Reviewing ISO Compliant Multifunctionality Practices in Environmental Life Cycle Modeling

Abstract

1. Introduction

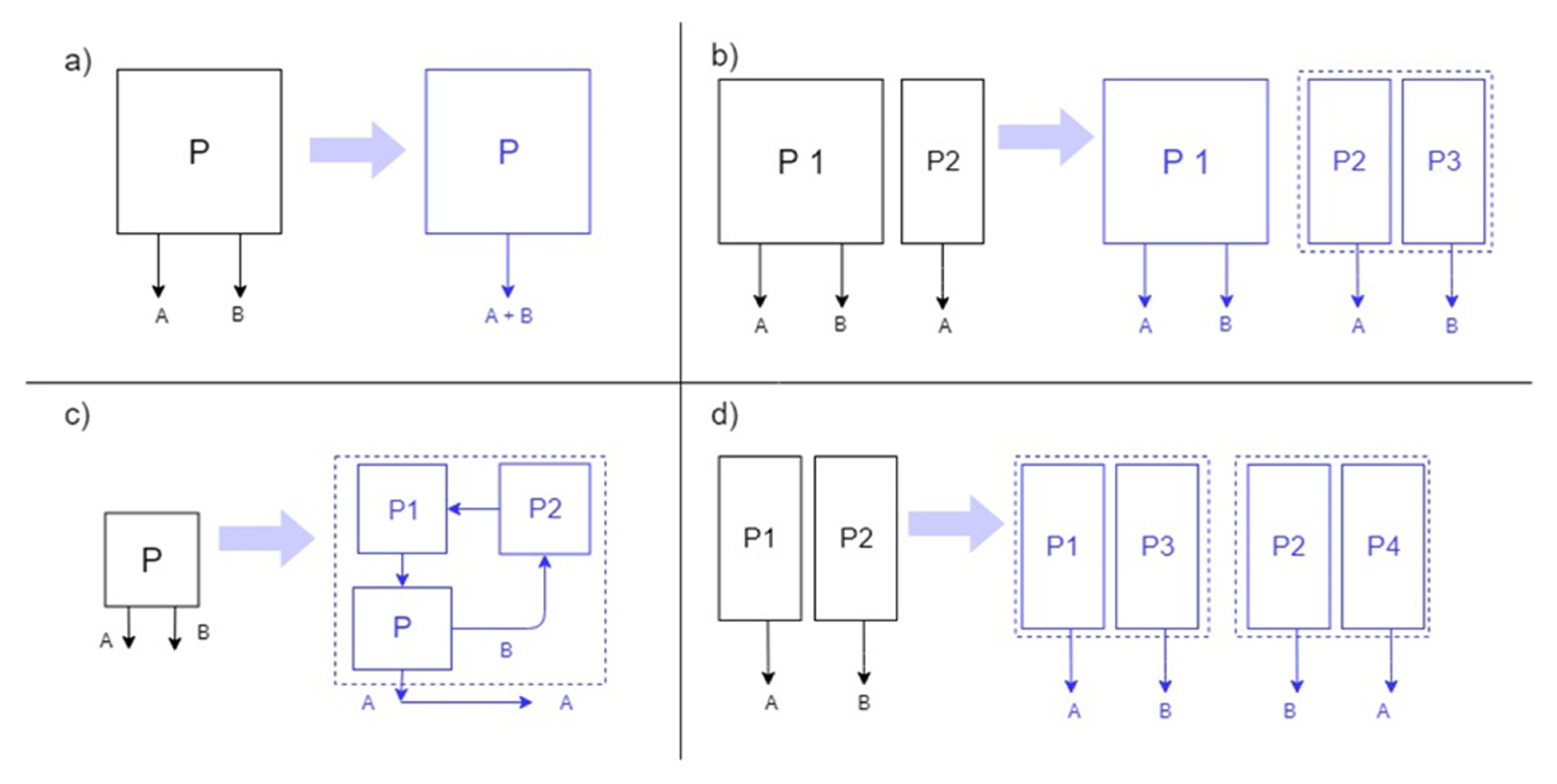

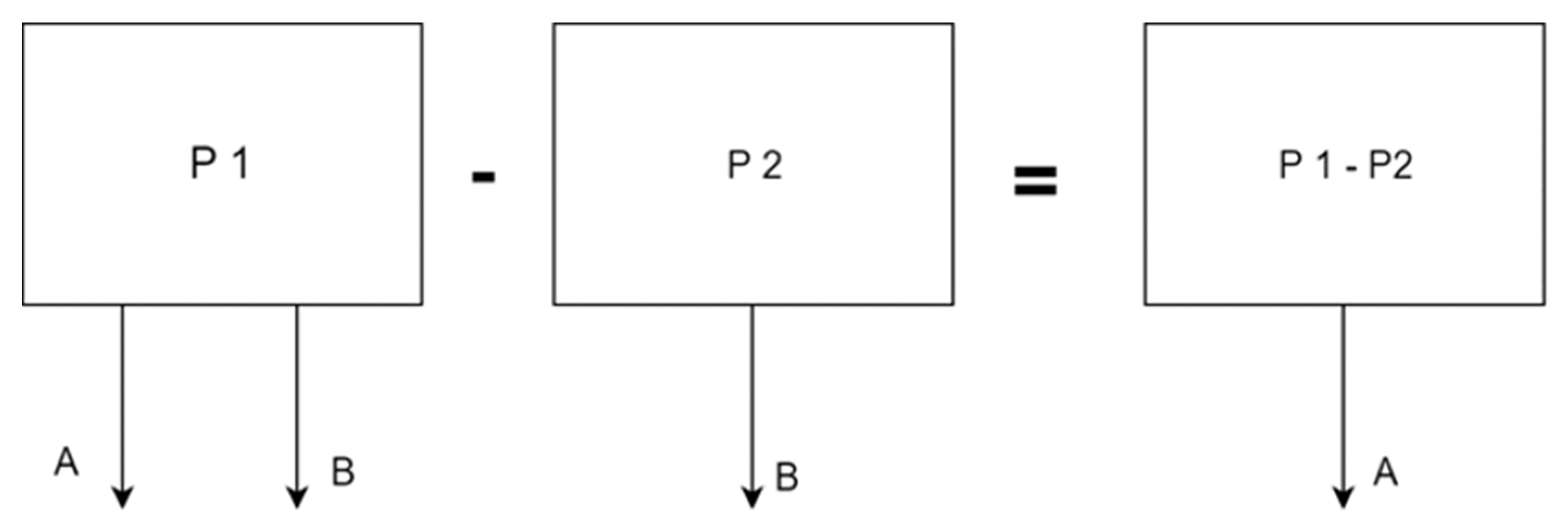

- Avoiding allocation by subdivision (dividing the unit process into two or more sub-processes) or system expansion (“expanding the product system to include the additional functions related to the co-products”);

- Allocation following underlying physical relationships (i.e., an allocation that quantitatively reflects how the inputs and outputs are changed by changes in the amount of each product of the system);

- Allocation (partitioning) based on other relationships (e.g., economic value).

