Eco-Efficient Value Creation of Residential Street Lighting Systems by Simultaneously Analysing the Value, the Costs and the Eco-Costs during the Design and Engineering Phase

Abstract

1. Introduction

1.1. The Issue: Progress in Sustainable Product Innovation, and Circular Business Models

1.2. The Challenge: A Sustainable Street Lighting System for the City of Rotterdam

2. The Methods

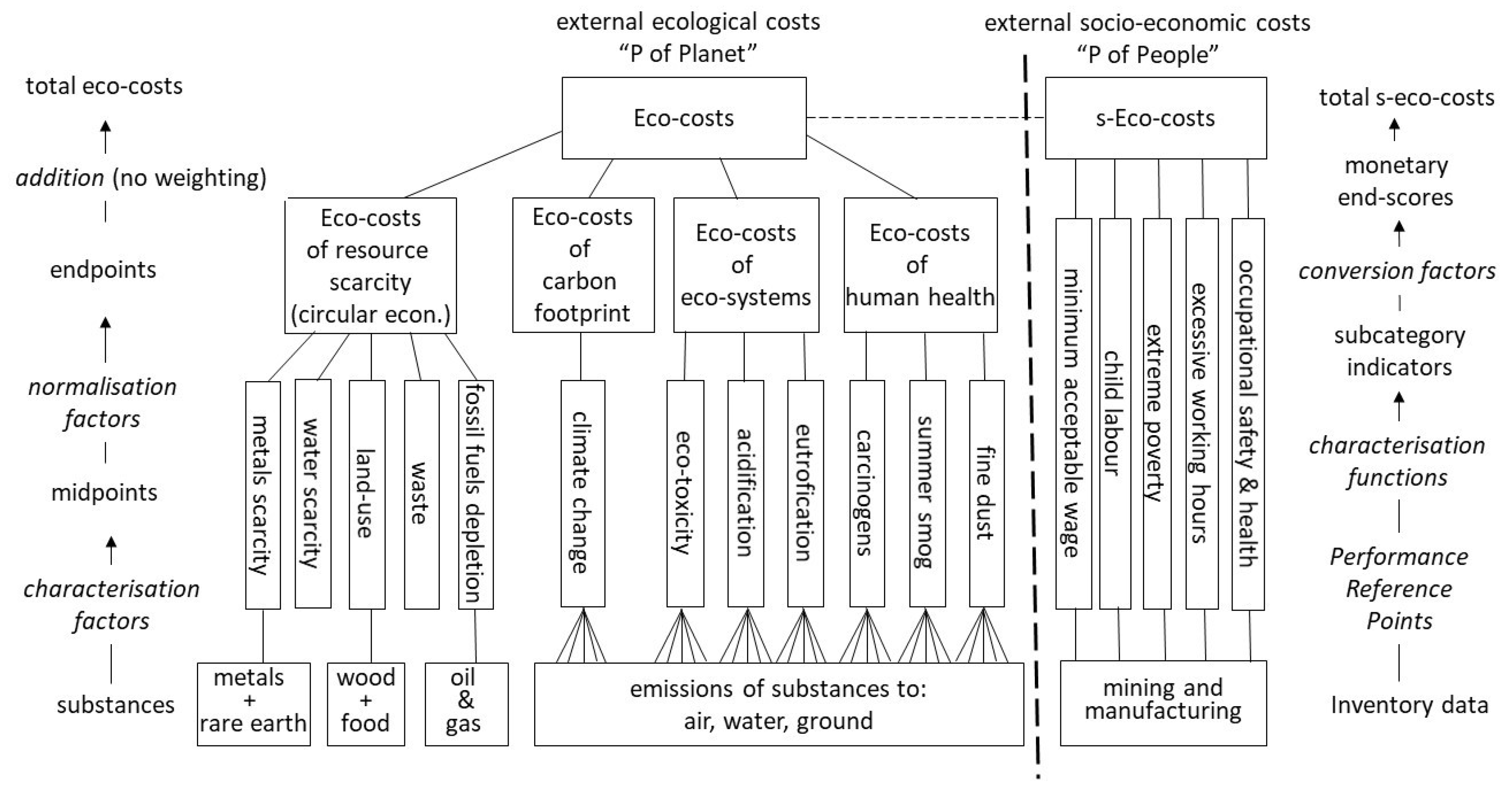

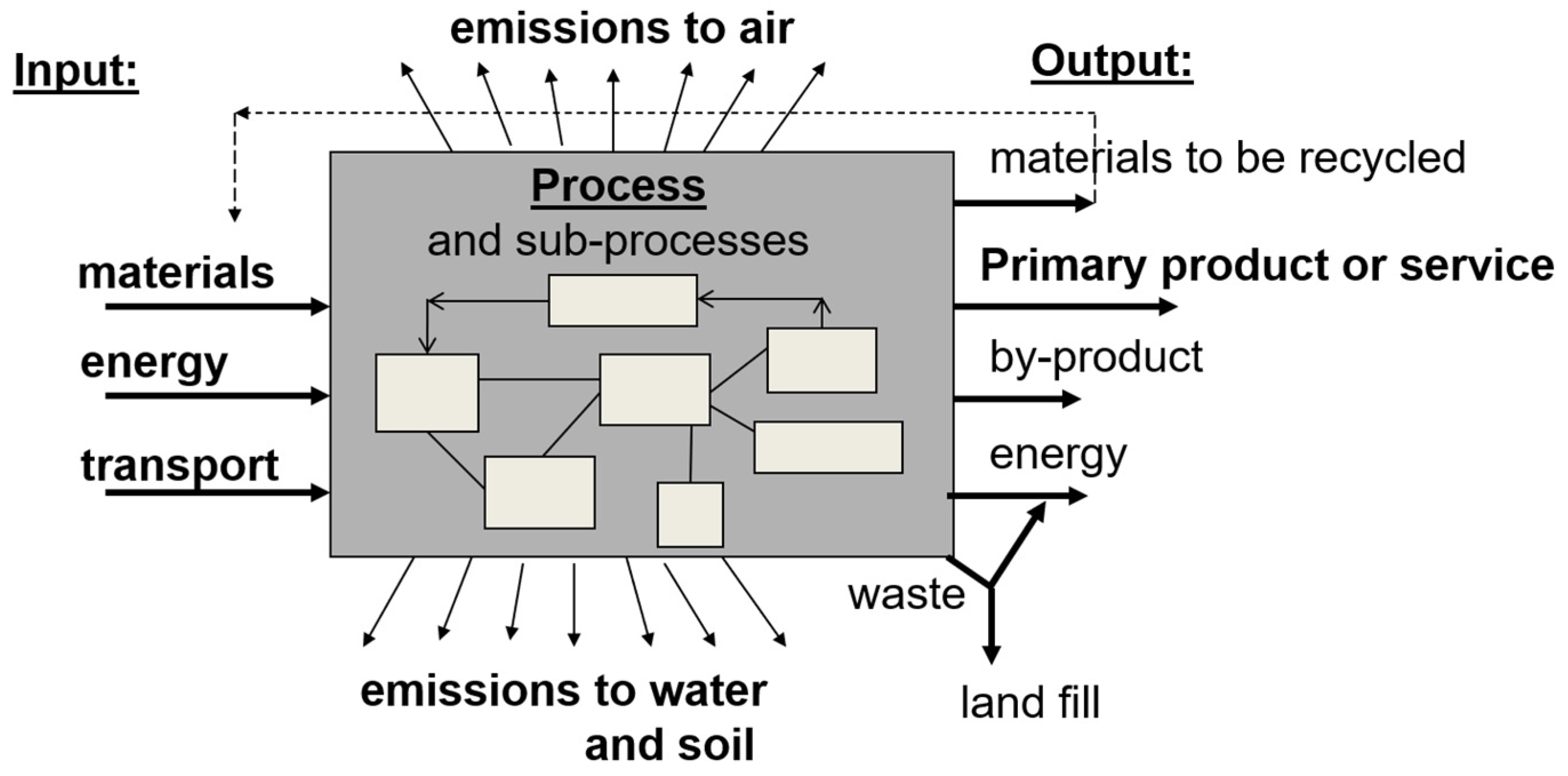

2.1. The Eco-Costs, a Monetized Single Indicator in LCA

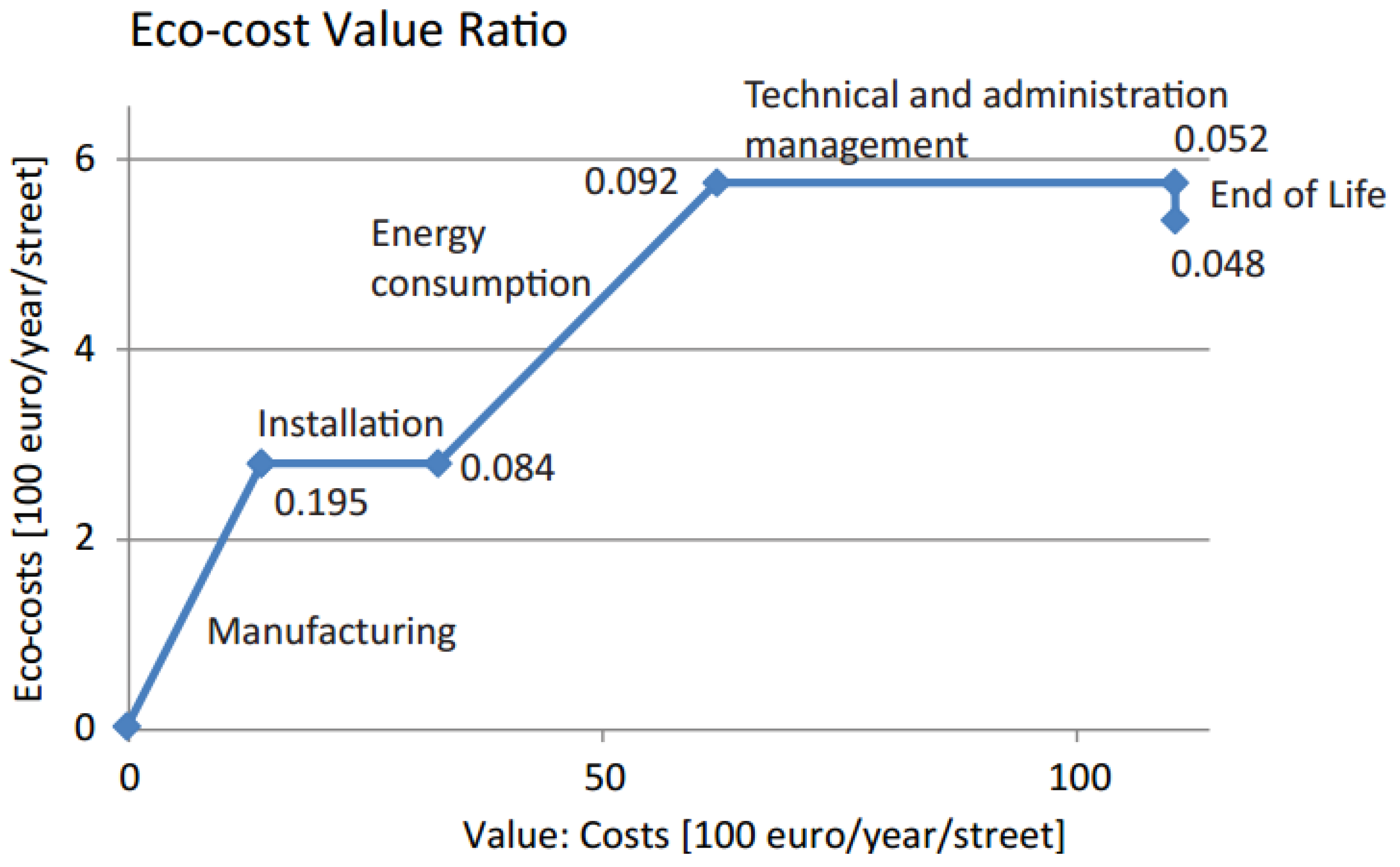

2.2. The Model of the Eco-Costs/Value Ratio

- force industry to reduce the eco-costs of their products (this will shift the curve downward);

- try to reduce expenditures of consumers in the high end of the curve, by attractive offerings at the low end of the curve (this will shift the middle part of the curve to the right).

2.3. Eco-Efficient Value Creation

- to increase value where value is high (more quality, service, life span, and image);

- to decrease the eco-costs where the eco-costs are high (a shift to bio-based materials, recycling and renewable energy).

- Stpe 1

- Life Cycle Thinking: At the start of the design process, the basic questions on circular design are whether or not the product must be suitable for easy repair, takeback + remanufacturing, or takeback + recycling of the materials. Note that circular designs are not always realistic in practice (because of long life times, high costs of return transport to the factory, low quantities, high remanufacturing costs, governmental regulations etc.). So Life Cycle Thinking must comprise many aspects that are on a higher level than the product chain itself [45].

- Step 2

- Functional requirements, and possible add-ons to enhance the CPV: Establish the ‘musts’ and the ‘wants’ in terms of functionalities, and in terms of enhancing the CPV [46].

