Optimal Operation Strategies into Deregulated Markets for 50 MWe Parabolic Trough Solar Thermal Power Plants with Thermal Storage

Abstract

1. Introduction

2. Materials and Methods

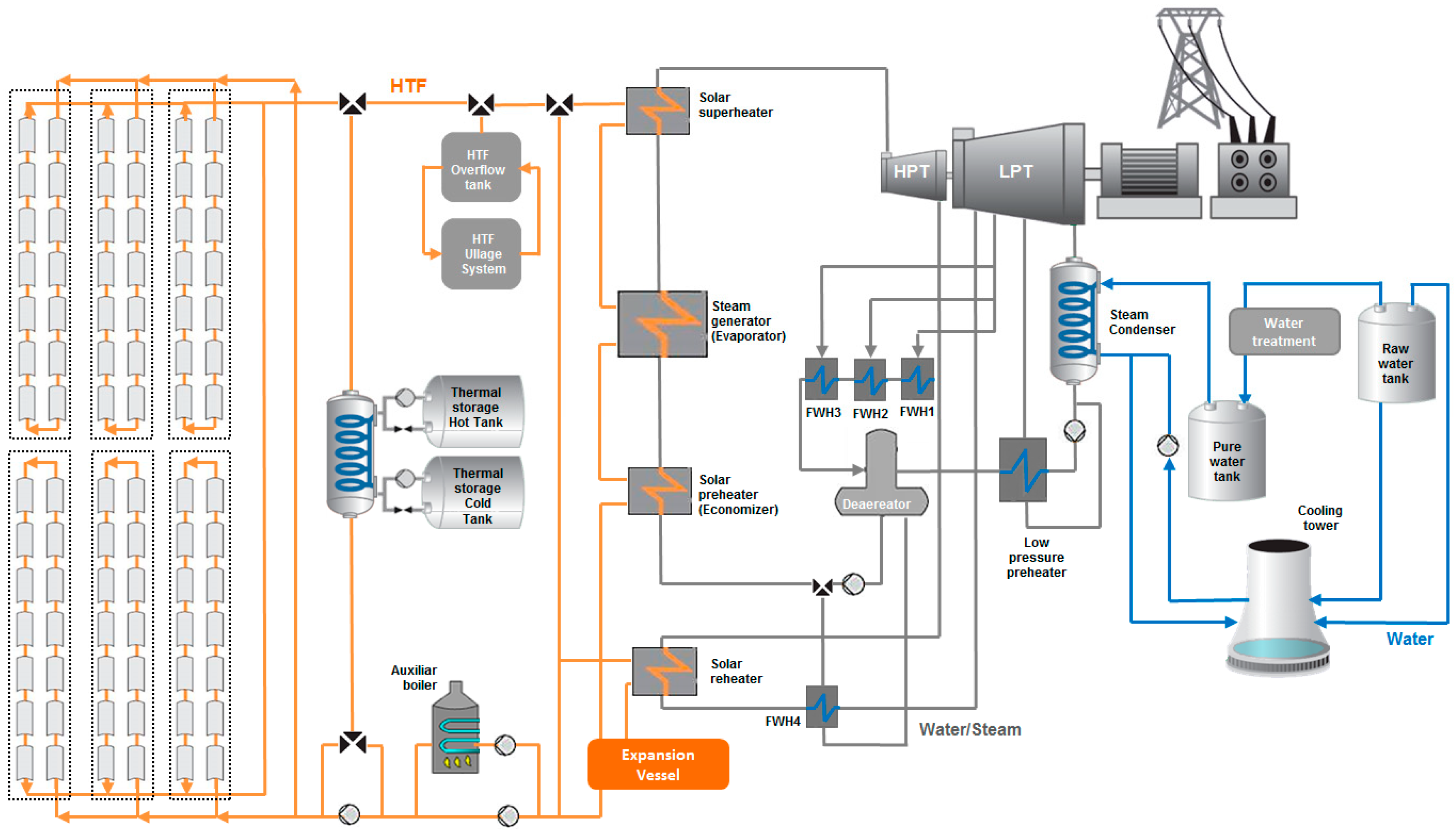

2.1. Solar Thermal Power Plant and Thermal Energy Management

2.1.1. Solar Field and Heat Transfer Fluid (HTF)

2.1.2. Thermal Storage System

2.1.3. Reference Values for the PT Plant Model

2.2. Mathematical Model and Optimization

2.2.1. Mathematical Simulation Model

2.2.2. Implementation of the Model in Real PT Plants

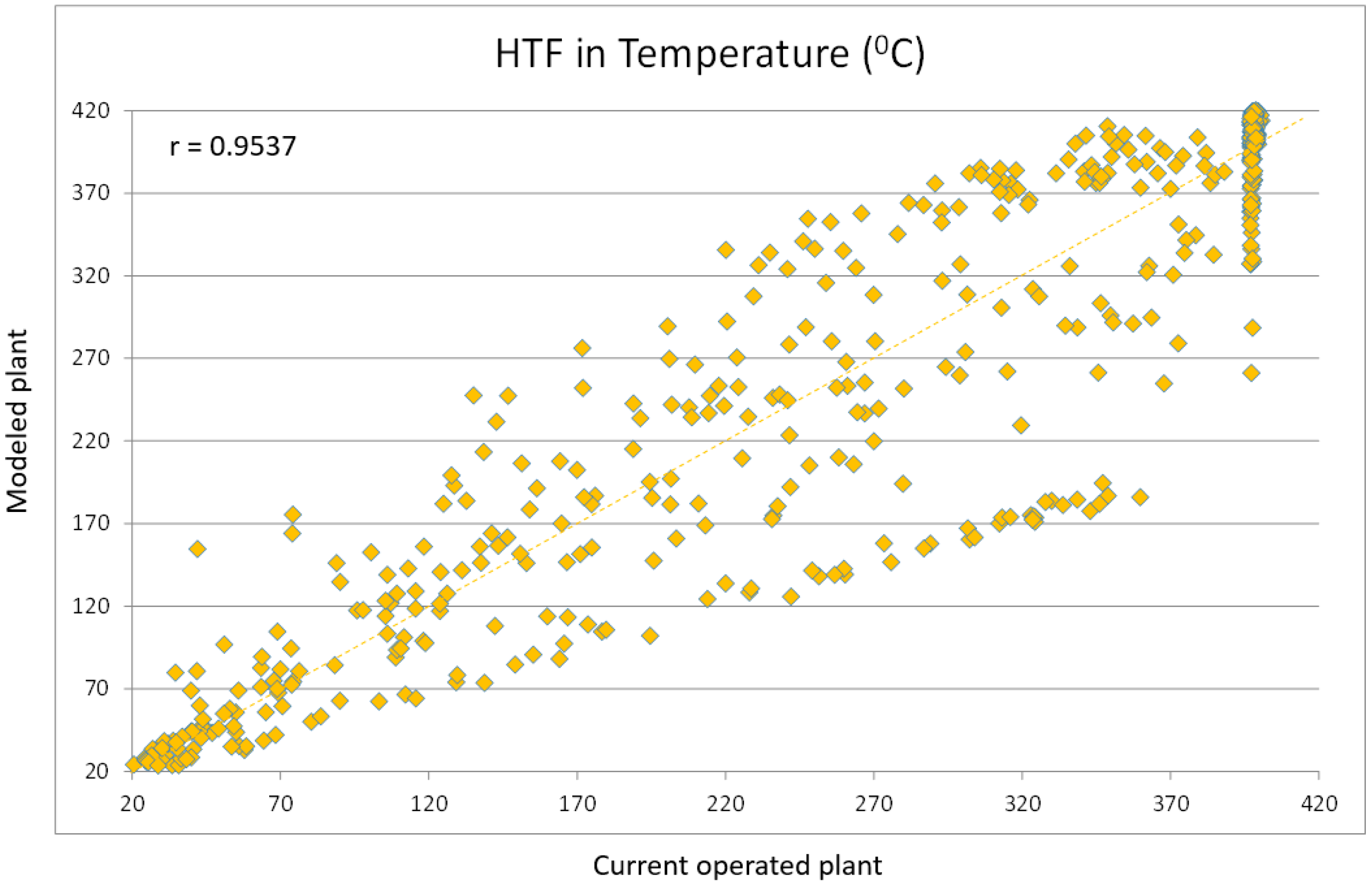

Calibration of the PT Solar Thermal Power Plant Model

Short Time Analysis

2.2.3. Economic Parameters

