Measurements of Energy Consumption and Environment Quality of High-Speed Railway Stations in China

Abstract

1. Introduction

2. Description of Energy Use Characteristics

2.1. Description of Data Source

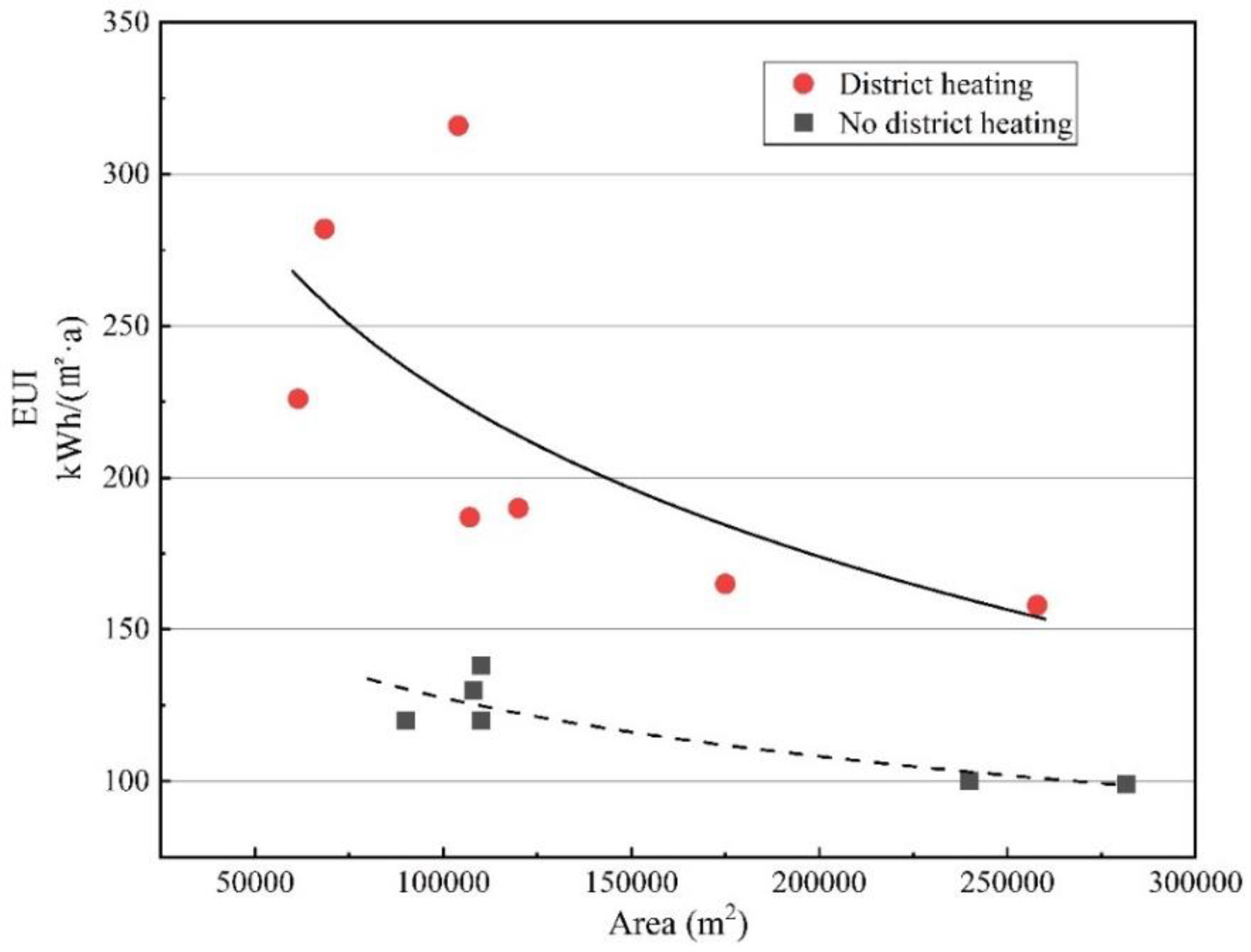

2.2. Energy Consumption Characteristics of High-Speed Railway Stations

3. Environment Measurements

3.1. Error Analysis

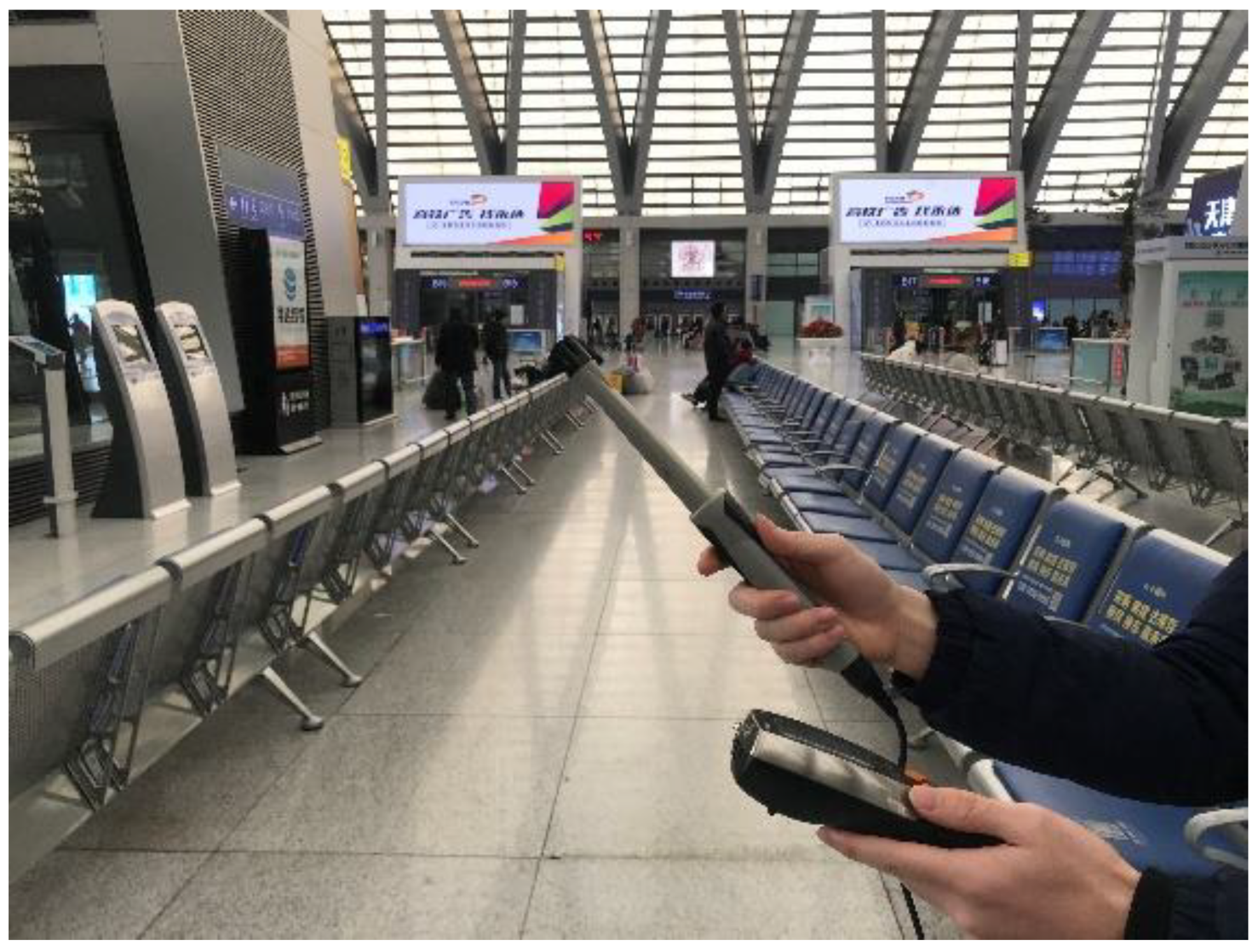

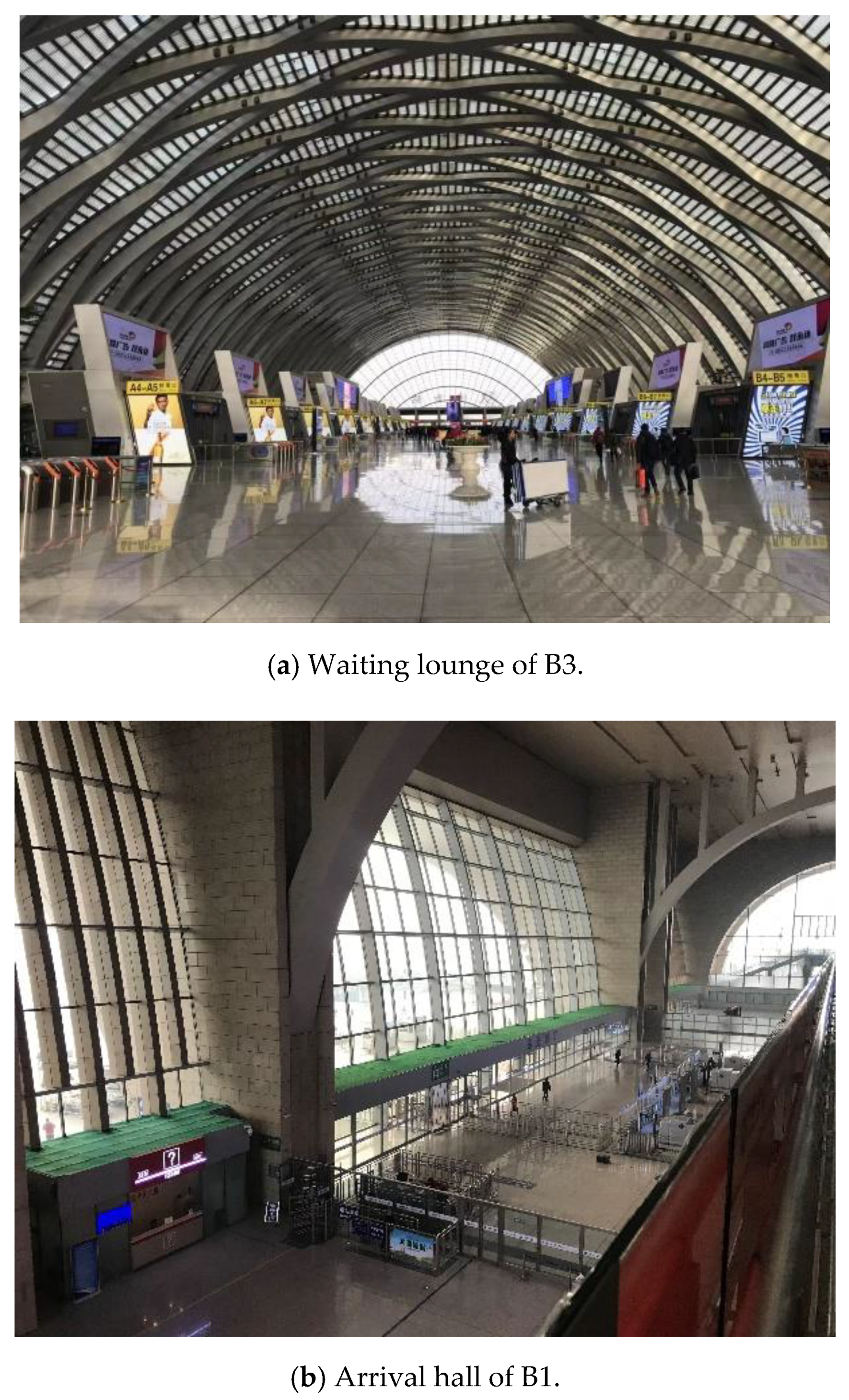

3.2. Measurement Method

3.3. Results

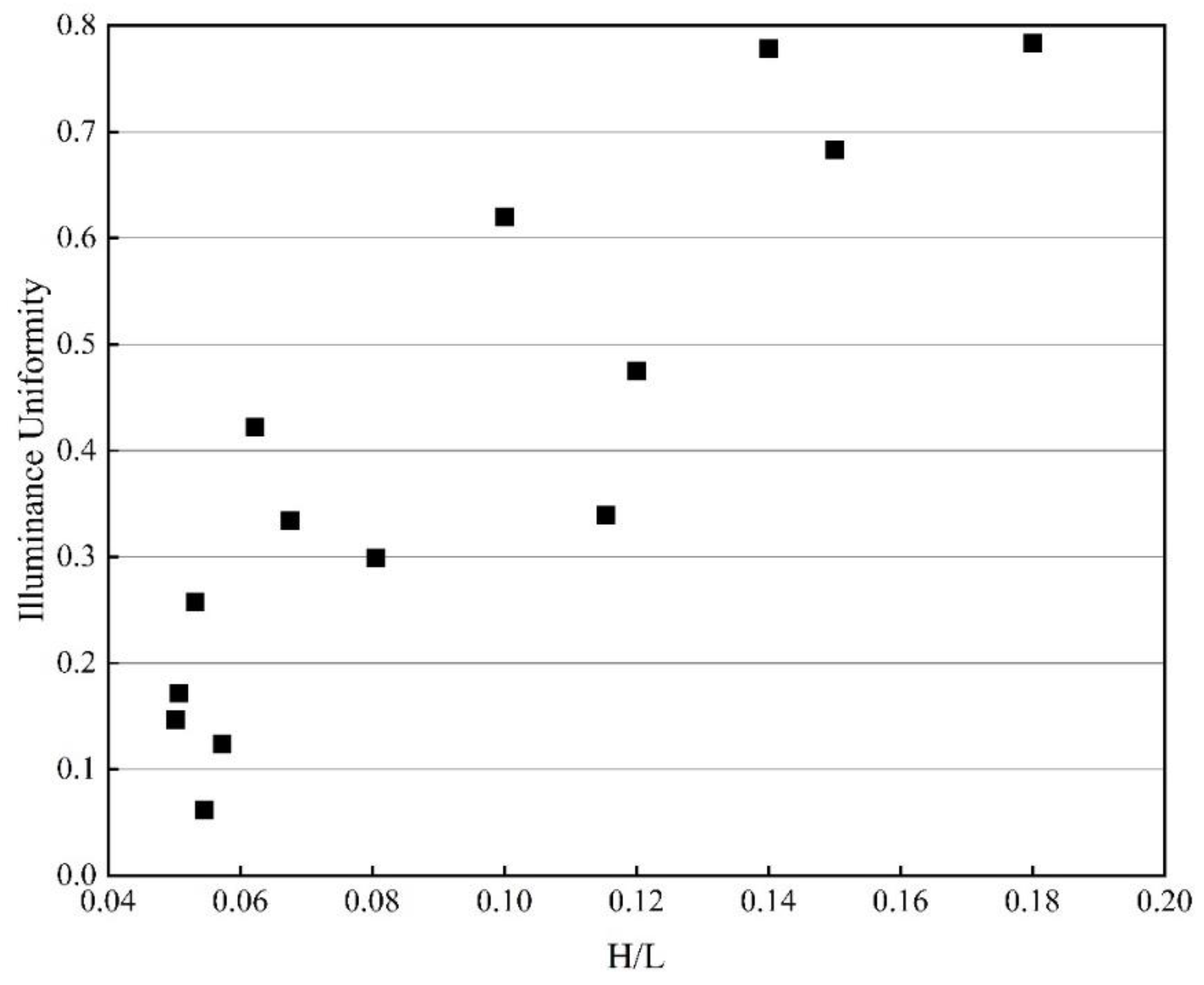

3.2.1. Light Environment

3.2.2. Thermal Comfort and Thermal Environment

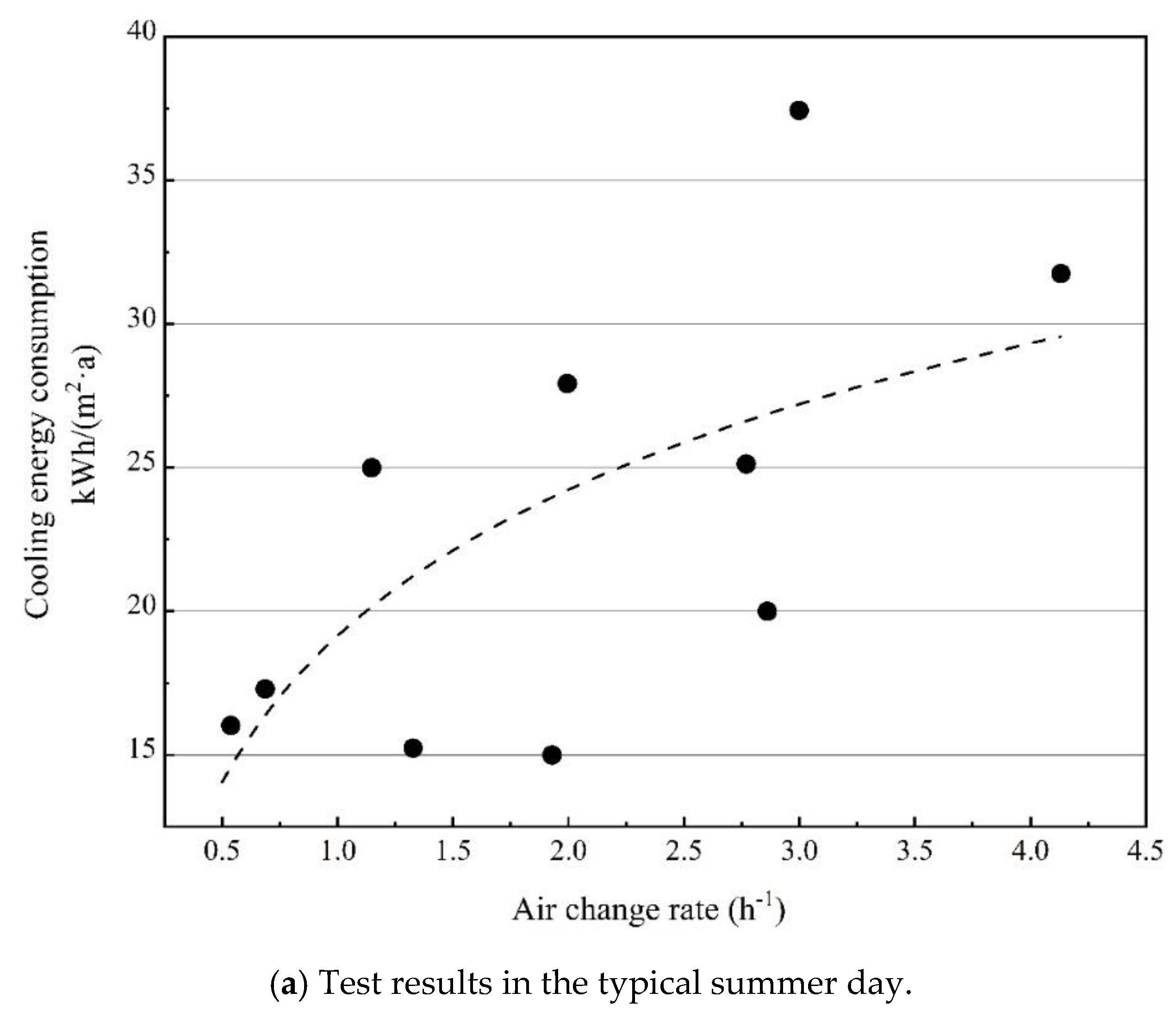

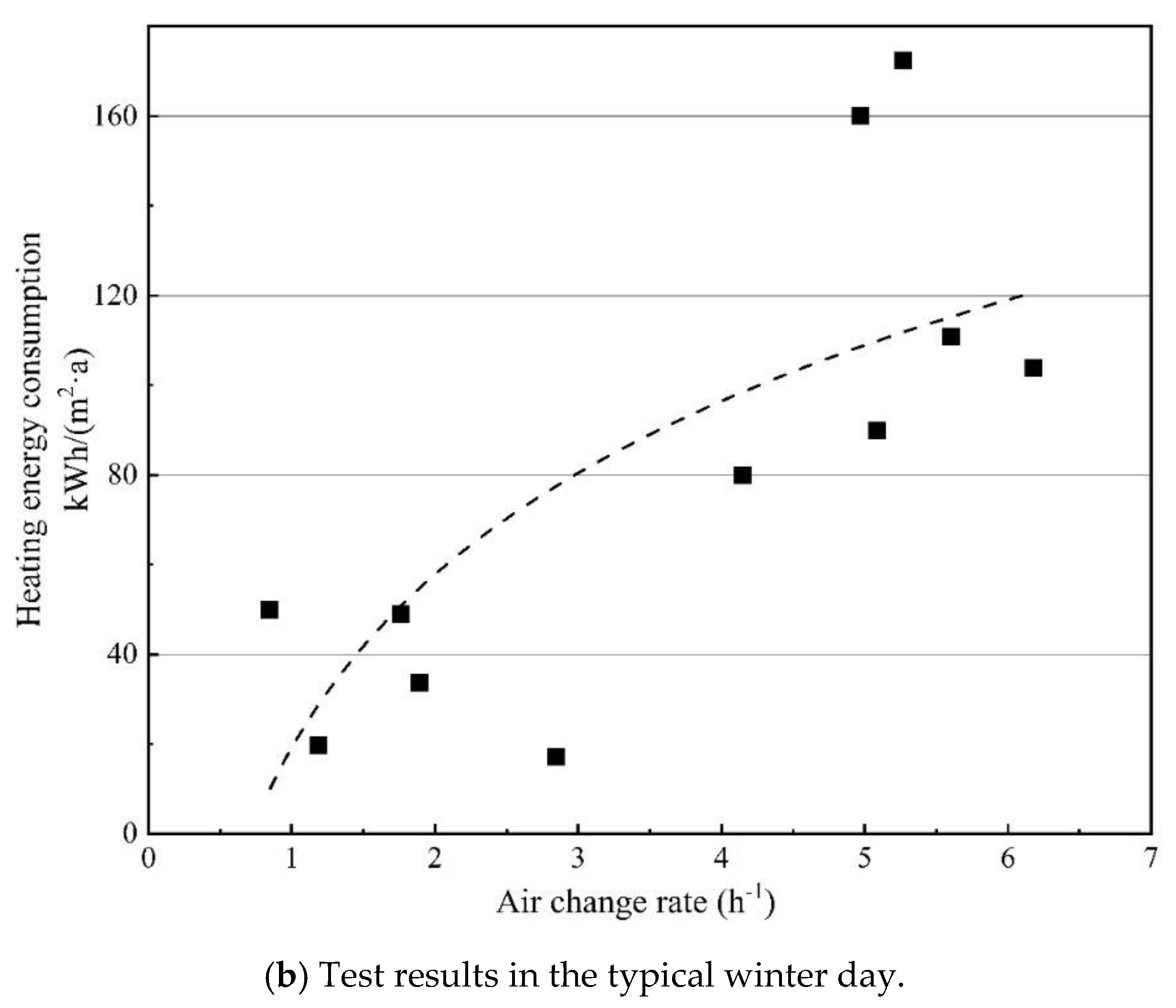

3.2.3. Air Infiltration

4. Conclusions

