Abstract

In order to limit the anthropic emissions of CO2, research is currently investigating new materials for the building sector. The main purpose is the reduction in the embodied energy consumption, especially in the residential sector, and consequently the limitation of the direct and indirect utilization of fossil fuels, for the indoor heating, cooling, and ventilation services. Indeed, the residential sector is affected by a high energy demand, thus the choice of improved materials is fundamental to improve the sustainability. All phases: construction, building life, and dismantling are impacting in terms of resource and energy consumption, both associated with the emissions of pollutants in the atmosphere. The aim of this experimental research is to study the thermal insulation and the acoustic absorption of a material composed by natural lime, water, and shives from sativa hemp, a variety of hemp usable for industrial applications. In order to assess the main characteristics of this material, some specimens have been made according to required shapes and sizes to test them in specific machines. The results obtained from the tests are compared with the values of similar lime-based materials already available on the market. The comparison shows how, in certain aspects, the lime and hemp shives materials represent a concrete alternative to conventional materials. This completely natural material would like to achieve thermal and acoustic comfort in indoor environments.

1. Introduction

The adoption of energy saving approaches in the construction sector is called “green building” [1]. In fact, this term is associated with the philosophy, techniques, science, and know-how related to the saving of energy and resources used from “cradle to grave” of a building [2]. The concept was introduced in Europe by the “Directive on the energy performance of buildings” (2010/31/EU) and implemented in subsequent years by all European countries [3]. In Italy, it was converted into law n. 90/2013 [4]. In order to develop this construction technique, it was decided to create a database of case studies. In this way, useful guidelines are created to design and build ever more efficient buildings [5].

Embodied energy reduction allows to preserve the environment by reducing climate-changing emissions substances such as CO2 [6]. Among the techniques used for this purpose there are: using waste materials from other sectors, recycled materials [7], natural materials [8], and renewable energy [9]. The use of plant-based materials is considered a technique with many future implications in the environmental acoustics sector. These products have cost, weight, and sound absorption characteristics comparable with traditional materials [10].

In addition to the engineering characteristics, innovative materials must be able to make the environment comply with the specifications required by the standards. In Italy, the decree 5 December 1997 of the President of the Council of Ministers dictated the guidelines that a building must possess to comply. From an acoustic point of view, it must guarantee that it has passive acoustic requirements, such as reverberation time [11] and soundproofing power of elements separating rooms [12].

The “green” material creation composed of bio-lime and shives has the purpose of challenging the materials traditionally used in the thermal insulation and sound absorption fields. These materials, such as traditional insulating mortars, rock wool and various kinds of polyurethanes, are highly impactful in their construction and therefore the ideal would be to replace them with materials that have a significantly lower embodied energy, that represents the energy used throughout the entire life cycle of a good or service [13,14]. From this point of view, the material object of the study is much less impactful than a mortar commonly available on the market. This theory is reinforced by the fact that hemp is a plant that, during its life cycle, absorbs CO2 and transforms it into oxygen. Therefore, the compound under examination generates a lower amount of CO2eq than a traditional mortar [15].

The material that is the object of the study has the great advantage of being able to be used in the restoration of heritage buildings [16]. Both natural hydraulic lime and hemp are considered to be materials with the technical and chemical-physical specifics that are required by heritage building. Thanks to the absence of harmful materials, such as water-soluble salts, the mixture in lime and shives is safe and respectful of the ancient constructions. The clinker-based cement, despite having a great structural capacity, does not possess the qualities of a natural material, therefore it is not usable [17].

Sustainable restoration involves the use of materials, compatible with those already present in the building, which are long-lasting and recyclable in the future [18]. Natural lime and shives respect these specifics, thence they can be adopted. Another positive aspect related to a possible use of this material is related to its flammability class which, according to UNI EN 13501-1 of 2019 [19], is classified in the A1 category (incombustible material), like traditional insulators.

There are some studies based on the same topic in the literature [20,21,22,23]. Hamzaoui et al. recently investigated the mechanical performance of mortar, considering the addition of hemp [20]. The paper reveals that the addition of shives or fibres produces a reduction in the mechanical performance of the material, while the addition of milled fly ashes shows benefits for the compressive and flexural performance. Çomak et al. investigated the mechanical performance due to the addition of hemp fibres in a cement-based mortar, obtaining similar results [21].

The heat conductivity of a hemp–lime composite material has been recently assessed by Pochwala et al., reporting interesting values for the building insulation [22].

The physical and mechanical properties of composites based on hemp shives and lime have been assessed by Przemysław Brzyski and Grzegorz Łagód in [23]. In detail, mechanical, thermal, and hygroscopic tests have been carried out on lime and hemp shives-based specimens. In addition, in this case it has been shown that the values are influenced by the relationship between the two mixed products. If the presence of the filler increases, the thermal characteristics improve, and the mechanical and hygroscopic ones worsen. This study encourages the adoption of this type of material thanks to the good thermal characteristics that are obtained by increasing the percentage of hemp shives. A substantial increase can only be accepted if there are no structural strength problems. In fact, the mixture must be used as an insulator placed on a supporting structure.