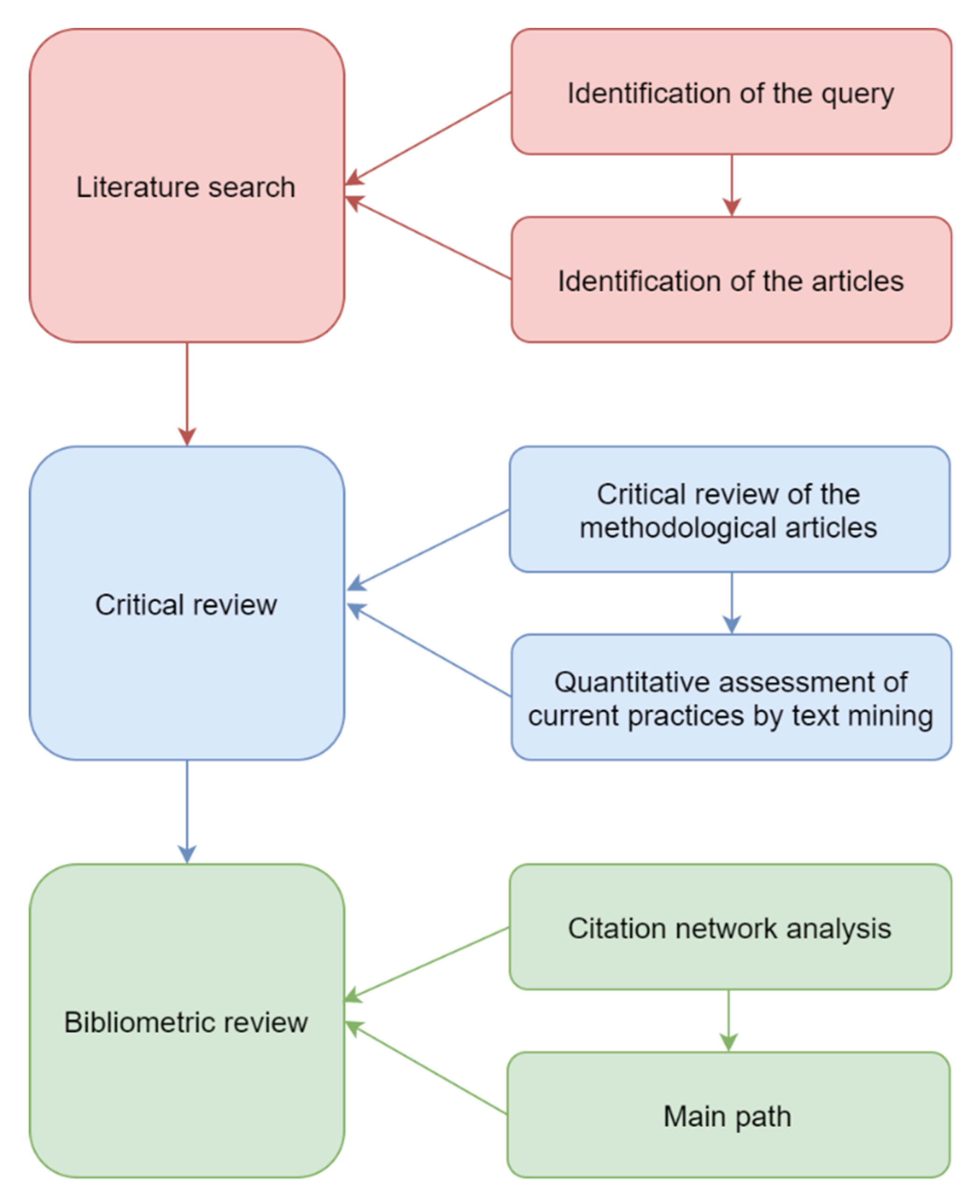

2. Methodology

3. The Critical Review Combined with Text Mining

3.1. Debate on the Interpretation of ISO’s System Expansion

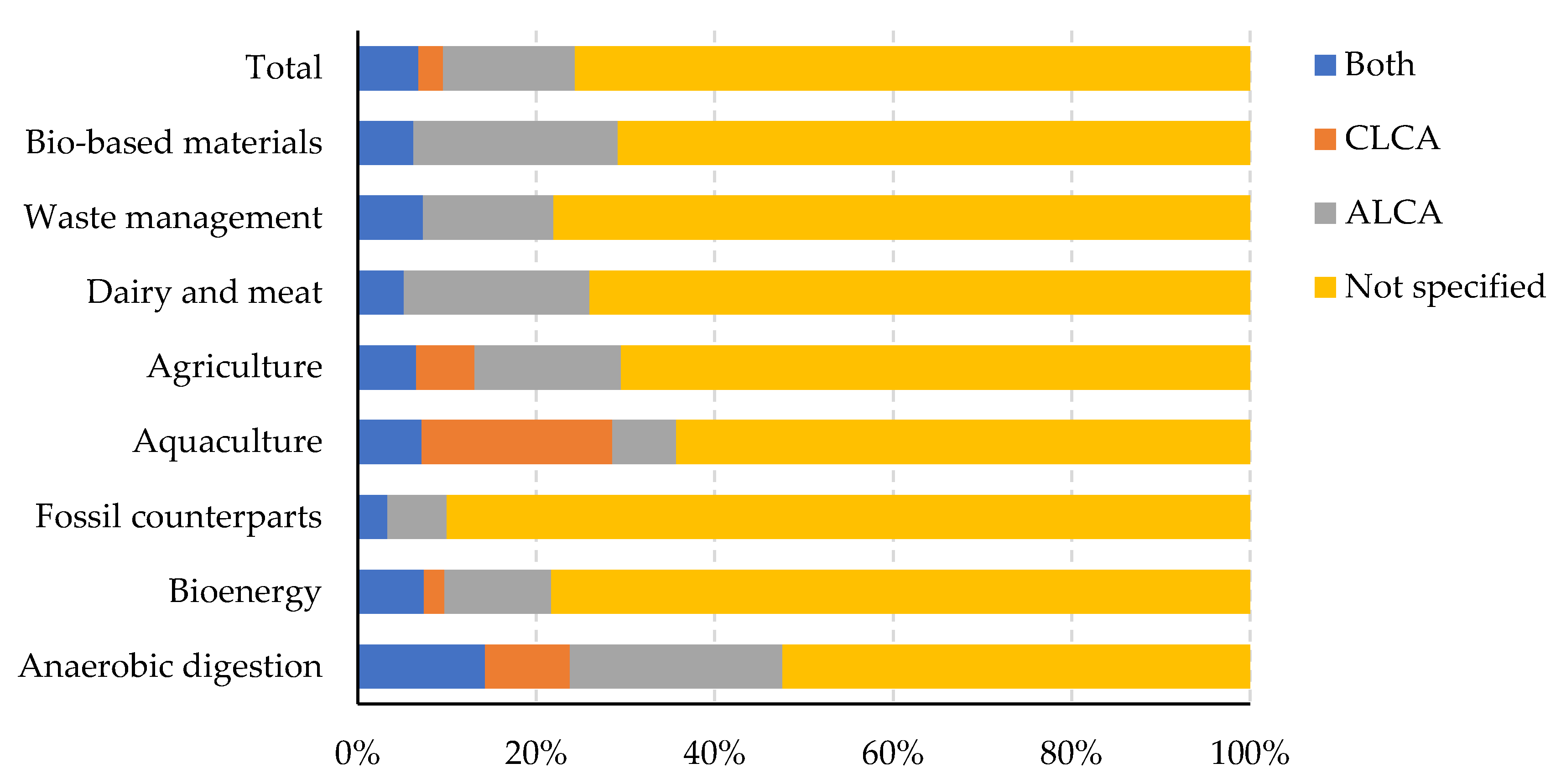

3.1.1. Current Practices in Specifying the Modeling Approach

3.1.2. The Application of Substitution as System Expansion Method

3.1.3. Using Substitution as the Allocation Method

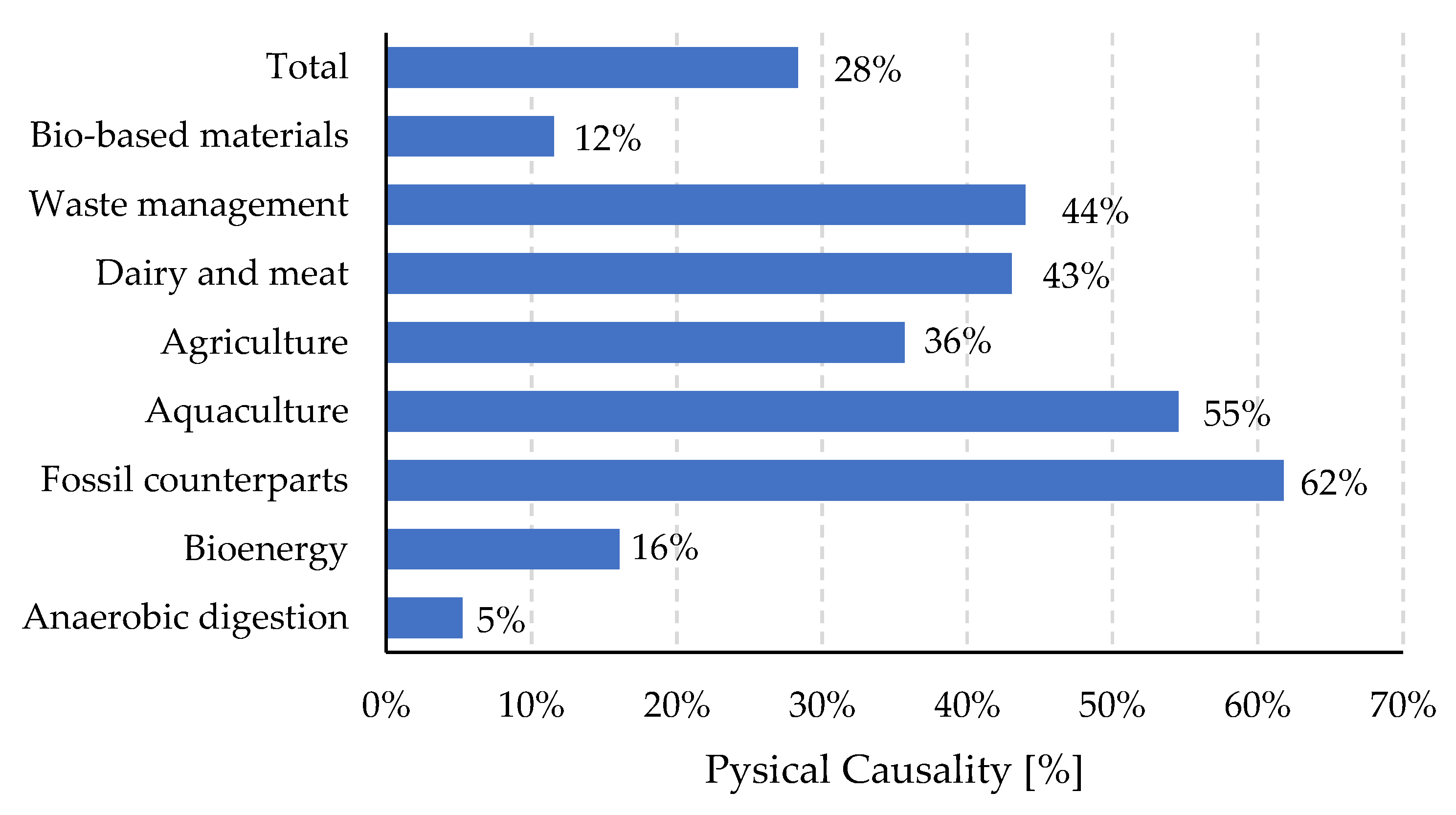

