Development of Total Capital Investment Estimation Module for Waste Heat Power Plant

Abstract

:1. Introduction

2. Theoretical Background

2.1. Introduction of Waste Heat Power Plant

2.2. Basic Concept of the Economic Analysis

3. Design of TCI Estimation Module

3.1. Objective to TCI Estimation Module

3.2. Requirements Definition of the TCI Estimation Module

3.2.1. Stakeholder Identification

3.2.2. Stakeholder Requirements Definition

3.2.3. System Requirements Definition

3.3. Equipment Cost Model Development

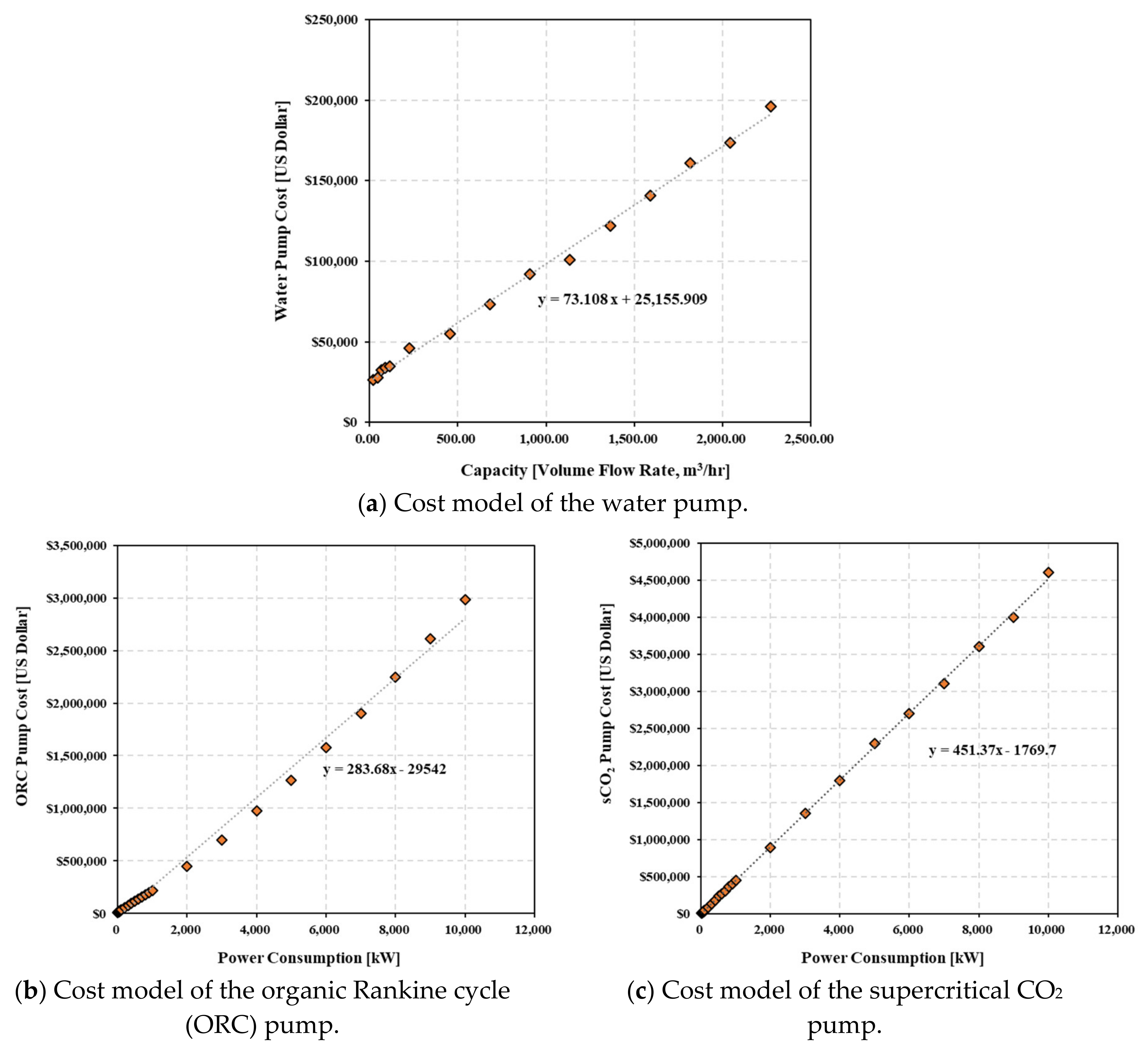

3.3.1. Pump Cost Model

3.3.2. Turbine Cost Model

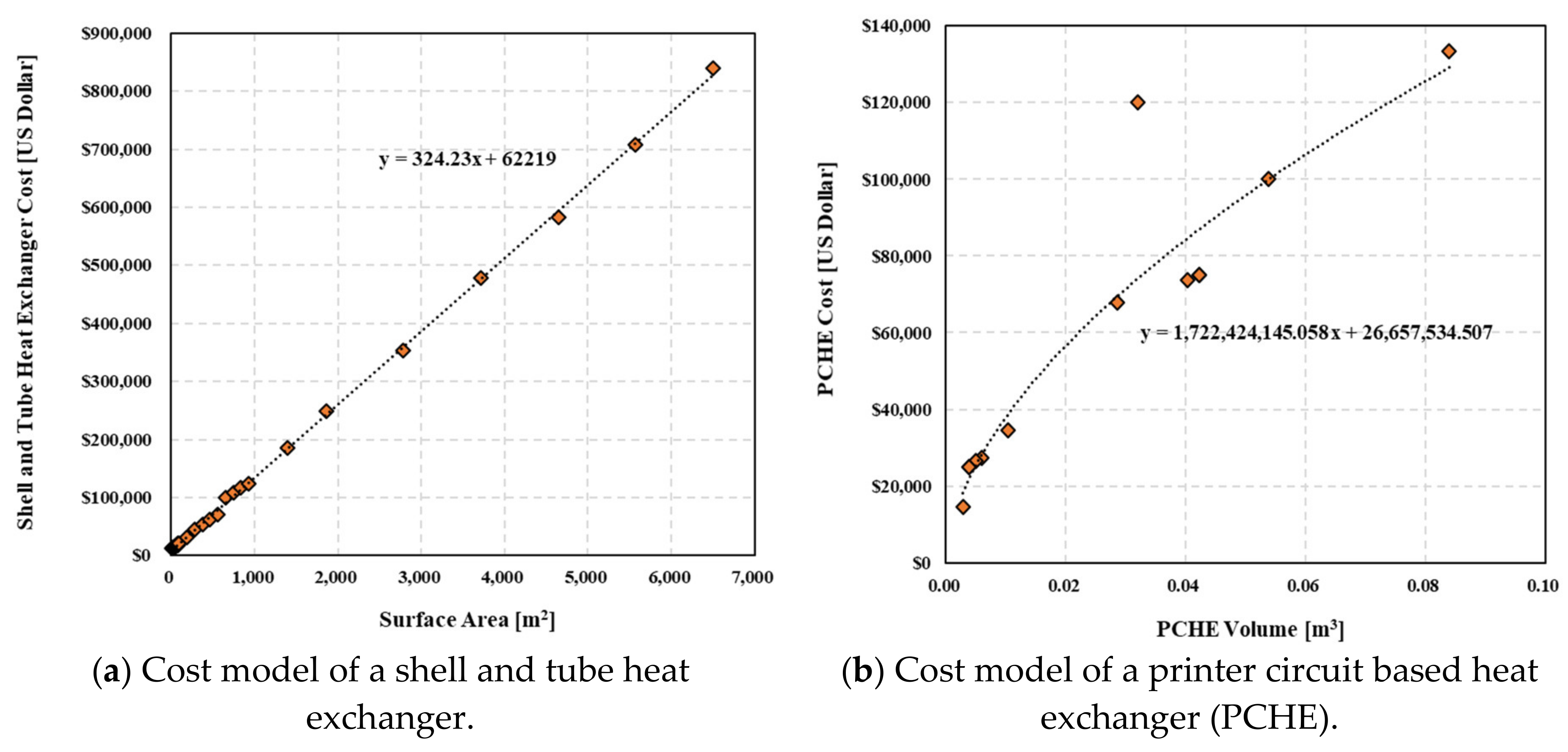

3.3.3. Heat Exchanger Cost Model

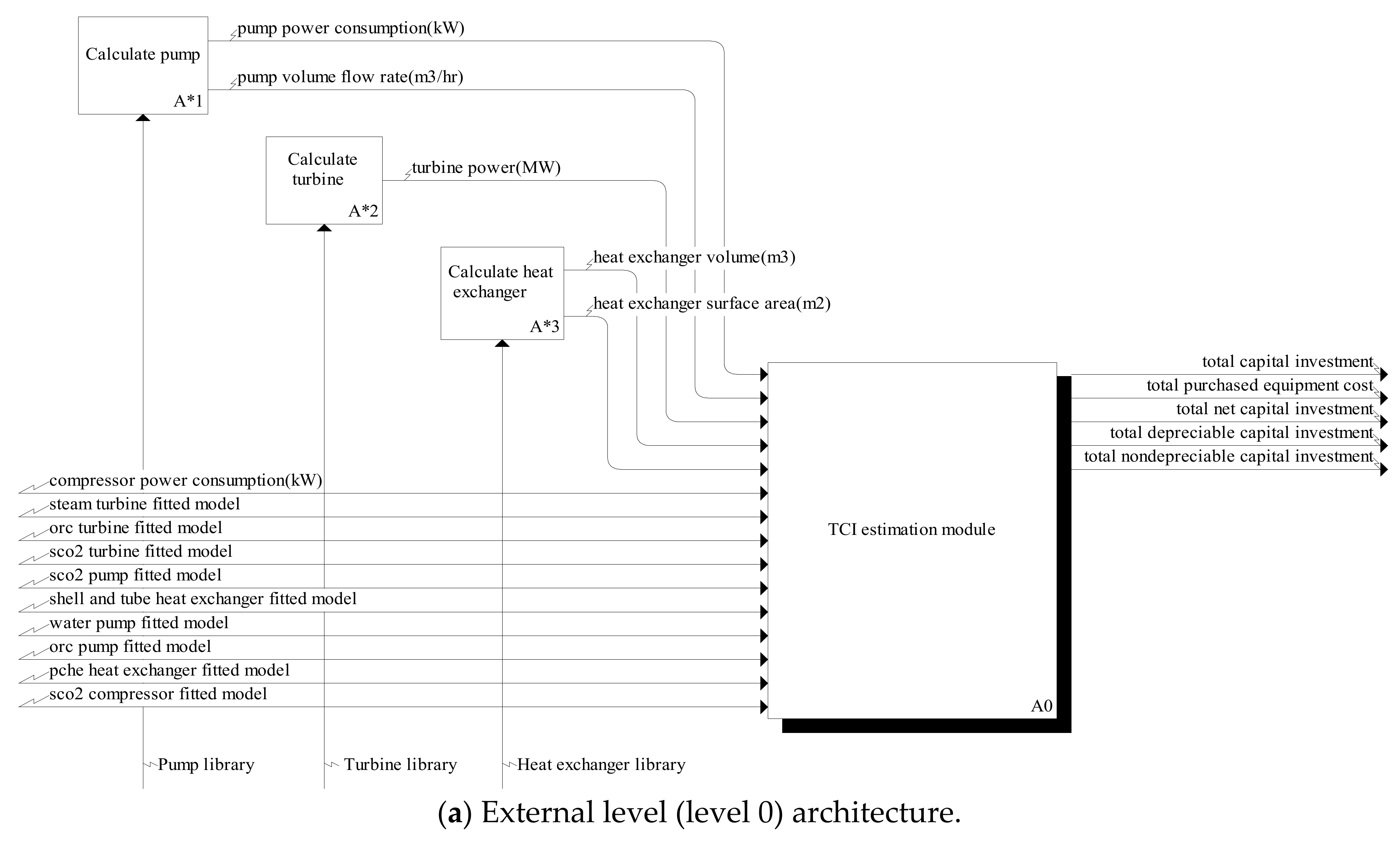

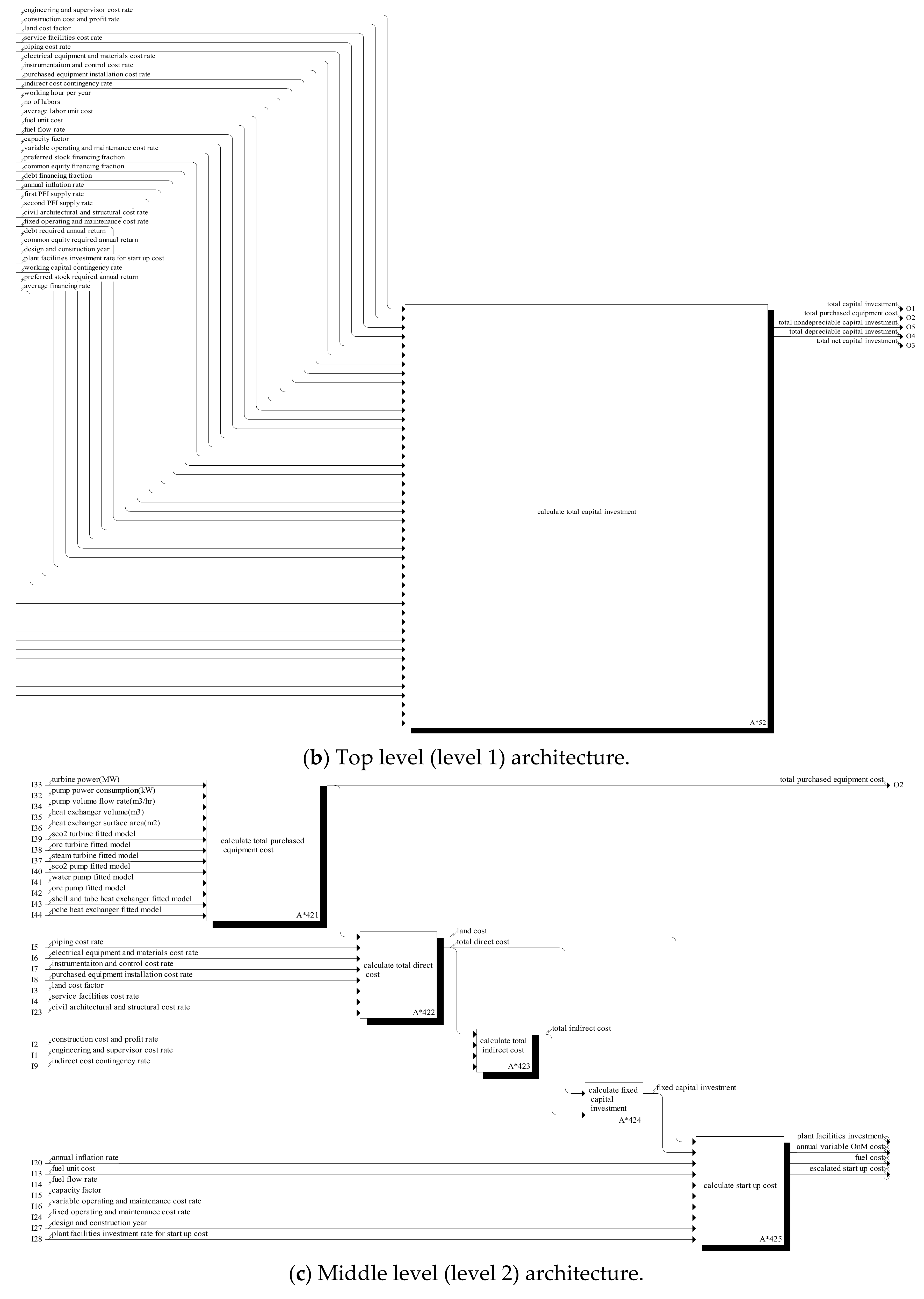

3.4. Functional Architecture Design of TCI Estimation Module

4. TCI Estimation Module Implementation and Case Study

4.1. Development of TCI Estimation Module Prototype

4.2. TCI Estimation Module Performance Verification

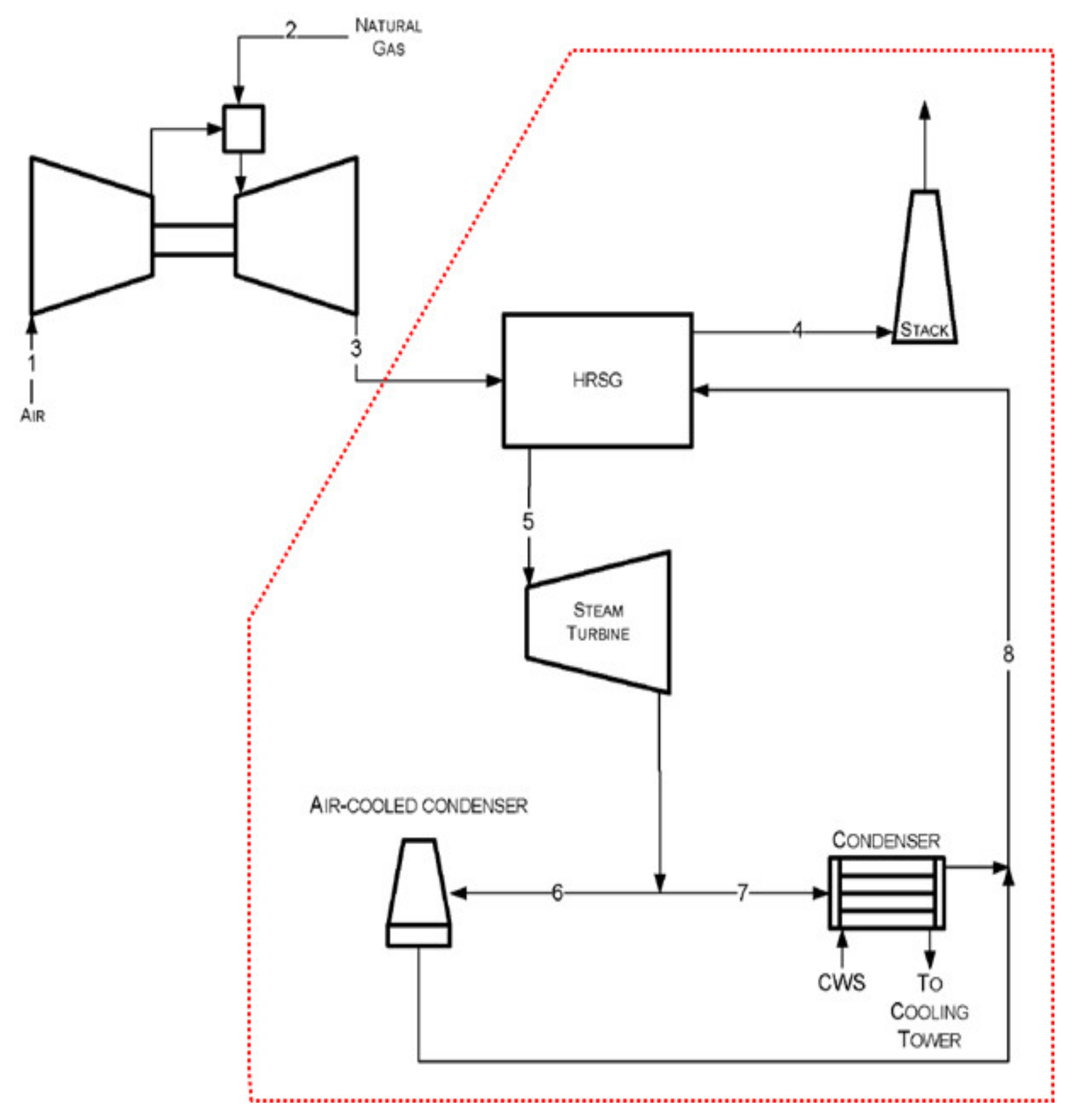

4.2.1. NETL NGCC Case Study

4.2.2. TCI Analysis and Comparison

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bendig, M.; Maréchal, F.; Favrat, D. Defining waste heat for industrial processes. Appl. Therm. Eng. 2013, 61, 134–142. [Google Scholar] [CrossRef]

- Kreith, F.; Goswami, D.Y. Energy Management and Conservation Handbook; CRC Press: Boca Raton, FL, USA, 2008; ISBN 1420044303. [Google Scholar]

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial waste heat: Estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the global waste heat potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- COMFAR–UNIDO. Available online: https://www.unido.org/resources/publications/publications-type/comfar-software (accessed on 27 January 2019).

- ENetOPT-Infotrol Technology Co., Ltd. Available online: http://www.infotrol.co.kr/products/enetopt_en.php (accessed on 27 January 2019).

- ISO/IEC/IEEE 15288: Systems and Software Engineering—System Life Cycle Processes. Available online: https://www.iso.org/standard/63711.html (accessed on 11 March 2019).