According to the authors’ knowledge, an integrated study assessing the mechanical, thermal, and acoustic properties of this kind of material is necessary for practical applications. Thence, this paper focuses on the realization of three types of specimens by varying shives percentage and then testing them mechanically (flexion and compression), thermally (thermal conductivity coefficient λ) and acoustically (sound absorption coefficient α). The results obtained from the experimental test have been compared with the values present in the literature of materials commonly available on the market, highlighting the differences, the advantages, and the critical points.

Shives: Role in Construction

The benefits obtainable from hemp use are variegated [24]. As an example, its presence guarantees humidity control, due to its hygroscopicity, which allows it to accumulate and release humidity and consequently guarantee good hygrometric conditions in the environment. As an example, glass wool and classic materials do not have this property [25].

In the treatment of the thermal conductivity coefficient, it is necessary to examine the thermal bridges generated in the various areas of the building. This aspect has been studied on various composite materials obtained with a hemp base. Thermal bridges, such as external edges and windows in the wall, are very common and present in every building structure. In both cases, it has been obtained that, with the appropriate construction strategies, such as the accurate stratigraphy of the wall and the presence of wooden elements, thermal bridges can be managed, limiting the heat dispersion [26].

Therefore, the adoption of new materials, such as the hemp–lime composite, requires the realization of specific tests, in order to verify the correct thermal insulation and sound absorption [27]. The possibility of making bricks has been also studied [28,29]. They guarantee greater massiveness than a panel of less thickness. This technique has shown that the load-bearing structure itself guarantees acoustic comfort without further intervention on the wall stratigraphy [30].

From the thermal point of view, there are many studies that affirm the good response of composed material of lime and hemp shives [24,31]. As the material density decreases, the thermal conductivity coefficient decreases as well and, therefore, the wall thermal performance improves. At the same time, there is a limit due to the mechanical strength of the compound. Therefore, an appropriate compromise must be found between mechanical resistance and thermal insulation [32].

2. Materials and Methods

The compound here considered was made with natural products. The matrix is a white Natural Hydraulic Lime NHL 3.5 according to the UNI EN 459-1 classification [33]. This lime does not contain clinker or cement. Water is used as binder. This type of lime has a low environmental impact since it has a long-life cycle and can be recycled to create new mortars [34].

The filler is shives, obtained by the woody part of the hemp plant without psychotropic effects. The European Industrial Hemp Association (EIHA) reports growing values regarding its cultivation in European territory. This growth is linked to the diffusion of its use in industrial fields, such as textiles, food and construction [35]. In Italy, the cultivation and processing of hemp is regulated by law n. 242 of 2 December 2016 [36].

The experimental protocol focused on the creation of specimens necessary to establish the mechanical, thermal, and acoustic characteristics of the material being tested. The study was divided into three phases:

- Preliminary analysis and material preparation

- Screening and specimen’s preparation

- Experimental tests

2.1. Preliminary Analysis and Material Preparation

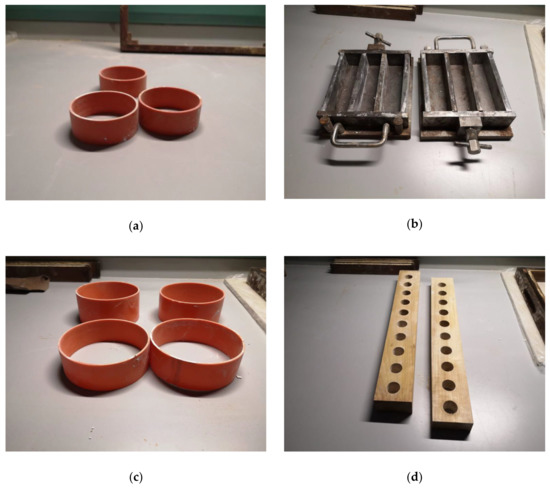

In this phase, all the templates necessary for the specimen’s realization were found. Below are the templates (Figure 1) to make thermal tests, mechanical tests, and acoustic tests.

Figure 1.

Templates for making specimens. (a) Templates for thermal specimens; (b) Templates for mechanical specimens; (c) Templates for acoustic specimens Φ = 100 mm; (d) Templates for acoustic specimens Φ = 28 mm.

In this phase, the devices necessary for testing were prepared:

- Electronic scale;

- Tray to calculate apparent density;

- Shredder RETSCH SM 100 with 2 mm screen;

- Dough utensils.

Therefore, the shives were shredded from 6 mm to 2 mm, so it was evenly distributed in specimens, especially in the smaller ones. Finally, the volume of all templates was calculated. In this way, in the screening phase, it was possible to calculate the matrix/filler ratio.

