Improved CRM Model for Inter-Well Connectivity Estimation and Production Optimization: Case Study for Karst Reservoirs

Abstract

1. Introduction

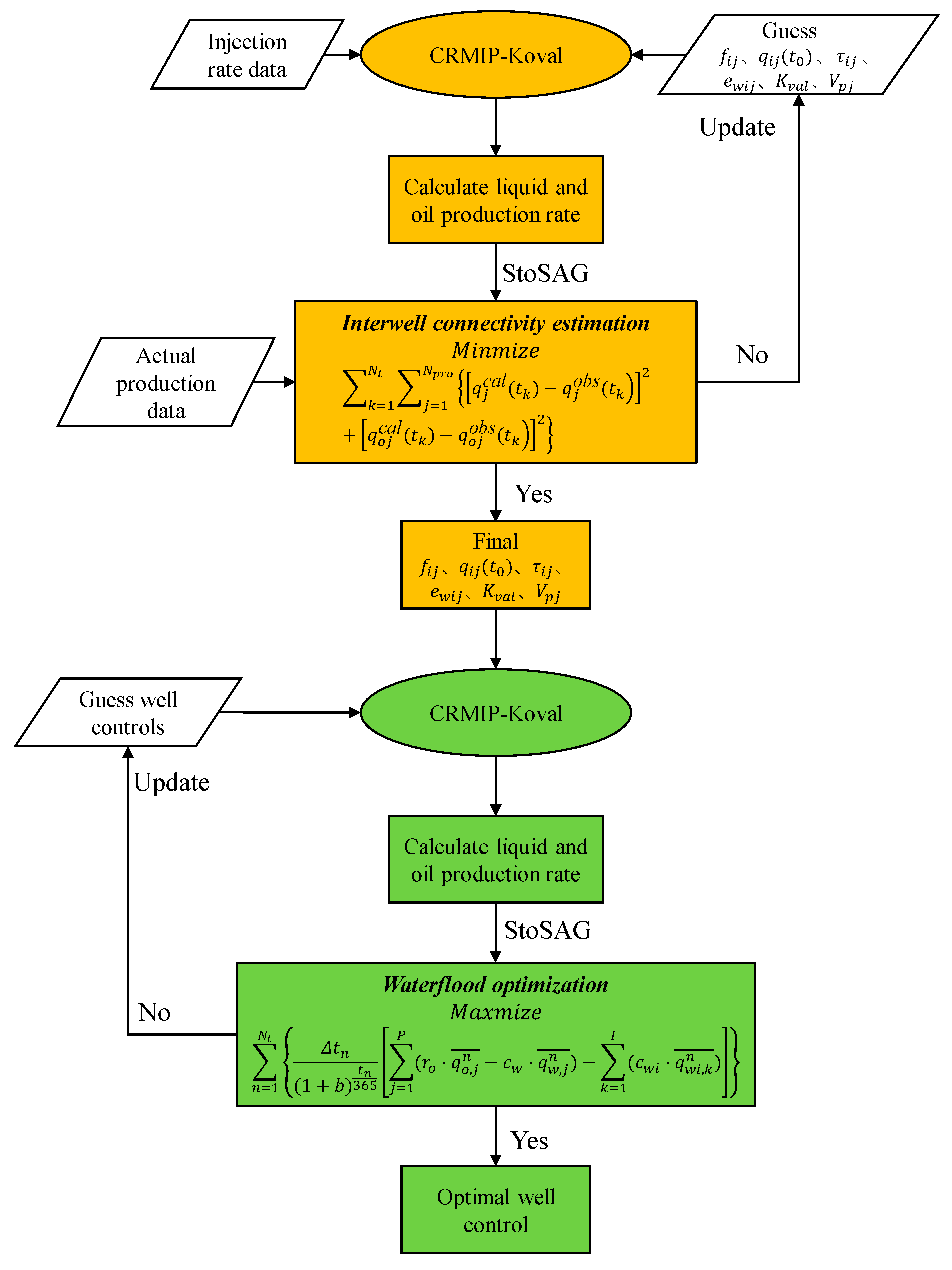

2. Methodology

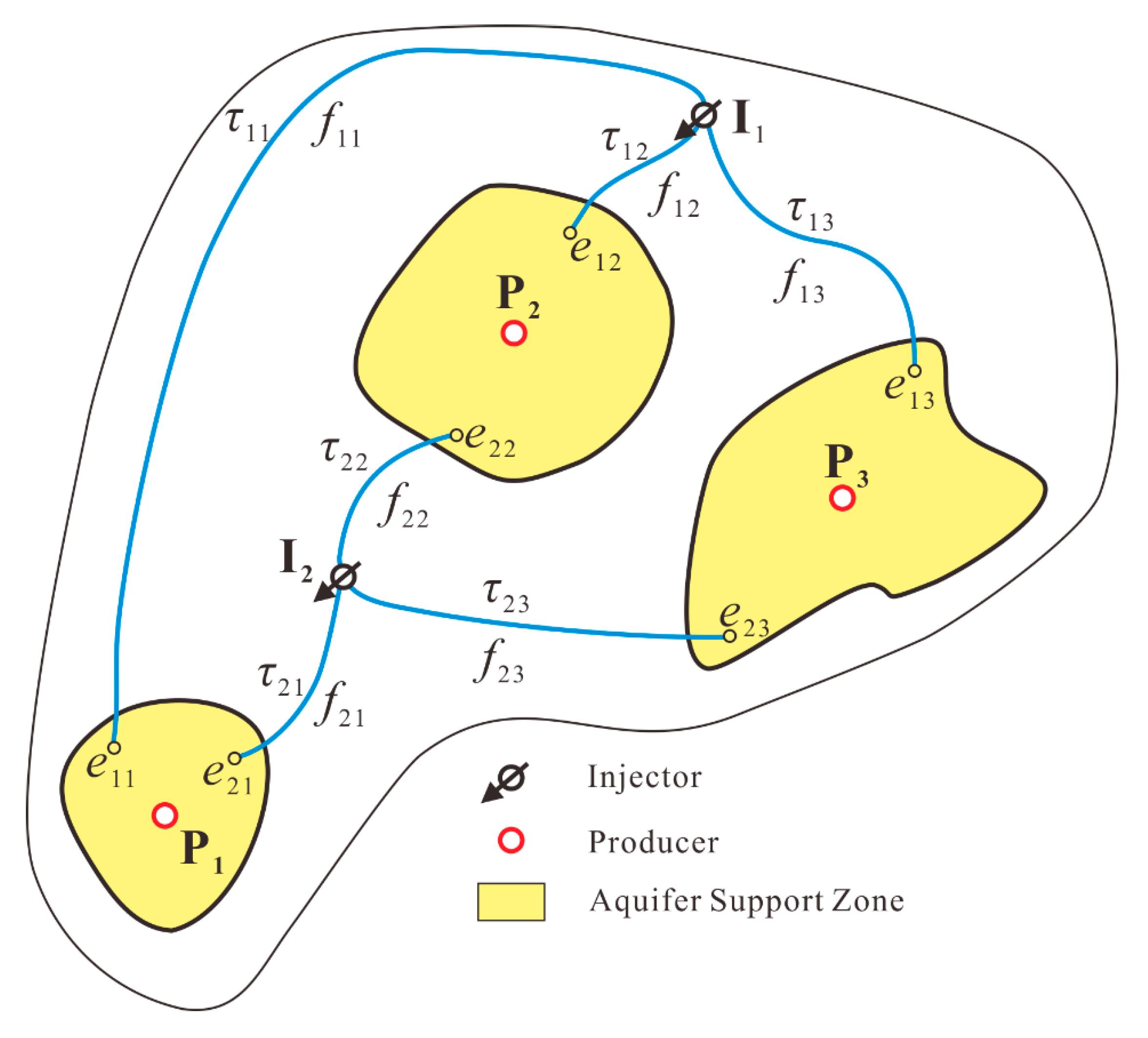

2.1. The Improved CRM–Koval Model

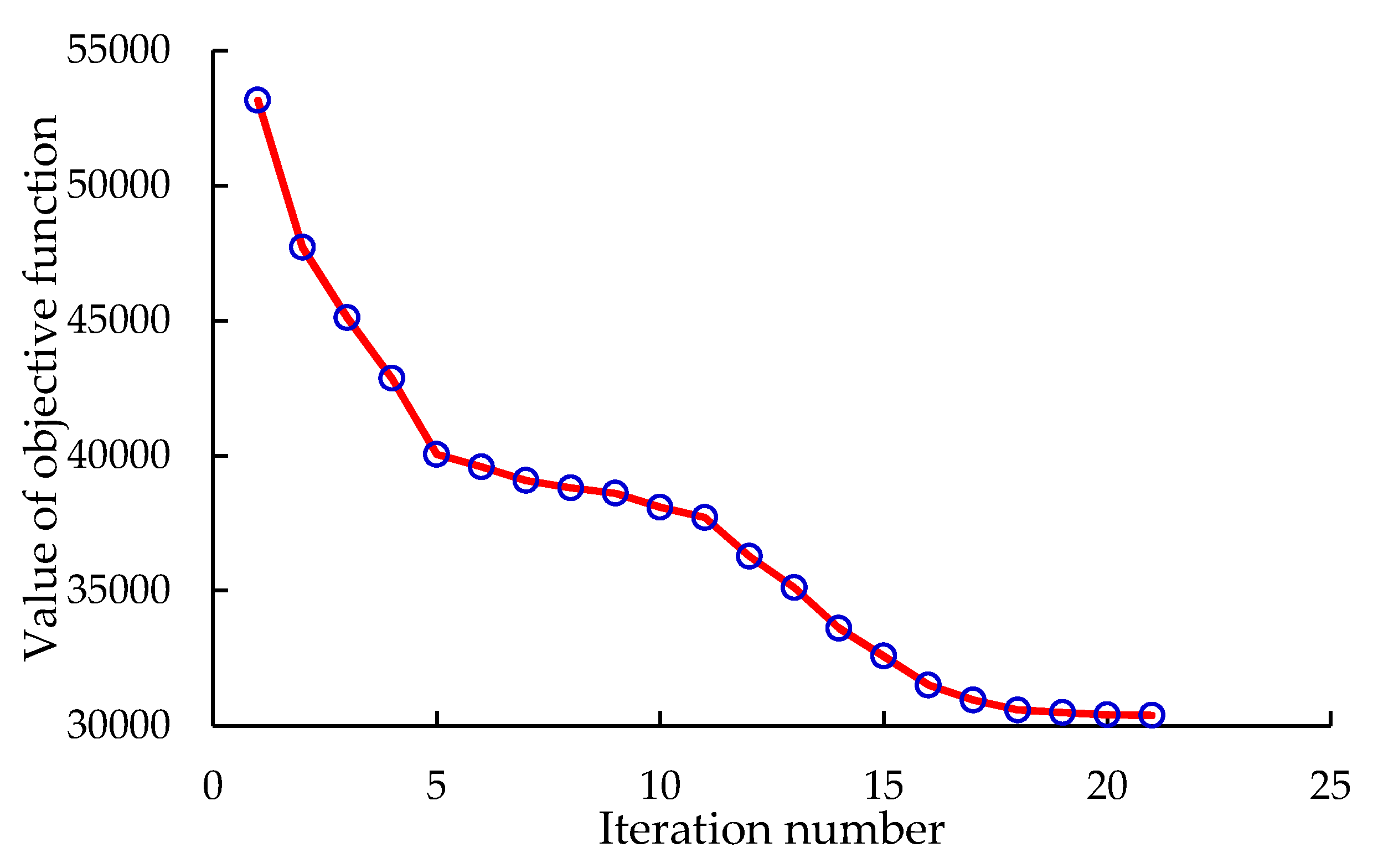

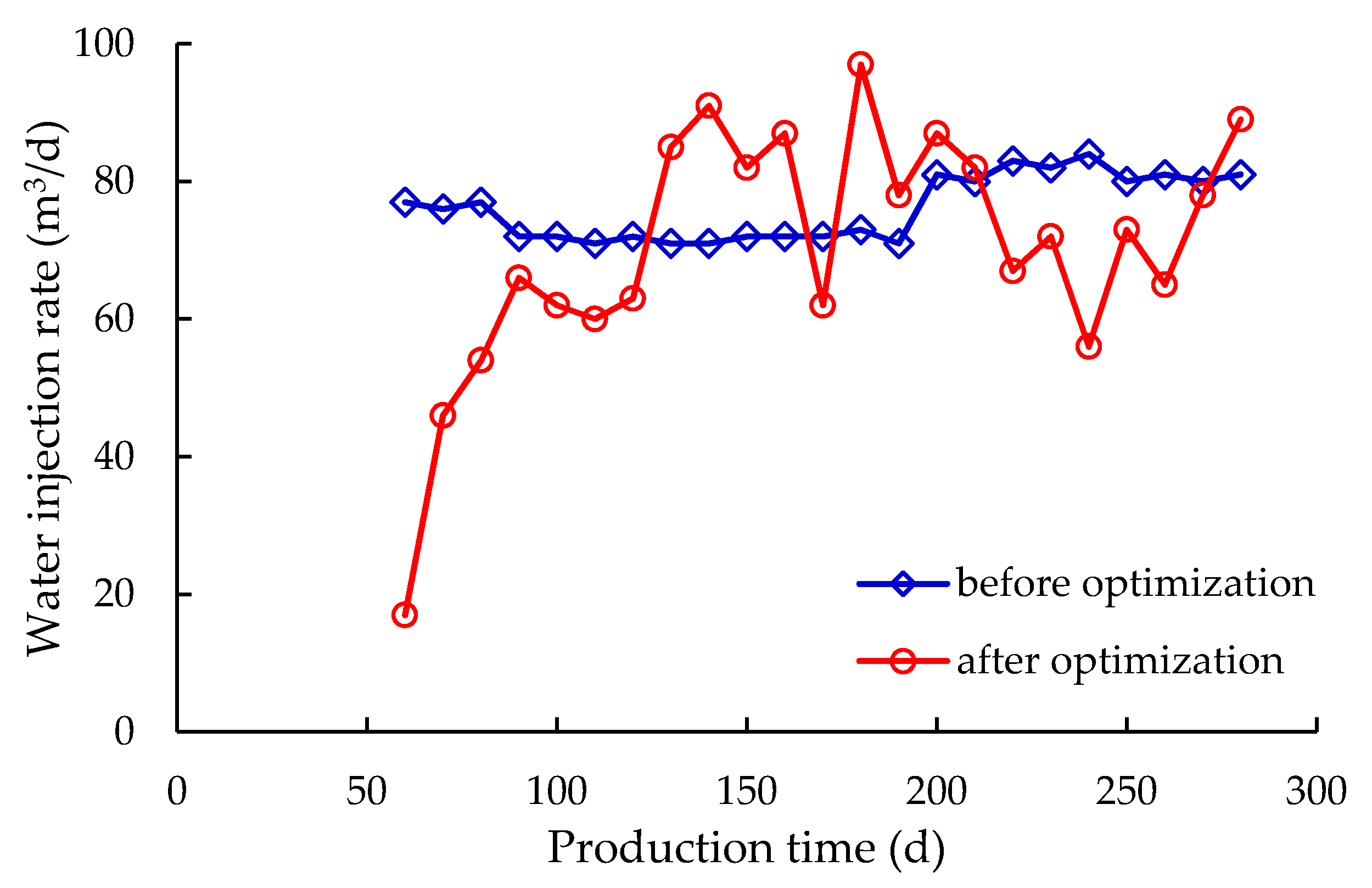

