Small Vessel with Inboard Engine Retrofitting Concepts; Real Boat Tests, Laboratory Hybrid Drive Tests and Theoretical Studies

Abstract

1. Introduction

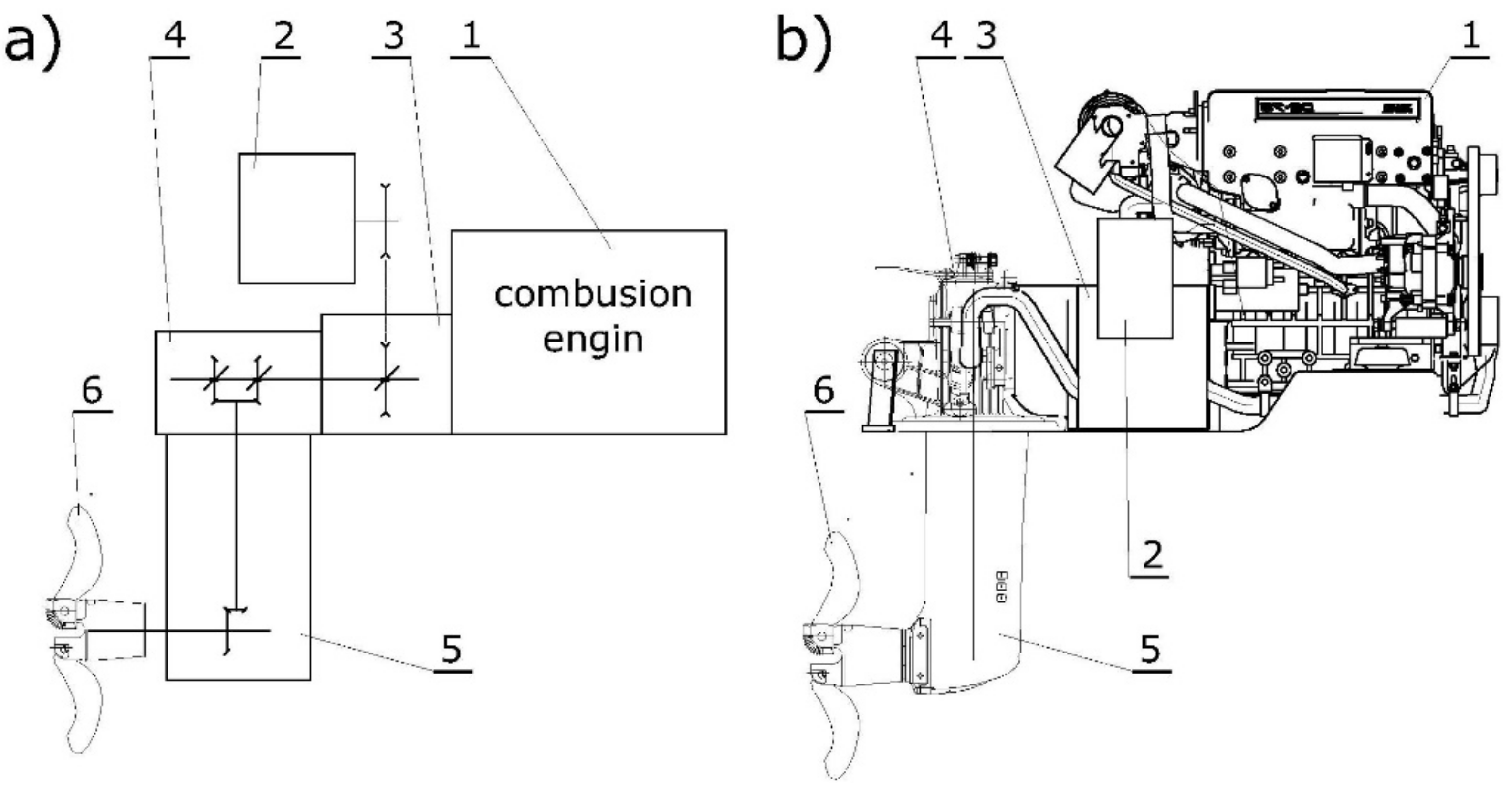

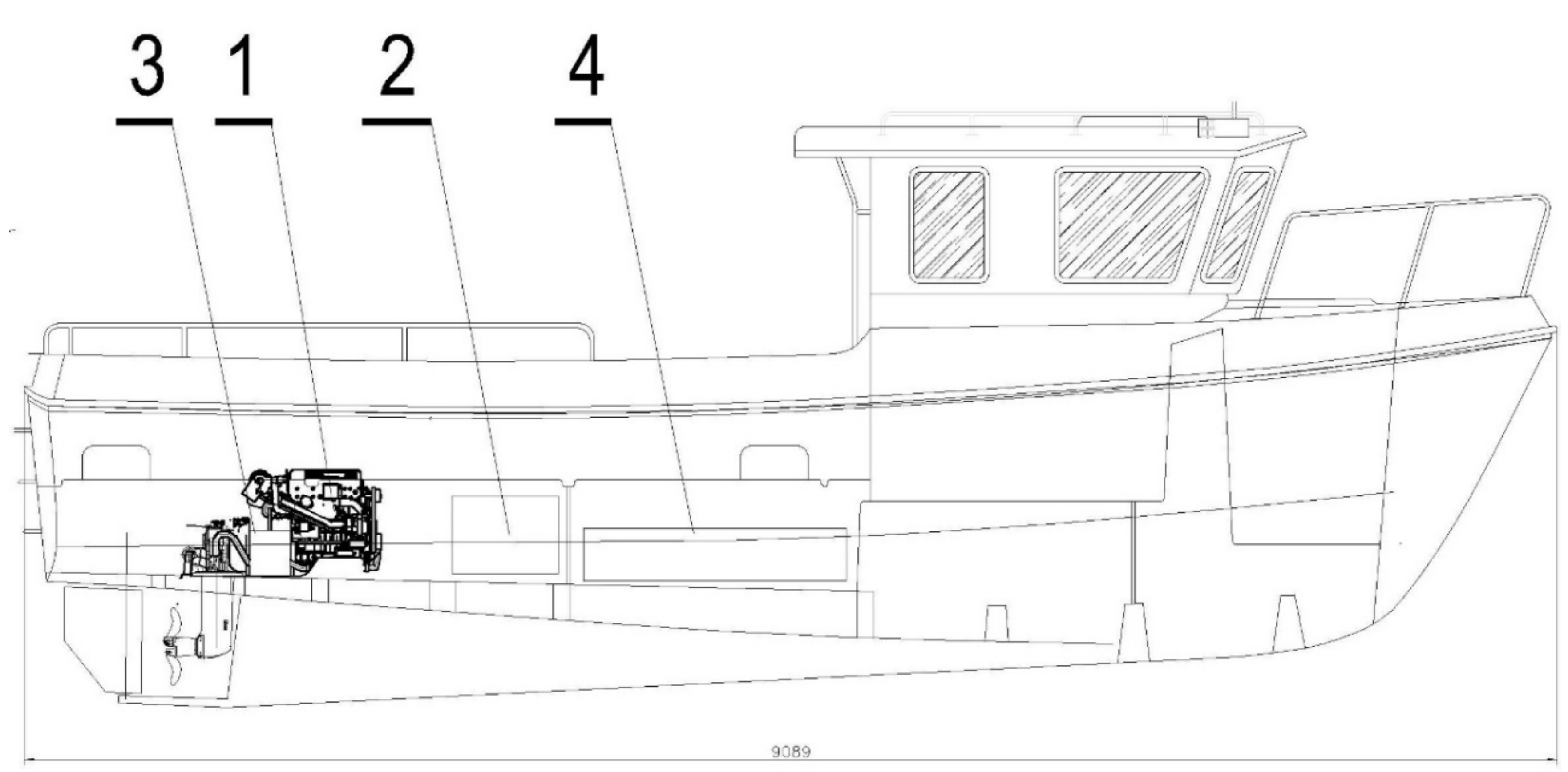

2. Concept of Design and Research Works

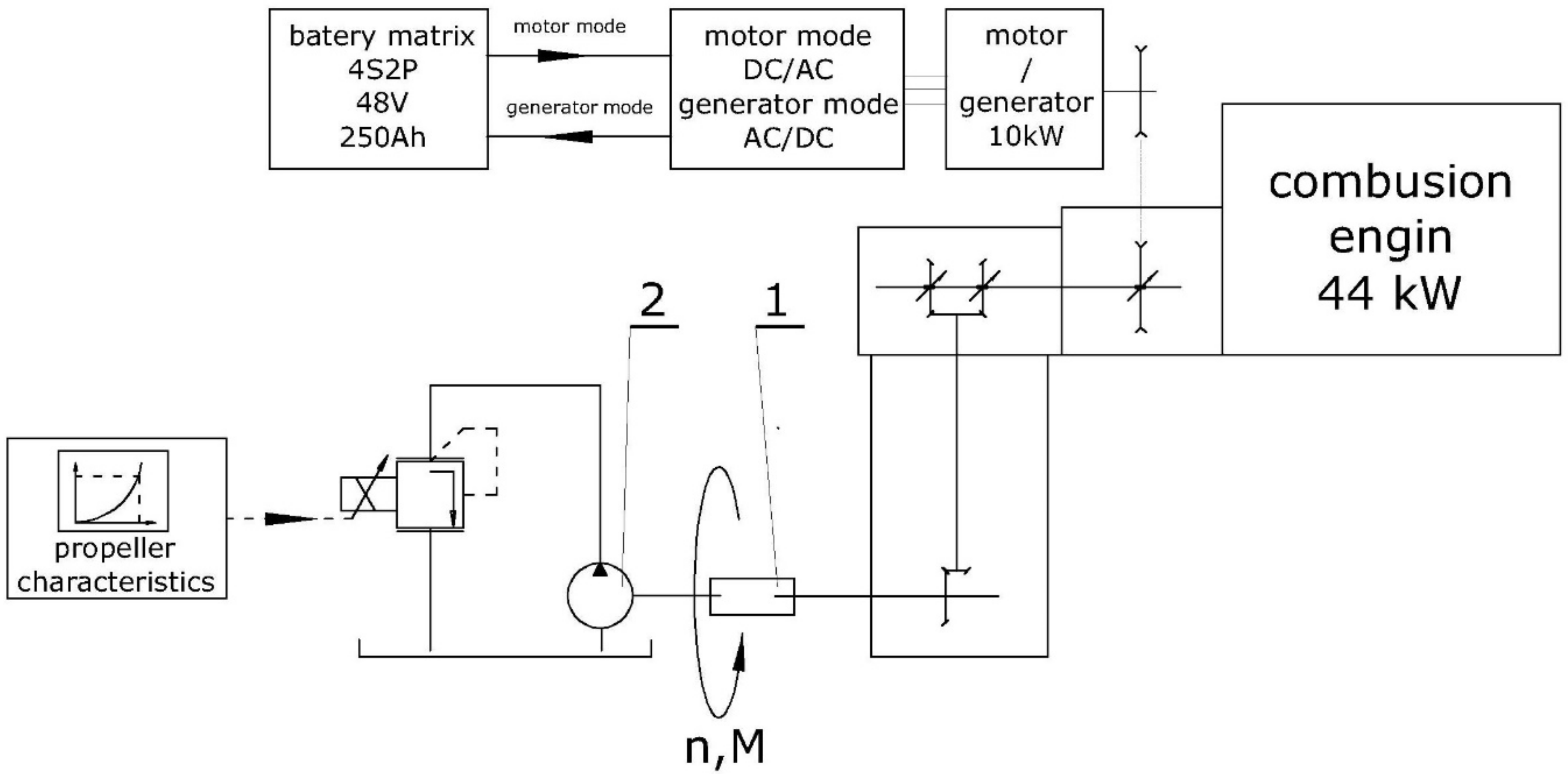