2.2. Screening and Specimen’s Preparation

In this phase, the characteristics of the specimens were assessed. It was decided to create three different types of material by changing the volume percentage of shives in the compound, namely 5%, 10%, 20%. In all three cases, the mass of water was equal to half of the mass of lime. These concentrations were chosen by considering the most common mixes available in the literature and other previous studies realized at the Department of Engineering of Palermo University [24,28,32,37].

Once the screening phase was over, the specimens were made in the laboratory “for indoor environments and sustainable technologies” of the Engineering Department. The doughs were made to fill the templates to be used. The specimens were classified with the notation “XX-Φ-%-S”, assuming that:

- XX: indicates the test type to which the sample will be subjected; PA (acoustic test, Prova Acustica in Italian), PT (thermal test, Prova Termica), PM (mechanical test, Prova Meccanica).

- Φ: specimen’s diameter (millimetres). This parameter is omitted in the specimens for mechanical tests because they are parallelepiped.

- %: hemp shives percentage.

- S: specimen’s thickness (centimetres). This parameter is omitted in the specimens for mechanical tests since the thickness variation is not necessary for the study.

Thence, when there is only one number after the type of test (PM, PA, PT), only the percentage of hemp shives was indicated, since diameter and thickness do not affect the tests.

Knowing the lime and shives’ density and specimen’s volume, it was possible to calculate the mass of total dough necessary to create all the specimens for each single percentage. These mass values for each percentage are reported in Table 1.

Table 1.

Mass compound to create specimens with different hemp shives percentage.

According to the Italian legislation (DM 17 January 2018) [38], the compound must mature for 28 days. The specimens were disarmed 4 days after the realization (see Figure 2), weighed and left to rest until the twenty-eighth day. On the last day, they were weighed again to evaluate the weight percentage loss due to the water evaporation (see data reported in Table 2, Table 3 and Table 4). The environment thermo-hygrometric conditions during weighing were:

Figure 2.

Specimens disarmed (5%, 10% and 20%, respectively).

Table 2.

Weight variation during maturation of hemp shives specimens for the thermal test.

Table 3.

Weight variation during maturation of hemp shives specimens for the mechanical test.

Table 4.

Weight variation during maturation of hemp shives specimens for the acoustic test.

- Temperature: 24 ± 2 °C

- Relative humidity: 50–60%

- To make the table easier to be read, it is necessary to consider that:

- In order to have more truthful values after the experimental tests, it was decided to create more specimens of the same type and mediate the results.

- The mechanical test specimens are parallelepipeds, 16 cm long, 4 cm high and 4 cm wide. Thence, in their nomenclature both geometric parameters are omitted.

All specimens are subject to weight loss, depending on the shape of the specimens and the hemp percentage. In fact, the weight reduction is between 17 and 27%, except the specimens for high frequency acoustic tests (Φ = 28 mm), which were affected by a limited weight reduction between 6 and 8%. In these smaller specimens, there is less hemp in absolute value and therefore a smaller weight variation compared to larger specimens in which there is much more hemp. The weight loss is only due to the evaporation of the water contained in the specimens; in fact, the thickness of the specimens has not significantly changed. Table 2, Table 3 and Table 4 report data on weight variation for thermal, mechanical, and acoustic specimens, respectively, indicating the average value and the standard deviation.

2.3. Experimental Tests

In this section, the results from the acoustic, thermal, and mechanical tests are reported, considering the three different mixes of hemp and lime.

2.3.1. Acoustic Tests

The tests were carried out in the acoustic laboratory located in the Engineering Department. Following the UNI EN ISO 10534-2 standard [39], the acoustic absorption of specimens was tested using Kundt tubes. The device is made up of two cylinders, having different diameters (100 and 28 mm). The largest one measures the sound absorption coefficient (α) in the frequency range from 100 to 1600 Hz. The smallest one measures in the range from 500 to 10,000 Hz. The main specifics of the Kundt’s tube are reported in Table 5 [40].

Table 5.

Specifics of Kundt’s tubes for the acoustic tests.

The test is based on white noise emission that hits the specimen perpendicularly. The specimen attenuates the incident wave, turning it into heat. Thus, the device measures its sound absorption capacity. Although a different test should be performed (for example according to UNI EN ISO 717-2 or ISO 140-12) to evaluate the transmission coefficient, if the material presents a high absorption coefficient, the transmission coefficient is consequently limited, also allowing good performance for the acoustic insulation of impact sounds [41].

The “dBAlphaTest” software, connected to the tube, returns the sound absorption coefficient trend. Among the obtained results, it can be noted that, as the shives percentage increases, α improves following a non-linear trend.

