Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments

Abstract

1. Introduction

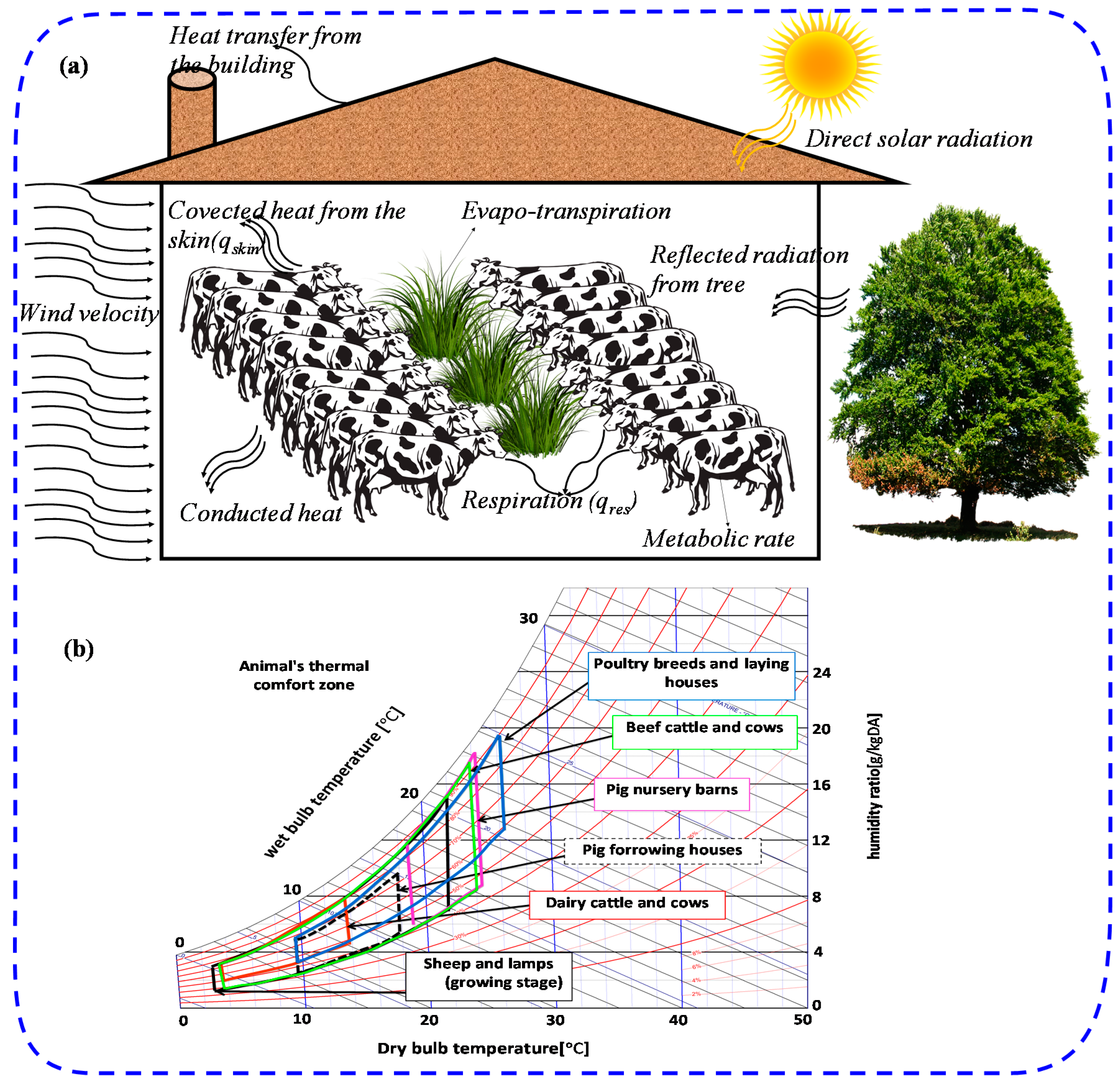

Air-Conditioning Requirements for Animals

2. Proposed Air-Conditioning (AC) Systems

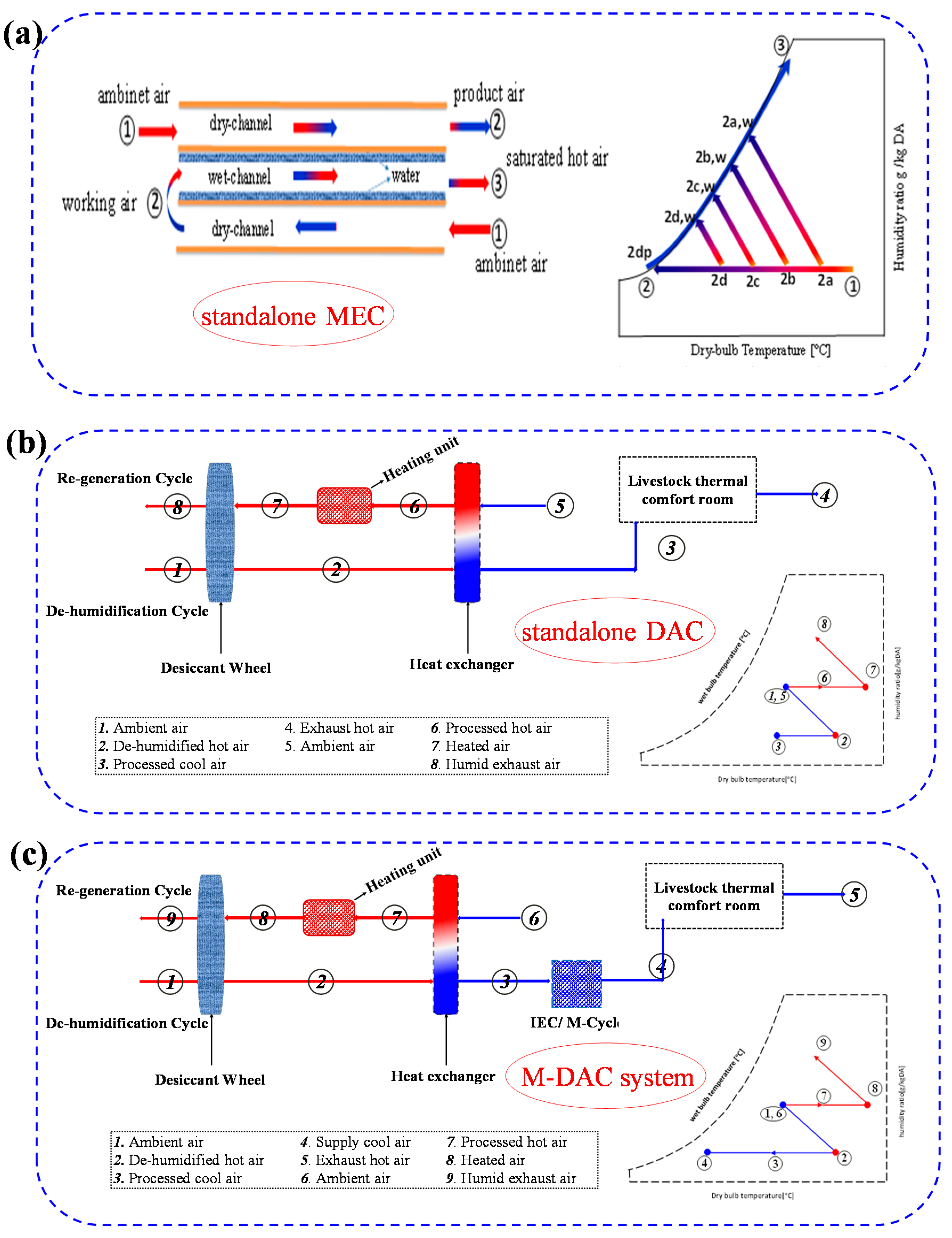

2.1. Stand-Alone M-Cycle Evaporative Cooling System (MEC)