3.2. Selection of the ISO Allocation Criterion

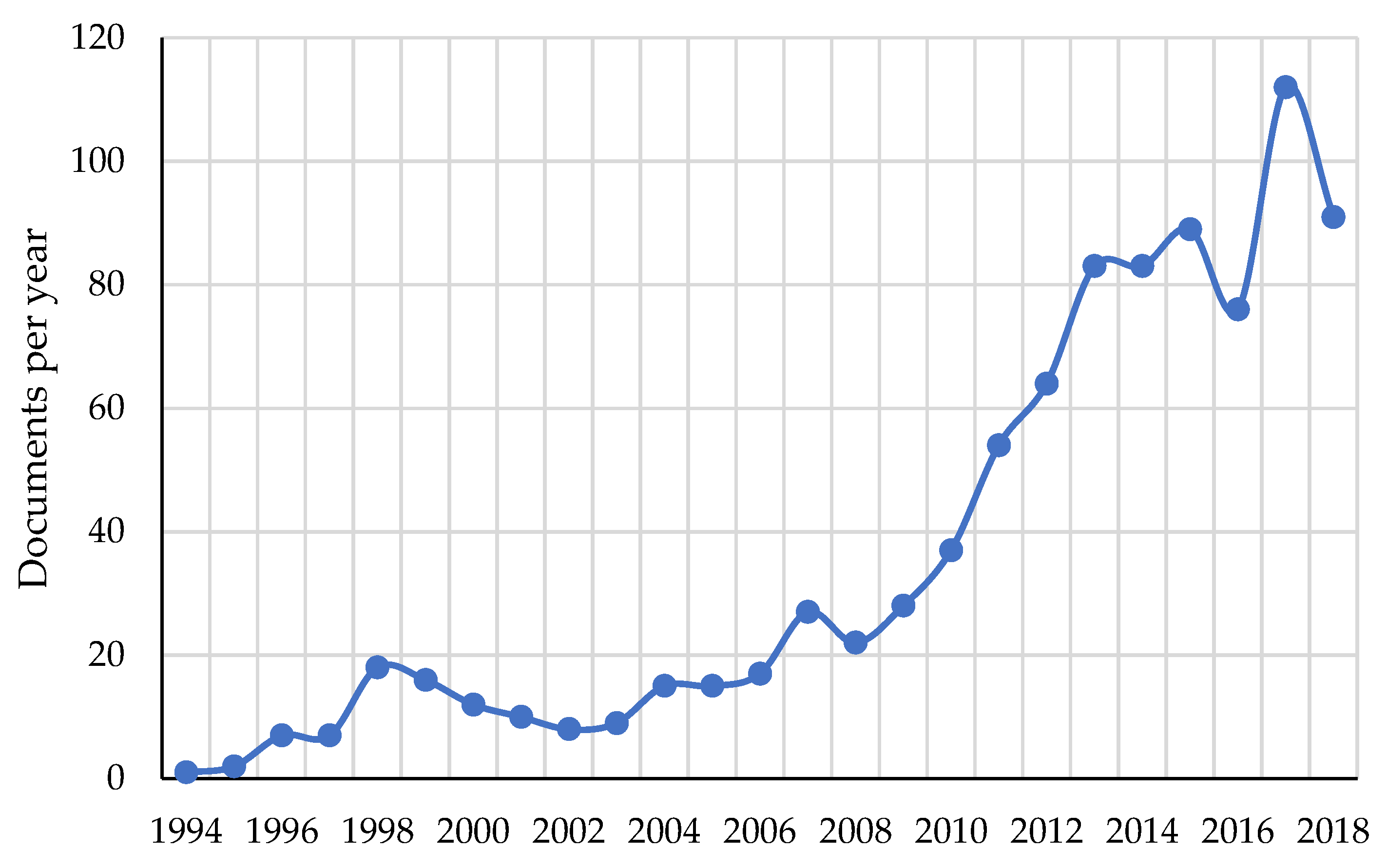

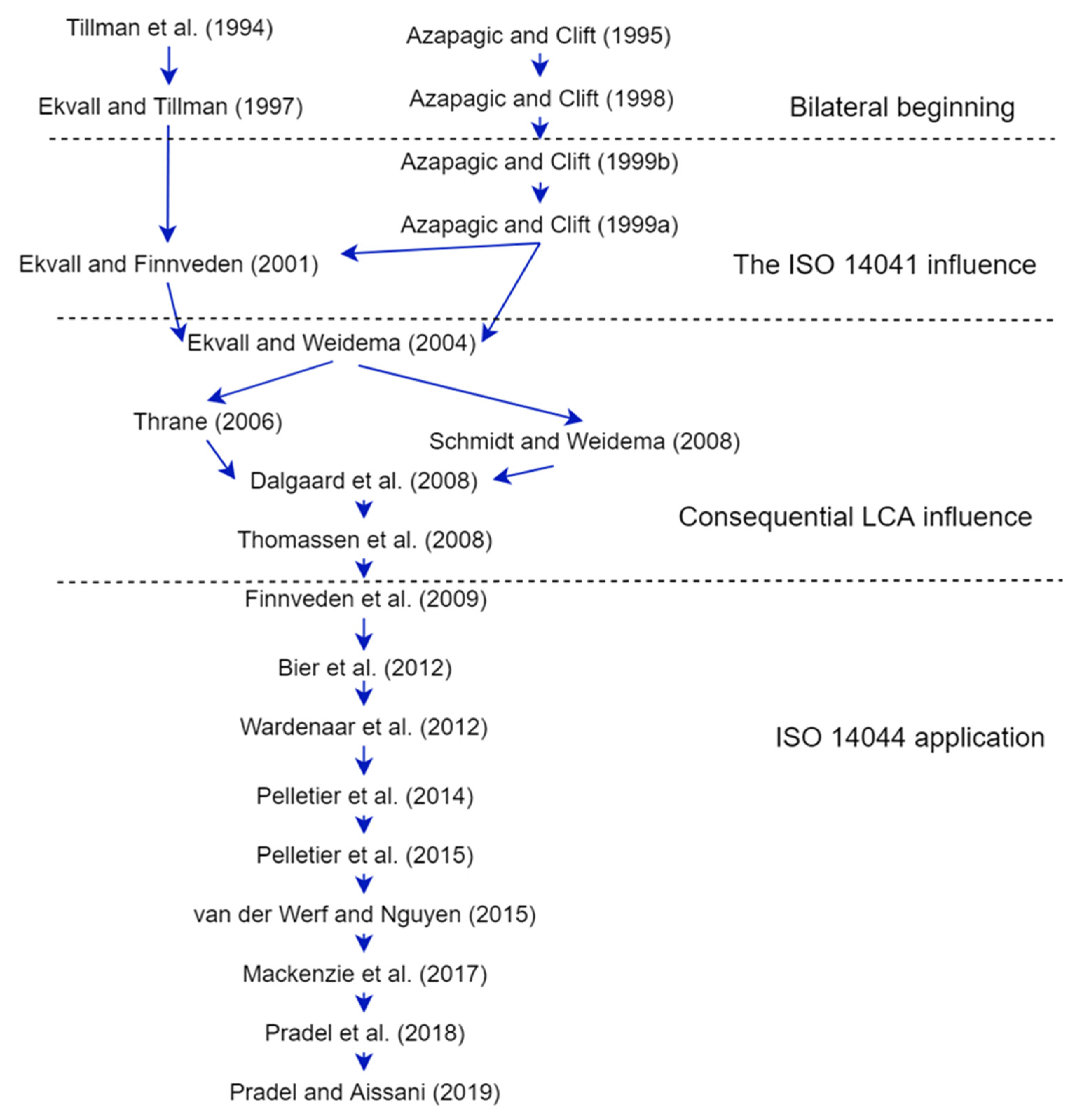

4. The Bibliometric Review Based on Main Path Analysis

4.1. Bilateral Beginning (1994–1998)

4.2. The ISO 14041 Influence (1999–2003)

4.3. Consequential LCA Influence (2004–2008)

4.4. ISO 14044:2006 Application (from 2009)

5. Discussion and Conclusions

- Clearly state if distinguishing between attributional and consequential LCA is a key principle to implement the hierarchy. If yes, then it should differentiate the hierarchy for the two approaches and clarify if the hierarchy allows substitution as a system expansion method in attributional LCAs.

- Clarify the meaning of allocation by “physical relationships” and “other relationships”, providing more examples and details than the ones reported in ISO 14044:2006 and ISO 14049:2012.

