180, 316–324. [Google Scholar] [CrossRef]

- Vargas, A.V.; Zenón, E.; Oswald, U.; Islas, J.M.; Güereca, L.P.; Manzini, F.L. Life cycle assessment: A case study of two wind turbines used in Mexico. Appl. Therm. Eng. 2015, 75, 1210–1216. [Google Scholar] [CrossRef]

- Crawford, R.H. Life cycle energy and greenhouse emissions analysis of wind turbines and the effect of size on energy yield. Renew. Sustain. Energy Rev. 2009, 13, 2653–2660. [Google Scholar] [CrossRef]

- Smoucha, E.A.; Fitzpatrick, K.; Buckingham, S.; Knox, O.G. Life cycle analysis of the embodied carbon emissions from 14 wind turbines with rated powers between 50KW and 3.4 MW. J. Fund. Renew. Energy Appl. 2016, 6, 1000211. [Google Scholar] [CrossRef]

- Xu, L.; Pang, M.; Zhang, L.; Poganietz, W.R.; Marathe, S.D. Life cycle assessment of onshore wind power systems in China. Resour. Conserv. Recycl. 2018, 132, 361–368. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P. Comparative life cycle assessment of electricity generation by different wind turbine types. J. Clean. Prod. 2019, 233, 561–572. [Google Scholar] [CrossRef]

- Tremeac, B.; Meunier, F. Life cycle analysis of 4.5 MW and 250W wind turbines. Renew. Sustain. Energy Rev. 2009, 13, 2104–2110. [Google Scholar] [CrossRef]

- Bonou, A.; Laurent, A.; Olsen, S.I. Life cycle assessment of onshore and offshore wind energy-from theory to application. Appl. Energy 2016, 180, 327–337. [Google Scholar] [CrossRef]

- Demir, N.; Taşkın, A. Life cycle assessment of wind turbines in Pınarbaşı-Kayseri. J. Clean. Prod. 2013, 54, 253–263. [Google Scholar] [CrossRef]

- Oebels, K.B.; Pacca, S. Life cycle assessment of an onshore wind farm located at the northeastern coast of Brazil. Renew. Energy 2013, 53, 60–70. [Google Scholar] [CrossRef]

- Gervásio, H.; Rebelo, C.; Moura, A.; Veljkovic, M.; da Silva, L.S. Comparative life cycle assessment of tubular wind towers and foundations–Part 2: Life cycle analysis. Eng. Struct. 2014, 74, 292–299. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life cycle assessment of a multi-megawatt wind turbine. Renew. Energy 2009, 34, 667–673. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; No. NREL/TP-500-38060; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2009. [Google Scholar]

- Ancona, D.; McVeigh, J. Wind turbine-materials and manufacturing fact sheet. In Princeton Energy Resources International for the Office of Industrial Technologies; LLC: Washington, DC, USA, 2001. [Google Scholar]

- Martifer. Available online: https://www.martifer.pt/en (accessed on 6 July 2020).

- GEMIS. Global Emission Model for Integrated Systems; Version 5.0; Öko-Institut: Freiburg, Germany, 2019; Available online: http://iinas.org/gemis.html (accessed on 6 July 2020).

| Publication | Tower Type | Height (m) | Size (MW) | Location | Software | Main Conclusions |

|---|---|---|---|---|---|---|

| Garrett and Rønde [27] | steel tube | - | 2.0 | Denmark | Gabi | The wind plant produces energy to society 22 to 30 times more than what it consumes |

| Lee and Tzeng [28] | steel tube | 45, 46, 60 | 0.66, 0.60, 1.75 | Taiwan | - | Outstanding EPT (1.3 months) compared to literature data (6–8 months) |

| Schleisner [29] | steel tube | 40.5 | 0.5 | Denmark | - | Material production and manufacturing procedure have the largest contributions to the total emissions |

| Ardente et al. [30] | steel tube | 55 | 0.66 | Italy | - | Largest impact due to manufacturing of wind turbines and building works |

| Guezuraga et al. [31] | steel tube | 105, 65 | 1.8, 2.0 | Austria | GEMIS | Largest contribution of energy requirement during the manufacturing phase |

| Chipindula et al. [32] | steel tube | 90 | 1, 2, 2.3 | US, Texas | SimaPro | The installation and operation stages contributed very little to the total emissions |

| Martínez et al. [33] | steel tube | 70 | 2.0 | - | SimaPro | Copper in the nacelle and fiberglass in the rotor are some of the components with high contributions |

| Razdan and Garrett [34] | steel tube | 80 | 2.0 | - | Gabi 7 dfx | The use of iron, steel, aluminium and concrete are the primary contributors to environmental impacts |

| Yang et al. [35] | steel tube | 90, 100 | 3.6, 5.0 | China | - | LCA footprints were dominated by wind turbine manufacturing and materials for the foundation |

| Vargas et al. [36] | steel tube | - | 2.0 | Mexico | SimaPro | Major environmental impacts due to tower and nacelle |

| Crawford [37] | steel tube | 60, 80 | 0.85, 3.0 | Australia | - | No significant variation in the energy yield between small and large wind turbines |

