A Method for Rapid Evaluation of Thermal Performance of Wall Assemblies Based on Geographical Location

Abstract

1. Introduction

2. Methods

2.1. Climatic Data

2.2. Studied Wall Assemblies

2.3. Computational Simulation

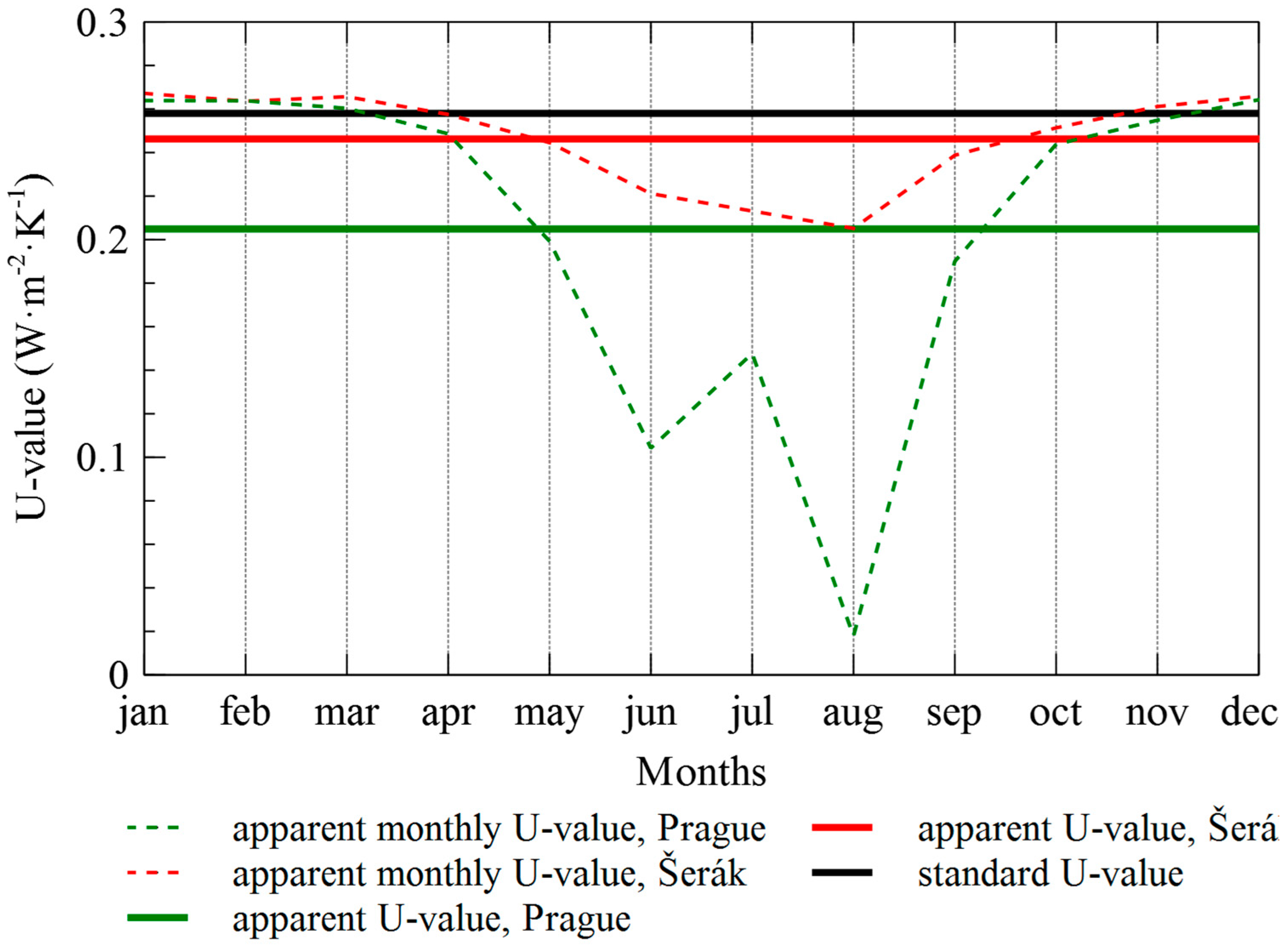

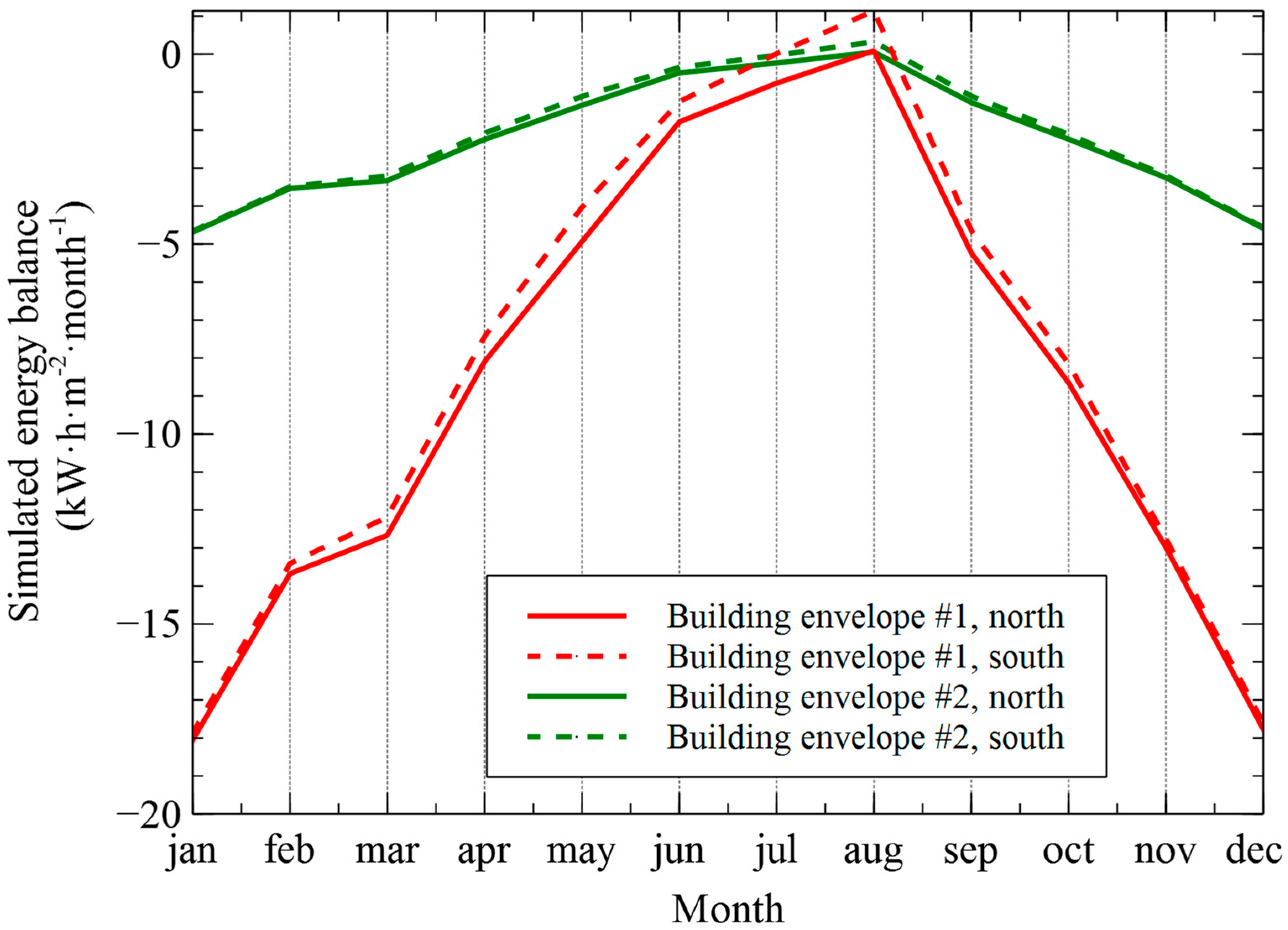

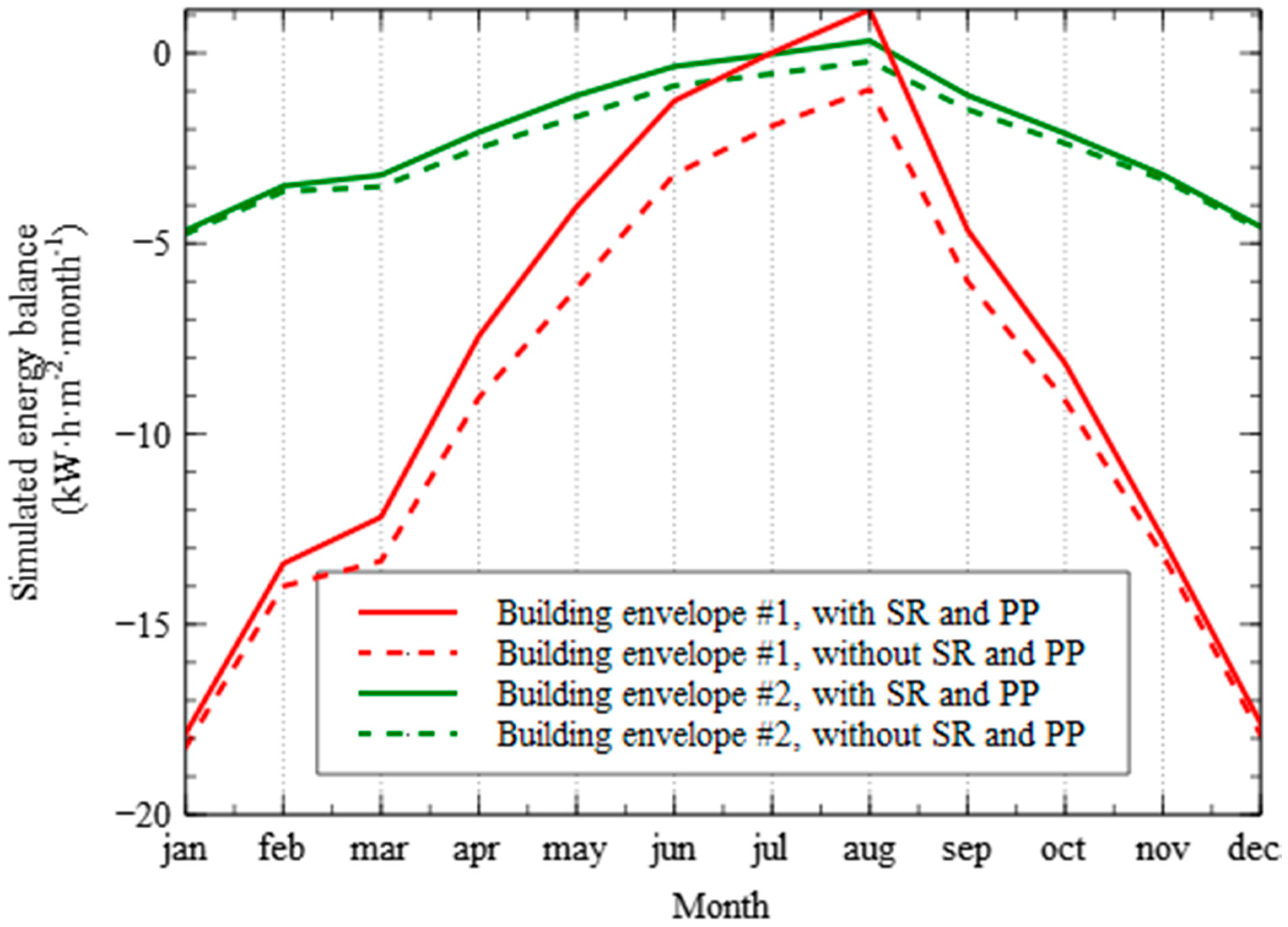

2.4. Assessment of Thermal Performance

2.5. Identification Procedure