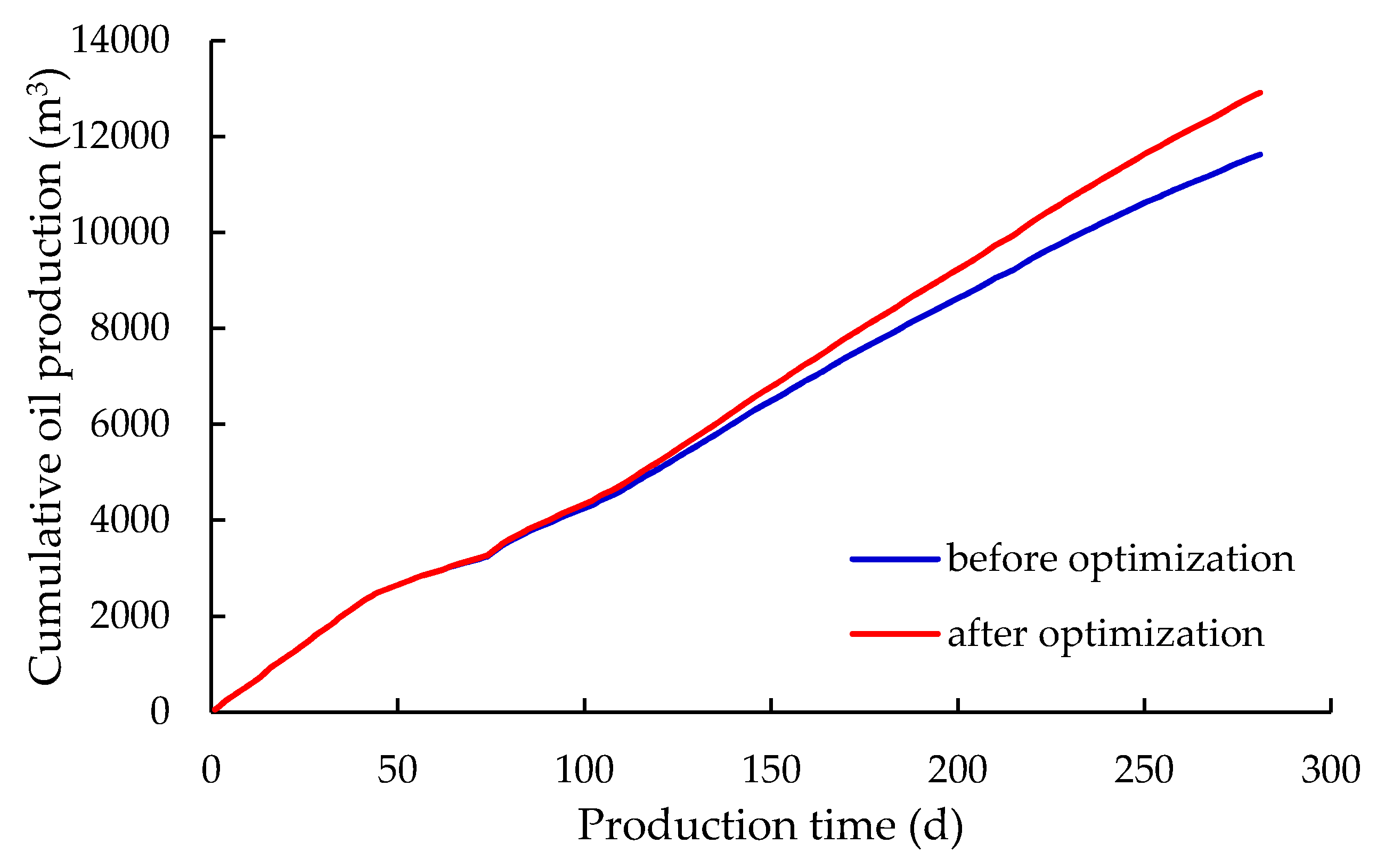

2.2. Waterflood Production Optimization

2.3. Ensemble-Based Optimization Method

2.3.1. Augmented Lagrange Objective Function

2.3.2. StoSAG Gradient Computation

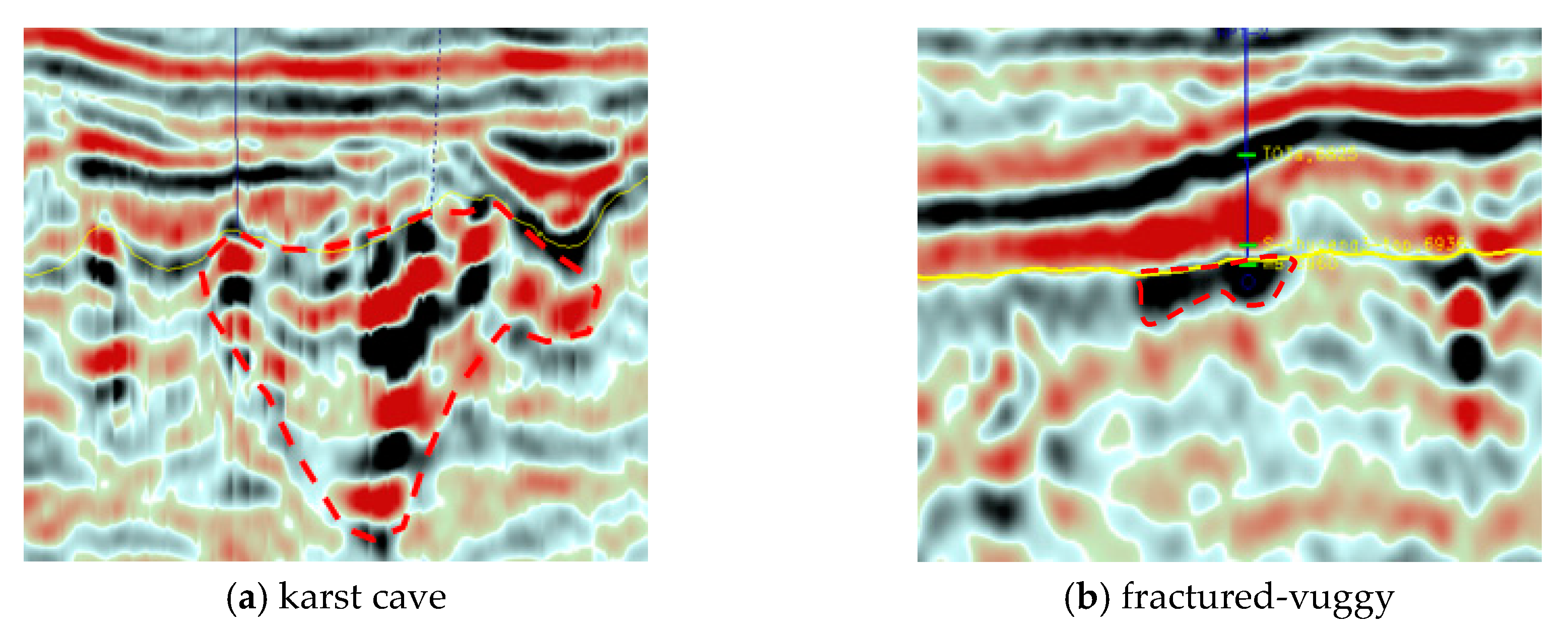

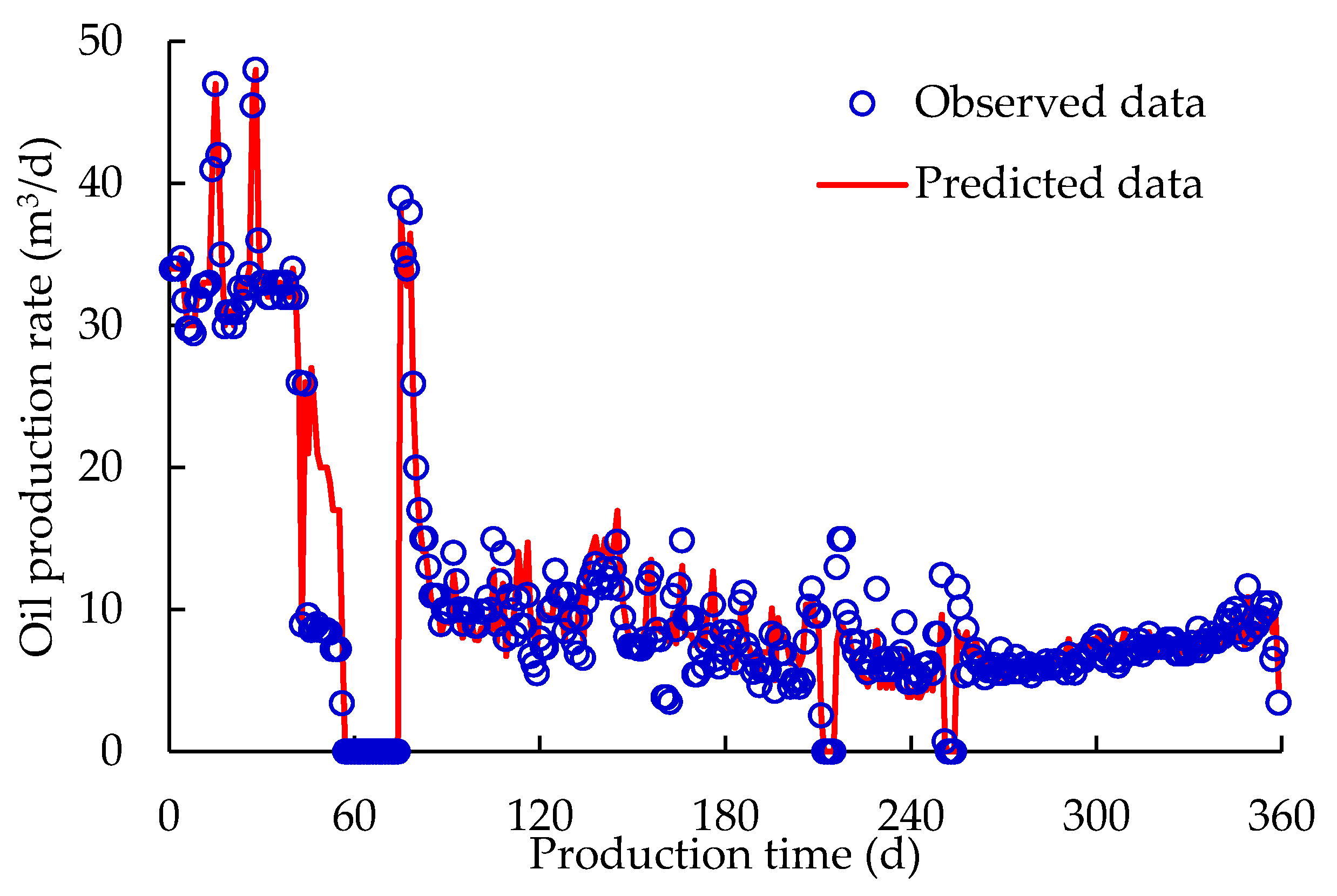

3. Case Study for Karst Carbonate Reservoir