- The EUI of different high-speed railway stations is between 115 and 470 kWh/(m2·a), which is related to the climate region and the area of the station. The average energy consumption of a station using district heating is 11.5 kWh/(m2·a), while that of a station without district heating is 18.5 kWh/(m2·a). EUI in stations decreases with the increase of area, and this trend is more obvious in stations using central heating.

- The use of a large number of glass maintenance structures makes the illumination in the station vary greatly during the day. The average illumination in most stations is much higher than the standard requirement of 100 Lux. However, this does not mean that the good lighting effect is obtained, and the distribution needs to be considered. The lighting evenness and the height of the station are related to the depth of the lighting direction. Increasing the height can achieve better evenness but with the increasing energy consumption of HVAC.

- The thermal neutral temperature of the waiting lounge varies greatly in different climate regions. Most passengers can accept the indoor temperatures below 18 °C or lower, which is related to the outdoor temperature. The main reason is that the short waiting time (40–60 min) of passengers and the requirements of thermal environment are different from those of office buildings. The acceptable temperature range in high-speed railway stations is larger in winter than in summer.

- The measured CO2 concentration in the waiting lounge of each station is very close to the outdoor value. Results show that the infiltration air volume in the station can meet or even exceed the indoor fresh air demand. Maybe the mechanical fresh air can be canceled to save energy. There is a logarithmic relationship between the infiltration air volume and the energy consumption of the station and influence of infiltration air on energy consumption in winter is greater than that in summer.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Perez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Jiang, Y. Annual Report on China Building Energy Efficiency; Building Energy Conservation Research Center of Tsinghua University; China Architecture & Building Press: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Xiao, H.; Wei, Q.; Jiang, Y. The reality and statistical distribution of energy consumption in office buildings in China. Energy Build. 2012, 50, 259–265. [Google Scholar] [CrossRef]

- Bracke, W.; Delghust, M.; Laverge, J.; Janssens, A. Building energy performance: Sphere area as a fair normalization concept. Build. Res. Inf. 2019, 47, 549–566. [Google Scholar] [CrossRef]

