Energy Analysis of a Dual-Source Heat Pump Coupled with Phase Change Materials

Abstract

1. Introduction

2. Methodology

2.1. Description of the Dual System

2.2. Building Energy Demand and Heat Pump Efficiency

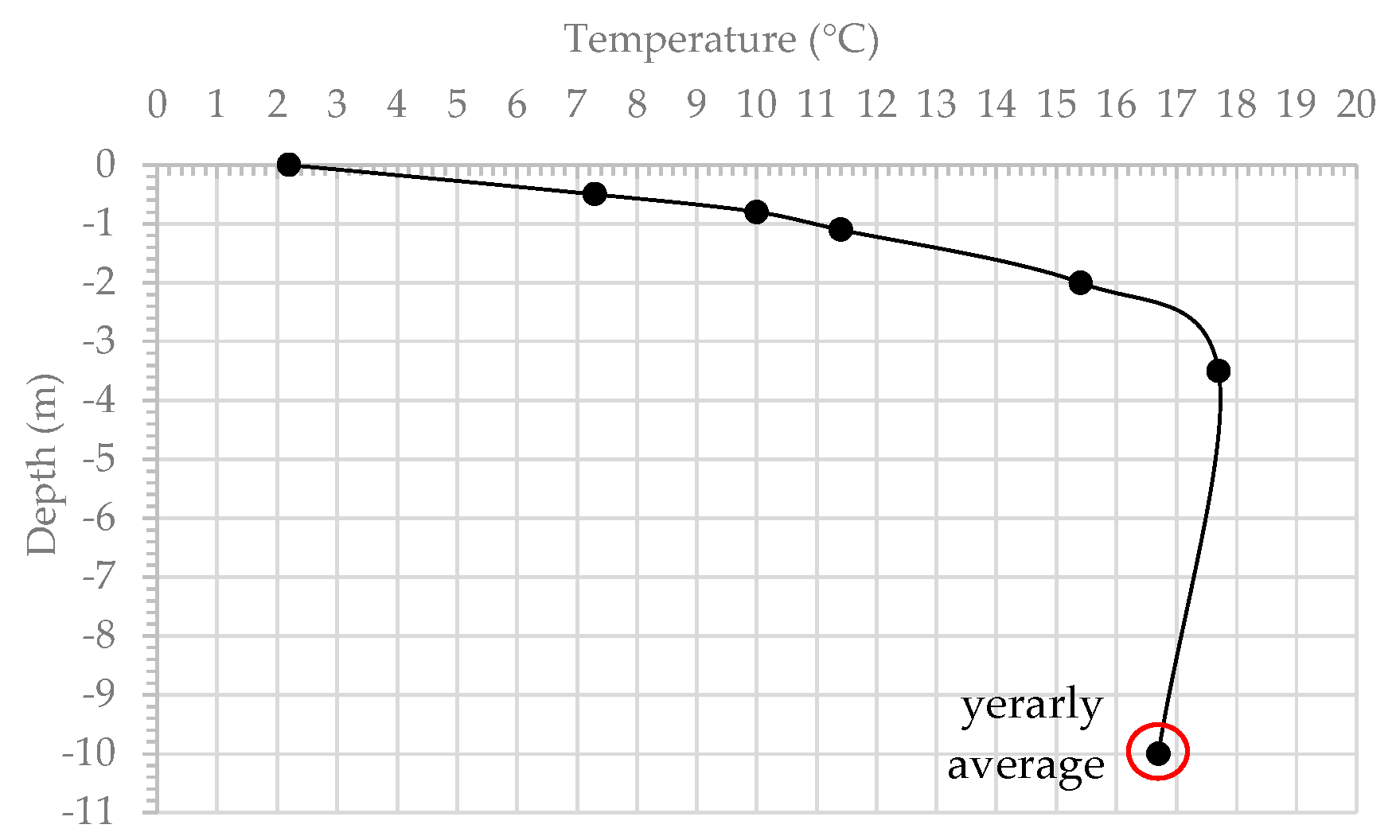

2.3. Numerical Modelling and Boundary Conditions

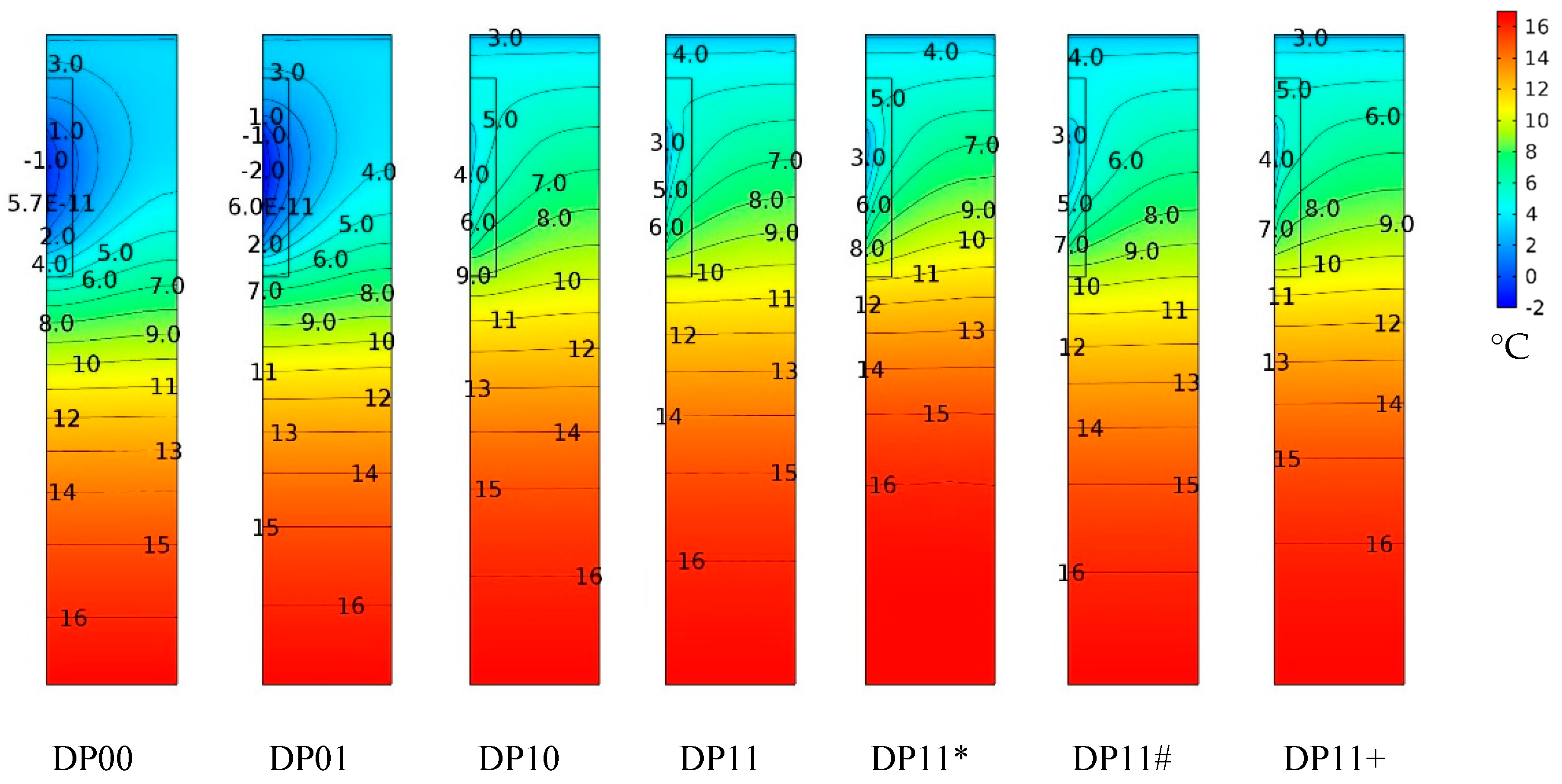

2.4. Case Studies

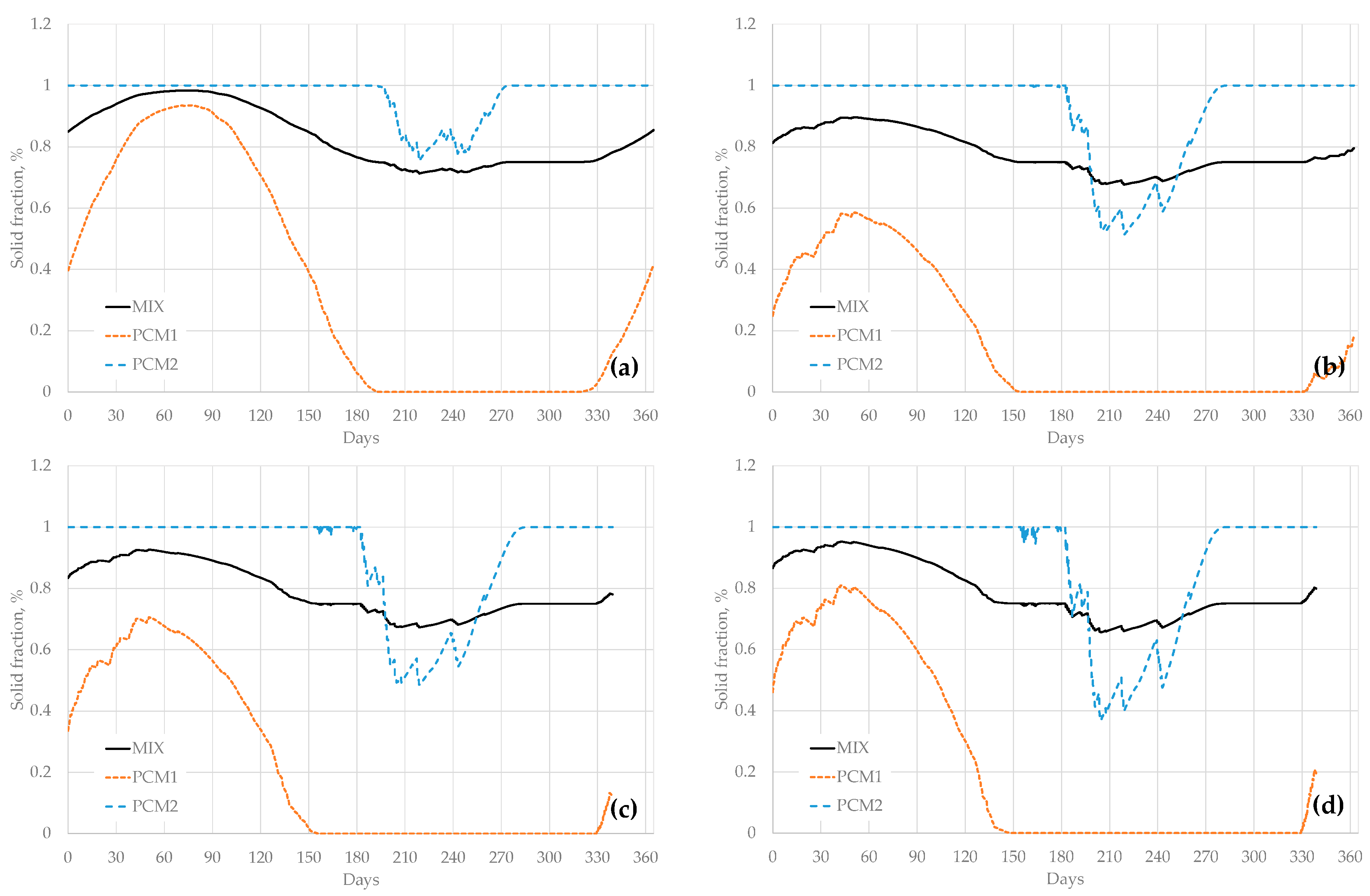

3. Results and Discussion

4. Conclusions

- ▪

- Numerical simulations show that the overall performance of a ground source heat pump is higher, although not very significantly, than the one given by an air source heat pump.

- ▪

- The use of shallow HGHEs avoids thermal drift of ground temperature and shows significant values of heat flux value per unit length of the exchanger, even when compared to vertical boreholes. The flat-panel shows an annual average heat flux of around 33 W/m when it is coupled with a GCHP, and more than 140 W/m with a DSHP.

- ▪

- The dual-source functionality optimises the performance of a heat pump and drastically allows the reduction of the HGHE length to up to several times that of a full GCHP, causing a significant reduction in installation costs. Moreover, the value estimated for the lowest working fluid temperature precludes the use of glycol, with benefits in terms of costs and environmental impact.

- ▪

- The use of PCMs as backfilling material can improve the overall energy performance only if a significant increase of their thermal conductivity is carried out, as the common low value of the pure paraffins’ conductivity reduces the benefit of their high latent heat. Therefore, the improvement of their thermal conductivity is a key factor for their exploitation in similar applications.