| Smoucha et al. [38] | steel tube | - | 0.05÷3.4 | UK | - | Installation of higher-rated over lower-rated turbines allows for greater environmental benefits |

| Xu et al. [39] | Steel tube | 70 | 0.75, 1.5 | China | Gabi 6 | Optimising the structural design and raw materials application can improve environmental performance |

| Schreiber et al. [40] | steel tube | 84 | 3 | Germany | Gabi | Replacement of material components can affect the impacts |

| Tremeac and Meunier [41] | concrete | 124 | 4.50, 0.25 | France | SimaPro | Important to minimise components transportation and maximise recycling during decommissioning |

| Bonou et al. [42] | steel tube | 92.5 | 2.3, 3.2 | North America | SimaPro | EPT was less than year, whilst end-of-life treatments can enhance the LCA performance |

| Demir and Taskin [43] | steel tube | 50, 80, 100 | 2.05, 3.2 | Pakistan | Gabi 4 | Wind turbines with high hub heights (i.e., installed in optimum wind speed regions) decreased environmental impacts |

| Oebels and Pacca [44] | concrete, steel tube | 80 | 1.423 | Germany Denmark China | - | Steel tower had the largest contribution (over 50%) to total carbon emissions |

| Gervásio et al. [45] | concrete, steel, composite | 80, 100, 150 | 2.0, 3.6, 5.0 | Europe | Gabi | Reuse of materials in steel towers improves the environmental performance |

| Martínez et al. [46] | steel tube | 70 | 2.0 | - | SimaPro | Owing its recycling properties, steel is suggested for towers with increased hub heights and larger rotor blades |

| Component | Materials |

|---|---|

| Tower | Lattice part: steel |

| Tubular part: steel | |

| Transition piece: steel | |

| Connections: steel | |

| Rotor | Hub: cast iron, glass fibre, epoxy |

| Blades: glass fibre and epoxy (95%), steel (5%) | |

| Nacelle | Gearbox: steel (98%), aluminium (1%), copper (1%) |

| Generator: steel (65%), copper (35%) | |

| Frame, Machinery, Shell: steel (85%), aluminium (9%), copper (4%), glass reinforced plastic (3%) | |

| Foundation | Concrete |

| Steel reinforcement bars |

| Component | Number of Trucks | Type of Truck | |

|---|---|---|---|

| Lattice part of tower | 33 | 15 ton | 15 ton truck |

| Tubular part of tower | 3 | special | |

| Transition piece | 3 | 15 ton | |

| Bolts | 1 | 15 ton | |

| Concrete | 90 | concrete mixer | |

| Reinforcement bars | 8 | 15 ton | Special truck |

| Rotor | 4 | special | |

| Nacelle | 4 | special | |

| Equipment for RNA | 5 | 15 ton | |

| Crawler crane - body | 5 | special | |

| Crawler crane | 15 | 15 ton | Concrete mixer |

| Total number of trucks (per type) | 90 | concrete mixer | |

| 65 | 15 ton | ||

| 16 | special | ||

| Total number of trucks (all types) | 171 | - | - |

| Description | Duration | Crane | Personnel |

|---|---|---|---|

| Step 1: Assembling the lattice part | |||

| Divide the lattice part to units 1–5 and assemble them on site, close to the erection point. | 6 weeks | 1 × 150 ton crane | 10 persons |

| Step 2: Building the lattice tower and the tubular part | |||

| Assemble in turn the lattice and the tubular part, with the following order unit 1 of lattice & unit 1 of tubular unit 2 of lattice & unit 2 of tubular unit 3 of lattice & unit 3 of tubular unit 4 of lattice & unit 5 of lattice | 2 weeks | 1 × 150 ton crane 1 × 750 ton crawler crane | 10 persons |

| Step 3: Lifting the tubular part | |||

| Install strand jacks and unit 6 of the lattice part. Install strand carousel and lift the tubular part. | 1 week | 1 × 150 ton crane 1 × 750 ton crawler crane | 10 persons |

| Step 4: RNA installation | |||

| Install the nacelle and the rotor with blades. | 1 week | 1 × 150 ton crane 1 × 750 ton crawler crane | 10 persons |