- Walden, D.D.; Roedler, G.J.; Forsberg, K. INCOSE Systems Engineering Handbook Version 4; INCOSE: Santiago, CA, USA, 2014. [Google Scholar]

- Turner, W.C. Energy Management Handbook; Fairmont Press: Lilburn, GA, USA, 2001; ISBN 0881733377. [Google Scholar]

- Reay, D.A. Industrial Energy Conservation: A Handbook for Engineers and Managers; Pergamon Press: Oxford, NY, USA, 1977; ISBN 0080208673. [Google Scholar]

- Bonilla, J.J.; Blanco, J.M.; Lopez, L.; Sala, J.M. Technological recovery potential of waste heat in the industry of the Basque Country. Appl. Therm. Eng. 1997, 17, 283–288. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Woolley, E.; Luo, Y.; Simeone, A. Industrial waste heat recovery: A systematic approach. Sustain. Energy Technol. Assess. 2018, 29, 50–59. [Google Scholar]

- Gupta, A.; Singh Bais, A. Waste Heat to Power Market Share Size 2019–2025 Growth Report; Global Market Insights, Inc.: Selbyville, DE, USA, 2019. [Google Scholar]

- Andreasen, J.G.; Meroni, A.; Haglind, F. A comparison of organic and steam Rankine cycle power systems for waste heat recovery on large ships. Energies 2017, 10, 547. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, L.; Wang, X.; Ju, G. Comparative study of waste heat steam SRC, ORC and S-ORC power generation systems in medium-low temperature. Appl. Therm. Eng. 2016, 106, 1427–1439. [Google Scholar] [CrossRef]

- Pierobon, L.; Benato, A.; Scolari, E.; Haglind, F.; Stoppato, A. Waste heat recovery technologies for offshore platforms. Appl. Energy 2014, 136, 228–241. [Google Scholar] [CrossRef]

- Incropera, F.P.; Bergman, T.L.; Lavine, A. Foundations of Heat Transfer, 6th ed.; Wiley: Hoboken, NJ, USA; ISBN 0470646160.

- Hung, T.C.; Shai, T.Y.; Wang, S.K. A review of organic rankine cycles (ORCs) for the recovery of low-grade waste heat. Energy 1997, 22, 661–667. [Google Scholar] [CrossRef]

- Drescher, U.; Brüggemann, D. Fluid selection for the Organic Rankine Cycle (ORC) in biomass power and heat plants. Appl. Therm. Eng. 2007, 27, 223–228. [Google Scholar] [CrossRef]

- Chen, Y.; Lundqvist, P.; Johansson, A.; Platell, P. A comparative study of the carbon dioxide transcritical power cycle compared with an organic rankine cycle with R123 as working fluid in waste heat recovery. Appl. Therm. Eng. 2006, 26, 2142–2147. [Google Scholar] [CrossRef]

- Dostal, V.; Hejzlar, P.; Driscoll, M.J. The Supercritical Carbon Dioxide Power Cycle: Comparison to Other Advanced Power Cycles. Nucl. Technol. 2006, 154, 283–301. [Google Scholar] [CrossRef]

- Park, S.; Kim, J.; Yoon, M.; Rhim, D.; Yeom, C. Thermodynamic and economic investigation of coal-fired power plant combined with various supercritical CO2 Brayton power cycle. Appl. Therm. Eng. 2018, 130, 611–623. [Google Scholar] [CrossRef]

- Short, W.; Packey, D.J.; Holt, T. A Manual for the Economic Evaluation of Energy Efficiency and Renewable Energy Technologies; National Renewable Energy Laboratory: Golden, CO, USA, 2005; ISBN 1410221059.

- Bejan, A.; Tsatsaronis, G.; Moran, M.J. Thermal Design and Optimization; Wiley: Hoboken, NJ, USA, 1996; ISBN 0471584673. [Google Scholar]

- Humphreys, K.K.; Wellman, P. Basic Cost Engineering, 3rd ed.; CRC Press: Boca Raton, FL, USA, 1995; ISBN 9780429259104. [Google Scholar]

- Couper, J.R. Process Engineering Economics; Marcel Dekker: New York, NY, USA, 2003; ISBN 0203911393. [Google Scholar]

- Brown, T. Engineering Economics and Economic Design for Process Engineers; CRC Press: Boca Raton, FL, USA; ISBN 1420008102.

- Conkling, R.L. Energy Pricing: Economics and Principles; Springer: Heidelberg, Germany, 2011; ISBN 3642154913. [Google Scholar]

- Drbal, L.F.; Boston, P.G.; Westra, K.L. Power Plant Engineering; Kluwer Academic Publishers: Norwell, MA, USA, 1996; ISBN 146130427X. [Google Scholar]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill: New York, NY, USA, 2003; ISBN 0072392665. [Google Scholar]

- Glosten, L.R.; Harris, L.E. Estimating the components of the bid/ask spread. J. Financ. Econ. 1988, 21, 123–142. [Google Scholar] [CrossRef]

- McKetta, J.J.; Cunningham, W.A. Encyclopedia of Chemical Processing and Design; Marcel Dekker: New York, NY, USA, 1976; ISBN 0824724933. [Google Scholar]

- Sinha, V.T. Estimating capital costs from an equipment list: A case study. Eng. Costs Prod. Econ. 1988, 14, 259–266. [Google Scholar] [CrossRef]

- Garrett, D.E. Chemical Engineering Economics; Van Nostrand Reinhol: New York, NY, USA; Springer: Berlin/Heidelberg, Germany, 1989; ISBN 9401165440. [Google Scholar]

- AACE-International. AACE International Recommended Practice No. 18R-97 Cost Estimate Classification System—As Applied in Engineering, Procurement, and Construction for the Process Industries; AACE-International: Morgantown, WV, USA, 2011. [Google Scholar]

- Kim, J.-Y. Smart chemical plant architecture development based on a systems engineering. In Proceedings of the 2017 IEEE International Systems Engineering Symposium (ISSE), Vienna, Austria, 11–13 October 2017; pp. 1–5. [Google Scholar]

- ISO/IEC/IEEE 29148: Systems and Software Engineering—Life Cycle Processes—Requirements Engineering. Available online: https://ieeexplore.ieee.org/document/6146379 (accessed on 11 March 2019).

