Abstract

To solve the problem of the slow convergence of the geometry-based correction (GC) method in the design of a steam turbine blade, this paper proposes a geometry-load-based hybrid correction (GLHC) method. In this method, the deformation of the blade caused by the centrifugal load is still corrected by the GC method, while the deformation caused by the aerodynamic load is corrected by the load-based correction (LC) method instead of the GC method. The LC method updates the cold shape of the blade by reversely applying the aerodynamic load to the ideal shape according to the balance between the internal force generated by the deformation of the blade and the aerodynamic load acting on surface of the hot blade shape, thereby reducing the number of iterations by reducing the shape deviation in each step of the iteration. The GLHC method, which combines the GC and LC methods, is used to improve the design process. The efficiency of the GLHC and GC methods are compared with the maximum number of position deviations of the corresponding mesh nodes between the hot blade and ideal blade shapes, which acts as the criterion. The results show that the GLHC method reduces the number of iterations.

1. Introduction

Steam turbines are important power equipment for industrial production. During the operation of a steam turbine, high-temperature and high-pressure steam act on the blade surface and drive the spindle to rotate, thereby realizing energy conversion and output [1,2]. Therefore, the blades of the steam turbine are very significant for the efficient conversion of energy, especially those in the low-pressure stage [3,4,5].

The traditional design method mainly involves obtaining an ideal blade shape according to the aerodynamic performance of a steam turbine in operation [6,7], then the strength, modality and life of the blade are analyzed to ensure its reliability [2,8,9,10,11,12,13].

However, the deformation of the blade under multiple complex loads causes the actual shape to deviate from the ideal shape obtained by theoretical design [14], which influences the aerodynamic performance of the blade and reduces the efficiency of the turbine [7,15,16]. Therefore, the ideal shape of the blade cannot be directly used for manufacturing [17].

The pre-deformation design method is proposed to solve this problem [5,18,19,20,21,22,23,24,25], and the main process is as follows [26,27]: first, the ideal shape of the blade is designed by the theoretical calculation method; second, a hot shape is constructed based on the ideal shape according to the load acting on the running blade, and the geometric deviation between the hot blade shape and the ideal blade shape is calculated; finally, the deviation is reversely applied to the ideal shape to obtain a cold shape meeting the design expectations.

Analysis of blade deformation using traditional design methods mainly relies on calculations based on theoretical formulas [17]. However, the deformation of a blade is very complicated due to its twisted shape, the nonlinear steam flow field around it and the coupling between their changes [28,29,30]. Therefore, it is difficult to obtain accurate deformation about a blade using calculations and analyses based on theoretical formulas [7].

With the development of the finite element method [4,11,31,32,33,34,35] and computational fluid dynamics technology [36,37,38,39,40], numerical calculation methods based on iteration solutions have gradually been used in blade analysis [41,42,43]. With these methods, the construction of a hot shape and the correction of a cold shape are executed alternately and repeatedly so that the hot shape gradually approaches the ideal shape, and the iteration is stopped until the error between them is sufficiently small. The obtained cold shape is the final design result of the blade that meets the pre-deformation design requirements. Thus, the correction method for the cold shape directly affects the convergence speed of the iteration.

Geometry-based correction (GC) is a concise and intuitive method used in pre-deformation design with the following main steps [27,38,44,45,46,47]: based on the mesh model of the blade, the position deviations between the corresponding mesh nodes of the hot blade shape and ideal blade shape are calculated to establish a set of deviation vectors, which are then reversely applied to the corresponding mesh nodes of the cold shape to correct the cold shape.

However, the GC method does not consider the effect of the load variation caused by the blade deformation on the correction [27]. The main loads acting on the blades during steam turbine operations include centrifugal and aerodynamic loads [35].

The centrifugal load is related to the mass distribution of the blade, but the effect of the change in the centrifugal load mainly exists in the radial direction of each mass unit, which is relatively regular; thus, the GC method is appropriate for analyzing blade deformation caused by centrifugal loads [47].

However, the aerodynamic load acting on the blade surface shows nonuniformity in its distribution, magnitude and direction due to the complexity of the blade shape. Moreover, the aerodynamic load is changed due to the change in the blade shape during operation, and the coupling change results in a complicated deformation of the blade [44,48,49,50].

Due to the variable cross-section and torsional shape of the blades, the aerodynamic and centrifugal loads and blade stiffness matrix are all functions of the blade shape and will be significantly changed if the blade has a slight shape change [51].

In addition, the operating conditions of the low-pressure stage of the steam turbine are relatively special. When superheated steam flows through the high-pressure cylinder to the low-pressure cylinder, the reduction in pressure and temperature will cause the superheated steam to appear as a vapor–liquid two-phase flow state in which steam and water droplets coexist. This change will produce corresponding erosion and corrosion effects on the blade surface, namely, water erosion. However, the flow of superheated steam inside the steam turbine is very complicated and the internal flow field of the steam turbine is always in an unsteady state. Therefore, this paper does not consider the effect of water erosion on the blade and the effect of an internal unsteady flow state on the aerodynamic load.