- Step 3

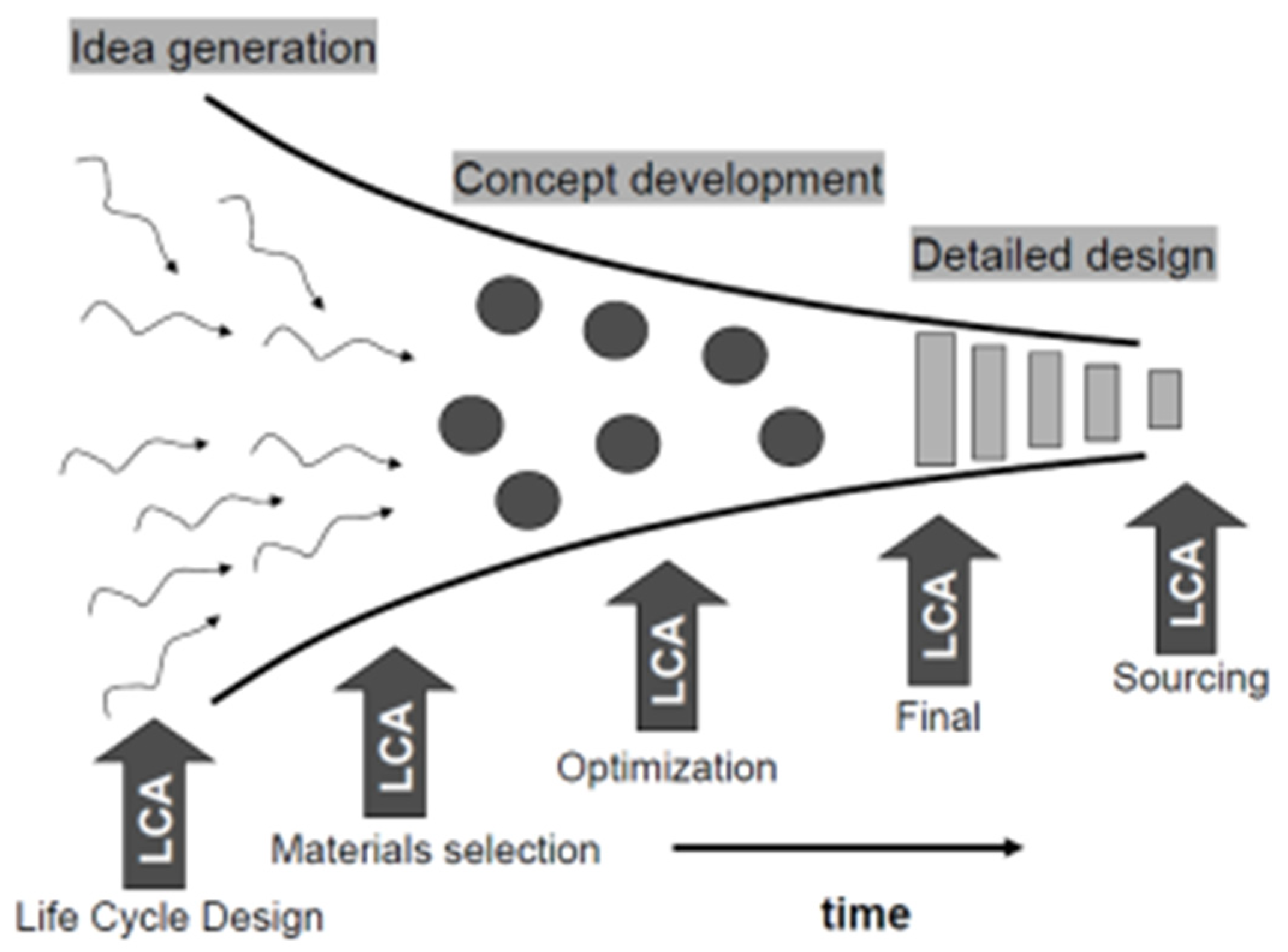

- Idea generation and materials selection: The designer might be inspired by biomimicry, nature-inspired design, bio-inspired design, C2C, and other philosophies and design tools [47]. Since the choice of materials plays a governing role in this design stage [48], the LCA-based Idemat app for materials selection (specially developed to support eco-efficient value design) might be applied [43].

- Step 4

- Concept development and design optimisation: This is a highly iterative process as depicted in Figure 7.

- Step 5

- Detailed design with a final product LCA and with sourcing of components (materials): This is the stage of the classical LCA, to find the environmental the hotspots of the final design.

- Step 6

- Selection of suppliers: At the stage of sourcing of the components and materials, LCA should be applied to select the preferred suppliers.