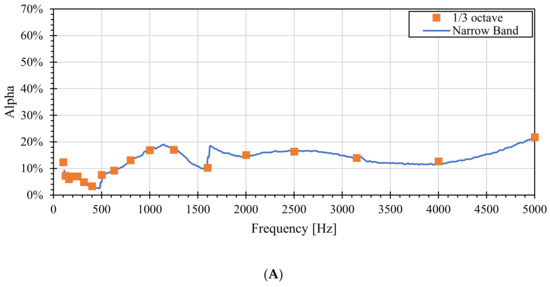

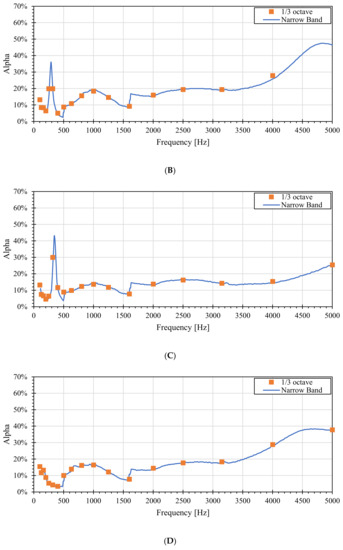

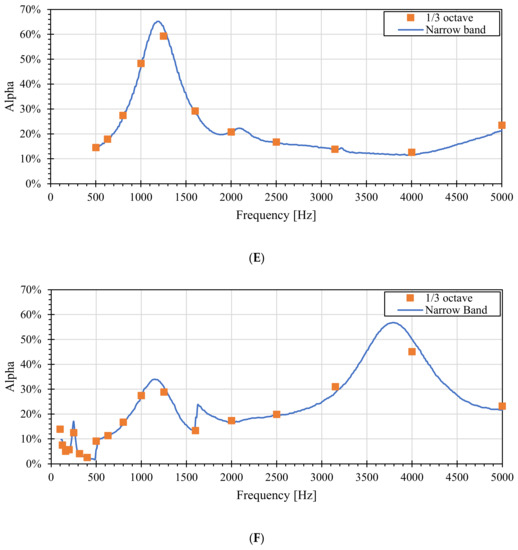

During the experimentation, all specimens, both 3 cm and 4 cm, were tested in the Kundt’s tube. To compare the material acoustic response to the variation of the fibre percentage, a graph is given for each type (see Figure 3A–F).

Figure 3.

(A) PA-5-3 in narrow band and 1/3 octave; (B) PA-5-4 in narrow band and 1/3 octave; (C) PA-10-3 in narrow band and 1/3 octave; (D) PA-10-4 in narrow band and 1/3 octave; (E) Best result, PA-20-3 in narrow band and 1/3 octave; (F) PA-20-4 in narrow band and 1/3 octave.

The 20% specimens have the best absorption coefficient compared to the others. This result is due to the greater presence of hemp shives, which favours the transformation of the sound wave into thermal energy. For domestic use, the trend of the material at 20% hemp shives and 3 cm thickness is preferred (Figure 3E). This because it reaches a peak of 65% around 1000 Hz, which is comparable to the speech range, i.e. the dominant frequency in domestic environments.

2.3.2. Thermal Tests

The thermal measurements were carried out in the laboratory for “indoor environments and sustainable technologies” of the Engineering Department. The standards ISO 8301:1991 [42], ASTM C518-17 [43], UNI EN 12667:2002 [44] and UNI EN 12664:2002 [45] were followed.

The FOX 50 device was used to derive the material thermal conductivity coefficient. The main specifics are reported in Table 6 [46].

Table 6.

Specifics of FOX 50 for the thermal tests.

A temperature difference is set between the device plates, in this case 15 °C. This generates a thermal flow that passes through the specimen; therefore, it is possible to measure its thermal insulation capacity , according to Equation (1).

where is the thickness of the specimen and the surface orthogonal to the thermal flow. The tests were repeated three times for each specimen to obtain averaged values over multiple trials. As expected, if the shives percentage increases, the apparent density decreases and the thermal insulation capacity improves, as reported in Table 7.

Table 7.

Thermal test results for the three types of specimens.

2.3.3. Mechanical Tests

The mechanical tests have the aim of studying the compression and bending material resistance. These characteristics worsen as the shives content grows, thence a right compromise must be found. This phase was performed in the “materials and structures” laboratory of the Engineering Department in Palermo University. The standard UNI EN 1015-11 was followed for these tests [47]. The bending test was performed by using the “Zwick/Roell Z005” machine, which breaks the specimen through a concentrated load in the middle, setting the load cell at 5 kN. The specifics of Zwick/Roell Z005 machine are reported in Table 8 [48].

Table 8.

Specifics of Zwick/Roell Z005 for the bending test.

During the mechanical test, “testXper II” software drew the graph showing the trend of the lowering as a function of the load. These values were converted to bending strength, . (Equation (2)), and deformation, . (Equation (3)):

where:

- is the maximum load applied to the specimen, in Newton.

- is the distance between the support rollers, in millimetres.

- is the width of specimen, in millimetres.

- is the thickness of the specimen, in millimetres.