The GC method cannot quickly reduce the error in each iteration step because of the coupling changes, which result in a slow iteration convergence. A load-based correction (LC) method is proposed to analyze the coupling change and quickly reduce the correction, which is also combined with the GC method to establish a geometry-load-based hybrid correction (GLHC) method to reduce the iteration steps and improve efficiency of the pre-deformation design.

2. Blade Deformation under Aerodynamic Loading

The stiffness of the blade is changed during the deformation process due to its complex and nonlinear shape. The basic equation of a blade for nonlinear finite element analysis can be expressed as

where is the displacement vector of the mesh nodes of the blade; is the nonlinear internal force vector of ; and is an external force vector.

In the iteration method for solving the blade deformation, if is assumed to be an approximate solution for the shape in the -th iteration step, then based on the first-order Taylor expansion, the approximate solution in the next iteration step is expressed as

where is the node displacement increment and is the tangential stiffness matrix in the -th iteration step, reflecting the nonlinear stiffness of the blade.

In addition, based on numerical simulation analysis, the structural mechanics solver is used to calculate the deformation of nodes on the grid mesh of the blade shape, and the deformation is transmitted to the fluid mesh, which is updated by the dynamic mesh technique. The complex curved surface boundary of the blade is restored by the grid mesh of blade shape.

Similarly, in an iteration step, the ideal shape, hot shape and cold shape are assumed to be , , and , respectively, and their corresponding aerodynamic loads are assumed to be , and , respectively.

The basic equation of a hot blade according to Equation (1) is

where is the nonlinear internal force vector of .

Equation (3) is linearized according to Equation (2) to obtain

where is the node displacement increment and is the tangential stiffness matrix of the hot blade.

The blade in the initial cold shape has no deformation and no internal force; thus, it will deform under the action of the aerodynamic load , and the nonlinear relationship between the deformation and the force is

where is the node displacement increment, is the nonlinear internal force vector of , and is the tangential stiffness matrix of the cold blade.

To discuss the possible deformation of the blade in an iteration step without loss of generality, it is assumed that the aerodynamic load is slightly larger than the internal force caused by the deformation when the blade is deformed into the ideal shape . The blade will then deviate from the equilibrium condition and continue to deform until it stabilizes as the hot shape . The deformation caused by the deviation between and generates an internal force to balance the external force, that is,

It is difficult to directly obtain the internal force caused by the deformation of the blade due to its variable stiffness. However, the aerodynamic loads at some representative positions can be used as a reference for the internal forces at these positions according to the abovementioned analysis of the forces and the deformation of the blade.

If the hot shape constructed from the cold blade shape coincides with the ideal blade shape, the blade is in equilibrium under the action of the internal force caused by the deformation and the aerodynamic load; that is, the internal force of the hot shape and the aerodynamic load acting on the ideal shape have the same magnitude and opposite direction.

The ideal shape is taken as the cold shape in the first iteration step, and the data of the aerodynamic load are obtained by the numerical simulation and used for subsequent iteration steps.

Taking a rotor blade in the low-pressure stage of a steam turbine as an example, the material 2Cr13 with the characteristics shown in Table 1 is used to construct the blade model.

Table 1.

Material characteristics of the blade.

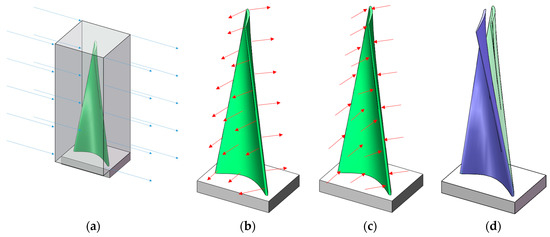

Before the iteration of deviation analysis starts, the initial cold shape of the blade needs to be obtained. Considering that the initial condition of the iteration is an ideal shape, the aerodynamic load analysis starts from the ideal shape of the blade to obtain . Under the set boundary condition, the Computational Fluid Dynamics (CFD) solver is applied to perform numerical simulation analysis on the flow field around the blade and extract the aerodynamic load on the representative nodes on the blade grid surface. Then, is reversely applied to the ideal shape to obtain the initial cold shape . The extracted aerodynamic load is reversely loaded to the corresponding representative nodes on the grid surface of ideal blade shape, so the ideal shape of the blade deforms under the load and the final shape of the blade is the initial cold shape .The process is shown in Figure 1.

Figure 1.

Process of obtaining the initial cold shape. (a) Flow field around the ideal shape; (b) aerodynamic load acting on the ideal shape; (c) aerodynamic load reversely applied to the ideal shape; (d) initial cold shape.