3. Design of the Hybrid Propulsion System

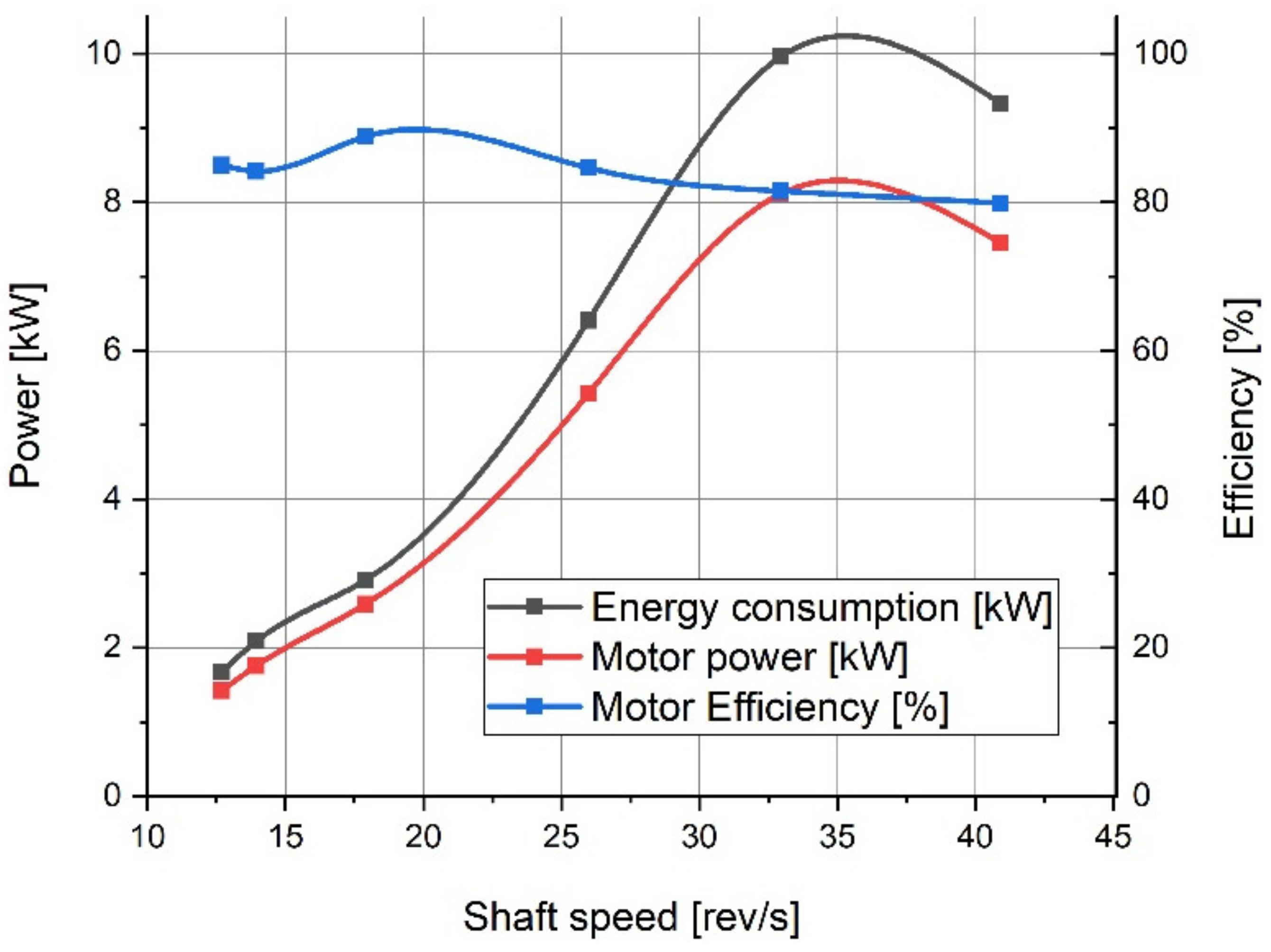

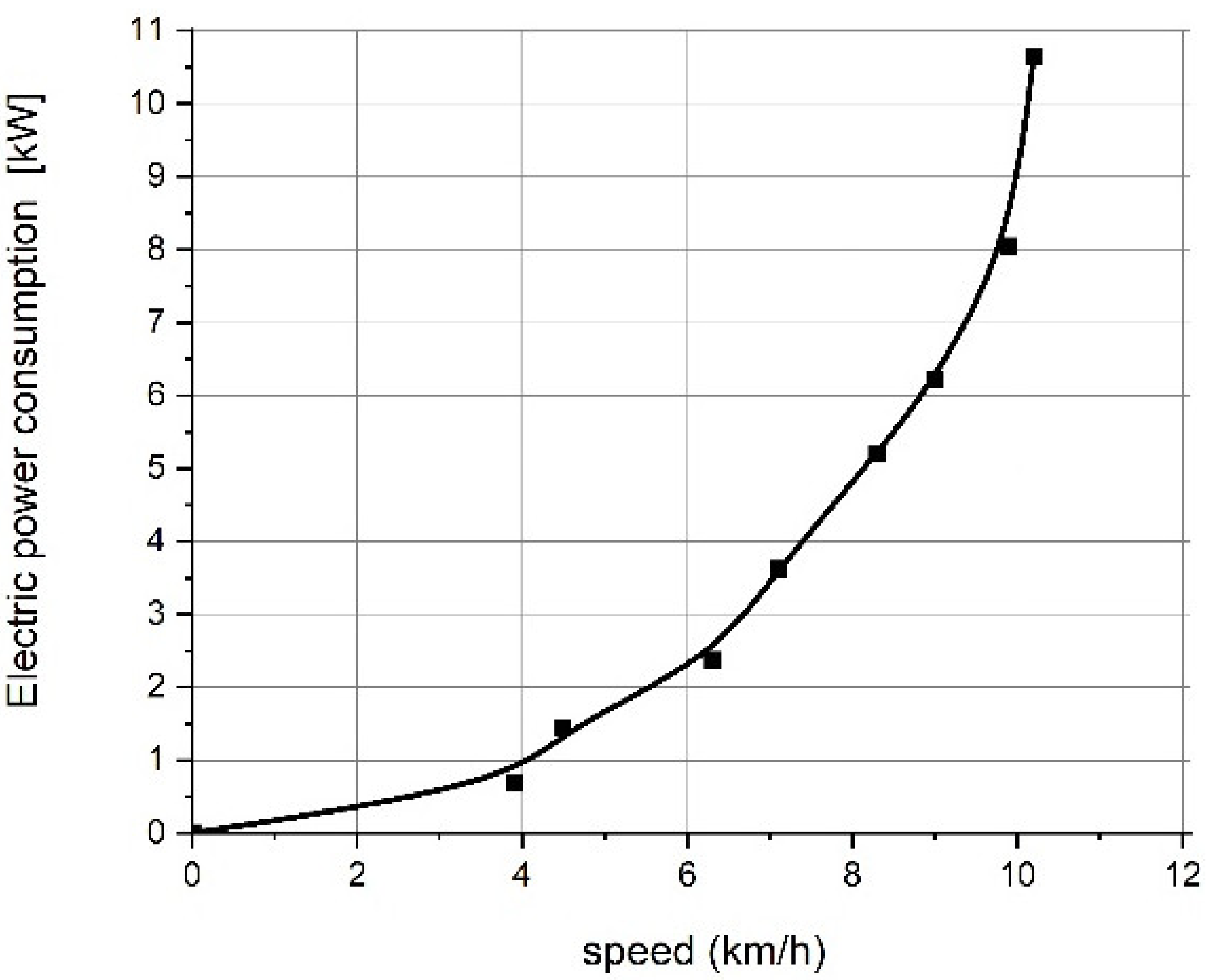

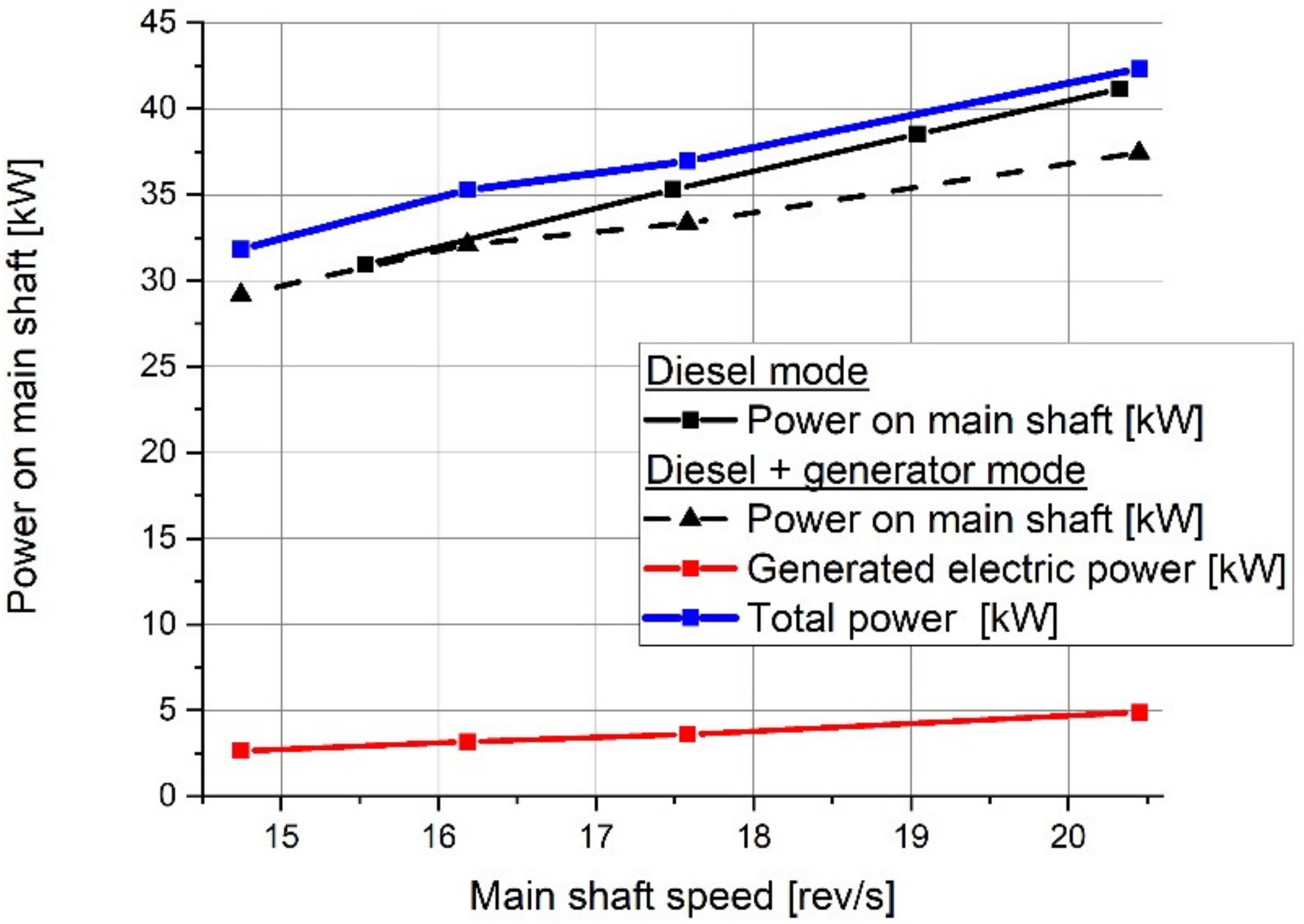

4. Experimental Research and Discussion of Results

- diesel engine mode;

- electric motor mode;

- diesel engine mode with simultaneous electricity generation (diesel + generator mode).