2.2. Stand-Alone Desiccant AC System (DAC)

2.3. M-Cycle Supported Desiccant AC System (M-DAC)

3. Materials and Methods

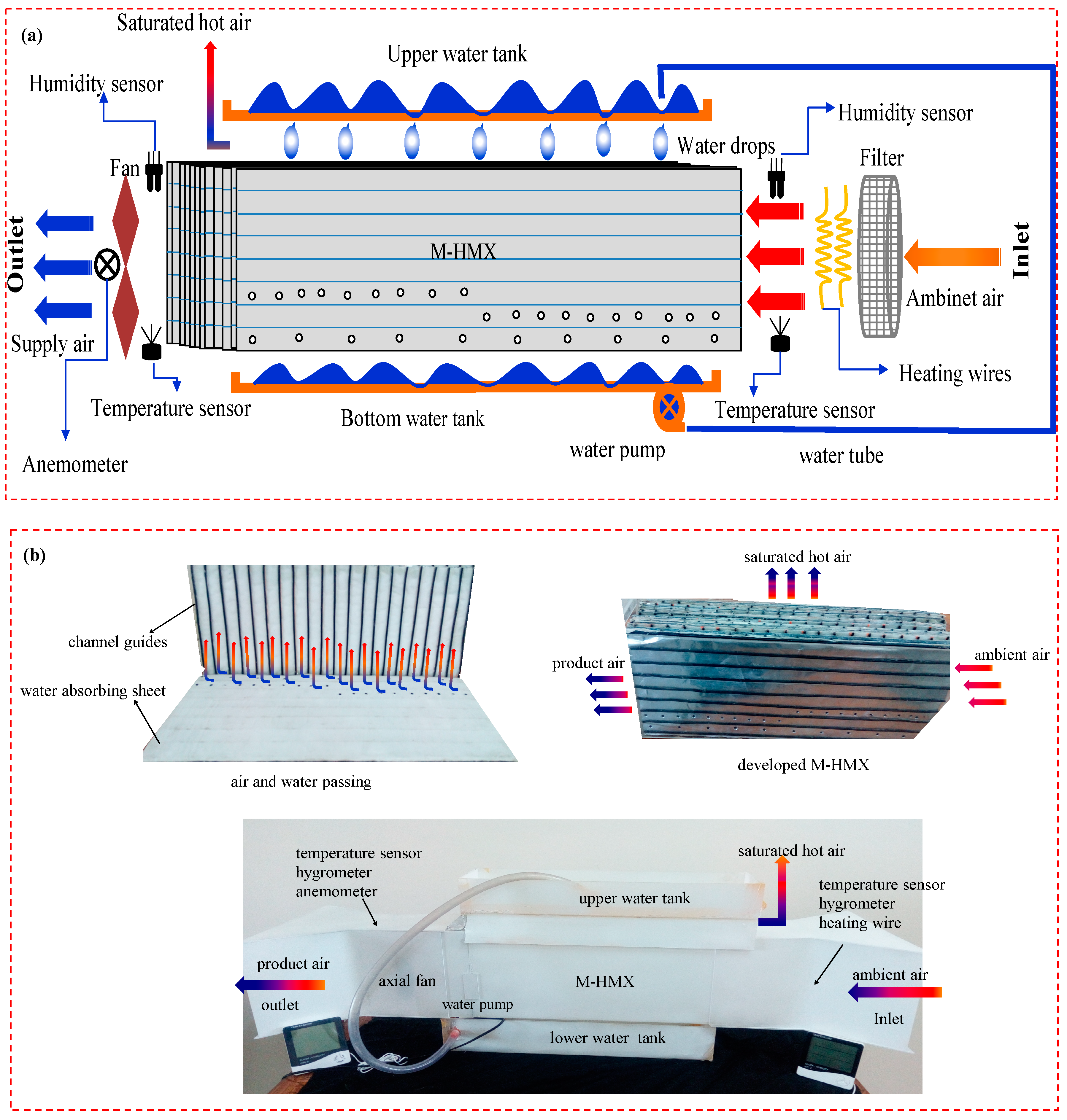

3.1. Experimental Section

3.2. Load Calculation for Livestock Application

3.3. Methodology for Maisotsenko-Cycle Evaporative Cooling (MEC) System

- The whole system was thermally in-conductance;

- Water as coolant agent with no corrosion effect;

- Wet channels remained completely saturated because of uniform water distribution.

- Relative humidity at inlet and outlet sections (RHin, RHout);

- Dry-bulb temperature at inlet and outlet sections (Tin, Tout);

- Air velocity at outlet section (Vout).

