3.1. Static Analysis: Free-End Displacement

With reference to

Figure 2, the free-end displacement is computed by the Virtual Work Principle (VWP). In particular, the strain field

and the displacement field

along the beam axis are linked by the relation:

In a generic system Π, the displacement field can be determined by minimizing the relative potential energy with the Rayleigh–Ritz method: the displacement field is therefore a linear combination of a function

, and its

differentials via m coefficients are calculated as follows:

In the case of the bending beam, according to the Euler–Bernoulli theory, the axial displacement field can be given as a function of the rotation

and the orthogonal displacement field

:

with

being a Hermite polynomial function. Since the axial strain field is obtained as the differential of the axial displacement field

with respect to

, the

z displacement field has to be a second-degree polynomial, so that the strain field is at least constant. However, when a continuous domain is discretized via finite elements that are linked through several nodes, a displacement field is valid if there is a correspondence between the total degree of freedom of the nodes and the number of

coefficients used. Therefore, the minimum degree possible for the sought polynomial is the third degree:

Given that

and the boundary conditions

and

imposed by the joint configuration, it can be simply verified that the first two constants are null, so that the elastic internal energy is:

Naturally,

is related to the displacement of the beam free end by the relation:

From (9) and (10),

and

are determined. In particular:

Once the shape function is introduced:

the strain field can be written as:

Concerning the (12), which refers to a homogeneous beam, an equivalent expression can be given for a composite beam, using an approximated calculation of the stiffness [

27]:

The modeled beam is a composite, so that (15) represents an approximation with respect to the Classical Lamination Theory. The comparison between the results obtained by the analytical model and the finite element (FE) model will give a measure of this approximation. The parameter

D is the equivalent to the Young constant of a homogenous beam multiplied by its bending inertial moment, so that for a composite beam, it results in the following:

The inertial moment of the generic layer is related to its thickness, its width, and the orthogonal distance between its center of mass and the neutral bending axis. The neutral bending axis position can be found according to the geometric/mechanical properties of the layers considered. Assuming the lower layer as the steel one, the neutral bending axis coordinate is:

Consequently, it results in the following:

An equivalent stiffness of the PZT material can be determined by using the constitutive piezoelectric Equation (1). Since:

by assuming a mono-dimensional and constant electric field, and by imposing

, the voltage

is obtained:

The electric stiffness of the system can be calculated by imposing that the internal work

is the result of the work where the stresses perform for the virtual strains

, and the one that the electric displacement performs for the virtual electric field

. Thus, by expressing the stress and the electric displacement according to Equation (1), the following relation can be written:

Using (14) and (23), the integrals in (24) can be evaluated by assuming a linear behavior, and by splitting each contribution in the correspondent layer. In particular, the steel layer will contribute only to the stiffness term, while the PZT one will contribute to all terms. Given the isotropic assumption for the PZT and that the Young modules are constants, the mechanical stiffness is calculated as:

where the term

is defined in order to separate the surface and the linear integrals.

The surface integral of

is the inertial moment with respect to the x-axis, and it has already been calculated in (18). By computing the remaining integral, the mechanical stiffness of the beam is derived:

which obviously coincides with (20), since this term is not affected by the electro-mechanical effect.

The volume piezoelectric coupling constant is given by:

Based on the computed strain along y and electric field along z, by taking into account the piezoelectric constant

, (27) becomes:

Hence, the PZT volume dielectric constant is calculated as:

The polarization occurs along z, and it is assumed to be independent of the length and the width of the beam. The remaining integral can be therefore computed as:

Analogously, the external work is based on the contributions of the work surface charge density

, and the external force

:

By constraining

to zero, the integral constitutive equation for the beam is derived:

from which the electric equivalent stiffness of the beam is obtained as:

Equation (33) is higher than the (20). Indeed, the electric properties of PZT tighten up the system and, consequently, the actual displacement of the free end is lower than (21):

