Abstract

A technical evaluation of CO2 capture technologies when retrofitted to a cement plant is performed. The investigated technologies are the oxyfuel process, the chilled ammonia process, membrane-assisted CO2 liquefaction, and the calcium looping process with tail-end and integrated configurations. For comparison, absorption with monoethanolamine (MEA) is used as reference technology. The focus of the evaluation is on emission abatement, energy performance, and retrofitability. All the investigated technologies perform better than the reference both in terms of emission abatement and energy consumption. The equivalent CO2 avoided are 73–90%, while it is 64% for MEA, considering the average EU-28 electricity mix. The specific primary energy consumption for CO2 avoided is 1.63–4.07 MJ/kg CO2, compared to 7.08 MJ/kg CO2 for MEA. The calcium looping technologies have the highest emission abatement potential, while the oxyfuel process has the best energy performance. When it comes to retrofitability, the post-combustion technologies show significant advantages compared to the oxyfuel and to the integrated calcium looping technologies. Furthermore, the performance of the individual technologies shows strong dependencies on site-specific and plant-specific factors. Therefore, rather than identifying one single best technology, it is emphasized that CO2 capture in the cement industry should be performed with a portfolio of capture technologies, where the preferred choice for each specific plant depends on local factors.

1. Introduction

Production of cement is estimated to account for around 7% of global CO2 emissions (2018) [1]. The cement industry can reduce its specific CO2 emissions through a variety of different techniques, such as increased energy efficiency, utilization of alternative fuels, application of alternative raw materials, and reduction of the clinker to cement ratio. However, these techniques have already been exploited to a significant extent, and they can only partly reduce the emissions [2]. Around two-thirds of the CO2 emissions from the cement industry are process related, originating from the calcination of limestone where CaCO3 is converted to CaO and CO2, while one-third of the emissions come from combustion of fuels in the cement plant’s calciner and rotary kiln. A measure such as fuel switch can therefore only remove one-third of the CO2 emissions. CO2 capture and storage (CCS) can significantly reduce both the process related and fuel related emissions. It is identified as the single measure that has the largest potential for further overall emission reductions in the cement industry [1,2].

Cement kilns usually have a lifetime of 30–50 years [3]. Although a few kilns might have to be rebuilt to meet EU requirements on pollutant emissions and technical standards [4], it is not likely that many kilns are to be built in Europe in a foreseeable future, as the cement production is anticipated to be approximately constant in the next decades [1]. Therefore, in order to abate CO2 emissions from European cement production, it is important that CO2 capture technologies can be retrofitted to existing cement plants.

The most mature CO2 capture technology at present is chemical absorption with amine. However, this technology may not necessarily be the best option when alternative technologies have matured. In literature, several CO2 capture technologies have been evaluated for use in the cement industry. Most of the studies have focused on amine-based CO2 capture [2,5,6,7,8,9], followed by fewer studies on calcium looping [6,10,11], oxyfuel [2,8], and membrane-based technologies [6,7,12]. Comprehensive work has been performed in each of the studies, but technical and economic performance cannot be directly compared between studies since they are based on different assumptions. A consistent evaluation of more than two types of CO2 capture technologies for the cement industry is not available.

In most of the assessments of CO2 capture technologies in the cement industry, retrofit to an existing cement plant is assumed. However, there are several practical aspects linked to retrofitability that are not necessarily reflected in energy performance and cost. For instance, aspects such as space requirement or added load to the local power grid could potentially determine whether a technology can be implemented or not. Liang and Li [5] defined a list of criteria for assessing the potential of a cement plant to be retrofitted with CO2 capture technologies. However, there is to the authors’ knowledge no such work done on assessing retrofitability of capture technologies to cement plants.

This paper presents a consistent technical evaluation of CO2 capture technologies for retrofit in the cement industry. The evaluation focusses on emission abatement, energy performance, and retrofitability. The following technologies are investigated:

- oxyfuel process

- chilled ammonia process

- membrane-assisted CO2 liquefaction

- calcium looping (tail-end and integrated configuration)

These technologies comprise a set of fundamentally different technologies that appear promising for application in the cement sector. Absorption with monoethanloamine (MEA) is used as reference technology due to its benchmark status in the literature.

This work has been carried out as a part of the Horizon 2020 project “CO2 capture from cement production” (CEMCAP) [13], which has the overall objective to prepare the ground for large-scale implementation of CO2 capture in the European cement industry. An essential element in responding to this objective has been to perform a comprehensive techno-economic comparative assessment of CO2 capture, which can be used as a decision basis for future evaluations of CO2 capture implementation at cement plants. An extraction of this work is presented as a paper series, where the technical evaluation presented in the current paper forms Part 1, and an economic analysis forms Part 2.

2. Reference Cement Plant and CO2 Capture Technologies

2.1. Reference Cement Plant

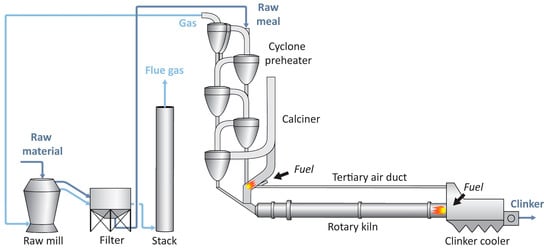

The reference cement plant is a Best Available Technique (BAT) plant defined by the so-called European Bref document [14] and adopted by the European Cement Research Academy (ECRA) and CEMCAP [2,9,15]. It is based on a dry kiln process, consisting of a five-stage cyclone preheater, calciner with tertiary air duct, rotary kiln, and grate cooler. The most important characteristics of the plant are summarized in Table 1. It has a capacity of 3.0 kt clinker per day, which corresponds to ca. 1.0 Mt clinker per year, or 1.4 Mt cement per year, with a run time of >330 days per year.

Table 1.

Characteristics of the reference cement plant.

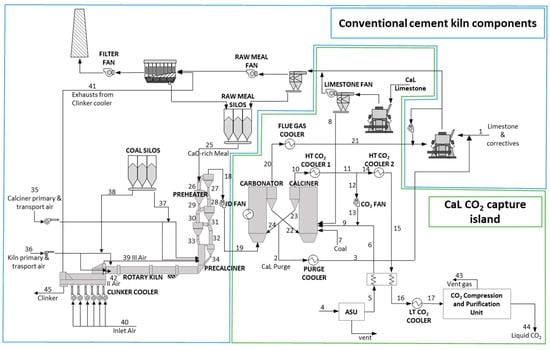

The clinker burning line of the plant is shown in Figure 1. The raw material, which consists of 77 wt% CaCO3, 14 wt% SiO2, and small amounts of Al2O3, Fe2O3, MgCO3, and water, is first ground in the raw mill to form raw meal, where it is also dried by hot flue gas from the preheater. The flue gas and the raw meal are subsequently separated in a dust filter, and the raw meal is sent to the preheater while the flue gas is sent to the stack. In the preheater the meal is heated by hot flue gas coming from the calciner and the rotary kiln. The meal and the hot gases are first mixed for heat transfer and then separated again in cyclones arranged above one another. The preheated raw meal enters the calciner, where the major part of the calcination (CaCO3 -> CaO + CO2) is performed. Around 60% of the plant’s total fuel input is consumed here to achieve a suitable temperature (~860 °C) and drive the endothermic reaction. After the calciner, the calcined (>95%) raw meal enters the rotary kiln, where the still unreacted part of the limestone is calcined after a few meters and the formation of clinker takes place. The rotary kiln is heated by the main burner where the remaining 40% of the plant’s fuel input is consumed. The solid material reaches 1450 °C, and the temperature of the gas phase can reach 2000 °C. The hot clinker is discharged from the kiln to a clinker cooler, where the clinker is cooled with ambient air. Some of the resulting hot air is used as combustion air in the main burner (secondary air) and in the calciner (tertiary air).

Figure 1.

The clinker burning line of the reference cement plant.

Emissions of NOx are controlled by selective non-catalytic reduction (SNCR) to not exceed the permitted limit of 500 mg/Nm3 at 10% O2 [16]. In practice this means that ammonia solution is injected in the kiln system to reduce NOx to N2. No system is installed for SOx emission control, because the SOx emissions are already below the permitted limit. The CEMCAP reference plant is identical to the ECRA reference plant, with the exception that SNCR is assumed to be implemented in the CEMCAP reference plant and not in the ECRA reference plant.

The composition and flow rate of the flue gas depends on the amount of air leaking into the system. The nominal air leak increases with time and operation of the plant, while it is reinstated via the yearly plant maintenance. The air leak in the raw mill is predominant, so variation over the year is only considered after the mill. Flue gas conditions at the stack during the first and second part of the year are given in Table 2.

Table 2.

Flue gas conditions at stack. Nm3 refers to normal cubic meters (volume at 0 °C and 1 atm).

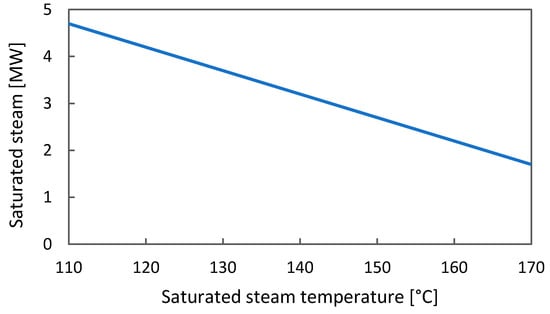

Waste heat can be recovered from the cooler exhaust air to produce steam (Figure 2). The dust in the exhaust air is assumed to be removed with a ceramic filter prior to the heat recovery steam generator, which is assumed to have a minimum approach temperature of 80 °C.