3.4. Methodology for Desiccant AC System (DAC)

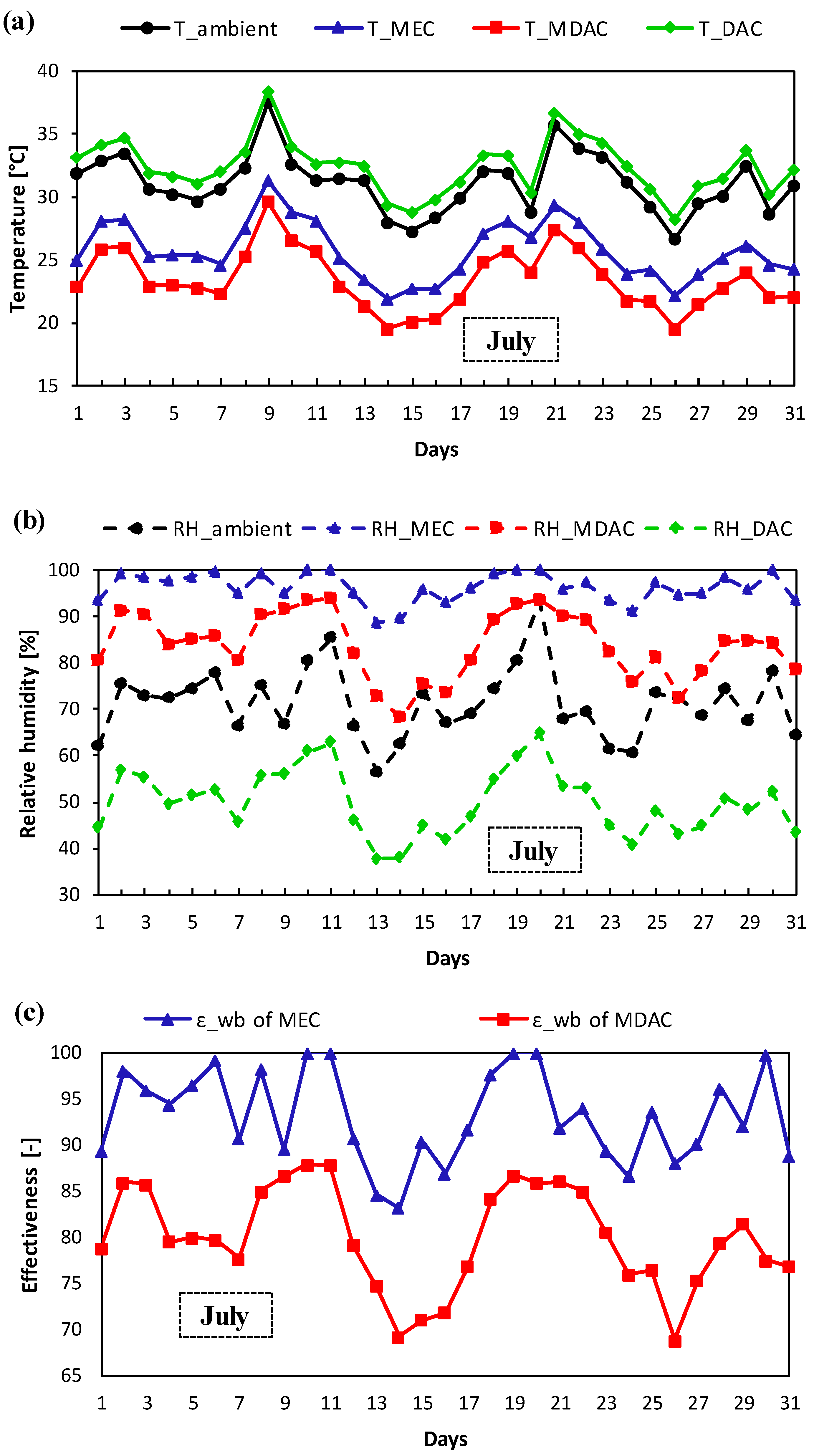

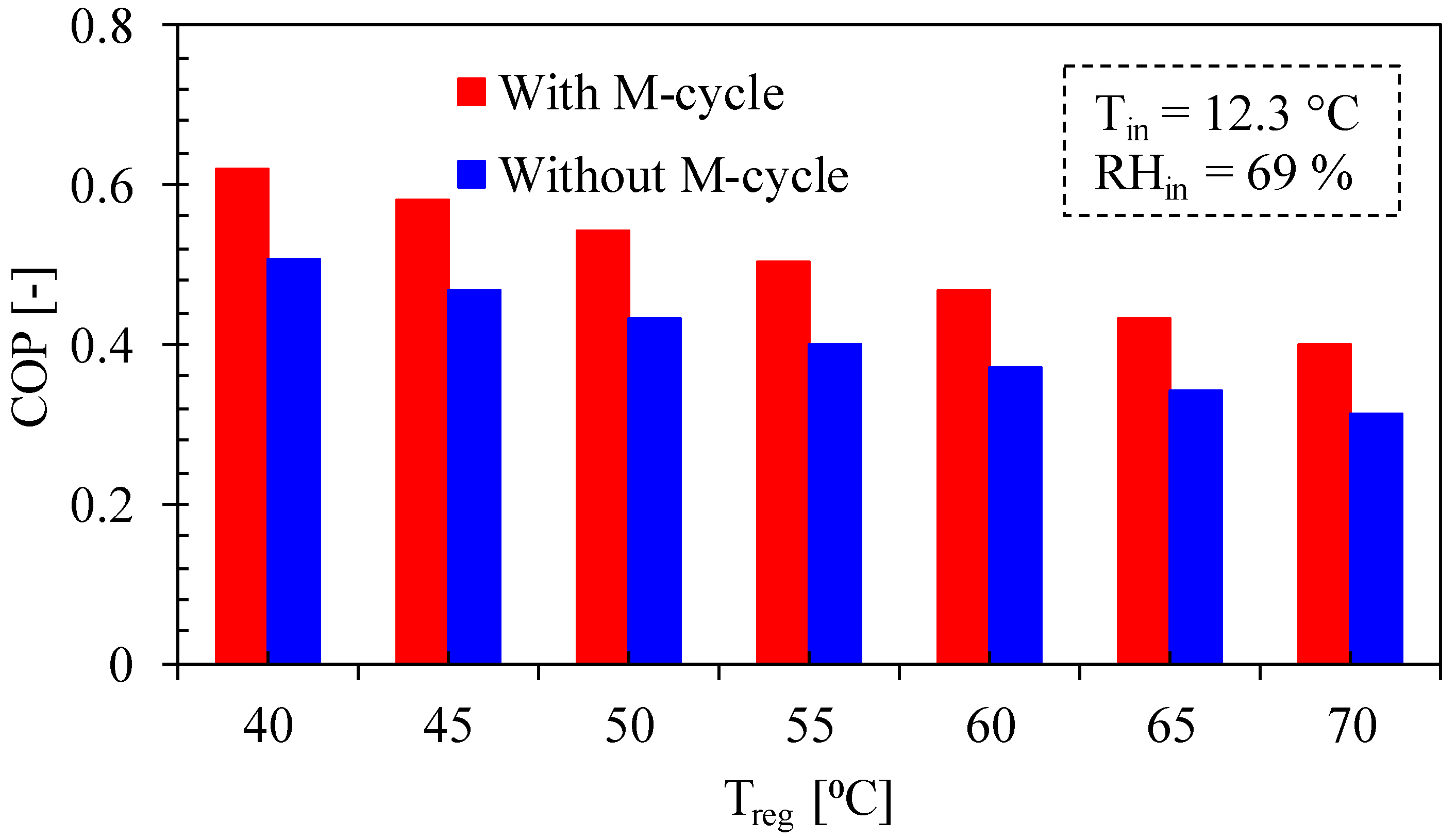

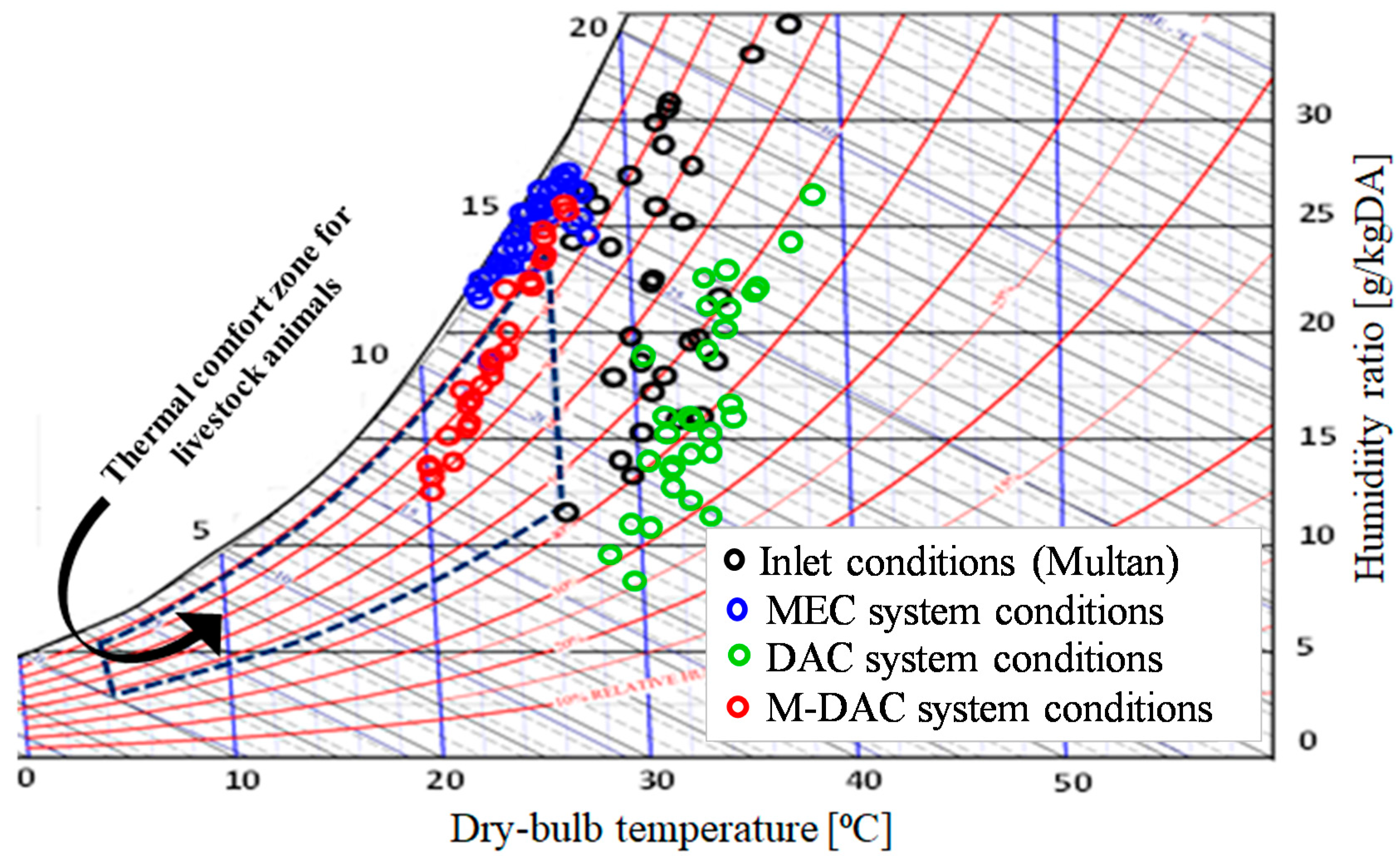

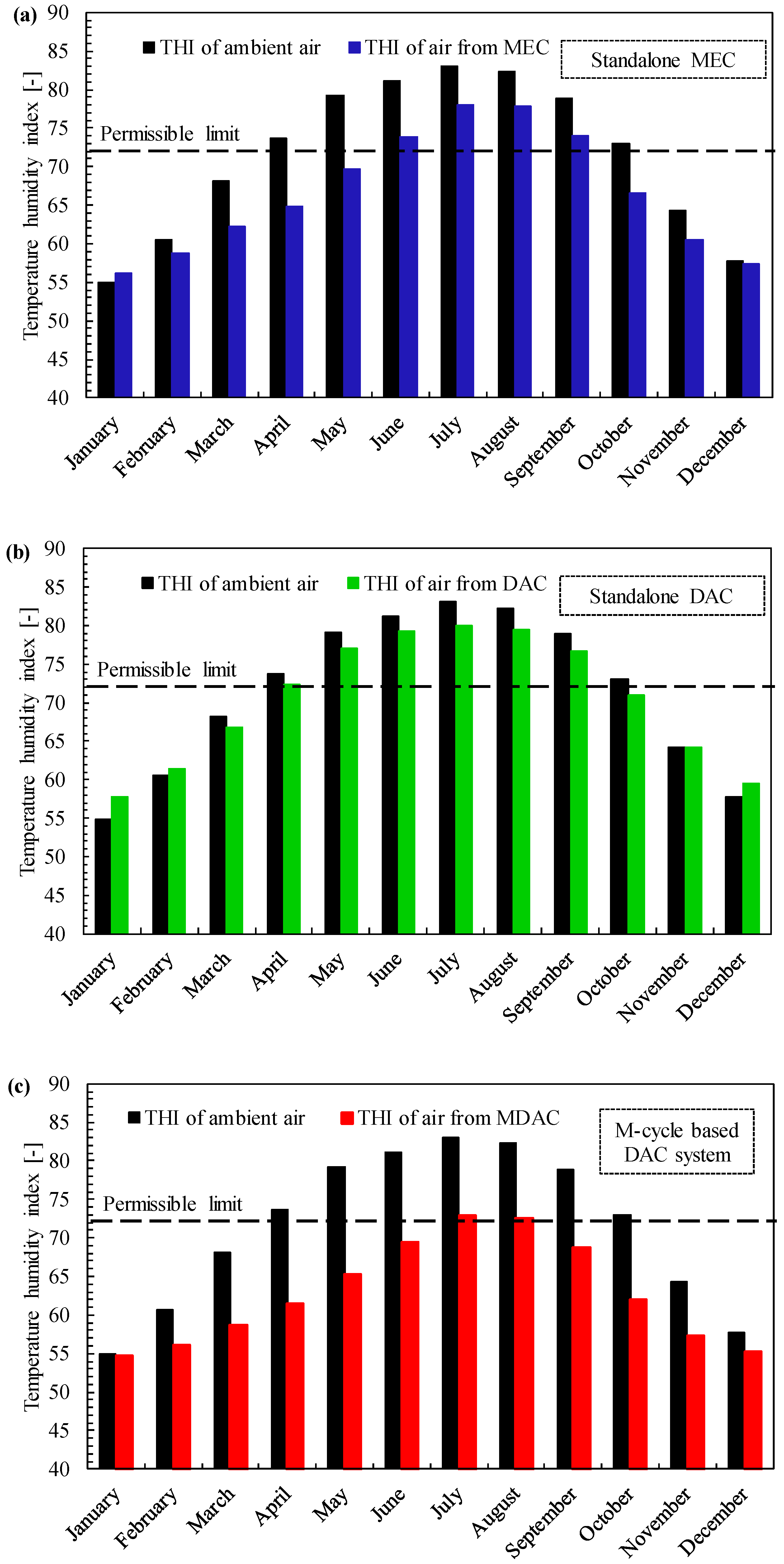

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. An overview of solid desiccants dehumidification and air conditioning systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Koyama, S.; Khan, Z.M. Performance evaluation of hydrophilic organic polymer sorbents for desiccant air-conditioning applications. Adsorpt. Sci. Technol. 2017, 36, 1–16. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. Experimental study on carbon-based adsorbents for greenhouse dehumidification. Evergreen 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Niaz, H.; Shabir, F.; Ashraf, S.; Khan, Z.M.; Mahmood, M.H.; Reza, H.M.U. Thermodynamic assessment of solar chimney based airconditioning system for agricultural and livestock applications. In Proceedings of the 4th International Conference on Energy and Environment and Sustainable Development (EESD-2016), Jamshoro, Pakistan, 1–3 November 2016. [Google Scholar]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification update. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Naphon, P. Study on the heat transfer characteristics of an evaporative cooling tower. Int. Commun. Heat Mass Transf. 2005, 32, 1066–1074. [Google Scholar] [CrossRef]