3. Results

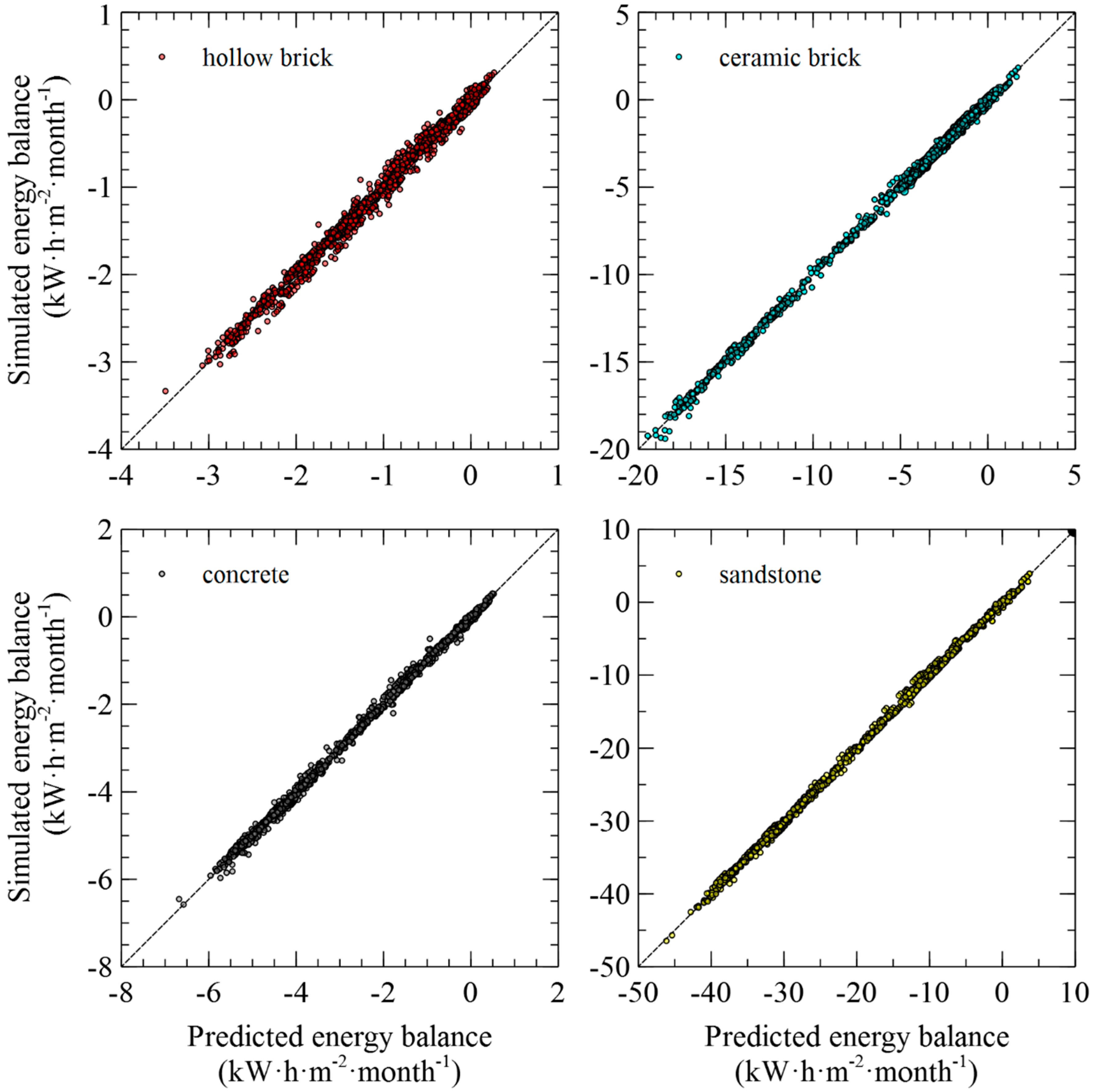

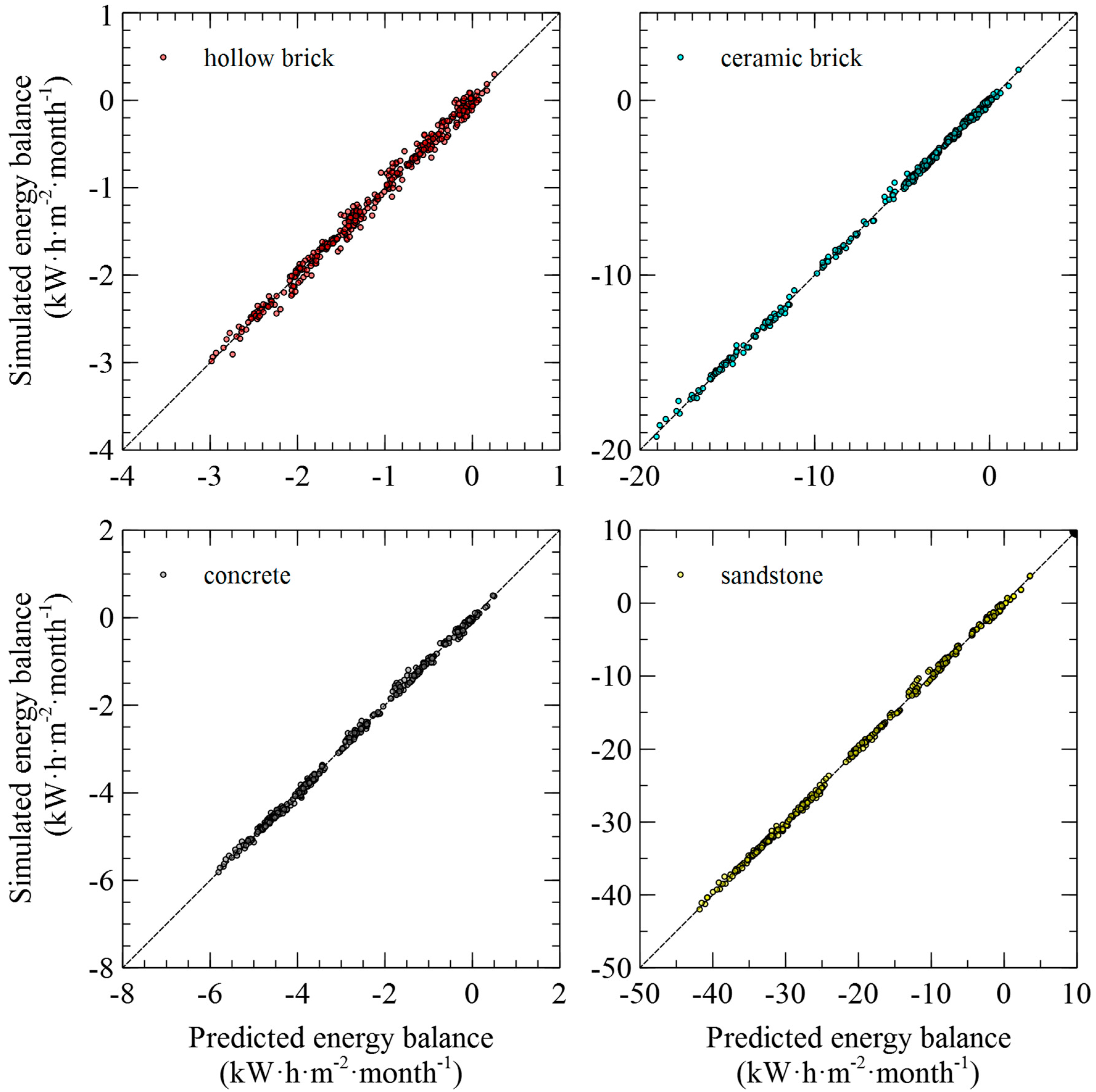

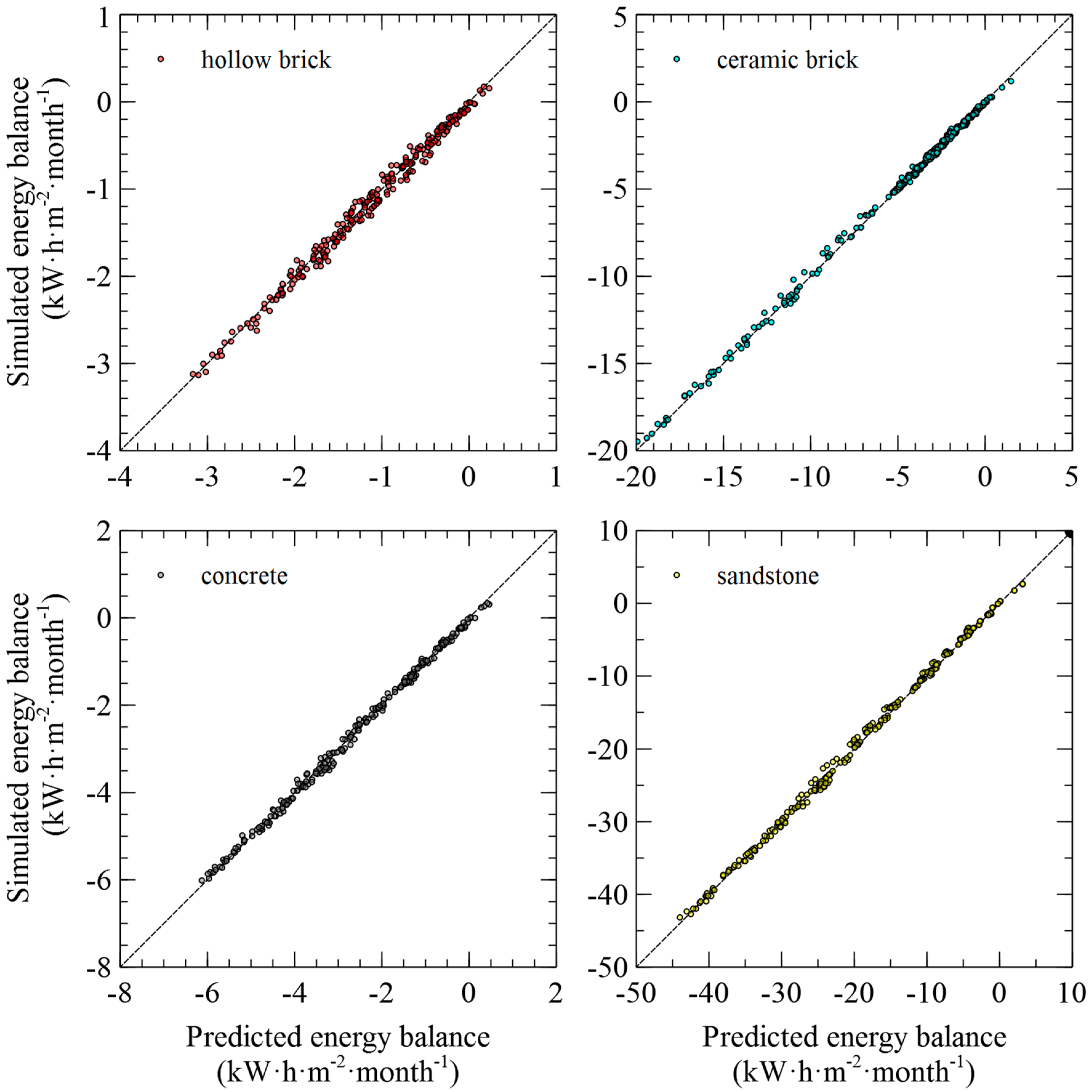

3.1. Identification Procedure

3.2. Verification Using Meteonorm Data

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Consumption of Energy. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Consumption_of_energy (accessed on 17 January 2018).