Figure 2.

Maximum amount of saturated steam that can be generated by heat recovery from the cooler exhaust air as function of the saturated steam temperature, considering a minimum approach temperature of 80 °C.

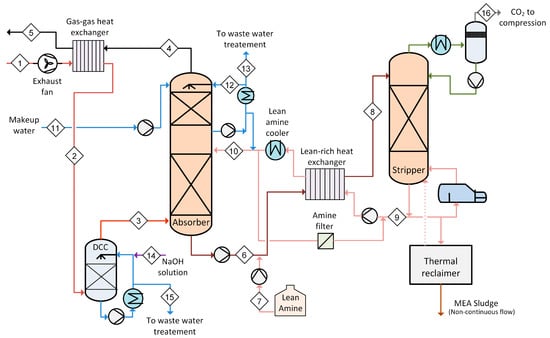

2.2. MEA Absorption

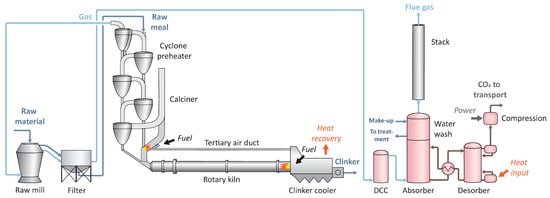

The reference technology MEA absorption is a post-combustion technology, where CO2 is absorbed from the flue gas with MEA solvent (Figure 3). To limit solvent degradation, the content of NOx and SOx in the flue gas must be reduced beyond the permitted emission limits before the flue gas comes in contact with the solvent. The already existing SNCR system is assumed to be utilized to remove additional NOx before the flue gas leaves the kiln. This flue gas is then cooled in a direct contact cooler (DCC) where water also is removed, and SOx is removed by scrubbing with NaOH. The cooled flue gas can then be sent to the absorber column where aqueous MEA solution (30 wt %) absorbs CO2 from the gas. Evaporated MEA is recovered from the purified flue gas in a water wash section at the top of the absorber. The CO2 rich MEA solvent is regenerated in a desorber column, and the resulting high-purity CO2 is compressed to reach the transport specifications.

Figure 3.

Reference clinker burning line with MEA absorption.

The process requires a considerable amount of heat for solvent regeneration, and power is required for fans and pumps in the absorption process and for compression of the captured CO2. Waste heat can be used to cover some of the heat demand. For the reference cement plant, the available waste heat can cover 4% of the total heat demand.

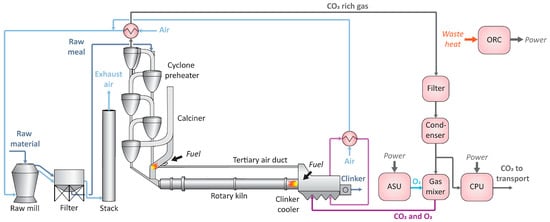

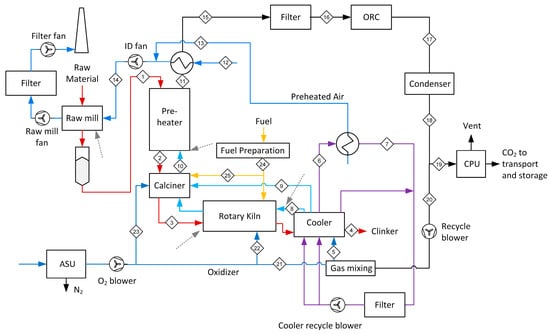

2.3. Oxyfuel Process

In the oxyfuel process (Figure 4), combustion is performed with an oxidizer consisting mainly of oxygen mixed with recycled CO2, to produce a CO2 rich flue gas which allows a relatively easy purification with a CO2 purification unit (CPU). As opposed to the MEA technology, the cement kiln process itself must be modified. The gas atmosphere in the clinker cooler, the rotary kiln, the calciner and the preheater is changed, and some of the flue gas is recycled. Air that is heated by hot gases from the preheater and the clinker cooler is sent to the raw mill to dry the raw material, instead of the flue gas.

Figure 4.

Reference clinker burning line with oxyfuel CO2 capture.

Additional power is required for the oxyfuel process compared to a plant without capture, mainly by an air separation unit (ASU) providing oxygen and the CPU. Some of this power demand can be covered by a waste heat recovery system. In this analysis, an organic Rankine cycle (ORC) is assumed to be installed.

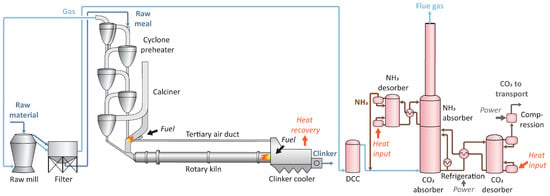

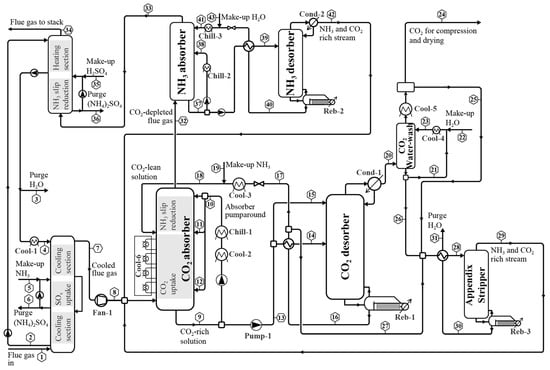

2.4. Chilled Ammonia Process

The chilled ammonia process (CAP) is a post-combustion technology based on absorption, where CO2 is removed from the flue gas using chilled ammonia as solvent (Figure 5). The flue gas is first conditioned in a DCC where it is cooled and SOx is removed by scrubbing with ammonia, before it is sent to an absorption column where CO2 is removed by an ammonia solution. The temperature in the absorber is controlled by a solvent pump-around that is chilled down to temperatures around 12–13 °C. Ammonia is recovered from the flue gas in a water wash section at the top of the absorber, before purified flue gas is released to the atmosphere. Ammonia is desorbed from the wash water in a desorption column and recycled into the process. CO2 rich ammonia solvent is regenerated in a CO2 desorber that is operated at around 25 bar. The resulting high-purity CO2 stream must be further pressurized to meet the transport specifications.

Figure 5.

Reference clinker burning line with CAP CO2 capture.

In this process heat is required for solvent regeneration and for the ammonia recovery system, and power is required for chilling, pumping, and compression. Waste heat can be utilized to cover a part of the heat demand. This amounts to 7–8% of the total heat demand in the case of the reference cement plant.

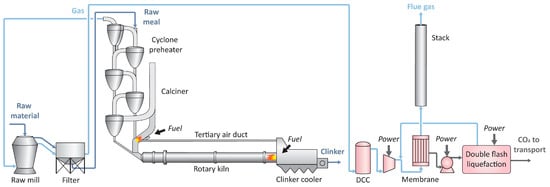

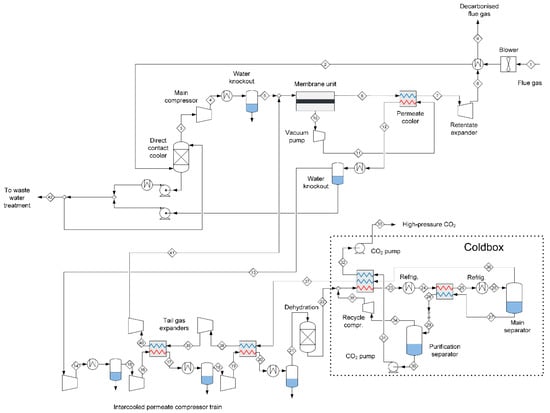

2.5. Membrane-Assisted CO2 Liquefaction

The membrane-assisted CO2 liquefaction (MAL) technology comprises a combination of polymeric membranes and a CO2 liquefaction process (Figure 6). The polymeric membranes are utilized for bulk separation resulting in CO2 a product with moderate purity. This product is further treated in the CO2 liquefaction process, where CO2 is liquefied to form high purity CO2, while the partially decarbonized tail gas is recycled to the membrane feed gas.

Figure 6.

Reference clinker burning line with membrane-assisted CO2 liquefaction.

The flue gas entering the process is first cooled and water is removed in a DCC, before it is compressed and sent to the membrane module. The pressure difference and pressure ratio over the membrane module is generated both by the flue gas compression on the feed side and vacuum pumps on the permeate side of the membrane. The chemical stability of polymeric membranes depends on the type of polymer, and the tolerance of such membranes to SOx and NOx is often highlighted as uncertain [17]. However, some membrane producers report on high tolerances for their membranes [18]. In this work, the same strategy for SOx and NOx removal prior to the capture system as for MEA absorption is assumed.

The technology is a post-combustion technology with no additional integration or feedback to the cement plant. Only electric power is required as input to the process.

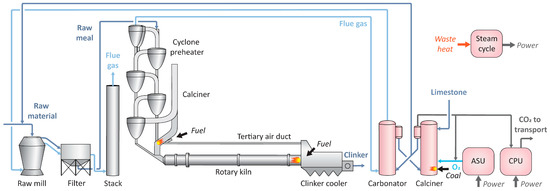

2.6. Calcium Looping—Tail-End Configuration

The calcium looping (CaL) technology is based on the reversible carbonation reaction (CaO + CO2 ⇌ CaCO3), which is exploited to separate carbon dioxide from flue gas. The technology can be applied to a cement plant in a tail-end configuration (Figure 7) or it can be integrated with the calcination process in the cement kiln. In the tail-end configuration the flue gas from the cement kiln is sent to a carbonator where CO2 is removed by reaction with CaO-based sorbent. The sorbent is regenerated in a calciner where coal is burnt under oxyfuel conditions to reach the calcination temperature of around 920 °C. The captured CO2 requires some additional purification in a CPU. CaO-rich purge from the system is sent to the cement kiln and used as constituents of the raw meal.