| Total estimated time needed for erection: 10 weeks | |||

| Component | Stage | Description | Unit | 6-Legged | 4-Legged |

|---|---|---|---|---|---|

| Quantities | |||||

| Tower | Manufacture | lattice part (steel) | ton | 469.45 | 305.91 |

| Tower | Manufacture | tubular part (steel) | ton | 165.63 | 165.63 |

| Tower | Manufacture | transition piece (steel) | ton | 144.81 | 165.64 |

| Tower | Manufacture | connections | ton | 6.53 | 9.47 |

| Rotor | Manufacture | glass fibre & epoxy | ton | 53.22 | 53.22 |

| Rotor | Manufacture | cast iron | ton | 56.78 | 56.78 |

| Nacelle | Manufacture | steel | ton | 197.60 | 197.60 |

| Nacelle | Manufacture | aluminium | ton | 8.00 | 8.00 |

| Nacelle | Manufacture | copper | ton | 32.00 | 32.00 |

| Nacelle | Manufacture | glass reinforce plastic | ton | 2.40 | 2.40 |

| Foundation | Manufacture | concrete | ton | 2160.00 | 2160.00 |

| Foundation | Manufacture | Steel reinforcement bars | ton | 69.30 | 69.30 |

| Tower | Transport | truck | tkm | 108,641.56 | 64,370.53 |

| Rotor | Transport | truck | tkm | 11,000.00 | 11,000.00 |

| Nacelle | Transport | truck | tkm | 31,500.00 | 24,000.00 |

| Foundation | Transport | truck | tkm | 222,930.00 | 222,930.00 |

| Tower | Erection | crane | h | 105.60 | 105.60 |

| Rotor | Erection | crane | h | 7.92 | 7.92 |

| Nacelle | Erection | crane | h | 7.92 | 7.92 |

| Foundation | Erection | crane | h | 10.56 | 10.56 |

| Tower | Operation | truck | tkm | 652.66 | 946.96 |

| Tower | Disposal | landfill | ton | 117.96 | 95.58 |

| Rotor | Disposal | landfill | ton | 8.52 | 8.52 |

| Rotor | Disposal | incinerator | ton | 26.61 | 26.61 |

| Nacelle | Disposal | landfill | ton | 35.64 | 35.64 |

| Nacelle | Disposal | incinerator | ton | 1.20 | 1.20 |

| Foundation | Disposal | landfill | ton | 2170.40 | 2170.40 |

| Tower | Disposal | transport to | tkm | 2359.25 | 1911.54 |

| Rotor | Disposal | transport to | tkm | 170.34 | 170.34 |

| Rotor | Disposal | transport to | tkm | 532.20 | 532.20 |

| Nacelle | Disposal | transport to | tkm | 712.80 | 712.80 |

| Nacelle | Disposal | transport to | tkm | 24.00 | 24.00 |

| Foundation | Disposal | transport to | tkm | 43,407.90 | 43,407.90 |

| LCA Results | Unit | 6-Legged | 4-Legged |

|---|---|---|---|

| AD | GWh | 5.53 | 5.11 |

| GWP | tonnes CO2-eq | 2065.15 | 1923.95 |

| EPT | months | 6.48 | 6.09 |

| Case Study | 6-Legged | 4-Legged | ||

|---|---|---|---|---|

| Component | AD (GWh) | GWP (tonnes CO2-eq) | AD (GWh) | GWP (tonnes CO2-eq) |

| Tower | 2.97 | 1072.29 | 2.55 | 905.51 |

| Rotor | 0.68 | 193.42 | 0.68 | 193.42 |

| Nacelle | 0.90 | 312.55 | 0.90 | 312.55 |

| Foundation | 0.99 | 490.90 | 0.99 | 490.90 |

| Stage | ||||

| Manufacture | 4.42 | 1748.25 | 4.01 | 1585.66 |

| Transport | 0.12 | 34.50 | 0.11 | 29.72 |

| Erection | 0.54 | 145.63 | 0.54 | 145.63 |

| Operation | 0.16 | 44.19 | 0.25 | 66.28 |

| Disposal | 0.27 | 92.58 | 0.28 | 96.65 |

| Reference | Tower Height (m) | Turbine Size (MW) | GWP (g CO2-eq/kWh) | EPT (months) |

|---|---|---|---|---|

| Garrett and Rønde [27] | 80 | 2 | 8 | 9 |

| Martínez et al. [33] | 70 | 2 | 6.58 | 4.8 |

| Tremeac and Meunier [41] | 124 | 4.5 | 15.8 | 6.96 |

| Bonou et al. [42] | 99.5 | 2.3 | 6 | 6.2 |

| Demir and Taskin [43] | 80 | 3.02 | 23.77 | 22.5 |

| Hybrid towers [herein] | 185 | 5 | 9.62, 10.33 | 6.09, 6.48 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gkantou, M.; Rebelo, C.; Baniotopoulos, C. Life Cycle Assessment of Tall Onshore Hybrid Steel Wind Turbine Towers. Energies 2020, 13, 3950. https://doi.org/10.3390/en13153950

Gkantou M, Rebelo C, Baniotopoulos C. Life Cycle Assessment of Tall Onshore Hybrid Steel Wind Turbine Towers. Energies. 2020; 13(15):3950. https://doi.org/10.3390/en13153950

Chicago/Turabian StyleGkantou, Michaela, Carlos Rebelo, and Charalampos Baniotopoulos. 2020. "Life Cycle Assessment of Tall Onshore Hybrid Steel Wind Turbine Towers" Energies 13, no. 15: 3950. https://doi.org/10.3390/en13153950

APA StyleGkantou, M., Rebelo, C., & Baniotopoulos, C. (2020). Life Cycle Assessment of Tall Onshore Hybrid Steel Wind Turbine Towers. Energies, 13(15), 3950. https://doi.org/10.3390/en13153950