- Cansino, J.M.; Pablo-Romero, M.d.P.; Román, R.; Yniguez, R. Promoting renewable energy sources for heating and cooling in EU-27 countries. Energy Policy 2011, 39, 3803–3812. [Google Scholar] [CrossRef]

- ČSN 73 0540, Thermal Protection of Buildings—Part 3: Design Value Quantities; Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2005.

- UNE-EN 673 Glass in Building—Determination of Thermal Transmittance (U Value)—Calculation Method; Deutsches Institut für Normung: Berlin, Germany, 2011.

- BS EN ISO 10077-2, Thermal Performance of Windows, Doors and Shutters. Calculation of Thermal Transmittance; Numerical Method for Frames; British Standards Institution: London, UK, 2017.

- Caruana, C.; Yousif, C.; Bacher, P.; Buhagiar, S.; Grima, C. Determination of thermal characteristics of standard and improved hollow concrete blocks using different measurement techniques. J. Build. Eng. 2017, 13, 336–346. [Google Scholar] [CrossRef]

- EN ISO 8990:1994, Thermal Insulation—Determination of Steady State Thermal Transmission Properties—Calibrated and Guarded Hot Box; International Organization for Standardization: Geneva, Switzerland, 1994.

- ASTM C1363-11, Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus; ASTM International: West Conshohocken, PA, USA, 2011.