- Cohen, L. Quality Function Deployment: How to Make QFD Work for You, 1st ed.; Addison-Wesley: Boston, MA, USA, 1995; ISBN 0201633302. [Google Scholar]

- Macchi, E. Organic Rankine Cycle (ORC) Power Systems; Woodhead Publishing: Duxford, UK, 2016; ISBN 0081005113. [Google Scholar]

- Ishigai, S. Steam Power Engineering: Thermal and Hydraulic Design Principles; Cambridge University Press: Cambridge, UK, 1999; ISBN 0521626358. [Google Scholar]

- Sarkar, J. Review and future trends of supercritical CO2 Rankine cycle for low-grade heat conversion. Renew. Sustain. Energy Rev. 2015, 48, 434–451. [Google Scholar] [CrossRef]

- Jones, G.M.; Sanks, R.L.; Tchobanoglous, G.; Bosserman, B.E. Pumping Station Design, 3rd ed.; Elsevier/Butterworth-Heinemann: Burlington, MA, USA, 2008; ISBN 0080560059. [Google Scholar]

- Loh, H.P.; Jennifer, L.; White, C.W., III. Process Equipment Cost Estimation; National Energy Technology Laboratory: Morgantown, WV, USA, 2002.

- Karassik, I.J. Pump Handbook; McGraw-Hill: New York, NY, USA, 2001; ISBN 0070340323. [Google Scholar]

- Hou, S.; Zhou, Y.; Yu, L.; Zhang, F.; Cao, S.; Wu, Y. Optimization of a novel cogeneration system including a gas turbine, a supercritical CO2 recompression cycle, a steam power cycle and an organic Rankine cycle. Energy Convers. Manag. 2018, 172, 457–471. [Google Scholar] [CrossRef]

- Mignard, D. Correlating the chemical engineering plant cost index with macro-economic indicators. Chem. Eng. Res. Des. 2014, 92, 285–294. [Google Scholar] [CrossRef]

- Dick, E. Fundamentals of Turbomachines; Springer: Heidelberg, Germany; ISBN 9401796270.

- Bloch, H.P.; Singh, M.P.; Bloch, H.P. Steam Turbines: Design, Applications, and Rerating, 2nd ed.; McGraw-Hill: New York, NY, USA, 2009; ISBN 0071641009. [Google Scholar]

- Fielding, L. Turbine Design: The Effect on Axial Flow Turbine Performance of Parameter Variation; ASME Press: New York, NY, USA, 2000; ISBN 0791800865. [Google Scholar]

- Driscoll, M.J. Supercritical CO2 Plant Cost Assessment; Center for Advanced Nuclear Energy Systems: Massachusetts Institute of Technology: Cambridge, MA, USA, 2004; Volume MIT-GFR-01. [Google Scholar]

- Thulukkanam, K. Heat Exchanger Design Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; Volume 20135140, ISBN 1439842124. [Google Scholar]

- Ahn, Y.; Bae, S.J.; Kim, M.; Cho, S.K.; Baik, S.; Lee, J.I.; Cha, J.E. Review of supercritical CO2 power cycle technology and current status of research and development. Nucl. Eng. Technol. 2015, 47, 647–661. [Google Scholar] [CrossRef]

- Shah, R.K.; Sekulić, D.P. Fundamentals of Heat Exchanger Design; John Wiley & Sons: Hoboken, NJ, USA, 2003; ISBN 0471321710. [Google Scholar]

- Mylavarapu, S.K.; Sun, X.; Christensen, R.N.; Unocic, R.R.; Glosup, R.E.; Patterson, M.W. Fabrication and design aspects of high-temperature compact diffusion bonded heat exchangers. Nucl. Eng. Des. 2012, 249, 49–56. [Google Scholar] [CrossRef]

- Southall, D. Diffusion bonding in compact heat exchangers. In Proceedings of the 2nd International Supercritical CO2 Power Cycles Symposium, Troy, NY, USA, 29–30 April 2009; SwRI: San Antonio, TX, USA, 2009. [Google Scholar]

- Dostál, V. A Supercritical Carbon Dioxide Cycle for Next Generation Nuclear Reactors. Ph.D. Thesis, MIT, Cambridge, MA, USA, 2004. [Google Scholar]

- Dewson, S.; Grady, C. PCHE–Printed Circuit Heat Exchangers. In Proceedings of the Heatric Workshop; MIT: Cambridge, MA, USA, 2003. [Google Scholar]

- Shiferaw, D.; Carrero, J.M.; Le Pierres, R. Economic analysis of SCO2 cycles with PCHE recuperator design optimisation. In Proceedings of the 5th International Supercritical CO2 Power Cycles Symposium, San Antonio, TX, USA, 29–31 March 2016; SwRI: San Antonio, TX, USA, 2016. [Google Scholar]