3. Results: Example of the Design of a Street Lighting System

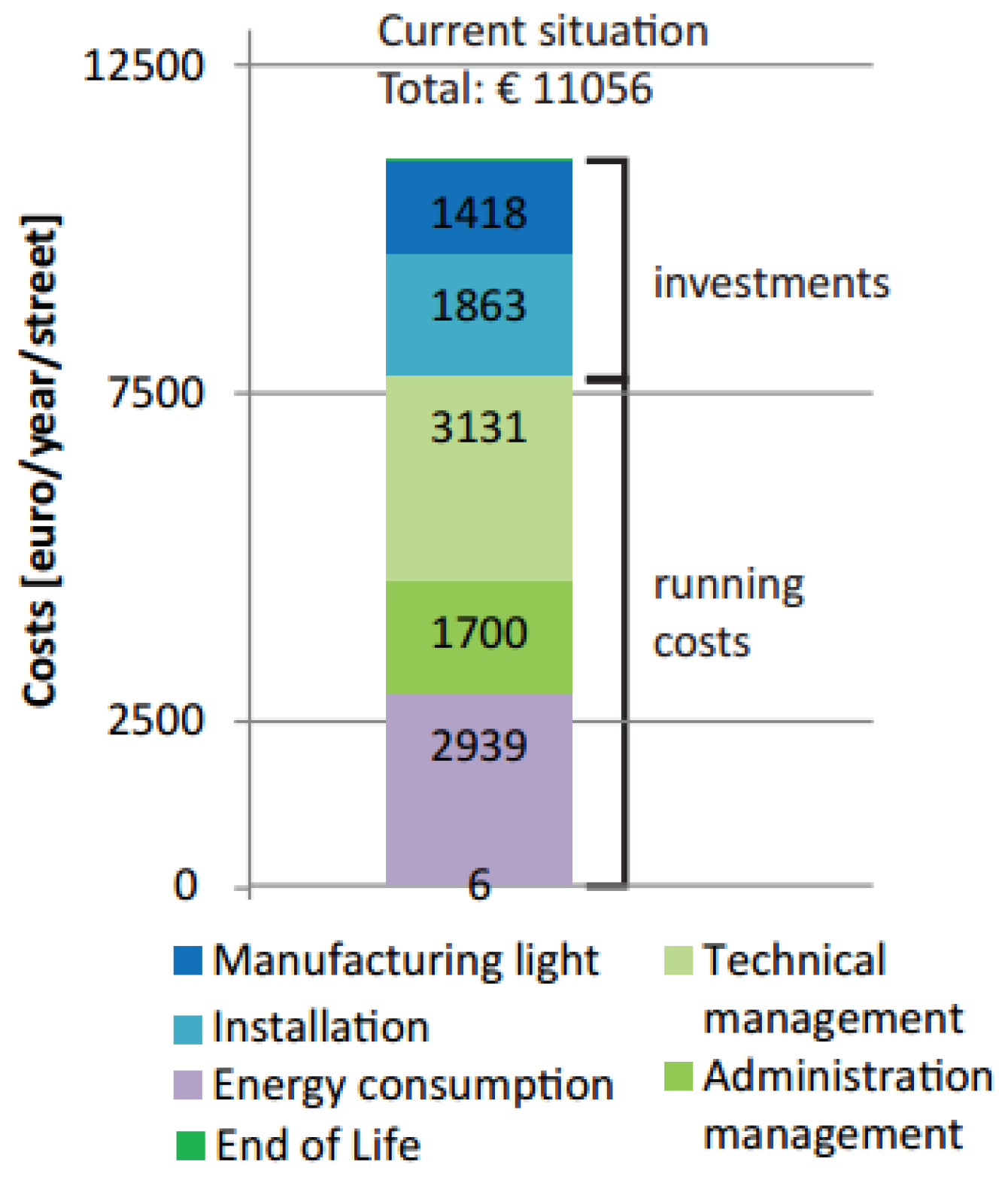

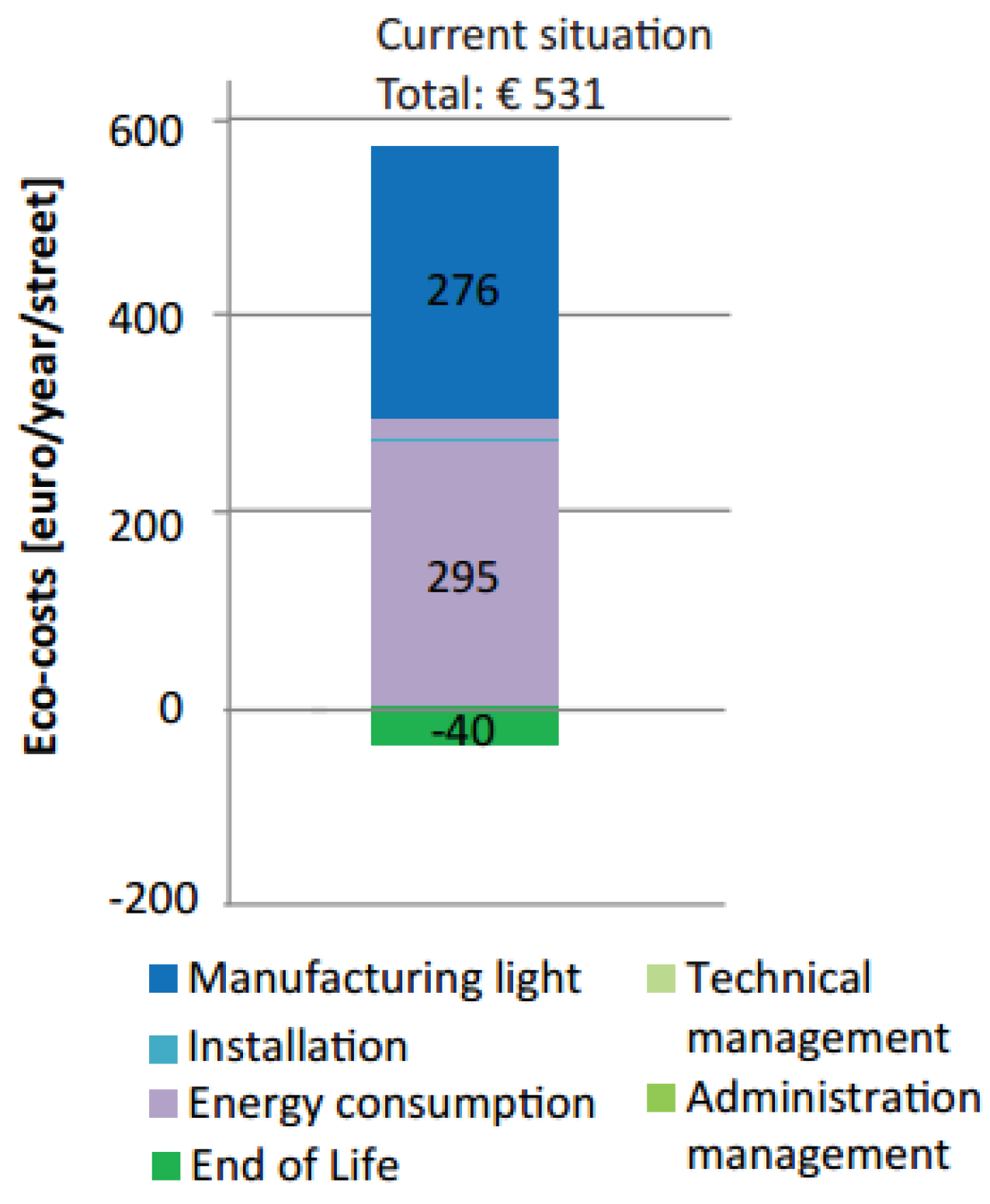

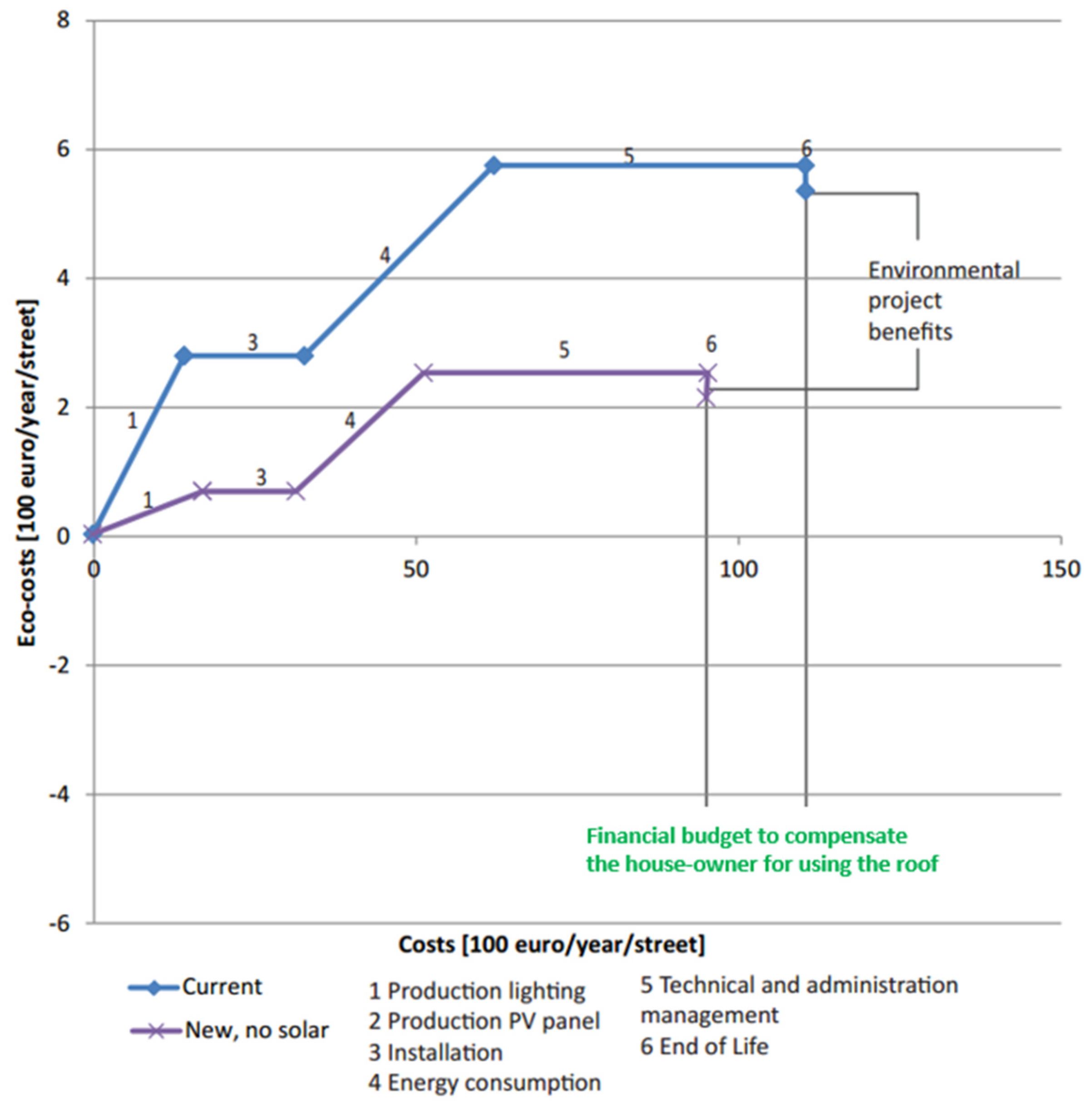

3.1. Base Case: the EVR of a Traditional Design in the City of Rotterdam

- Manufacturing and installation costs. These costs include the purchasing costs of the pole and luminaire and the working hours and administration costs of the installation process. Creating a grid connection, digging for cables and the pole are expensive: about 55% of the installing costs. Purchasing the pole and luminaire is the other 45%.

