Fuzzy Rule-Based and Particle Swarm Optimisation MPPT Techniques for a Fuel Cell Stack

Abstract

1. Introduction

- Higher power efficiency;

- Noise-free operation;

- Less maintenance requirement;

- Economical, as it does not need any fossil fuel for its operation.

2. System Modelling

2.1. PEMFC Characteristics

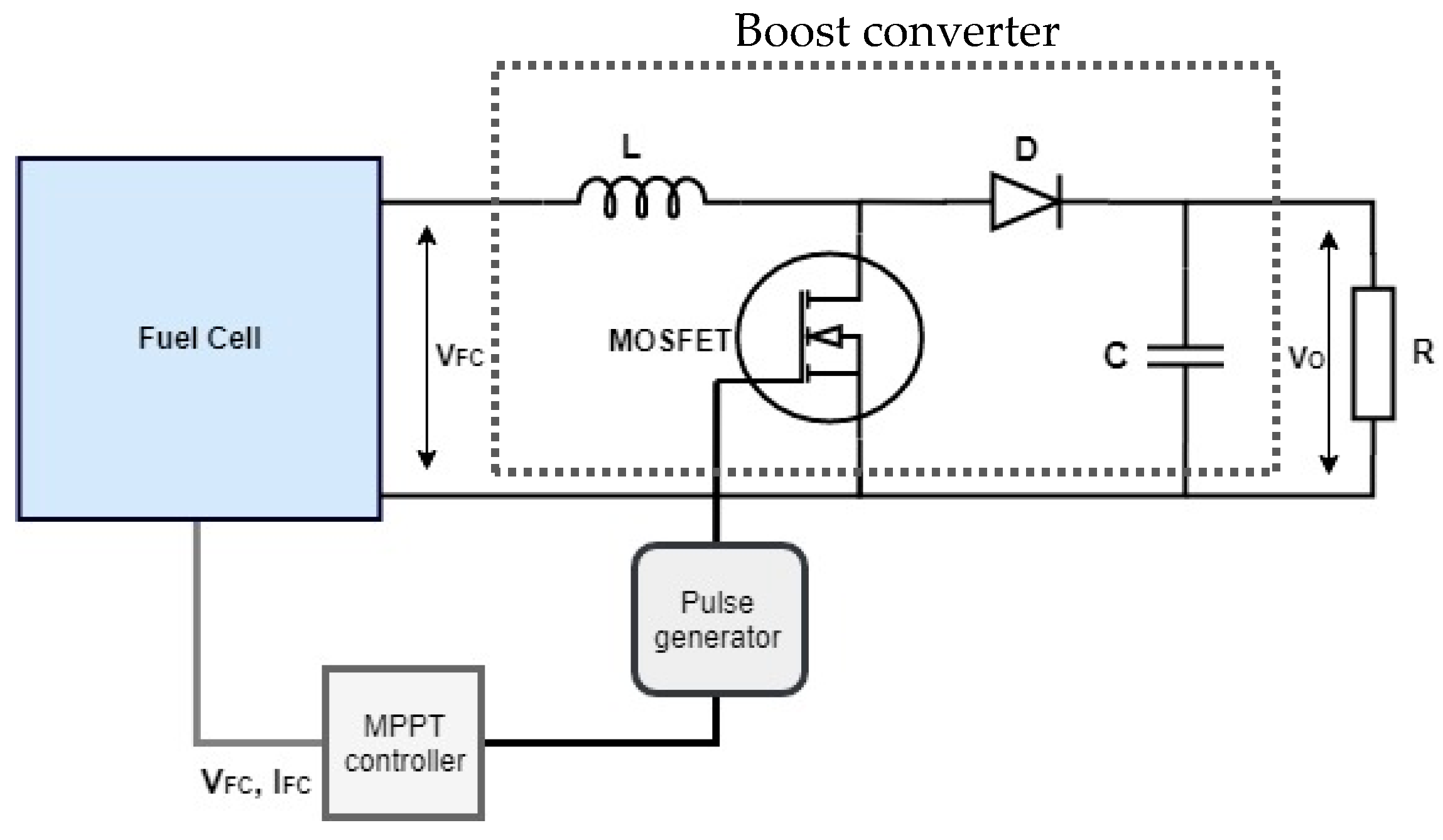

2.2. DC-to-DC Converter

3. Maximum Power Point Tracking Controllers Design

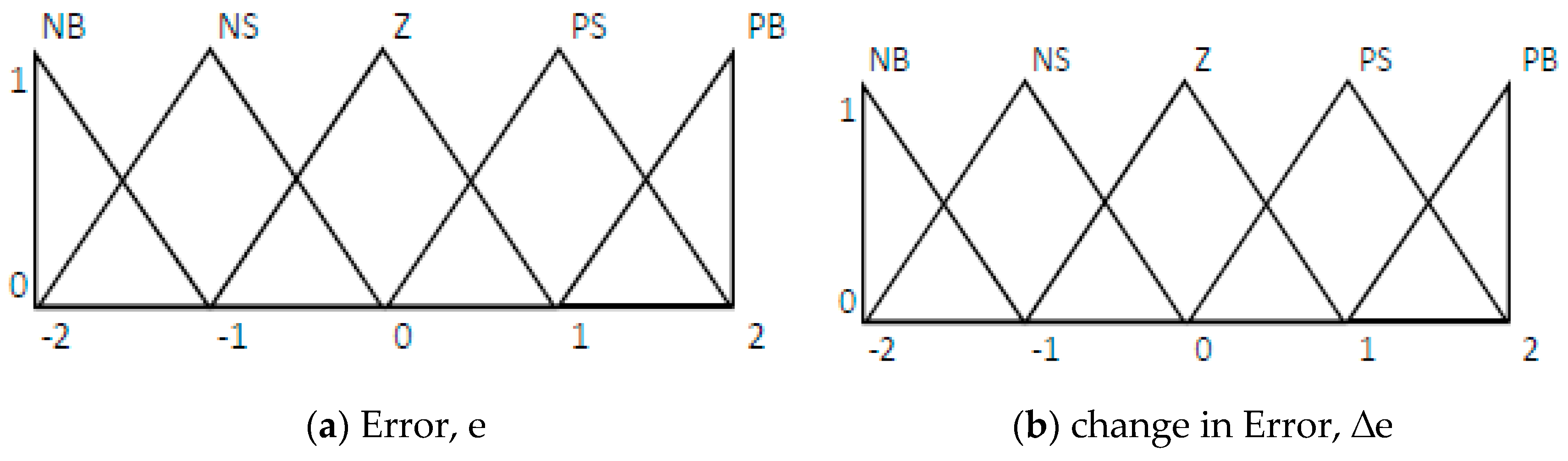

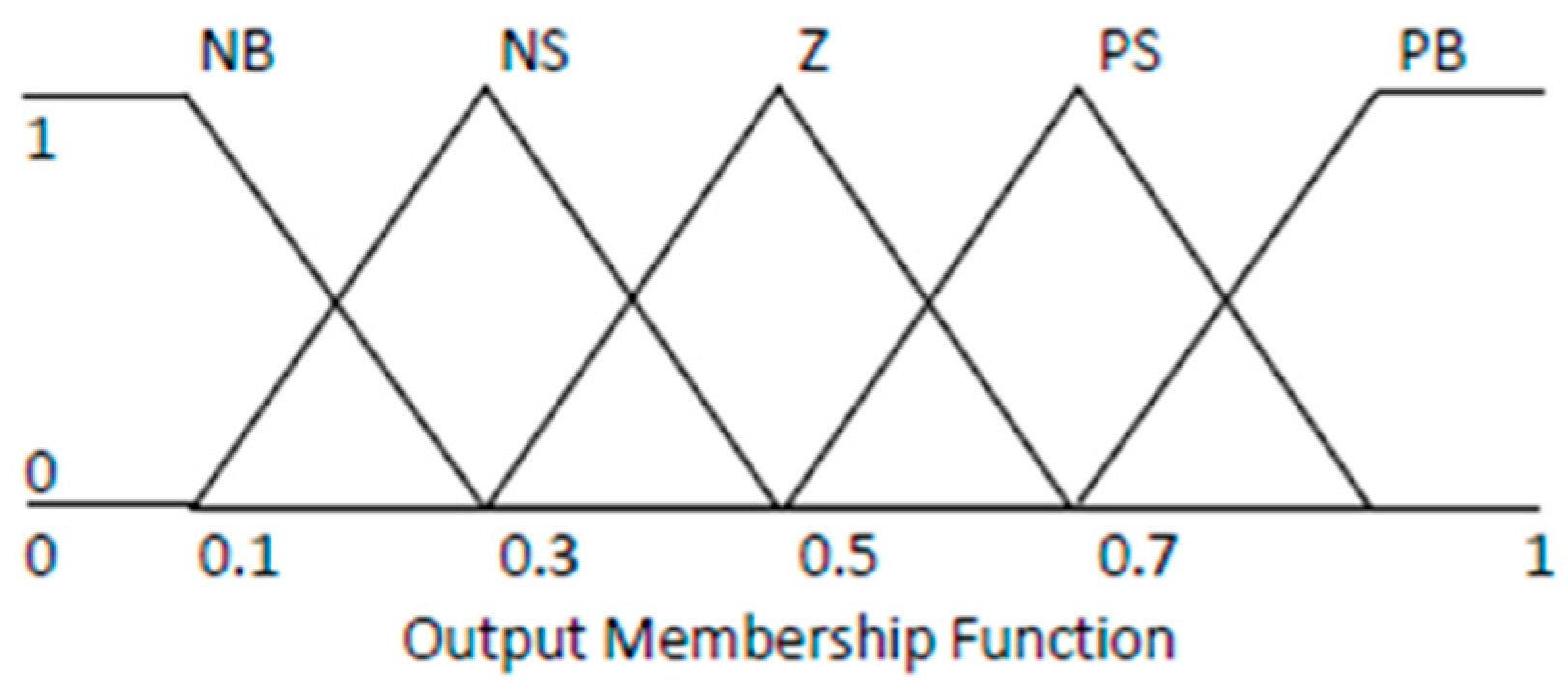

