Co-Doping Effect of BiGaO3 and (Bi,Na,K,Li)ZrO3 on Multi-Phase Structure and Piezoelectric Properties of (K,Na)NbO3 Lead-Free Ceramics

Abstract

:1. Introduction

2. Materials and Methods

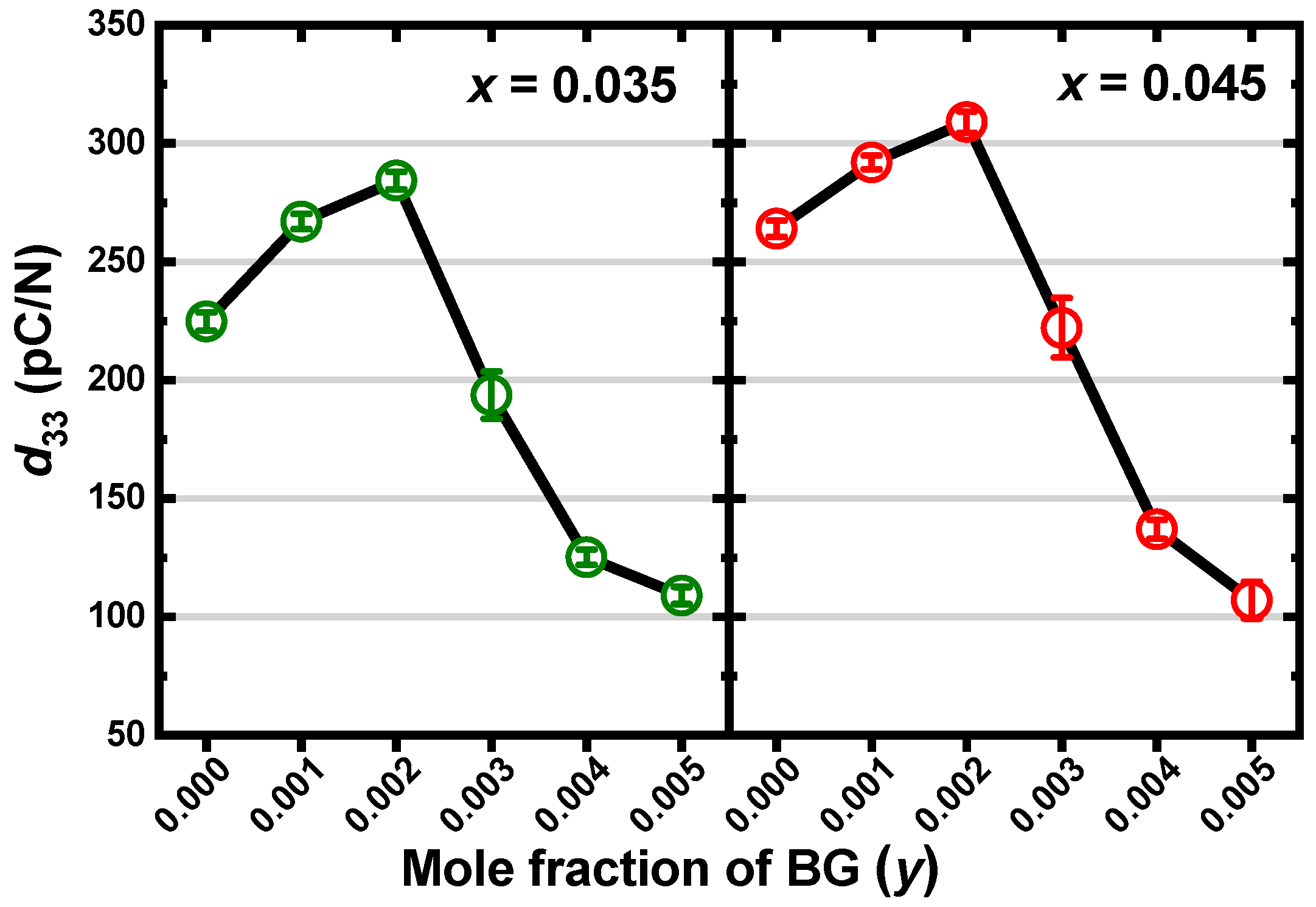

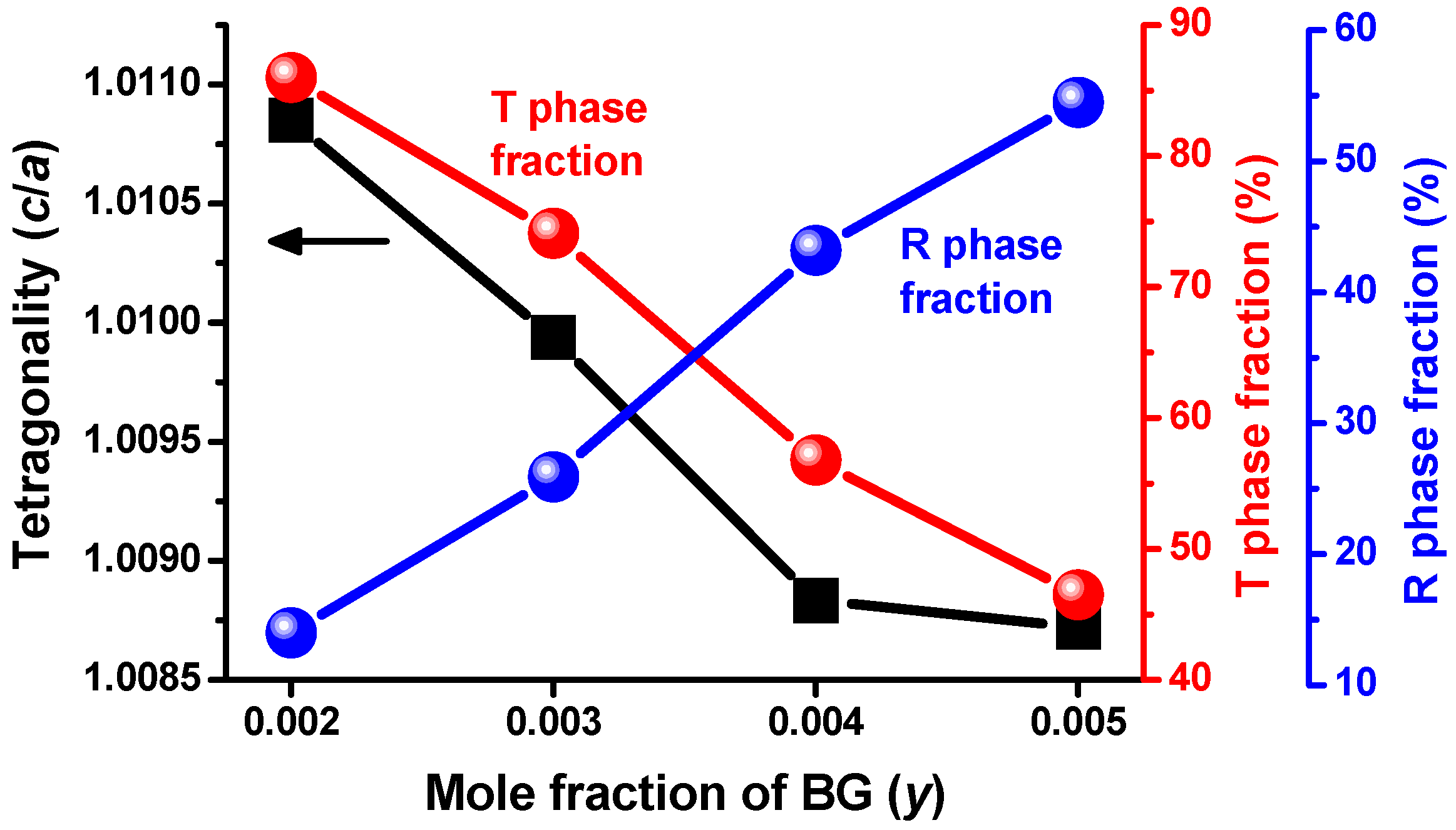

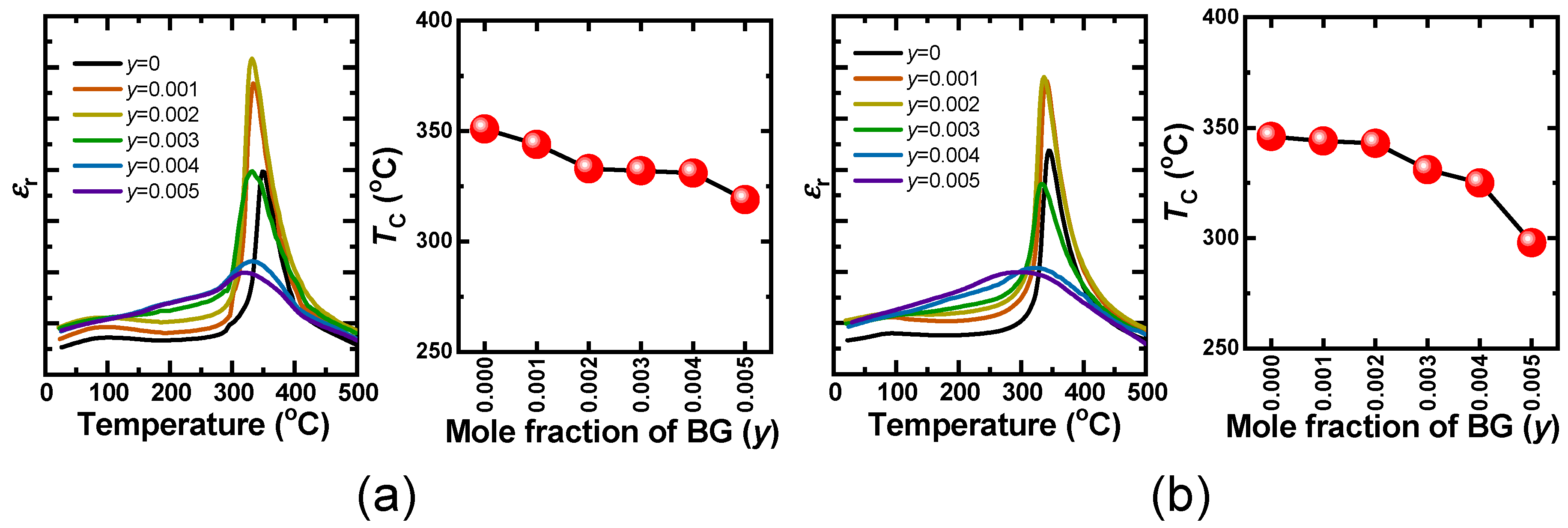

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, K.; Li, J.; Lv, X.; Wu, J.; Zhang, X.; Xiao, D.; Zhu, J. Superior piezoelectric properties in potassium-sodium niobate lead-free ceramics. Adv. Mater. 2016, 28, 8519–8523. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wu, J.; Xiao, D.; Zhu, J.; Cheng, X.; Zheng, T.; Zhang, B.; Lou, X.; Wang, X. Giant piezoelectricity in potassium-sodium niobate lead-free ceramics. J. Am. Chem. Soc. 2014, 136, 2905–2910. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Wu, H.; Wu, J.; Xiao, D.; Zhu, J.; Pennycook, S.J. Giant piezoelectricity and high Curie temperature in nanostructured alkali niobate lead-free piezoceramics through phase coexistence. J. Am. Chem. Soc. 2016, 138, 15459–15464. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zheng, T.; Wu, J.; Xiao, D.; Zhu, J.; Wang, H.; Wang, X.; Lou, X.; Gu, Y. Characteristics of giant piezoelectricity around the rhombohedral-tetragonal phase boundary in (K,Na)NbO3-based ceramics with different additives. J. Mater. Chem. A 2015, 3, 15951–15961. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Xiao, D.; Cheng, X.; Zheng, T.; Zhang, B.; Lou, X.; Zhu, J. Large d33 in (K,Na)(Nb,Ta,Sb)O3-(Bi,Na,K)ZrO3 lead-free ceramics. J. Mater. Chem. A 2014, 2, 4122–4126. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. Potassium-sodium niobate lead-free ceramics: Modified strain as well as piezoelectricity. J. Mater. Chem. A 2015, 3, 1868–1874. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J. Enhanced piezoelectricity over a wide sintering temperature (400–1050 °C) range in potassium sodium niobate-based ceramics by two step sintering. J. Mater. Chem. A 2015, 3, 6772–6780. [Google Scholar] [CrossRef]

- Lv, X.; Wu, J.; Yang, S.; Xiao, D.; Zhu, J. Identification of phase boundaries and electrical properties in ternary potassium-sodium niobate-based ceramics. ACS Appl. Mater. Interfaces 2016, 8, 18943–18953. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Ma, J.; Wu, S.; Wu, B. Phase structure and electrical properties of (1−x)K0.48Na0.52NbO3-xBi0.46La0.04(Na0.82K0.18)0.5ZrO3 lead-free piezoceramics. J. Mater. Sci. Mater. Electron. 2017, 28, 3299–3308. [Google Scholar] [CrossRef]