2.2.4. Electricity Generation Optimization Functions

Solar Field and Thermal Storage System

Electricity Supply to Power Grid

Objective Function, Power Limits, and Restrictions

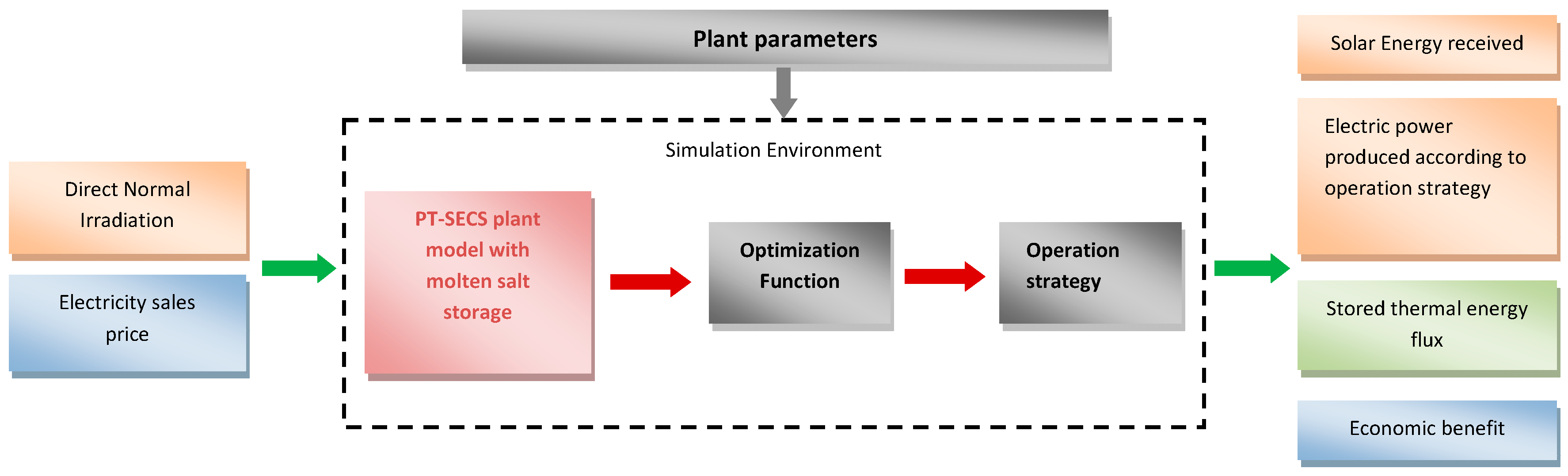

2.3. Simulation Environment and Model Implementation

3. Results

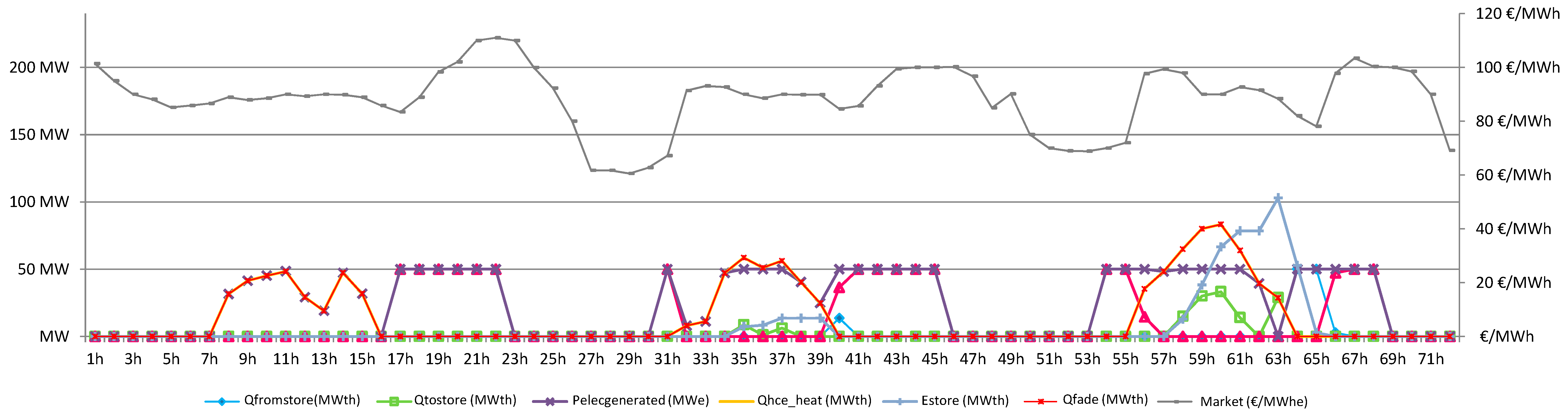

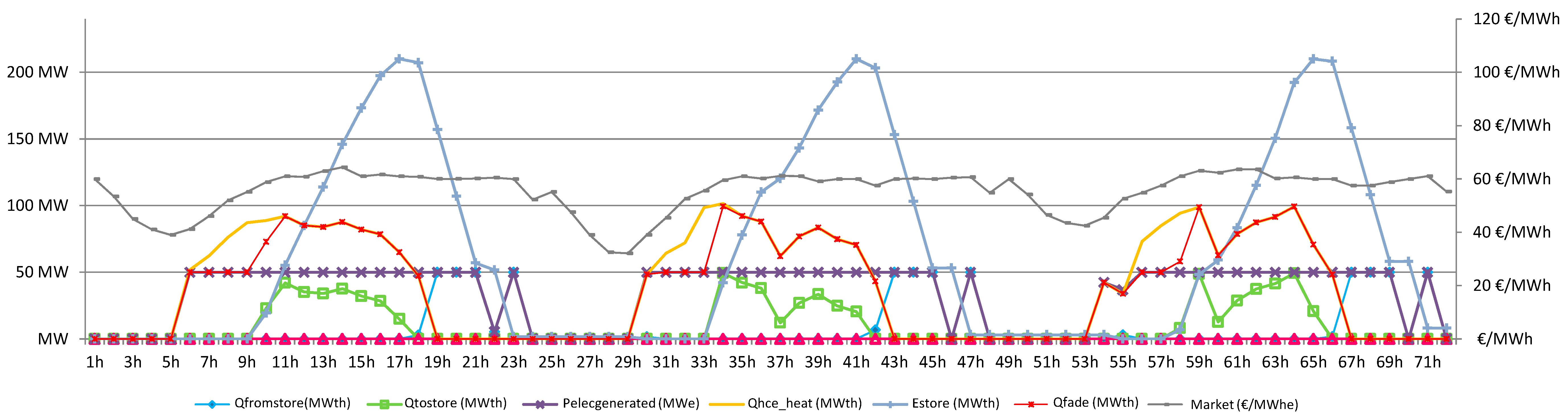

3.1. Optimization of the Daily Operation in Plant

3.2. Economical Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Solar parameters | |

| Real Collection surface for 50 MW solar thermal plant (m2) | |

| Thermal loses coefficient in solar field (%) | |

| Stored energy in period j (MWth) | |

| Minimum stored thermal energy in tanks (MWhth) | |