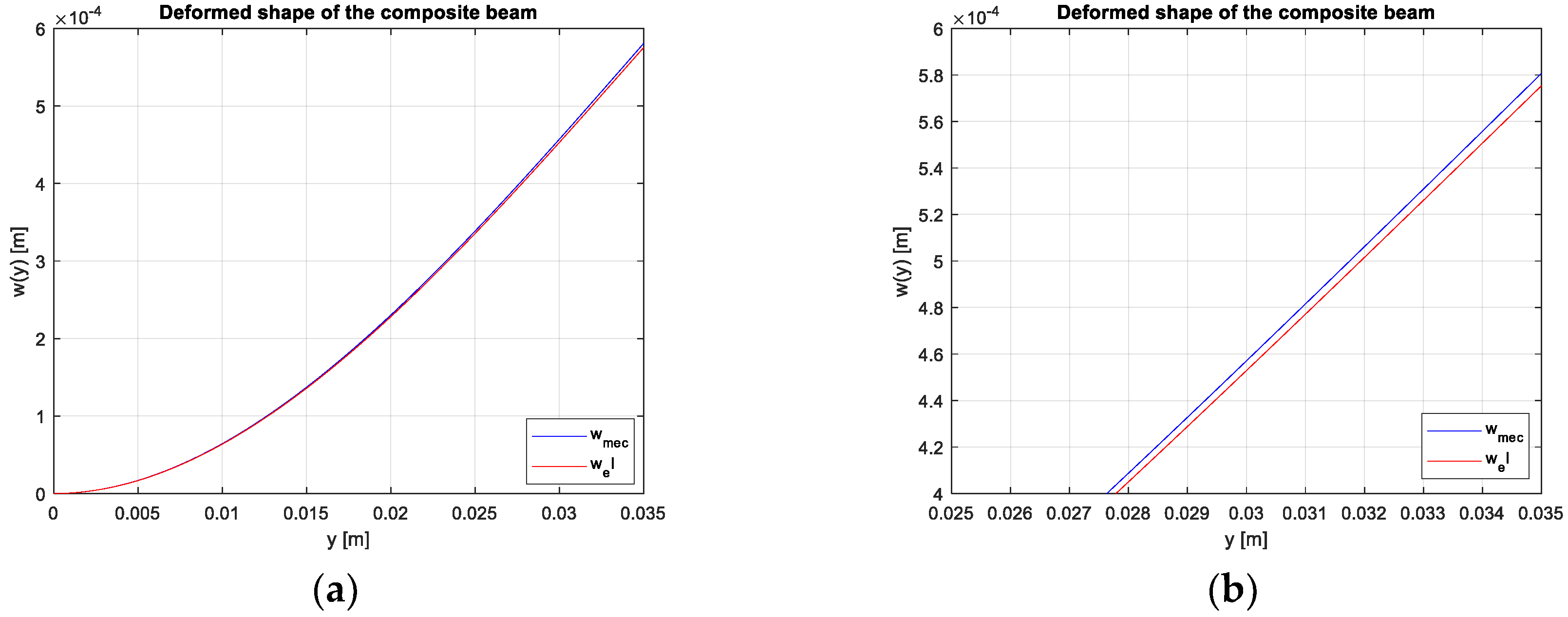

The deformed shapes of the beam have been represented in

Figure 3, solving the displacement field in a Matlab

® script.