5. Conclusions

- It worth observing certain significant limitations of the propulsion system stemming from using a simple, inexpensive and widely used fixed pitch propeller. In a typical case, when the propeller is selected for a precise combustion engine, during travel using electric propulsion, it might turn out that the lesser-powered electric motor is not capable of effective work with the propeller, as it is not able to generate sufficient torque. Usually, in such a case, a reduction gear is used, which allows for increasing the torque on the propeller shaft, while accepting that the lesser-powered electric motor drives the propeller shaft at a lower speed. However, a problem appears during work in the generator mode. The reduction gear becomes a multiplying gear and the electric machine works at a significantly faster pace than in the motor mode. Since the voltage generated by the electric machine with permanent magnets depends on the rotational speed of the shaft, it turns out that the generated voltage is much greater than the supplied voltage. This may cause a system failure with dangerous consequences. Therefore, in the case of a hybrid propulsion system, an ideal solution would be to employ continuously variable transmission (CVT)—similar to its use in vehicles. Another very good but complex solution would be to use an adjustable pitch propeller, which can change the attack angle of the blades to fit sailing conditions [30,31,32,33].

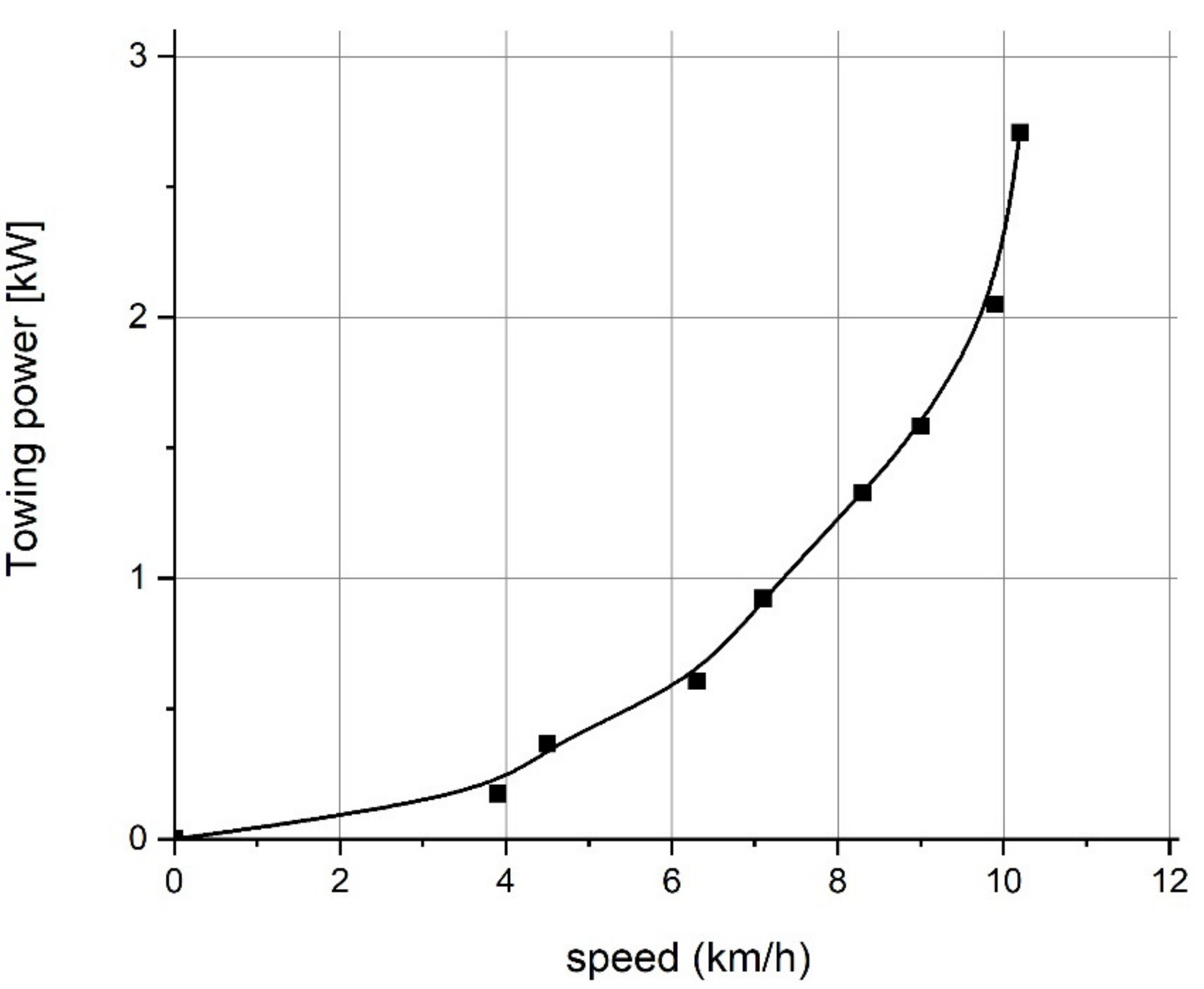

- Retrofitting the vessel will result in increasing its total mass by approximately 5%–7%. Consequently, there will be increases in resistance and energy demand. Based on our own model studies of comparably sized objects, one may speculate that the levels of resistance will increase by approximately 5%.

- No successful tests were completed in the mode of two engines operating simultaneously. There was a problem with the electric motor being powered by a frequency converter with rotational speed control. Work on modifying the controller’s software is problematic as the manufacturer is not very co-operative when it comes to sharing technical specifications of the device.

