Design of a Passive Downdraught Evaporative Cooling Windcatcher (PDEC-WC) System for Greenhouses in Hot Climates

Abstract

1. Introduction

2. Literature Review

3. Methods

3.1. CFD Theory

3.2. Computational Domain

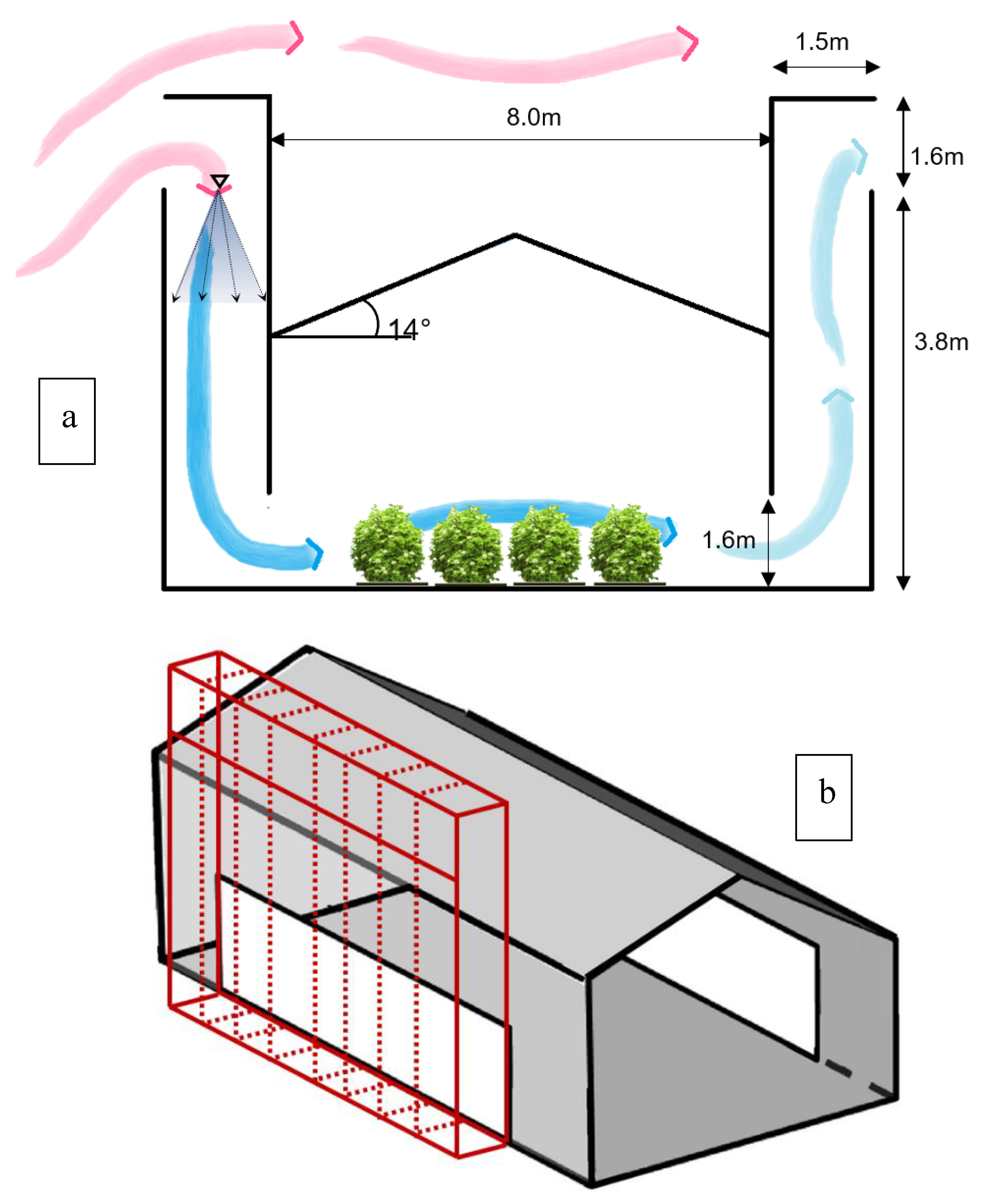

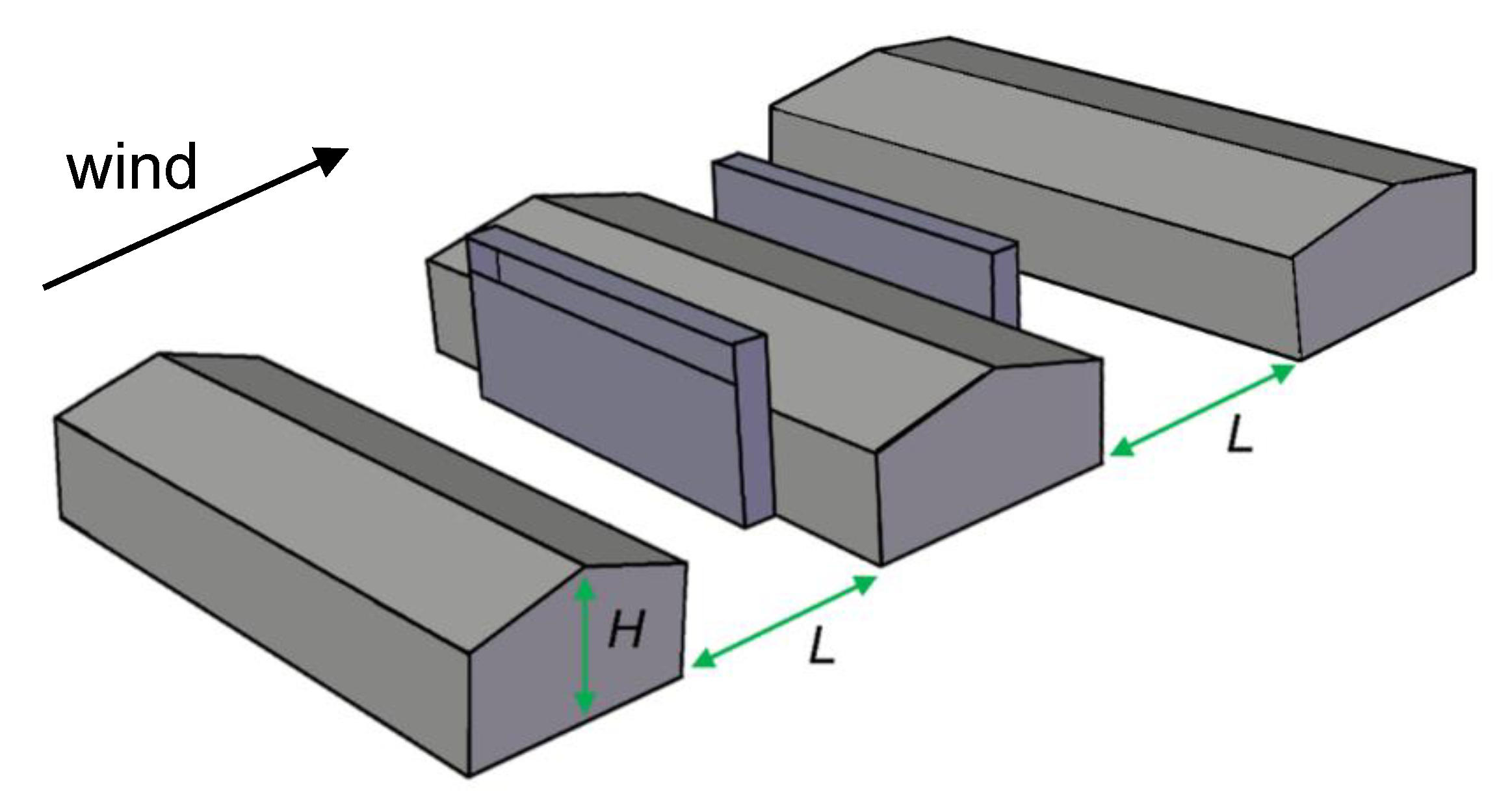

3.3. Design Geometry and Configurations

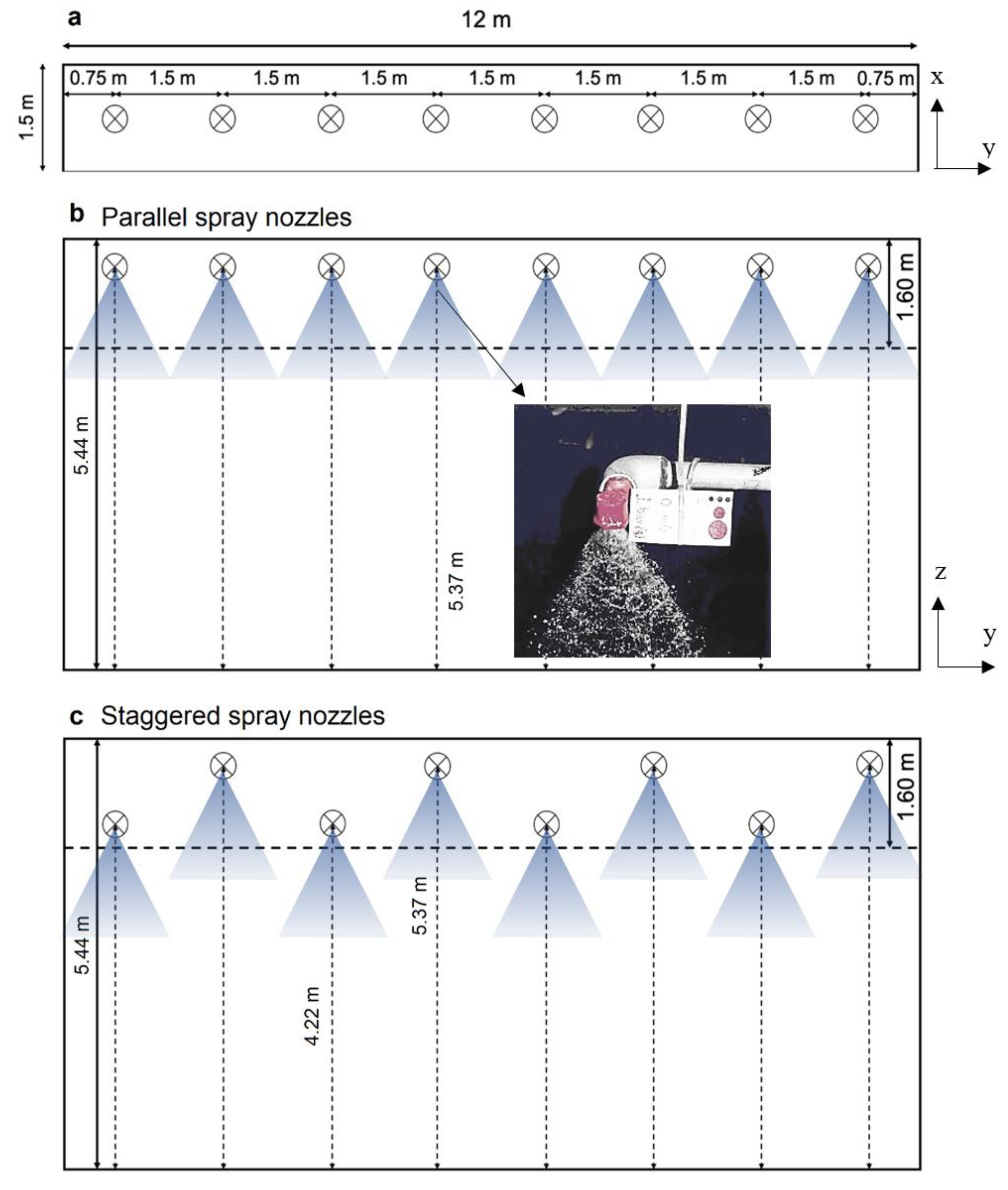

3.4. Ambient Conditions and Spray Properties

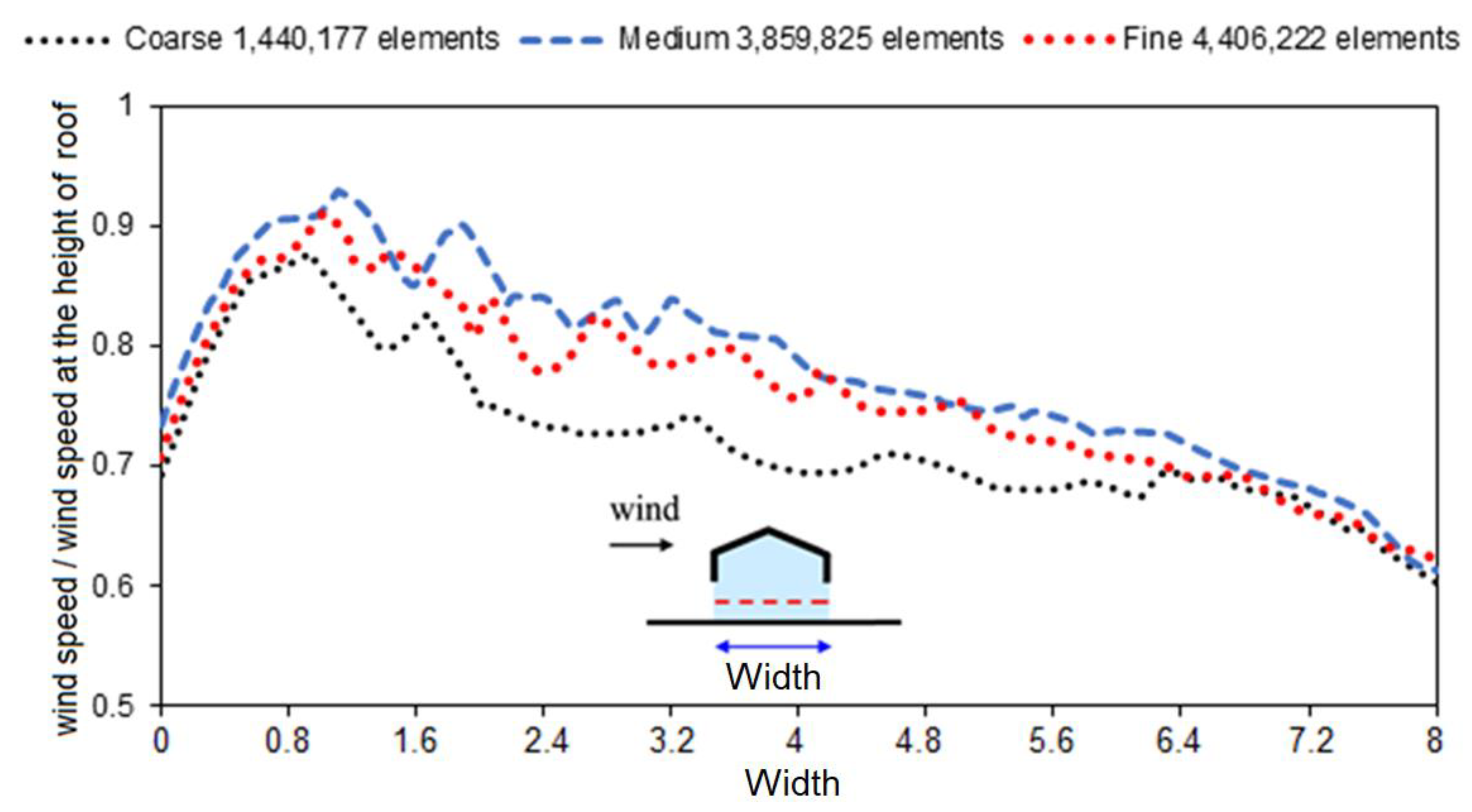

3.5. Mesh and Sensitivity Analysis

3.6. Boundary Conditions

4. Results and Discussion

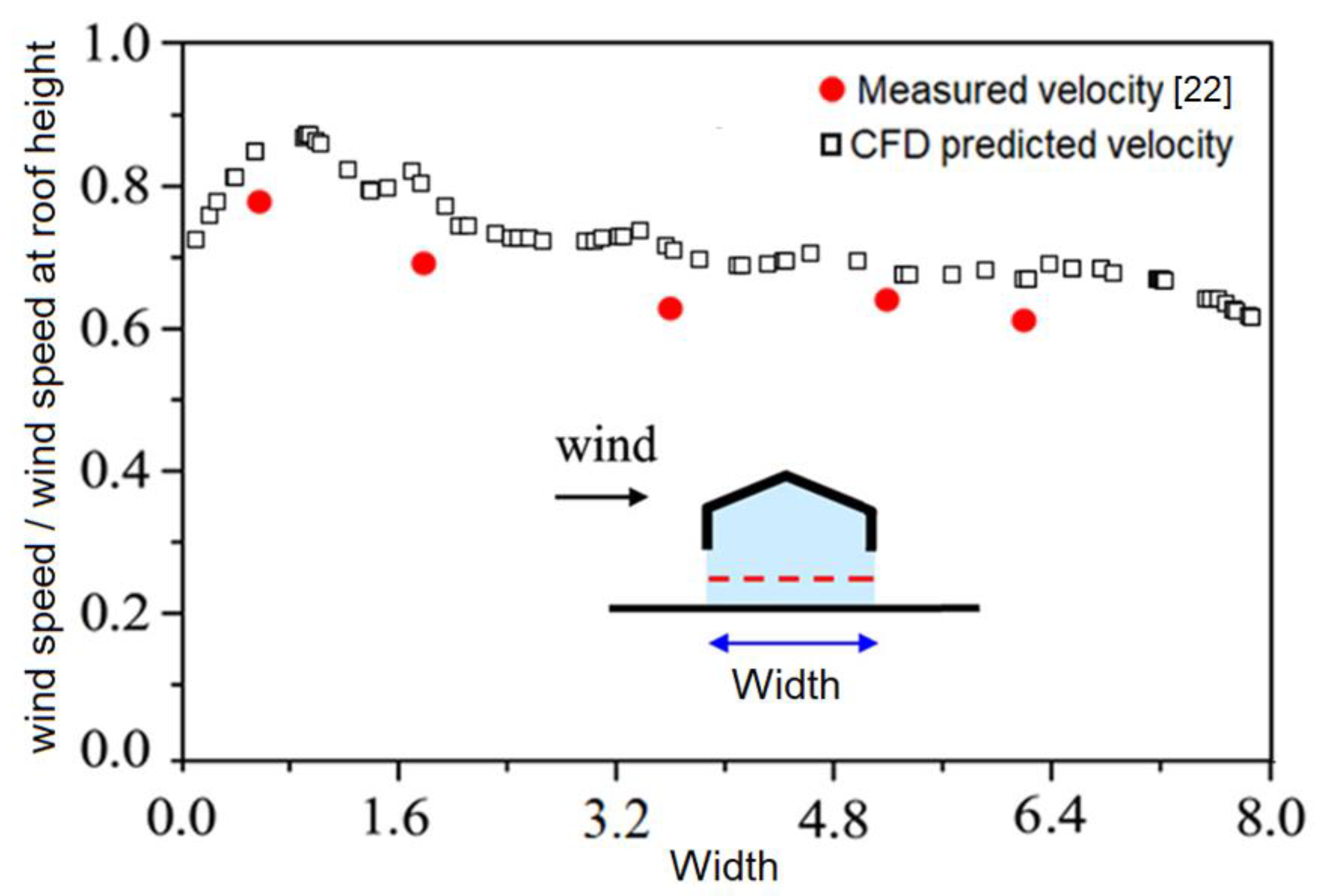

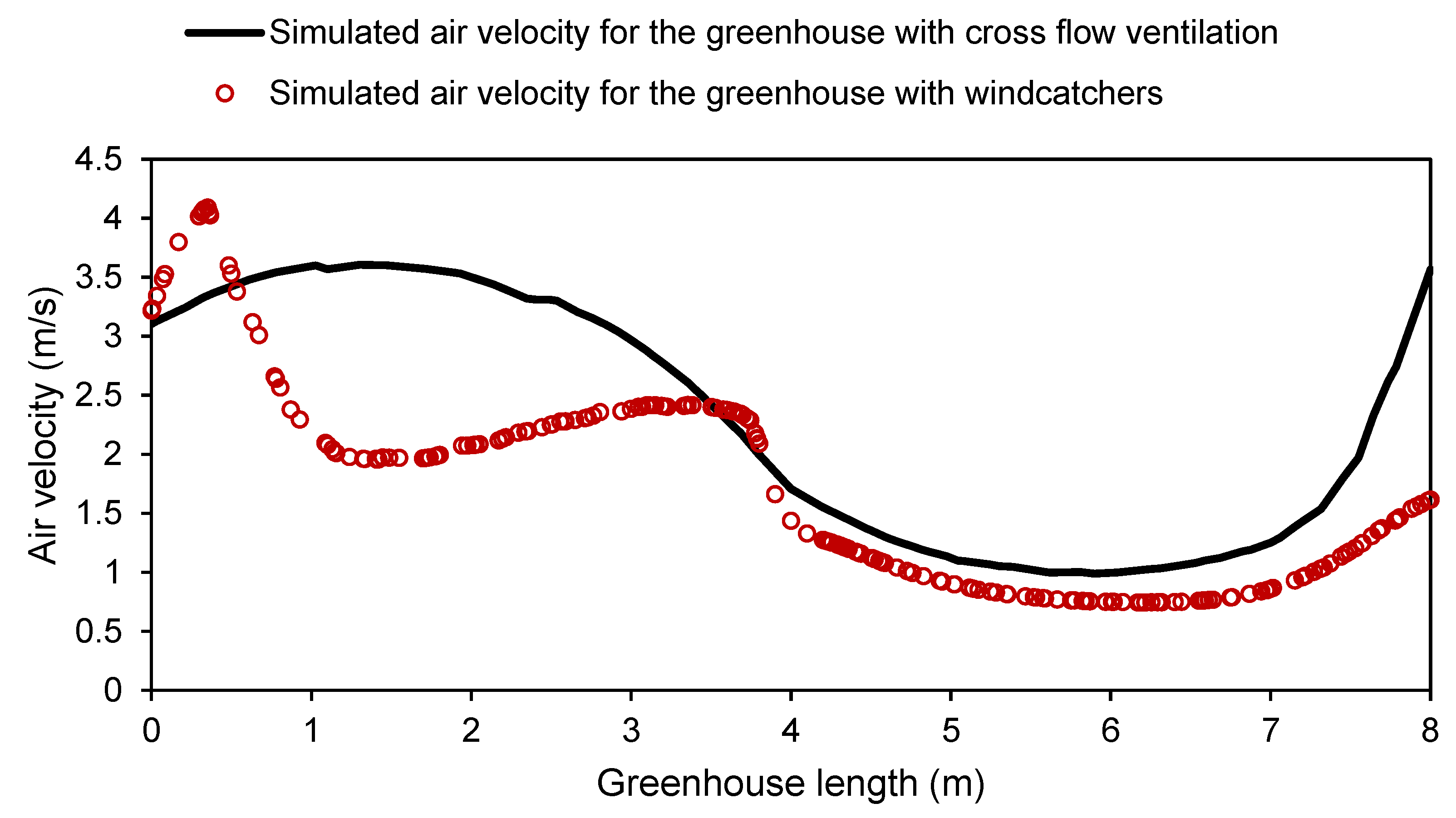

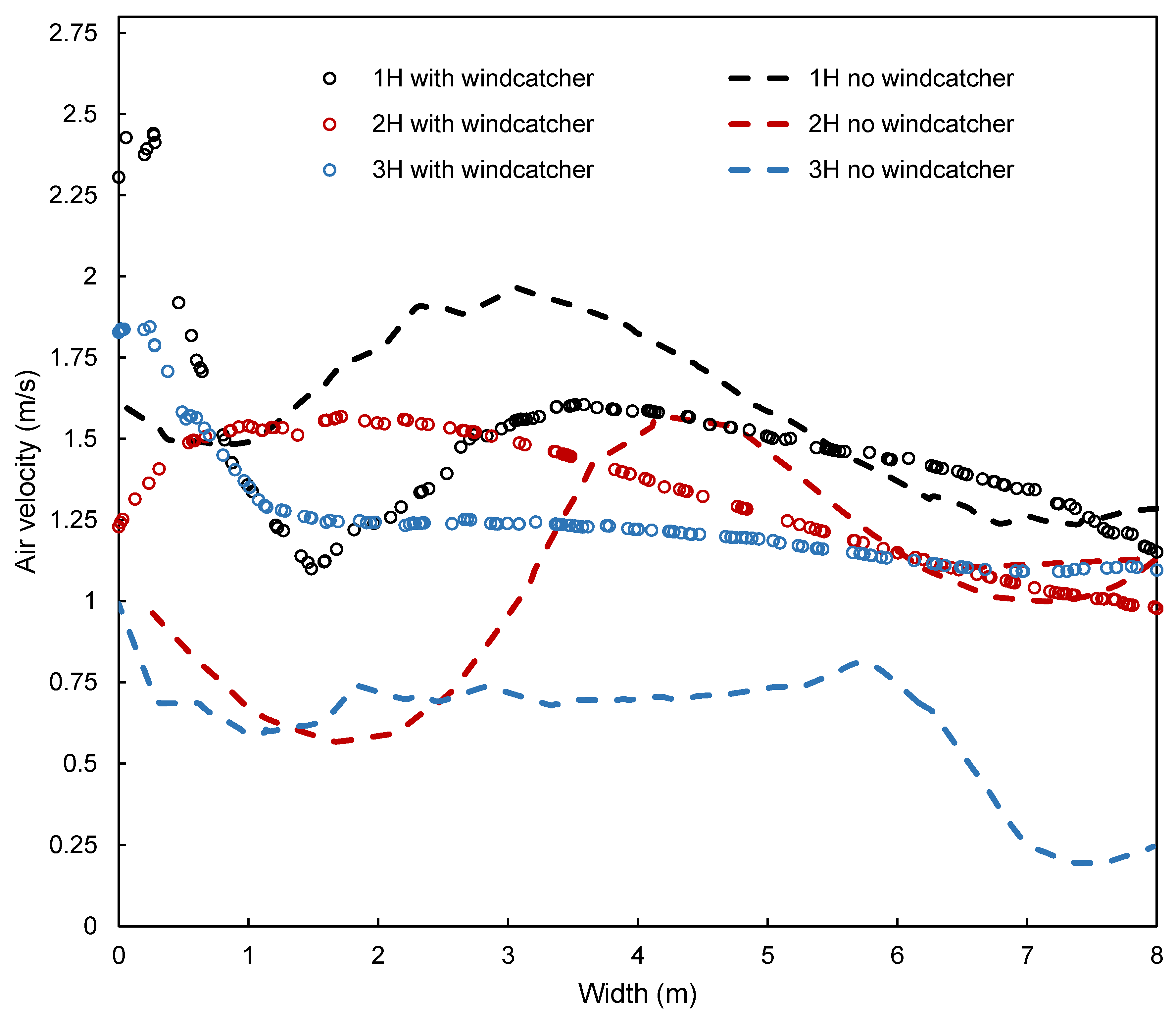

4.1. Validation of the Greenhouse Model

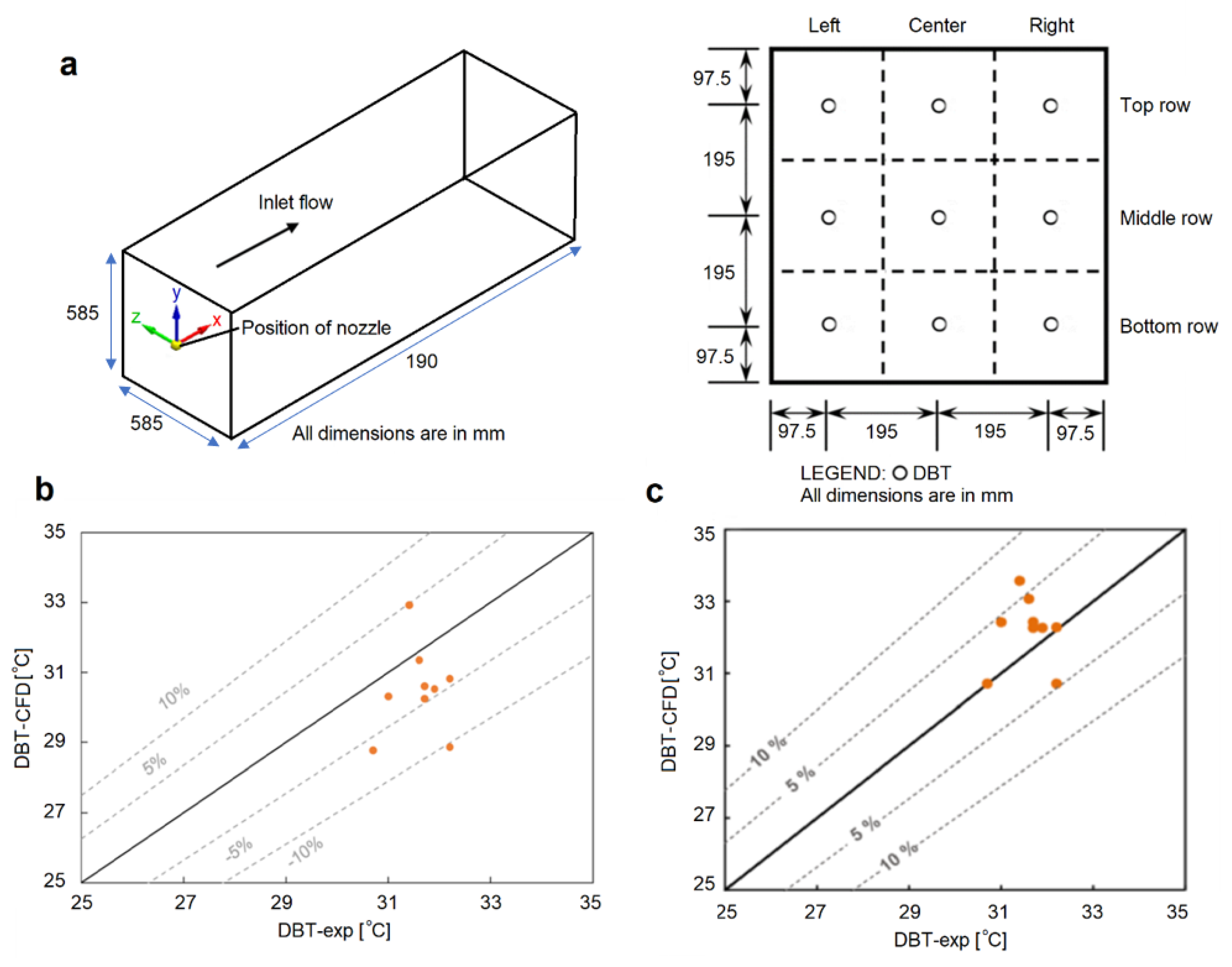

4.2. Validation of the Water Spray System

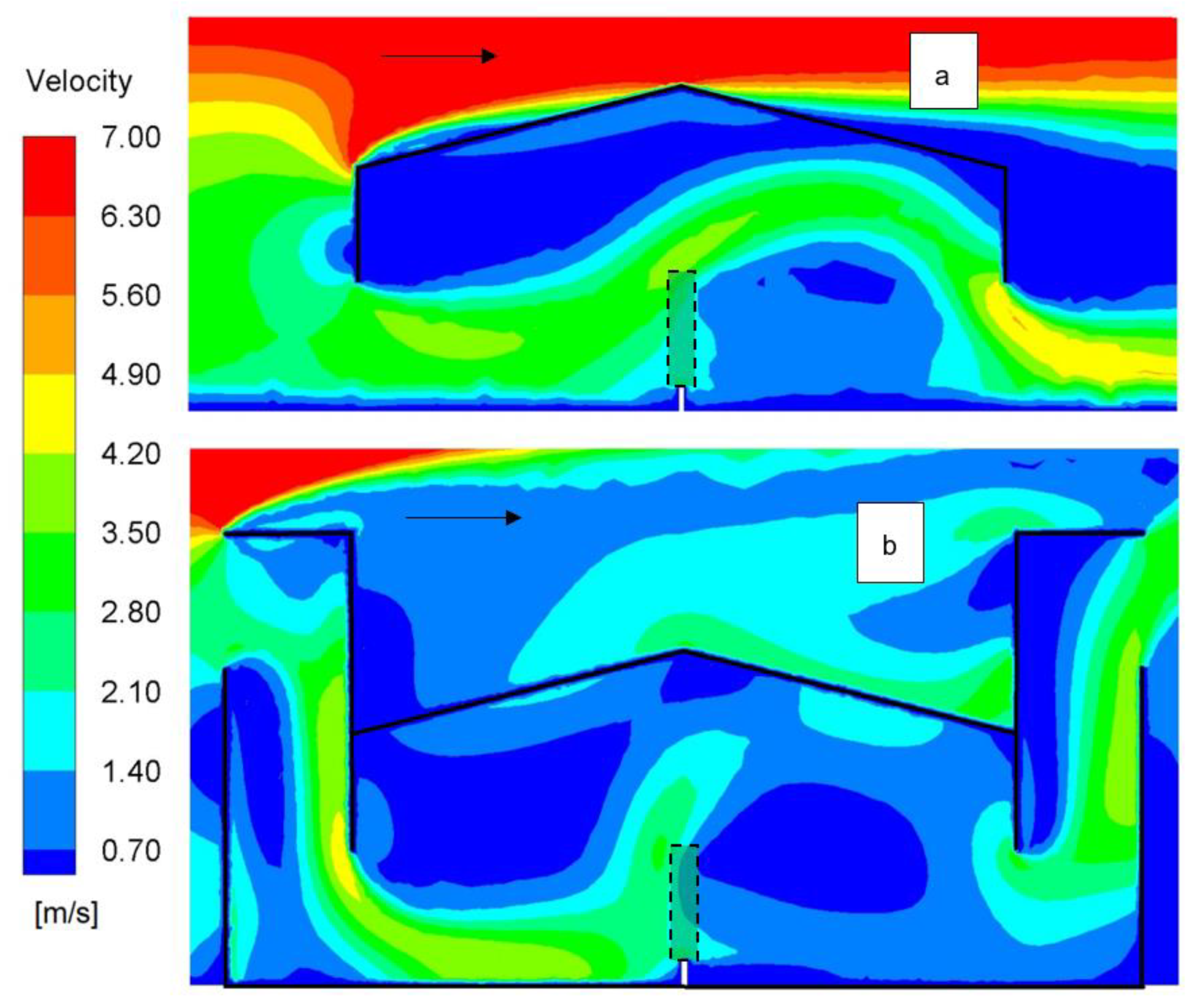

4.3. Impact of Crops on Airflow Characteristics

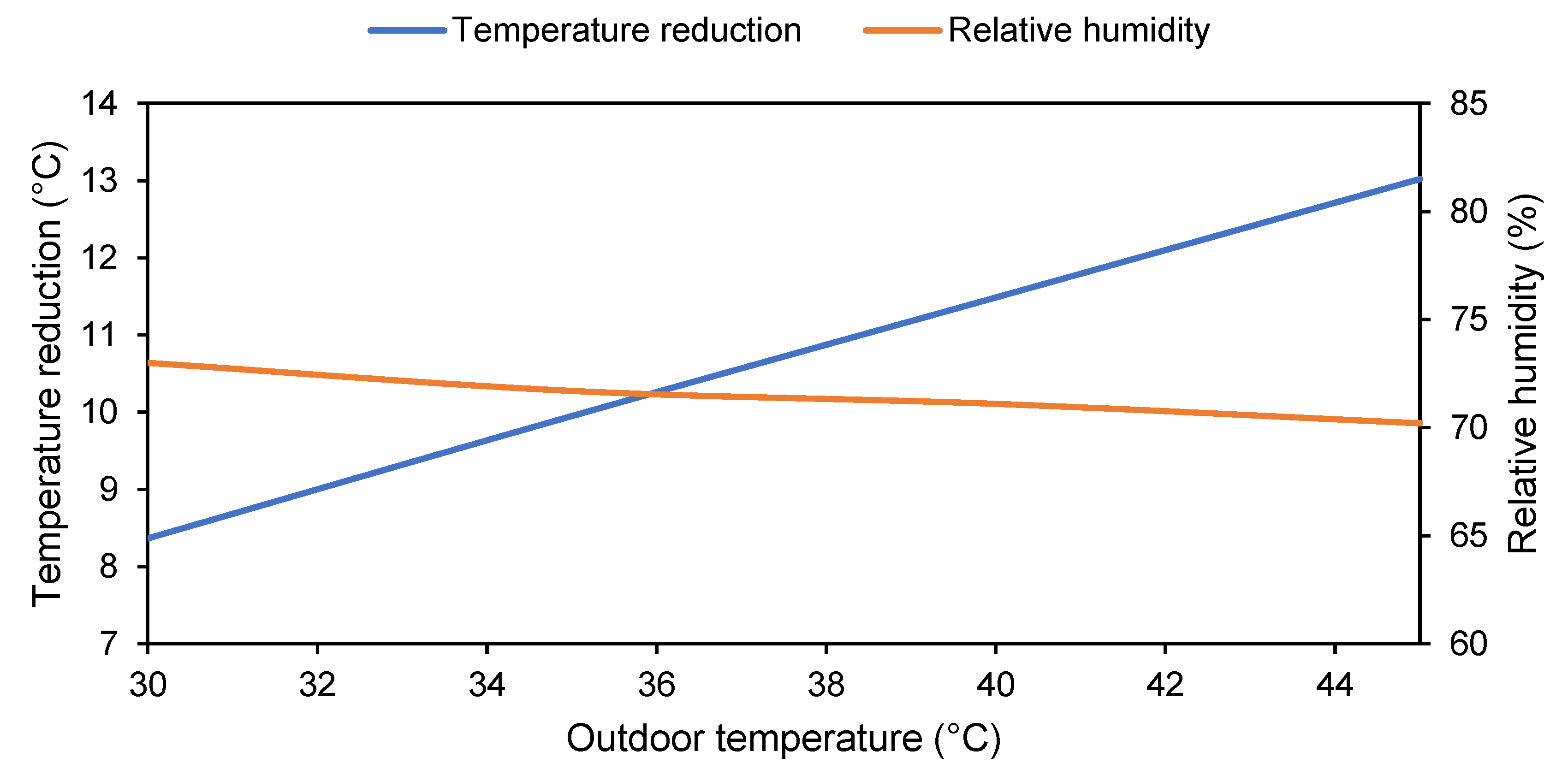

4.4. Impact of Outdoor Air Temperature

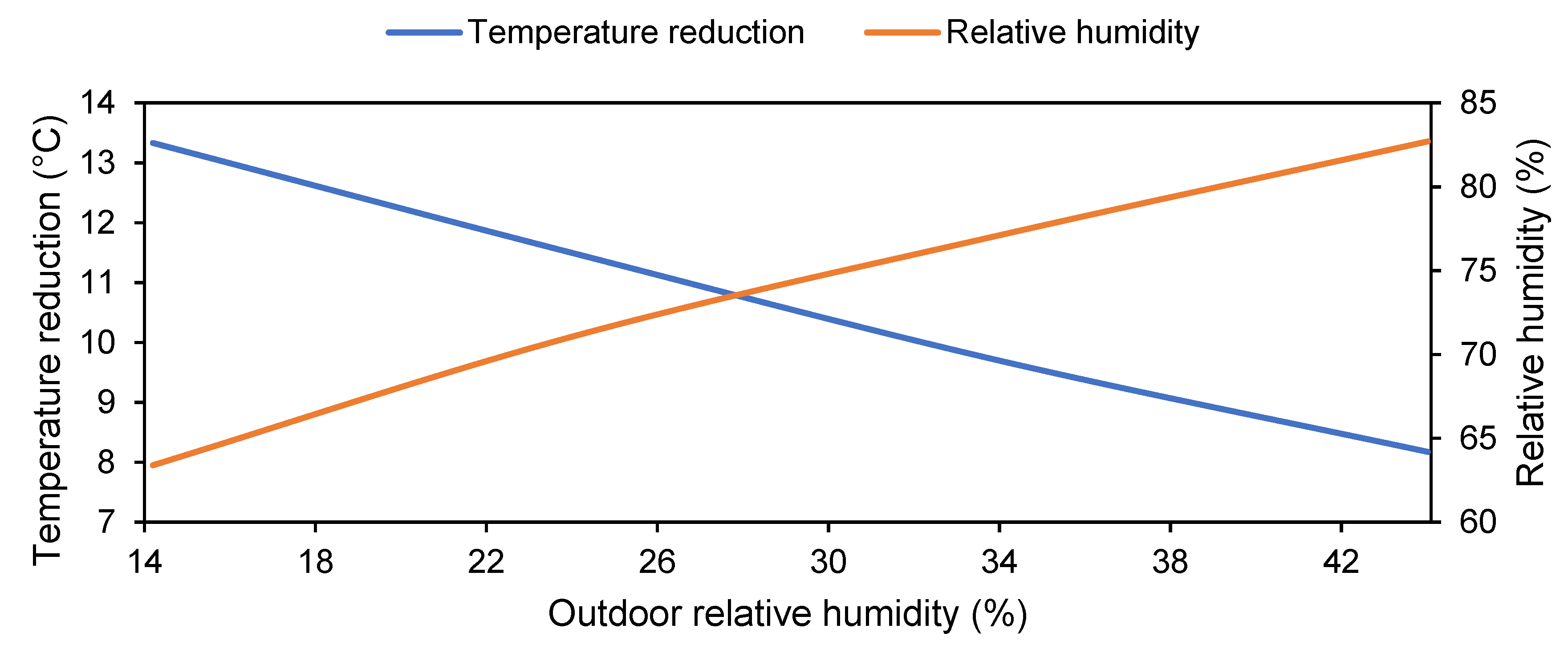

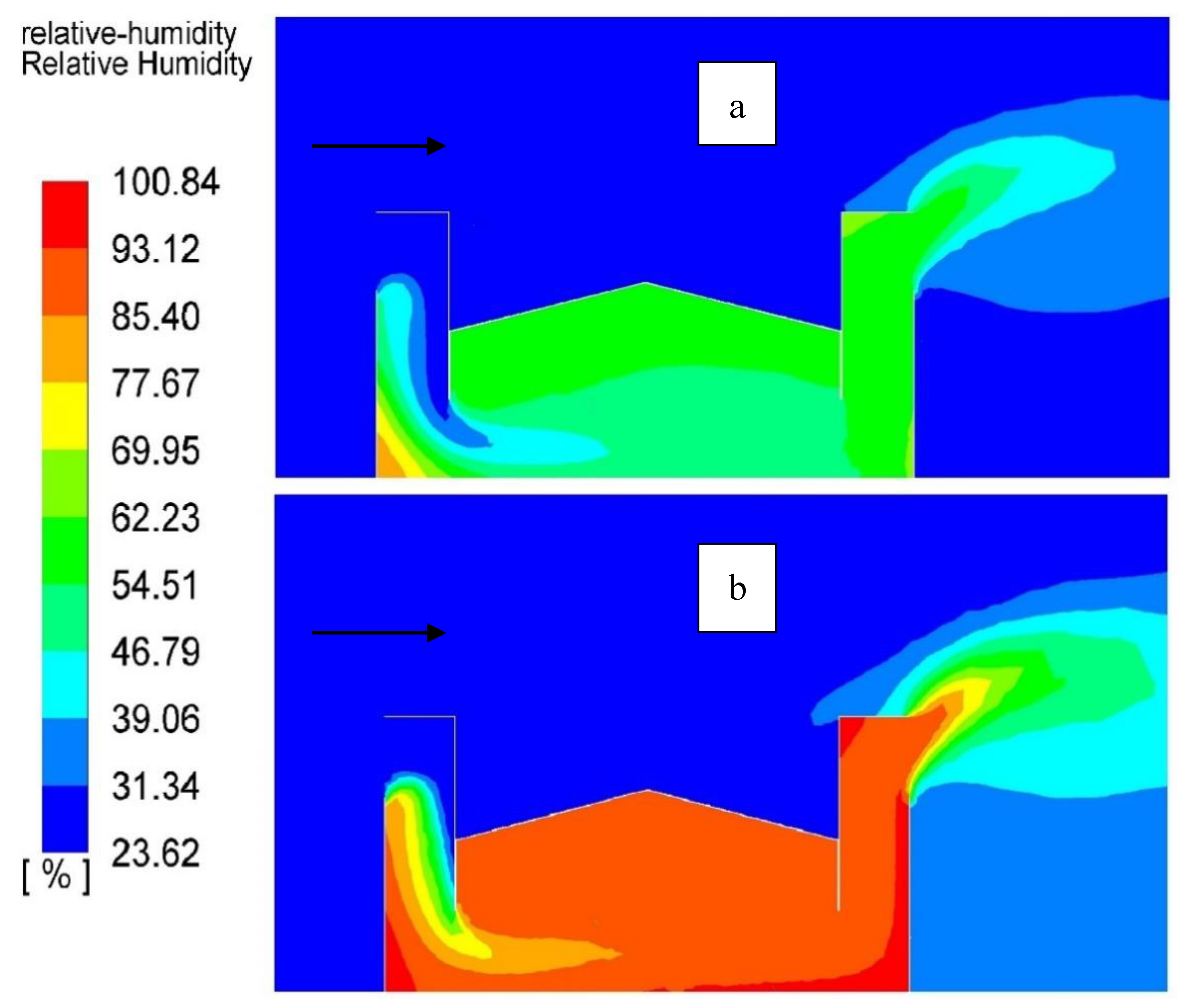

4.5. Impact of Outdoor Relative Humidity