3.1. Mamdani Fuzzy Inference MPPT Controller Design

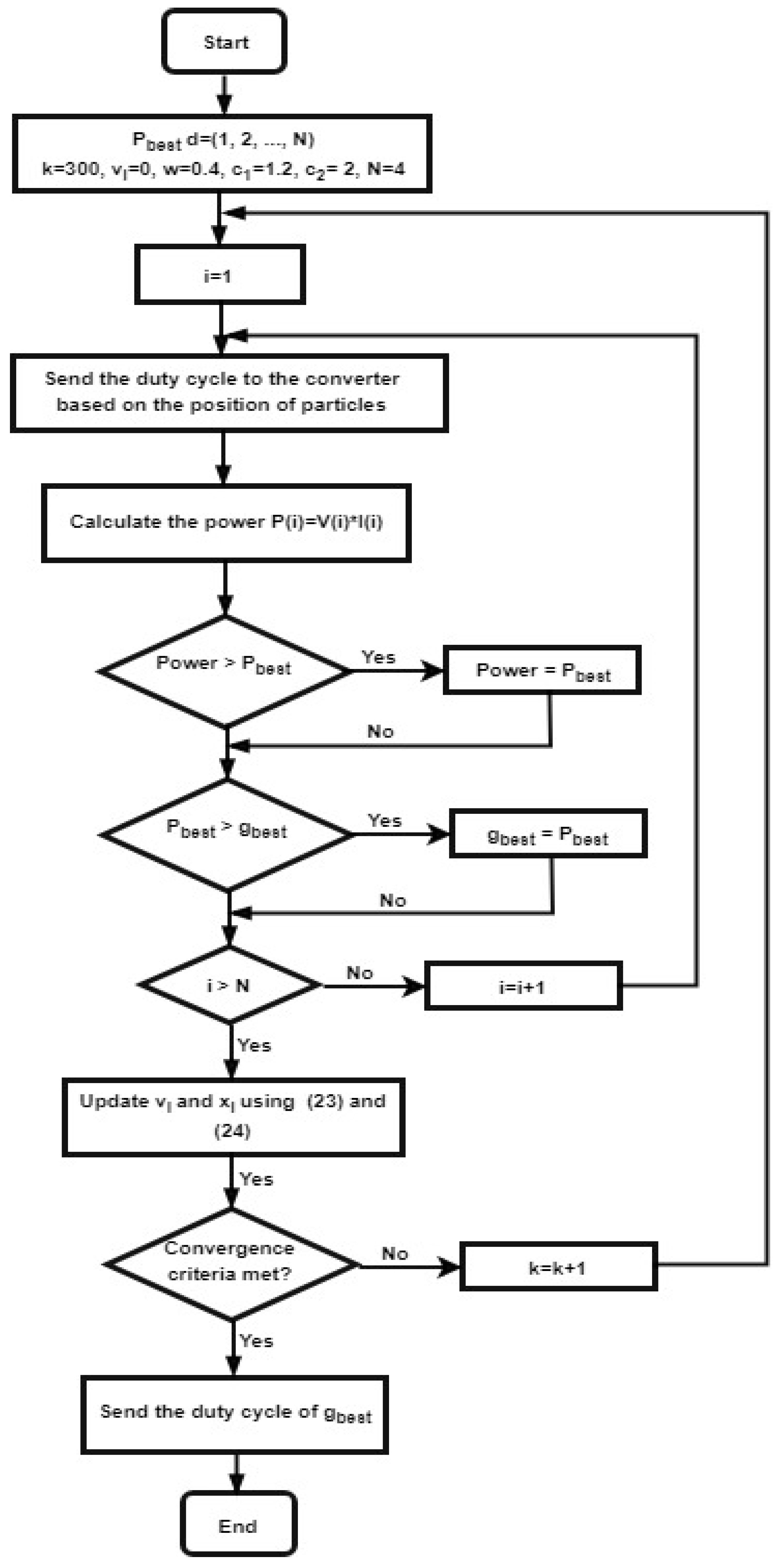

3.2. Particle Swarm Optimisation MPPT Controller Design

- The first step consists of randomly initialising the particles in the same distribution either over the search space or on grid nodes covering the search space in equidistant points.

- The second step concerns the evaluation of the fitness of particles one by one, by giving the possible solution to the objective function.

- In the third step, individual and global best fitness values (Pbest and Gbest) are updated through the comparison of their previous values against the newly calculated and the replacement of Pbest and Gbest including their corresponding positions.

- The fourth step involves the update of the velocity and position of particles one by one in the swarm using Equations (23) and (24).

- The last step consists of verifying if the convergence criterion is satisfied in order to end the process or to increase the number of iteration by 1 and move to step 2.