- Technical management. This is mainly related to maintenance work, such as: replace light bulbs, repair electronics and cable failures (after accidents), clean luminaires.

- Administrative management. These costs are related to desk work. Examples are: office expenses and taxes, inspections of luminaries and processing of the inspection reports.

- Energy consumption. This is based on the most used light source for residential streets: 36 W PL fluorescent lamps. The yearly operating time of a single light bulb is 4200 h. In addition, some taxes are included in the energy consumption costs.

- End of life. These are the costs for the removal tax of a pole and luminaire, and the removal costs of the current grid connection.

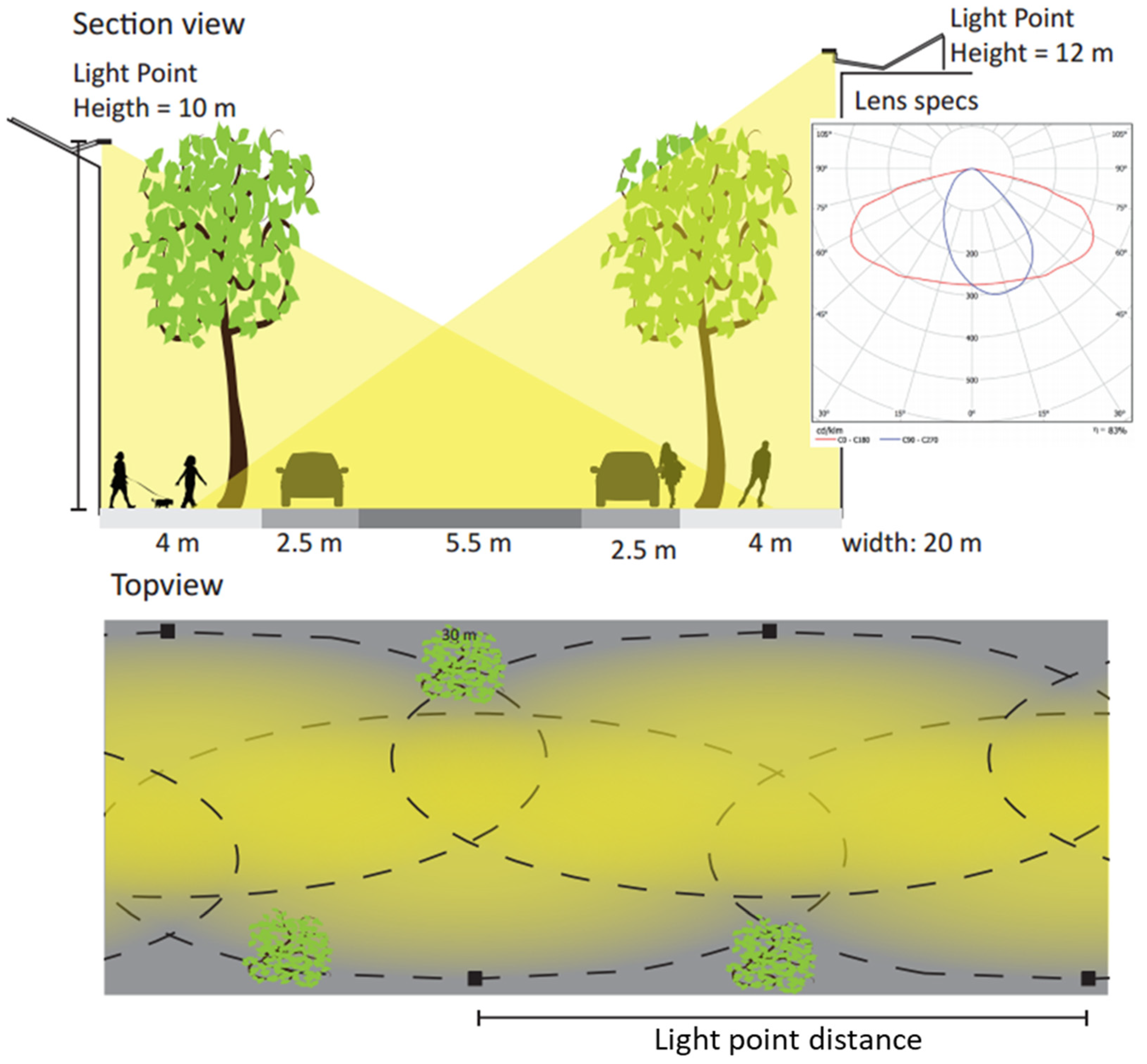

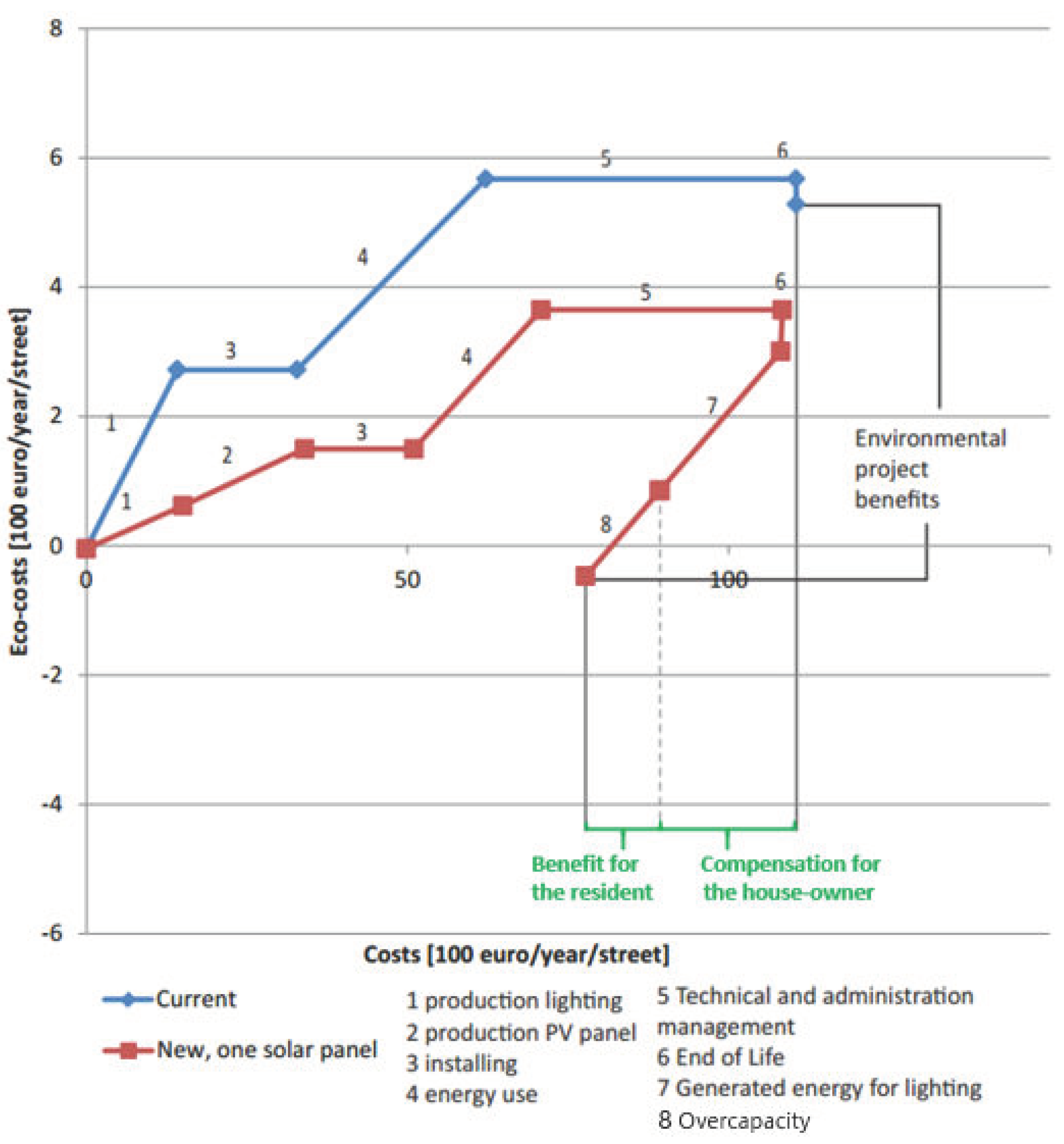

3.2. The Design of the New System

4. Discussion and Conclusions

- The sustainable innovation is not necessarily found in the application of radically new technologies, products or services. Sustainable innovation is the way in which existing technologies, products and services constitute a new sustainable product-service system with a viable business model that adds value to all the three stakeholders: (1) the municipality, by more value for the same costs; (2) the citizens in the street, by adding safety at night in combination with the trees in the street; (3) the owner and/or residents of the building, by reducing the costs of electricity.

- the chosen solution actually has potentially a spin-off effect that might become even more important than the system itself: the design concept inspires end-users to place additional, privately owned, solar panels on their roofs, alongside the solar panel of the municipality. Note that this is a very cost-effective way, since the installation of extra panels hardly adds to the installation costs.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- McDonough and Braungart. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy. Available online: www.ellenmacarthurfoundation.org (accessed on 30 August 2014).

- McKinsey. The Circular Economy: Moving from Theory to practice Special Edition, October 2016. Available online: https://www.mckinsey.com/~/media/McKinsey/Business%20Functions/Sustainability/Our%20Insights/The%20circular%20economy%20Moving%20from%20theory%20to%20practice/The%20circular%20economy%20Moving%20from%20theory%20to%20practice.ashx (accessed on 15 April 2020).

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strategy Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Oghazi, P.; Mostaghel, R. Circular Business Model Challenges and Lessons Learned—An Industrial Perspective. Sustainability 2018, 10, 739. [Google Scholar] [CrossRef]

- Vogtlander, J.G.; Scheepens, A.E.; Bocken, N.M.P.; Peck, D. Combined analyses of costs, market value and eco-costs in circular business models: Eco-efficient value creation in remanufacturing. J. Rem. 2017, 7, 1–17. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtlander, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- White, A.L.; Stoughton, M.; Feng, L. Report. Servicing: The Quiet Transition to Extended Product Responsibility; U.S. Environmental Protection Agency, Office of Solid Waste: Washington, DC, USA, 1999; pp. 1–89. [Google Scholar]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Wiley Online Library. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Shluzas, L.A.; Steinert, M.; Katila, R. User-Centered Innovation for the Design and Development of Complex Products and Systems. In Design Thinking Research: Building Innovation Eco-Systems; Stanford University, Springer Science & Business Media: Berlin/Heidelberg, Germany, 2014; pp. 135–149. ISBN 978-3-319-01303-9. [Google Scholar]

- Brezet, J.C.; Van Hemel, C. Book Ecodesign: A Promising Approach to Sustainable Production and Consumption; United Nations Environment Programme, Industry and Environment, Cleaner Production: Paris, France, 1997. [Google Scholar]