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Type of Products

Appendix A.2. Type of Multifunctional Processes

Appendix A.3. Type of Modeling Approaches

Appendix A.4. Type of System Expansion Approach and Substitution

References

- ISO (International Standard Organization). ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework; Technical Committee ISO/TC 207; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO (International Standard Organization). ISO 14044, Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO/TC 207/SC 5; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Sandin, G.; Røyne, F.; Berlin, J.; Peters, G.M.; Svanström, M. Allocation in LCAs of biorefinery products: Implications for results and decision-making. J. Clean. Prod. 2015, 93, 213–221. [Google Scholar] [CrossRef]

- Zamagni, A.; Buttol, P.; Porta, P.L.; Buonamici, R.; Masoni, P.; Guinée, J.; Heijungs, R.; Ekvall, T.; Bersani, R.; Bieńkowska, A.; et al. Critical Review of the Current Research Needs and Limitations Related to ISO-LCA Practice; Enea: Rome, Italy, 2008. [Google Scholar]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Developing a systematic framework for consistent allocation in LCA. Int. J. Life Cycle Assess. 2016, 21, 976–993. [Google Scholar] [CrossRef]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A survey of unresolved problems in life cycle assessment. Part 1: Goal and scope and inventory analysis. Int. J. Life Cycle Assess. 2008, 13, 290–300. [Google Scholar] [CrossRef]

- Weidema, B. Avoiding Co-Product Allocation in Life-Cycle Assessment. J. Ind. Ecol. 2000, 4, 11–33. [Google Scholar] [CrossRef]

- Muench, S.; Guenther, E. A systematic review of bioenergy life cycle assessments. Appl. Energy 2013, 112, 257–273. [Google Scholar] [CrossRef]

- Pelletier, N.; Ardente, F.; Brandão, M.; De Camillis, C.; Pennington, D. Rationales for and limitations of preferred solutions for multi-functionality problems in LCA: Is increased consistency possible? Int. J. Life Cycle Assess. 2015, 20, 74–86. [Google Scholar] [CrossRef]

- Agostini, A.; Giuntoli, J.; Marelli, L.; Amaducci, S. Flaws in the interpretation phase of bioenergy LCA fuel the debate and mislead policymakers. Int. J. Life Cycle Assess. 2019, 25, 17–35. [Google Scholar] [CrossRef]

- Lloyd, S.M.; Ries, R. Characterizing, propagating, and analyzing uncertainty in life-cycle assessment: A survey of quantitative approaches. J. Ind. Ecol. 2007, 11, 161–179. [Google Scholar] [CrossRef]

- Klöpffer, W. The critical review of life cycle assessment studies according to ISO 14040 and 14044. Int. J. Life Cycle Assess 2012, 17, 1087–1093. [Google Scholar] [CrossRef]

- Moretti, C.; Junginger, M.; Shen, L. Environmental life cycle assessment of polypropylene made from used cooking oil. Resour. Conserv. Recycl. 2020, 157, 104750. [Google Scholar] [CrossRef]

- Brando, M.; Martin, M.; Cowie, A.; Hamelin, L.; Zamagni, A. Consequential Life Cycle Assessment: What, How, and Why? Encycl. Sustain. Technol. 2017, 1, 277–284. [Google Scholar]

- Benetto, E.; Jury, C.; Kneip, G.; Vázquez-Rowe, I.; Huck, V.; Minette, F. Life cycle assessment of heat production from grape marc pellets. J. Clean. Prod. 2015, 87, 149–158. [Google Scholar] [CrossRef]

- Zaimes, G.G.; Khanna, V. The role of allocation and coproducts in environmental evaluation of microalgal biofuels: How important? Sustain. Energy Technol. Assess. 2014, 7, 247–256. [Google Scholar] [CrossRef]

- Śliwińska, A.; Burchart-Korol, D.; Smoliński, A. Environmental life cycle assessment of methanol and electricity co-production system based on coal gasification technology. Sci. Total Environ. 2017, 574, 1571–1579. [Google Scholar] [CrossRef]

- Bava, L.; Bacenetti, J.; Gislon, G.; Pellegrino, L.; D’Incecco, P.; Sandrucci, A.; Tamburini, A.; Fiala, M.; Zucali, M. Impact assessment of traditional food manufacturing: The case of Grana Padano cheese. Sci. Total Environ. 2018, 626, 1200–1209. [Google Scholar] [CrossRef]

- Esteves, V.P.; Esteves, E.M.; Bungenstab, D.J.; Feijó, G.L.; Araújo, O.D.; Morgado, C.D. Assessment of greenhouse gases (GHG) emissions from the tallow biodiesel production chain including land use change (LUC). J. Clean. Prod. 2017, 151, 578–591. [Google Scholar] [CrossRef]

- Pa, A.; Craven, J.S.; Bi, X.T.; Melin, S.; Sokhansanj, S. Environmental footprints of British Columbia wood pellets from a simplified life cycle analysis. Int. J. Life Cycle Assess. 2012, 17, 220–231. [Google Scholar] [CrossRef]

- Liu, J.S.; Chen, H.H.; Ho, M.H.C.; Li, Y.C. Citations with different levels of relevancy: Tracing the main paths of legal opinions. J. Assoc. Inf. Sci. Technol. 2014, 65, 2479–2488. [Google Scholar] [CrossRef]

- Xiao, Y.; Lu, L.Y.Y.; Liu, J.S.; Zhou, Z. Knowledge diffusion path analysis of data quality literature: A main path analysis. J. Informetr. 2014, 8, 594–605. [Google Scholar] [CrossRef]

- ISO (International Standard Organization). TECHNICAL REPORT ISO/TR 14049 Environmental Management—Life Cycle Assessment—Examples of Application of ISO 14041 to Goal and Scope Definition and Scope Definition and Inventory Analysis; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO (International Standard Organization). ISO/TR 14049:2012. Environmental Management—Life Cycle Assessment—Illustrative Examples on How to Apply ISO 14044 to Goal and Scope Definition and Inventory Analysis; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO (International Standard Organization). ISO 14041. Environmental Management—Life Cycle Assessment—Goal and Scope Definition and Inventory Analysis; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- ISO (International Standard Organization). ISO/TS 14072:2014. Environmental Management—Life Cycle Assessment—Requirements and Guidelines for Organizational Life Cycle Assessment; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- ILCD. ILCD Handbook—General guide on LCA—Detailed guidance. Constraints 2010, 15, 524–525. [Google Scholar]

- Manfredi, S.; Allacker, K.; Pelletier, N.; Chomkhamsri, K.; de Souza, D.M. European Commission Product Environmental Footprint (PEF) Guide; European Commission—Joint Research Centre: Ispra, Italy, 2012; p. 154. [Google Scholar]

- European Commission. PEFCR Guidance Document Guidance for the Development of Product Environmental Footprint Category Rules (PEFCRs), Version 6.3 ed; European Commission: Brussels, Belgium, 2017; p. 2018. [Google Scholar]