| Oversize of solar collection surface referred to the 50MW solar thermal plant without storage (%) | |

| Equivalent time of production of electricity under full load regime (h) | |

| Equivalent time of operation of the plant in annual period (h) | |

| Maximum stored energy in thermal tanks (equiv. hours of max. production (h)) | |

| Thermal flow from storage system to power block in period j (MWth) | |

| Thermal power to storage system in period j (MWth) | |

| Solar power received from the concentrators in the hour j (kWth) | |

| Reduction of radiation by fade out when production peaks occur (kWth) | |

| Electrical power generated in steam turbine for the period j (kWe) | |

| Nominal power in steam turbine (kWe) | |

| Min output power in power block (MWe) | |

| Gradient of power generation (MWe) | |

| Max slope of generation in power plant | |

| Maximum slope of thermal discharge or power off | |

| Nominal thermal energy received from the solar field (kWhth) | |

| Thermal energy input to the hot tank in period j (kWth) | |

| Thermal energy from the hot tank to the steam turbine in period j (kWth) | |

| Nominal thermal energy to the steam turbine (kWth) | |

| Thermal energy to the steam turbine in period j (kWth) | |

| Direct Normal Radiation as solar resource (kWhth/m2) | |

| Solar thermal efficiency (optical efficiency and loses in pumps and pipes (%) | |