- Lv, X.; Wu, J.; Xiao, D.; Tao, H.; Yuan, Y.; Zhu, J.; Wang, X.; Lou, X. (1−x)(K0.48Na0.52)(Nb0.95-y-zTazSby)O3-xBi0.5(Na0.82K0.18)0.5ZrO3 lead-free ceramics: Composition dependence of the phase boundaries and electrical properties. Dalton Trans. 2015, 44, 4440–4448. [Google Scholar] [CrossRef] [PubMed]

- Rödel, J.; Jo, W.; Seifert, K.T.P.; Anton, E.-M.; Granzow, T. Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Zhu, J. Potassium-sodium niobate lead-free piezoelectric materials: Past, present, and future of phase boundaries. Chem. Rev. 2015, 115, 2559–2595. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Xiao, D.; Zhu, J. Potassium-sodium niobate lead-free piezoelectric ceramics: Recent advances and perspectives. J. Mater. Sci. Mater. Electron. 2015, 26, 9297–9308. [Google Scholar] [CrossRef]

- Wang, H.; Wu, J.; Cheng, X.; Xiao, D.; Zhu, J. New phase boundary and piezoelectric properties in (K,Na)NbO3 based ceramics. J. Alloy. Compd. 2014, 585, 748–752. [Google Scholar] [CrossRef]

- Du, H.; Liu, D.; Tang, F.; Zhu, D.; Zhou, W. Microstructure, piezoelectric, and ferroelectric properties of Bi2O3-added (K0.5Na0.5)NbO3 lead-free ceramics. J. Am. Ceram. Soc. 2007, 90, 2824–2829. [Google Scholar] [CrossRef]

- Kim, B.H.; Yang, S.A.; Lee, M.K.; Lee, G.J. Properties of (Bi,M)ZrO3 (M: Alkali metals)-modified (K,Na)NbO3 lead-free piezoceramics. Ceram. Int. 2017, 43, 15880–15885. [Google Scholar] [CrossRef]

- Baettig, P.; Schelle, C.F.; LeSar, R.; Waghmare, U.V.; Spaldin, N.A. Theoretical prediction of new high-performance lead-free piezoelectrics. Chem. Mater. 2005, 17, 1376–1380. [Google Scholar] [CrossRef]

- Li, C.; Wang, B.; Wang, R.; Wang, H.; Lu, X. First-principle study of structural, elastic, electronic, and optical properties of orthorhombic BiGaO3. Comput. Mater. Sci. 2008, 42, 614–618. [Google Scholar] [CrossRef]

- Long, C.; Li, T.; Fan, H.; Wu, Y.; Zhou, L.; Li, Y.; Xiao, L.; Li, Y. Li-substituted K0.5Na0.5NbO3-based piezoelectric ceramics: Crystal structures and the effect of atmosphere on electrical properties. J. Alloy. Compd. 2016, 658, 839–847. [Google Scholar] [CrossRef]

- Mgbemere, H.E.; Schneider, G.A. Effect of Ti on the properties of (KxNa1−x)NbO3 based lead-freeceramics. Ceram. Int. 2015, 41, 13232–13240. [Google Scholar] [CrossRef]

- Jiang, L.; Xing, J.; Tan, Z.; Wu, J.; Chen, Q.; Xiao, D.; Zhu, J. High piezoelectricity in (K,Na)(Nb,Sb)O3-(Bi,La,Na,Li)ZrO3 lead-free ceramics. J. Mater. Sci. 2016, 51, 4963–4972. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Y.; Xing, J.; Wu, J.; Chen, Q.; Liu, H.; Xiao, D.; Zhu, J. Phase structure and enhanced piezoelectric properties in (1−x)(K0.48Na0.52)(Nb0.95Sb0.05)O3-x(Bi0.5Na0.42Li0.08)0.9Sr0.1ZrO3 lead-free piezoelectric ceramics. Ceram. Int. 2017, 43, 2100–2106. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Cheng, X.; Wang, X.; Zhang, B.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. High strain in (K0.40Na0.60)(Nb0.955Sb0.045)O3-Bi0.50Na0.50ZrO3 lead-free ceramics with large piezoelectricity. J. Mater. Chem. C 2014, 2, 8796–8803. [Google Scholar] [CrossRef]