- ▪

- Summer thermal performance of a DSHP coupled with a flat-panel GHE and a mixture of enhanced PCMs as backfill material is better than in wintertime, according to the higher temperature difference between undisturbed ground and GHE.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Specific heat capacity, J/(kg·K) | |

| Mixture specific heat capacity, J/(kg·K) | |

| Specific heat capacity of component i, J/(kg·K) | |

| Specific heat capacity of wet sand, J/(kg·K) | |

| Specific heat capacity of component i in solid phase, J/(kg·K) | |

| Specific heat capacity of component i in liquid phase, J/(kg·K) | |

| Dirac’s pulse function, K−1 | |

| Latent heat of fusion, J/kg | |

| Step function | |

| k | Solid thermal conductivity, W/(m·K) |

| Mixture thermal conductivity, W/(m·K) | |

| Thermal conductivity of component i, W/(m·K) | |

| Thermal conductivity of wet sand, W/(m·K) | |

| Thermal conductivity of component i in solid phase, W/(m·K) | |

| Thermal conductivity of component i in liquid phase, W/(m·K) | |

| Flat-panel height, m | |

| Normal unit vector | |

| Heat load for unit building volume, W/m3 | |

| Heat flux at flat-panel, W/m2 | |

| Energy load per unit volume of building space at time t, W/m3 | |

| Q | Heat source/sink, W/m3 |

| Qe | Thermal energy exchanged per unit length of trench, kWh/m |

| Qt | Electrical energy exchanged per unit length of trench, kWh/m |

| Load factor, m3/m | |

| Volume fraction of i component, m3 component i/m3 mixture | |

| Flat-panel heat transfer surface per unit of trench length, m2/m | |

| t | Time, s |

| T | Temperature, K |

| Air temperature, K | |

| Limiting air temperature, K | |

| Temperature at the bottom of the domain, K | |

| Condenser temperature, K | |

| Evaporator temperature, K | |

| Average Flat-panel temperature, K | |

| Ground temperature, K | |

| Limiting ground temperature, K | |

| Temperature at ground surface, K | |

| Trench width, m | |

| Mass fraction of component i | |

| Greek Symbols | |

| Mixture density, kg/m3 | |

| Density of component i, kg/m3 | |

| Density of wet sand, kg/m3 | |

| Density of component i in solid phase, kg/m3 | |

| Density of component i in liquid phase, kg/m3 | |

| Acronyms | |

| ASHP | Air source heat pump |

| DSHP | Dual source heat pump |

| COP | Coefficient of performance |

| EER | Energy efficiency ratio |

| FP | Flat-panel |

| GHE | Ground heat exchanger |

| GCHP | Ground-coupled heat pump |

| HGHE | Horizontal ground heat exchanger |

| PCM | Phase change material |

References

- Benli, H.; Durmus, A. Evaluation of ground-source heat pump combined latent heat storage system performance in greenhouse heating. Energy Build. 2009, 41, 220–228. [Google Scholar] [CrossRef]

- Urchueguía, J.F.; Zacarés, M.; Corberán, J.M. Comparison between the energy performance of a ground coupled water to water heat pump system and an air to water heat pump system for heating and cooling in typical conditions of the European Mediterranean coast. Energy Convers. Manag. 2008, 49, 2917–2923. [Google Scholar] [CrossRef]

- Bayer, P.; Saner, D.; Bolay, S.; Rybach, L.; Blum, P. Greenhouse gas emission savings of ground source heat pump systems in Europe: A review. Renew. Sust. Energy Rev. 2012, 16, 1256–1267. [Google Scholar] [CrossRef]

- Bertermann, D.; Bernardi, A.; Pockelé, L.; Galgaro, A.; Cultrera, M.; de Carli, M.; Müller, J. European project “Cheap-GSHPs”: Installation and monitoring of newly designed helicoidal ground source heat exchangeron the German test site. Environ. Earth Sci. 2018, 77, 180. [Google Scholar] [CrossRef]

- Bortoloni, M.; Bottarelli, M.; Su, Y. A study on the effect of ground surface boundary conditions in modelling shallow ground heat exchangers. Appl. Eng. 2017, 111, 1371–1377. [Google Scholar] [CrossRef]