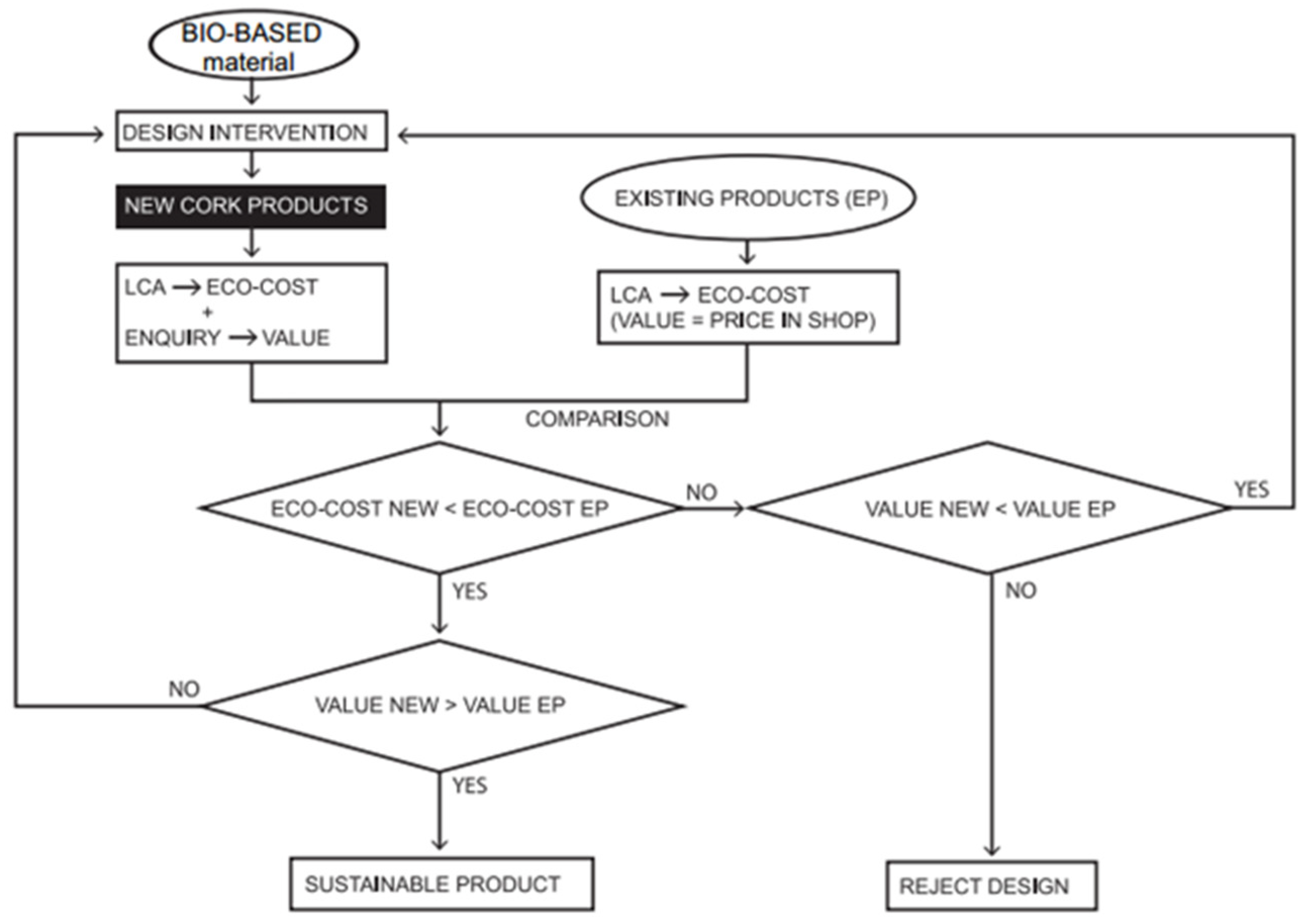

- Mestre, A.; Vogtlander, J.G. Eco-efficient Value Creation of Cork products: An LCA based method for design intervention. J. Clean. Prod. 2013, 57, 101–114. [Google Scholar] [CrossRef]

- Welsh, B.C.; Farrington, D.P. Effects of Improved Street Lighting on Crime. Camb. Systematic. Rev. 2008. [Google Scholar] [CrossRef]

- Haans, A.; de Kort, Y.A.W. Light distribution in dynamic street lighting: Two experimental studies on its effects on perceived safety, prospect, concealment, and escape. J. Environ. Psychol. 2012, 32, 342–352. [Google Scholar] [CrossRef]

- Kardan, O.; Gozdyra, P.; Misic, B.; Moola, F.; Palmer, L.J.; Paus, T.; Berman, M.G. Neighborhood Greenspace and Health in A Large Urban Center. Sci. Rep. 2015, 5, nr 11610. Available online: https://www.nature.com/articles/srep11610 (accessed on 15 April 2020). [CrossRef]

- Schusler, T.M.; Weiss, L.; Treering, D.; Balderama, E. Research note: Examining the association between tree canopy, parks and crime in Chicago. Landsc. Urb. Plan. 2017, 170, 309–313. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Zijp, M.; Hollander, A.; van Zelm, R.E.F. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Lehmann, A.; Bach, V.; Finkbeiner, M. Product environmental footprint in policy and market decisions: Applicability and impact assessment. Integr. Environ. Assess. Manag. 2015, 11, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Environmental Priority Strategies (EPS). Available online: https://www.ivl.se/english/startpage/pages/our-focus-areas/environmental-engineering-and-sustainable-production/lca/eps.html (accessed on 15 April 2020).

- Vogtlander, J.G.; Baetens, B.; Bijma, A.; Brandjes, E.; Lindeijer, E.; Segers, M.; Witte, J.P.M.; Brezet, J.C.; Hendriks, C.F. LCA-based Assessment of Sustainability: The Eco-costs/Value Ratio (EVR); Delft Academic Press: Delft, The Netherlands, 2010; ISBN 9789065622334. [Google Scholar]

- Sala, S.; Cerutti, A.K.; Pant, R. Report. Development of a Weighting Approach for the Environmental Footprint; Publications Office of the European Union: Brussels, Belgium, 2019; Available online: https://ec.europa.eu/jrc/en/publication/development-weighting-approach-environmental-footprint (accessed on 30 June 2020).

- Olindo, R.; Schmitt, N.; Vogtlander, J.G. Electricity in LCA: Inconvenient uncertainties in leading databases, and the need for extra calculation rules. Cases: Calculations on battery electrical cars and hydrogen from electrolysis. Sustainability 2009. Unpublished. [Google Scholar]

- Vogtlander, J.G.; Bijma, A. The virtual pollution prevention costs ‘99: A single LCA-based indicator for emissions. Int. J. Life Cycle Assess. 2000, 5, 113–124. [Google Scholar] [CrossRef]

- Vogtlander, J.G.; Brezet, J.C.; Hendriks, C.F. The Virtual Eco-costs ‘99, a single LCA-based indicator for sustainability and the Eco-costs/Value Ratio (EVR) model for economic allocation. Int. J. LCA 2001, 6, 157–166. [Google Scholar] [CrossRef]

- Vogtlander, J.G.; Bijma, A.; Brezet, J.C. Communicating the eco-efficiency of products and services by means of the Eco-costs/Value Model. J. Clean. Prod. 2002, 10, 57–67. [Google Scholar] [CrossRef]

- Vogtländer, J.; Peck, D.; Kurowicka, D. The Eco-Costs of Material Scarcity, a Resource Indicator for LCA, Derived from a Statistical Analysis on Excessive Price Peaks. Sustainability 2019, 11, 2446. [Google Scholar] [CrossRef]

- ISO 14008:2019. Monetary Valuation of Environmental Impacts and Related Environmental Aspects; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- The Model of the Eco-costs/Value Ratio (EVR): The concept of the eco-costs. Available online: https://www.ecocostsvalue.com/EVR/model/theory/subject/2-eco-costs.html (accessed on 15 April 2020).

- ISO 14044:2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- The Model of the Eco-costs/Value Ratio (EVR): Data on eco-costs, Carbon Footprint, and Other indicators: The Idematapp and Idemat Databases. Available online: https://www.ecocostsvalue.com/EVR/model/theory/subject/5-data.html (accessed on 15 April 2020).

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Simon and Schuster: New York, NY, USA, 1985; ISBN 9781416595847. [Google Scholar]

- Vogtlander, J.G.; Mestre, A.; Van de Helm, R.; Scheepens, A.; Wever, R. Eco-efficiënt Value Creation, Sustainable Strategies for the Circular Economy, 2nd ed.; Delft Academic Press: Delft, The Netherlands, 2014; ISBN 9789065623683. [Google Scholar]

- Gadiesh, O.; Gilbert, J.L. Profit Pools: A Fresh Look at Strategy. Harv. Bus. Rev. 1998, 76, 139–148. [Google Scholar]

- McDougall, G.H.G.; Levesque, T. Customer satisfaction with services: Putting perceived value into the equation. J. Serv. Market. 2000, 14, 392–410. [Google Scholar] [CrossRef]

- Lin, C.; Sher, P.J.; Shih, H. Past progress and future directions in conceptualizing customer perceived value. Int. J. Serv. Ind. Manag. 2005, 16, 318–336. [Google Scholar] [CrossRef]

- Gautama, N.; Singhb, N. Lean product development: Maximizing the customer perceived value through design change (redesign). Int. J. Prod. Econ. 2008, 114, 313–332. [Google Scholar] [CrossRef]

- EU Joint Research Centre. Environmental Impact of Products: EIPRO, Analysis of the Life Cycle Environmental Impacts Related to the Final Consumption of the EU-25. Joint Research Centre, European Commission. 2006. Available online: https://ec.europa.eu/environment/ipp/pdf/eipro_report.pdf (accessed on 15 April 2020).