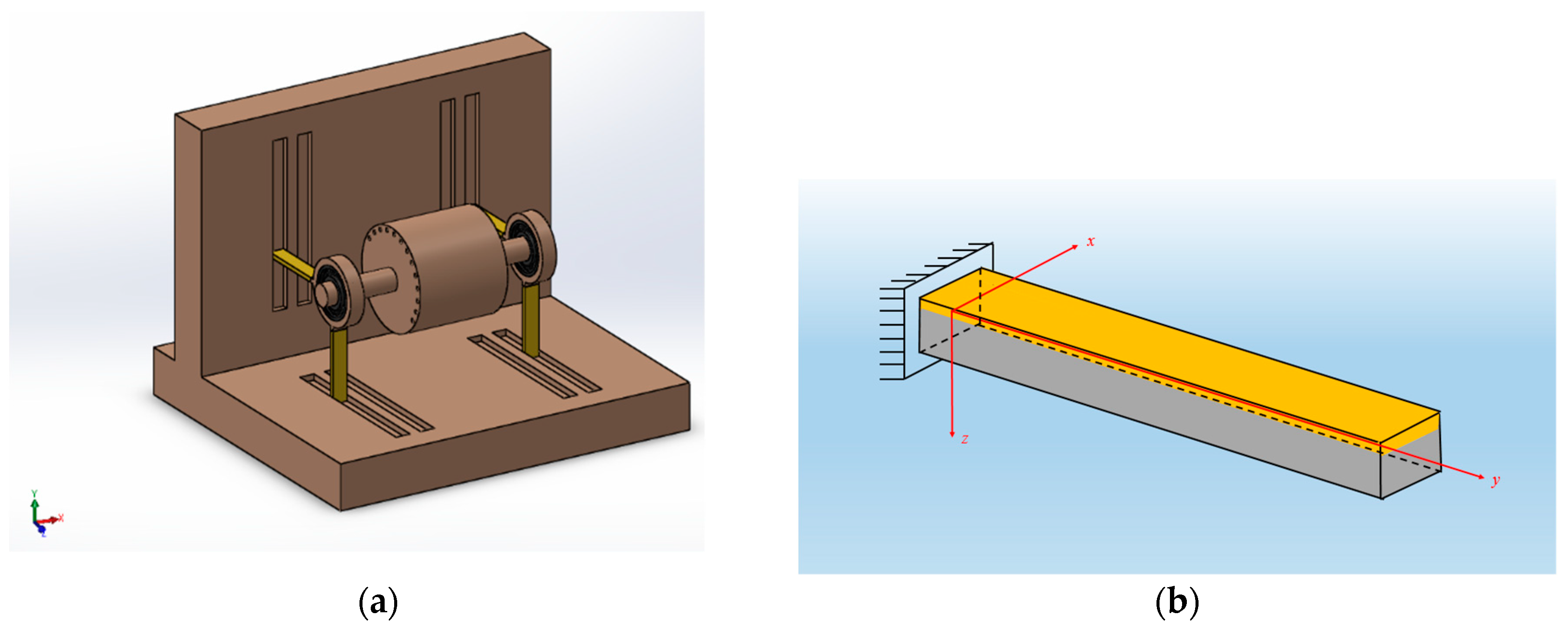

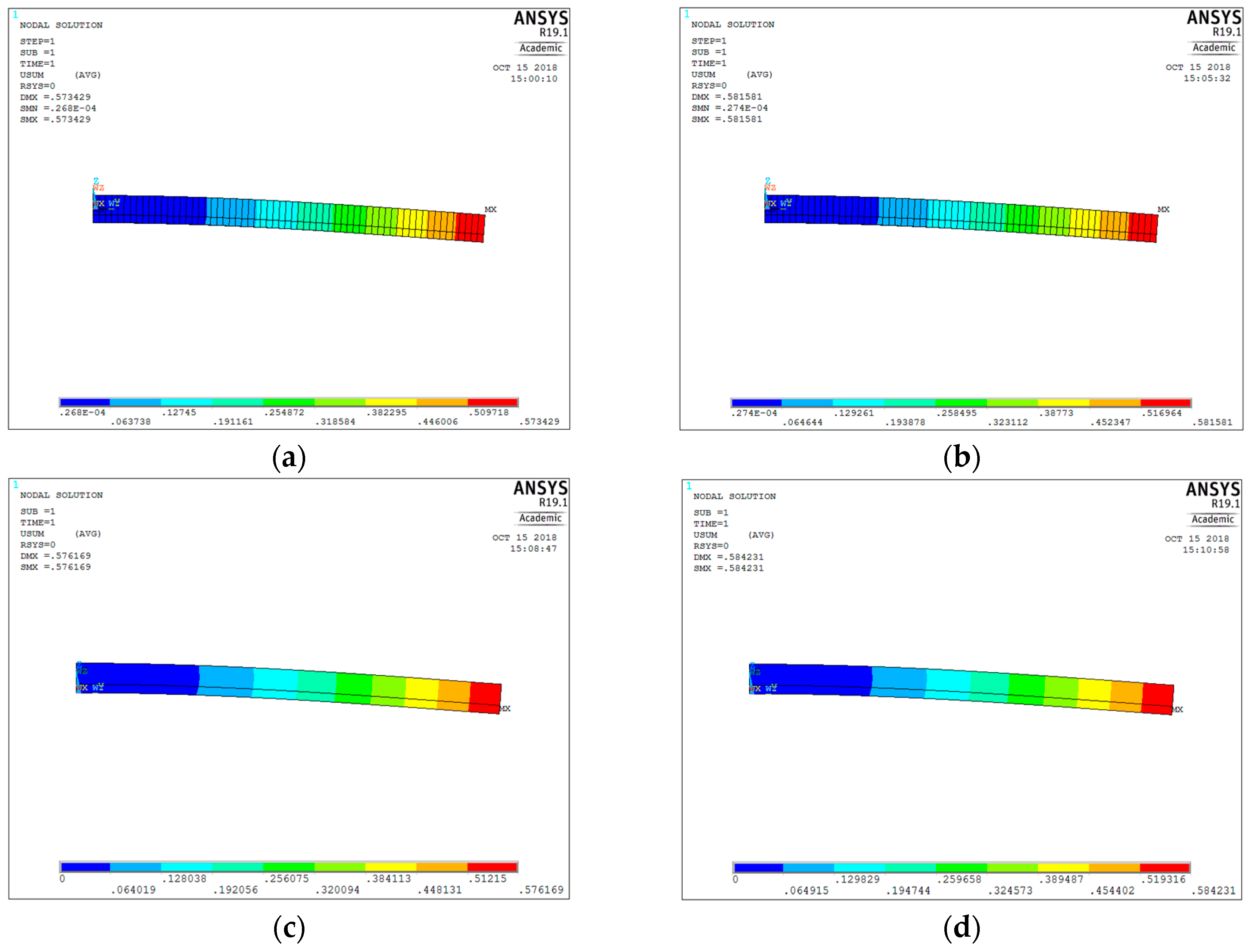

After the analytical solution, a 3D model of the support has been produced with Ansys

® Mechanical APDL, to determine both the mechanical and the electric–mechanical responses, in terms of the free-end displacement of the beam. SHELL281 elements have been used in purely mechanical analyses, with these being the most suitable for the analysis of a thin composite structure. The deformed shapes for the isotropic and the orthotropic models are depicted, respectively, in

Figure 4.

Comparing the analytical results (21) with the simulation ones in 4a and 4b, and (34) with 4c and 4b, the deviations in

Table 5 have been found:

With reference to the first column of the table, it is evident that in an isotropic condition, the FE model is stiffer than the analytical one. This aspect can be attributed to the discretization operated by the meshing process. Naturally, the orthotropic model registers a higher deviation, even though the accuracy is still acceptable. A purely mechanical analysis has been performed with the SOLID226 model, whose results are consistent with analytical ones.

All of the results from the analytical analyses are summarized in

Table 6.

It should be pointed out that the Young constant derived from the piezoelectric results of the SOLID226 model gives .