- Hinze, J.F.; Nellis, G.F.; Anderson, M.H. Cost comparison of printed circuit heat exchanger to low cost periodic flow regenerator for use as recuperator in a s-CO2 Brayton cycle. Appl. Energy 2017, 208, 1150–1161. [Google Scholar] [CrossRef]

- Engineering Sciences Data Unit. Selection and Costing of Heat Exchangers; Engineering Sciences Data Unit: London, UK, 2006; ISBN 0856798185. [Google Scholar]

- U.S. Department of Energy—National Energy Technology Laboratory. Cost and Performance Baseline for Fossil Energy Plants; Volume 3c: Natural Gas Combined Cycle at Elevation; National Energy Technology Laboratory: Morgantown, WV, USA, 2011.

- Jaramillo, P.; Griffin, W.M.; Matthews, H.S. Comparative life-cycle air emissions of coal, domestic natural gas, LNG, and SNG for electricity generation. Environ. Sci. Technol. 2007, 41, 6290–6296. [Google Scholar] [CrossRef]

- De Gouw, J.A.; Parrish, D.D.; Frost, G.J.; Trainer, M. Reduced Emissions of CO2, NOx and SO2 from U.S. Power Plants Due to the Switch from Coal to Natural Gas with Combined Cycle Technology. Earth’s Future 2014. [Google Scholar] [CrossRef]

| Cost Estimation Method | Vendor Quotation-Based Calculation Approach | Cost Model-Based Calculation Approach |

|---|---|---|

| Calculation basis | Quotations provided by the manufacturing vendors | Correlation between equipment’s specification/size and cost |

| Advantage | (1) High accuracy (2) Able to predict various specifications/material quality | (1) Able to predict the price fluctuation based on the specification change (2) Able to develop the cost model based on the former research or quotation |

| Disadvantage | (1) Difficult to collect quotations (2) Difficult to predict the price fluctuations based on the specification change | (1) Might be different with the manufacture vendors’ quotation (2) Difficult to predict various specifications/material quality |

| Estimate Class | Project Definition Maturity | Typical Purpose of Estimate | Expected Accuracy Range | Preparation Effort 1 |

|---|---|---|---|---|

| Class 5 | 0% to 2% | Concept screening | L: −20% to −50% H: +30% to +100% | 1 |

| Class 4 | 1% to 15% | Study or feasibility | L: −15% to −30% H: +20% to +50% | 2 to 4 |

| Class 3 | 10% to 40% | Budget, authorization, or control | L: −10% to −20% H: +10 % to +30% | 3 to 10 |

| Class 2 | 30% to 70% | Control or bid/tender | L: −5% to −15% H: +5% to +20% | 4 to 20 |

| Class 1 | 50% to 100% | Check estimate or bid/tender | L: –3% to −10% H: +3% to +15% | 5 to 100 |

| Category | Name | Description |

|---|---|---|

| Developers | TCI module developing companies | Algorithms, UX/UI developers, … |

| Users | Plant operating companies | Public, private power corporation, … |

| Energy demanding companies | Steel-making, cement plants, … | |

| Plant equipment manufacturing companies | Turbines, pump manufacturers, … | |

| Plant engineering companies | Basic, detailed design companies, … | |

| Plant constructing companies | Civil, structural works companies, … | |

| Maintainers | TCI module maintaining companies | Operating, maintenance agencies, … |

| No. | Name | Description |

|---|---|---|

| StR#1 | Working fluid model application | TCI estimation module shall apply working fluid model of the waste heat power plant |

| StR#2 | Equipment cost estimation | TCI estimation module shall calculate the equipment cost of the waste heat power plant |

| StR#3 | Total direct cost estimation | TCI estimation module shall calculate the total direct cost of the waste heat power plant |

| StR#4 | Total indirect cost estimation | TCI estimation module shall calculate the total indirect cost of the waste heat power plant |

| StR#5 | Fixed capital investment estimation | TCI estimation module shall calculate the fixed capital investment of the waste heat power plant |

| StR#6 | Working capital estimation | TCI estimation module shall calculate the working capital of the waste heat power plant |

| … | … | … |

| No. | Name | Description |

|---|---|---|

| SyR#1 | Steam model application | TCI estimation module shall be able to apply steam model as the working fluid. (Related stakeholder requirement: StR#1) |

| SyR#2 | Organic refrigerant model application | TCI estimation module shall be able to apply organic refrigerant model as the working fluid. (StR#1) |

| SyR#3 | Supercritical carbon dioxide (CO2) model application | TCI estimation module shall be able to apply supercritical carbon dioxide (CO2) model as the working fluid. (StR#1) |

| SyR#4 | Pump cost estimation | TCI estimation module shall be able to calculate the cost of the pump used in the waste heat power plant. (StR#2) |

| SyR#5 | Turbine cost estimation | TCI estimation module shall be able to calculate the cost of the turbine used in the waste heat power plant. (StR#2) |

| SyR#6 | Heat exchanger cost estimation | TCI estimation module shall be able to calculate the cost of the heat exchanger used in the waste heat power plant. (StR#2) |

| SyR#7 | Total onsite cost estimation | TCI estimation module shall be able to calculate the cost occurred at the construction site of waste heat power plant. (StR#3) |