The iteration of the deviation analysis begins with the initial cold shape. In each step of the iteration, the deformation of the blade starts from the cold shape and ends with the hot shape . Thus, the internal force caused by the deformation is

If the end of the iteration step is changed to the ideal shape , the next step will be close to the final shape of the blade in the pre-deformation design.

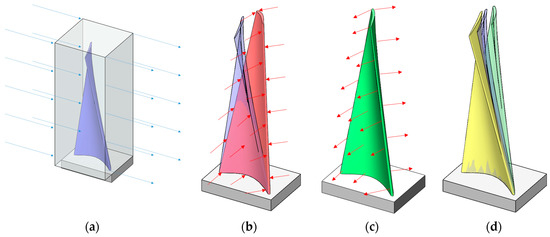

The aerodynamic load acting on the representative nodes on the grid surface of hot blade is extracted based on the CFD solver and then reversely loaded to the corresponding representative nodes on the grid surface of the ideal shape so that the blade will be changed from the ideal shape to the cold shape .

When the blade is changed to , the internal force caused by the deformation is still unbalanced with the external force , and the blade will continue to deform until the internal force is large enough to balance . The blade finally stabilizes as a new cold shape , as shown in Figure 2.

Figure 2.

Process of obtaining a new cold shape. (a) Flow field around the cold shape; (b) aerodynamic load acting on the hot shape; (c) aerodynamic load reversely applied to the ideal shape; (d) new cold shape.

In the abovementioned process, the internal force caused by the deformation from to is transferred to the deformation from to ; that is, the internal force is transferred from to . Therefore, the new cold shape can be derived from the ideal shape , which ends the current iteration step.

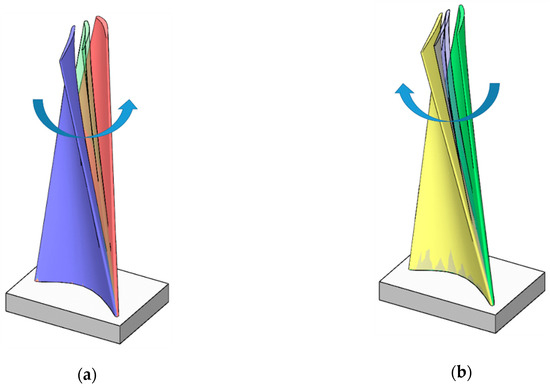

Figure 3 shows the change in the blade shape during the iteration of the deviation analysis.

Figure 3.

The change in the blade shape during the iteration of the deviation analysis. (a) Changes in the cold shape under the aerodynamic load; (b) changes in the ideal shape under the reverse load.

There are two errors in the deviation analysis of the blade shape: one is caused by the change in the blade stiffness, and the other is caused by the change in the aerodynamic load acting on the blade.

On the one hand, the LC method constructs a new cold shape by transforming the deformation interval without the geometric deviation vector set, which is less affected by the change in the blade stiffness than the GC. On the other hand, the LC method uses the aerodynamic load acting on the hot shape to solve the internal force generated by the deformation and transfers it to the cold shape instead of the deformation, which is also less affected by the change in the aerodynamic load than the GC method. Therefore, the LC method has less errors than the GC method.

3. Implementation and Analysis of the GLHC Method

The GLHC method uses the GC and LC methods to correct the shape deviation caused by the centrifugal load and the aerodynamic load, respectively, and combines the results of the two methods to obtain the cold shape of the blade.

There are three main steps in the GLHC method, which are discussed as follows. First, the GC method is used to correct the blade shape deviation caused by the centrifugal load when the blade is in the ideal shape. Second, the LC method is used to extract the aerodynamic load acting on the hot shape and then apply it to the ideal shape, which has been corrected by the GC method. Third, the finite element method is used to solve the blade mesh, and the new cold shape obtained is the result of the current iteration step.

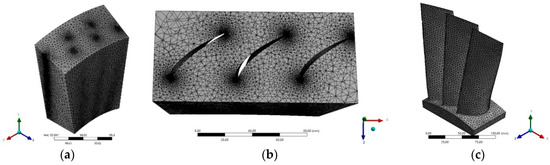

The material properties of a rotor blade taken from the low-pressure stage of a steam turbine are shown in Table 1. Unstructured tetrahedral meshes are used to mesh the flow field on the complex surface of the rotor blade. The mesh of the flow field model and the mesh of the blade model are shown in Figure 4.

Figure 4.

[51]. Meshes of the blade and flow field model. (a) Mesh of the whole flow field model; (b) cutaway view of the mesh of the blade model; (c) mesh of the blade model. ANSYS CFX is applied to conduct the numerical simulation analysis. The three-dimensional nonlinear Navier–Stokes computational fluid dynamics (CFD) solver and the structural mechanics finite element solver are used to execute the analysis. The CFD solver is used to simulate the flow field around the blade under the pre-set boundary conditions to obtain the aerodynamic load acting on the blade surface. The deformation of the blade shape is calculated by the structural mechanics solver.