4. Simulation and Results

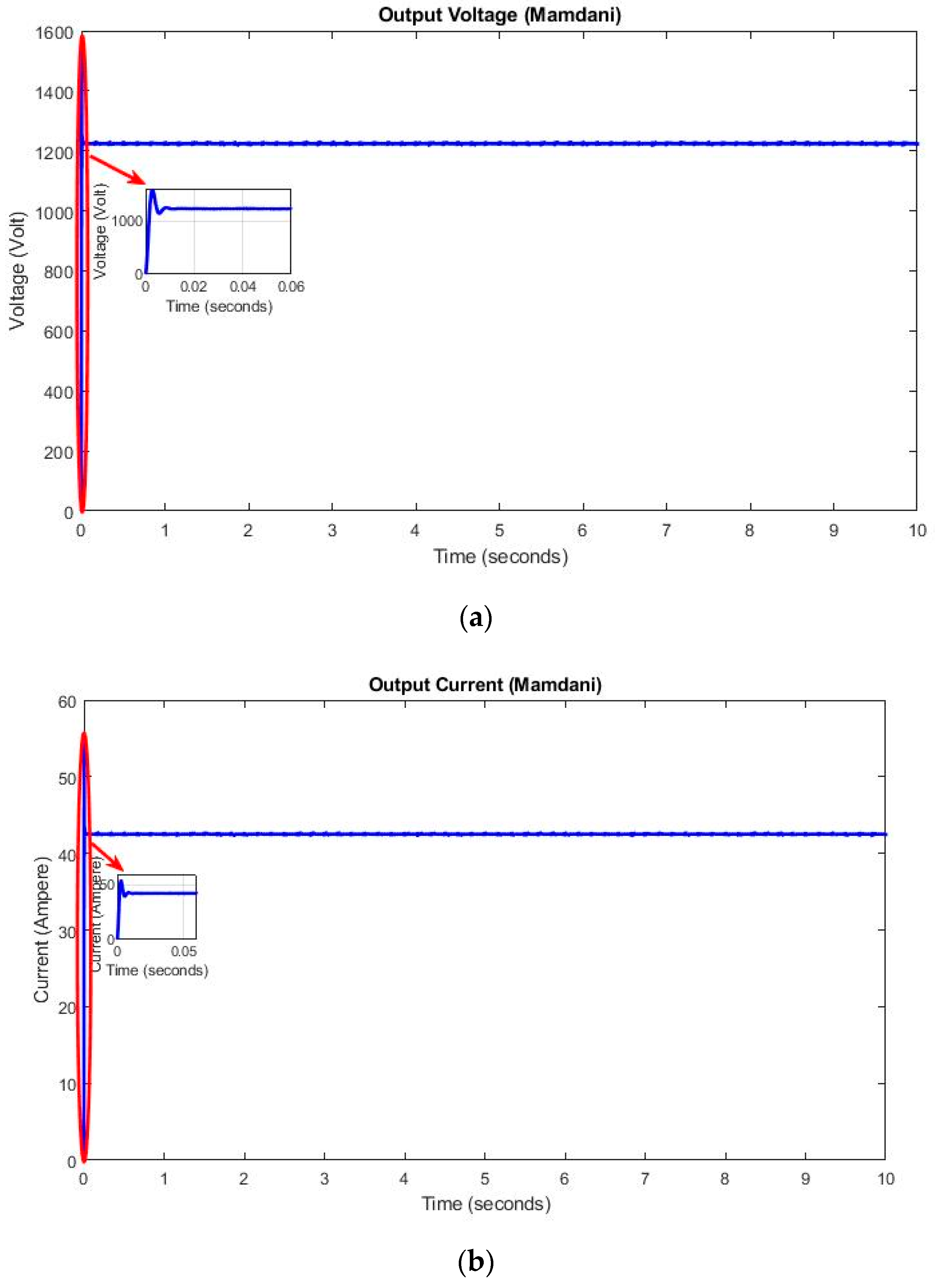

4.1. Results Using the Mamdani MPPT Controller

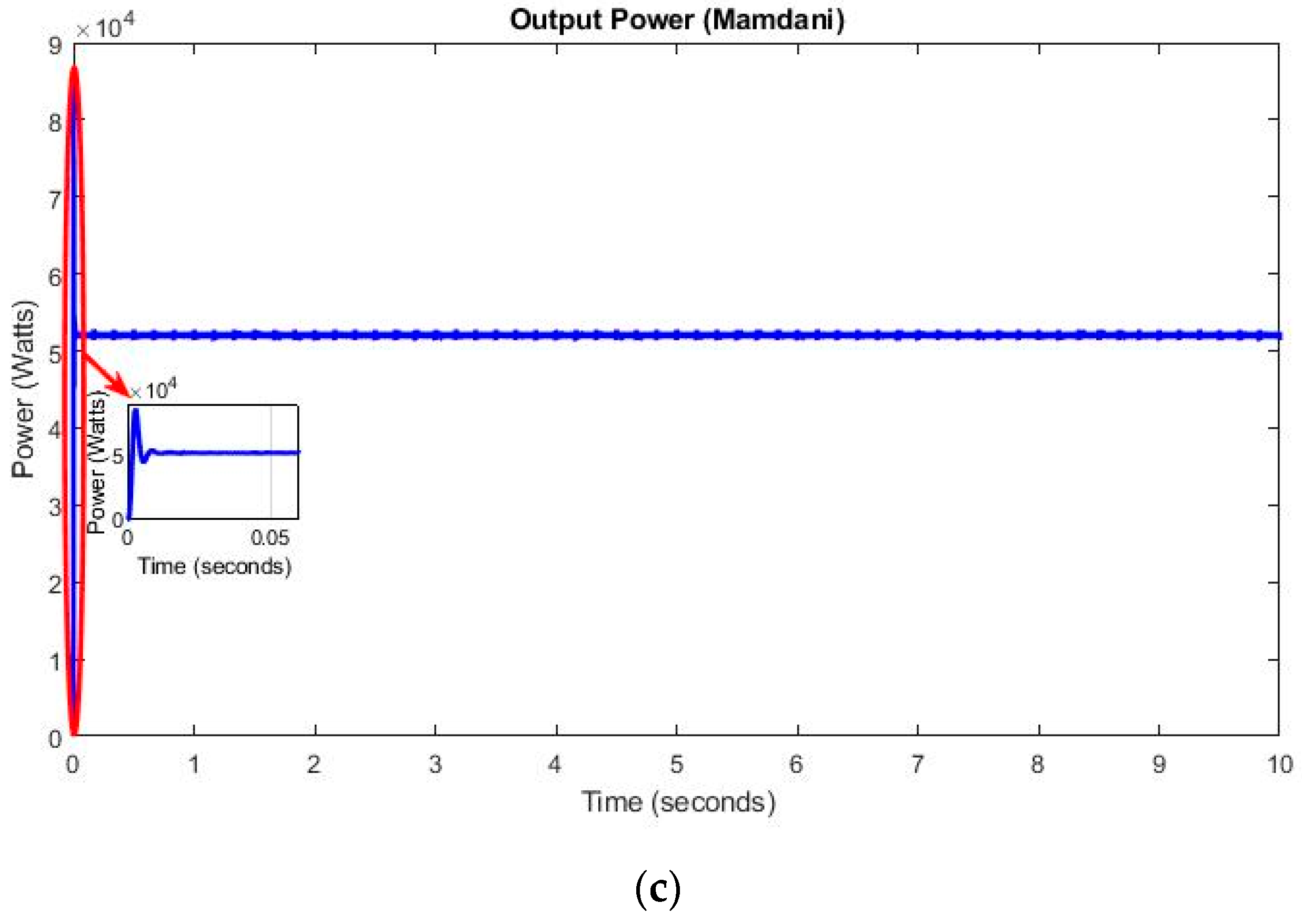

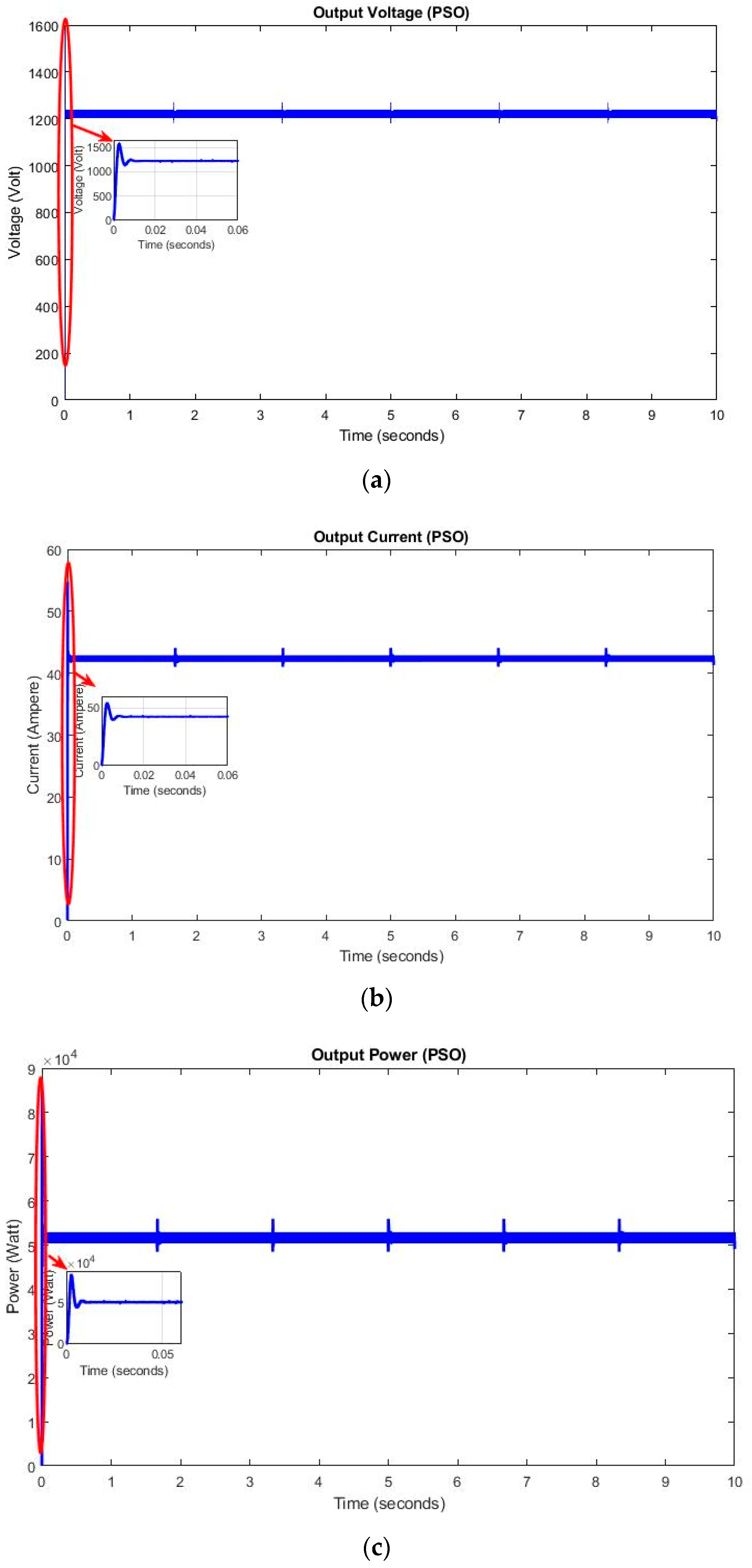

4.2. Results Using the PSO MPPT Controller

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Caisheng, W.; Nehrir, M.H.; Shaw, S.R. Dynamic models and model validation for PEM fuel cells using electrical circuits. IEEE Trans. Energy Convers. 2005, 20, 442–451. [Google Scholar] [CrossRef]

- Nehrir, M.H.; Caisheng, W.; Shaw, S.R. Fuel cells: Promising devices for distributed generation. IEEE Power Energy Mag. 2006, 4, 47–53. [Google Scholar] [CrossRef]

- Larminie, J.; Dicks, A. Fuel Cell Systems Explained, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2003; ISBN 047084857X. [Google Scholar]

- Revankar, S.; Majumdar, P. Fuel Cells: Principles, Design and Analysis; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Luta, D.N.; Raji, A.K. Optimal sizing of hybrid fuel cell-supercapacitor storage system for off-grid renewable applications. Energy 2018, 166, 530–540. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Decision-making between a grid extension and a rural renewable off-grid system with hydrogen generation. Int. J. Hydrogen Energy 2018, 43, 1–14. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Comparing fuzzy rule-based MPPT techniques for fuel cell stack applications. Energy Procedia 2019, 156, 177–182. [Google Scholar] [CrossRef]

- Lucia, U. Overview on fuel cells. Renew. Sustain. Energy Rev. 2014, 30, 164–169. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Potential benefits of renewable fuel cell systems for rural communities’ power supply. In Proceedings of the 2nd EAI International Conference for Research, Innovation and Development for Africa, European Alliance for Innovation, Victoria Falls, Zimbabwe, 20–21 June 2017. [Google Scholar]