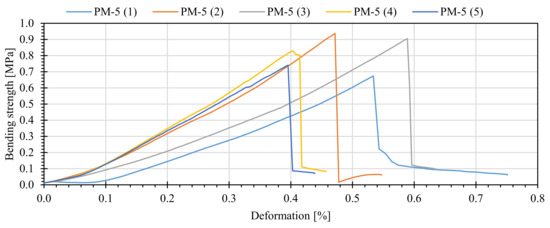

Figure 4.

Bending strength PM-5.

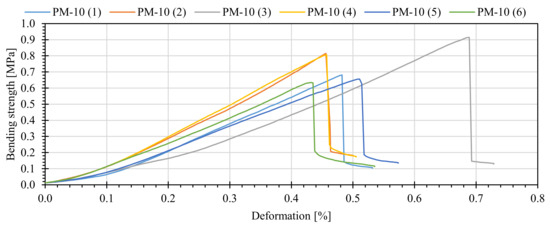

Figure 5.

Bending strength PM-10.

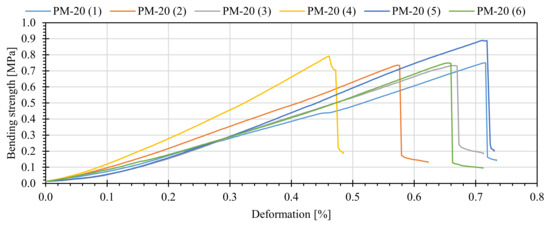

Figure 6.

Bending strength PM-20.

The results obtained show that the greatest resistance was recorded in the case of the 5% shives material (Figure 4).

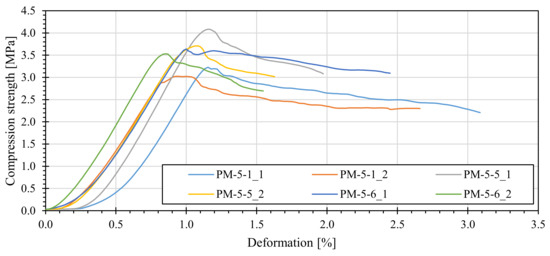

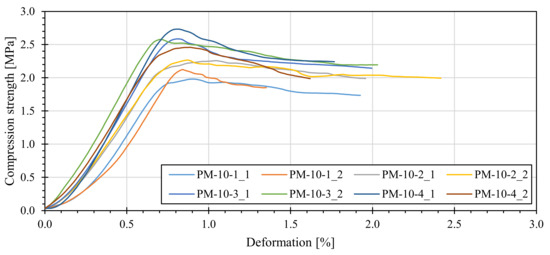

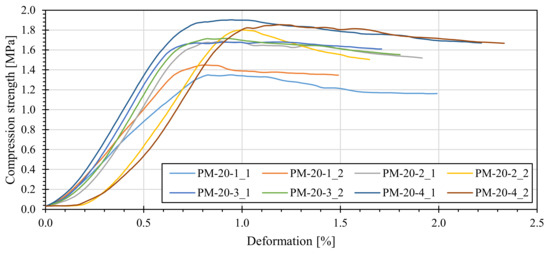

Subsequently, the compression test was carried out using the two parts obtained from the bending test. Following the same procedure, with “TestPilotETM” software, the values of the load impressed in relation to the lowering are obtained. In the same way of the previous test, the parameters are converted into compression strength, , and deformation, . In detail, the compression strength is given by Equation (4):

where is maximum force measured during the test and the surface calculated as the product of the specimen thickness and the machine support. The compression stresses trends for specimens at 5% (Figure 7), 10% (Figure 8) and 20% (Figure 9) are shown below.

Figure 7.

Compression strength PM-5.

Figure 8.

Compression strength PM-10.

Figure 9.

Compression strength PM-20.

In particular, the graph with the trend of the specimens at 5% shows the values of compressive strength higher than the other two percentages. Here the tested specimens are six and not eight because two accidentally broke after the bending tests.

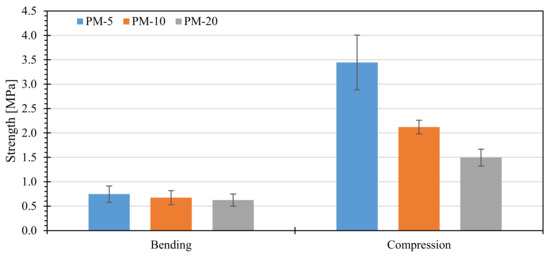

To get an overview, all the mechanical results have been brought together in a single diagram, for bending and compression, where the average values by percentage are shown (Figure 10).

Figure 10.

Average bending and compression strength by percentage.

3. Conclusions

An experimentation on this type of topic makes it possible to deal with very current issues such as green building and environmental sustainability. Bio-lime and shives lend themselves well to supporting this topic, being of natural origin and recyclable. Analysing the mixture from an ecological point of view, it turns out that the union of these two natural materials gives benefits: to the environment, because the hemp plant during its life transforms CO2 into oxygen, thus removing it from the air. The union of lime and hemp gives benefits to the indoor environment because it returns it to healthiness. In fact, lime is often referred to as a “hygrometric lung” of a home, because its high vapor permeability facilitates the transfer of humidity and prevents the development of condensation inside the environment. Thus, mould does not develop, which can be harmful to the occupant’s health [49]. Its union with the shives gives birth to a material that can be used in a delicate sector such as that of restoration of heritage buildings.