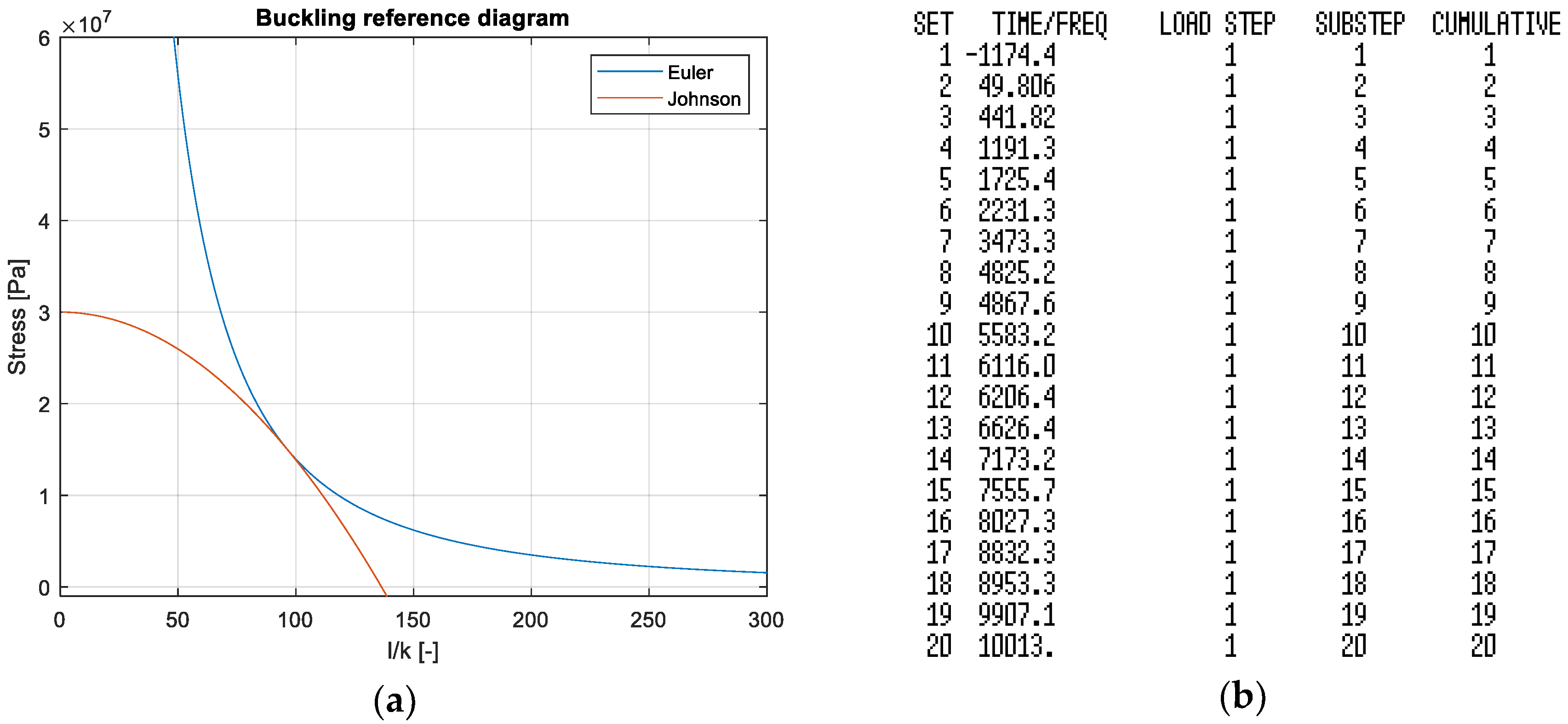

3.2. Static Analysis: Buckling

When a structure has a preponderant dimension with respect to the other two, an instability may occurs if the mechanical stress acts along the considered direction. To analysis this aspect in the case of an embedded beam with an axial force exerted on the free end, the beam equilibrium is considered with respect to the deformed shape, since the hypothesis of small displacements no longer applies.

The critical buckling load for a composite beam can be evaluated by the Euler relation (16):

where

is the beam length and

is a constrain factor. The evaluated critical load is two orders of magnitude bigger than the load considered in this context,

, so that the stability test is satisfied. By considering the slim ratio

, the buckling analysis also has to be extended to the Euler buckling hyperbole, which is defined by the relation:

Finally, the Johnsons critical stress also has to be considered:

The intersection between (36) and the (37), represented in

Figure 5a, gives the threshold slim ratio, such that if the slim ratio of the considered beam is smaller than this limit, the critical stress has to be calculated with (36), otherwise (37) must be used. In this case, the threshold slim ratio is higher than the beam slim ratio, so that the critical load is evaluated via (37):

From (38), it can be deduced that the bucking verification is also satisfied.

The same analysis has been performed on the SHELL281 model, and the eigenvalues in

Figure 5b have been obtained. The buckling analysis can indeed be expressed as an eigenvalues problem resulting from the deformed shape equilibrium:

where

is the stiffness matrix of the system,

is the geometric stiffness matrix of the system, whose value depends on the baseline load fixed

, and

is an eigenvalue such that the characteristic polynomial

.

Supposing a baseline load

, a static analysis followed by the buckling analysis has been performed, obtaining the eigenvalues in

Figure 5b. It has to be noted that since the beam is a composite, the instability could be misinterpreted as an excessive bending reaction. With respect to the first positive eigenvalue, the Euler critical load can be determined as:

so that the deviation between the analytical model (35) and the FE model (40) can be calculated as:

The software has therefore overestimated the structural resistance, although the deviation is acceptable.