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yousef, A.A.; Gentil, P.H.; Jensen, J.L.; Lake, L.W. A capacitance model to infer interwell connectivity from production and injection rate fluctuations. SPE Reserv. Eval. Eng. 2006, 9, 630–646. [Google Scholar] [CrossRef]

- Sayarpour, M.; Zuluaga, E.; Kabir, C.S.; Lake, L.W. The use of capacitance-resistance models for rapid estimation of waterflood performance and optimization. J. Pet. Sci. Eng. 2009, 69, 227–238. [Google Scholar] [CrossRef]

- Weber, D. The Use of Capacitance-resistance Models to Optimize Injection Allocation and Well Location in Water Floods. Ph.D. Thesis, University of Texas, Austin, TX, USA, 2009. [Google Scholar]

- De Holanda, R.W.; Gildin, E.; Jensen, J.L.; Lake, L.W.; Kabir, C.S. A State-of-the-Art Literature Review on Capacitance Resistance Models for Reservoir Characterization and Performance Forecasting. Energies 2018, 11, 3368. [Google Scholar] [CrossRef]

- Lerlertpakdee, P.; Jafarpour, B.; Gildin, E. Efficient production optimization with flow-network models. SPE J. 2014, 19, 1083–1095. [Google Scholar] [CrossRef]

- Zhao, H.; Li, Y.; Cui, S.; Shang, G.; Reynolds, A.C.; Guo, Z.; Li, H.A. History matching and production optimization of water flooding based on a data-driven interwell numerical simulation model. J. Nat. Gas Sci. Eng. 2016, 31, 48–66. [Google Scholar] [CrossRef]

- Guo, Z.; Reynolds, A.C.; Zhao, H. Waterflooding optimization with the INSIM-FT data-driven model. Comput. Geosci. 2018, 22, 745–761. [Google Scholar] [CrossRef]