This aspect combines the need to modernize an ancient structure with the need to make it energetically efficient. In fact, the values of thermal conductivity coefficient between 0.05 and 0.1 W/m are acceptable to achieve good energy savings compared to a non-thermally insulated structure.

We have chosen to compare the values obtained from the experimental study with those of some lime-based plasters that are currently on the market (Table 6). The comparison considers materials that can be used to create the surface layer of the walls, where otherwise the insulating material would be applied in existing buildings.

The values reported in Table 9 reveal that the mixture in shives lime gives comparable thermomechanical characteristics, and in some cases even better than the products already on the market. The study carried out has shown that the increase in percentage of hemp shives in the mixture allows it to have a material with good performances. As expected, before the thermal test, as the percentage of filler increases, the thermal conductivity decreases more. This improves the insulating effect. This claim is supported by the fact that λ values of 0.01 W/mK are found in the literature. As regards the sound absorption values, it has been shown that they increase as the percentage of hemp shives increases. The material, subject of the evaluation, compared to commercial mortars is often superior, like Table 9 shown.

Table 9.

Comparison with plasters on the market.

The results here reported encourage the development of this kind of material, due to its good thermal, mechanical and acoustic properties. There is room for further improvements of all characteristics, considering for example the sizes of hemp shives and their ratio in the mix. Future works will consider the effects on the thermal and acoustic properties due to different levels of environmental humidity, as well as the evaluation of the fire resistance performance, which is an important aspect, especially for heritage buildings.

Author Contributions

Conceptualization, V.F. and A.G.; methodology, V.F. and A.G.; software, A.G.; validation, A.G. and D.C.; formal analysis, V.F. and A.G.; investigation, A.G. and D.C.; resources, V.F.; data curation, A.G. and D.C.; writing—original draft preparation, A.G. and D.C.; writing—review and editing, A.G., D.C. and V.F.; visualization, D.C.; supervision, V.F. and D.C.; project administration, V.F.; funding acquisition, V.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| CO2 | Carbon dioxide |

| CO2eq | Carbon dioxide equivalent |

| NHL | Natural hydraulic lime |

| PA | Acoustic test specimens |

| PM | Mechanical test specimens |

| PT | Thermal test specimens |

| Acoustic absorption coefficient | |

| Surface calculated as the product of the specimen thickness and the machine support | |

| The width of specimen | |

| Diameter | |

| Temperature difference | |

| Deformation | |

| Depth of the specimen | |

| Compression strength | |

| Flexural strength | |

| Maximum load during the test | |

| Thermal insulation coefficient | |

| Distance between the support rollers | |

| Thickness |

References

- Gupta, A. Building a Green Home Using Local Resources and Sustainable Technology in Jammu Region—A Case Study. Energy Procedia 2017, 115, 59–69. [Google Scholar] [CrossRef]

- Cole, L.B. Green building literacy: A framework for advancing green building education. Int. J. Stem Educ. 2019, 6, 18. [Google Scholar] [CrossRef]

- European Commission. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings (recast). Off. J. Eur. Union 2010, L 153, 13–35. [Google Scholar]

- Presidente della Repubblica Italiana. LEGGE 3 Agosto 2013, n. 90. Conversione in Legge, con Modificazioni, del Decreto-Legge 4 Giugno 2013, n. 63, Recante Disposizioni Urgenti per il Recepimento Della Direttiva 2010/31/UE del Parlamento Europeo e del Consiglio del 19 Maggio 2010, Sulla Prestazione Energetica Nell’edilizia per la Definizione Delle Procedure D’infrazione Avviate Dalla Commissione Europea, Nonché Altre Disposizioni in Materia di Coesione Sociale; Gazzetta Ufficiale della Repubblica Italiana (13G00133): Rome, Italy, 2013.

- Becchio, C.; Buonomano, A.; Cappelletti, F.; Corgnati, S.P.; Mora, T.D.; Palombo, A.; Peron, F.; Romagnoni, P. Towards nZEBs: Experiences in Italy. In Proceedings of the 12th Rehva World Congress—Clima 2016, Aalborg, Denmark, 22–25 May 2016; Volume 10, pp. 1–10. [Google Scholar]

- Banteli, A.; Stevenson, V.E. Building information modelling (BIM) as an enabler for whole-building embodied energy and carbon calculation in early-stage building design. WIT Trans. Built Environ. 2017, 169, 89–100. [Google Scholar] [CrossRef]

- Saccani, A.; Manzi, S.; Lancellotti, I.; Lipparini, L. Composites obtained by recycling carbon fibre/epoxy composite wastes in building materials. Constr. Build. Mater. 2019, 204, 296–302. [Google Scholar] [CrossRef]