- Zhou, N.; Lin, J. The reality and future scenarios of commercial building energy consumption in China. Energy Build. 2008, 40, 2121–2127. [Google Scholar] [CrossRef]

- Doctor-Pingel, M.; Vardhan, V.; Manu, S.; Brager, G.; Rawal, R. A study of indoor thermal parameters for naturally ventilated occupied buildings in the warm-humid climate of southern India. Build. Environ. 2019, 151, 1–14. [Google Scholar] [CrossRef]

- Hoyt, T.; Arens, E.; Zhang, H. Extending air temperature setpoints: Simulated energy savings and design considerations for new and retrofit buildings. Build. Environ. 2015, 88, 89–96. [Google Scholar] [CrossRef]

- Nicol, J.F.; Humphreys, M.A. Adaptive thermal comfort and sustainable thermal standards for buildings. Energy Build. 2002, 34, 563–572. [Google Scholar] [CrossRef]

- Song, L.; Wang, Y.; Li, X. Energy performance and environmental quality of typical railway passenger stations in northern China. Indoor Built Environ. 2016, 27, 296–307. [Google Scholar] [CrossRef]

- Yan, H.; Wang, K. 2011 National Railway Passenger Station Energy Consumption Special Investigation Situation Analysis. Railw. Econ. Res. 2012, 5, 8–13. [Google Scholar]

- Wang, L.; Li, Q.; Dang, R.; Liu, G.; Liu, H. Comfort-Based Energy Efficiency Reconstruction of Waiting-room of Railway Station. Build. Energy Effic. 2014, 3, 97–102. [Google Scholar]

- Yang, L.; Xia, J. Case Study of Space Cooling and Heating Energy Demand of a High-speed Railway Station in China. Procedia Eng. 2015, 121, 1887–1893. [Google Scholar] [CrossRef][Green Version]

- Ma, W.W.; Liu, X.Y.; Zhou, C.Q. Research on the waiting time of passengers and escalator energy consumption at the railway station. Energy Build. 2009, 41, 1313–1318. [Google Scholar] [CrossRef]

- Shi, L.; Xie, M.J. Optimal Simulation Analysis of Day lighting Design in New Guangzhou Railway Station. In Advanced Information Technology in Education; Thaung, K.S., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 197–206. [Google Scholar]

- Brenna, M.; Dolara, A.; Foiadelli, F.; Leva, S.; Longo, M.; Zaninelli, D.; Casiraghi, F.M. Power quality analysis of LED lighting system for railway applications. In Proceedings of the IEEE International Conference on Harmonics & Quality of Power, Bucharest, Romania, 25–28 May 2014. [Google Scholar]

- Xiao, J.; Liu, C.J. Lighting Control and Its Power Management in Railway Passenger Station. In Proceedings of the 2009 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 28–30 March 2009. [Google Scholar]

- Sengor, I.; Kilickiran, H.C.; Akdemir, H.; Kekezoglu, B.; Erdinc, O.; Catalao, J.P.S. Energy Management of a Smart Railway Station Considering Regenerative Braking and Stochastic Behaviour of ESS and PV Generation. IEEE Trans. Sustain. Energy 2018, 9, 1041–1050. [Google Scholar] [CrossRef]

- Dounis, A.I.; Caraiscos, C. Advanced control systems engineering for energy and comfort management in a building environment—A review. Renew. Sustain. Energy Rev. 2009, 13, 1246–1261. [Google Scholar] [CrossRef]

- Arens, E.; Humphreys, M.A.; de Dear, R.; Zhang, H. Are ‘class A’ temperature requirements realistic or desirable? Build. Environ. 2010, 45, 4–10. [Google Scholar] [CrossRef]

- Tong, Z.; Chen, Y.; Malkawi, A.; Liu, Z.; Freeman, R.B. Energy saving potential of natural ventilation in China: The impact of ambient air pollution. Appl. Energy 2016, 179, 660–668. [Google Scholar] [CrossRef]

- Kalz, D.E.; Pfafferott, J. Thermal Indoor Environment, Thermal Comfort and Energy-Efficient Cooling of Nonresidential Buildings; Springer: New York, NY, USA, 2014; pp. 15–20. [Google Scholar]

- Nakano, J.; Tanabe, S.; Morii, T.; Uruno, M.; Goto, Y.; Sakamoto, K. Field Study on Optimum Thermal Environmental Control of Train Stations; The Society of Heating, Air-Conditioning Sanitary Engineers of Japan: Tokyo, Japan, 2006. [Google Scholar]

- Kwong, Q.J.; Adam, N.M.; Sahari, B.B. Thermal comfort assessment and potential for energy efficiency enhancement in modern tropical buildings: A review. Energy Build. 2014, 68, 547–557. [Google Scholar] [CrossRef]

- Boerstra, A.C.; te Kulve, M.; Toftum, J.; Loomans, M.G.; Olesen, B.W.; Hensen, J.L. Comfort and performance impact of personal control over thermal environment in summer: Results from a laboratory study. Build. Environ. 2015, 87, 315–326. [Google Scholar] [CrossRef]

- del Ferraro, S.; Iavicoli, S.; Russo, S.; Molinaro, V. A field study on thermal comfort in an Italian hospital considering differences in gender and age. Appl. Ergon. 2015, 50, 177–184. [Google Scholar] [CrossRef]

- Caniato, M.; Gasparella, A. Discriminating People’s Attitude towards Building Physical Features in Sustainable and Conventional Buildings. Energies 2019, 12, 1429. [Google Scholar] [CrossRef]

- Sant’Anna, D.O.; Dos Santos, P.H.; Vianna, N.S.; Romero, M.A. Indoor environmental quality perception and users’ satisfaction of conventional and green buildings in Brazil. Sustain. Cities Soc. 2018, 43, 95–110. [Google Scholar] [CrossRef]

- Huang, M.; Lin, Y. Thermal comfort of railway station’s waiting room in severe cold regions of China. Sustain. Energy Build. 2017, 134, 749–756. [Google Scholar] [CrossRef]

- Kawamoto, R.; Umemiya, N.; Atsuta, H.; Cie, T.S. Relation between Light Environment Evaluation and Personal Attributes; C I E Central Bureau: Vienna, Austria, 2011. [Google Scholar]

- Liu, Y.; Yu, G.; Zheng, S.W. Gymnasium Natural Light Environment Optimization Design Oriented by Environment-behavior Studies. In Advanced Materials Research; Albahar, S.K., Zhao, J.Y., Eds.; Trans Tech Publications: Zurich, Switzerland, 2014; pp. 223–227. [Google Scholar]