- Gabrielli, L.; Bottarelli, M. Financial and economic analysis for ground coupled heat pump using shallow ground heat exchangers. Sustain. Cities Soc. 2016, 20, 71–80. [Google Scholar] [CrossRef]

- Arrizabalaga, I.; De Gregorio, M.; De Santiago, C.; García de la Noceda, C.; Pérez, P.; Urchueguía, J.F. Geothermal Energy Use, Country Update for Spain. In Proceedings of the European Geothermal Congress 2019, Den Haag, The Netherlands, 11–14 June 2019. [Google Scholar]

- Manzella, A.; Serra, D.; Cesari, G.; Bargiacchi, E.; Cei, M.; Cerutti, P.; Conti, P.; Giudetti, G.; Lupi, M.; Vaccaro, M. Geothermal Energy Use, Country Update for Italy. In Proceedings of the European Geothermal Congress 2019, Den Haag, The Netherlands, 11–14 June 2019. [Google Scholar]

- Papachristou, M.; Arvanitis, A.; Mendrinos, D.; Dalabakis, P.P.; Karytsas, C.; Andritsos, N. Geothermal Energy Use, Country Update for Greece (2016-2019). In Proceedings of the European Geothermal Congress 2019, Den Haag, The Netherlands, 11–14 June 2019. [Google Scholar]

- Spitler, J.; Bernier, M. Ground-source heat pump systems: The first century and beyond. HVAC&R Res. 2011, 17, 891–894. [Google Scholar]

- Eslami-nejad, P.; Bernier, M. A preliminary assessment on the use of phase change materials around geothermal boreholes. ASHRAE Trans. 2013, 119, 312–321. [Google Scholar]

- Lei, H.Y.; Dai, C.S. Comparative experiment of different backfill grouts for concentric ground heat exchangers. Grc. Trans. 2013, 37, 597–600. [Google Scholar]

- Lei, H.Y.; Zhu, N. Analysis of phase change materials (PCMs) used for borehole fill materials. Trans. Geoth Resour. Counc. 2009, 33, 92–98. [Google Scholar]

- Wang, J.L.; Zhao, J.D.; Liu, N. Numerical simulation of borehole heat transfer with phase change material as grout. Appl. Mech. Mater. 2014, 577, 44–47. [Google Scholar] [CrossRef]

- Yang, W.; Xu, R.; Yang, B.; Yang, J. Experimental and numerical investigations on the thermal performance of a borehole ground heat exchanger with PCM backfill. Energy 2019, 174, 216–235. [Google Scholar] [CrossRef]

- Bottarelli, M.; Bortoloni, M.; Su, Y.; Yousif, C.; Aydın, A.A.; Georgiev, A. Numerical analysis of a novel ground heat exchanger coupled with phase change materials. Appl. Eng. 2015, 88, 369–375. [Google Scholar] [CrossRef]

- Corberán, J.M.; Cazorla-Marín, A.; Marchante-Avellaneda, J.; Montagud, C. Dual source heat pump, a high efficiency and cost-effective alternative for heating, cooling and DHW production. Int. J. Low-Carbon Tec. 2018, 13, 161–176. [Google Scholar]

- Grossi, I.; Dongellini, M.; Piazzi, A.; Morini, G.L. Dynamic modelling and energy performance analysis of an innovative dual-source heat pump system. Appl. Eng. 2018, 142, 745–759. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Feng, G.; Kang, Z.; Luo, Y.; Bai, B.; Chi, L. Simulation analysis of air-ground dual source heat pump operating efficiency. Proced. Eng. 2015, 121, 1413–1419. [Google Scholar] [CrossRef]

- Cannistraro, M.; Mainardi, E.; Bottarelli, M. Testing a dual-source heat pump. Math Model. Eng. Probl. 2018, 5, 205–210. [Google Scholar]

- Bottarelli, M.; Bortoloni, M.; Su, Y. On the sizing of a novel Flat-panel ground heat exchanger in coupling with a dual-source heat pump. Renew. Energy 2019, 142, 552–560. [Google Scholar] [CrossRef]

- Phase Change Material Products Limited. Available online: http://www.pcmproducts.net/ (accessed on 20 March 2020).

- UNI. UNI 11466:2012, Heat Pump Geothermal Systems-Design and Sizing Requirements. Available online: www.uni.com (accessed on 23 November 2018).