The CFD analysis conditions are as follows: the inlet pressure is 49.25 kPa, the temperature is 348.27 K and the outlet pressure is 0.0135 MPa. The settings for the CFD analysis is shown in Table 2.

Table 2.

[51]. Settings of the CFD analysis.

The correction effects of the GLHC and GC methods are compared by constructing the hot shape of the blade and calculating the deviation of the hot blade shape from the ideal blade shape. The first iteration step is analyzed separately from the subsequent steps due to its initial input condition (the ideal shape is taken as the cold shape). The entire blade is analyzed based on an ANSYS CFD simulation, and the top trailing edge of the blade is used for comparison analysis because the deformation here is the largest under loading, which can best reflect the deviation of the hot blade shape from the ideal blade shape [51].

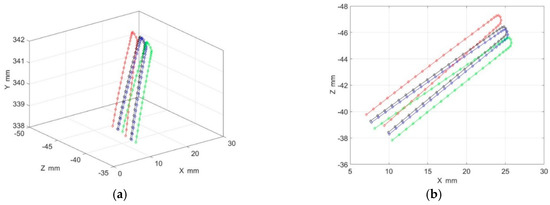

The comparison of the node positions on the top trailing edge of the ideal shape, the uncorrected hot shape and the hot shapes corrected by different methods are shown in Figure 5.

Figure 5.

Comparison of the node positions on the top trailing edge of the blade in the first iteration step. (a) Spatial positions of the nodes; (b) projection of the nodes on the XZ plane; (c) projection of the nodes on the XY plane; (d) projection of the nodes on the XY plane.

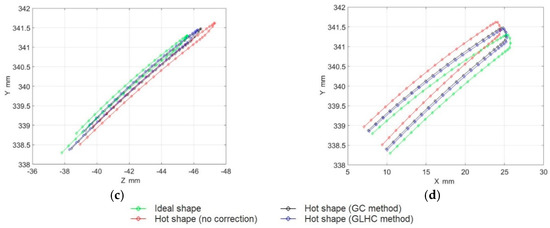

In the subsequent iteration steps, the input condition is not the ideal shape, but the cold shape obtained by the correction of the previous iteration step, and the other operations are similar. The analysis results of the second step are shown in Figure 6.

Figure 6.

Comparison of the node positions on the top trailing edge of the blade in the second iteration step. (a) Spatial positions of the nodes; (b) projection of the nodes on the XZ plane; (c) projection of the nodes on the XY plane; (d) projection of the nodes on the XY plane.

Figure 5 shows that the deviation in the hot shape constructed based on the cold shape corrected using the GLHC method from the ideal shape is smaller than that using the GC method in the axial, radial and tangential directions, especially in the axial direction. Therefore, the correction effect of the GLHC method is better than that of the GC method in the first iteration step.

Figure 6 shows that the correction effect of the second iteration step is similar to that of the first iteration step, but the difference between them decreases; that is, the correction effect of the GLHC method in the subsequent iteration steps is not as good as that in the first iteration step, but is still better than that of the GC method.

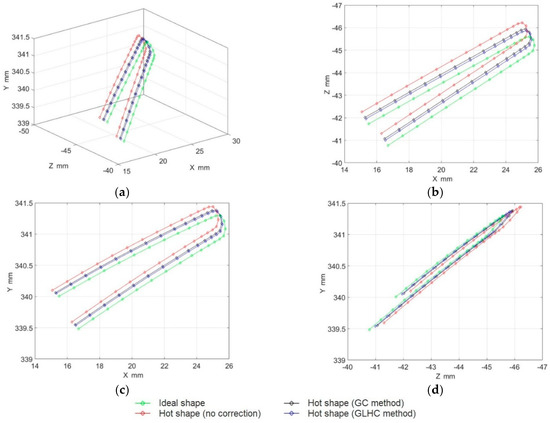

4. Pre-Deformation Design Process Based on the GLHC

The GLHC method is used to improve the pre-deformation design process based on the GC method, as shown in Figure 7.

Figure 7.

Pre-deformation design process based on the GLHC method.

The convergence condition reflects the deviation between the hot shape of blades and ideal shape of blades. When the number of iterations is more, the deviation between the hot shape of blades and the ideal shape of blades is small, so the hot shape of blades is close to the ideal shape of blades. In addition, the blades made of alloy steel have sufficient strength and large stiffness through the surface hardening treatment, so the deformation is relatively small. Therefore, according to the computing power of the computer and the accuracy that can be achieved by CFD simulation, the convergence condition of the pre-deformation design is set to 0.00001 mm; that is, if the maximum of the position deviations of the corresponding nodes between the hot blade shape and the ideal blade shape is less than 0.00001 mm, the cold shape used to construct this hot shape is considered to meet the pre-deformation design requirements.