- Ouda, A.S.; Gharieb, M. Development the properties of brick geopolymer pastes using concrete waste incorporating dolomite aggregate. J. Build. Eng. 2020, 27, 100919. [Google Scholar] [CrossRef]

- Asim, M.; Uddin, G.M.; Jamshaid, H.; Raza, A.; ul Rehman, Z.; Hussain, U.; Satti, A.N.; Hayat, N.; Arafat, S.M. Comparative experimental investigation of natural fibers reinforced light weight concrete as thermally efficient building materials. J. Build. Eng. 2020, 31, 101411. [Google Scholar] [CrossRef]

- Zhu, X.; Kim, B.J.; Wang, Q.W.; Wu, Q. Recent advances in the sound insulation properties of bio-based materials. BioResources 2014, 9, 1764–1786. [Google Scholar] [CrossRef]

- Ente Italiano di Normazione (UNI). UNI EN ISO 3382-1 Acoustics. Measurement of Room Acoustic Parameters. Part 1: Performances Spaces; Ente Italiano di Normazione (UNI): Milan, Italy, 2010. [Google Scholar]

- Ente Italiano di Normazione (UNI). UNI EN ISO 16283-1. Acoustics—Field Measurement of Sound Insulation in Buildings and of Building Elements—Part. 1: Airborne Sound Insulation; Ente Italiano di Normazione (UNI): Milan, Italy, 2018. [Google Scholar]

- Taffese, W.Z.; Abegaz, K.A. Embodied energy and CO2 emissions of widely used building materials: The Ethiopian context. Buildings 2019, 9, 136. [Google Scholar] [CrossRef]

- Lin, L.; Fan, Y.; Xu, M.; Sun, C. A decomposition analysis of embodied energy consumption in China’s construction industry. Sustainability 2017, 9, 1583. [Google Scholar] [CrossRef]

- Reilly, A.; Kinnane, O. The Thermal Behaviour and Embodied Energy of Hemplime Construction. In Proceedings of the International Conference for Sustainable Design of the Built Environment (SDBE), London, UK, 20–21 December 2017. [Google Scholar]

- Dai, S. Building limes for cultural heritage conservation in China. Herit. Sci. 2013, 1, 25. [Google Scholar] [CrossRef]

- Kang, S.H.; Lee, S.O.; Hong, S.G.; Kwon, Y.H. Historical and scientific investigations into the use of hydraulic lime in Korea and preventive conservation of historic masonry structures. Sustainability 2019, 11, 5169. [Google Scholar] [CrossRef]

- Corradi, M. Naturalis materia vs. materiali innovativi. In Proceedings of the Estratti del 30° Convegno di Studi Scienza e Beni Culturali, Brixen, Italy, 1–4 July 2014. [Google Scholar]

- Ente Italiano di Normazione (UNI). UNI EN 13501-1. Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests; Ente Italiano di Normazione (UNI): Milan, Italy, 2019; p. 48. [Google Scholar]

- Hamzaoui, R.; Guessasma, S.; Abahri, K. Mechanical performance of mortars modified with hemp fibres, shives and milled fly ashes. In Proceedings of the 2nd International RILEM/COST Conference on Early Age Cracking and Serviceability in Cement-based Materials and Structures—EAC2, Brussels, Belgium, 12–14 September 2017. [Google Scholar]

- Çomak, B.; Bideci, A.; Salli Bideci, Ö. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Pochwała, S.; Makiola, D.; Anweiler, S.; Böhm, M. The heat conductivity properties of hemp-lime composite material used in single-family buildings. Materials 2020, 13, 1011. [Google Scholar] [CrossRef]

- Brzyski, P.; Lagód, G. Physical and mechanical properties of composites based on hemp shives and lime. In Proceedings of the 7th Conference SOLINA Sustainable Development: Architecture—Building Construction—Environmental Engineering and Protection Innovative Energy-Efficient Technologies—Utilization of Renewable Energy Sources, Solina, Poland, 19–23 June 2018. [Google Scholar]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. A review of the factors affecting the properties and performance of hemp aggregate concretes. J. Build. Eng. 2020, 31, 101323. [Google Scholar] [CrossRef]

- Agliata, R.; Gianoglio, S.; Mollo, L. Hemp-lime composite for buildings insulation: Material properties and regulatory framework. Vitr. Int. J. Archit. Technol. Sustain. 2019, 4, 48. [Google Scholar] [CrossRef]

- Grudzińska, M.; Brzyski, P. The Occurrence of Thermal Bridges in Hemp-Lime Construction Junctions. Period. Polytech. Civ. Eng. 2019, 63, 377–387. [Google Scholar] [CrossRef]

- Fiala, L.; Konrád, P.; Fořt, J.; Keppert, M.; Černý, R. Application of ceramic waste in brick blocks with enhanced acoustic properties. J. Clean. Prod. 2020, 261, 121185. [Google Scholar] [CrossRef]

