Optimal Design of IPMSM for FCEV Using Novel Immune Algorithm Combined with Steepest Descent Method

Abstract

:1. Introduction

2. Conventional Immune Algorithm

- Problem definition: Objective function and restrictions are defined.

- Generation of antibody: Initial antibodies are generated randomly in the problem region and initial memory cells are selected according to antibody-antigen affinity. When the algorithm is applied to find peaks, the antibody-antigen affinity of an antibody (v) is defined as follows:If the aim of the algorithm is minimization, antibody-antigen affinity is defined as:where curv is the objective function value.

- Expectation calculation: The expectation of each antibody is calculated and antibodies with low expectations are removed. The expectation of antibody (i) is calculated as follows:where ci is the concentration, which is defined as the number of antibodies having the similar value as antibody (i), divided by the total number of antibodies. Figure 2 and Table 1 show how expectation works in the algorithm. When the value of B and D is considered as similar, the concentration of A and C is low, and concentration of B and D is relatively high. Therefore, the expectation is calculated as listed in Table 1, and you can figure out that the local peak A is more likely to survive than B or D.

- Crossover, mutation: The antibody group is updated by replacing removed antibodies. Mutants are randomly generated in the entire problem area and crossover is done by the antibodies remaining from step 3.

- Affinity calculation: The antibody-antigen affinity of the new antibody group is calculated with (3). Additionally, the antibody-antibody affinity of the memory cell is calculated as follows:where distv,w is the distance between newly generated antibody (v) and antigen (w). Antigens are entities involved in the memory cells. With this step, antibodies near the memory cells are candidates of elimination, enhancing the ability to find unknown areas.

- Memory cell renewal: Cells with high antibody-antibody affinity in memory cells are removed, and antibodies with high antibody-antigen affinity are added to the memory cell.

- Convergence check: If the value of the memory cell group is not changed by N iteration, it is judged that the convergence condition is satisfied, and the algorithm terminates and the optimal solutions are saved to the memory cell. If the convergence condition is not satisfied, each step is repeated from step 4, and the algorithm proceeds.