- Moro, A.; Joanny, G.; Moretti, C. Emerging technologies in the renewable energy sector: A comparison of expert review with a text mining software. Futures 2020, 117, 102511. [Google Scholar] [CrossRef]

- Batagelj, V.; Mrvar, A. Pajek—analysis and visualization of large networks. In Graph Drawing Software; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-540-45848-7. [Google Scholar]

- Ciano, M.P.; Strozzi, F.; Minelli, E.; Pozzi, R.; Rossi, T. The link between lean and human resource management or organizational behaviour: A bibliometric review. In Proceedings of the XXIV Summer School “Francesco Turco”—Industrial Systems Engineering, Brescia, Italy, 11–13 September 2019; pp. 321–328. [Google Scholar]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature review on the ‘smart factory’ concept using bibliometric tools. Int. J. Prod. Res. 2017, 55, 6572–6591. [Google Scholar] [CrossRef]

- Liu, J.S.; Lu, L.Y.Y. An integrated approach for main path analysis: Development of the Hirsch index as an example. J. Am. Soc. Inf. Sci. Technol. 2012, 63, 528–542. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Dandres, T.; Pauliuk, S.; Wood, R.; Hertwich, E.; Samson, R.; Strømman, A.H. Choice of allocations and constructs for attributional or consequential life cycle assessment and input-output analysis. J. Ind. Ecol. 2018, 22, 656–670. [Google Scholar] [CrossRef]

- De Camillis, C.; Brandão, M.; Zamagni, A.; Pennington, D. Sustainability Assessment of Future-Oriented Scenarios: A Review of Data Modelling Approaches in Life Cycle Assessment. Towards Recommendations for Policy Making and Business Strategies; Publications Office of the European Union: Luxemburg, 2013; ISBN 9789279325229. [Google Scholar]

- Sandin, G.; Peters, G.M.; Svanström, M. Life cycle assessment of construction materials: The influence of assumptions in end-of-life modelling. Int. J. Life Cycle Assess. 2014, 19, 723–731. [Google Scholar] [CrossRef]

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 2016, 125, 219–226. [Google Scholar] [CrossRef]

- Heijungs, R. Economic Drama and the Environmental Stage: Formal Derivation of Algorithmic Tools for Environmental Analysis and Decisionsupport from a Unified Epistemological Principle; Leiden University: Leiden, The Netherlands, 1997. [Google Scholar]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.; Ventura, A. LCA allocation procedure used as an incitative method for waste recycling: An application to mineral additions in concrete. Resour. Conserv. Recycl. 2010, 54, 1231–1240. [Google Scholar] [CrossRef]

- Bailis, R.; Kavlak, G. Environmental implications of Jatropha biofuel from a silvi-pastoral production system in central-west Brazil. Environ. Sci. Technol. 2013, 47, 8042–8050. [Google Scholar] [CrossRef]

- Schau, E.M.; Fet, A.M. LCA studies of food products as background for environmental product declarations. Int. J. Life Cycle Assess. 2008, 13, 255–264. [Google Scholar] [CrossRef]

- Heijungs, R.; Guinée, J.B. Allocation and “what-if” scenarios in life cycle assessment of waste management systems. Waste Manag. 2007, 27, 997–1005. [Google Scholar] [CrossRef]

- Heijungs, R. Ten easy lessons for good communication of LCA. Int. J. Life Cycle Assess. 2014, 19, 473–476. [Google Scholar] [CrossRef]

- Marvuglia, A.; Cellura, M.; Heijungs, R. Toward a solution of allocation in life cycle inventories: The use of least-squares techniques. Int. J. Life Cycle Assess. 2010, 15, 1020–1040. [Google Scholar] [CrossRef]

- Steubing, B.; Wernet, G.; Reinhard, J.; Bauer, C.; Moreno-Ruiz, E. The ecoinvent database version 3 (part II): Analyzing LCA results and comparison to version 2. Int. J. Life Cycle Assess. 2016, 21, 1269–1281. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Hermansen, J.E. System expansion for handling co-products in LCA of sugar cane bio-energy systems: GHG consequences of using molasses for ethanol production. Appl. Energy 2012, 89, 254–261. [Google Scholar] [CrossRef]

- Corrado, S.; Ardente, F.; Sala, S.; Saouter, E. Modelling of food loss within life cycle assessment: From current practice towards a systematisation. J. Clean. Prod. 2017, 140, 847–859. [Google Scholar] [CrossRef]

- Brander, M.; Wylie, C. The use of substitution in attributional life cycle assessment. Greenh. Gas Meas. Manag. 2011, 1, 161–166. [Google Scholar] [CrossRef]

- Nhu, T.T.; Dewulf, J.; Serruys, P.; Huysveld, S.; Nguyen, C.V.; Sorgeloos, P.; Schaubroeck, T. Resource usage of integrated Pig-Biogas-Fish system: Partitioning and substitution within attributional life cycle assessment. Resour. Conserv. Recycl. 2015, 102, 27–38. [Google Scholar] [CrossRef]

- Weidema, B. ISO System Expansion = Substitution 2.0. 2014. Available online: https://lca-net.com/blog/iso-system-expansion-substitution/ (accessed on 15 November 2019).

- Forman, G.S.; Hahn, T.E.; Jensen, S.D. Greenhouse gas emission evaluation of the GTL pathway. Environ. Sci. Technol. 2011, 45, 9084–9092. [Google Scholar] [CrossRef]

- Manninen, K.; Koskela, S.; Nuppunen, A.; Sorvari, J.; Nevalainen, O.; Siitonen, S. The applicability of the renewable energy directive calculation to assess the sustainability of biogas production. Energy Policy 2013, 56, 549–557. [Google Scholar] [CrossRef]

- Karlsson, H.; Börjesson, P.; Hansson, P.A.; Ahlgren, S. Ethanol production in biorefineries using lignocellulosic feedstock—GHG performance, energy balance and implications of life cycle calculation methodology. J. Clean. Prod. 2014, 83, 420–427. [Google Scholar] [CrossRef]

- García, C.A.; Fuentes, A.; Hennecke, A.; Riegelhaupt, E.; Manzini, F.; Masera, O. Life-cycle greenhouse gas emissions and energy balances of sugarcane ethanol production in Mexico. Appl. Energy 2011, 88, 2088–2097. [Google Scholar] [CrossRef]

- Li, X.; Mupondwa, E. Life cycle assessment of camelina oil derived biodiesel and jet fuel in the Canadian Prairies. Sci. Total Environ. 2014, 481, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Brockmann, D.; Pradinaud, C.; Champenois, J.; Benoit, M.; Hélias, A. Environmental assessment of bioethanol from onshore grown green seaweed. Biofuels Bioprod. Biorefining 2015, 9, 696–708. [Google Scholar] [CrossRef]

- Tillman, A.M.; Ekvall, T.; Baumann, H.; Rydberg, T. Choice of system boundaries in life cycle assessment. J. Clean. Prod. 1994, 2, 21–29. [Google Scholar] [CrossRef]