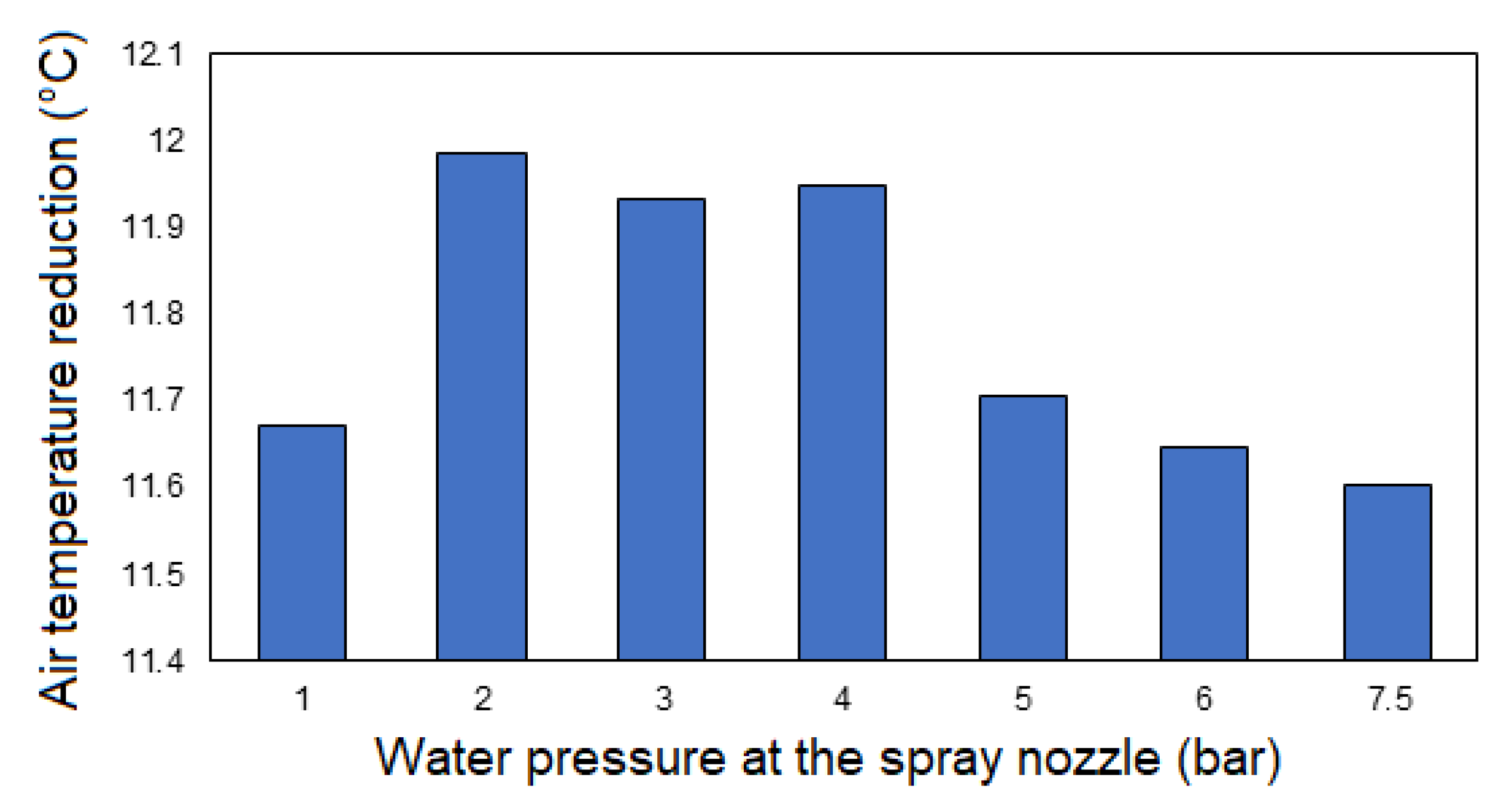

4.6. Impact of Inlet Nozzle Gauge Pressure

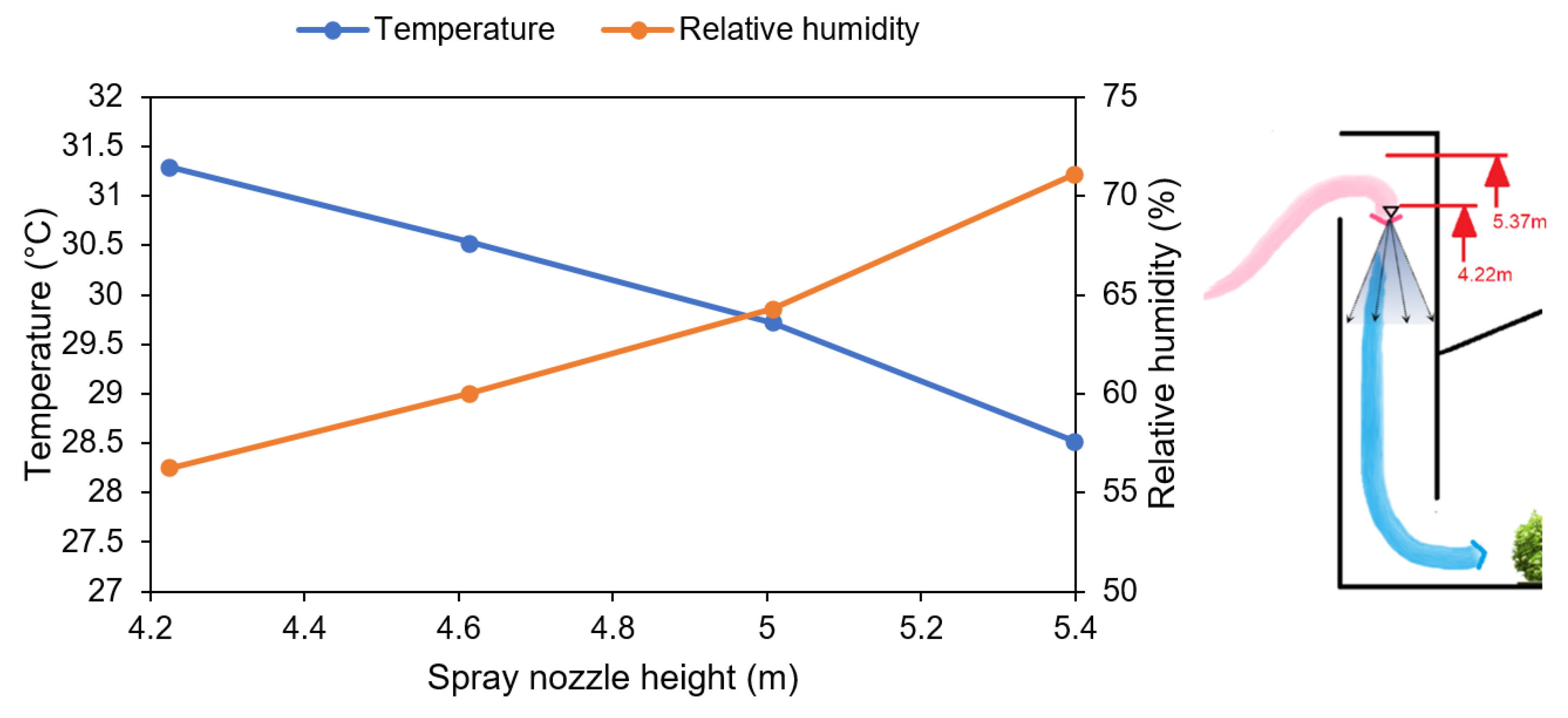

4.7. Impact of the Height of Nozzles

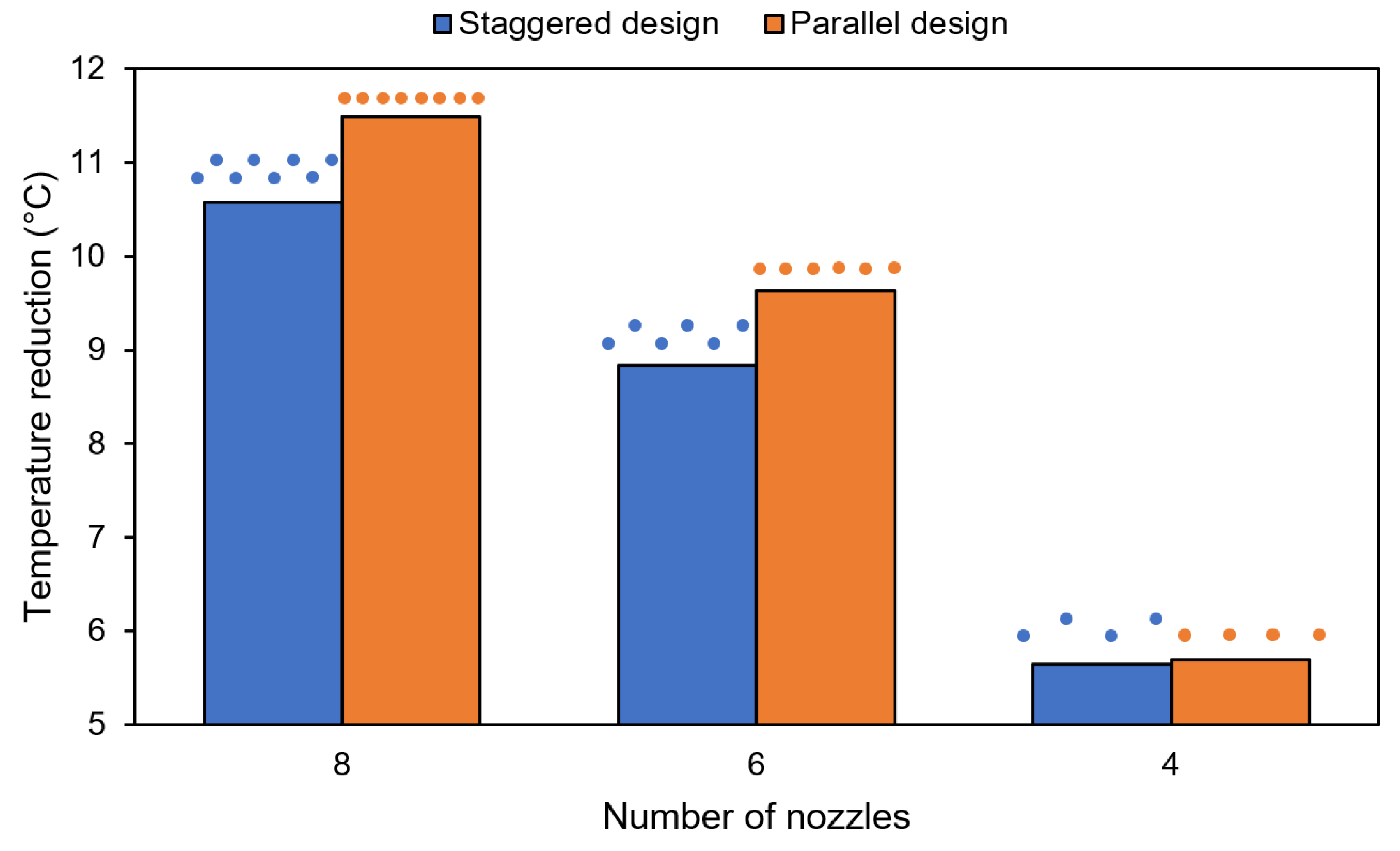

4.8. Impact of the Layout of Nozzles

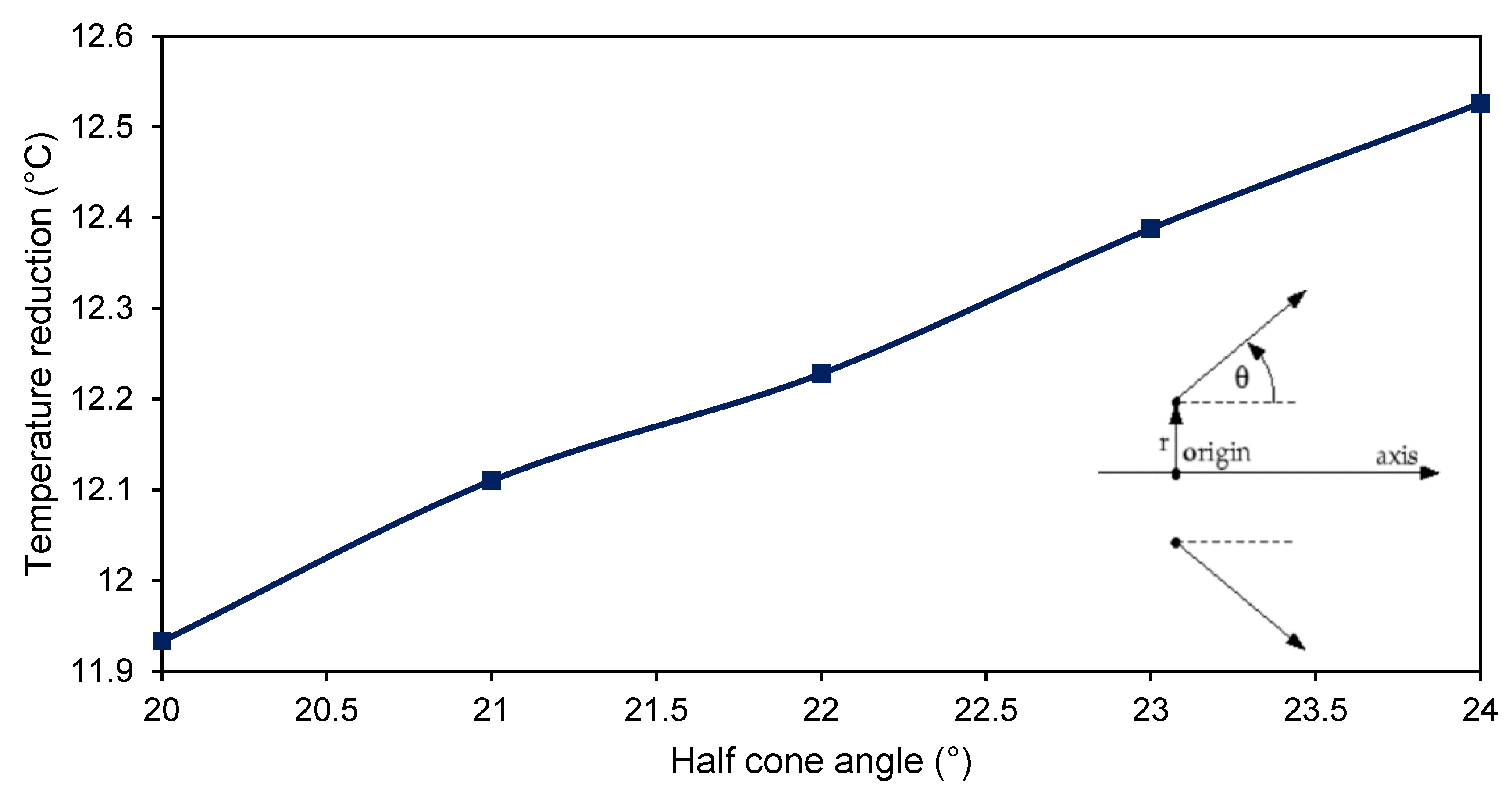

4.9. Impact of the Nozzle Half Cone Angle

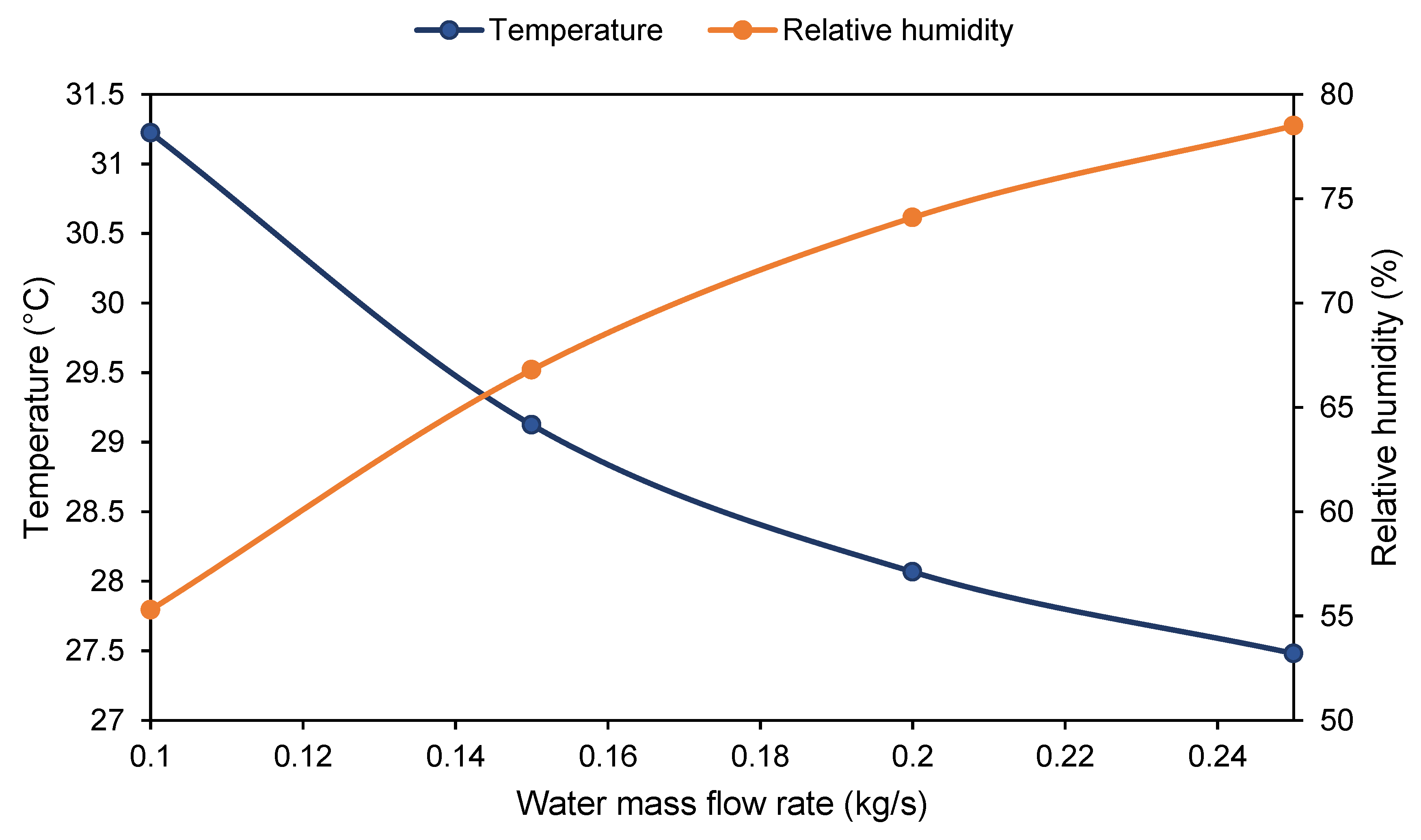

4.10. Impact of the Mass Flow Rate of the Spray Water

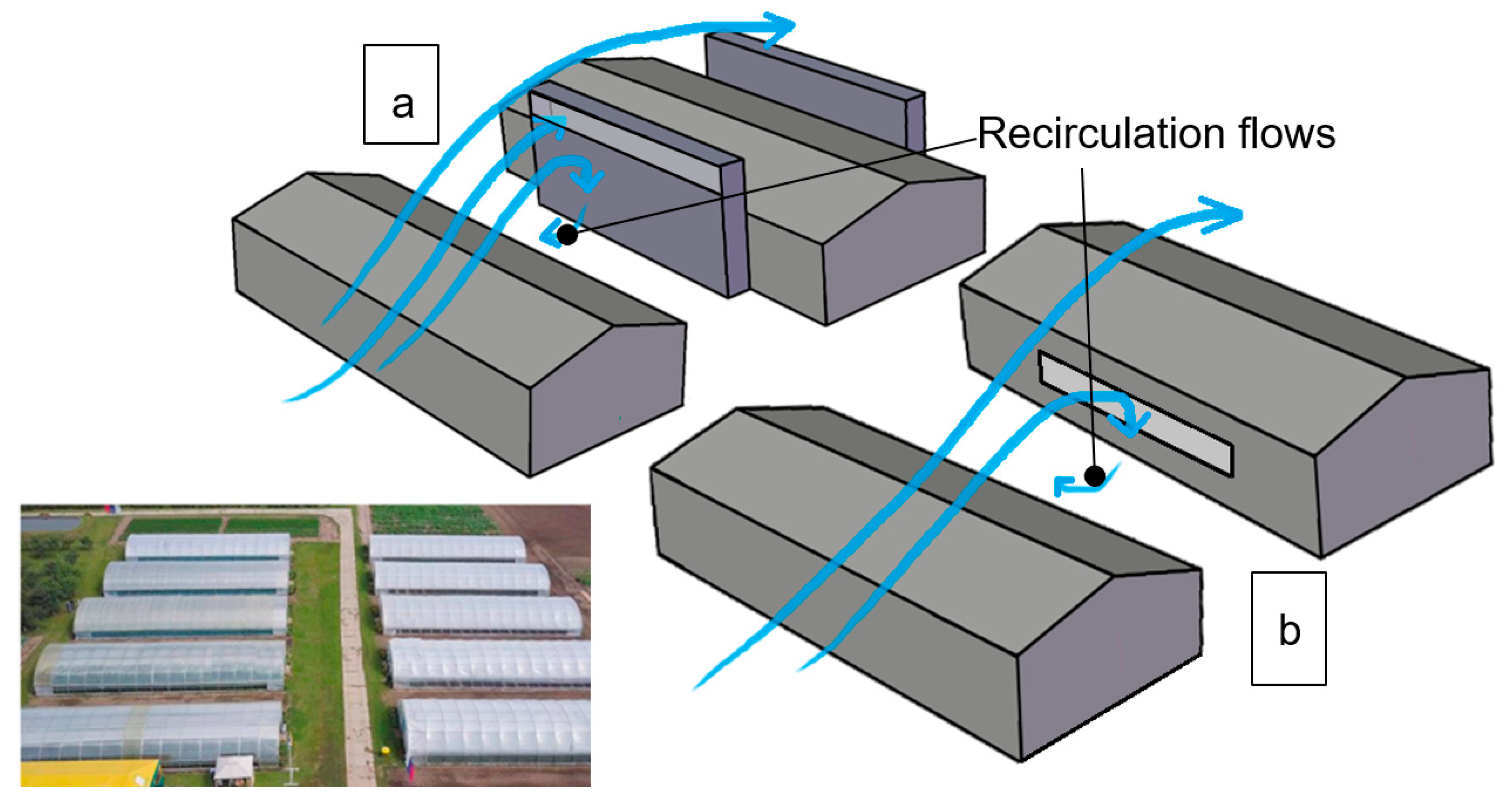

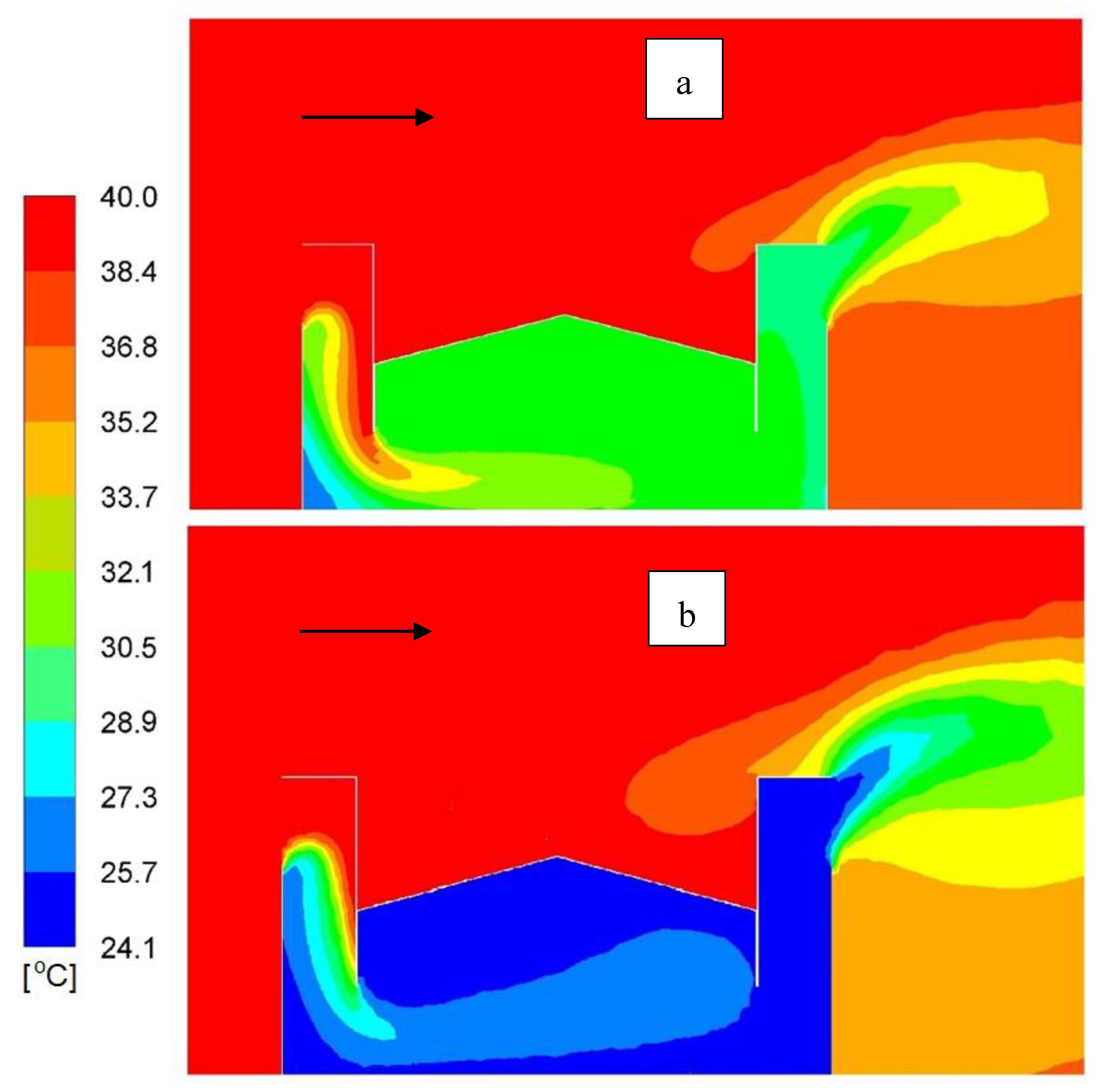

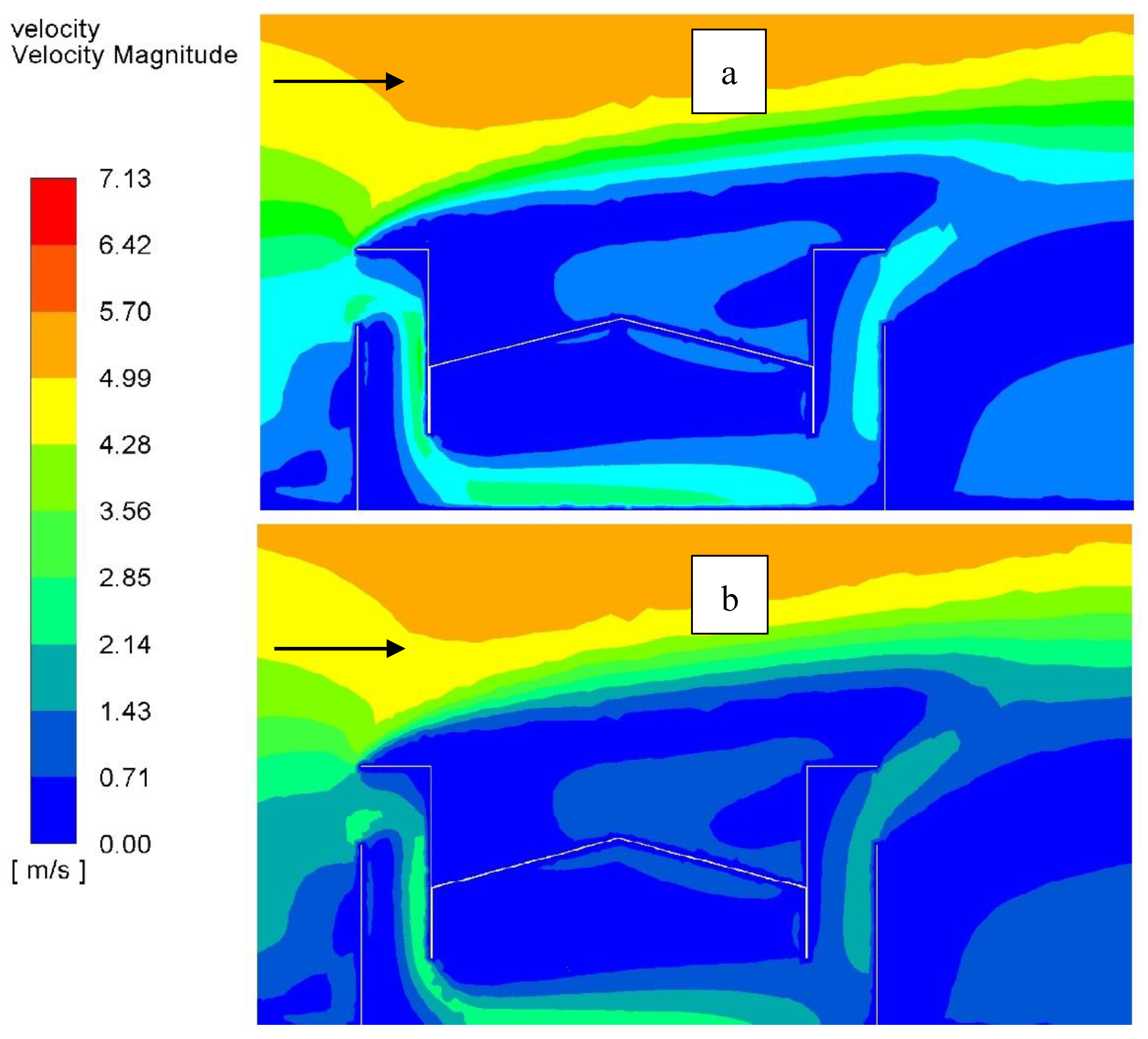

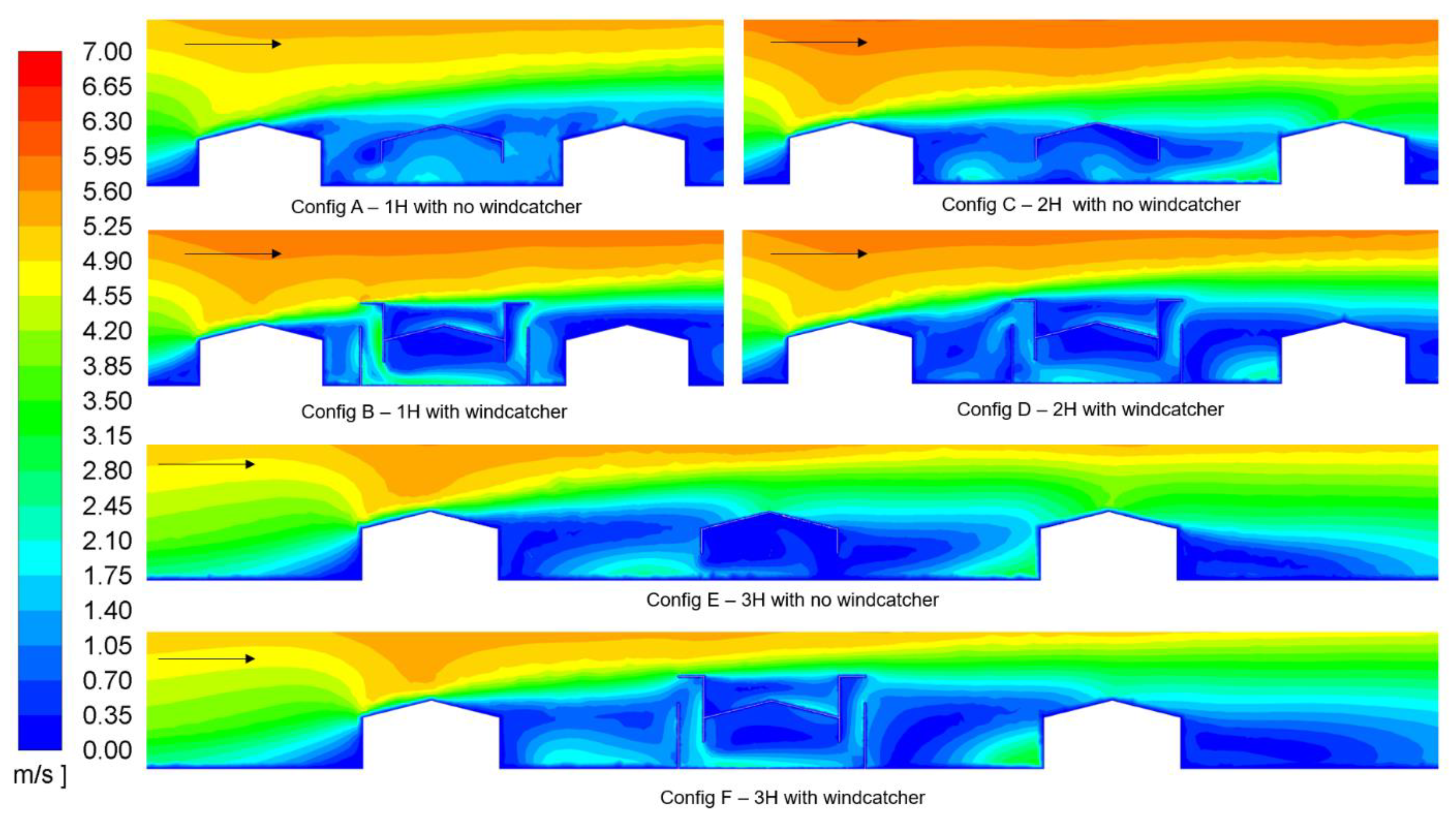

4.11. Impact of the Surrounding Structures

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Du, K.; Calautit, J.; Wang, Z.; Wu, Y.; Liu, H. A review of the applications of phase change materials in cooling, heating and power generation in different temperature ranges. Appl. Energy 2018, 220, 242–273. [Google Scholar] [CrossRef]

- Boukhanouf, R.; Amer, O.; Ibrahim, H.; Calautit, J. Design and performance analysis of a regenerative evaporative cooler for cooling of buildings in arid climates. Build. Environ. 2018, 142, 1–10. [Google Scholar] [CrossRef]