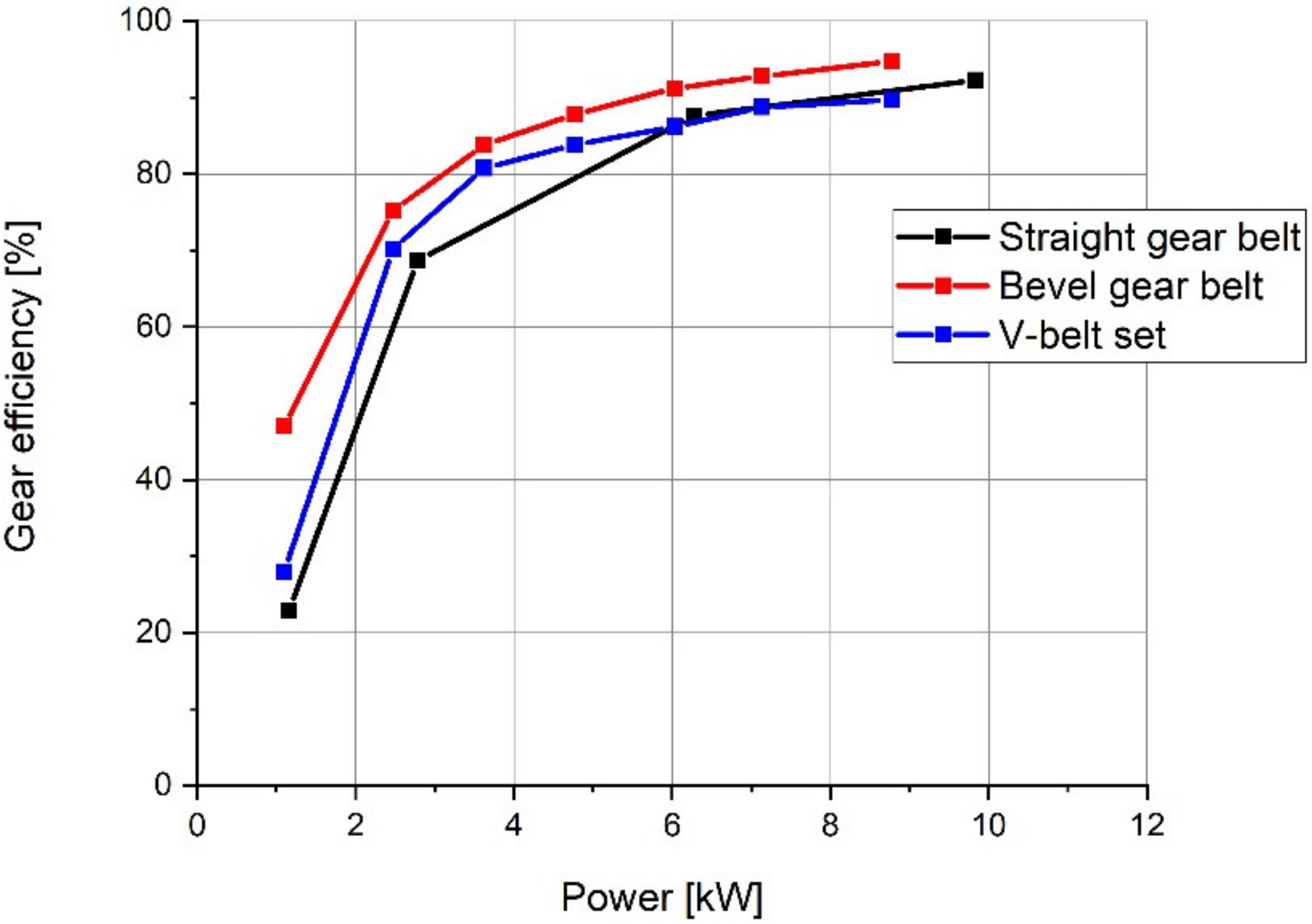

- Losses in the mechanical power transfer system are, on average, 5%–10%, which is acceptable. If the absolute priority were energy efficiency, then a tooth gear transmission should be used instead of a belt one. However, belt transmission has a unique characteristic that is especially useful at the prototype test stage. By changing one of the wheels, the gearing ratio may be modified to fit a specific propeller.