- EnergyPlus Building Energy Simulation Program. Available online: https://energyplus.net/testing (accessed on 23 November 2018).

- Bottarelli, M.; Zang, L.; Bortoloni, M.; Su, Y. Energy performance of a dual air and ground-source heat pump coupled with a Flat-panel ground heat exchanger. Bulg. Chem. Commun. 2016, 48, 64–70. [Google Scholar]

- Nam, Y.J.; Gao, X.Y.; Yoon, S.H.; Lee, K.H. Study on the performance of a ground source heat pump system assisted by solar thermal storage. Energies 2015, 8, 13378–13394. [Google Scholar] [CrossRef]

- Comsol Multiphysics Reference Manual. 2017. Available online: https://doc.comsol.com/5.3/doc/com.comsol.help.comsol/COMSOL_ReferenceManual.pdf (accessed on 30 March 2020).

- Ozturk, T.; Ceber, Z.P.; Türkeş, M.; Kurnaz, M.L. Projections of climate change in the Mediterranean Basin by using downscaled global climate model outputs. Int. J. Climatol. 2015, 35, 4276–4292. [Google Scholar] [CrossRef]

- Dongellini, M.; Naldia, C.; Morini, G.L. Annual performances of reversible air source heat pumps for space conditioning. Energy Procedia. 2015, 78, 1123–1128. [Google Scholar] [CrossRef]

| Material | Density | Thermal Conductivity | Specific Heat Capacity | Latent Heat Capacity | Melting Point |

|---|---|---|---|---|---|

| (kg/m3) | (W/mK) | (J/kgK) | (kJ/kg) | (°C) | |

| Paraffin A8, PCM1 [22] | 770 | 0.21 | 2160 | 180 | 8 |

| Paraffin A24, PCM2 [22] | 768 | 0.22 | 2220 | 250 | 24 |

| Wet sand (trench) | 2100 | 2.40 | 1200 | -- | -- |

| Wet clay (surrounding ground) | 2100 | 1.80 | 1150 | -- | -- |

| Case | Heat Pump | Backfill Material | Load Factor, lf (m3/m) | Trench Width, wt (m) |

|---|---|---|---|---|

| DP00 | GCHP | Sand | 10 | 0.60 |

| DP01 | GCHP | Sand and PCMs | 10 | 0.60 |

| DP10 | DSHP | Sand | 20 | 0.60 |

| DP11 | DSHP | Sand and PCMs | 20 | 0.60 |

| DP11* | DSHP | Sand and PCMs | 30 | 0.60 |

| DP11# | DSHP | Sand and PCMs | 30 | 0.40 |

| DP11+ | DSHP | Sand and PCMs | 20 | 0.60 |

| Variable | Unit | ASHP | DP00 | DP01 | DP10 | DP11 | DP11* | DP11# | DP11+ |

|---|---|---|---|---|---|---|---|---|---|

| lf | m3/m | (10) | 10 | 10 | 20 | 20 | 30 | 30 | 20 |

| wt | m | -- | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.4 | 0.6 |

| Qt DSHP | kWh/m | -- | -- | -- | −295.1 | −295.1 | −442.7 | −442.7 | −295.1 |

| Qt GCHP | kWh/m | -- | −147.6 | −147.6 | −58.5 | −60.0 | −70.5 | −69.7 | −69.1 |

| Qt ASHP | kWh/m | −147.6 | -- | -- | −236.6 | −235.1 | −372.2 | −373.0 | −226.1 |

| Qe DSHP | kWh/m | -- | -- | -- | 121.3 | 121.1 | 184.6 | 184.6 | 119.9 |

| Qe GCHP | kWh/m | -- | 65.4 | 65.9 | 23.8 | 24.4 | 29.6 | 29.3 | 27.7 |

| Qe ASHP | kWh/m | 63.8 | -- | -- | 97.5 | 96.8 | 155.0 | 155.3 | 92.2 |

| COPDSHP | -- | -- | -- | -- | 3.43 | 3.44 | 3.40 | 3.40 | 3.46 |

| COPGCHP | -- | -- | 3.26 | 3.24 | 3.46 | 3.46 | 3.38 | 3.38 | 3.50 |

| COPASHP | -- | 3.31 | -- | -- | 3.43 | 3.43 | 3.40 | 3.40 | 3.45 |

| Time | h | 5228 | 5228 | 5228 | 637 | 641 | 504 | 500 | 720 |

| q FP_ave | W/m | -- | −28.2 | −28.2 | −91.9 | −93.7 | −139.9 | −139.9 | −95.9 |