- Guo, Z.; Reynolds, A.C. INSIM-FT in three-dimensions with gravity. J. Comput. Phys. 2019, 380, 143–169. [Google Scholar] [CrossRef]

- Albertoni, A.; Lake, L. Inferring interwell connectivity only from well-rate fluctuations in water floods. SPE Reserv. Eval. Eng. 2003, 6, 6–16. [Google Scholar] [CrossRef]

- Parekh, B.; Kabir, C.S. A case study of improved understanding of reservoir connectivity in an evolving water flood with surveillance data. J. Pet. Sci. Eng. 2013, 102, 1–9. [Google Scholar] [CrossRef]

- Moreno, G.A.; Lake, L.W. On the uncertainty of interwell connectivity estimations from the capacitance-resistance model. Pet. Sci. 2014, 11, 265–271. [Google Scholar] [CrossRef]

- Laochamroonvorapongse, R.; Kabir, C.S.; Lake, L.W. Performance assessment of miscible and immiscible water-alternating gas floods with simple tools. J. Pet. Sci. Eng. 2014, 122, 18–30. [Google Scholar] [CrossRef]

- Olsen, C.; Kabir, C.S. Waterflood performance evaluation in a chalk reservoir with an ensemble of tools. J. Pet. Sci. Eng. 2014, 124, 60–71. [Google Scholar] [CrossRef]

- Tao, Q.; Bryant, S.L. Optimizing carbon sequestration with the capacitance/resistance model. SPE J. 2015, 20, 1094–1102. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y.; Chen, B.; Hu, Y.; Li, B.; Gao, D.; Fu, B. Ensemble-based optimization of interwell connectivity in heterogeneous waterflooding reservoirs. J. Nat. Gas Sci. Eng. 2017, 38, 245–256. [Google Scholar] [CrossRef]

- Mamghaderi, A.; Pourafshary, P. Water flooding performance prediction in layered reservoirs using improved capacitance-resistive model. J. Pet. Sci. Eng. 2013, 108, 107–117. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Zhang, D. Water flooding performance prediction by multi-layer capacitance-resistive models combined with the ensemble Kalman filter. J. Pet. Sci. Eng. 2015, 127, 1–19. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Zhang, D. Reservoir characterization and production optimization using the ensemble-based optimization method and multi-layer capacitance-resistive models. J. Pet. Sci. Eng. 2017, 156, 633–653. [Google Scholar] [CrossRef]

- Holanda, R.W.; Gildin, E.; Jensen, J.L. A generalized framework for Capacitance Resistance Models and a comparison with streamline allocation factors. J. Pet. Sci. Eng. 2018, 162, 260–282. [Google Scholar] [CrossRef]

- Gentil, P.H. The Use of Multi-Linear Regression Models in Patterned Waterfloods: Physical Meaning of the Regression Coefficients. Ph.D. Thesis, The University of Texas, Austin, TX, USA, 2005. [Google Scholar]

- Cao, F.; Luo, H.S.; Lake, L.W. Oil-rate forecast by inferring fractional-flow models from field data with Koval method combined with the capacitance-resistance model. SPE Reserv. Eval. Eng. 2015, 18, 534–553. [Google Scholar] [CrossRef]

- Jansen, J.D. Adjoint-based optimization of multiphase flow through porous media-a review. Comput. Fluids 2011, 46, 40–51. [Google Scholar] [CrossRef]

- Brouwer, D.R.; Jansen, J.D. Dynamic optimization of water flooding with smart wells using optimal control theory. SPE J. 2004, 9, 391–402. [Google Scholar] [CrossRef]

- Chen, Y.; Oliver, D.S.; Zhang, D. Efficient ensemble-based closed-loop production optimization. SPE J. 2009, 14, 634–645. [Google Scholar] [CrossRef]

- Chen, Y.; Oliver, D.S. Ensemble-based closed-loop optimization applied to Brugge field. SPE Reserv. Eval. Eng. 2010, 13, 56–71. [Google Scholar] [CrossRef]

- Su, H.J.; Oliver, D.S. Smart well production optimization using an ensemble-based method. SPE Reserv. Eval. Eng. 2010, 13, 884–892. [Google Scholar] [CrossRef]

- Dehdari, V.; Oliver, D.S. Sequential quadratic programming for solving constrained production optimization: Case study from Brugge field. SPE J. 2012, 17, 874–884. [Google Scholar] [CrossRef]

- Sarma, P.; Chen, W. Improved estimation of the stochastic gradient with Quasi-Monte Carlo methods. In Proceedings of the 14th European Conference on the Mathematics of Oil Recovery (ECMOR XIV), Catania, Italy, 8–11 September 2014; pp. 8–11. [Google Scholar]