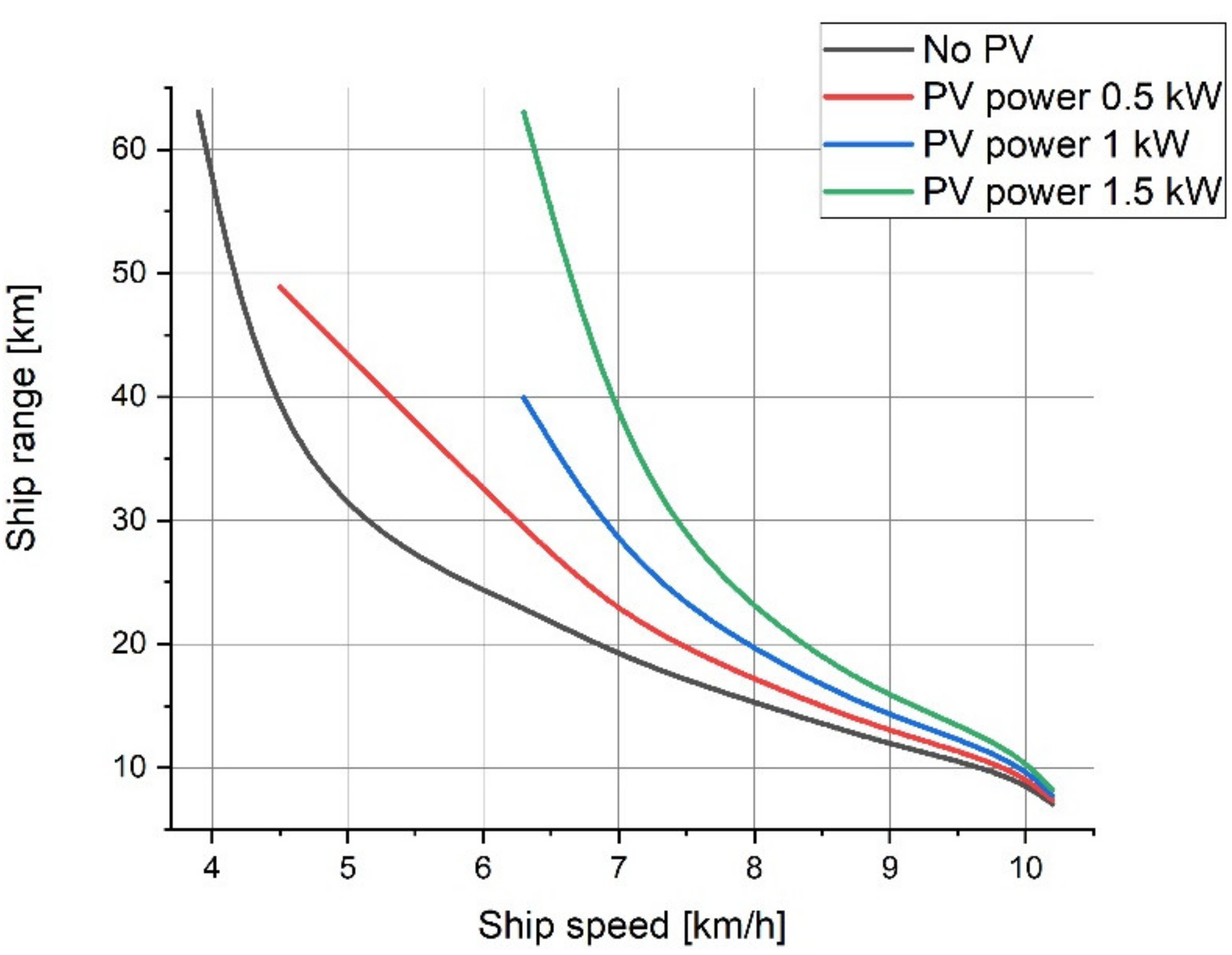

- The range and autonomous character of the vessel may be substantially increased by adding photovoltaic panels. It is anticipated that six panels having 1.5 kWp combined peak power will be installed on the retrofitted watercraft.

- It is worth adding that installing a parallel hybrid propulsion system on a vessel generally increases the level of safety. This is due to the fact that the unit has two drive units mounted, which can work independently. So if one of the systems brakes, the second can operate.

Author Contributions

Funding

Conflicts of Interest

References

- Misyris, G.; Marinopoulos, A.; Doukas, D.; Tengnér, T.; Labridis, D. On battery state estimation algorithms for electric ship applications. Electr. Power Syst. Res. 2017, 151, 115–124. [Google Scholar] [CrossRef]

- Geertsma, R.; Negenborn, R.; Visser, K.; Hopman, J. Parallel control for hybrid propulsion of multifunction ships. IFAC PapersOnLine 2017, 50, 2296–2303. [Google Scholar] [CrossRef]

- García, P.; Fernández, L.M.; Torreglosa, J.P.; Jurado, F.; Fernandez-Ramirez, L.M. Operation mode control of a hybrid power system based on fuel cell/battery/ultracapacitor for an electric tramway. Comput. Electr. Eng. 2013, 39, 1993–2004. [Google Scholar] [CrossRef]

- Gao, D.; Jin, Z.; Zhang, J.; Li, J.; Ouyang, M. Comparative study of two different powertrains for a fuel cell hybrid bus. J. Power Sources 2016, 319, 9–18. [Google Scholar] [CrossRef]

- Yang, R.; Yuan, Y.; Ying, R.; Shen, B.; Long, T. A novel energy management strategy for a ship’s hybrid solar energy generation system using a particle swarm optimization algorithm. Energies 2020, 13, 1380. [Google Scholar] [CrossRef]

- Hayajneh, H.S.; Zhang, X. Logistics design for mobile battery energy storage systems. Energies 2020, 13, 1157. [Google Scholar] [CrossRef]

- Tillig, F.; Ringsberg, J.W.; Mao, W.; Ramne, B. Analysis of uncertainties in the prediction of ships’ fuel consumption—From early design to operation conditions design to operation conditions. Ships Offshore Struct. 2018. [Google Scholar] [CrossRef]

- Kalargaris, I.; Tian, G.; Gu, S. Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process. Technol. 2017, 157, 108–115. [Google Scholar] [CrossRef]

- Shih, N.-C.; Weng, B.-J.; Lee, J.-Y.; Hsiao, Y.-C. Development of a 20 kW generic hybrid fuel cell power system for small ships and underwater vehicles. Int. J. Hydrogen Energy 2014, 39, 13894–13901. [Google Scholar] [CrossRef]

- Gagatsi, E.; Estrup, T.; Halatsis, A. Exploring the potentials of electrical waterborne transport in Europe: The E-ferry concept. Transp. Res. Procedia 2016, 14, 1571–1580. [Google Scholar] [CrossRef]

- Nasirudin, A.; Chao, R.-M.; Utama, I.K.A.P. Solar powered boat design optimization. Procedia Eng. 2017, 194, 260–267. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Qi, X.; Han, Y.; Lu, F. Estimation of PV output power in moving and rocking hybrid energy marine ships. Appl. Energy 2017, 204, 362–372. [Google Scholar] [CrossRef]

- Tang, R. Large-scale photovoltaic system on green ship and its MPPT controlling. Sol. Energy 2017, 157, 614–628. [Google Scholar] [CrossRef]

- Dymarski, C. A concept design of diesel—Hydraulic propulsion system for passenger ship intended for inland shallow water navigation. Pol. Marit. Res. 2019, 26, 30–38. [Google Scholar] [CrossRef]

- Piątek, D. New concept of hybrid propulsion with hydrostatic gear for inland water transport. Pol. Marit. Res. 2019, 26, 134–141. [Google Scholar] [CrossRef]

- Alfonsín, V.; Suarez, A.; Cancela, A.; Sanchez, A.; Maceiras, R. Modelization of hybrid systems with hydrogen and renewable energy oriented to electric propulsion in sailboats. Int. J. Hydrogen Energy 2014, 39, 11763–11773. [Google Scholar] [CrossRef]

- Carter, C. Zero oil means zero enviromental impact. Nav. Archit. 2012, 5, 32–36. [Google Scholar]

- Kazienko, D.; Chybowski, L. Instantaneous rotational speed algorithm for locating malfunctions in marine diesel engines. Energies 2020, 13, 1396. [Google Scholar] [CrossRef]

- Verge, T. An Inside Look at the World’s Largest Solar-Powered Boat. 2016, pp. 1–13. Available online: http://www.theverge.com/2013/6/22/4454980/ms-turanor-planetsolar-s (accessed on 18 May 2020).