- Zheng, T.; Zu, Y.; Wu, J. Composition dependence of phase structure and electrical properties in lead-free (1−x)(K0.42Na0.585)(Nb1−ySby)O3-xBi0.5K0.5ZrO3 piezoceramics. J. Alloy. Compd. 2015, 647, 927–934. [Google Scholar] [CrossRef]

- Cheng, X.; Wu, J.; Lou, X.; Wang, X.; Wang, X.; Xiao, D.; Zhu, J. Achieving both giant d33 and high TC in potassium-sodium niobate ternary system. ACS Appl. Mater. Interfaces 2014, 6, 750–756. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.; Tan, Z.; Jiang, L.; Chen, Q.; Wu, J.; Zhang, W.; Xiao, D.; Zhu, J. Phase structure and piezoelectric properties of (1−x)K0.48Na0.52Nb0.95Sb0.05O3-x(Bi0.5Na0.5)0.9(Li0.5Ce0.5)0.1ZrO3 lead-free piezoelectric ceramics. J. Appl. Phys. 2016, 119, 034101. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Wang, X.; Xiao, D.; Zhu, J. Phase transition and piezoelectric properties of (1−x)(K0.42Na0.58)(Nb0.96Sb0.04)O3-x(Bi0.5Na0.5)0.90Mg0.10ZrO3 lead-free ceramics. J. Mater. Sci. Mater. Electron. 2014, 25, 4650–4656. [Google Scholar] [CrossRef]

- Ahn, C.W.; Park, C.S.; Viehland, D.; Nahm, S.; Kang, D.H.; Bae, K.S.; Priya, S. Correlation between phase transitions and piezoelectric properties in lead-free (K,Na,Li)NbO3-BaTiO3 ceramics. Jpn. J. Appl. Phys. 2008, 47, 8880–8883. [Google Scholar] [CrossRef]

- Rubio-Marcos, F.; Fernandez, J.F.; Ochoa, D.A.; García, J.E.; Rojas-Hernandez, R.E.; Castro, M.; Ramajo, L. Understanding the piezoelectric properties in potassium-sodium niobate-based lead-free piezoceramics: Interrelationship between intrinsic and extrinsic factors. J. Eur. Ceram. Soc. 2017, 37, 3501–3509. [Google Scholar] [CrossRef]

- Rubio-Marcos, F.; López-Juárez, R.; Rojas-Hernandez, R.E.; Del Campo, A.; Razo-Pérez, N.; Fernandez, J.F. Lead-free piezoceramics: Revealing the role of the rhombohedral-tetragonal phase coexistence in enhancement of the piezoelectric properties. ACS Appl. Mater. Interfaces 2015, 7, 23080–23088. [Google Scholar] [CrossRef] [PubMed]

- Lv, X.; Wu, J.; Zhu, J.; Xiao, D.; Zhang, X. A new method to improve the electrical properties of KNN-based ceramics: Tailoring phase fraction. J. Eur. Ceram. Soc. 2018, 38, 85–94. [Google Scholar] [CrossRef]

- Fu, J.; Zuo, R.; Wu, S.C.; Jiang, J.Z.; Li, L.; Tang, T.Y.; Wang, X.; Li, L. Electric field induced intermediate phase and polarization rotation path in alkaline niobate based piezoceramics close to the rhombohedral and tetragonal phase boundary. Appl. Phys. Lett. 2012, 100, 122902. [Google Scholar] [CrossRef]

- Iamsasri, T.; Tutuncu, G.; Uthaisar, C.; Wongsaenmai, S.; Pojprapai, S.; Jones, J.L. Electric field-induced phase transitions in Li-modified Na0.5K0.5NbO3 at the polymorphic phase boundary. J. Appl. Phys. 2015, 117, 024101. [Google Scholar] [CrossRef]