- Caliskan, H.; Dincer, I.; Hepbasli, A. Exergetic and sustainability performance comparison of novel and conventional air cooling systems for building applications. Energy Build. 2011, 43, 1461–1472. [Google Scholar] [CrossRef]

- Zhan, C.; Duan, Z.; Zhao, X.; Smith, S.; Jin, H.; Riffat, S. Comparative study of the performance of the M-cycle counter-flow and cross-flow heat exchangers for indirect evaporative cooling–paving the path toward sustainable cooling of buildings. Energy 2011, 36, 6790–6805. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Koyama, S. Optimization of adsorption isotherm types for desiccant air-conditioning applications. Renew. Energy 2018, 121, 441–450. [Google Scholar] [CrossRef]

- Caliskan, H.; Hepbasli, A.; Dincer, I.; Maisotsenko, V. Thermodynamic performance assessment of a novel air cooling cycle: Maisotsenko cycle. Int. J. Refrig. 2011, 34, 980–990. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook, Fundamentals; American Society of Heating, Refrigerating Air-Condition Engineers Inc.: Atlanta, GA, USA, 2005. [Google Scholar]

- Jiang, Y.; Xie, X. Theoretical and testing performance of an innovative indirect evaporative chiller. Solar Energy 2010, 84, 2041–2055. [Google Scholar] [CrossRef]

- Anisimov, S.; Pandelidis, D.; Danielewicz, J. Numerical analysis of selected evaporative exchangers with the Maisotsenko cycle. Energy Convers. Manag. 2014, 88, 426–441. [Google Scholar] [CrossRef]

- Costelloe, B.; Finn, D. Indirect evaporative cooling potential in air–water systems in temperate climates. Energy Build. 2003, 35, 573–591. [Google Scholar] [CrossRef]

- Wu, J.M.; Huang, X.; Zhang, H. Theoretical analysis on heat and mass transfer in a direct evaporative cooler. Appl. Therm. Eng. 2009, 29, 980–984. [Google Scholar] [CrossRef]

- Maheshwari, G.P.; Al-Ragom, F.; Suri, R.K. Energy saving potential of an indirect evaporative cooler. Appl. Energy 2001, 69, 69–76. [Google Scholar] [CrossRef]

- Gómez, E.V.; Martínez, F.J.R.; González, A.T. Experimental characterisation of the operation and comparative study of two semi-indirect evaporative systems. Appl. Therm. Eng. 2010, 30, 1447–1454. [Google Scholar] [CrossRef]

- Ray, W.T. Conditioning Liquids and Air and Other Gases. U.S. Patent 1986529, 1 January 1935. [Google Scholar]

- Anisimov, S.; Pandelidis, D. Theoretical study of the basic cycles for indirect evaporative air cooling. Int. J. Heat Mass Transf. 2015, 84, 974–989. [Google Scholar] [CrossRef]

- Cengel, Y.A. Heat and Mass Transfer: A Practical Approach with EES CD; McGraw-Hill Higher Education: New York, NY, USA, 2006. [Google Scholar]

- Anisimov, S.; Pandelidis, D. Numerical study of the Maisotsenko cycle heat and mass exchanger. Int. J. Heat Mass Transf. 2014, 75, 75–96. [Google Scholar] [CrossRef]

- Niaz, H.; Sultan, M.; Khan, Z.M.; Mahmood, M.H.; Niaz, Y. Thermodynamic investigation of M-cycle assisted open-cycle desiccant air conditioning systems. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V.S. Overview of the Maisotsenko cycle–A way towards dew point evaporative cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Riangvilaikul, B.; Kumar, S. Numerical study of a novel dew point evaporative cooling system. Energy Build. 2010, 42, 2241–2250. [Google Scholar] [CrossRef]

- Lee, J.; Choi, B.; Lee, D. Comparison of configurations for a compact regenerative evaporative cooler. Int. J. Heat Mass Transf. 2013, 62, 192–198. [Google Scholar] [CrossRef]

- Gillan, L. Maisotsenko cycle for cooling process. Clean Air 2008, 9, 1–18. [Google Scholar]

- Hasan, A. Indirect evaporative cooling of air to a sub-wet bulb temperature. Appl. Therm. Eng. 2010, 30, 2460–2468. [Google Scholar] [CrossRef]

- Zube, D.; Gillan, L. Evaluating Coolerado Corportion’s heat–mass exchanger performance through experimental analysis. Int. J. Energy Clean Environ. 2011, 12, 101–116. [Google Scholar] [CrossRef]

- Ren, C.; Yang, H. An analytical model for the heat and mass transfer process in indirect evaporative cooling with parallel/counter flow configuration. Int. J. Heat Mass Transf. 2006, 49, 617–627. [Google Scholar]

- Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Khan, Z.M. Solar assisted evaporative cooling based passive air-conditioning system for agricultural and livestock applications. J. Eng. Sci. Technol. 2018, 13, 693–703. [Google Scholar]