Figure 7.

Reference clinker burning line with calcium looping CO2 capture—tail-end configuration.

The tail-end CaL process requires supply of limestone and coal. Power is required for an ASU providing oxygen, fans, and the CPU. A steam cycle recovers high temperature waste heat and produces power. Depending on the case this results in net import or net export of power.

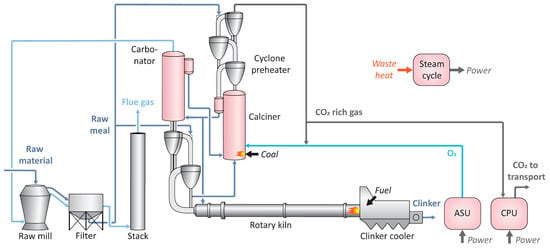

2.7. Calcium Looping—Integrated Configuration

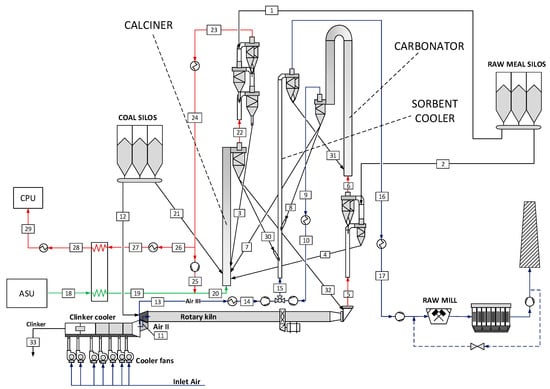

In the integrated calcium looping configuration, the CO2 capture calciner is combined with the calciner of the cement kiln for a more energy efficient process (Figure 8). Because of the small size of the particles required in the calciner of the cement kiln, which make them hardly fluidizable, the carbonation and calcination reactions must take place in entrained flow reactors instead of circulating fluidized bed reactors that are normally used in CaL processes.

Figure 8.

Reference clinker burning line with calcium looping CO2 capture—integrated configuration.

As for the tail-end configuration, additional fuel is required, and the calciner must be operated under oxyfuel conditions. Power is required for an ASU, a CPU and fans, but power is also generated by a steam cycle utilizing waste heat in the process.

3. Methodology

Process simulations of the reference plant and each of the technologies are established as a basis for the analysis. Common assumptions for the process simulations such as specifications for different types of process units are used as defined in the CEMCAP framework [15], and the simulations are aligned with experimental research performed within the project [19,20,21,22,23,24,25,26].

The oxyfuel and calcium looping technologies are closely integrated with the kiln, while the other technologies are only connected to the kiln by the flue gas entering the system and heat integration if heat is required. Due to the integration with the kiln, the two partners simulating these processes, VDZ, and Politecnico di Milano (PoliMi), have established their own simulations of the reference kiln. The other technologies are simulated using flue gas from the VDZ simulation of the reference kiln as feed to the process.

The captured CO2, direct and indirect CO2 emissions, and primary energy consumption of the reference cement plant with and without CO2 capture are quantified based on the process simulations and used to calculate quantitative key performance indicators (KPIs) on emission abatement and energy performance. It should be noted that since simulations of MEA, oxyfuel, CAP, and MAL are based on the VDZ simulation of the reference kiln, values from this simulation are used as reference in the KPI calculations, while for the calcium looping technologies, values from the PoliMi simulation of the reference kiln are used as reference.

Finally, an assessment of retrofitability of all capture technologies is performed with respect to qualitative KPIs.

3.1. Common Design Specifications

All the capture processes are designed for minimum 90% CO2 avoided from flue gas, , and pipeline transport, which requires >95% CO2, <300 ppmwt H2O, and 110 bar. For MEA, CAP, and MAL, which are installed after the raw mill, the process is designed for medium air leak and assumed to be operated with low air leak half of the year and medium air leak the other half of the year. The oxyfuel and CaL technologies are implemented before the mill, and the effect of change in air leak over the year is this neglected for these technologies.

3.2. Utility Energy Consumption and CO2 Emissions

Calculated emissions and energy consumption of utilities are based on assumptions presented in Table 3. For the electricity generation efficiency and CO2 emissions, the average electricity mix in EU-28 in 2014 is used as base case, but alternative scenarios that also are investigated are summarized in Table 4. For MEA and CAP, which require steam, it is assumed that the available waste heat will be used to cover the demand as far as possible, and that the rest is covered by a natural gas (NG) fired boiler.

Table 3.

Assumptions on energy consumption (lower heating value) and CO2 emissions related to utilities.

Table 4.

Generation efficiency and specific CO2 emissions of electric power in alternative scenarios for electric power generation.

3.3. Technical Key Performance Indicators

Key performance indicators for evaluation of emission abatement, energy performance, and retrofitability are defined.

3.3.1. Emission Abatement

The CO2 capture ratio is a common KPI for CO2 capture processes. It is defined as the CO2 captured, , divided by the CO2 generated, :

The CO2 generated is both CO2 generated in the cement kiln and CO2 generated by fuel combustion internally in the capture process, but not CO2 generated in the NG fired boilers or CO2 generated indirectly by power consumption. The CO2 captured is the total amount of CO2 captured. There is no distinction between CO2 originating from the cement process, and CO2 originating from additional fuel combustion.

The CO2 avoided from flue gas evaluates the direct CO2 emission reduction from the flue gas of the cement kiln. It is defined as

where denotes specific CO2 emissions with the kiln flue gas in the reference plant, and denotes the specific CO2 emissions with the flue gas of the kiln with capture. For technologies where a CPU is used, the CPU vent gas is accounted as a part of the flue gas. Emissions from steam generation (NG fired boilers) and indirect emissions related to power consumption/generation are not considered. This indicator differs from the CCR, because CO2 captured from additional fuel combustion internally in the capture process is not counted as CO2 avoided.

The equivalent CO2 avoided evaluates the total equivalent CO2 emissions avoided at the plant, taking the direct emissions related to the steam generation (NG fired boilers) in addition to the direct emissions with the flue gas, as well as the indirect CO2 emissions associated to electric power consumption/generation, into account. It is defined as:

where is specific equivalent emissions from the kiln without capture, and is the specific equivalent emission from the kiln with capture. Equivalent emissions are defined as the sum of direct and indirect emissions

Indirect emissions can be calculated using the equation

where is the specific power consumption per unit mass of clinker produced, which is positive when power is consumed and negative when it is generated, and is the CO2 emissions associated with each unit of electric power consumed. This value depends on the electricity mix considered (see Table 4).

The equivalent CO2 avoided takes all direct and indirect emissions into account. It gives the best indication on the overall reduction in CO2 emissions of the cement plant when a certain capture technology is implemented and allows a fair comparison of different technologies.

3.3.2. Energy Performance

The specific primary energy consumption for CO2 avoided, SPECCA, evaluates the primary energy used to avoid CO2 emissions to the atmosphere. It is defined as the difference in equivalent primary energy consumption of the cement plant with and without CO2 capture, divided by the difference in equivalent CO2 emissions without and with capture

Equivalent specific primary energy consumption is the sum of direct () and indirect () specific primary energy consumption

The direct specific primary energy consumption is the amount of energy (lower heating value), supplied in the form of fuel (coal or natural gas), that is used per ton of clinker

The indirect specific primary energy consumption is the amount of energy consumed by the generation of power required per ton of clinker. It can be calculated by

where is the electricity generation efficiency, which depends on the electricity mix considered.

3.3.3. Retrofitability

To assess retrofitability, a qualitative assessment is performed. The following set of indicators is defined for the assessment:

- impact on the cement production process

- equipment and footprint

- utilities and services

- introduction of new chemicals/subsystems

- available operational experiences

These indicators evaluate different aspects that will affect the selection of capture technology for retrofit to an existing cement plant. Each of them is described in more detail below.

The evaluation is performed using the color-coding system presented in Table 5. For the color green, retrofit is evaluated as fairly straightforward; for yellow, retrofit is in most cases straightforward but some attention is needed; for orange more attention is needed, or important aspects are unknown so further assessment/research is needed; for red, a retrofit is evaluated not to be possible.

Table 5.

Color coding for assessment of retrofitability.

3.4. Impact on the Cement Production Process

For a cement producer, the first priority is the production of high-quality clinker that can be ground and mixed with additives to produce cement. It is therefore very important that the installation of a CO2 capture system does not influence the operability of the plant and the quality of the product. Some technologies imply modifications of the kiln system itself, and then the risk for effects on plant operability and product quality is increased. Furthermore, if fundamental modifications of the cement kiln system are required, long production stops during the installation of the technology may be required. This indicator evaluates the potential impact on clinker quality and plant operability, taking the phase with normal operation after installation as well as the installation phase into account.

3.5. Equipment and Footprint

The application of CO2 capture technologies in cement plants requires the installation of additional equipment which demands a certain amount of space. The footprint of a typical cement plant with a 3000 t/d cement kiln is around 15 ha (150,000 m2; a cement plant including the quarries can cover 100–150 ha). In general, if the new equipment can be installed anywhere at the plant, the space requirement would need some attention, but can in most cases be handled quite easily. However, in many cement plants the free space close to the kiln line is limited. If the new equipment must be installed near the kiln line, the footprint of the equipment could then be a limiting factor for individual capture technologies, and more attention to the characteristics of each site is required for assessing the applicability of the technology as a retrofit.