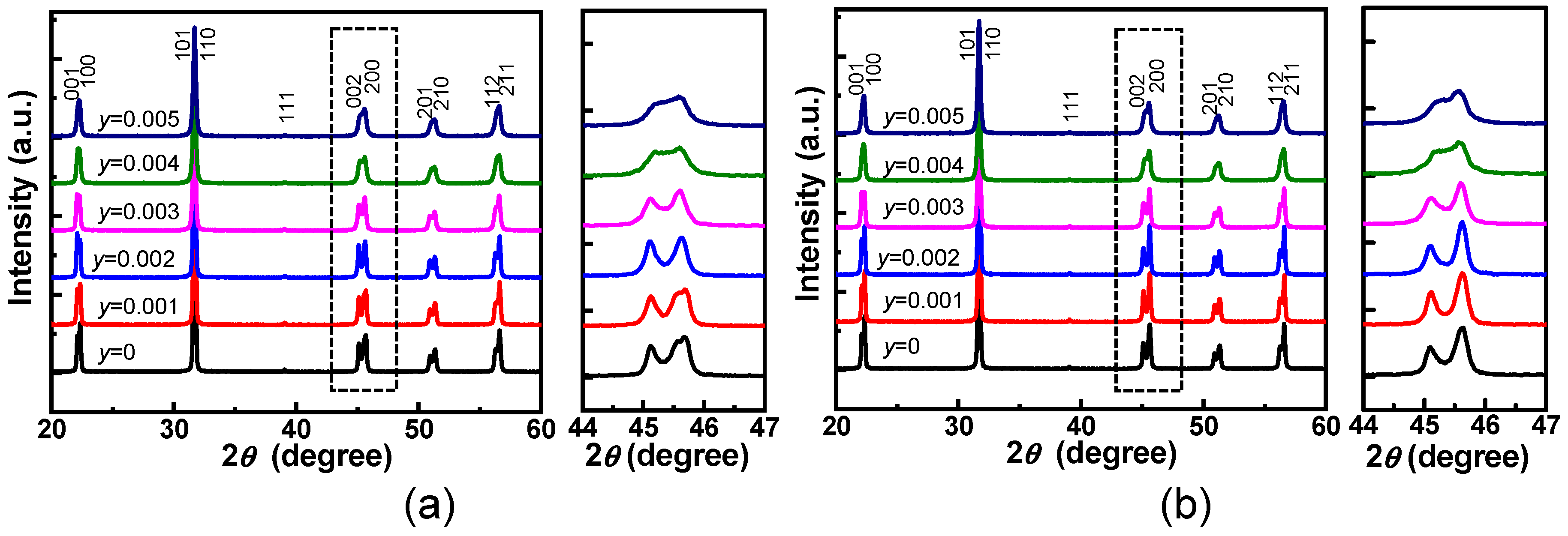

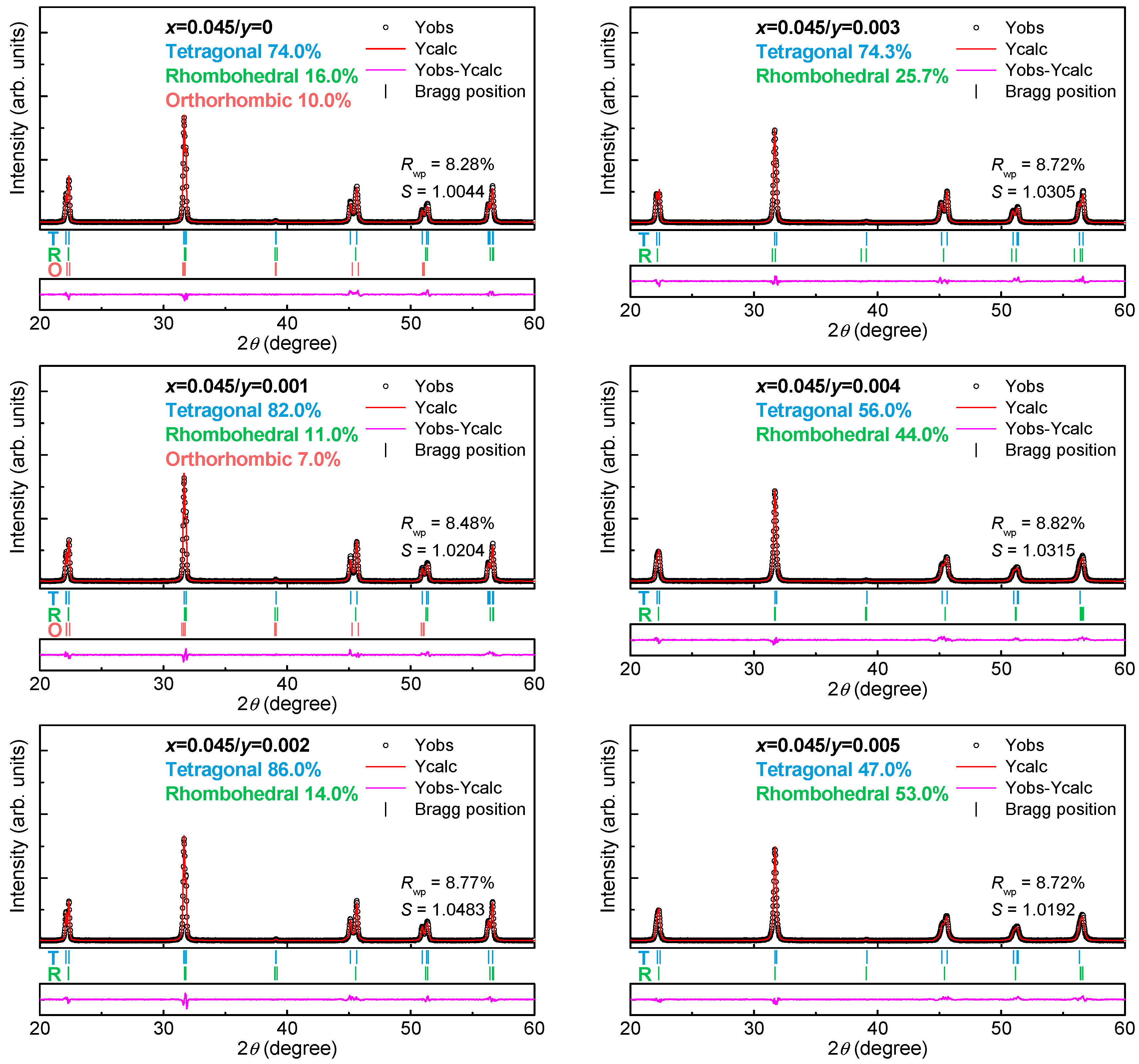

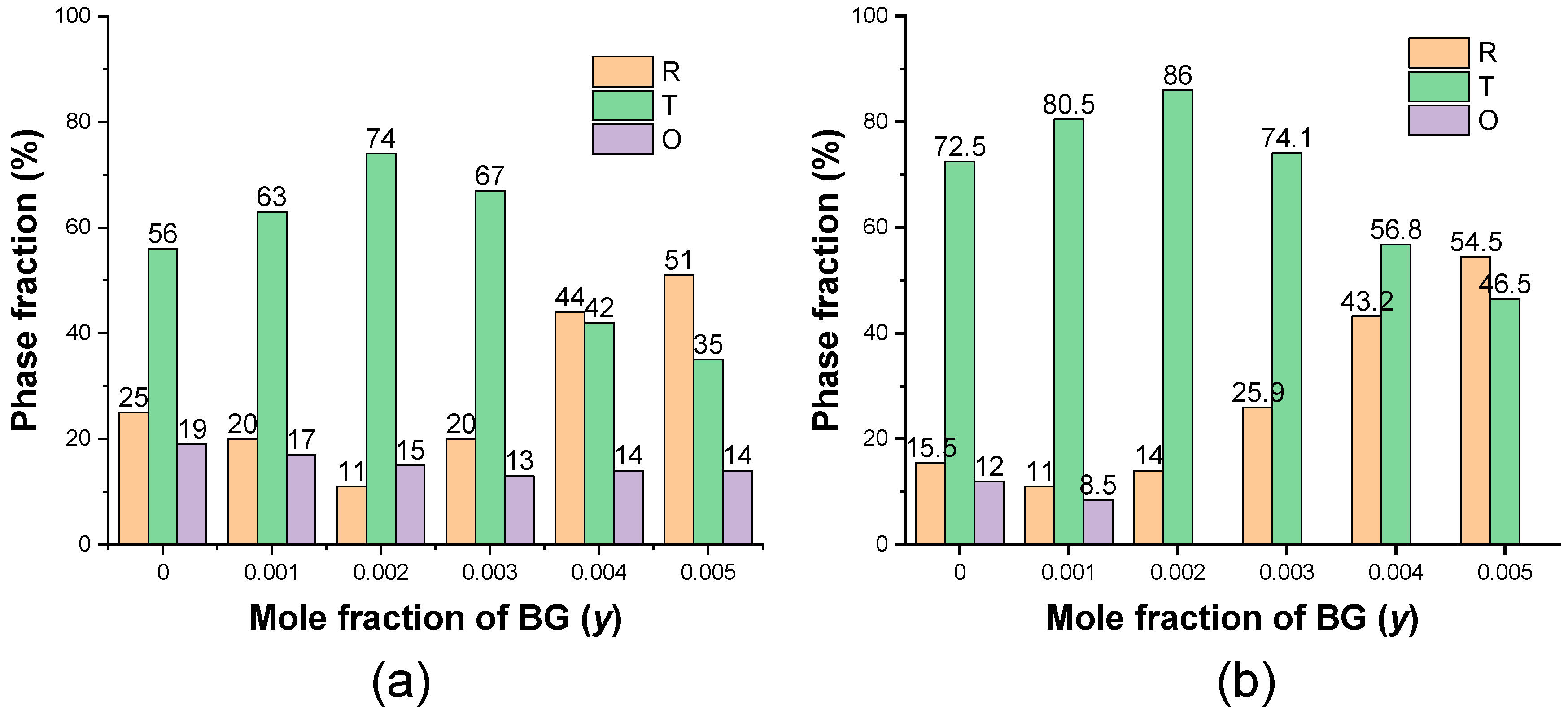

| Mole Fraction of BiGaO3 (y) | Phase Structure | Cell Parameters | Phase Fraction (%) | Rwp (%) | S | |||

|---|---|---|---|---|---|---|---|---|

| a (Å) | b (Å) | c (Å) | α (= γ = β) (°) | |||||

| 0 | R-O-T | 3.9813 | 3.9813 | 3.9813 | 89.820 | 15.5 (R3m) | 8.28 | 1.0044 |

| 3.9635 | 5.664 | 5.656 | 90 | 12 (Amm2) | ||||

| 3.9723 | 3.9723 | 4.0164 | 90 | 72.5 (P4mm) | ||||

| 0.001 | R-O-T | 3.9808 | 3.9808 | 3.9808 | 89.815 | 11 (R3m) | 8.48 | 1.0204 |

| 3.9630 | 5.655 | 5.6770 | 90 | 8.5 (Amm2) | ||||

| 3.9721 | 3.9721 | 4.0152 | 90 | 80.5 (P4mm) | ||||

| 0.002 | R-T | 3.9811 | 3.9811 | 3.9811 | 89.806 | 14 (R3m) | 8.77 | 1.0483 |