- ASHRAE Transactions 92, Thermal Resistance Measurements of Well-Insulated and Super Insulated Residential Walls Using a Calibrated Hotbox; ASHRAE Inc.: Atlanta, GA, USA, 1986; pp. 604–619.

- Szodrai, F.; Lakatos, A.; Kalmar, F. Analysis of the change of the specific heat loss coefficient of buildings resulted by the variation of the geometry and the moisture load. Energy 2016, 115, 820–829. [Google Scholar] [CrossRef]

- Jerman, M.; Černý, R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Khan, M.I. Factors affecting the thermal properties of concrete and applicability of its prediction models. Build. Environ. 2002, 37, 607–614. [Google Scholar] [CrossRef]

- Byrne, A.; Byrne, G.; Davies, A.; Robinson, A.J. Transient and quasi-steady thermal behaviour of a building envelope due to retrofitted cavity wall and ceiling insulation. Energy Build. 2013, 61, 356–365. [Google Scholar] [CrossRef]

- Marchio, D.; Rabl, A. Energy-efficient gas-heated housing in France: Predicted and observed performance. Energy Build. 1991, 17, 131–139. [Google Scholar] [CrossRef]

- Branco, G.; Lachal, B.; Callinelli, P.; Weber, W. Predicted versus observed heat consumption of a low energy multifamily complex in Switzerland based on long-term experimental data. Energy Build. 2004, 36, 543–555. [Google Scholar] [CrossRef]

- Roels, S.; Bacher, P.; Bauwens, G.; Castano, S.; Jiménez, M.J.; Madsen, H. On site characterisation of the overall heat loss coefficient: Comparison of different assessment methods by a blind validation exercise on a round robin test box. Energy Build. 2017, 153, 179–189. [Google Scholar] [CrossRef]

- Ficco, G.; Iannetta, F.; Ianniello, E.; Romana d’Ambrosio Alfano, F.; Dell’sola, M. U-value in situ measurement for energy diagnosis of existing buildings. Energy Build. 2015, 104, 108–121. [Google Scholar] [CrossRef]

- Robinson, A.J.; Lesage, F.J.; Reilly, A.; McGranaghan, G.; Byrne, G.; O’Hegarty, R.; Kinnane, O. A new transient method for determining thermal properties of wall section. Energy Build. 2017, 142, 139–146. [Google Scholar] [CrossRef]

- Byrne, A.; Byrne, G.; Robinson, A. Compact facility for testing steady and transient thermal performanceof building walls. Energy Build. 2017, 152, 602–614. [Google Scholar] [CrossRef]

- Perilli, S.; Sfarra, S.; Guerrini, M.; Bisegna, F.; Ambrosini, D. The thermophysical behaviour of cork supports doped with an innovative thermal insulation and protective coating: A numerical analysis based on in situ experimental data. Energy Build. 2018, 159, 508–528. [Google Scholar] [CrossRef]

- O’Grady, M.; Lechowska, A.A.; Harte, A.M. Quantification of heat losses through building envelope thermal bridges influenced by wind velocity using the outdoor infrared thermography technique. Appl. Energy 2017, 208, 1038–1052. [Google Scholar] [CrossRef]

- Olofsson, T.; Andersson, S. Overall heat loss coefficient and domestic energy gain factor for single-family buildings. Build. Environ. 2002, 37, 1019–1026. [Google Scholar] [CrossRef]

- Liu, Y.; Harris, D.J. Full-scale measurements of convective coefficient on external surface of a low-rise building in sheltered conditions. Energy Build. 2007, 42, 2718–2736. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Srinivasan, R.S.; Shi, J. Artificial Intelligent Models for Improved Prediction of Residential Space Heating. J. Energy Eng. 2016, 142, 04016006. [Google Scholar] [CrossRef]

- Meteonorm, Version 6.0, Software Version 6.1.0.20 from April 2010; Meteotest: Bern, Switzerland, 2010.

- Bilbao, J.; Miguel, A.; Franco, J.A.; Ayuso, A. Test Reference Year Generation and Evaluation Methods in the Continental Mediterranean Area. J. Appl. Meteorol. 2004, 43, 390–400. [Google Scholar] [CrossRef]

- Kalamees, T.; Kurnitski, J. Estonian test reference year for energy calculations. Proc. Estonian Acad. Sci. Eng. 2006, 12, 40–58. [Google Scholar]

- Lee, K.; Yoo, H.; Levermore, G.J. Generation of typical weather data using the ISO Test Reference Year (TRY) method for major cities of South Korea. Build. Environ. 2010, 45, 956–963. [Google Scholar] [CrossRef]

- Künzel, H.M. Simultaneous Heat and Moisture Transport in Building Components. Ph.D. Thesis, IRB Verlag, Stuttgart, Germany, 1995. [Google Scholar]

- Maděra, J.; Kočí, J.; Kočí, V.; Kruis, J. Parallel modelling of hygrothermal performance of external wall made of highly perforated bricks. Adv. Eng. Softw. 2017, 113, 47–53. [Google Scholar] [CrossRef]