3.6. Utilities and Services

The application of certain CO2 capture technologies requires additional utilities and services. This includes the need of additional electric power, steam (or NG for steam boilers), coal, or chemicals. Out of this, the most limiting factor is the electric power demand, since the availability is dependent on the local grid capacity. Infrastructure for import of natural gas and coal normally already exists at cement plants, and an increase in the import of these fuels can be handled easily up to a certain point, before the capacity of the infrastructure must be increased. In addition, some technologies require that the raw meal fed to the plant has certain properties. This indicator evaluates the technologies with respect to such aspects.

3.7. Introduction of New Chemicals/Subsystems

This indicator evaluates the attention needed concerning the introduction of new chemicals/subsystems at the plant. If new chemicals or subsystems are introduced, e.g., MEA, ammonia, oxygen, ASU, refrigeration system, ORC, or steam cycle, new procedures, and routines must be implemented to ensure safe operation. The utilization of new chemicals could also require additional permits. The relevant regulatory framework might vary from country to country. Constraints related to the handling of CO2 at the plant are not included, since this will be the same for all technologies.

3.8. Available Operational Experiences

For the installation of CO2 capture technologies at cement kilns, technology maturity is important to limit the associated risks. The assessment should take into account the available experiences with the application in the cement industry, but also the available experiences from other industrial sectors like the power industry.

4. Process Modeling and Key Process Data

In this section, the process modeling of the reference cement kiln and the capture technologies, as well as the most important process data are summarized. Stream data and PFDs of the complete systems, including CPUs and waste heat recovery systems, can be found in the Supplementary Materials.

4.1. Reference Cement Kiln

The core process of the reference cement kiln is simulated by VDZ with their in-house cement kiln process model [29,30], and by PoliMi with their in-house process simulation tool GS [31] (Table 6). The difference in specific heat input and specific CO2 emissions between these two simulations is 2%. The effect of these differences will be considerably lower in the final quantitative KPIs, since values referring to the cement plant with and without CO2 capture for the calculation of KPIs for each technology, will have been obtained using the same tool. Details on the simulations and a comparison of them are given by Campanari et al. [32].

Table 6.

Key process data of reference cement kiln.

4.2. MEA Absorption

The MEA system is modelled as shown in Figure 9 using the process simulator Aspen HYSYS V9, with resulting key process data as summarized in Table 7. The acid gas property package is selected for modelling the part of the process including MEA solvent. The SRK property package is used for calculation of properties of the flue gas and CO2 streams.

Figure 9.

Process flowsheet of the MEA CO2 capture process.

Table 7.

Key process data for the MEA process.

The regenerator reboiler requires 96–97 MW steam, corresponding to 3.76–3.80 MJ/kg CO2, at approximately 128 °C. Out of this, 3.7 MW can be covered by heat recovery at the cement plant (Figure 2), while the rest must be covered by a NG fired boiler.

The concentration of NOx at the absorber inlet should be limited to 410 mg/Nm3 for MEA-based CO2 absorption [33]. An increase in NOx reduction rate to reach the acceptable level is achieved by increasing the injection rate of ammonia solution in the SNCR system, with 1.5 times the stochiometric amount of the additional NOx to be reduced. The concentration of SOx at the absorber inlet should be limited to 10 ppmv prior to the MEA capture process. The SOx level is reduced by injection of 50% NaOH solution in the DCC. It is assumed that SOx is selectively removed by the stochiometric amount of NaOH.

Thermal reclaiming of MEA solvent for removal of amine degradation products is not included in the process model. In this sub-process a slipstream with amine solution is vaporized, the vapor is returned to the main process, while the less volatile degradation products are removed from the process. The amount of degradation products, the energy requirement of the reclaimer, and the amount of solvent lost in the reclaimer waste stream are estimated based on the studies by IEAGHG [34] and Knudsen et al. [35].

The captured CO2 is assumed to be conditioned for pipeline transport by three stage compression up to 80 bar with triethylene glycol (TEG) dehydration and pumping to 110 bar.

4.3. Oxyfuel

The core oxyfuel cement process is simulated with VDZs in-house cement process model. A process flowsheet of the plant model is shown in Figure 10, and resulting key process data are presented in Table 8. The model is based on a model of the reference cement plant [29,30]. It has been adapted to the oxyfuel process as part of the work in the ECRA CCS project [36,37,38,39], and model parameters are tuned based on experimental work in CEMCAP [19,20].

Figure 10.

Process flowsheet of the oxyfuel plant.

Table 8.

Key process data for the oxyfuel process.

The CPU is simulated using Aspen HYSYS V9, as a single stage flash self-refrigerated unit. The power consumption of the CPU is 0.4 MJ/kg CO2. The heat required for dehydration is assumed to be 21.9 kJ/kg CO2 (estimated based on [40]) and provided by electric heaters. The waste heat recovery system is designed and simulated using the Sequential Framework for heat exchanger network synthesis [41]. The heat required for ASU dehydration is assumed to be provided by electric heaters.

The power demand related to other utilities at the plant are slightly changed compared to the reference kiln (cf. Table 3), due to changed gas compositions and flow rates in some existing fans, and the added power demand of new fans. This gives a small increase in power consumption of cement plant utilities from 132 kWh/tclk to 139 kWh/tclk [42].

Details about the design and operating parameters of the waste heat recovery system and the CPU are described by Jamali et al. [20].

4.4. Chilled Ammonia Process

The chilled ammonia process is simulated in Aspen Plus V8.6 using a rate-based model developed with experimental data from pilot tests [18]. These pilot plant tests, which were performed with synthetic cement plant flue gas streams, are additionally used to verify the final process simulations [34]. A process flowsheet of the system is shown in Figure 11 and resulting key process data are presented in Table 9.

Figure 11.

Process flowsheet of the chilled ammonia process.

Table 9.

Key process data for the chilled ammonia process.

Waste heat from the cement plant (Figure 2) is assumed to cover all the heat required for the reboiler in the NH3 desorber and the appendix stripper (steam at ~110 °C), and a small part of the remaining heat demand (steam at ~145 °C for the CO2 desorber). Refrigeration of the CO2 absorber pumparound and of the water stream entering the top of the NH3 absorber to 12–13 °C and to 15 °C, respectively, is required. For estimation of power consumption and cooling demand of the refrigeration system, coefficients of performance of 7–8 are assumed [15]. Since the captured CO2 leaves the CO2 desorber at elevated pressure—i.e., 25 bar which is optimal for minimization of SPECCA—only one compression stage in addition to the final pumping is assumed in the compression process.

A detailed description of the simulation and optimisation procedure of the core process is described in the original work by Pérez-Calvo et al. [43].

4.5. Membrane-Assisted CO2 Liquefaction

The membrane-assisted CO2 liquefaction system is simulated with Aspen HYSYS V9, with the Peng–Robinson equation of state. A multicomponent membrane model that has been integrated into the HYSYS interface is used to simulate the membrane unit. A process flowsheet of the system is shown in Figure 12 and resulting key process data are presented in Table 10.

Figure 12.

Process flowsheet of the membrane-assisted CO2 liquefaction process.

Table 10.

Key process data for membrane-assisted CO2 liquefaction system.

Membrane permeance data representative for the membrane that was tested within CEMCAP are used in the model (Table 11). It should be noted that the selection of membranes available for testing was limited.

Table 11.

Membrane permeance and CO2 selectivity for relevant components.

The need for NOx and SOx removal from the flue gas stream beyond what is already required to not exceed the permitted limits for pollutant emissions depends on the tolerance of the membrane material. It is assumed that NOx and SOx removal is performed the same way and to the same extent as for the MEA absorption process.

A more detailed description of the process design and simulation is given by Berstad et al. [44].

4.6. Calcium Looping—Tail-End Configuration

The tail-end calcium looping process and its integration with the reference cement kiln are modeled with PoliMi’s in-house process simulator GS [31]. A process flowsheet of the system is shown in Figure 13 and resulting key process data are presented in Table 12.

Figure 13.

Process flowsheet of the tail-end calcium looping process integrated with the reference cement kiln.

Table 12.

Key process data for the reference cement kiln with tail-end calcium looping CO2 capture.

The circulating fluidized bed (CFB) reactor model presented by Romano [45] is used to simulate the carbonator, which includes the carbonation kinetic expression proposed by Grasa et al. [46]. The calciner is modeled assuming complete calcination of the sorbent. Based on the data presented by Martínez et al. [47], this assumption is justified considering the high residence time of the solids in a CFB calciner and the assumed calcination temperature of 920 °C. Further details about simulations of the CaL reactors are given by Spinelli et al. [48], and details on the methodology used for simulation of the overall process, with extensive sensitivity analysis on the main process parameters are given by De Lena et al. [49].

The heat recovery steam cycle parameters are set according to the thermal input available as defined in the CEMCAP framework [15]. The CPU is simulated using Aspen HYSYS V9, as a single stage flash self-refrigerated unit, slightly modified compared to the CPU of the oxyfuel process. The resulting power consumption of the CPU is 0.4 MJ/kg CO2. The heat required for dehydration in the CPU is assumed to be 16.6 MJ/kg H2O (estimated based on Kemper et al. [40]). The dehydration heat required in the CPU and the ASU are assumed to be provided by some of the steam generated in the process.