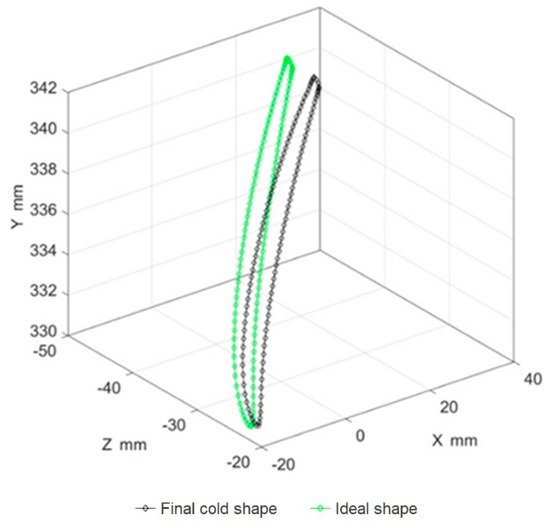

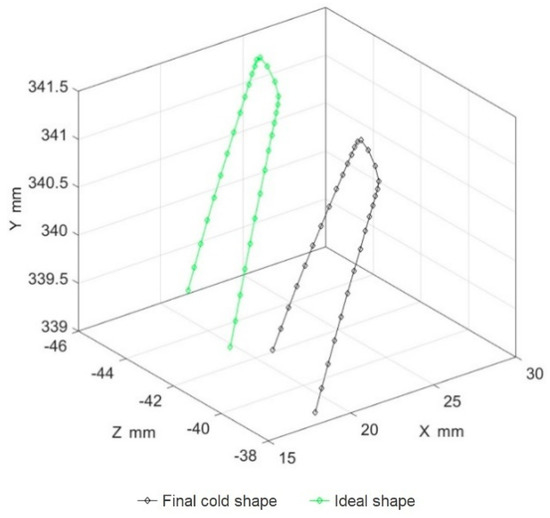

The positions of the contour nodes at the top and the top trailing edge of the cold shape of the blade designed by the abovementioned method are shown in Figure 8 and Figure 9, respectively.

Figure 8.

Positions of the contour nodes at the top of the cold blade shape.

Figure 9.

Positions of some contour nodes at the top trailing edge of the cold blade shape.

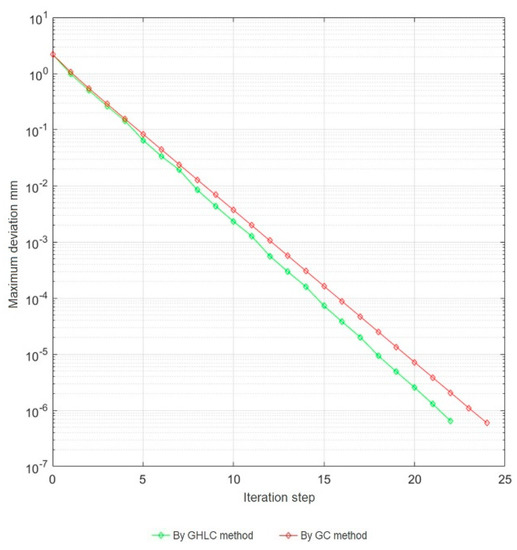

The data obtained by the GLHC and GC methods are compared with the same ideal shape, numerical calculation method and convergence condition as the design input. The maximum deviations in each iteration step are shown in Table 3.

Table 3.

The maximum deviations in each iteration step.

Table 3 shows that the GLHC and GC methods satisfy the convergence condition in the 18th and the 20th steps of the iteration, respectively. To verify the accuracy of convergence, five additional steps are performed, and the maximum deviations continue to decrease without exceeding the convergence condition. Therefore, the GLHC method reduces the iteration steps by nearly 10% with 0.00001 mm as the convergence condition compared with the GC method for the pre-deformation design of a blade.

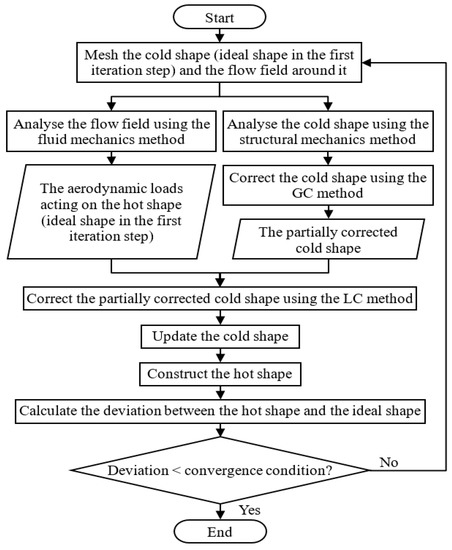

The maximum deviations varying with the iteration steps are shown in Figure 10.