| Storage load efficiency (%) | |

| Storage unload efficiency (%) | |

| Thermal-electrical conversion efficiency by design (%) | |

| Efficiency coefficient in power block (%) | |

| Coefficient of efficiency of thermal energy storage (%) | |

| Price of electricity in Spanish daily market (€/MWhe) | |

| Index | |

| Ct | Solar thermal field parameters |

| DM | Daily market |

| DTurbineGross | Design parameters for steam turbine |

| DWN | Discharge |

| HCE | Heat from the solar field |

| HEDFROMST | Heat from storage system |

| HEDTOST | Heat to storage system |

| Time, as variable | |

| Planning of operating period in hours | |

| Max | Maximum value |

| Min | Minimum value |

| Spill | Defocus factor |

| Up | Charge |

| Acronyms | |

| CS | Case Study |

| CF | Capacity Factor |

| DIPS | Delayed Intermediate Production System |

| DNI | Direct Normal Irradiance |

| HP | High Market Price |

| HSR | High solar Resource |

| HTF | Heat Transfer Fluid |

| LCOE | Levelized cost of energy |

| LP | Low Market price |

| LRS | Low Solar Resource |

| PLP | Peak Load Plant |

| PT | Parabolic Trough |

| SM | Solar Multiple |

| TGHP | Thermal Group Hourly Program |

References

- Llamas, J.; Bullejos, D.; Barranco, V.; de Adana, M.R. World location as associated factor for optimal operation model of Parabolic Trough Concentrating Solar Thermal Power Plants. In Proceedings of the IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; IEEE: Florence, Italy, 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Zervos, A. Renewables 2018 Global Status Report; REN21 Secretariat: Paris, France, 2018. [Google Scholar]

- Osório, G.J.; Lujano-Rojas, J.M.; Matias, J.C.O.; Catalão, J.P.S. A new scenario generation-based method to solve the unit commitment problem with high penetration of renewable energies. Int. J. Electr. Power Energy Syst. 2015, 64, 1063–1072. [Google Scholar] [CrossRef]

- Zsiborács, H.; Pintér, G.; Bai, A.; Popp, J.; Gabnai, Z.; Pályi, B.; Farkas, I.; Baranyai, N.; Gützer, C.; Trimmel, H.; et al. Comparison of Thermal Models for Ground-Mounted South-Facing Photovoltaic Technologies: A Practical Case Study. Energies 2018, 11, 1114. [Google Scholar] [CrossRef]

- Sioshanshi, R.; Denholm, P. The Value of Concentrating Solar Power and Thermal Energy Storage; Technical Report NREL-TP-6A2-45833; National Renewable Energy Laboratory: Golden, CO, USA, 2010.

- Wittman, M.E.; Eck, M.; Pitz-Paal, R.; Müller-Steinhagen, H. Methodology for optimized operation strategies of solar thermal power plants with integrated heat storage. Sol. Energy 2011, 85, 653–659. [Google Scholar] [CrossRef]

- Porras, M.; Serrano, E.; Wiesenberg, R. Optimization in the operation of a solar thermal power plant using the S2M solver 1.0 tool. In Proceedings of the 2010 Solar PACES Symposium, Perpignan, France, 21–24 September 2010. [Google Scholar]

- Usaola, J. Operation of concentrating solar power plants with storage in spot electricity markets. IET Renew. Power Gener. 2012, 6–1, 59–66. [Google Scholar] [CrossRef]

- Almasabi, A.; Alobaidli, A.; Zhang, T.J. Transient Characterization of Multiple Parabolic Trough Collector Loops in a 100 MW CSP Plant for Solar Energy Harvesting. Energy Procedia 2015, 69, 24–33. [Google Scholar] [CrossRef]

- Habib, L.; Hassan, M.I.; Shatilla, Y. A Realistic Numerical Model of Lengthy Solar Thermal Receivers Used in Parabolic Trough CSP Plants. Energy Procedia 2015, 75, 473–478. [Google Scholar] [CrossRef]

- García de Jalón, A.; Pérez, D.; Benito, P.; Zaversky, F. Inspection Receiver Tubes Device for CSP Plants. Energy Procedia 2015, 69, 1868–1876. [Google Scholar] [CrossRef]