- Giuntoli, J.; Commission, E.; Bulgheroni, C.; Commission, E.; Marelli, L.; Commission, E.; Sala, S.; Commission, E. Brief on the use of Life Cycle Assessment (LCA) to evaluate environmental impacts of the bioeconomy. J. Sustain. Energy Environ. Spec. Issue 2019, 1–8. [Google Scholar] [CrossRef]

- Cherubini, E.; Franco, D.; Zanghelini, G.M.; Soares, S.R. Uncertainty in LCA case study due to allocation approaches and life cycle impact assessment methods. Int. J. Life Cycle Assess. 2018, 23, 2055–2070. [Google Scholar] [CrossRef]

- Herrmann, I.T.; Jørgensen, A.; Bruun, S.; Hauschild, M.Z. Potential for optimized production and use of rapeseed biodiesel. Based on a comprehensive real-time LCA case study in Denmark with multiple pathways. Int. J. Life Cycle Assess. 2013, 18, 418–430. [Google Scholar] [CrossRef]

- Forman, G.S.; Hauser, A.B.; Adda, S.M. Life cycle analysis of gas to liquids (GTL) derived linear alkyl benzene. J. Clean. Prod. 2014, 80, 30–37. [Google Scholar] [CrossRef]

- Weidema, B.P.; Frees, N.; Nielsen, A.M. Marginal production technologies for life cycle inventories. Int. J. Life Cycle Assess. 1999, 4, 48–56. [Google Scholar] [CrossRef]

- Hermansson, F.; Janssen, M.; Svanström, M. Allocation in life cycle assessment of lignin. Int. J. Life Cycle Assess. 2020. Article in Press. [Google Scholar] [CrossRef]

- Pelletier, N.; Allacker, K.; Pant, R.; Manfredi, S. The European Commission Organisation Environmental Footprint method: Comparison with other methods, and rationales for key requirements. Int. J. Life Cycle Assess. 2014, 19, 387–404. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H.; Ulgiati, S. Influence of allocation methods on the environmental performance of biorefinery products—A case study. Resour. Conserv. Recycl. 2011, 55, 1070–1077. [Google Scholar] [CrossRef]

- Moretti, C.; Corona, B.; Rühlin, V.; Götz, T.; Junginger, M.; Brunner, T.; Obernberger, I.; Shen, L. Combining biomass gasification and solid oxid fuel cell for heat and power generation: An early-stage life cycle assessment. Energies 2020, 13, 2773. [Google Scholar] [CrossRef]

- Ahlgren, S.; Björklund, A.; Ekman, A.; Karlsson, H.; Berlin, J.; Börjesson, P.; Ekvall, T.; Finnveden, G.; Janssen, M.; Strid, I. Review of methodological choices in LCA of biorefinery systems—Key issues and recommendations. Biofuels Bioprod. Biorefining 2015, 9, 606–619. [Google Scholar] [CrossRef]

- Mackenzie, S.G.; Leinonen, I.; Kyriazakis, I. The need for co-product allocation in the life cycle assessment of agricultural systems—Is “biophysical” allocation progress? Int. J. Life Cycle Assess. 2017, 22, 128–137. [Google Scholar] [CrossRef]

- Azapagic, A.; Clift, R. Allocation of environmental burdens in multiple-function systems. J. Clean. Prod. 1999, 7, 101–119. [Google Scholar] [CrossRef]

- Azapagic, A.; Clift, R. Allocation of environmental burdens in co-product systems: Process and product-related burdens (part 2). Int. J. Life Cycle Assess. 2000, 5, 31–36. [Google Scholar] [CrossRef]

- Ekvall, T.; Finnveden, G. Allocation in ISO 14041—A critical review. J. Clean. Prod. 2001, 9, 197–208. [Google Scholar] [CrossRef]

- Azapagic, A.; Clift, R. Linear programming as a tool in life cycle assessment. Int. J. Life Cycle Assess. 1998, 3, 305–316. [Google Scholar] [CrossRef]

- Bernier, E.; Lavigne, C.; Robidoux, P.Y. Life cycle assessment of kraft lignin for polymer applications. Int. J. Life Cycle Assess. 2013, 18, 520–5288. [Google Scholar] [CrossRef]

- González-García, S.; Moreira, M.T.; Feijoo, G. Environmental performance of lignocellulosic bioethanol production from alfalfa stems. Biofuels Bioprod. Biorefining 2010, 4, 118–131. [Google Scholar] [CrossRef]

- Finnveden, G.; Albertsson, A.C.; Berendson, J.; Eriksson, E.; Höglund, L.O.; Karlsson, S.; Sundqvist, J.O. Solid waste treatment within the framework of life-cycle assessment. J. Clean. Prod. 1995, 3, 189–199. [Google Scholar] [CrossRef]

- Jungmeier, G.; Werner, F.; Jarnehammar, A.; Hohenthal, C.; Richter, K. Allocation in LCA of wood-based products—Experiences of cost action E9: Part II. Examples. Int. J. Life Cycle Assess. 2002, 7, 290–294. [Google Scholar] [CrossRef]

- Nejad, A.T.M.; Saint-Antonin, V. Factors driving refinery CO2 intensity, with allocation into products: Comment. Int. J. Life Cycle Assess. 2014, 19, 24–28. [Google Scholar]

- Moretti, C.; Moro, A.; Edwards, R.; Rocco, M.V.; Colombo, E. Analysis of standard and innovative methods for allocating upstream and refinery GHG emissions to oil products. Appl. Energy 2017, 206, 372–381. [Google Scholar] [CrossRef]

- International Dairy Federation. A Common Carbon Footprint Approach for Dairy: The IDF Guide to Standard Lifecycle Assessment Methodology for the Dairy Sector. 2015. Available online: https://store.fil-idf.org/product/a-common-carbon-footprint-approach-for-the-dairy-sector-the-idf-guide-to-standard-life-cycle-assessment-methodology/ (accessed on 10 July 2020).