Figure 10.

The maximum deviations varying with the iteration steps.

Figure 10 shows that the GLHC method reduces the iteration steps and improves the efficiency of the pre-deformation design.

5. Conclusions

This paper proposes a GLHC method to solve the slow convergence of the iteration based on the GC method in the current pre-deformation design.

First, the coupling relationship between the blade deformation and change in the aerodynamic load was analyzed to establish the iteration process based on the LC method. The internal force caused by the deformation from the cold blade shape to the hot blade shape was transferred to the deformation from the ideal shape to the new cold shape; thus, the LC method had less errors than the GC method.

Second, the GLHC method was established by combining the LC and GC methods. The GC and LC methods were used to correct the shape deviation caused by the centrifugal load and the aerodynamic load, respectively, and the results of the two methods were combined to obtain the cold shape of the blade. The shape deviation of the blade obtained by the GLHC method was smaller than that of the GC method.

Third, the GLHC method was used to improve the pre-deformation design process. The data obtained by the pre-deformation design using two methods were compared with the same design input, calculation method and convergence condition. The results show that the GLHC method reduced the iteration steps by nearly 10%, with 0.00001 mm as the convergence condition compared with the GC method.

In summary, the GLHC method improved the efficiency of the pre-deformation design.

Author Contributions

Methodology, G.Y. and L.Q.; investigation, H.Z. and J.W.; writing—original draft preparation, G.Y. and J.W.; writing—review and editing, G.Y., L.Q. and H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China, grant number 2018YFB1701600 and the National Natural Science Foundation of China, grant number 51875515.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sarkar, D.K. Steam Turbines. In Thermal Power Plant; Sarkar, D.K., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 189–237. [Google Scholar] [CrossRef]

- Kaneko, Y.; Kanki, H.; Kawashita, R. Steam turbine rotor design and rotor dynamics analysis. In Advances in Steam Turbines for Modern Power Plants; Tanuma, T., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 127–151. [Google Scholar] [CrossRef]

- Lucacci, G. Steels and alloys for turbine blades in ultra-supercritical power plants. In Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants; Di Gianfrancesco, A., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 175–196. [Google Scholar] [CrossRef]

- Prabhunandan, G.S.; Byregowda, H.V. Dynamic Analysis of A Steam Turbine With Numerical Approach. Mater. Today-Proc. 2018, 5, 5414–5420. [Google Scholar] [CrossRef]

- Tanuma, T. Development of last-stage long blades for steam turbines. In Advances in Steam Turbines for Modern Power Plants; Tanuma, T., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 279–305. [Google Scholar] [CrossRef]

- Eleftheriou, K.D.; Efstathiadis, T.G.; Kalfas, A.I. Stator Blade Design of an Axial Turbine using Non-Ideal Gases with Low Real-Flow Effects. Energy Procedia 2017, 105, 1606–1613. [Google Scholar] [CrossRef]

- Moheban, M.; Young, J.B. A study of thermal nonequilibrium effects in low-pressure wet-steam turbines using a blade-to-blade time-marching technique. Int. J. Heat Fluid Flow 1985, 6, 269–278. [Google Scholar] [CrossRef]

- Bhagi, L.K.; Rastogi, V.; Gupta, P.; Pradhan, S. Dynamic Stress Analysis of L-1 Low Pressure Steam Turbine Blade: Mathematical Modelling and Finite Element Method. Mater. Today-Proc. 2018, 5, 28117–28126. [Google Scholar] [CrossRef]

- Chatterjee, A. Lumped parameter modelling of turbine blade packets for analysis of modal characteristics and identification of damage induced mistuning. Appl. Math. Model. 2016, 40, 2119–2133. [Google Scholar] [CrossRef]

- Choi, W.; Kang, H.; Baek, T. A turbine-blade balancing problem. Int. J. Prod. Econ. 1999, 60–61, 405–410. [Google Scholar] [CrossRef]

- Shukla, A.; Harsha, S.P. An experimental and FEM modal analysis of cracked and normal Steam Turbine Blade. Mater. Today-Proc. 2015, 2, 2056–2063. [Google Scholar] [CrossRef]

- Ahmad, S.; Suman, A.; Sidharth, T.; Pawar, G.; Kumar, V.; Vyas, N.S. Structural Integrity Analysis and Life Estimation of a Gas Turbine Bladed-Disc. Procedia Struct. Integr. 2019, 17, 758–765. [Google Scholar] [CrossRef]

- Kim, B.; Kim, W.; Lee, S.; Bae, S.; Lee, Y. Developement and verification of a performance based optimal design software for wind turbine blades. Renew. Energy 2013, 54, 166–172. [Google Scholar] [CrossRef]