- Durak, A.; Olgunturk, N.C.; Yener, C.; Guvenc, D.; Gurcinar, Y. Impact of lighting arrangements and illuminances on different impressions of a room. Build. Environ. 2007, 42, 3476–3482. [Google Scholar] [CrossRef]

- Li, D.H.W.; Lam, J.C.; Wong, S.L. Daylighting and its implications to overall thermal transfer value (OTTV) determinations. Energy 2002, 27, 991–1008. [Google Scholar] [CrossRef]

- Ai, Z.T.; Mak, C.M.; Cui, D.J.; Xue, P. Ventilation of air-conditioned residential buildings: A case study in Hong Kong. Energy Build. 2016, 127, 116–127. [Google Scholar] [CrossRef]

- Caciolo, M.; Cui, S.Q.; Stabat, P.; Marchio, D. Development of a new correlation for single-sided natural ventilation adapted to leeward conditions. Energy Build. 2013, 60, 372–382. [Google Scholar] [CrossRef]

- de Dear, R.J.; Brager, G.S. Thermal comfort in naturally ventilated buildings: Revisions to ASHRAE Standard 55. Energy Build. 2002, 34, 549–561. [Google Scholar] [CrossRef]

- Ai, Z.T.; Mak, C.M.; Cui, D.J. On-site measurements of ventilation performance and indoor air quality in naturally ventilated high-rise residential buildings in Hong Kong. Indoor Built Environ. 2015, 24, 214–224. [Google Scholar] [CrossRef]

- Huang, C.; Zou, Z.; Li, M.; Wang, X.; Li, W.; Huang, W.; Yang, J.; Xiao, X. Measurements of indoor thermal environment and energy analysis in a large space building in typical seasons. Build. Environ. 2007, 42, 1869–1877. [Google Scholar] [CrossRef]

- Said, M.N.A.; Macdonald, R.A.; Durrant, G.C. Measurement of thermal stratification in large single-cell buildings. Energy Build. 1996, 24, 105–115. [Google Scholar] [CrossRef]

- Taraldsen, G. On the ISO Guide to the Expression of Uncertainty in Measurements. J. Radioanal. Nucl. Chem. 1995. [Google Scholar]

- Design Stand for Energy Efficiency of Public Buildings; GB50189-2015; China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- Code for Design of Railway Passenger Station; TB 10100-2018; China Railway Publishing House: Beijing, China, 2018. (In Chinese)

- Ma, W.; Li, L.; He, S.; Cheng, J.; Huang, G.; Zhou, C.Q. Influencing Factors on Energy Consumption of Air Conditioning System in Railway Passenger Station Based on Orthogonal Experiment. In Proceedings of the Second International Conference on Intelligent System Design & Engineering Application, Sanya, China, 6–7 January 2012. [Google Scholar]

- Wu, Z.; Huang, K.; Wei, Y. Energy Consumption Division of HVAC System in Building Energy Audits. In Building Energy Efficiency; Shenyang, China, 2012. [Google Scholar]

- Bouden, C. Influence of glass curtain walls on the building thermal energy consumption under Tunisian climatic conditions: The case of administrative buildings. Renew. Energy 2007, 32, 141–156. [Google Scholar] [CrossRef]

- Classification and Presentation of Civil Building Energy Use; GB T34913-2017; China Quality and Standards Publishing: Beijing, China, 2017. (In Chinese)

- Liu, X. Research on Air-Conditioning Energy Consumption at the Passenger Railway Station in Summer; Central South University: Changsha, China, 2010. (In Chinese) [Google Scholar]

- Code for Design of Railway Passenger Station Buildings; GB 50266-2007; Standardization Administration of China (SAC): Beijing, China, 2007. (In Chinese)

- Enescu, D. A review of thermal comfort models and indicators for indoor environments. Renew. Sustain. Energy Rev. 2017, 79, 1353–1379. [Google Scholar] [CrossRef]

- Liu, X.; Ma, W. Research of Waiting Time of Passengers at Railway Stations. J. China Railw. Soc. 2009, 31, 104–107. (In Chinese) [Google Scholar]

- Concepts, R. Thermal Environmental Conditions for Human Occupancy; ASHRAE Standard: Atlanta, GA, USA, 2014. [Google Scholar]

- Thermal Environmental Conditions for Human Occupancy; ASHARE 55-2017; American Society of Heating, Refigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2017.

- Candido, C.; de Dear, R.J.; Lamberts, R.; Bittencourt, L. Air movement acceptability limits and thermal comfort in Brazil’s hot humid climate zone. Build. Environ. 2010, 45, 222–229. [Google Scholar] [CrossRef]

- Moderate Thermal Environment-Determination of the PMV and PPD Indices and Specification of the Condition for Thermal Comfort; ISO 7730; International Standard Organization: Copenhagen, Denmark, 2016.

- Peeters, L.; de Dear, R.; Hensen, J.; D’haeseleer, W. Thermal comfort in residential buildings: Comfort values and scales for building energy simulation. Appl. Energy 2009, 86, 772–780. [Google Scholar] [CrossRef]

| Climate Zone | Station Number | Construction Area (104 m2) | Annual Passenger Flow (104) | Station Scale | Area of Waiting Lounge (104 m2) | Maximum Height (m) |