- Das, V.; Padmanaban, S.; Venkitusamy, K.; Selvamuthukumaran, R.; Blaabjerg, F.; Siano, P. Recent advances and challenges of fuel cell based power system architectures and control—A review. Renew. Sustain. Energy Rev. 2017, 73, 10–18. [Google Scholar] [CrossRef]

- Raji, A.K.; Kahn, M.T.E. Can Fuel Cell Systems Be Efficient and Effective As Domestic Distributed Generation Units? In Proceedings of the Domestic Use of Energy Conference (DUE), Cape Town, South Africa, 2–5 November 2003. [Google Scholar]

- Harrag, A.; Messalti, S. How fuzzy logic can improve PEM fuel cell MPPT performances? Int. J. Hydrogen Energy 2018, 43, 537–550. [Google Scholar] [CrossRef]

- Mann, R.F.; Amphlett, J.C.; Hooper, M.A.I.; Jensen, H.M.; Peppley, B.A.; Roberge, P.R. Development and application of a generalised steady-state electrochemical model for a PEM fuel cell. J. Power Sources 2000, 86, 173–180. [Google Scholar] [CrossRef]

- Gupta, A.K.; Saxena, R. Review on widely-used MPPT Techniques for PV Applications. In Proceedings of the International Conference on Innovation and Challenges in Cyber Security, Greater Noida, India, 3–5 February 2016; pp. 270–273. [Google Scholar]

- Amir, A.; Amir, A.; Selvaraj, J.; Rahim, N.A.; Abusorrah, A.M. Conventional and modified MPPT techniques with direct control and dual scaled adaptive step-size. Sol. Energy 2017, 157, 1017–1031. [Google Scholar] [CrossRef]

- Karami, N.; Moubayed, N.; Outbib, R. General review and classification of different MPPT Techniques. Renew. Sustain. Energy Rev. 2017, 68, 1–18. [Google Scholar] [CrossRef]

- Aslam, M.; Tariq, A.; Hameed, S.; Bin, M.S. Comparative assessment of maximum power point tracking procedures for photovoltaic systems. Green Energy Environ. 2017, 2, 5–17. [Google Scholar]

- Rezk, H.; Eltamaly, A.M. A comprehensive comparison of different MPPT techniques for photovoltaic systems. Sol. Energy 2015, 112, 1–11. [Google Scholar] [CrossRef]

- Stosovic, M.A.; Dimitrijevic, M.; Litovski, V. MPPT controller design for a standalone PV system. In Proceedings of the 11th International Conference on Telecommunication in Modern Satellite, Cable and Broadcasting Services (TELSIKS 2013), Nis, Serbia, 16–19 October 2013; Volume 2, pp. 501–504. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Zhao, Z. MPPT techniques for photovoltaic applications. Renew. Sustain. Energy Rev. 2013, 25, 793–813. [Google Scholar] [CrossRef]

- Cheng, P.C.; Peng, B.R.; Liu, Y.H.; Cheng, Y.S.; Huang, J.W. Optimization of a fuzzy-logic-control-based MPPT algorithm using the particle Swarm optimization technique. Energies 2015, 8, 5338–5360. [Google Scholar] [CrossRef]

- Kumar, D.; Chatterjee, K. A review of conventional and advanced MPPT algorithms for wind energy systems. Renew. Sustain. Energy Rev. 2016, 55, 957–970. [Google Scholar] [CrossRef]

- Venkateshkumar, M.; Ieee, M.; Description, A. Intelligent Control Based MPPT Method for Fuel Cell Power System. In Proceedings of the 2013 International Conference on Renewable Energy and Sustainable Energy (ICRESE), Coimbatore, India, 5–6 December 2013; pp. 253–257. [Google Scholar]

- Raj, A.; Sreekumar, M. A Comparison of MPPT Control of Photovoltaic System using Conventional and Artificial Intelligence Techniques. Int. J. Eng. Trends Technol. 2016, 38, 16–19. [Google Scholar] [CrossRef]

- Mohapatra, A.; Nayak, B.; Das, P.; Mohanty, K.B. A review on MPPT techniques of PV system under partial shading condition. Renew. Sustain. Energy Rev. 2017, 80, 854–867. [Google Scholar] [CrossRef]

- Koad, R.B.A.; Zobaa, A.F.; El-Shahat, A. A Novel MPPT Algorithm Based on Particle Swarm Optimization for Photovoltaic Systems. IEEE Trans. Sustain. Energy 2017, 8, 468–476. [Google Scholar] [CrossRef]

- Khaldi, N.; Mahmoudi, H.; Zazi, M.; Barradi, Y. Implementation of a MPPT neural controller for photovoltaic systems on FPGA circuit. WSEAS Trans. Power Syst. 2014, 9, 471–478. [Google Scholar] [CrossRef]

- Penella, M.T.; Gasulla, M. A simple and efficient MPPT method for low-power PV cells. Int. J. Photoenergy 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Das, N.; Wongsodihardjo, H.; Islam, S. A Preliminary Study on Conversion Efficiency Improvement of a Multi-junction PV Cell with MPPT. In Smart Power Systems and Renewable Energy System Integration; Jayaweera, D., Ed.; Springer: Berlin, Germany, 2016; pp. 49–73. ISBN 9783319304250. [Google Scholar]

- Esram, T.; Chapman, P.L. Comparison of Photovoltaic Array Maximum Power Point Tracking Techniques. IEEE Trans. Energy Convers. 2007, 22, 439–449. [Google Scholar] [CrossRef]

- Wolfs, P.; Li, Q. A current-Sensor-Free Incremental Conductance Single Cell MPPT for High Performance Vehicle Solar Arrays. In Proceedings of the 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006. [Google Scholar]