| Variable | Unit | ASHP | DP00 | DP01 | DP10 | DP11 | DP11* | DP11# | DP11+ |

|---|---|---|---|---|---|---|---|---|---|

| lf | m3/m | (10) | 10 | 10 | 20 | 20 | 30 | 30 | 20 |

| wt | m | -- | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.4 | 0.6 |

| Qt DSHP | kWh/m | -- | -- | -- | 131.3 | 131.3 | 197.0 | 197.0 | 131.3 |

| Qt GCHP | kWh/m | -- | 65.7 | 65.7 | 65.3 | 63.3 | 68.5 | 69.7 | 66.9 |

| Qt ASHP | kWh/m | 65.7 | -- | -- | 66.1 | 68.0 | 128.5 | 127.3 | 64.4 |

| Qe DSHP | kWh/m | -- | -- | -- | 26.3 | 26.4 | 40.6 | 40.6 | 26.2 |

| Qe GCHP | kWh/m | -- | 12.4 | 12.2 | 12.6 | 12.2 | 13.3 | 13.6 | 12.8 |

| Qe ASHP | kWh/m | 14.2 | -- | -- | 13.7 | 14.2 | 27.3 | 27.0 | 13.4 |

| EERDSHP | -- | -- | -- | -- | 3.99 | 3.98 | 3.85 | 3.85 | 4.02 |

| EERGCHP | -- | -- | 4.31 | 4.37 | 4.18 | 4.20 | 4.14 | 4.13 | 4.24 |

| EERASHP | -- | 3.61 | -- | -- | 3.81 | 3.79 | 3.70 | 3.71 | 3.80 |

| Time | h | 1304 | 1304 | 1304 | 608 | 604 | 494 | 488 | 635 |

| q FP_ave | W/m | -- | 50.4 | 50.4 | 107.3 | 104.8 | 138.6 | 142.8 | 105.4 |

| Variable | Unit | ASHP | DP00 | DP01 | DP10 | DP11 | DP11* | DP11# | DP11+ |

|---|---|---|---|---|---|---|---|---|---|

| lf | m3/m | (10) | 10 | 10 | 20 | 20 | 30 | 30 | 20 |

| wt | m | -- | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.4 | 0.6 |

| Tmin | °C | -- | −1.3 | −2.4 | 2.1 | 1.7 | −0.3 | −0.6 | 1.3 |

| Tmax | °C | -- | 26.1 | 24.9 | 27.3 | 25.7 | 26.1 | 26.2 | 24.7 |

| Qt | kWh/m | 213.2 | 213.2 | 213.2 | 426.5 | 426.5 | 639.7 | 639.7 | 426.5 |

| Qe | kWh/m | 77.7 | 77.7 | 78.2 | 147.6 | 147.5 | 225.2 | 225.2 | 146.1 |

| COP/EER | -- | 3.37 | 3.42 | 3.42 | 3.53 | 3.53 | 3.48 | 3.48 | 3.56 |

| Time | h | 6532 | 6532 | 6532 | 1245 | 1245 | 998 | 988 | 1355 |

| q FP_ave | W/m | -- | 32.7 | 32.7 | 99.4 | 99.1 | 139.2 | 141.1 | 100.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bottarelli, M.; González Gallero, F.J. Energy Analysis of a Dual-Source Heat Pump Coupled with Phase Change Materials. Energies 2020, 13, 2933. https://doi.org/10.3390/en13112933

Bottarelli M, González Gallero FJ. Energy Analysis of a Dual-Source Heat Pump Coupled with Phase Change Materials. Energies. 2020; 13(11):2933. https://doi.org/10.3390/en13112933

Chicago/Turabian StyleBottarelli, Michele, and Francisco Javier González Gallero. 2020. "Energy Analysis of a Dual-Source Heat Pump Coupled with Phase Change Materials" Energies 13, no. 11: 2933. https://doi.org/10.3390/en13112933

APA StyleBottarelli, M., & González Gallero, F. J. (2020). Energy Analysis of a Dual-Source Heat Pump Coupled with Phase Change Materials. Energies, 13(11), 2933. https://doi.org/10.3390/en13112933