- Huppes, G.; Ishikawa, M. A Framework for Quantified Eco-efficiency Analysis. J. Ind. Ecol. 2005, 9, 25–41. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; de Freitas Dias, R.; Mattos, L.V.; Quelhas, O.L.G.; Leal Filho, W. Towards sustainable development through the perspective of eco-efficiency—A systematic literature review. J. Clean. Prod. 2017, 165, 890–904. [Google Scholar] [CrossRef]

- Huguet Ferran, P.; Heijungs, R.; Vogtländer, J.G. Critical Analysis of Methods for Integrating Economic and Environmental Indicators. Ecol. Econ. 2018, 146, 549–559. [Google Scholar] [CrossRef]

- Lofthouse, V. Ecodesign tools for designers: Defifining the requirements. J. Clean. Prod. 2006, 14, 1386–1395. [Google Scholar] [CrossRef]

- Available online: www.idematapp.com (accessed on 15 April 2020).

- Vogtlander, J.G. A practical Guide to, L.C.A. In For Students, Designers and Business Managers; Cradle-to-crave and Cradle-to-cradle, 5th ed.; Delft Academic Press: Delft, The Netherlands, 2017; ISBN 9789065623614. [Google Scholar]

- Rivas-Hermann, R.; Köhler, J.A.; Scheepens, A.E. Innovation in product and services in the shipping retrofit industry: A case study of ballast water treatment systems. J. Clean. Prod. 2015, 106, 443–454. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y.; Bernarda, G.; Smith, A. Value Proposition Design; Wiley: London, UK, 2014; ISBN 9781118968055. [Google Scholar]

- Van Boeijen, A.; Daalhuizen, J.; Zijlstra, J.; Van de Schoor, R. Delft Design Guide; BIS Publishers: Amsterdam, The Netherlands, 2017; ISBN 9789063693275. [Google Scholar]

- Karana, E. Meanings of Materials. Ph.D. Thesis, Delft University of Technology, Delft, Netherland, 29 May 2009. Available online: https://repository.tudelft.nl/islandora/object/uuid:092da92d-437c-47b7-a2f1-b49c93cf2b1e (accessed on 15 April 2020).

- Scheepens, A.E.; Vogtlander, J.G. Insulation or Smart Temperature Control for Domestic Heating: A Combined Analysis of the Costs, the Eco-Costs, the Customer Perceived Value, and the Rebound Effect of Energy Saving. Sustainability 2018, 10, 3231. [Google Scholar] [CrossRef]

| Unit | Amount for 1 FU | LCI Database Line | Eco-Costs Per Unit | CO2e Per Unit | Eco-Costs Per FU | CO2e Per FU |

|---|---|---|---|---|---|---|

| kg | 3.52 | Aluminium trade mix (45% prim 55% sec) | 2.12 | 6.26 | 7.5 | 22.0 |

| kg | 34.93 | Steel (21% sec = market mix average) | 0.60 | 1.61 | 20.8 | 56.2 |

| kg | 2.10 | Polyester (unsaturated) 70% | 2.04 | 7.46 | 4.3 | 15.7 |

| kg | 0.90 | Glass fibre 30% | 0.10 | 0.48 | 0.1 | 0.4 |

| kg | 1.78 | PC pellets | 2.05 | 7.78 | 3.7 | 13.9 |

| kg | 0.07 | Copper trade mix (56% prim 44% sec) | 2.70 | 1.82 | 0.2 | 0.1 |

| kg | 0.31 | PP pellets | 1.05 | 1.97 | 0.3 | 0.6 |

| kg | 0.04 | ABS pellets 50% | 1.32 | 3.40 | 0.1 | 0.1 |

| kg | 0.04 | PC pellets 50% | 2.05 | 7.78 | 0.1 | 0.3 |

| kg | 1.50 | Glass, uncoated | 0.22 | 0.98 | 0.3 | 1.5 |

| kg | 0.08 | PWB desktop, including components and Ics | 60.71 | 160.41 | 4.9 | 12.8 |

| m | 16.60 | Electric cord, 1000 W, 3 × 0.5 mm2, domestic | 0.07 | 0.14 | 1.2 | 2.3 |

| kg | 0.06 | Crude iron | 0.42 | 1.51 | 0.0 | 0.1 |

| kg | 0.002 | Silicon | 2.21 | 10.59 | 0.0 | 0.0 |

| kg | 0.07 | 67SiCr5, spring-steel | 0.77 | 1.85 | 0.1 | 0.1 |

| kg | 0.55 | X5CrNi18 (Stainless steel 304) | 2.66 | 3.85 | 1.5 | 2.1 |

| kg | 0.41 | PVC | 0.702 | 2.006 | 0.3 | 0.8 |

| Material supplies | 45 | 129 | ||||

| Production processes | ||||||

| kg | 34.00 | Drawing of pipe, steel | 0.170 | 0.360 | 5.8 | 12.2 |

| m2 | 10.25 | Electroplating Zinc, outside use, per 10 years | 5.479 | 2.974 | 56.2 | 30.5 |

| m2 | 2.56 | Powder coating, steel/RER S | 1.105 | 4.570 | 2.8 | 11.7 |

| kg | 5.43 | Injection molding plastics | 0.264 | 1.333 | 1.4 | 7.2 |

| kg | 2.02 | Casting, aluminium | 0.018 | 0.157 | 0.0 | 0.3 |

| kg | 1.50 | Cold transforming Al | 0.019 | 0.104 | 0.0 | 0.2 |

| kg | 0.99 | Deep drawing steel | 0.065 | 0.316 | 0.1 | 0.3 |

| Manufacturing processes | 66 | 62 | ||||

| Material supplies + manufacturing processes excluding transport and installation | 112 | 192 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klaassen, N.; Scheepens, A.; Flipsen, B.; Vogtlander, J. Eco-Efficient Value Creation of Residential Street Lighting Systems by Simultaneously Analysing the Value, the Costs and the Eco-Costs during the Design and Engineering Phase. Energies 2020, 13, 3351. https://doi.org/10.3390/en13133351

Klaassen N, Scheepens A, Flipsen B, Vogtlander J. Eco-Efficient Value Creation of Residential Street Lighting Systems by Simultaneously Analysing the Value, the Costs and the Eco-Costs during the Design and Engineering Phase. Energies. 2020; 13(13):3351. https://doi.org/10.3390/en13133351

Chicago/Turabian StyleKlaassen, Nine, Arno Scheepens, Bas Flipsen, and Joost Vogtlander. 2020. "Eco-Efficient Value Creation of Residential Street Lighting Systems by Simultaneously Analysing the Value, the Costs and the Eco-Costs during the Design and Engineering Phase" Energies 13, no. 13: 3351. https://doi.org/10.3390/en13133351

APA StyleKlaassen, N., Scheepens, A., Flipsen, B., & Vogtlander, J. (2020). Eco-Efficient Value Creation of Residential Street Lighting Systems by Simultaneously Analysing the Value, the Costs and the Eco-Costs during the Design and Engineering Phase. Energies, 13(13), 3351. https://doi.org/10.3390/en13133351