- Boudaoud, S.; Khellaf, A.; Mohammedi, K.; Behar, O. Thermal performance prediction and sensitivity analysis for future deployment of molten salt cavity receiver solar power plants in Algeria. Energy Convers. Manag. 2015, 89-02, 655–664. [Google Scholar] [CrossRef]

- Enjavi-Arsanjani, M.; Hirbodi, K.; Yaghoubi, M. Solar Energy Potential and Performance Assessment of CSP Plants in Different Areas of Iran. Energy Procedia 2015, 69, 2039–2048. [Google Scholar] [CrossRef]

- Zarza, E. Generación directa de vapor con colectores solares cilindro parabólicos. Proyecto DIrect Solar Steam (DISS). Ph.D. Thesis, Universidad de Sevilla, Seville, Spain, 2002. [Google Scholar]

- Kelly, B. Thermal Storage Commercial Plant Design Study for a 2-Tank Indirect Molten Slat System; Report No. NREL/SR-550-40166; National Renewable Energy Laboratory: Golden, CO, USA, 2006.

- Bullejos, D.; Llamas, J.; De Adana, M.R. Spanish regulated scenarios for renewable energy and CSP plants. Arpn J. Eng. Appl. Sci. 2015, 10, 7217–7222. [Google Scholar]

- Turchi, C. Parabolic Trough Reference Plant for Cost Modeling with the Solar Advisor Model (SAM); Technical Report NREL/TP-550-47605; National Renewable Energy Laboratory: Golden, CO, USA, 2010.

- Blake, D. Overview on Use of a Molten Salt HTF in a Trough Solar Field. In Proceedings of the NREL: Parabolic Trough Thermal Energy Storage Workshop, Golden, CO, USA, 20–21 February 2003. [Google Scholar]

- Llamas, J.; Bullejos, D.; Ruiz de Adana, M. Techno-Economic Assessment of Heat Transfer Fluid Buffering for Thermal Energy Storage in the Solar Field of Parabolic Trough Solar Thermal Power Plants. Energies 2017, 10, 1123. [Google Scholar] [CrossRef]

- Operador del Mercado (Ibérico) de Electricidad (OMEL/OMIE). Available online: http://www.omel.es (accessed on 8 January 2019).

- Eutech Scientific Engineering. Thermolib User Manual. Available online: https://www.thermolib.de/media/thermolib/downloads/Thermolib-UserManual.pdf (accessed on 24 August 2015).

- Mathworks. The Mathwork, SymPowerSystems 5. Available online: http://www.mathworks.com. (accessed on 28 February 2019).

- Castronuovo, E. Optimization Advances in Electric Power Systems; Nova Science Publishers Inc.: New York, NY, USA, 2008; ISBN 978-1-60692-613-0. [Google Scholar]

- International Energy Agency Technology Roadmap. Concentrating Solar Power. Available online: http://www.iea.org (accessed on 11 December 2018).

- Kalogirou, S. Solar Energy Engineering: Processes and Systems; Elsevier Inc.: Burlington, MA, USA, 2009; ISBN 978-0-12-374501-9. [Google Scholar]

- Soleymani, S.; Ranjbar, A.M.; Shirani, A.R. Strategic bidding of generating units in competitive electricity market with considering their reliability. Electr. Power Energy Syst. 2008, 30, 193–201. [Google Scholar] [CrossRef]

- Union, E. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. Eur. Parliam. Off. J. 2009, 5, 2009. [Google Scholar]