- Chou, S.K.; Chua, K.J.; Ho, J.C.; Ooi, C.L. On the study of an energy-efficient greenhouse for heating, cooling and dehumidification applications. Appl. Energy 2004, 77, 355–373. [Google Scholar] [CrossRef]

- IEA. Worldwide Trends in Energy Use and Efficiency: Key Insights from IEA Indicator Analysis; OECD/IEA: Paris, France, 2008. [Google Scholar]

- Hughes, B.R.; Calautit, J.K.; Ghani, S.A. The development of commercial wind towers for natural ventilation: A review. Appl. Energy 2012, 92, 606–627. [Google Scholar] [CrossRef]

- Jomehzadeh, F.; Nejat, P.; Calautit, J.K.; Yusof, M.B.M.; Zaki, S.A. A review on windcatcher for passive cooling and natural ventilation in buildings, Part 1: Indoor air quality and thermal comfort assessment. Renew. Sustain. Energy Rev. 2017, 70, 736–756. [Google Scholar] [CrossRef]

- Nejat, P.; Jomehzadeh, F.; Hussen, H.M.; Calautit, J.K.; Abd Majid, M.Z. Application of wind as a renewable energy source for passive cooling through windcatchers integrated with wing walls. Energies 2018, 11, 2536. [Google Scholar] [CrossRef]