3.3. Dynamic Analysis: Fatigue

The mechanical stress applied on the free end of the support is an alternative bending with amplitude:

The frequency of the load is equal to the speed of the rotor, set to

,

, and

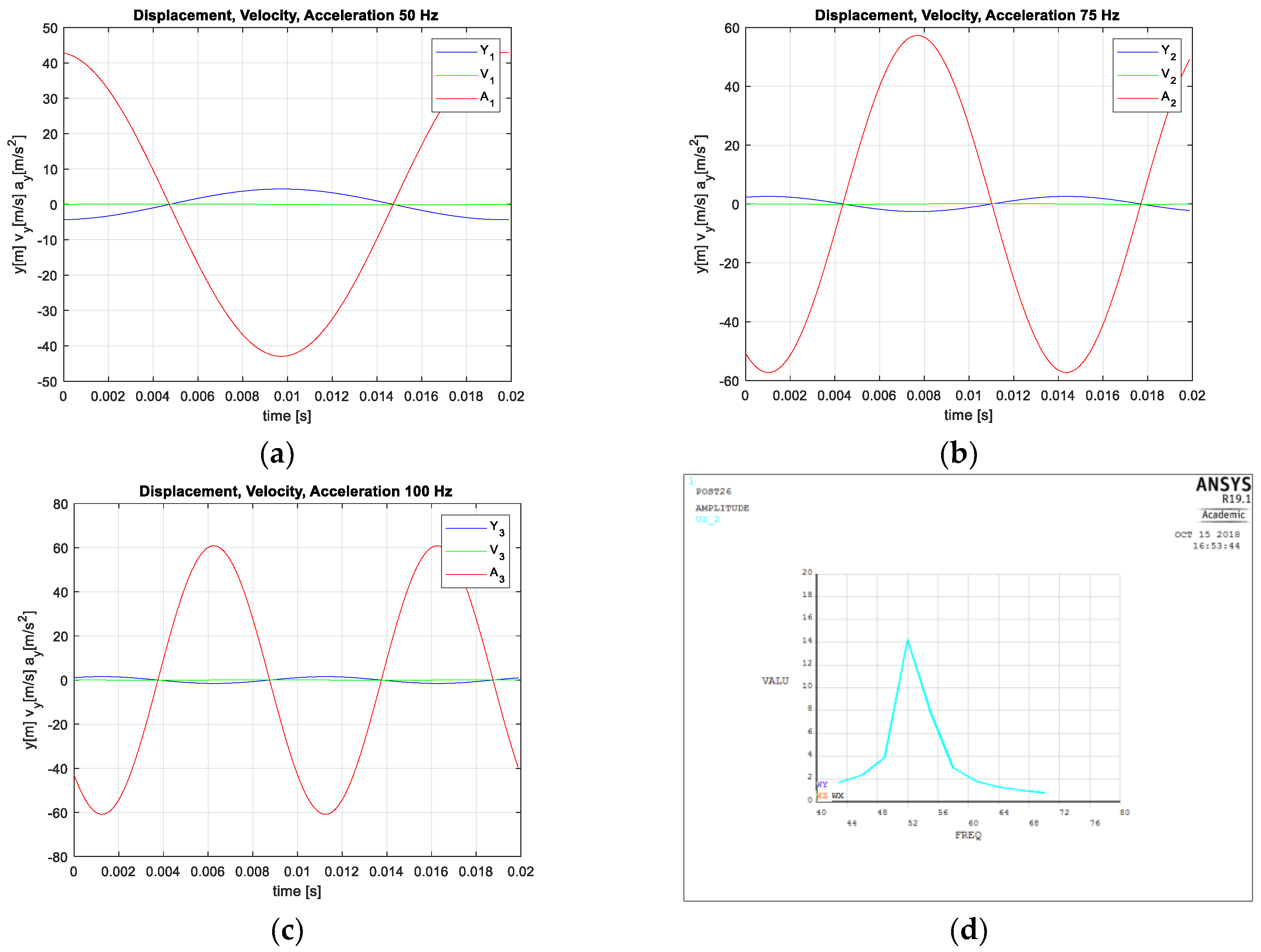

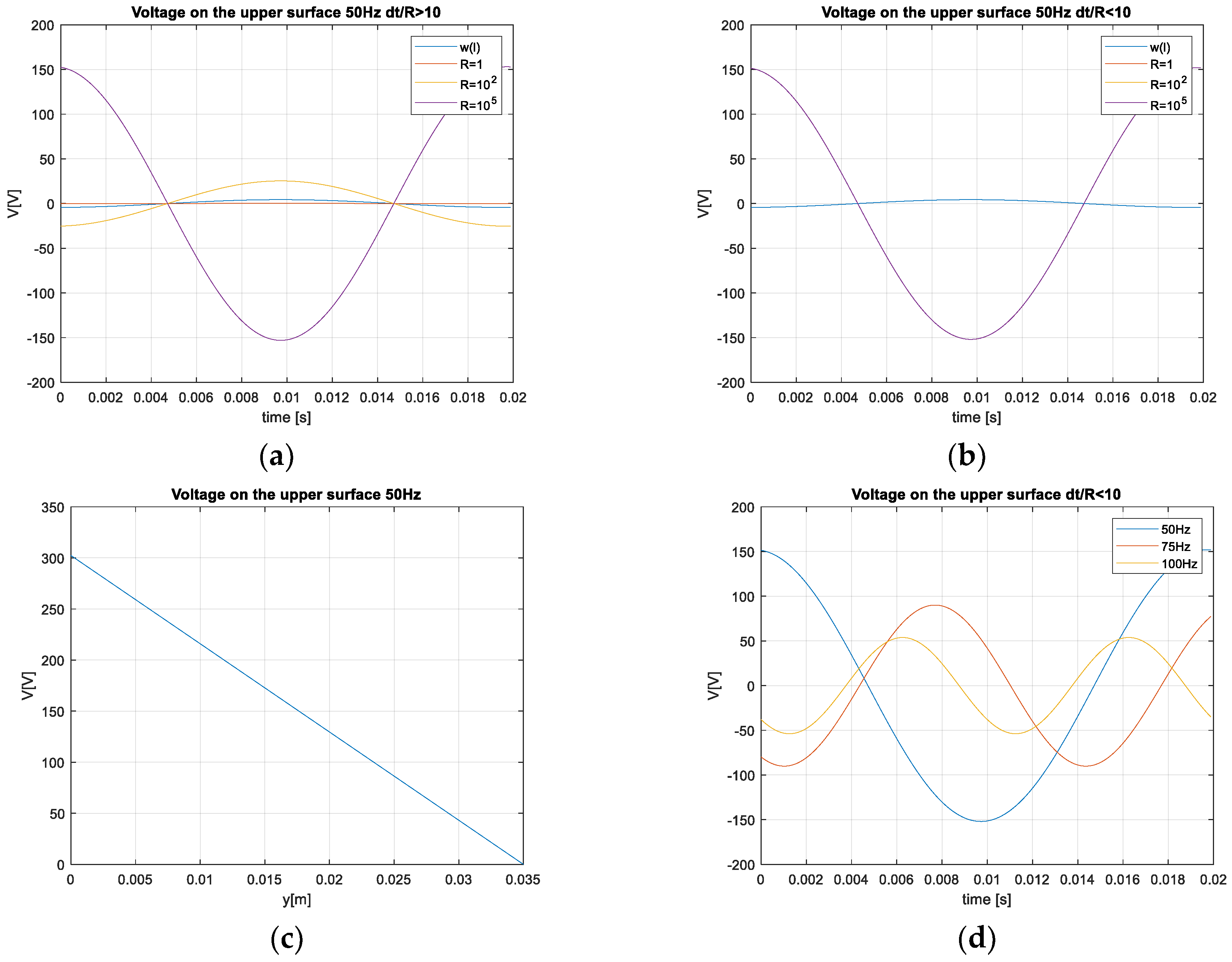

. The amplitude is maintained as a constant for the variation of the speed, by adjusting the eccentricity value. In this case, the term eccentricity has been improperly used to represent the product between the mass and the actual eccentricity, i.e., the distance between the center of mass and the center of rotation. The three load curves have been plotted in

Figure 6a with respect to the period of the slower one, while the Whӧler plot of the material has been represented in

Figure 6b. This plot is divided in three successive parts: the first part, low fatigue cycle (LFC), starts from the ultimate strength of the material, and the third part is a plateau representing the stress magnitude that corresponds to an infinite life of the component (Cutoff), while for the second part high fatigue cycle (HFC) the following relation has been used:

where

and

are two parameters derived by forcing the line (43) to pass through the following points:

with

as the maximum stress amplitude that can be applied for

cycles before collapse, and

as the cutoff stress limit. While

can be estimated from the ultimate strength via a factor

, which decreases as the ultimate strength increases,

can be assigned once the stress amplitude

is identified. Once

, the fatigue limit of a sample that is stressed with alternative bending, is estimated as being half the ultimate strength of the material,

is obtained as:

The Whӧler plot parameters and the service life of the component can then be evaluated:

Inter alia, in this case, since the cutoff limit (45) is above the stress amplitude exerted on the material (42), the service life of the component has been assumed as being infinite.

3.4. Dynamic Analysis: Equation of Motion

The rotor-support system can be modeled according to the Jeffcott rotor model, assuming a rigid rotor suspended on elastic supports. The rotor is assumed to be fixed at the mid-section of the drive, so that the system is symmetrical with respect to the yz plane. The four supports, assumed to be identical, have been modeled as a spring-damper system with uniform stiffness and dumping coefficients in the

y and

z directions. If the rotor is statically unbalanced, the motion equations can be written as [

28]:

with

as the rotor mass and

as the eccentricity. Given the aforementioned assumptions, the motions along the two axis are therefore decoupled. In particular, the force amplitude evaluated in (4) is exerted on each support, so that the following relation applies:

Given that (48) is constant, the three resulting eccentricity values are immediately obtained; they are listed in

Table 7.

Clearly, the eccentricity decreases with progressively smaller decrements as the speed increases.