| Solar Field | ||

| PT Collectors | Units | 624 |

| Total collectors’ surface | m2 | 475438 |

| Solar Multiple | - | 2 |

| Solar-thermal efficiency () | % | 51.6 |

| Solar field loses | % | <1 |

| Operation average temperatures | °C | 260–393 |

| Solar field input temperature | °C | 293 |

| Solar field output temperature | °C | 393 |

| Pressure in checkpoints | ||

| Thermal fluid pumps output | bar | 15.30 |

| Solar field input | bar | 14–28 |

| Solar field output | bar | 10–15 |

| Steam generation system input/output | bar | 393/293 |

| Molten salt exchange input/output | bar | 293–380 |

| Yearly received thermal energy | MWhth | 1090000 |

| Total thermal energy collected by the HTF system | MWhth | 465000 |

| Collectors thermal efficiency | % | 43 |

| Total average efficiency | % | 16 |

| Thermal Storage (Double Tank of Molten Salt) | ||

| Total storage capacity | MWhth | 1010 |

| Storage efficiency () | % | 98 |

| Storage recovery efficiency () | % | 97 |

| Steam Turbine. Single Recirculation, 4 Steam Extractions | ||

| Nominal electric power | MWe | 49.9 |

| Residual loses | MWe | 5.0 |

| Efficiency () | % | 99 |

| Net energy production | MWhe | 160000 |

| Input steam to turbine | bar | 100 (370°C) |

| Recirculation | bar | 16.5 (370°C) |

| Steam nominal flux | kg/s | 59 |

| Scenario CS[SR][ME] | Solar Resource Availability [Low DNI; High DNI] | Market of Electricity Behavior [Low price; High price] |

|---|---|---|

| CS[LSR][LP] | LSR | LP |

| CS[LSR][HP] | LSR | HP |

| CS[HSR][LP] | HSR | LP |

| CS[HSR][HP] | HSR | HP |

| Scenario | Generated Energy (MWhe) | Auxiliary Energy Needed (MWhth) |

|---|---|---|

| CS [LSR][LP] | 920.82 | 0.0 |

| CS [LSR][HP] | 2061.31 | 898.20 |

| CS [HSR][LP] | 2716.69 | 0.0 |

| CS [HSR][HP] | 2734.02 | 0.0 |

| Scenario | Generated energy (MWhe) | ||

|---|---|---|---|

| Direct Algebraical Results | Optimized REsults | ∆ | |

| CS [LSR][LP] | 873.23 | 920.82 | 5.45% |

| CS [LSR][HP] | 1912.69 | 2061.31 | 7.77% |

| CS [HSR][LP] | 2505.02 | 2716.69 | 8.45% |

| CS [HSR][HP] | 2534.55 | 2734.02 | 7.87% |

| Scenario | Sales Incomings Gross in Spanish Market (€) | Improved Incomings Gross in Spanish Market (€) | Sales Incomings Improvement (%) |

|---|---|---|---|

| CS[LSR][LP] | 20373.68 | 21426.99 | 5.17% |

| CS[LSR][HP] | 169714.86 | 181951.30 | 7.21% |

| CS[HSR][LP] | 84295.88 | 90862.52 | 7.79% |

| CS[HSR][HP] | 111104.39 | 119215.01 | 7.30% |

| Scenario | Generated Energy (MWhe) | Optimization of Generation (%) | Improved Incomings Gross in Spanish Market (€) | Sales Incomings Improvement (%) |

|---|---|---|---|---|

| CS[LSR][LP] | 920.82 | 5.45% | 21426.99 | 5.17% |

| CS[LSR][HP] | 2061.31 | 7.77% | 181951.30 | 7.21% |

| CS[HSR][LP] | 2716.69 | 8.45% | 90862.52 | 7.79% |

| CS[HSR][HP] | 2734.02 | 7.87% | 119215.01 | 7.30% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llamas, J.M.; Bullejos, D.; Ruiz de Adana, M. Optimal Operation Strategies into Deregulated Markets for 50 MWe Parabolic Trough Solar Thermal Power Plants with Thermal Storage. Energies 2019, 12, 935. https://doi.org/10.3390/en12050935

Llamas JM, Bullejos D, Ruiz de Adana M. Optimal Operation Strategies into Deregulated Markets for 50 MWe Parabolic Trough Solar Thermal Power Plants with Thermal Storage. Energies. 2019; 12(5):935. https://doi.org/10.3390/en12050935

Chicago/Turabian StyleLlamas, Jorge M., David Bullejos, and Manuel Ruiz de Adana. 2019. "Optimal Operation Strategies into Deregulated Markets for 50 MWe Parabolic Trough Solar Thermal Power Plants with Thermal Storage" Energies 12, no. 5: 935. https://doi.org/10.3390/en12050935

APA StyleLlamas, J. M., Bullejos, D., & Ruiz de Adana, M. (2019). Optimal Operation Strategies into Deregulated Markets for 50 MWe Parabolic Trough Solar Thermal Power Plants with Thermal Storage. Energies, 12(5), 935. https://doi.org/10.3390/en12050935