- Zhu, X.C.; Chen, H.F.; Xuan, F.Z.; Chen, X.H. Cyclic plasticity behaviors of steam turbine rotor subjected to cyclic thermal and mechanical loads. Eur. J. Mech. -A/Solids 2017, 66, 243–255. [Google Scholar] [CrossRef]

- Jiang, S.; Chen, F.; Yu, J.Y.; Chen, S.W.; Song, Y.P. Treatment and optimization of casing and blade tip for aerodynamic control of tip leakage flow in a turbine cascade. Aerosp. Sci. Technol. 2019, 86, 704–713. [Google Scholar] [CrossRef]

- Diamond, D.H.; Heyns, P.S.; Oberholster, A.J. Improved Blade Tip Timing measurements during transient conditions using a State Space Model. Mech. Syst. Signal Process. 2019, 122, 555–579. [Google Scholar] [CrossRef]

- McBean, I. Manufacturing technologies for key steam turbine parts. In Advances in Steam Turbines for Modern Power Plants; Tanuma, T., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 381–393. [Google Scholar] [CrossRef]

- Chen, L.-C.; Lin, G.C.I. Reverse engineering in the design of turbine blades–a case study in applying the MAMDP. Robot. Comput. Integr. Manuf. 2000, 16, 161–167. [Google Scholar] [CrossRef]

- Albanesi, A.; Fachinotti, V.; Peralta, I.; Storti, B.; Gebhardt, C. Application of the inverse finite element method to design wind turbine blades. Compos. Struct. 2017, 161, 160–172. [Google Scholar] [CrossRef]

- Albanesi, A.; Bre, F.; Fachinotti, V.; Gebhardt, C. Simultaneous ply-order, ply-number and ply-drop optimization of laminate wind turbine blades using the inverse finite element method. Compos. Struct. 2018, 184, 894–903. [Google Scholar] [CrossRef]

- Chen, S.T.; Sun, W.; Niu, L.; Chen, L.; Hou, Y. Effect of impeller blade profile on the cryogenic two-phase turbo-expander performance. Appl. Therm. Eng. 2017, 126, 884–891. [Google Scholar] [CrossRef]

- Saeed, H.A.H.; Elmekawy, A.M.N.; Kassab, S.Z. Numerical study of improving Savonius turbine power coefficient by various blade shapes. Alex. Eng. J. 2019, 58, 429–441. [Google Scholar] [CrossRef]

- Hou, Y.H.; Zhang, Y.; Zhang, D.H. Geometric error analysis of compressor blade based on reconstructing leading and trailing edges smoothly. Proc. Cirp. 2016, 56, 272–278. [Google Scholar] [CrossRef][Green Version]

- Kamoun, B.; Afungchui, D.; Abid, M. The inverse design of the wind turbine blade sections by the singularities method. Renew. Energy 2006, 31, 2091–2107. [Google Scholar] [CrossRef]

- Kollar, L.E.; Mishra, R. Inverse design of wind turbine blade sections for operation under icing conditions. Energy Convers. Manage. 2019, 180, 844–858. [Google Scholar] [CrossRef]

- Yang, H.; Wang, B.; Zhen, S.; Zheng, Y. Comparative analysis of numerical methods for rotor blade unrunning design. In Proceedings of the 2014 ISFMFE—6th International Symposium on Fluid Machinery and Fluid Engineering, Wuhan, China, 22 October 2014; pp. 1–8. [Google Scholar]

- Timon, V.P.; Corral, R. A study on the effects of geometric non linearities on the un-running transformation of compressor blades. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Wood, N.B.; Morton, V.M. Inlet angle distribution of last stage moving blades for large steam turbines. Int. J. Heat Fluid Flow 1984, 5, 101–111. [Google Scholar] [CrossRef]

- Chaibakhsh, A.; Ghaffari, A. Steam turbine model. Simul. Model. Pract. Theory 2008, 16, 1145–1162. [Google Scholar] [CrossRef]

- Fadl, M.; Stein, P.; He, L. Full conjugate heat transfer modelling for steam turbines in transient operations. Int. J. Therm. Sci 2018, 124, 240–250. [Google Scholar] [CrossRef]

- Han, X.; Zeng, W.; Han, Z.H. Investigation of the comprehensive performance of turbine stator cascades with heating endwall fences. Energy 2019, 174, 1188–1199. [Google Scholar] [CrossRef]

- Hashemian, A.; Lakzian, E.; Ebrahimi-Fizik, A. On the application of isogeometric finite volume method in numerical analysis of wet-steam flow through turbine cascades. Comput. Math. Appl. 2019, 79, 1687–1705. [Google Scholar] [CrossRef]

- Shankar, M.; Kumar, K.; Prasad, S.L.A. T-root blades in a steam turbine rotor: A case study. Eng. Fail. Anal. 2010, 17, 1205–1212. [Google Scholar] [CrossRef]