- Do, S.T.; Reynolds, A.C. Theoretical connections between optimization algorithms based on an approximate gradient. Comput. Geosci. 2013, 17, 959–973. [Google Scholar] [CrossRef]

- Stordal, A.S.; Szklarz, S.P.; Leeuwenburgh, O. A theoretical look at ensemble-based optimization in reservoir management. Math. Geosci. 2016, 48, 399–417. [Google Scholar] [CrossRef]

- Jafroodi, N.; Zhang, D. New method for reservoir characterization and optimization using CRM-EnOpt approach. J. Pet. Sci. Eng. 2011, 77, 155–171. [Google Scholar] [CrossRef]

- Hong, A.J.; Bratvold, R.B.; Nævdal, G. Robust production optimization with capacitance-resistance model as precursor. Comput. Geosci. 2017, 21, 1423–1442. [Google Scholar] [CrossRef]

- Fonseca, R.M.; Chen, B.; Jansen, J.D.; Reynolds, A.C. A stochastic simplex approximate gradient (StoSAG) for optimization under uncertainty. Int. J. Numer. Methods Eng. 2016, 109, 1756–1776. [Google Scholar] [CrossRef]

- Fonseca, R.M.; Kahrobaei, S.S.; van Gastel, L.J.T.; Leeuwenburgh, O.; Jansen, J.D. Quantification of the impact of ensemble size on the quality of an ensemble gradient using principles of hypothesis testing. In Proceedings of the SPE Reservoir Simulation Symposium, Houston, TX, USA, 23–25 February 2015. [Google Scholar]

- Chen, B.; Reynolds, A.C. Optimal control of ICV’s and well operating conditions for the water-alternating-gas injection process. J. Pet. Sci. Eng. 2017, 149, 623–640. [Google Scholar] [CrossRef]

- Chen, B.; Fonseca, R.M.; Leeuwenburgh, O.; Reynolds, A.C. Minimizing the Risk in the robust life-cycle production optimization using stochastic simplex approximate gradient. J. Pet. Sci. Eng. 2017, 153, 331–344. [Google Scholar] [CrossRef]

- Ding, S.W.; Lu, R.R.; Xi, Y.; Wang, S.L.; Wu, Y.P. Well placement optimization using direct mapping of productivity potential and threshold value of productivity potential management strategy. Comput. Chem. Eng. 2019, 121, 327–337. [Google Scholar] [CrossRef]

- Guo, Z.; Reynolds, A.C. Robust Life-Cycle Production Optimization with a Support-Vector-Regression Proxy. SPE J. 2018, 23, 2409–2427. [Google Scholar] [CrossRef]

- Moraes, R.J.; Fonseca, R.M.; Helici, M.A.; Heemink, A.W.; Jansen, J.D. An Efficient Robust Optimization Workflow using Multiscale Simulation and Stochastic Gradients. J. Pet. Sci. Eng. 2019, 172, 247–258. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y.; Hu, Y.; Li, B.; Deng, X.; Liu, Z. Integrated dynamic evaluation of depletion-drive performance in naturally fractured-vuggy carbonate reservoirs using DPSO–FCM clustering. Fuel 2016, 181, 996–1010. [Google Scholar] [CrossRef]

| The Estimated Control Variables | Inj_1 | ||||

|---|---|---|---|---|---|

| Connectivity Coefficient | Time Delay Constant (d) | Water Influx Rate (m3/d) | Koval Factor | Drainage Volume (m3) | |

| Pro_1 | 0.433 | 230.34 | 0.36 | 4.22 | 1.54 × 105 |

| Pro_2 | 0.037 | 39.40 | 9.59 | 4.45 | 1537.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Li, Y.; Zhang, J.; Wei, C.; Jiao, Y.; Wang, Q. Improved CRM Model for Inter-Well Connectivity Estimation and Production Optimization: Case Study for Karst Reservoirs. Energies 2019, 12, 816. https://doi.org/10.3390/en12050816

Wang D, Li Y, Zhang J, Wei C, Jiao Y, Wang Q. Improved CRM Model for Inter-Well Connectivity Estimation and Production Optimization: Case Study for Karst Reservoirs. Energies. 2019; 12(5):816. https://doi.org/10.3390/en12050816

Chicago/Turabian StyleWang, Daigang, Yong Li, Jing Zhang, Chenji Wei, Yuwei Jiao, and Qi Wang. 2019. "Improved CRM Model for Inter-Well Connectivity Estimation and Production Optimization: Case Study for Karst Reservoirs" Energies 12, no. 5: 816. https://doi.org/10.3390/en12050816

APA StyleWang, D., Li, Y., Zhang, J., Wei, C., Jiao, Y., & Wang, Q. (2019). Improved CRM Model for Inter-Well Connectivity Estimation and Production Optimization: Case Study for Karst Reservoirs. Energies, 12(5), 816. https://doi.org/10.3390/en12050816