4.7. Calcium Looping—Integrated Configuration

As for the tail-end CaL technology, the process evaluation is based on simulations performed with Polimi’s in-house process simulation code GS [31]. A process flowsheet of the system and its integration with the reference plant is shown in Figure 14 and resulting key process data are summarized in Table 13.

Figure 14.

Process flowsheet of the reference cement kiln with integrated calcium looping CO2 capture.

Table 13.

Key process data for the reference cement kiln with integrated calcium looping CO2 capture.

A one-dimensional, steady-state model, which is described by Spinelli et al. [48,50], has been used for the calculation of the entrained flow carbonator. Sorbent conversion kinetics are described by the random pore model proposed by Grasa et al. [51]. For the calciner, an outlet temperature of 920 °C has been assumed to calculate the heat input needed in that reactor to heat up and calcine the recarbonated raw meal from the carbonator. Further details about simulations of the cement kiln with the integrated CaL configuration are given by De Lena et al. [52].

For the heat recovery steam cycle, the CPU and the ASU the same simulation approaches and assumptions as for the CaL tail-end process are used.

5. Comparative Technical Evaluation of the CO2 Capture Technologies

5.1. Emission Abatement

The CO2 capture ratio, the CO2 avoided from the flue gas, and the equivalent CO2 avoided evaluate the effect that the implementation of a capture technology has on the CO2 emissions of a plant. These KPIs calculated for the investigated technologies and the reference technology are given in Table 14.

Table 14.

Direct and indirect emissions, CO2 capture ratio, and CO2 avoided.

The CCR of all technologies range between 90% and 95%, and the CO2 avoided from the flue gas range between 90 and 93%. For the MEA, CAP, and MAL technologies, the CO2 avoided from flue gas is by definition equal to the CCR, since there is no change in internal fuel combustion generating CO2 within the kiln or the capture process when these technologies are installed. For the oxyfuel technology the value is approximately the same as the CCR—the specific fuel consumption changes in the oxyfuel technology compared to the standard reference kiln, but the change is very small. For the calcium looping technology, the CO2 avoided from the flue gas is lower than the CCR, because the capture of CO2 generated by fuel combustion within the calciner is not counted as CO2 avoided.

The equivalent CO2 avoided of all technologies range between 64% and 90%. With this KPI all direct emissions at the plant, as well as indirect emissions related to power consumption or generation are taken into account. This value is lower than the CO2 avoided for all technologies due to the contribution of direct emissions from steam generation and indirect emissions associated to power import.

All the investigated technologies have equivalent CO2 avoided in the range 73–90%, which is higher than the reference technology MEA with 64%. The CaL technologies end up with the highest equivalent CO2 avoided. These technologies have no additional direct emissions as most of the CO2 from the additional coal combustion is captured, and negative or low added indirect CO2 emissions thanks to the internal power production.

5.2. Energy Performance

The energy inputs of the reference cement plant without and with CO2 capture are in the form of coal, natural gas, and power. For some CO2 capture technologies power is also generated on-site. A summary of the energy inputs is given in Table 15.

Table 15.

Reference plant energy input without and with CO2 capture technologies.

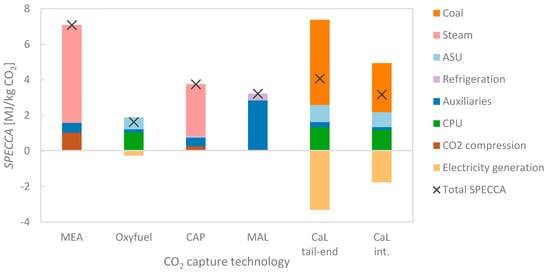

The specific primary energy consumption for CO2 avoided of the technologies are presented in Figure 15 and Table 16. All the investigated technologies have clearly lower SPECCA values than the reference technology. The oxyfuel technology has a SPECCA of 1.63 MJ/kg CO2, which is the lowest value among the SPECCA values of the investigated technologies. The chilled ammonia and membrane-assisted liquefaction technologies have SPECCA values of 3.75 and 3.22 MJ/kg CO2 respectively, while the calcium looping tail-end and integrated technologies have SPECCA values of 4.07 and 3.17 MJ/kg CO2.

Figure 15.

Specific primary energy consumption for CO2 avoided (SPECCA).

Table 16.

Break-down of specific primary energy consumption for CO2 avoided (SPECCA).

The most important contributions to the SPECCA differ among the technologies. For the MEA technology the primary energy consumption related to the steam required in the process is responsible for the largest part of the added equivalent primary energy consumption and reduction in equivalent CO2 avoided. For the oxyfuel technology, the added equivalent primary energy consumption and reduction in equivalent CO2 avoided are almost entirely due to the increased electric power consumption. The CPU is the largest power consumer, followed by the ASU and the fans. Electric power generation from waste heat reduces the net power consumption by almost one fifth. For the chilled ammonia process, the steam consumption makes up the largest part of the primary energy consumption and reduction in equivalent CO2 avoided. The steam consumption makes up around three-quarters of these values, while the electric power consumption is responsible for the rest. For the membrane-assisted CO2 liquefaction process, electric power consumption is responsible for all added equivalent primary energy consumption and reduction in equivalent CO2 avoided, where around four-fifths are due to fan, pump and compressor work in the process, and the rest is mainly due to the refrigeration system. For both calcium looping processes, coal consumption, electric power consumption and electric power generation are important for the final SPECCA value. The considerable electric power generation is especially important for the tail-end technology as it contributes to a reduction in both added equivalent specific primary energy consumption and equivalent specific CO2 avoided. This essentially means that the electricity generated covers a part of the cement plant’s demand as well as the demand of the CO2 capture process, resulting in lower electric power consumption per unit of clinker produced.

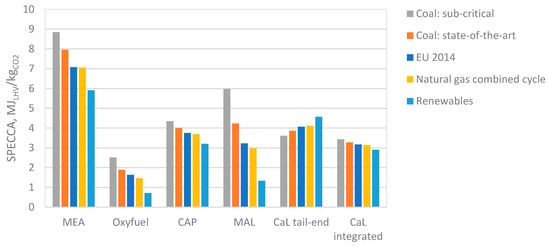

The characteristics of the power generation system in terms of electricity generation efficiency, , and the specific CO2 emissions of the electricity generation, , have an impact on the SPECCA. The generation efficiency and specific CO2 emissions are directly linked to the power generation technology that is assumed to provide the electricity required by the processes.

To investigate the impact of the values of

and , SPECCA values are calculated with several different options for power generation. The average electricity mix in EU-28 in 2014 is used as basis in the calculations. The alternative cases are summarized in Table 4, and the results are shown in Figure 16. For the calcium looping tail-end technology, the SPECCA increases with increasing electricity generation efficiency and decreasing specific CO2 emissions, while the opposite is observed for all the other CO2 capture technologies. This is because the CaL tail-end technology generates enough electricity to cover both its own demand and a part of the electricity demand of the cement plant, effectively substituting some of the electricity that was bought from the grid in the reference cement plant. With increasing generation efficiency of the power system and a decrease in the associated specific CO2 emissions, the reduction in indirect added equivalent specific primary energy consumption becomes smaller, as well as the indirect avoided equivalent specific CO2 emissions.

Figure 16.

Specific primary energy consumption for CO2 avoided (SPECCA) of the technologies with different power generation scenarios.

For oxyfuel and MAL technologies, where the main added energy input is in the form of electric power, the SPECCA value is highly dependent on the characteristics of the power generation system. In the case of electricity being solely generated from renewables, the SPECCA is reduced by more than half compared to the EU 2014. On the other hand, the SPECCA of the MAL technology is almost doubled in the worst case of electricity generation from sub-critical pulverized coal plants. The SPECCA values of the MEA and CAP technologies are also significantly affected by the different power generation cases.

As mentioned, the generation of steam is responsible for the largest part of the added primary energy consumption and equivalent CO2 emissions for the absorption-based technologies, MEA and CAP. The SPECCA is therefore largely dependent on amount of waste heat available at the plant, and the selected strategy for steam supply. One alternative to steam generation in NG fired boilers is steam import from a coal fired combined heat and power (CHP) plant. The associated primary energy consumption can be assumed to be 0.34-0.68 MWth/MWth and the associated CO2 emissions 116-231 kg/MWhth for steam temperatures in the range 100-160 °C, considering a conversion efficiency for coal to power without steam extraction of 39.1% and a conversion efficiency for steam to power of 13.3-26.6% for steam in this temperature range [24]. The energy consumption and CO2 emissions of the CHP plant are partly assigned to the generated steam and partly to the generated electric power. The SPECCA is reduced with 47% for MEA and 35% for CAP in this case, but it should be mentioned that few cement plants are located close to a power plant.

It is assumed in this study that cooling water is supplied by a cooling tower, that requires power for fans and water pumping, and delivers cooling water at 18 °C. If the cooling could be performed with water from the sea or a river, less power consumption would be required by the cooling system itself, and the cooling water could in many cases be delivered at lower temperature levels. This would benefit all the technologies slightly.

5.3. Retrofitability

The overall retrofitability assessment of the technologies is shown in Table 17, and more detailed reasoning is given in the following subsections. In general, it can be noted that the post-combustion technologies are easier to retrofit, while the integrated technologies are more challenging.

Table 17.

Assessment of retrofitability.

5.3.1. Impact on the Cement Production Process

The application of post-combustion technologies does not affect the actual clinker burning process or the clinker quality, as they can be installed as independent units that flue gas is sent to before the stack. During the construction phase, only a short stop of the clinker production would be required for the rerouting of the flue gas. This rerouting can be performed during the yearly maintenance period when the plant is shut down and does therefore not need to affect the operability of the plant. The tail-end CaL process is slightly integrated with the cement kiln since sorbent purge is ground and used as raw meal in the kiln. However, this does not include any risk for the plant operability or the clinker quality. Therefore, all post-combustion technologies are marked green.