3. Proposed Algorithm

3.1. Multi-Jittered Sampling

3.2. Hybrid Steepest Descent Method

3.3. Antibody Radius

3.4. Flow Chart of the NIA

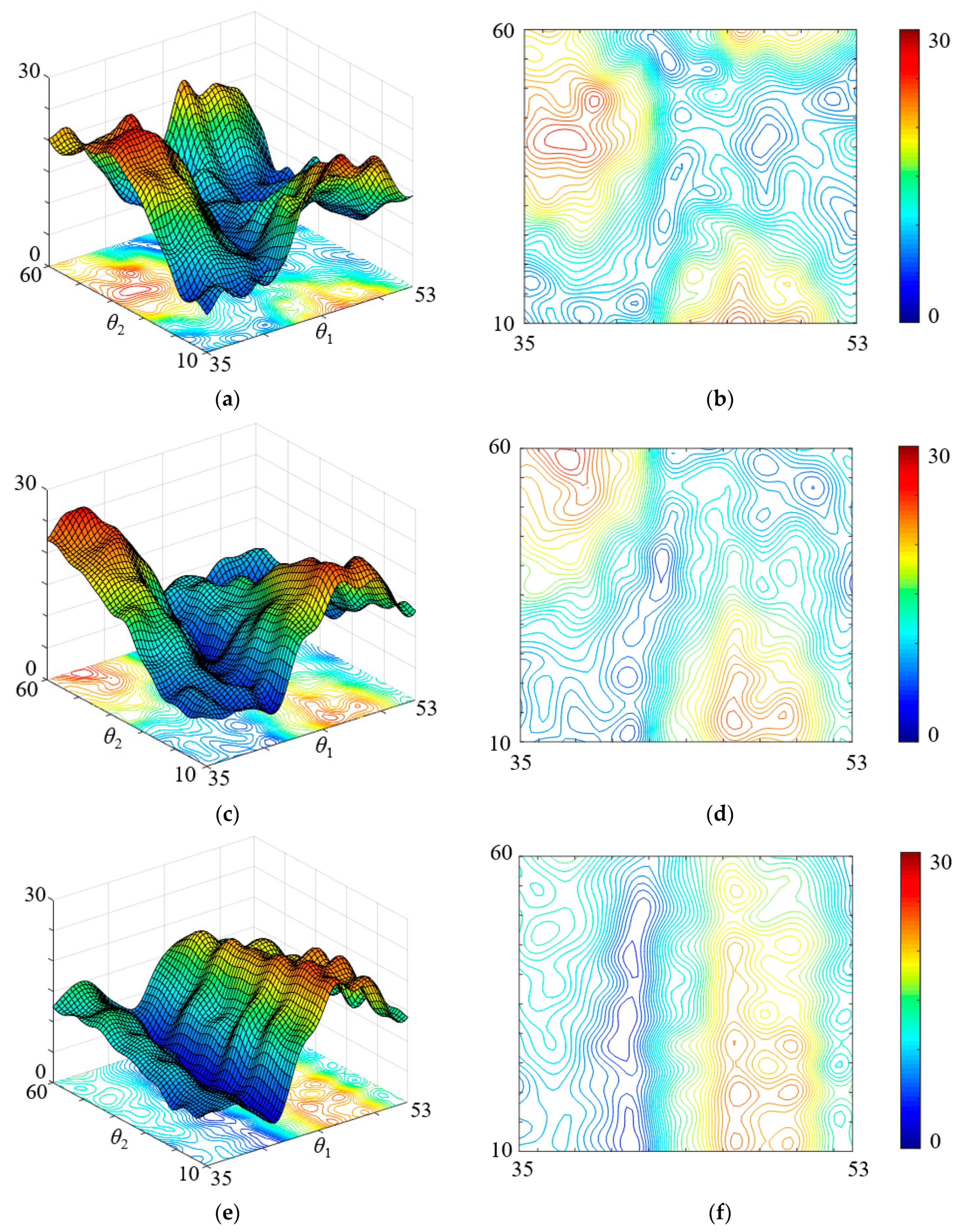

3.5. Verification of the Proposed Algorithm

4. Application to the Optimal Design of IPMSM for FCEV

4.1. Analysis Model and Design Variables

4.2. Optimization Results

4.3. Result Analysis of Optimum Design

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Ho, S.L.; Fu, W.; Zhang, X. Design Optimization of a Novel Doubly Fed Dual-Rotor Flux-Modulated Machine for Hybrid Electric Vehicles. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Zheng, P.; Liu, Y.; Wang, Y.; Cheng, S. Magnetization analysis of the brushless DC motor used for hybrid electric vehicle. IEEE Trans. Magn. 2005, 41, 522–524. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Gan, C.; Sun, Q.; Kong, W. Efficiency Optimization of PMSM Drives Using Field-Circuit Coupled FEM for EV/HEV Applications. IEEE Access 2018, 6, 15192–15201. [Google Scholar] [CrossRef]

- Li, H.; Zhang, X.; Yang, S.; Li, E.; Hong, J. Multi-Objective Controller Design of IPMSM Drives Based on DTD D-Partition Method Considering Parameters Uncertainties. IEEE Trans. Energy Convers. 2018, 34, 1052–1062. [Google Scholar] [CrossRef]

- Yin, Q.; Li, H.; Luo, H.; Wang, Q.; Xu, C. An Improved Sensorless Vector Control Method for IPMSM Drive with Small DC-Link Capacitors. Energies 2020, 13, 580. [Google Scholar] [CrossRef] [Green Version]

- Seo, J.-H.; Woo, D.-K.; Chung, T.-K.; Jung, H.-K. A Study on Loss Characteristics of IPMSM for FCEV Considering the Rotating Field. IEEE Trans. Magn. 2010, 46, 3213–3216. [Google Scholar] [CrossRef]

- Wu, C.; Yang, J.; Li, Q. GPIO-Based Nonlinear Predictive Control for Flux-Weakening Current Control of the IPMSM Servo System. Energies 2020, 13, 1716. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-S.; Kwon, B.-I. Optimal design of motor shape and magnetisation direction to obtain vibration reduction and average torque improvement in IPM BLDC motor. IET Electr. Power Appl. 2017, 11, 378–385. [Google Scholar] [CrossRef]

- Ren, W.; Xu, Q.; Li, Q.; Zhou, L. Reduction of Cogging Torque and Torque Ripple in Interior PM Machines With Asymmetrical V-Type Rotor Design. IEEE Trans. Magn. 2016, 52, 1–5. [Google Scholar] [CrossRef]