- Van der Harst, E.; Potting, J.; Kroeze, C. Comparison of different methods to include recycling in LCAs of aluminium cans and disposable polystyrene cups. Waste Manag. 2016, 48, 565–583. [Google Scholar] [CrossRef] [PubMed]

- Silva, D.A.L.; Lahr, F.A.R.; Pavan, A.L.R.; Saavedra, Y.M.B.; Mendes, N.C.; Sousa, S.R.; Sanches, R.; Ometto, A.R. Do wood-based panels made with agro-industrial residues provide environmentally benign alternatives? An LCA case study of sugarcane bagasse addition to particle board manufacturing. Int. J. Life Cycle Assess. 2014, 19, 1767–1778. [Google Scholar] [CrossRef]

- Palmieri, N.; Forleo, M.B.; Giannoccaro, G.; Suardi, A. Environmental impact of cereal straw management: An on-farm assessment. J. Clean. Prod. 2017, 142, 2950–2964. [Google Scholar] [CrossRef]

- Vergé, X.; Maxime, D.; Desjardins, R.L.; Vanderzaag, A.C. Allocation factors and issues in agricultural carbon footprint: A case study of the Canadian pork industry. J. Clean. Prod. 2016, 113, 587–595. [Google Scholar] [CrossRef]

- Tufvesson, L.M.; Tufvesson, P.; Woodley, J.M.; Börjesson, P. Life cycle assessment in green chemistry: Overview of key parameters and methodological concerns. Int. J. Life Cycle Assess. 2013, 18, 431–444. [Google Scholar] [CrossRef]

- Vidal, R.; Martínez, P.; Garraín, D. Life cycle assessment of composite materials made of recycled thermoplastics combined with rice husks and cotton linters. Int. J. Life Cycle Assess. 2009, 14, 73–82. [Google Scholar] [CrossRef]

- Vera, I.; Hoefnagels, R.; van der Kooij, A.; Moretti, C.; Junginger, M. A carbon footprint assessment of multi-output biorefineries with international biomass supply: A case study for the Netherlands. Biofuels Bioprod. Biorefining 2020, 14, 198–224. [Google Scholar] [CrossRef]

- Ekvall, T.; Tillman, A.M. Open-loop recycling: Criteria for allocation procedures. Int. J. Life Cycle Assess. 1997, 2, 155–162. [Google Scholar] [CrossRef]

- Clift, R. Chairman’s report of session 3: Causality and allocation procedures. In Proceedings of the European Workshop on Allocation in LCA, Leiden, The Netherlands, 24–25 February 1994; pp. 3–4. [Google Scholar]

- Clift, R. Report from setac-europe working group on life cycle inventory analysis. In Abstract Book, 6th SETAC-Europe, Proceedings of the Annual Meeting, Taormina, Italy, 19–22 May 1996; SETAC-Europe: Brussels, Belgium, 1996; p. 17. [Google Scholar]

- Azapagic, A.; Clift, R. Life cycle assessment and linear programming environmental optimisation of product system. Comput. Chem. Eng. 1995, 19, 229–234. [Google Scholar] [CrossRef]

- ISO (International Standard Organization). ISO/TC 207/SC 5/AXIG2: CD 14 041.2. N99, DIN. 1996 (as Cited by Ekvall and Tillman in Open-loop Recycling: Criteria for Allocation Procedures-[88]); ISO: Geneva, Switzerland, 1996. [Google Scholar]

- Azapagic, A.; Clift, R. Allocation of Environmental Burdens in Co-product Systems: Product-related Burdens (Part 1). Int. J. Life Cycle Assess. 1999, 4, 357–369. [Google Scholar] [CrossRef]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Thrane, M. LCA of Danish fish products: New methods and insights. Int. J. Life Cycle Assess. 2006, 11, 66–74. [Google Scholar] [CrossRef]

- Schmidt, J.H.; Weidema, B.P. Shift in the marginal supply of vegetable oil. Int. J. Life Cycle Assess. 2008, 13, 235–239. [Google Scholar] [CrossRef]

- Dalgaard, R.; Schmidt, J.; Halberg, N.; Christensen, P.; Thrane, M.; Pengue, W.A. LCA for soybean meal. LCA Food Prod. 2008, 10, 240–254. [Google Scholar] [CrossRef]

- Thomassen, M.A.; Dalgaard, R.; Heijungs, R.; De Boer, I. Attributional and consequential LCA of milk production. Int. J. Life Cycle Assess. 2008, 13, 339–349. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Bier, J.M.; Verbeek, C.J.R.; Lay, M.C. An eco-profile of thermoplastic protein derived from blood meal Part 1: Allocation issues. Int. J. Life Cycle Assess. 2012, 17, 208–219. [Google Scholar] [CrossRef]

- Wardenaar, T.; Van Ruijven, T.; Beltran, A.M.; Vad, K.; Guinée, J.; Heijungs, R. Differences between LCA for analysis and LCA for policy: A case study on the consequences of allocation choices in bio-energy policies. Int. J. Life Cycle Assess. 2012, 17, 1059–1067. [Google Scholar] [CrossRef]

- Van der Werf, H.M.G.; Nguyen, T.T.H. Construction cost of plant compounds provides a physical relationship for co-product allocation in life cycle assessment. Int. J. Life Cycle Assess. 2015, 20, 777–784. [Google Scholar] [CrossRef]

- Pradel, M.; Aissani, L.; Canler, J.P.; Roux, J.C.; Villot, J.; Baudez, J.C.; Laforest, V. Constructing an allocation factor based on product- and process-related parameters to assess environmental burdens of producing value-added sludge-based products. J. Clean. Prod. 2018, 171, 1546–1557. [Google Scholar] [CrossRef]

- Pradel, M.; Aissani, L. Environmental impacts of phosphorus recovery from a “product” Life Cycle Assessment perspective: Allocating burdens of wastewater treatment in the production of sludge-based phosphate fertilizers. Sci. Total Environ. 2019, 656, 55–69. [Google Scholar] [CrossRef] [PubMed]

- European Union Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; LexUriServ; European Union: Brussels, Belgium, 2008.

- Curran, M.A.; Mann, M.; Norris, G. The international workshop on electricity data for life cycle inventories. J. Clean. Prod. 2005, 13, 853–862. [Google Scholar] [CrossRef]

- Plevin, R.J.; Delucchi, M.A.; Creutzig, F. Using Attributional Life Cycle Assessment to Estimate Climate-Change Mitigation Benefits Misleads Policy Makers. J. Ind. Ecol. 2014, 18, 73–83. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moretti, C.; Corona, B.; Edwards, R.; Junginger, M.; Moro, A.; Rocco, M.; Shen, L. Reviewing ISO Compliant Multifunctionality Practices in Environmental Life Cycle Modeling. Energies 2020, 13, 3579. https://doi.org/10.3390/en13143579

Moretti C, Corona B, Edwards R, Junginger M, Moro A, Rocco M, Shen L. Reviewing ISO Compliant Multifunctionality Practices in Environmental Life Cycle Modeling. Energies. 2020; 13(14):3579. https://doi.org/10.3390/en13143579

Chicago/Turabian StyleMoretti, Christian, Blanca Corona, Robert Edwards, Martin Junginger, Alberto Moro, Matteo Rocco, and Li Shen. 2020. "Reviewing ISO Compliant Multifunctionality Practices in Environmental Life Cycle Modeling" Energies 13, no. 14: 3579. https://doi.org/10.3390/en13143579

APA StyleMoretti, C., Corona, B., Edwards, R., Junginger, M., Moro, A., Rocco, M., & Shen, L. (2020). Reviewing ISO Compliant Multifunctionality Practices in Environmental Life Cycle Modeling. Energies, 13(14), 3579. https://doi.org/10.3390/en13143579