- Hughes, B.R.; Cheuk-Ming, M. A study of wind and buoyancy driven flows through commercial wind towers. Energy Build. 2011, 43, 1784–1791. [Google Scholar] [CrossRef]

- Nejat, P.; Calautit, J.K.; Majid, M.Z.A.; Hughes, B.R.; Zeynali, I.; Jomehzadeh, F. Evaluation of a two-sided windcatcher integrated with wing wall (as a new design) and comparison with a conventional windcatcher. Energy Build. 2016, 126, 287–300. [Google Scholar] [CrossRef]

- Khani, S.M.R.; Bahadori, M.N.; Dehghani-Sanij, A.; Nourbakhsh, A. Performance evaluation of a modular design of wind tower with wetted surfaces. Energies 2017, 10, 845. [Google Scholar] [CrossRef]

- Noroozi, A.; Veneris, Y.S. Thermal assessment of a novel combine evaporative cooling wind catcher. Energies 2018, 11, 442. [Google Scholar] [CrossRef]

- Zaki, A.; Richards, P.; Sharma, R. Analysis of airflow inside a two-sided wind catcher building. J. Wind Eng. Ind. Aerod. 2019, 190, 71–82. [Google Scholar] [CrossRef]

- Calautit, J.K.; Hughes, B.R. Measurement and prediction of the indoor airflow in a room ventilated with a commercial wind tower. Energy Build. 2014, 84, 367–377. [Google Scholar] [CrossRef]