- Lee, J.-G.; Lim, D.-K.; Jung, H.-K. Analysis and Design of Interior Permanent Magnet Synchronous Motor Using a Sequential-Stage Magnetic Equivalent Circuit. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Watanabe, K.; Campelo, F.; Igarashi, H. Topology Optimization Based on Immune Algorithm and Multigrid Method. IEEE Trans. Magn. 2007, 43, 1637–1640. [Google Scholar] [CrossRef] [Green Version]

- Chun, J.-S.; Jung, H.-K.; Hahn, S.-Y. A study on comparison of optimization performances between immune algorithm and other heuristic algorithms. IEEE Trans. Magn. 1998, 34, 2972–2975. [Google Scholar] [CrossRef]

- Boccaletti, C.; Elia, S.; Nistico, E. Deterministic and stochastic optimisation algorithms in conventional design of axial flux PM machines. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, SPEEDAM 2006, Taormina, Italy, 23–26 May 2006. [Google Scholar]

- Zhu, J.; Cheng, K.W.E.; Xue, X.; Zou, Y. Design of a New Enhanced Torque In-Wheel Switched Reluctance Motor with Divided Teeth for Electric Vehicles. IEEE Trans. Magn. 2017, 53, 2070–2073. [Google Scholar] [CrossRef]

- Lim, D.-K.; Yi, K.-P.; Jung, S.-Y.; Jung, H.-K.; Ro, J.-S.; Dong-Kuk, L. Optimal Design of an Interior Permanent Magnet Synchronous Motor by Using a New Surrogate-Assisted Multi-Objective Optimization. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Tang, Q.; Shen, A.; Luo, P.; Shen, H.; Li, W.; He, X. IPMSMs Sensorless MTPA Control Based on Virtual q-Axis Inductance by Using Virtual High-Frequency Signal Injection. IEEE Trans. Ind. Electron. 2020, 67, 136–146. [Google Scholar] [CrossRef]

- Hong, G.; Wei, T.; Ding, X. Multi-Objective Optimal Design of Permanent Magnet Synchronous Motor for High Efficiency and High Dynamic Performance. IEEE Access 2018, 6, 23568–23581. [Google Scholar] [CrossRef]

- Kim, D.-W.; Park, G.-J.; Lee, J.-H.; Kim, J.-W.; Kim, Y.-J.; Jung, S.-Y. Hybridization Algorithm of Fireworks Optimization and Generating Set Search for Optimal Design of IPMSM. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Goto, H.; Sato, M.; Guo, H.; Ichinokura, O. A Simple Method to Reduce Torque Ripple of SR Motors using Freewheeling mode for Electric Vehicles. In Proceedings of the 2006 IEEE International Magnetics Conference (INTERMAG), San Diego, CA, USA, 8–12 May 2006. [Google Scholar]

- Hao, J.; Suo, S.; Yang, Y.; Wang, Y.; Wang, W.; Chen, X. Optimization of Torque Ripples in an Interior Permanent Magnet Synchronous Motor Based on the Orthogonal Experimental Method and MIGA and RBF Neural Networks. IEEE Access 2020, 8, 27202–27209. [Google Scholar] [CrossRef]

- Fang, L.; Kim, S.-I.; Kwon, S.-O.; Hong, J.-P. Novel Double-Barrier Rotor Designs in Interior-PM Motor for Reducing Torque Pulsation. IEEE Trans. Magn. 2010, 46, 2183–2186. [Google Scholar] [CrossRef]

- Gwak, S.Y. Characteristic Analysis and Design of Multi-Layer Buried Permanent Magnet Motor for Vehicle Traction. Ph.D. Thesis, Seoul National University, Seoul, Korea, 2008. [Google Scholar]

- Chu, G.; Dutta, R.; Rahman, M.; Lovatt, H.C.; Sarlioglu, B. Analytical Calculation of Maximum Mechanical Stress on the Rotor of Interior Permanent-Magnet Synchronous Machines. IEEE Trans. Ind. Appl. 2020, 56, 1321–1331. [Google Scholar] [CrossRef]