- Kruis, J.; Koudelka, T.; Krejčí, T. Efficient computer implementation of coupled hydro-thermo-mechanical analysis. Math. Comput. Simul. 2010, 80, 1578–1588. [Google Scholar] [CrossRef]

- Kočí, V.; Kočí, J.; Maděra, J.; Pavlík, Z.; Gu, X.; Zhang, W.; Černý, R. Thermal and hygric assessment of an inside-insulated brick wall: 2D critical experiment and computational analysis. J. Build. Phys. 2018, 41, 497–520. [Google Scholar] [CrossRef]

- Pavlík, Z.; Fiala, L.; Vejmelková, E.; Černý, R. Application of Effective Media Theory for Determination of Thermal Properties of Hollow Bricks as a Function of Moisture Content. Int. J. Thermophys. 2013, 34, 894–908. [Google Scholar] [CrossRef]

- Čáchová, M.; Koňáková, D.; Vejmelková, E.; Keppert, M.; Polozhiy, K.; Černý, R. Pore Structure and Thermal Characteristics of Clay Bricks. Adv. Mater. Res. 2014, 982, 104–107. [Google Scholar] [CrossRef]

- Vejmelková, E.; Pavlíková, M.; Keppert, M.; Keršner, Z.; Rovnaníková, P.; Ondráček, M.; Sedlmajer, M.; Černý, R. High performance concrete with Czech metakaolin: Experimental analysis of strength, toughness and durability characteristics. Constr. Build. Mater. 2010, 24, 1404–1411. [Google Scholar] [CrossRef]

- Kočí, V.; Maděra, J.; Fořt, J.; Žumár, J.; Pavlíková, M.; Pavlík, Z.; Černý, R. Service Life Assessment of Historical Building Envelopes Constructed Using Different Types of Sandstone: A computational Analysis Based on Experimental Input Data. Sci. World J. 2014, 2014, 802509. [Google Scholar] [CrossRef]

- Jiřičková, M.; Černý, R. Effect of hydrophilic admixtures on moisture and heat transport and storage parameters of mineral wool. Constr. Build. Mater. 2006, 20, 425–434. [Google Scholar] [CrossRef]

- Kočí, V.; Maděra, J.; Jerman, M.; Žumár, J.; Koňáková, D.; Čáchová, M.; Vejmelková, E.; Reiterman, P.; Černý, R. Application of waste ceramic dust as a ready-to-use replacement of cement in lime-cement plasters: An environmental-friendly and energy-efficient solution. Clean Technol. Environ. Policy 2016, 18, 1725–1733. [Google Scholar] [CrossRef]

- Vejmelková, E.; Keppert, M.; Keršner, Z.; Rovnaníková, P.; Černý, R. Mechanical, fracture-mechanical, hydric, thermal, and durability properties of lime-metakaolin plasters for renovation of historical buildings. Constr. Build. Mater. 2012, 31, 22–28. [Google Scholar] [CrossRef]

| Location (Elevation) | Location (Elevation) | Location (Elevation) |

|---|---|---|

| 1 Bělotín (306 m) | 23 Pec p. Sněžkou (816 m) | 45 Kocelovice (519 m) |

| 2 Bílá Třemošná (322 m) | 24 Praha–Karlov (261 m) | 46 Kuchařovice (334 m) |

| 3 Brod nad Dyjí (177 m) | 25 Přerov (210 m) | 47 Liberec (398 m) |

| 4 Čáslav (238 m) | 26 Přimda (743 m) | 48 Luka (510 m) |

| 5 Červená (748 m) | 27 Smolenice (345 m) | 49 Lysá Hora (1322 m) |

| 6 České Budějovice (394 m) | 28 Stříbro (412 m) | 50 Ostrava (253 m) |

| 7 Doksany (158 m) | 29 Šerák (1328 m) | 51 Praha–Ruzyně (364 m) |

| 8 Domažlice (458 m) | 30 Svratouch (734 m) | 52 Přibyslav (533 m) |

| 9 Dukovany (400 m) | 31 Tábor (459 m) | 53 Ústí n. Labem (375 m) |

| 10 Harrachov (675 m) | 32 Temelín (500 m) | 54 Horní Bečva (565 m) |

| 11 Heřmanův Městec (275 m) | 33 Tuhaň (160 m) | 55 Úpice (413 m) |

| 12 Holenice (432 m) | 34 Tušimice (322 m) | 56 Šumperk (328 m) |

| 13 Holešov (222 m) | 35 Ústí nad Orlicí (402 m) | 57 Krušovice (379 m) |

| 14 Cheb (483 m) | 36 Val. Klobouky (160 m) | 58 Mladá Boleslav (221 m) |

| 15 Ivanovice na Hané (243 m) | 37 Velké Meziříčí (452 m) | 59 Filipova Huť (1110 m) |