| SyR#8 | Total offsite cost estimation | TCI estimation module shall be able to calculate the cost occurred outside the construction site of waste heat power plant. (StR#3) |

| SyR#9 | Total direct cost estimation | TCI estimation module shall be able to calculate the total direct cost that includes the total onsite and offsite cost. (StR#3) |

| SyR#10 | Engineering and supervisor cost estimation | TCI estimation module shall be able to calculate the design and construction supervision cost of waste heat power plant. (StR#4) |

| SyR#11 | Construction cost estimation | TCI estimation module shall be able to calculate the cost required for construction of waste heat power plant. (StR#4) |

| SyR#12 | Contingency estimation | TCI estimation module shall be able to calculate the extra cost additionally occurred for the design and construction of waste heat power plant. (StR#4) |

| … | … | … |

| Name | Description |

|---|---|

| Function | Calculate AFUDC details |

| Input variables | (1) Plant facilities investment |

| (2) land cost | |

| (3) escalated start-up cost | |

| (4) annual inflation rate | |

| (5) first PFI supply rate | |

| (6) second PFI supply rate | |

| (7) common equity financing fraction | |

| (8) common equity required annual return | |

| (9) preferred stock financing fraction | |

| (10) preferred stock required annual return | |

| (11) debt financing fraction | |

| (12) debt required annual return | |

| Output variables | (1) AFUDC common equity |

| (2) AFUDC preferred stock | |

| (3) AFUDC debt | |

| (4) AFUDC PFI escalated investment | |

| Operation principles | Calculate the detailed factors of AFUDC based on the calculated plant equipment investment cost |

| Calculate annual investment cost by estimating the ratio of owner’s equity, preferred stock, and debt | |

| Algorithm | [PFI & PFI escalated investment calculation] |

| (1) PFI = plant facilities investment × (first PFI supply rate); | |

| (2) PFI escalated investment = PFI × (1 + (annual inflation rate))2; | |

| [AFUDC Common equity calculation] | |

| (1) common equity escalated investment = PFI escalated investment × (common equity financing fraction); | |

| (2) AFUDC common equity = common equity escalated investment × (1 + (common equity required annual return))1.5—common equity escalated investment; | |

| … |

| Name | Value |

|---|---|

| Economic life | 35 years |

| Design and construction year | 1 years |

| No. of labors | 5 |

| Working hours per year | 2600 h |

| Average labor unit cost | $34.65 /h |

| Capacity factor | 85% |

| Equipment installation | 20% |

| Land cost | 0.03% |

| Civil architectural and structural | 20% |

| Service facilities | 30% |

| Engineering and supervisor cost | 10% |

| Construction cost and contractor’s profit | 15% |

| Fixed O&M cost | 9% |

| Variable O&M cost | 9% |

| Indirect cost contingency | 15% |

| Plant Facilities investment for start up | 2% |

| Annual inflation rate | 3% |

| Fuel escalation rate | 3% |

| Common equity | 2.25% |

| Debt | 6% |

| Total income tax rate | 3.8% |

| Purchased equipment | $112,022,000 |

| Category | Name | Value ($) |

|---|---|---|

| TCI estimation module | Total purchased equipment cost | 112,022,000 |

| Total onsite cost | 134,426,400 | |

| Total offsite cost | 59,371,660 | |

| Total direct cost | 193,798,060 | |

| Total indirect cost | 84,786,651 | |

| Fixed capital investment | 278,584,711 | |

| Start-up cost | 7,825,426 | |

| Escalated start-up cost | 8,301,995 | |

| Fuel cost | 3,729,571 | |

| Escalated fuel cost | 10,188,835 | |

| Working capital | 3,439,355 | |

| Escalated working capital | 3,648,812 | |

| AFUDC total current | 18,549,480 | |

| AFUDC total future | 18,742,668 | |

| Total capital investment (TCIM) | 325,353,306 | |

| NETL S31A | Total purchased equipment cost | 112,022,000 |

| Total plant cost | 206,921,000 | |

| Total owner’s costs | 79,197,000 | |

| Total overnight cost | 286,118,000 | |

| TCI multiplier | 1.075 | |

| Total capital investment (TCIR) | 307,576,850 | |

| Difference between TCI estimated by the module and NETL (D) (D = Abs(TCIM − TCIR)) | 17,776,456 | |

| TCI estimation module error (E) (E = D/TCIR × 100) | +5.78% | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-Y.; Salim, S.; Cha, J.-M.; Park, S. Development of Total Capital Investment Estimation Module for Waste Heat Power Plant. Energies 2019, 12, 1492. https://doi.org/10.3390/en12081492

Kim J-Y, Salim S, Cha J-M, Park S. Development of Total Capital Investment Estimation Module for Waste Heat Power Plant. Energies. 2019; 12(8):1492. https://doi.org/10.3390/en12081492

Chicago/Turabian StyleKim, Joon-Young, Shelly Salim, Jae-Min Cha, and Sungho Park. 2019. "Development of Total Capital Investment Estimation Module for Waste Heat Power Plant" Energies 12, no. 8: 1492. https://doi.org/10.3390/en12081492

APA StyleKim, J.-Y., Salim, S., Cha, J.-M., & Park, S. (2019). Development of Total Capital Investment Estimation Module for Waste Heat Power Plant. Energies, 12(8), 1492. https://doi.org/10.3390/en12081492