- Li, Q.; Wolfs, P. Experimental Evaluation of the MPPT Hardware for Vehicle Solar Arrays with Silicon Junction Cells. In Proceedings of the Australasian Universities Power Engineering Conference, Perth, Australia, 9–12 December 2007. [Google Scholar]

- Njoya Motapon, S. Design and Simulation of a Fuel Cell Hybrid Emergency Power System for a More Electric Aircraft: Evaluation of Energy Management Schemes; University du Quebec: Quebec City, QC, Canada, 2013. [Google Scholar]

- Motapon, S.N.; Tremblay, O.; Ieee, M.; Dessaint, L.; Ieee, S.M. A Generic Fuel Cell Model for the Simulation of Fuel Cell Vehicles. In Proceedings of the Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 1722–1729. [Google Scholar] [CrossRef]

- Dos Reis, J.V.; Raddo, T.R.; Sanches, A.L.; Borges, B.H.V. Comparison between Mamdani and Sugeno fuzzy inference systems for the mitigation of environmental temperature variations in OCDMA-PONs. In Proceedings of the 2015 17th International Conference on Transparent Optical Networks (ICTON), Budapest, Hungary, 5–9 July 2015. [Google Scholar] [CrossRef]

- Sari, W.E.; Wahyunggoro, O.; Fauziati, S. A comparative study on fuzzy Mamdani-Sugeno-Tsukamoto for the childhood tuberculosis diagnosis. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2016; p. 070003. [Google Scholar] [CrossRef]

- Takagi, T.; Sugeno, M. Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man Cybern. 1985, SMC-15, 116–132. [Google Scholar] [CrossRef]

- Hamam, A.; Georganas, N.D. A comparison of mamdani and sugeno fuzzy inference systems for evaluating the quality of experience of hapto-audio-visual applications. In Proceedings of the IEEE International Workshop on Haptic Audio Visual Environments and Games, Ottawa, ON, Canada, 18–19 October 2008; pp. 87–92. [Google Scholar] [CrossRef]

- Blej, M.; Azizi, M. Comparison of Mamdani-Type and Sugeno-Type Fuzzy Inference Systems for Fuzzy Real Time Scheduling. Int. J. Appl. Eng. Res. 2016, 11, 11071–11075. [Google Scholar]

- Lilly, J.H. Fuzzy Control and Identification; Wiley & Sons Ltd.: Hoboken, NJ, USA, 2010; ISBN 9780470542774. [Google Scholar]

- Egaji, O.A.; Griffiths, A.; Hasan, M.S.; Yu, H.N. A comparison of Mamdani and Sugeno fuzzy based packet scheduler for MANET with a realistic wireless propagation model. Int. J. Autom. Comput. 2015, 12, 1–13. [Google Scholar] [CrossRef]

- Ariff, R.M.; Hanafi, D.; Utomo, W.M.; Sim, S.Y.; Bohari, A.A. Comparison of Sugeno-Type and Mamdani-Type Speed Controller for Induction Motor Drive System. In Proceedings of the 3rd International Conference on Computer Engineering and Mathematical Sciences (ICCEMS 2014), Langkawi, Malaysia, 4–5 December 2014; pp. 387–391. [Google Scholar] [CrossRef]

- Subhedar, M.; Birajdar, G. Comparison of mamdani and sugeno inference systems for dynamic spectrum allocation in cognitive radio networks. Wirel. Pers. Commun. 2013, 71, 805–819. [Google Scholar] [CrossRef]

- Wong, L.K.; Leung, F.H.F.; Tam, P.K.S. Design of fuzzy logic controllers for Takagi–Sugeno fuzzy model based system with guaranteed performance. Int. J. Approx. Reason. 2002, 30, 41–55. [Google Scholar] [CrossRef]

- Kaur, A.; Kaur, A. Comparison of Mamdani-Type and Sugeno-Type Fuzzy Inference Systems for Air Conditioning System. Int. J. Soft Comput. Eng. 2012, 2, 323–325. [Google Scholar]

- Zaher, H.; Kandil, A.E.; Fahmy, R. Comparison of Mamdani and Sugeno Fuzzy Inference Systems for Prediction (With Application to Prices of Fund in Egypt). Br. J. Math. Comput. Sci. 2014, 4, 3014–3022. [Google Scholar] [CrossRef]

- Saepullah, A.; Romi, S.W. Comparative Analysis of Mamdani, Sugeno And Tsukamoto Method of Fuzzy Inference System for Air Conditioner Energy Saving. J. Intell. Syst. 2015, 1, 143–147. [Google Scholar]

- ElNounou, K.T. Design of GA-Sugeno Fuzzy Controller for Maximum Power Point And Sun Tracking in Solar Array Systems; Islamic University of Gaza: Gaza City, Palestine, 2013. [Google Scholar]

- Shi, J.; Zhang, W.; Zhang, Y.; Xue, F.; Yang, T. MPPT for PV systems based on a dormant PSO algorithm. Electr. Power Syst. Res. 2015, 123, 100–107. [Google Scholar] [CrossRef]

- Ahmadi, S.; Abdi, S.; Kakavand, M. Maximum power point tracking of a proton exchange membrane fuel cell system using PSO-PID controller. Int. J. Hydrogen Energy 2017, 42, 20430–20443. [Google Scholar] [CrossRef]