|---|---|---|---|---|---|---|

| A | A1 | 12.0 | 2675 | Large | 2.7 | 30 |

| A2 | 6.2 | 1500 | Medium | 1.7 | 18 | |

| B | B1 | 10.7 | 2500 | Large | 6.0 | 21 |

| B2 | 25.8 | 8546 | Large | 5.0 | 18 | |

| B3 | 10.4 | 892 | Medium | 4.1 | 37 | |

| B4 | 6.9 | 649 | Medium | 2.5 | 30 | |

| C | C1 | 24.0 | 4486 | Large | 7.8 | 21 |

| C2 | 28.2 | 6667 | Large | 8.1 | 33 | |

| C3 | 10.8 | 4564 | Large | 4.0 | 25 | |

| C4 | 11.0 | 2448 | Large | 3.4 | 18 | |

| D | D1 | 16.8 | 6796 | Large | 7.6 | 20 |

| D2 | 9.0 | 3650 | Medium | 4.3 | 20 | |

| D3 | 6.9 | 680 | Medium | NA a | NA | |

| E | E1 | 12.0 | 858 | Large | 5.4 | 18.5 |

| E2 | 11.0 | 2448 | Large | 4.0 | 21 |

| Annual | Cooling | Heating | Lighting | Others | |

|---|---|---|---|---|---|

| High-speed station (kWh/(m2·a)) | 117–450 | 25% | 39% | 13% | 23% |

| Traditional station (kWh/(m2·a)) | 101–269 | 20% | 44% | 18% | 18% |

| Urban office building (kWh/(m2·a)) | 30–107 | 35% | 40% | 15% | 10% |

| Name | Type | Parameter | Accuracy | Measurement Error |

|---|---|---|---|---|

| Hot wire anemometer | Testo-425 | Wind speed | ±0.03 m/s | 0.017 m/s |

| Range finder | BS-GLM80 | Distance | ±0.002 m | 0.001 m |

| Multifunctional Tester | Testo-435 | Temperature, humidity and CO2 | ±0.2 °C, ±1%, ±10 ppm | 0.115 °C, 0.57%, 5.7 ppm |

| Luminometer | TES-1335 | Illumination | ±0.01 Lux | 0.0057 Lux |

| Black-bulb thermometer | AZ8758 | Black-bulb temperature | ±0.2 °C | 0.115 °C |

| Number | Indoor Temperature (°C) | Humidity (%) | Radiation Temperature (°C) | Outdoor Temperature (°C) | Wind Speed (m/s) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | |

| A1 | 22.0 | 16.1 | 18.5 | 24.4 | 14.1 | 18.8 | 22.1 | 17.2 | 19.4 | 4.2 | −0.2 | 3.1 | 0.8 | 0.05 | 0.3 |

| A2 | 22.5 | 11.6 | 18.7 | 12.9 | 6.5 | 8.1 | 22.1 | 11.6 | 18.4 | −4.7 | −5.6 | −5.3 | 1.7 | 0.05 | 0.5 |

| B1 | 17.5 | 10.6 | 15.3 | 25.4 | 14.8 | 17.2 | 17.4 | 4.8 | 14.9 | 1.5 | 0.2 | 1.0 | 1.2 | 0.01 | 0.4 |

| B2 | 21.2 | 11.8 | 17.4 | 19.8 | 11.1 | 15.1 | 20.6 | 11.7 | 17.3 | 0.7 | −3.3 | −0.9 | 1.8 | 0.01 | 0.5 |

| B3 | 20.2 | 13.6 | 17.7 | 21.8 | 9.9 | 20.3 | 19.4 | 11.7 | 12.2 | 5.7 | 1.7 | 3.6 | 1.0 | 0.01 | 0.2 |

| B4 | 21.6 | 13.5 | 18.9 | 40.0 | 24.3 | 28.8 | 21.5 | 16.1 | 19.4 | 5.5 | 3.7 | 4.4 | 1.0 | 0.01 | 0.4 |

| C1 | 20.8 | 12.0 | 16.1 | 40.4 | 23.5 | 31.2 | 19.3 | 10.8 | 15.8 | 6.9 | 2.8 | 4.8 | 1.1 | 0.02 | 0.3 |

| C2 | 23.1 | 16.4 | 20.1 | 65.7 | 45.3 | 52.4 | 22.7 | 15.5 | 20.1 | 13.8 | 9.9 | 12.1 | 1.0 | 0.01 | 0.3 |

| C4 | 20.8 | 12.0 | 16.1 | 40.4 | 23.5 | 31.2 | 19.3 | 10.8 | 15.8 | 6.9 | 2.8 | 4.8 | 1.1 | 0.02 | 0.3 |

| D1 | 23.1 | 16.4 | 20.1 | 65.7 | 45.3 | 52.4 | 22.7 | 15.5 | 20.1 | 13.8 | 9.9 | 12.1 | 1.0 | 0.01 | 0.3 |

| D2 | 22.0 | 20.5 | 21.4 | 67.7 | 61.6 | 64.6 | 22.4 | 20.5 | 21.5 | 21.1 | 18.9 | 20.1 | 0.5 | 0.01 | 0.2 |

| D3 | 20.0 | 17.6 | 18.8 | 86.8 | 73.2 | 82.8 | 21.8 | 17.8 | 19.6 | 20.5 | 20.1 | 20.3 | 0.5 | 0.1 | 0.2 |

| E1 | 15.4 | 13.0 | 14.0 | 70.5 | 62.4 | 65.8 | 15.0 | 11.7 | 13.6 | 12.5 | 11.6 | 11.9 | 0.8 | 0.1 | 0.3 |

| E2 | 18.5 | 14.6 | 16.8 | 63.9 | 55.3 | 59.1 | 18.6 | 14.6 | 16.9 | 17.0 | 15.6 | 16.5 | 0.6 | 0.01 | 0.2 |

| Number | Indoor Temperature (°C) | Humidity (%) | Radiation Temperature (°C) | Outdoor Temperature (°C) | Wind Speed (m/s) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | |

| A1 | 25.9 | 23.2 | 24.6 | 44.4 | 34.1 | 38.9 | 25.7 | 23.2 | 24.6 | 27.6 | 24.2 | 26.3 | 0.6 | 0.1 | 0.2 |

| A2 | 25.5 | 21.5 | 24.1 | 32.9 | 30.1 | 31.5 | 25.7 | 22.5 | 24.2 | 27.3 | 24.6 | 25.2 | 1.5 | 0.1 | 0.5 |

| B1 | 27.7 | 25.4 | 26.5 | 46.2 | 35.1 | 38.4 | 27.3 | 25.6 | 26.5 | 27.3 | 27.3 | 27.3 | 1.6 | 0.1 | 0.5 |

| B2 | 29.2 | 24.1 | 26.3 | 40.1 | 31.1 | 35.2 | 30.2 | 24.5 | 27.0 | 30.6 | 27.5 | 29.6 | 1.2 | 0.0 | 0.3 |

| B3 | 25.0 | 22.7 | 23.9 | 41.8 | 30.9 | 39.2 | 25.1 | 22.6 | 24.0 | 25.9 | 23.1 | 24.8 | 1.8 | 0.0 | 0.4 |

| B4 | 25.9 | 24.1 | 24.9 | 55.5 | 44.3 | 48.9 | 25.7 | 24.1 | 25.0 | 27.1 | 24.0 | 25.4 | 1.5 | 0.1 | 0.5 |

| C1 | 25.9 | 24.1 | 25.1 | 69.5 | 61.5 | 65.5 | 25.7 | 24.1 | 24.9 | 27.5 | 24.3 | 26.1 | 1.2 | 0.1 | 0.4 |

| C2 | 27.8 | 23.2 | 24.5 | 70.1 | 59.8 | 63.9 | 27.8 | 23.5 | 24.6 | 27.3 | 26.3 | 25.3 | 1.6 | 0.1 | 0.6 |

| C3 | 26.1 | 23.3 | 24.4 | 68.8 | 60.7 | 65.4 | 25.3 | 22.2 | 24.0 | 25.3 | 23.8 | 24.6 | 1.5 | 0.0 | 0.3 |

| C4 | 25.5 | 23.8 | 24.8 | 65.4 | 54.0 | 61.3 | 25.9 | 24.6 | 25.3 | 24.9 | 24.3 | 24.7 | 0.9 | 0.1 | 0.2 |

| D1 | 32.5 | 27.4 | 30.0 | 78.5 | 65.4 | 70.2 | 36.7 | 28.1 | 31.3 | 33.4 | 33.4 | 33.4 | 1.0 | 0.1 | 0.2 |

| D2 | 29.7 | 26.1 | 28.0 | 82.5 | 70.2 | 78.2 | 29.9 | 26.7 | 28.3 | 37.2 | 37.2 | 37.2 | 1.1 | 0.0 | 0.3 |

| D3 | 28.8 | 26.9 | 27.7 | 80.2 | 69.5 | 77.6 | 29.0 | 27.1 | 27.7 | 27.6 | 37.2 | 37.2 | 1.5 | 0.0 | 0.3 |

| E1 | 27.0 | 22.2 | 24.8 | 75.5 | 62.4 | 70.1 | 26.4 | 22.7 | 24.6 | 27.4 | 23.3 | 25.3 | 0.9 | 0.0 | 0.1 |

| E2 | 24.7 | 22.0 | 23.7 | 70.5 | 65.3 | 67.8 | 27.6 | 22.3 | 25.3 | 25.8 | 23.3 | 24.5 | 1.5 | 0.0 | 0.3 |

| A1 | 25.9 | 23.2 | 24.6 | 44.4 | 34.1 | 38.9 | 25.7 | 23.2 | 24.6 | 27.6 | 24.2 | 26.3 | 0.6 | 0.1 | 0.2 |

| A2 | 25.5 | 21.5 | 24.1 | 32.9 | 30.1 | 31.5 | 25.7 | 22.5 | 24.2 | 27.3 | 24.6 | 25.2 | 1.5 | 0.1 | 0.5 |

| B1 | 27.7 | 25.4 | 26.5 | 46.2 | 35.1 | 38.4 | 27.3 | 25.6 | 26.5 | 27.3 | 27.3 | 27.3 | 1.6 | 0.1 | 0.5 |

| B2 | 29.2 | 24.1 | 26.3 | 40.1 | 31.1 | 35.2 | 30.2 | 24.5 | 27.0 | 30.6 | 27.5 | 29.6 | 1.2 | 0.0 | 0.3 |

| Station Number | A1 | A2 | B1 | B2 | B3 | B4 | C4 | D1 | E1 | E2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Winter | T0 (°C) | 18.9 | 20.3 | 17.9 | 19.9 | 18.3 | 18.8 | 17.1 | 16.5 | 17.0 | 16.6 |

| Test temperature (°C) | 18.5 | 18.6 | 15.1 | 17.3 | 17.5 | 19 | 13.9 | 16.8 | 16.2 | 15.2 | |

| Summer | T0 (°C) | 25.4 | 26.0 | 26.4 | 25.5 | 25.6 | 25.8 | 25.1 | NA | 26.0 | 26.3 |

| Test temperature (°C) | 24.6 | 24.2 | 26.5 | 26.6 | 23.9 | 24.9 | 25.1 | NA | 25.0 | 25.2 |

| A1 | A2 | B1 | B2 | B3 | B4 | C4 | D1 | E1 | E2 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Winter | 17.9–19.8 | 18.1–21.5 | 16.4–20.0 | 17.4–21.7 | 17.5–19.9 | 17.9–20.9 | 15.1–18.8 | 15.4–18.5 | 15.2–18.6 | 15.6–18.0 |

| Summer | 24.6–26.5 | 25.5–26.5 | 25.0–26.5 | 25.4–26.4 | 24.5–26.5 | 25.3–26.5 | 25.0–26.3 | 25.5–27.0 | 25.6–26.7 | 25.7–26.9 |

| A1 | A2 | B1 | B2 | B3 | B4 | C1 | C2 | C4 | D1 | D2 | E1 | E2 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Winter | Air change (h−1) | 0.9 | 6.2 | 1.9 | 1.8 | 5.0 | 2.9 | 1.2 | 4.2 | 5.1 | 5.6 | 2.3 | 2.2 | 5.6 |

| Percent (%) | 10 | 36 | 25 | 21 | 63 | 24 | 18 | 34 | NA | NA | NA | 22 | NA | |

| Summer | Air change (h−1) | 0.7 | 2.0 | 1.9 | 1.2 | 1.3 | 2.9 | 0.5 | 3.0 | 2.7 | 1.3 | 1.2 | 4.1 | 2.8 |

| Percent (%) | 10 | 19 | 10 | 29 | 22 | 34 | 48 | 39 | 40 | NA | 20 | 51 | 33 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, B.; Yu, T.; Bi, H.; Lei, B. Measurements of Energy Consumption and Environment Quality of High-Speed Railway Stations in China. Energies 2020, 13, 168. https://doi.org/10.3390/en13010168

Qian B, Yu T, Bi H, Lei B. Measurements of Energy Consumption and Environment Quality of High-Speed Railway Stations in China. Energies. 2020; 13(1):168. https://doi.org/10.3390/en13010168

Chicago/Turabian StyleQian, Bin, Tao Yu, Haiquan Bi, and Bo Lei. 2020. "Measurements of Energy Consumption and Environment Quality of High-Speed Railway Stations in China" Energies 13, no. 1: 168. https://doi.org/10.3390/en13010168

APA StyleQian, B., Yu, T., Bi, H., & Lei, B. (2020). Measurements of Energy Consumption and Environment Quality of High-Speed Railway Stations in China. Energies, 13(1), 168. https://doi.org/10.3390/en13010168