- Calautit, J.K.; Hughes, B.R. Wind tunnel and CFD study of the natural ventilation performance of a commercial multi-directional wind tower. Build. Environ. 2014, 80, 71–83. [Google Scholar] [CrossRef]

- Calautit, J.K.; Wenbin Tien, P.; Wei, S.; Calautit, K.; Hughes, B.R. Numerical and experimental investigation of the indoor air quality and thermal comfort performance of a low energy cooling windcatcher with heat pipes and extended surfaces. Renew. Energy 2020, 145, 744–756. [Google Scholar] [CrossRef]

- Varela-Boydo, C.A.; Moya, S.L. Inlet extensions for wind towers to improve natural ventilation in buildings. Sustain. Cities Soc. 2020, 53, 101933. [Google Scholar] [CrossRef]

- Franco, A.; Valera, D.L.; Pena, A.; Perez, A.M. Aerodynamic analysis and CFD simulation of several cellulose evaporative cooling pads used in Mediterranean greenhouses. Comput. Electron. Agric. 2011, 76, 218–230. [Google Scholar] [CrossRef]

- Bartzanas, T.; Fidaros, D.; Baxevanou, C.; Kittas, C. Climate distribution in a fan and pad evaporative cooled greenhouse: A CFD approach. Acta Hortic. 2013, 1008, 185–190. [Google Scholar] [CrossRef]