The oxyfuel and the integrated CaL processes require significant modification of the production process. As a result, potential operational problems due to the capture technology can directly affect the operability of the plant. There is also an increased risk related to the quality of the produced clinker [53]. In theory changes of the gas atmosphere, of gas temperatures, and other process conditions can be managed so that optimum clinker production still can be achieved, but this remains to be proven. A long production stop is required during the construction phase for both these technologies.

In the oxyfuel process, the clinker cooler, rotary kiln, calciner, and preheater are modified, whereas for the integrated CaL technology only the calciner and preheater are changed, while the cooler and the kiln are unchanged. The oxyfuel process is therefore marked orange and the integrated CaL process is marked yellow.

5.3.2. Equipment and Footprint

Every capture process will need installation of some additional equipment which requires available space, and therefore at least some attention is required regarding this aspect for all technologies. The most important difference between the technologies is whether the equipment must be installed close to the kiln line or if it can be installed further away.

For all the post-combustion technologies the required equipment can be installed anywhere at the plant, and there is also some flexibility for splitting up the systems and installing different units at different locations at the plant, so these technologies are marked yellow. The oxyfuel and the integrated CaL processes are integrated with the kiln system itself, and these technologies require space close to the kiln line. These technologies are therefore marked as orange.

5.3.3. Utilities and Services

The need for utilities and services of the technologies is summarized in Table 18. The two solvent based processes MEA and CAP require considerable amounts of steam and also some power, in addition to the solvents MEA and ammonia. Each of these points should be possible to handle in most cases, but still require some attention. These technologies are therefore marked yellow.

Table 18.

Additional utilities and services required for the reference cement plant.

For the oxyfuel and MAL processes, only additional electric power is required, but in both cases the magnitude of the power demand is considerable. These technologies are marked yellow, because some attention is needed on the local power grid capacity.

For the CaL processes, additional coal is required. Additional electric power is also needed, but on the other hand power is also generated from the waste heat. Depending on the integration level, the net power consumption at the plant can be positive or negative. If there is power export from the plant, infrastructure would be required for this. If the power generation is balanced with the power consumption, there would not be any need for import of power, which is an advantage. For the tail-end configuration 15–20% of the calcium must be fed to the plant as limestone. Some attention is needed for the plant retrofit, with respect to coal import, import/export of power, and raw meal quality. The two CaL processes are therefore marked yellow.

5.3.4. Introduction of New Chemicals/Subsystems

The operation of the MAL requires the installation of a refrigeration system, which implies that refrigerants will be present at the plant, and small amounts of NaOH for SOx removal. This should be relatively easy to handle, and therefore this technology is marked in green.

All capture technologies which require the production and use of oxygen, a chemical that can increase the risk for fires and explosions at the plant, could require a more complex permitting process and would require that new procedures and routines are established. However, the use of oxygen is normal in many industries, so although attention is needed it can still be handled. Therefore, the oxyfuel and the CaL process are marked yellow.

The MEA process and the CAP require aqueous solutions of amines or ammonia as solvent. Amines and their degradation products, as well as ammonia, are poisonous and dangerous for the environment. The use of these chemicals requires a permitting process, whose complexity depends on national/local regulations. Furthermore, new procedures and routines must be established to ensure safe operation at the plant. Ammonia is already commonly used at cement plants for NOx removal systems, but in very low quantities compared to what is required for the CAP. As for oxygen, significant experience is available from other industries, so MEA and CAP are marked yellow.

5.3.5. Available Operational Experiences

The MEA process is the most mature capture technology and a lot of information is already available. Other types of amines have been tested for flue gas treatment from an operational plant, and it can be expected that a retrofit should be possible without major problems. The most advanced testing done so far with amines on cement flue gas so far are the pilot trials with Aker Solutions mobile test unit, which is a fully integrated prototype of the system, for six months in an operational kiln at Norcem in Brevik, Norway. The testing at Norcem showed good stability of the solvent towards cement flue gas, and no technical show-stopper was identified. A capture ratio of 90% was obtained, and 370 tonnes of CO2 were captured over 2700 h [54]. Furthermore, there is a lot of operational experience with amine absorption from the demonstration for coal power plants in commercial scale at Boundary Dam. Consequently, this technology is marked green.

For the oxyfuel process, burner, calciner, and clinker cooler pilot trials have been conducted in industrial relevant environment as a part of the CEMCAP project. A 500 kW oxyfuel cement kiln burner prototype has been successfully demonstrated at the University of Stuttgart [19,55]. Oxyfuel calcination has been demonstrated in a 50 kW reactor, also at the University of Stuttgart [56]. A clinker cooler pilot has been successfully operated with clinker directly from a real industrial kiln line at HeidelbergCement’s plant site in Hannover [57]. However, the full system has not been operated as a whole yet, and experience from the power sector is not directly transferrable to the cement sector, so the technology is marked orange.

The chilled ammonia process has been demonstrated for flue gas concentrations ranging from typical natural gas-fired power plants to typical coal-fired power plants in several pilots including the 58 MWth AEP Mountaineer pilot [58] and the 40 MWth TCM pilot [59]. In CEMCAP, the chilled ammonia absorber, direct contact cooler (DCC), and water wash units were tested for the cement application, since these are the units that are affected by a change in the flue gas conditions. All three units were tested in GE’s 1 tonne CO2 per day pilot facility in Vaxjö, verifying that the process can be applied in the cement industry [44]. Due to the experience from the pilot plants in the power sector, no major risks are foreseen for the operation of all units together or for the scale-up of the system. Based on this, the technology is marked yellow.

For the membrane-assisted CO2 liquefaction process, the liquefaction system and membranes have been tested separately. The liquefaction part of the process has been tested as a part of CEMCAP in a pilot facility at SINTEF Energy Research with liquefaction capacity of 10 tonne CO2 per day, and a separation performance consistent with expectations based on vapour-liquid equilibrium data was demonstrated [21]. One type of membranes as tested in the lab for cement specific flue gas in the CEMCAP project, but more advanced testing has been carried out for fixed-site-carrier membranes at the Norcem plant in Brevik with flue gas from an operational kiln [60]. The full process with membranes and the liquefaction system integrated has not been operated, so therefore the technology is marked orange.

The tail-end calcium looping technology has been demonstrated for coal at the “la Pereda” power plant in a 1.7 MWth pilot [61]. Within CEMCAP the technology has been tested for cement flue gas in a 30 kW pilot at CSIC, and a 200 kW pilot at the University of Stuttgart [26]. The testing has shown that fundamental parameters, such as the carbonation rate constant, are consistent with those in systems already tested for coal power plants at a large scale. This technology is therefore marked yellow.

For the calcium looping integrated technology, calcium looping experiments with entrained flow reactors have been carried out in the 30 kW pilot at CSIC. It has been shown on a laboratory scale that calcined materials with free CaO are able to adsorb CO2 in an entrained flow environment. There is not yet any operational experience with the full system, so this technology is marked orange.

6. Conclusions

A consistent technical assessment of the oxyfuel process, the chilled ammonia process, membrane-assisted liquefaction, and the calcium looping technology with tail-end and integrated configurations retrofitted to a reference cement plant is performed. The technologies are benchmarked against MEA absorption which is used as a reference technology.

All the investigated technologies perform better than the reference technology both in terms of emission abatement and primary energy consumption. The equivalent CO2 avoided under the defined conditions are in the range 73–90% for the investigated technologies, while it is 64% for the reference technology. The calcium looping technologies have the highest emission abatement performance with 89–90% equivalent CO2 avoided. For this technology, most of the CO2 generated by the additional primary energy consumption are also captured. The other technologies entail additional emissions due to imported electricity or steam generation, which reduce the equivalent CO2 avoided despite the fact that all technologies capture 90% of the cement plant’s emissions. The SPECCA values of the investigated technologies are in the range 1.63–4.07 MJ/kg CO2, compared to 7.08 MJ/kg CO2 for the reference technology. The oxyfuel process has the lowest SPECCA, with 1.63 MJ/kg CO2. This is explained by a significantly lower primary energy demand than the other technologies and a medium value for equivalent CO2 avoided.

The post-combustion technologies, particularly the reference technology MEA, are assessed as easier to retrofit than the integrated technologies. Clear advantages of the post combustion technologies are the low impact on the cement production process and the flexibility in the placing of new equipment at the cement plant. The oxyfuel and integrated CaL technologies, which are more integrated with the cement plant, are assessed as more challenging, although no ‘showstoppers’ were identified for their installation in existing plants.

Due to the different performance of the technologies with respect to the different KPIs, it is not possible to identify one overall winner among them. A high equivalent CO2 avoided and low SPECCA will always be desired but depending on the specific cement plant and the local conditions, other aspects may become dominant, such as space requirements, utility requirements in the light of available infrastructure, or available operational experience.

Furthermore, it is shown that for the technologies that require a considerable amount of electric power, the electricity mix has a large effect on the SPECCA. This is particularly important for the membrane-assisted liquefaction process which has a high electricity demand, but no other primary energy consumption. In a scenario with a large share of renewable electric energy—e.g., the Norwegian mix—this technology has the second lowest SPECCA among the technologies. On the contrary, in a scenario based on coal power, which is relevant for some Eastern Europe countries, this technology has the highest SPECCA after the reference technology. Similarly, it is highlighted that different assumptions on the availability of waste heat, co-generated steam, cooling water, etc. affect the performance of the different capture technologies to a varying extent.