By considering a rotor with a length of

and a diameter

, a balanced mass,

, is derived. The eccentricity property is then conferred to the system by removing

identical masses with a constant phase shift of

, starting from the mass

at

. Since the masses are symmetrically positioned with respect to the y-axis, the resultant mass center is simply shifted along the y-axis. By putting

and by solving the corresponding system of equations, the values listed in

Table 8 are calculated:

The rotor masses included in

Table 8 correspond to twice the mass of the rotor supports, which, indeed, has been schematized as pinned–pinned beams stressed by a concentrated force applied at the mid-section. This approximation leads to an underestimation of the resonance frequencies of the system.

With respect to the system stiffness, each support contributes to the values of the analytic electric stiffness and the SOLID226 electric stiffness found in

Table 6.

Assuming the stiffness constant with the speed, both the resonance frequencies and the critical dumping coefficients can be evaluated according to the following relations (see also

Table 9):

As expected, as the mass increases at a constant stiffness, and the natural frequency decreases.

The damping action of the system represents the hysteretic/friction phenomena that occur within and between the system parts. To calculate the corresponding coefficients, various methods can be used, and generally, the experimental interpolation of the data collected from the actual system methods are preferred. In this case, however, the proportional analytical damping model has been adopted:

Once the coefficients are assumed to be equal, the corresponding value can be calculated by fixing the magnitude of the damping ratio

. Inter alia, if

is fixed, the system law of motion will be an actual vibration, otherwise it would return with an exponential behavior to its initial condition. This assumes that the system has not been irreparably perturbed, in which case, it can either reach a new equilibrium state, or remain in a non-equilibrium state that can eventually take it to collapse. The values of the damping coefficients are reported in

Table 10 for different system configurations.

From the parameter characterization, it is finally possible to determine the motion law. By focusing on an upper support (the same results can be extended to a lower support), the dynamic Equation (47) can be written as:

from which:

The value of the gain factor

, of the speed ratio

and of the phase angle

are reported in

Table 11 for different speed values.

As expected, the gain factor is maximum when the rotor speed equals

, as the resonance frequency of the system is at

. It should be noted that the piezoelectric materials guarantee the best electro-mechanical conversion at around their resonance frequency, where indeed, the impedance of the correspondent equivalent electrical flow is minimized. The time behavior of motion, speed and acceleration at the three considered speeds is plotted in