- Geertsma, R.; Negenborn, R.; Visser, K.; Hopman, J. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Appl. Energy 2017, 194, 30–54. [Google Scholar] [CrossRef]

- Di Nicolantonio, M.; Lagatta, J.; Vallicelli, A. 80 Feet Sustainable Motoryacht: Technological Solutions Concept of the Living Spaces on Board. Procedia Manuf. 2015, 3, 2698–2705. [Google Scholar] [CrossRef][Green Version]

- Karczewski, A.; Kozak, J. Variant designing in the preliminary small ship design process. Pol. Marit. Res. 2017, 24, 77–82. [Google Scholar] [CrossRef]

- Gełesz, P.; Karczewski, A.; Kozak, J.; Litwin, W.; Piątek, Ł. Design methodology for small passenger ships on the example of the ferryboat Motława 2 driven by hybrid propulsion system. Pol. Marit. Res. 2017, 24, 67–73. [Google Scholar] [CrossRef]

- Łebkowski, A. Analysis of the use of electric drive systems for crew transfer vessels servicing offshore wind farms. Energies 2020, 13, 1466. [Google Scholar]

- Kunicka, M.; Litwin, W. Energy efficient small inlad passenger shuttle ferry with hybrcid propulsion—Concept design, calculations and model tests. Polish Marit. Res. 2019, 26, 85–92. [Google Scholar] [CrossRef]

- Kowalski, J.; Leśniewski, W.; Litwin, W. Multi-source-supplied parallel hybrid propulsion of the inland passenger ship STA.H. Research work on energy efficiency of a hybrid propulsion system operating in the electric motor drive mode. Pol. Marit. Res. 2013, 20, 20–27. [Google Scholar] [CrossRef]

- Kunicka, M.; Litwin, W. Energy demand of short-range inland ferry with series hybrid propulsion depending on the navigation strategy. Energies 2019, 12, 3499. [Google Scholar] [CrossRef]

- Wang, H.; Oguz, E.; Jeong, B.; Zhou, P. Life cycle and economic assessment of a solar panel array applied to a short route ferry. J. Clean. Prod. 2019, 219, 471–484. [Google Scholar] [CrossRef]

- Lan, H.; Wen, S.; Hong, Y.-Y.; Yu, D.C.; Zhang, L. Optimal sizing of hybrid PV/diesel/battery in ship power system. Appl. Energy 2015, 158, 26–34. [Google Scholar] [CrossRef]

- Bertini, L.; Carmignani, L.; Frendo, F. Analytical model for the power losses in rubber V-belt continuously variable transmission (CVT). Mech. Mach. Theory 2014, 78, 289–306. [Google Scholar] [CrossRef]

- Tomaselli, M.; Lino, P.; Carbone, G. Modelling and efficiency formulation of a planetary traction drive CVT. IFAC PapersOnLine 2019, 52, 411–416. [Google Scholar] [CrossRef]

- Liu, J.; Sun, D.; Ye, M.; Liu, X.; Li, B. Study on the transmission efficiency of electro-mechanical continuously variable transmission with adjustable clamping force. Mech. Mach. Theory 2018, 126, 468–478. [Google Scholar] [CrossRef]

- Chung, C.-T.; Wu, C.-H.; Hung, Y.-H. Evaluation of driving performance and energy efficiency for a novel full hybrid system with dual-motor electric drive and integrated input- and output-split e-CVT. Energy 2020, 191, 116508. [Google Scholar] [CrossRef]

| Length overall | 9.10 m |

| Waterline length | 8.2 m |

| Beam | 3 m |

| Draft | 0.95 m |

| Displacement | 3.5 tons |

| Engine | 60 kW |

| Propulsion System | ||

|---|---|---|

| 1 | Diesel-fuel powered combustion engine four cylinders, allowed for use on recreational and commercial vessels | 44 kW |

| 2 | 3-phase electric motor, 48 V with permanent magnets, encoder equipped, powered by a dedicated frequency converter | 10 kW |

| 3000 rev/min | ||

| Transmission Drive | ||

| 3 | Toothed gear with reverse | 2.19:1 |

| Bevel reduction gear | ||

| Power Supply | ||

| Lead-acid batteries, 8 × 12 V 230 Ah | 22 kWh | |

| Fuel tank | 200 Litres | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leśniewski, W.; Piątek, D.; Marszałkowski, K.; Litwin, W. Small Vessel with Inboard Engine Retrofitting Concepts; Real Boat Tests, Laboratory Hybrid Drive Tests and Theoretical Studies. Energies 2020, 13, 2586. https://doi.org/10.3390/en13102586

Leśniewski W, Piątek D, Marszałkowski K, Litwin W. Small Vessel with Inboard Engine Retrofitting Concepts; Real Boat Tests, Laboratory Hybrid Drive Tests and Theoretical Studies. Energies. 2020; 13(10):2586. https://doi.org/10.3390/en13102586

Chicago/Turabian StyleLeśniewski, Wojciech, Daniel Piątek, Konrad Marszałkowski, and Wojciech Litwin. 2020. "Small Vessel with Inboard Engine Retrofitting Concepts; Real Boat Tests, Laboratory Hybrid Drive Tests and Theoretical Studies" Energies 13, no. 10: 2586. https://doi.org/10.3390/en13102586

APA StyleLeśniewski, W., Piątek, D., Marszałkowski, K., & Litwin, W. (2020). Small Vessel with Inboard Engine Retrofitting Concepts; Real Boat Tests, Laboratory Hybrid Drive Tests and Theoretical Studies. Energies, 13(10), 2586. https://doi.org/10.3390/en13102586