Based on these findings, it can be concluded that CCS in the cement industry should be performed with a portfolio of capture technologies. For identification of the optimal capture technology for a specific plant, a case specific evaluation should be performed considering the local conditions and constraints. The results and the discussion of their sensitivity presented above provide robust indications on which technologies may be favored under certain conditions.

An economic evaluation of the technologies is presented in Part 2 of this paper series.

Supplementary Materials

The following are available online at http://www.mdpi.com/1996-1073/12/3/559/s1, Process flowsheets: Figures 1.1–7.1; Stream data: Tables 1.1–7.2.

Author Contributions

M.V. and S.O.G. assembled the data and calculated quantitative KPIs. E.D.L., J.-F.P.-C., A.J., D.B., C.F., and R.A. performed process simulations. H.H., M.V., D.S., M.M., and M.R. performed retrofitability analysis. R.A., S.R., M.R., M.V., and S.O.G. defined the methodology. G.C. validated the cement-specific technical base of the study. M.R., M.M., M.G., R.A., and K.J. supervised the work. All authors contributed to the overall analysis and this was coordinated by M.V. and S.O.G. M.V. wrote the paper; all authors contributed to the text.

Funding

This project has received funding from the European Union’s Horizon 2020 Research and Innovation Programme under grant agreement no. 641185, and the Swiss State Secretariat for Education, Research and Innovation (SERI) under contract number 15.0160.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| ASU | air separation unit |

| BAT | best-available technologies |

| CaL | calcium looping |

| CAP | chilled ammonia process |

| CAPEX | capital costs |

| CCS | carbon capture and storage |

| CFB | circulating fluidized bed |

| CPU | CO2 purification unit |

| DCC | direct contact cooler |

| ECRA | European Cement Research Academy |

| HSS | heat stable salts |

| IL | integration level |

| KPI | key performance indicator |

| MAL | membrane-assisted CO2 liquefaction |

| MEA | monoethanolamine |

| NG | natural gas |

| OPEX | operating costs |

| ORC | organic Rankine cycle |

| PC | pulverized coal |

| SNCR | selective non-catalytic reduction |

| SRK | Soave–Redlich–Kwong |

| TEG | triethylene glycol |

| Nomenclature | |

| electricity generation efficiency | |

| equivalent CO2 avoided | |

| CO2 avoided from flue gas | |

| CCR | carbon capture ratio |

| specific direct CO2 emissions | |

| specific equivalent CO2 emissions | |

| specific equivalent CO2 emissions in reference plant | |

| specific CO2 emissions with kiln flue gas | |

| specific CO2 emissions with kiln flue gas in reference plant | |

| CO2 emissions associated with electric power | |

| specific indirect CO2 emissions | |

| molar flowrate of fresh sorbent | |

| molar flowrate of CaO entering carbonator | |

| molar flowrate of CO2 | |

| mass flowrate of clinker | |

| mass flowrate of CO2 captured | |

| mass flowrate of CO2 generated | |

| mass flowrate of fuel | |

| specific power consumption | |

| direct specific primary energy consumption | |

| equivalent specific primary energy consumption | |

| equivalent specific primary energy consumption in reference plant | |

| indirect specific primary energy consumption | |

| SPECCA | specific primary energy consumption for CO2 avoided |

References

- International Energy Agency (IEA). Technology Roadmap: Low-Carbon Transition in the Cement Industry; IEA: Paris, France, 2018; Available online: https://webstore.iea.org/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 6 January 2019).

- IEAGHG. Deployment of CCS in the Cement Industry; Report Number 2013/19; IEAGHG: Cheltenham, UK, 2013; Available online: https://ieaghg.org/docs/General_Docs/Reports/2013-19.pdf (accessed on 8 January 2019).

- CSI (Cement Sustainability Initiative). In CSI/ECRA-Technology Papers 2017: Development of State of the Art Technologies in Cement Manufacturing: Trying to Look Ahead; World Business Council for Sustainable Development: Geneva, Switzerland, 2017; Available online: https://docs.wbcsd.org/2017/06/CSI_ECRA_Technology_Papers_2017.pdf (accessed on 6 January 2019).

- Potocnik, J. 2013/163/EU: Commission Implementing Decision of 26 March 2013 establishing the best available techniques (BAT) conclusions under Directive 2010/75/EU of the European Parliament and of the Council on industrial emissions for the production of cement, lime and magnesium oxide. Off. J. Eur. Union 2013, 1–45. Available online: http://data.europa.eu/eli/dec_impl/2013/163/oj (accessed on 6 January 2019).

- Liang, X.; Li, J. Assessing the value of retrofitting cement plants for carbon capture: A case study of a cement plant in Guangdong, China. Energy Convers. Manag. 2012, 64, 454–465. [Google Scholar] [CrossRef]

- Ozcan, D.C. Techno-Economic Study for the Calcium Looping Process for CO2 Capture from Cement and Biomass Power Plants. Ph.D. Thesis, University of Edinburgh, Edinburgh, UK, 2014. [Google Scholar]

- Jakobsen, J.; Roussanaly, S.; Anantharaman, R. A techno-economic case study of CO2 capture, transport and storage chain from a cement plant in Norway. J Clean Prod. 2017, 144, 523–539. [Google Scholar] [CrossRef]

- Gerbelová, H.; van der Spek, M.; Schakel, W. Feasibility Assessment of CO2 Capture Retrofitted to an Existing Cement Plant: Post-combustion vs. Oxy-fuel Combustion Technology. Energy Procedia 2017, 114, 6141–6149. [Google Scholar] [CrossRef]

- Roussanaly, S.; Fu, C.; Voldsund, M.; Anantharaman, R.; Spinelli, M.; Romano, M. Techno-economic Analysis of MEA CO2 Capture from a Cement Kiln—Impact of Steam Supply Scenario. Energy Procedia 2017, 114, 6229–6239. [Google Scholar] [CrossRef]

- Rodríguez, N.; Murillo, R.; Abanades, J.C. CO2 Capture from Cement Plants Using Oxyfired Precalcination and/or Calcium Looping. Environ. Sci. Technol. 2012, 46, 2460–2466. [Google Scholar] [CrossRef] [PubMed]

- Diego, M.E.; Arias, B.; Abanades, J.C. Analysis of a double calcium loop process configuration for CO2 capture in cement plants. J. Clean Prod. 2016, 117, 110–121. [Google Scholar] [CrossRef]

- Lindqvist, K.; Roussanaly, S.; Anantharaman, R. Multi-stage Membrane Processes for CO2 Capture from Cement Industry. Energy Procedia 2014, 63, 6476–6483. [Google Scholar] [CrossRef]

- Jordal, K.; Voldsund, M.; Størset, S.; Fleiger, K.; Ruppert, J.; Spörl, R.; Hornberger, M.; Cinti, G. CEMCAP—Making CO2 Capture Retrofittable to Cement Plants. Energy Procedia 2017, 114, 6175–6180. [Google Scholar] [CrossRef]

- Schorcht, F.; Kourti, I.; Scalet, B.M.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide. Industrial Emissions Directive 2010/75/EU. 2013. Available online: http://eippcb.jrc.ec.europa.eu/reference/BREF/CLM_Published_def.pdf (accessed on 8 January 2019).

- Voldsund, M.; Anantharaman, R.; Berstad, D.; Cinti, G.; De Lena, E.; Gatti, M.; Gazzani, M.; Hoppe, H.; Martínez, I.; Monteiro, J.G.M.-S.; et al. CEMCAP Framework for Comparative Techno-Economic Analysis of CO2 Capture from Cement Plants (D3.2); 2018. [Google Scholar] [CrossRef]

- Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control). 2010. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32010L0075 (accessed on 8 January 2019).

- Norahim, N.; Yaisanga, P.; Faungnawakij, K.; Charinpanitkul, T.; Klaysom, C. Recent Membrane Developments for CO2 Separation and Capture. Chem. Eng. Technol. 2018, 41, 211–223. [Google Scholar] [CrossRef]

- Casillas, C.; Chan, K.; Fulton, D.; Kaschemekat, J.; Kniep, J.; Ly, J.; Merkel, T.; Nguyen, V.; Sun, Z.; Wang, X.; et al. Pilot Test Results from a PolarisTM Membrane 1 MWe CO2 Capture System. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 17–20 July 2017; Available online: https://www.aiche.org/system/files/aiche-proceedings/conferences/404771/papers/485892/P485892.pdf (accessed on 9 January 2019).

- Carrasco, F.; Grathwohl, S.; Maier, J.; Ruppert, J.; Scheffknecht, G. Experimental investigations of oxyfuel burner for cement production application. Fuel 2019, 236, 608–614. [Google Scholar] [CrossRef]

- Jamali, A.; Fleiger, K.; Ruppert, J.; Hoenig, V.; Anantharaman, R. Optimised Opearation of an Oxyfuel Cement Plant (D6.1). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/d-6.1-optimized-oxyfuel-operation.pdf.pdf (accessed on 8 January 2019).

- Trædal, S.; Berstad, D. Experimental Investigation of CO2 Liquefaction for CO2 Capture from Cement Plants (D11.2). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/2018-11-14-deliverables/d11.2-experimental-co2-liquefaction.pdf (accessed on 8 January 2019).