- Speetjens, S.L.; Van der Walle, T.; Janssen, H.J.J.; Gieling, T.H.; Van Straten, G.; Stigter, J.D. Watergy, towards a closed greenhouse in semi-arid regions-experiment with a heat exchanger. Acta Hortic. 2005, 691, 845–852. [Google Scholar] [CrossRef]

- Ghoulem, M.; Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Calautit, J.K. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- ANSYS, Inc. Fluent User’s Guide 18.2. Available online: https://www.sharcnet.ca/Software/Ansys/18.2.2/en-us/help/flu_ug/flu_ug.html (accessed on 21 February 2020).

- Chu, C.R.; Lan, T.W.; Tasi, R.K.; Wu, T.R.; Yang, C.K. Wind-Driven natural ventilation of greenhouses with vegetation. Biosyst. Eng. 2017, 164, 221–234. [Google Scholar] [CrossRef]

- Montazeri, H.; Blocken, B.; Hensen, J.L.M. Evaporative cooling by water spray systems: CFD simulation, experimental validation and sensitivity analysis. Build. Environ. 2015, 83, 129–141. [Google Scholar] [CrossRef]

- Sureshkumar, R.; Kale, S.R.; Dhar, P.L. Heat and mass transfer processes between a water spray and ambient air-I. Experimental data. Appl. Therm. Eng. 2008, 28, 349–360. [Google Scholar] [CrossRef]