- Karimi, M.T.; Ghorbani, G.R.; Kargar, S.; Drackley, J.K. Late-gestation heat stress abatement on performance and behavior of Holstein dairy cows. J. Dairy Sci. 2015, 98, 6865–6875. [Google Scholar] [CrossRef]

- Palacio, S.; Bergeron, R.; Lachance, S.; Vasseur, E. The effects of providing portable shade at pasture on dairy cow behavior and physiology. J. Dairy Sci. 2015, 98, 6085–6093. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.M.; Riffat, S.B. Numerical study of a novel counter-flow heat and mass exchanger for dew point evaporative cooling. Appl. Therm. Eng. 2008, 28, 1942–1951. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Bozorgmehr, M.; Delfani, S.; Esmaeelian, J. Experimental investigation of two-stage indirect/direct evaporative cooling system in various climatic conditions. Build. Environ. 2009, 44, 2073–2079. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maruyama, T.; Maeda, S.; Nakamura, T. Water vapor sorption kinetics of polymer based sorbents: Theory and experiments. Appl. Therm. Eng. 2016, 106, 192–202. [Google Scholar] [CrossRef]

- Panaras, G.; Mathioulakis, E.; Belessiotis, V.; Kyriakis, N. Theoretical and experimental investigation of the performance of a desiccant air-conditioning system. Renew. Energy 2010, 35, 1368–1375. [Google Scholar] [CrossRef]

- Alonso, J.F.S.J.; Martinez, F.J.R.; Gomez, E.V.; Plasencia, M.A.G. Simulation model of an indirect evaporative cooler. Energy Build. 1998, 29, 23–27. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T. Energy-efficient air-conditioning systems for nonhuman applications. In Refrigeration; IntechOpen: London, UK, 2017; pp. 97–117. [Google Scholar]

- ASHRAE. Handbook of Fundamentals; Published by American Society of Heating, Refrigerating and Air-Conditioning Engineers Inc.: Atlanta, GA, USA, 2009. [Google Scholar]

- Wang, X.; Zhang, G.; Choi, C.Y. Effect of airflow speed and direction on convective heat transfer of standing and reclining cows. Biosyst. Eng. 2018, 167, 87–98. [Google Scholar] [CrossRef]

- Panaras, G.; Mathioulakis, E.; Belessiotis, V. Solid desiccant air-conditioning systems–design parameters. Energy 2011, 36, 2399–2406. [Google Scholar] [CrossRef]

- Sultan, M.; Niaz, H.; Miyazaki, T. Investigation of Desiccant and Evaporative Cooling Systems for Animal Air-Conditioning. In Refrigeration and Air-Conditioning; IntechOpen: London, UK, 2019. [Google Scholar]

| THI Value | Description |

|---|---|

| <68 | Thermal neutral region |

| 68–72 | Thermally stable region |

| 72–80 | Moderate heat stress region |

| >80 | Severe heat stress region |

| Constant | Value | Constant | Value |

|---|---|---|---|

| A1 | −2865 | A2 | 6360 |

| B1 | 4.344 | B2 | 1.127 |

| C1 | 0.8624 | C2 | 0.07969 |

| Months 1 | Air-Conditioning System Options | ||

|---|---|---|---|

| Standalone MEC System | Standalone DAC System | M-DAC System | |

| March | ✓ | ✗ | ✓ |

| April | ✓ | ✗ | ✓ |

| May | ✓ | ✗ | ✓ |

| June | ✓ | ✗ | ✓ |

| July | ✗ | ✗ | ✓ |

| August | ✗ | ✗ | ✓ |

| September | ✗ | ✗ | ✓ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kashif, M.; Niaz, H.; Sultan, M.; Miyazaki, T.; Feng, Y.; Usman, M.; Shahzad, M.W.; Niaz, Y.; M. Waqas, M.; Ali, I. Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies 2020, 13, 2675. https://doi.org/10.3390/en13112675

Kashif M, Niaz H, Sultan M, Miyazaki T, Feng Y, Usman M, Shahzad MW, Niaz Y, M. Waqas M, Ali I. Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies. 2020; 13(11):2675. https://doi.org/10.3390/en13112675

Chicago/Turabian StyleKashif, Muhammad, Hassan Niaz, Muhammad Sultan, Takahiko Miyazaki, Yongqiang Feng, Muhammad Usman, Muhammad W. Shahzad, Yasir Niaz, Muhammad M. Waqas, and Imran Ali. 2020. "Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments" Energies 13, no. 11: 2675. https://doi.org/10.3390/en13112675

APA StyleKashif, M., Niaz, H., Sultan, M., Miyazaki, T., Feng, Y., Usman, M., Shahzad, M. W., Niaz, Y., M. Waqas, M., & Ali, I. (2020). Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies, 13(11), 2675. https://doi.org/10.3390/en13112675