- Danso, H.; Manu, D. Influence of coconut fibres and lime on the properties of soil-cement mortar. Case Stud. Constr. Mater. 2020, 12, e00316. [Google Scholar] [CrossRef]

- Javed, U.; Khushnood, R.A.; Memon, S.A.; Jalal, F.E.; Zafar, M.S. Sustainable incorporation of lime-bentonite clay composite for production of ecofriendly bricks. J. Clean. Prod. 2020, 263, 121469. [Google Scholar] [CrossRef]

- Kinnane, O.; Reilly, A.; Grimes, J.; Pavia, S.; Walker, R. Acoustic absorption of hemp-lime construction. Constr. Build. Mater. 2016, 122, 674–682. [Google Scholar] [CrossRef]

- Balciunas, G.; Vejelis, S.; Lekunaite, L.; Kremensas, A. Assessment of structure influence on thermal conductivity of hemp shives composite. Environ. Eng. Manag. J. 2016, 15, 699–705. [Google Scholar] [CrossRef]

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G.; Scaccianoce, G.; Sorrentino, G. Thermal and structural properties of a hemp–lime biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

- Ente Italiano di Normazione (UNI). UNI EN 459-1:2015. Building Lime. Part 1: Definitions, Specifications and Conformity Criteria; Ente Italiano di Normazione (UNI): Milan, Italy, 2016. [Google Scholar]

- Moropoulou, A.; Koroneos, C.; Karoglou, M.; Aggelakopoulou, E.; Bakolas, A.; Dompros, A. Life cycle analysis of mortars and its environmental impact. MRS Proc. 2005, 895, 0895-G06-02. [Google Scholar] [CrossRef]

- European Industrial Hemp Association. Hemp and Agriculture. Report of 2018 Campaign; European Industrial Hemp Association: Wolfsburg, Germany, 2020. [Google Scholar]

- Presidente della Repubblica Italiana. Legge n. 242 del 2 Dicembre 2016. Disposizioni per la Promozione Della Coltivazione Agroindustriale Della Canapa; Gazzetta Ufficiale della Repubblica Italiana (16G00258): Rome, Italy, 2016.

- Arizzi, A.; Brümmer, M.; Martín-Sanchez, I.; Cultrone, G.; Viles, H. The influence of the type of lime on the hygric behaviour and bio-receptivity of hemp lime composites used for rendering applications in sustainable new construction and repair works. PLoS ONE 2015, 10, e0125520. [Google Scholar] [CrossRef]

- Italian Ministry for Infrastructures and Transport Norme Tecniche per le Costruzioni. DM 17/1/2018; Gazzetta Ufficiale della Repubblica Italiana (18A00716): Rome, Italy, 2018.

- Ente Italiano di Normazione (UNI). UNI EN ISO 10534-2:2001. Determination of Sound Absorption Coefficient and Impedance in Impedances Tubes. Transfer Function Method; Ente Italiano di Normazione (UNI): Milan, Italy, 2001. [Google Scholar]

- S.C.S. Controlli e Sistemi S.r.l. Acoustic Material Properties Measurement System. SCS9020B/K—Kundt/T60/TL Tubes; S.C.S. Controlli e Sistemi: Padua, Italy, 2005. [Google Scholar]

- Kumar, S.; Lee, H. The Present and Future Role of Acoustic Metamaterials for Architectural and Urban Noise Mitigations. Acoustics 2019, 1, 590–607. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). ISO 8301:1991. Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus; ISO: Geneva, Switzerland, 1991. [Google Scholar]

- ASTM. ASTM C518-17. Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Ente Italiano di Normazione (UNI). UNI EN 12667:2002. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Products of High and Medium Thermal Resistance; Ente Italiano di Normazione (UNI): Milan, Italy, 2002. [Google Scholar]

- Ente Italiano di Normazione (UNI). UNI EN 12664:2002. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Dry and Moist Products of Medium and Low Thermal Resistance; Ente Italiano di Normazione (UNI): Milan, Italy, 2002. [Google Scholar]

- TA Instruments. Thermal Conductivity Instruments. 2015. Available online: http://www.tainstruments.com/wp-content/uploads/BROCH-LC-2015-EN.pdf (accessed on 18 June 2020).

- Ente Italiano di Normazione (UNI). UNI EN 1015-11:2019. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Comprensive Strength of Hardened Mortar; Ente Italiano di Normazione (UNI): Milan, Italy, 2019. [Google Scholar]

- Zwich Roell. Product Information: ProLine Table-Top Machines Z005 up to Z100. Available online: https://www.zwickroell.com/-/media/files/sharepoint/vertriebsdoku_pi/02_375_proline_z005_up_to_z100_materials_testing_machine_pi_en.pdf (accessed on 18 June 2020).

- Cazacu, C.; Muntean, R.; Gălățanu, T.; Taus, D. Hemp Lime Technology. Bull. Transilv. Univ. Braşov Bullet 2016, 9, 19–24. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).