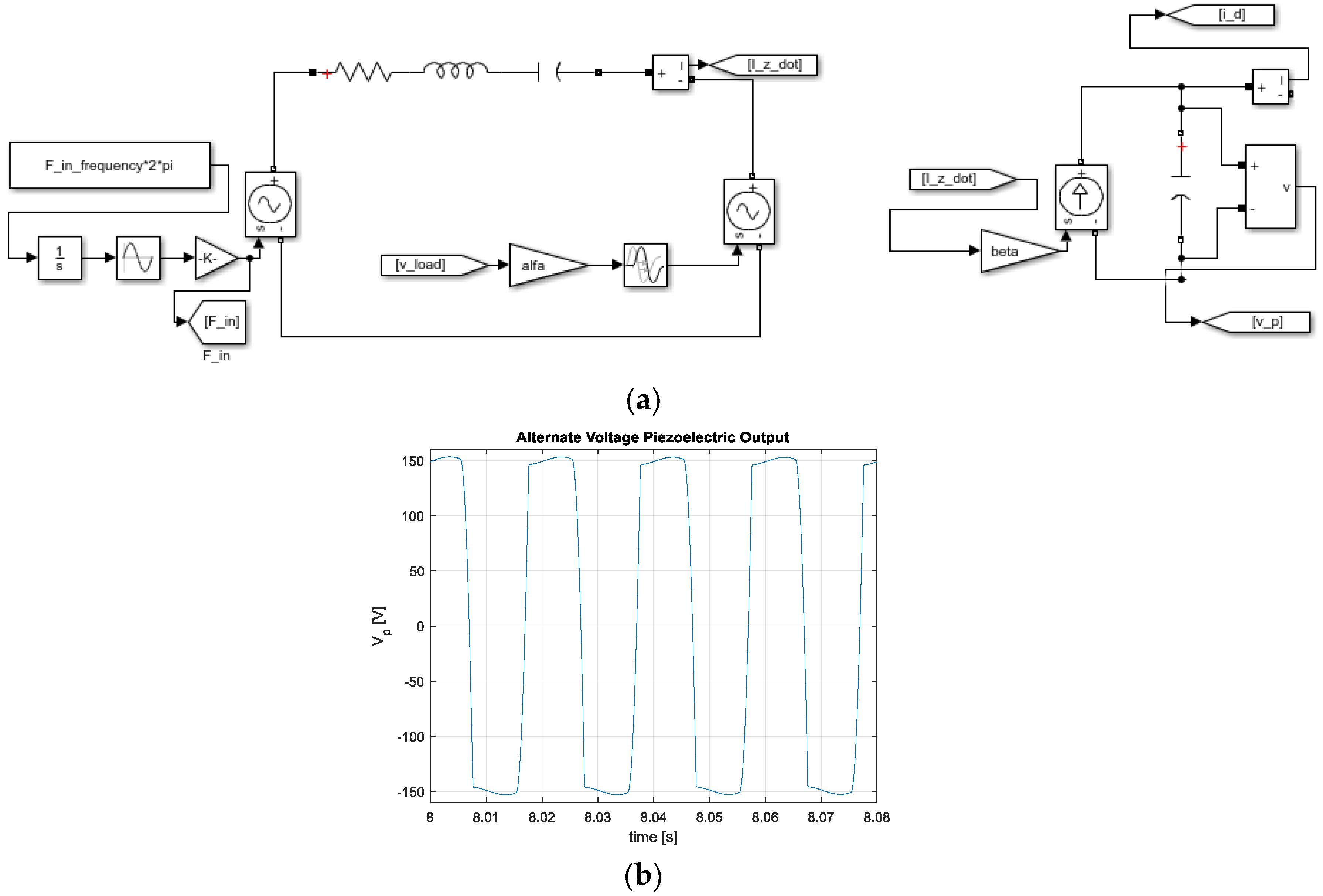

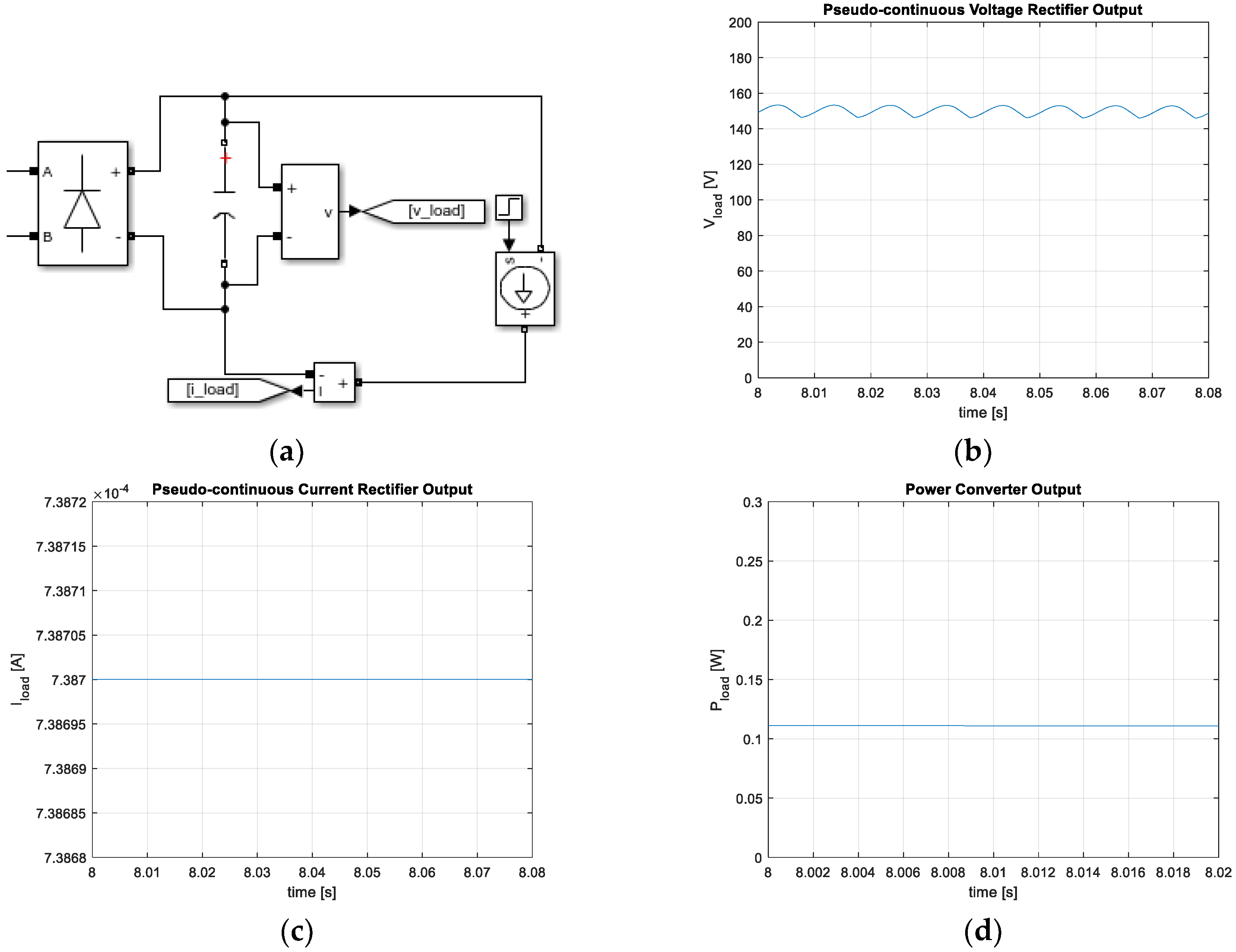

Figure 7.

The dynamic analyses have been performed on the SHELL281 FE model by including a MASS21 element whose

has been derived from the mass values shown in

Table 9. With respect to the values listed in

Table 8, the following deviations regarding the natural frequencies have been calculated:

It should be pointed out that all the estimated errors are very small.