| 16 Jindřichův Hradec (524 m) | 38 Vír (473 m) | 60 Bečov n. Teplou (535 m) |

| 17 Košetice (534 m) | 39 Zbiroh (476 m) | 61 Hustopeče (201 m) |

| 18 Kostelní Myslová (569 m) | 40 Železná Ruda (866 m) | 62 Kestřany (381 m) |

| 19 Měděnec (828 m) | 41 Brno–Tuřany (241 m) | 63 Slaný (307 m) |

| 20 Most (240 m) | 42 Hradec Králové (230 m) | 64 Město Albrechtice (498 m) |

| 21 Nepomuk (471 m) | 43 Churáňov (866 m) | |

| 22 Olomouc (215 m) | 44 Karlovy Vary (603 m) |

| Building Env. | Load-Bearing Material | Thermal Insulation (100 mm) | Plaster (10 mm) |

|---|---|---|---|

| 1 | Ceramic brick (450 mm) | N/A | LC plaster |

| 2 | Ceramic brick (450 mm) | Expanded polystyrene | LC plaster |

| 3 | Ceramic brick (450 mm) | Mineral wool | LC plaster |

| 4 | Concrete (300 mm) | Expanded polystyrene | LC plaster |

| 5 | Concrete (300 mm) | Mineral wool | LC plaster |

| 6 | Advanced hollow brick (500 mm) | N/A | LPC plaster |

| 7 | Advanced hollow brick (500 mm) | Expanded polystyrene | LPC plaster |

| 8 | Sandstone (800 mm) | N/A | N/A |

| 9 | Sandstone (800 mm) | N/A | RPHM |

| Material Parameter | AHB | CB | C | S |

|---|---|---|---|---|

| ρv (kg·m−3) | 1389 | 1831 | 2380 | 2191 |

| ρmat (kg·m−3) | 2830 | 2581 | 2715 | 2668 |

| ψ (%) | 50.9 | 27.9 | 12.3 | 17.9 |

| λ (W·m−1·K−1) | 0.084 | 0.59 | 1.66 | 2.77 |

| c (J·kg−1·K−1) | 1052 | 825 | 672 | 628 |

| μdry-cup (–) | 12.8 | 22.1 | 15.8 | 11.6 |

| Material Parameter | MW | EPS | LC | LPC | RPHM |

|---|---|---|---|---|---|

| ρv (kg·m−3) | 70 | 16.5 | 1244 | 1713 | 1637 |

| ρmat (kg·m−3) | 2260 | 1020 | 2480 | 2658 | 2478 |

| ψ (%) | 96.9 | 98.4 | 49.8 | 35.6 | 33.9 |

| λ (W·m−1·K−1) | 0.356 | 0.037 | 0.30 | 0.669 | 0.664 |

| c (J·kg−1·K−1) | 810 | 1570 | 1054 | 831 | 922 |

| μ (–) | 2.62 | 58.00 | 7.52 | 27.26 | 23.6 |

| Material | Reference |

|---|---|

| Advanced hollow brick | [33] |

| Ceramic brick | [34] |

| Concrete | [35] |

| Sandstone | [36] |

| Mineral wool | [37] |

| Expanded polystyrene | [11] |

| Lime-cement plaster | [38] |

| Lime-pozzolan plaster | [38] |

| Renovation plaster for historical masonry | [39] |

| BE# | c0 | c1 | c2 | c3 | % Error | R2 |

|---|---|---|---|---|---|---|

| 1 | −14144.67 | 809.76 | −16.21 | 0.2373 | 2.04 | 0.9985 |

| 2 | −4333.37 | 215.39 | 3.61 | 0.0716 | 3.27 | 0.9962 |

| 3 | −4232.08 | 212.14 | 3.62 | −0.0126 | 3.87 | 0.9948 |

| 4 | −4921.03 | 251.87 | 1.85 | 0.0830 | 1.70 | 0.9990 |

| 5 | −5538.32 | 254.04 | 10.81 | 0.0131 | 2.85 | 0.9968 |

| 6 | −2929.06 | 133.68 | 5.68 | 0.0334 | 4.57 | 0.9926 |

| 7 | −2367.72 | 94.08 | 8.34 | 0.0040 | 6.43 | 0.9852 |

| 8 | −31272.49 | 1782.25 | −35.56 | 0.7538 | 1.63 | 0.9991 |

| 9 | −30679.90 | 1747.26 | −33.68 | 0.5970 | 1.69 | 0.9990 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kočí, J.; Kočí, V.; Černý, R. A Method for Rapid Evaluation of Thermal Performance of Wall Assemblies Based on Geographical Location. Energies 2019, 12, 1353. https://doi.org/10.3390/en12071353

Kočí J, Kočí V, Černý R. A Method for Rapid Evaluation of Thermal Performance of Wall Assemblies Based on Geographical Location. Energies. 2019; 12(7):1353. https://doi.org/10.3390/en12071353

Chicago/Turabian StyleKočí, Jan, Václav Kočí, and Robert Černý. 2019. "A Method for Rapid Evaluation of Thermal Performance of Wall Assemblies Based on Geographical Location" Energies 12, no. 7: 1353. https://doi.org/10.3390/en12071353

APA StyleKočí, J., Kočí, V., & Černý, R. (2019). A Method for Rapid Evaluation of Thermal Performance of Wall Assemblies Based on Geographical Location. Energies, 12(7), 1353. https://doi.org/10.3390/en12071353