- Rosin, P.; Rammler, E. The laws governing the fineness of powdered coal. J. Inst. Fuel 1933, 31, 29–36. [Google Scholar]

- Morsi, S.A.; Alexander, A.J. An investigation of particle trajectories in two-phase flow systems. J. Fluid Mech. 1972, 55, 193–208. [Google Scholar] [CrossRef]

- Amer, O.; Boukhanouf, R.; Ibrahim, H.G. A review of evaporative cooling technologies. Int. J. Environ. Sci. Dev. 2015, 6, 111–117. [Google Scholar] [CrossRef]

| Configuration | Ventilation | L |

|---|---|---|

| A | Crossflow | H |

| B | Windcatcher | H |

| C | Crossflow | 2H |

| D | Windcatcher | 2H |

| E | Crossflow | 3H |

| F | Windcatcher | 3H |

| Spray Settings | |

|---|---|

| Mass flow rate of water spray streams | 12.50 |

| Temperature of water spray streams | 35.2 °C |

| Pressure difference between the supply water pipe and the spray nozzle | 3 bars |

| Sheet velocity | 22.05 m/s |

| Droplet Settings | |

| Number of droplet streams for each nozzle | 300 |

| Droplet size distribution model | Rosin–Rammler model |

| Number of diameters for each droplet stream | 20 |