- Pérez-Calvo, J.F.; Sutter, D.; Gazzani, M.; Mazzotti, M. Pilot tests and rate-based modelling of CO2 capture in cement plants using an aqueous ammonia solution. Chem. Eng. Trans. 2018, 69, 145–150. [Google Scholar] [CrossRef]

- Alonso, M.; Álvarez Criado, Y.; Fernández, J.R.; Abanades, C. CO2 Carrying Capacities of Cement Raw Meals in Calcium Looping Systems. Energy Fuels 2017, 31, 13955–13962. [Google Scholar] [CrossRef]

- Arias, B.; Alonso, M.; Abanades, C. CO2 Capture by Calcium Looping at Relevant Conditions for Cement Plants: Experimental Testing in a 30 kWth Pilot Plant. Ind. Eng. Chem. Res. 2017, 56, 2634–2640. [Google Scholar] [CrossRef]

- Turrado, S.; Arias, B.; Fernández, J.R.; Abanades, J.C. Carbonation of Fine CaO Particles in a Drop Tube Reactor. Ind. Eng. Chem. Res. 2018, 57, 13372–13380. [Google Scholar] [CrossRef]

- Hornberger, M.; Spörl, R.; Scheffknecht, G. Calcium Looping for CO2 Capture in Cement Plants—Pilot Scale Test. Energy Procedia 2017, 114, 6171–6174. [Google Scholar] [CrossRef]

- Queneau, P.E.; Marcuson, S.W. Oxygen pyrometallurgy at copper cliff—A half century of progress. J. Miner. Metals Mat. Soc. 1996, 48, 14–21. [Google Scholar] [CrossRef]

- IEAGHG. Oxy Combustion Processes for CO2 Capture from Power Plant; Report Number 2005/9; IEAGHG: Cheltenham, UK, 2005; Available online: https://ieaghg.org/docs/General_Docs/Reports/Report%202005-9%20oxycombustion.pdf (accessed on 12 January 2019).

- Locher, G. Mathematical models for the cement clinker burning process. Part 1–5. Zement-Kalk-Gips 2002, 55, 29–38. [Google Scholar]

- Klein, H.; Hoenig, V. Model calculations of the fuel energy requirement for the clinker burning process. Cem. Int. 2006, 3, 44–63. [Google Scholar]

- GECOS, GS Process Simulation Code. 2016. Available online: http://www.gecos.polimi.it/expertise/software-development/ (accessed on 12 January 2019).

- Campanari, S.; Cinti, G.; Consonni, S.; Fleiger, K.; Gatti, M.; Hoppe, H.; Martínez, I.; Romano, M.; Spinelli, M.; Voldsund, M. Design and Performance of CEMCAP Cement Plant without CO2 Capture (D4.1); 2016. [Google Scholar] [CrossRef]

- IEAGHG. CO2 Capture in the Cement Industry; Report Number 2008/03; IEAGHG: Cheltenham, UK, 2008; Available online: https://ieaghg.org/docs/General_Docs/Reports/2008-3.pdf (accessed on 8 January 2019).

- IEAGHG. Evaluation of Reclaimer Sludge Disposal from Post-Combustion CO2 Capture; Report Number 2014/02; IEAGHG: Cheltenham, UK, 2014; Available online: https://ieaghg.org/docs/General_Docs/Reports/2014-02.pdf (accessed on 8 January 2019).

- Knudsen, J.N.; Jensen, J.N.; Vilhelmsen, P.-J.; Biede, O. Experience with CO2 capture from coal flue gas in pilot-scale: Testing of different amine solvents. Energy Procedia 2009, 1, 783–790. [Google Scholar] [CrossRef]

- Koring, K. CO2-Emissionsminderungspotential und Technologische Auswirkungen der Oxyfuel-Technologie im Zementklinkerbrennprozess. Ph.D. Thesis, Verein Deutscher Zementwerke (VDZ), Düsseldorf, Germany, 2013. [Google Scholar]

- European Cement Research Academy GmbH (ECRA). ECRA CCS Project—Report about Phase II; Report Number TR-ECRA-106/2009; ECRA: Duesseldorf, Germany, 2009; Available online: https://www.ecra-online.org/fileadmin/redaktion/files/pdf/ECRA__Technical_Report_CCS_Phase_II.pdf (accessed on 8 January 2019).

- European Cement Research Academy GmbH (ECRA). ECRA CCS Project—Report on Phase III; ECRA: Duesseldorf, Germany, 2012; Available online: https://ecra-online.org/fileadmin/redaktion/files/pdf/ECRA_ 39. Technical_Report_CCS_Phase_III.pdf (accessed on 8 January 2019).

- Available online: Technical_Report_CCS_Phase_III.pdf (accessed on 8 January 2019).

- Kemper, J.; Sutherland, L.; Watt, J.; Santos, S. Evaluation and Analysis of the Performance of Dehydration Units for CO2 Capture. Energy Procedia 2014, 63, 7568–7584. [Google Scholar] [CrossRef]

- Anantharaman, R. Energy Efficiency in Process Plants with Emphasis on Heat Exchanger Networks. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2011. [Google Scholar]

- Voldsund, M.; Anantharaman, R.; Berstad, D.; De Lena, E.; Fu, C.; Gardarsdottir, S.O.; Jamali, A.; Pérez-Calvo, J.F.; Romano, M.; Roussanaly, S.; et al. CEMCAP Comparative Techno-Economic Analysis of CO2 Capture in Cement Plants (D4.6). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/2018-11-14-deliverables/d4.6-cemcap-comparative-techno-economic-analysis-of-co2-capture-in-cement-plants.pdf (accessed on 8 January 2019).

- Pérez-Calvo, J.F.; Sutter, D.; Gazzani, M.; Mazzotti, M. Chilled Ammonia Process (CAP) Optimization and Comparison with Pilot Plant Tests (D10.3). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/2018-11-14-deliverables/d10.3_cap-optimization.pdf (accessed on 8 January 2019).

- Berstad, D.; Trædal, S. Membrane-Assisted CO2 Liquefaction for CO2 Capture from Cement Plants (D11.3). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/2018-11-14-deliverables/d11.3.pdf (accessed on 8 January 2019).

- Romano, M.C. Modeling the carbonator of a Ca-looping process for CO2 capture from power plant flue gas. Chem. Eng. Sci. 2012, 69, 257–269. [Google Scholar] [CrossRef]

- Grasa, G.S.; Abanades, J.C.; Alonso, M.; González, B. Reactivity of highly cycled particles of CaO in a carbonation/calcination loop. Chem. Eng. J. 2008, 137, 561–567. [Google Scholar] [CrossRef]

- Martínez, I.; Grasa, G.; Murillo, R.; Arias, B.; Abanades, J.C. Modelling the continuous calcination of CaCO3 in a Ca-looping system. Chem. Eng. J. [CrossRef]

- Spinelli, M.; De Lena, E.; Romano, M.C. CaL Reactor Modelling and Process Simulations (D12.4); 2018. [Google Scholar] [CrossRef]

- De Lena, E.; Spinelli, M.; Martínez, I.; Gatti, M.; Scaccabarozzi, R.; Cinti, G.; Romano, M.C. Process integration study of tail-end Ca-Looping process for CO2 capture in cement plants. Int. J. Greenh. Gas Control 2017, 67, 71–92. [Google Scholar] [CrossRef]

- Spinelli, M.; Martínez, I.; Romano, M.C. One-dimensional model of entrained-flow carbonator for CO2 capture in cement kilns by Calcium looping process. Chem. Eng. Sci. 2018, 191, 100–114. [Google Scholar] [CrossRef]

- Grasa, G.S.; Murillo, R.; Alonso, M.; Abanades, J.C. Application of the random pore model to the carbonation cyclic reaction. AlChE J. 2009, 55, 1246–1255. [Google Scholar] [CrossRef]

- De Lena, E.; Spinelli, M.; Gatti, M.; Scaccabarozzi, R.; Campanari, S.; Consonni, S.; Cinti, G.; Romano, M.C. Techno-economic analysis of calcium looping processes for low CO2 emission cement plants. Int. J. Greenh. Gas Control 2019, 82, 244–260. [Google Scholar] [CrossRef]

- Van Der Spek, M.; Roussanaly, S.; Rubin, E. Best practices and recent advances in CCS cost engineering and economic analysis. Int. J. Greenh. Gas Control 2019. [Google Scholar] [CrossRef]

- Knudsen, J.N. Results and Future Perspectives of Aker Solutions’ Amine Project. In Proceedings of the Norcem International CCS Conference, Langesund, Norway, 20–21 May 2015. [Google Scholar]

- Carrasco, F.M.; Grathwohl, S.; Maier, J.; Wilms, E.; Ruppert, J. Oxyfuel Burner Prototype Performance Tests (D7.2). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/presentasjoner/d7.2-burner-tests_revision1.pdf (accessed on 12 January 2019).

- Paneru, M.; Mack, A.; Maier, J.; Cinti, G.; Ruppert, J. Oxyfuel Suspension Calciner Test Results (D8.2). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/cemcap-d-8-2-ustutt_final.pdf (accessed on 12 January 2019).

- Lindemann Lino, M.; Matthias, B.; Ruppert, J.; Hoenig, V.; Becker, S.; Mathai, R. Analysis of Oxyfuel Clinker Cooler Operational Performance (D9.2). 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/presentasjoner/d9.2_revision1_final.pdf (accessed on 12 January 2019).

- Telikapalli, V.; Kozak, F.; Francois, J.; Sherrick, B.; Black, J.; Muraskin, D.; Cage, M.; Hammond, M.; Spitznogle, G. CCS with the Alstom chilled ammonia process development program–Field pilot results. Energy Procedia 2011, 4, 273–281. [Google Scholar] [CrossRef]