| 3.9720 | 3.9720 | 4.0151 | 90 | 86 (P4mm) | ||||

| 0.003 | R-T | 3.9978 | 3.9978 | 3.9978 | 89.548 | 25.9 (R3m) | 8.72 | 1.0305 |

| 3.97124 | 3.97124 | 4.0107 | 90 | 74.1 (P4mm) | ||||

| 0.004 | R-T | 3.9895 | 3.9895 | 3.9895 | 89.91 | 43.2 (R3m) | 8.82 | 1.0315 |

| 3.9733 | 3.9733 | 4.0080 | 90 | 56.8 (P4mm) | ||||

| 0.005 | R-T | 3.9966 | 3.9966 | 3.9966 | 89.99 | 54.5 (R3m) | 8.72 | 1.0192 |

| 3.9792 | 3.9792 | 4.0147 | 90 | 46.5 (P4mm) | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.-K.; Bu, S.-D.; Lee, G.-J. Co-Doping Effect of BiGaO3 and (Bi,Na,K,Li)ZrO3 on Multi-Phase Structure and Piezoelectric Properties of (K,Na)NbO3 Lead-Free Ceramics. Energies 2019, 12, 886. https://doi.org/10.3390/en12050886

Lee M-K, Bu S-D, Lee G-J. Co-Doping Effect of BiGaO3 and (Bi,Na,K,Li)ZrO3 on Multi-Phase Structure and Piezoelectric Properties of (K,Na)NbO3 Lead-Free Ceramics. Energies. 2019; 12(5):886. https://doi.org/10.3390/en12050886

Chicago/Turabian StyleLee, Min-Ku, Sang-Don Bu, and Gyoung-Ja Lee. 2019. "Co-Doping Effect of BiGaO3 and (Bi,Na,K,Li)ZrO3 on Multi-Phase Structure and Piezoelectric Properties of (K,Na)NbO3 Lead-Free Ceramics" Energies 12, no. 5: 886. https://doi.org/10.3390/en12050886

APA StyleLee, M.-K., Bu, S.-D., & Lee, G.-J. (2019). Co-Doping Effect of BiGaO3 and (Bi,Na,K,Li)ZrO3 on Multi-Phase Structure and Piezoelectric Properties of (K,Na)NbO3 Lead-Free Ceramics. Energies, 12(5), 886. https://doi.org/10.3390/en12050886