| Mean diameter | 369 |

| Spread parameter | 3.67 |

| Minimum and maximum diameter | 74 518 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Zhong, F.; Calautit, J. Design of a Passive Downdraught Evaporative Cooling Windcatcher (PDEC-WC) System for Greenhouses in Hot Climates. Energies 2020, 13, 2934. https://doi.org/10.3390/en13112934

Ghoulem M, El Moueddeb K, Nehdi E, Zhong F, Calautit J. Design of a Passive Downdraught Evaporative Cooling Windcatcher (PDEC-WC) System for Greenhouses in Hot Climates. Energies. 2020; 13(11):2934. https://doi.org/10.3390/en13112934

Chicago/Turabian StyleGhoulem, Marouen, Khaled El Moueddeb, Ezzedine Nehdi, Fangliang Zhong, and John Calautit. 2020. "Design of a Passive Downdraught Evaporative Cooling Windcatcher (PDEC-WC) System for Greenhouses in Hot Climates" Energies 13, no. 11: 2934. https://doi.org/10.3390/en13112934

APA StyleGhoulem, M., El Moueddeb, K., Nehdi, E., Zhong, F., & Calautit, J. (2020). Design of a Passive Downdraught Evaporative Cooling Windcatcher (PDEC-WC) System for Greenhouses in Hot Climates. Energies, 13(11), 2934. https://doi.org/10.3390/en13112934