- Brahimi, F.; Ouibrahim, A. Blade dynamical response based on aeroelastic analysis of fluid structure interaction in turbomachinery. Energy 2016, 115, 986–995. [Google Scholar] [CrossRef]

- Richter, C.-H. Structural design of modern steam turbine blades using ADINA™. Comput. Struct. 2003, 81, 919–927. [Google Scholar] [CrossRef]

- Francesco, G.; Federico, M.; Adriano, M. CFD modelling of the condensation inside a cascade of steam turbine blades: comparison with an experimental test case. Energy Procedia 2017, 126, 730–737. [Google Scholar] [CrossRef]

- Jang, H.J.; Kang, S.Y.; Lee, J.J.; Kim, T.S.; Park, S.J. Performance analysis of a multi-stage ultra-supercritical steam turbine using computational fluid dynamics. Appl. Therm. Eng. 2015, 87, 352–361. [Google Scholar] [CrossRef]

- Noori Rahim Abadi, S.M.A.; Ahmadpour, A.; Abadi, S.M.N.R.; Meyer, J.P. CFD-based shape optimization of steam turbine blade cascade in transonic two phase flows. Appl. Therm. Eng 2017, 112, 1575–1589. [Google Scholar] [CrossRef]

- Obert, B.; Cinnella, P. Comparison of steady and unsteady RANS CFD simulation of a supersonic ORC turbine. Enrgy Procedia 2017, 129, 1063–1070. [Google Scholar] [CrossRef]

- Hassenpflug, W.C. The incompressible two-dimensional potential flow through blades of a rotating radial impeller. Math. Comput. Model. 2010, 52, 1299–1389. [Google Scholar] [CrossRef]

- Dulau, M.; Bica, D. Mathematical modelling and simulation of the behaviour of the steam turbine. Procedia Technol. 2014, 12, 723–729. [Google Scholar] [CrossRef]

- Wang, W.L.; Zhang, H.; Liu, P.; Li, Z.; Ni, W.D.; Uechi, H.; Matsumura, T. A finite element method approach to the temperature distribution in the inner casing of a steam turbine in a combined cycle power plant. Appl. Therm. Eng. 2016, 105, 18–27. [Google Scholar] [CrossRef]

- Hou, Y.H.; Zhang, D.H.; Mei, J.W.; Zhang, Y.; Luo, M. Geometric modelling of thin-walled blade based on compensation method of machining error and design intent. J. Manuf. Process. 2019, 44, 327–336. [Google Scholar] [CrossRef]

- Li, L.; Jiao, J.K.; Sun, S.Y.; Zhao, Z.A.; Kang, J.L. Aerodynamic shape optimization of a single turbine stage based on parameterized Free-Form Deformation with mapping design parameters. Energy 2019, 169, 444–455. [Google Scholar] [CrossRef]

- Zhu, W.; Wang, J.W.; Yang, L.; Zhou, Y.C.; Wei, Y.G.; Wu, R.T. Modeling and simulation of the temperature and stress fields in a 3D turbine blade coated with thermal barrier coatings. Surf. Coat. Technol. 2017, 315, 443–453. [Google Scholar] [CrossRef]

- Huang, C.H.; Hsiung, T.Y. An inverse design problem of estimating optimal shape of cooling passages in turbine blades. Int. J. Heat Mass Transf. 1999, 42, 4307–4319. [Google Scholar] [CrossRef]

- Pascoa, J.C.; Mendes, A.C.; Gato, L.M.C. A fast iterative inverse method for turbomachinery blade design. Mech. Res. Commun. 2009, 36, 630–637. [Google Scholar] [CrossRef]

- Jiang, X.Q.; Lin, A.Q.; Malik, A.; Chang, X.Y.; Xu, Y.Y. Numerical investigation on aerodynamic characteristics of exhaust passage with consideration of multi-factor components in a supercritical steam turbine. Appl. Therm. Eng. 2019, 162, 114085. [Google Scholar] [CrossRef]

- Tanuma, T. Design and analysis for aerodynamic efficiency enhancement of steam turbines. In Advances in Steam Turbines for Modern Power Plants; Tanuma, T., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 109–126. [Google Scholar] [CrossRef]

- Korakianitis, T.; Hamakhan, I.A.; Rezaienia, M.A.; Wheeler, A.P.S.; Avital, E.J.; Williams, J.J.R. Design of high-efficiency turbomachinery blades for energy conversion devices with the three-dimensional prescribed surface curvature distribution blade design (CIRCLE) method. Appl. Energy 2012, 89, 215–227. [Google Scholar] [CrossRef]

- Yi, G.; Zhou, H.; Qiu, L.; Wu, J. Hot Blade Shape Reconstruction Considering Variable Stiffness and Unbalanced Load in a Steam Turbine. Energies 2020, 13, 835. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).