- Chai, F.; Li, Y.; Liang, P.; Pei, Y. Calculation of the Maximum Mechanical Stress on the Rotor of Interior Permanent-Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2016, 63, 3420–3432. [Google Scholar] [CrossRef]

| Point | Concentration | Expectation |

|---|---|---|

| A | 1/4 | 2 × 4/1 = 8 |

| B | 2/4 | 3 × 4/2 = 6 |

| C | 1/4 | 5 × 4/1 = 20 |

| D | 2/4 | 3 × 4/2 = 6 |

| Test Function 1 [11 Peaks] | Number of Function Call | Success Rate [%] |

| IA | 2060.0 | 58.45 |

| NGA | 1650 | 89.09 |

| NIA | 1365.2 | 99.45 |

| Test Function 2 [36 Peaks] | Number of Function Call | Success Rate [%] |

| IA | 3390.0 | 84.0 |

| NGA | 3140 | 94.44 |

| NIA | 1878.1 | 99.64 |

| Parameter | Unit | Value |

|---|---|---|

| Pole number | - | 6 |

| Slot number | - | 27 |

| Rated torque | [Nm] | 310 |

| Rated power | [kW] | 97.4 |

| Rotation speed | [rev/min] | 3000 |

| Stator inner/outer diameter | [mm] | 172/240 |

| Rotor inner/outer diameter | [mm] | 50/170 |

| Air gap | [mm] | 1 |

| Stacking length | [mm] | 240 |

| Stator and rotor core material | - | JFE steel 35JN230 |

| Permanent magnet material | - | NEOMAX-42 |

| Variable | Unit | Range |

|---|---|---|

| θ1 | [degree] | 125–140 |

| θ2 | [degree] | 100–150 |

| length | [mm] | 12–18.5 |

| Model | Initial Model | Model 1 | Model 2 | Model 3 |

|---|---|---|---|---|

| θ1 [degree] | 127.67 | 130.77 | 141.50 | 131.33 |

| θ2 [degree] | 122.22 | 111.33 | 124.00 | 130.08 |

| length [mm] | 13.0 | 18.5 | 12.0 | 17.0 |

| Model | Initial Model | Model 1 | Model 2 | Model 3 |

|---|---|---|---|---|

| Torque Ripple [%] | 19.58 | 2.68 | 4.10 | 4.36 |

| Average Torque [Nm] | 322.39 | 304.97 | 323.71 | 315.49 |

| Cogging Torque [Nm] | 24.11 | 6.23 | 21.52 | 2.92 |

| AC phase [degree] | 43 | 45 | 39 | 44 |

| Model | Initial Model | Optimum Model |

|---|---|---|

| Iron loss [W] | 507.8 | 473.5 |

| Copper loss [W] | 2162.7 | 2162.7 |

| Total loss [W] | 2670.5 | 2636.1 |

| Input power [kW] | 103.9 | 101.7 |

| Output power [kW] | 101.3 | 99.1 |

| Efficiency [%] | 97.4 | 97.4 |

| Parameter | Value |

|---|---|

| Young’s modulus (Core/PM) | 210/120 [GPa] |

| Poisson’s ratio (Core/PM) | 0.3/0.3 |

| Density (Core/PM) | 7850/8400 [kg/m3] |

| Rotation speed | 3000/6000 [rpm] |

| Yield stress | 250 [MPa] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, J.-C.; Kang, Y.-R.; Lim, D.-K. Optimal Design of IPMSM for FCEV Using Novel Immune Algorithm Combined with Steepest Descent Method. Energies 2020, 13, 3395. https://doi.org/10.3390/en13133395

Son J-C, Kang Y-R, Lim D-K. Optimal Design of IPMSM for FCEV Using Novel Immune Algorithm Combined with Steepest Descent Method. Energies. 2020; 13(13):3395. https://doi.org/10.3390/en13133395

Chicago/Turabian StyleSon, Ji-Chang, Young-Rok Kang, and Dong-Kuk Lim. 2020. "Optimal Design of IPMSM for FCEV Using Novel Immune Algorithm Combined with Steepest Descent Method" Energies 13, no. 13: 3395. https://doi.org/10.3390/en13133395

APA StyleSon, J.-C., Kang, Y.-R., & Lim, D.-K. (2020). Optimal Design of IPMSM for FCEV Using Novel Immune Algorithm Combined with Steepest Descent Method. Energies, 13(13), 3395. https://doi.org/10.3390/en13133395