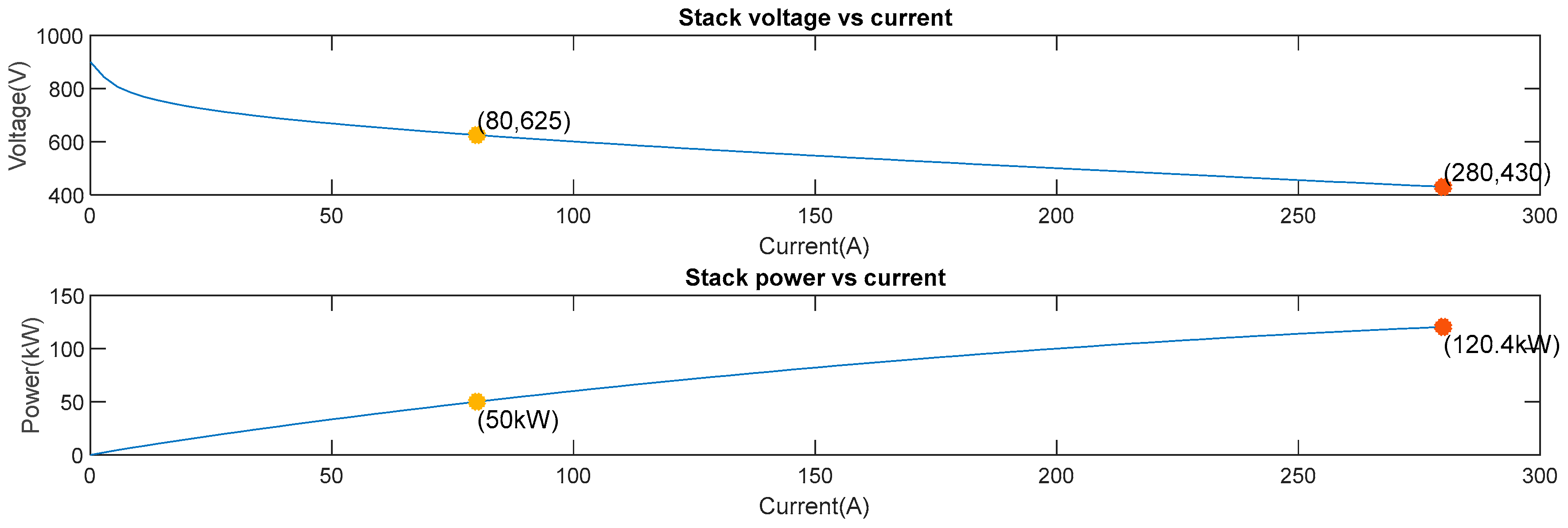

| Model Input Parameters for A 53 kW PEMFC Stack | |

|---|---|

| Voltage at 0 A and 1A | 900 V and 895 V |

| Nominal operating point | 80 A and 625 V |

| Maximum operating point | 280 A and 430 V |

| Number of cells | 900 |

| Nominal stack efficiency | 55% |

| Operating temperature | 338 K |

| Nominal air flow rate | 2100 litre per minute |

| Nominal supply pressure | 1.5 bar for hydrogen and 1 bar for oxygen |

| Nominal composition | 99.95% for hydrogen, 21% for oxygen and 1% for water |

| Voltage response time | 1 s |

| Boost Converter Design Parameters | |

|---|---|

| Inductor | 2.9 × 10−3 H |

| Capacitor | 70 × 10−6 F |

| Switching frequency | 30 kHz |

| Input voltage | 625 V |

| Output voltage | 1.2 kV |

| Efficiency | 90% |

| Load | 28.8 Ω |

| Change in Error | ||||||

|---|---|---|---|---|---|---|

| E/ΔE | NB | NS | Z | PS | PB | |

| Error | NB | Z | Z | Z | PS | PB |

| NS | Z | Z | NB | PS | PB | |

| Z | NB | NS | NS | PS | PB | |

| PS | NB | NS | NS | Z | Z | |

| PB | NB | NS | PS | Z | Z | |

| Comparison | Mamdani Fuzzy Inference System | Particle Swarm Optimisation Algorithm |

|---|---|---|

| Voltage | ||

| Amplitude | 1.214 kV | 1.228 kV |

| Rise Time | 1.172 ms | 1.177 ms |

| Overshoot | 29.221% | 27.564% |

| Undershoot | 5.816% | 7.925% |

| Settling Time | 8.072 ms | 19.981 ms |

| Current | ||

| Amplitude | 42.17 A | 42.66 A |

| Rise Time | 1.172 ms | 1.177 ms |

| Overshoot | 29.221% | 27.564% |

| Undershoot | 5.816% | 7.925% |

| Settling Time | 8.072 ms | 19.981 ms |

| Power | ||

| Amplitude | 51.83 kW | 52.68 kW |

| Rise Time | 896.288 μs | 834.688 μs |

| Overshoot | 65.833% | 63.115% |

| Undershoot | 1.121% | 3.736% |

| Settling Time | 10.53 ms | 20.009 ms |

| Tracking efficiency | 97.79% | 99.39% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luta, D.N.; Raji, A.K. Fuzzy Rule-Based and Particle Swarm Optimisation MPPT Techniques for a Fuel Cell Stack. Energies 2019, 12, 936. https://doi.org/10.3390/en12050936

Luta DN, Raji AK. Fuzzy Rule-Based and Particle Swarm Optimisation MPPT Techniques for a Fuel Cell Stack. Energies. 2019; 12(5):936. https://doi.org/10.3390/en12050936

Chicago/Turabian StyleLuta, Doudou N., and Atanda K. Raji. 2019. "Fuzzy Rule-Based and Particle Swarm Optimisation MPPT Techniques for a Fuel Cell Stack" Energies 12, no. 5: 936. https://doi.org/10.3390/en12050936

APA StyleLuta, D. N., & Raji, A. K. (2019). Fuzzy Rule-Based and Particle Swarm Optimisation MPPT Techniques for a Fuel Cell Stack. Energies, 12(5), 936. https://doi.org/10.3390/en12050936