Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review

Abstract

1. Introduction

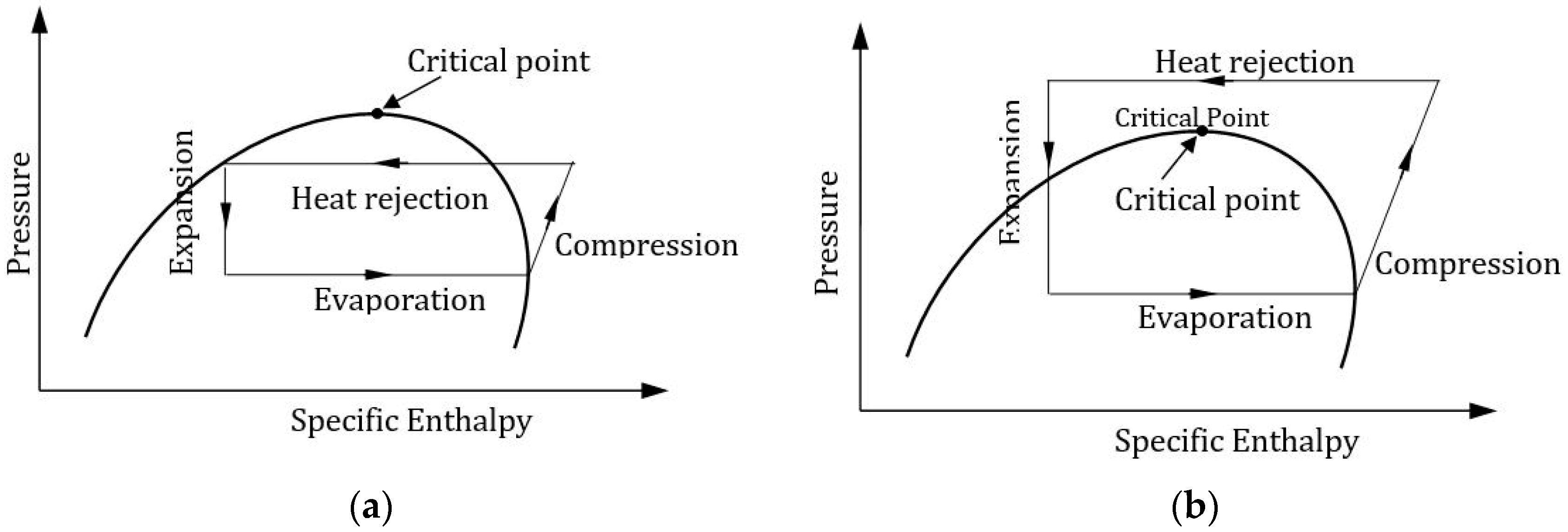

2. Comparison of Transcritical and Conventional Heat Pump Cycles

3. CO2 Heat Pump Component Modifications

3.1. Gas Cooler

3.2. Evaporator

3.3. Compressor

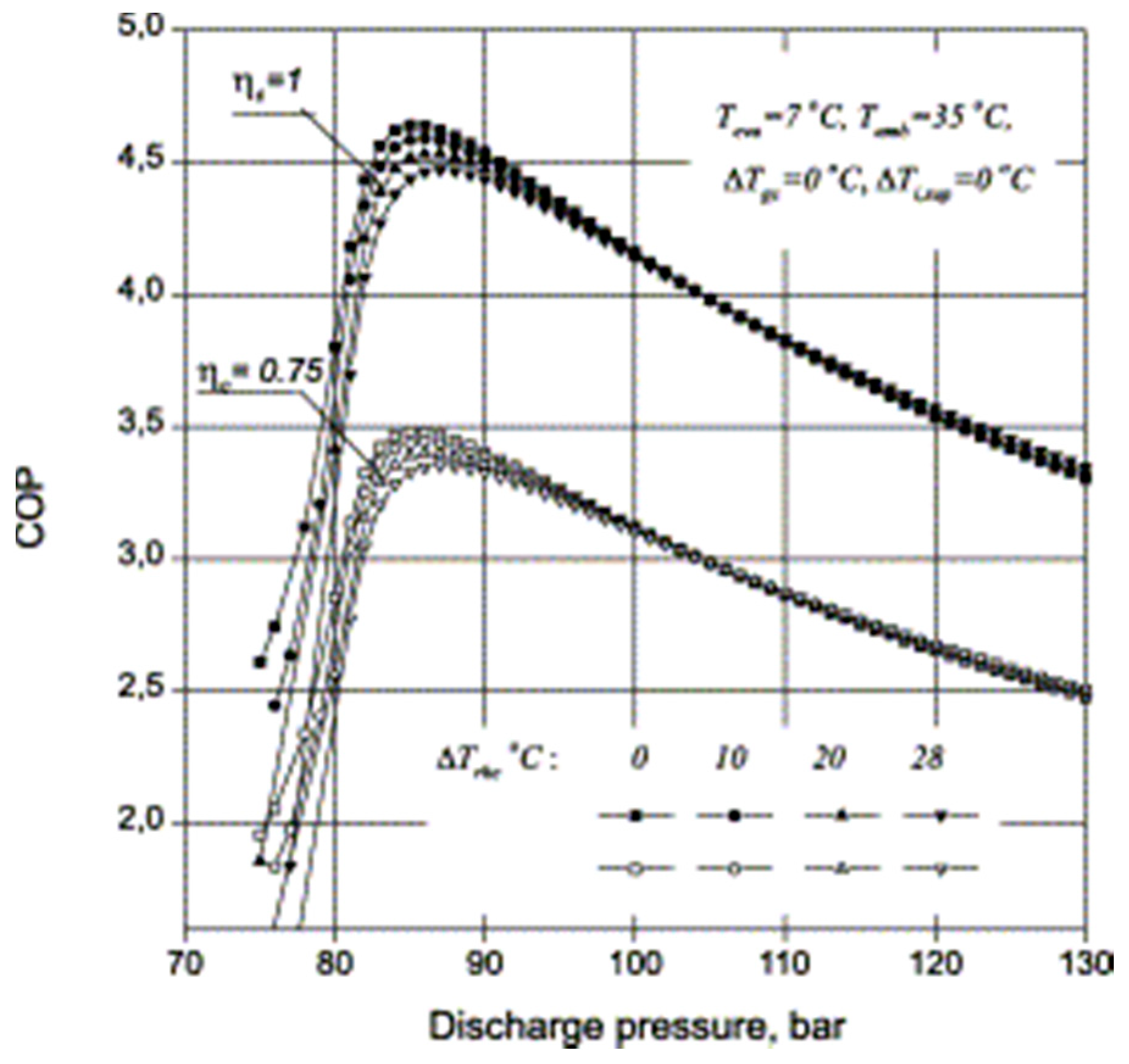

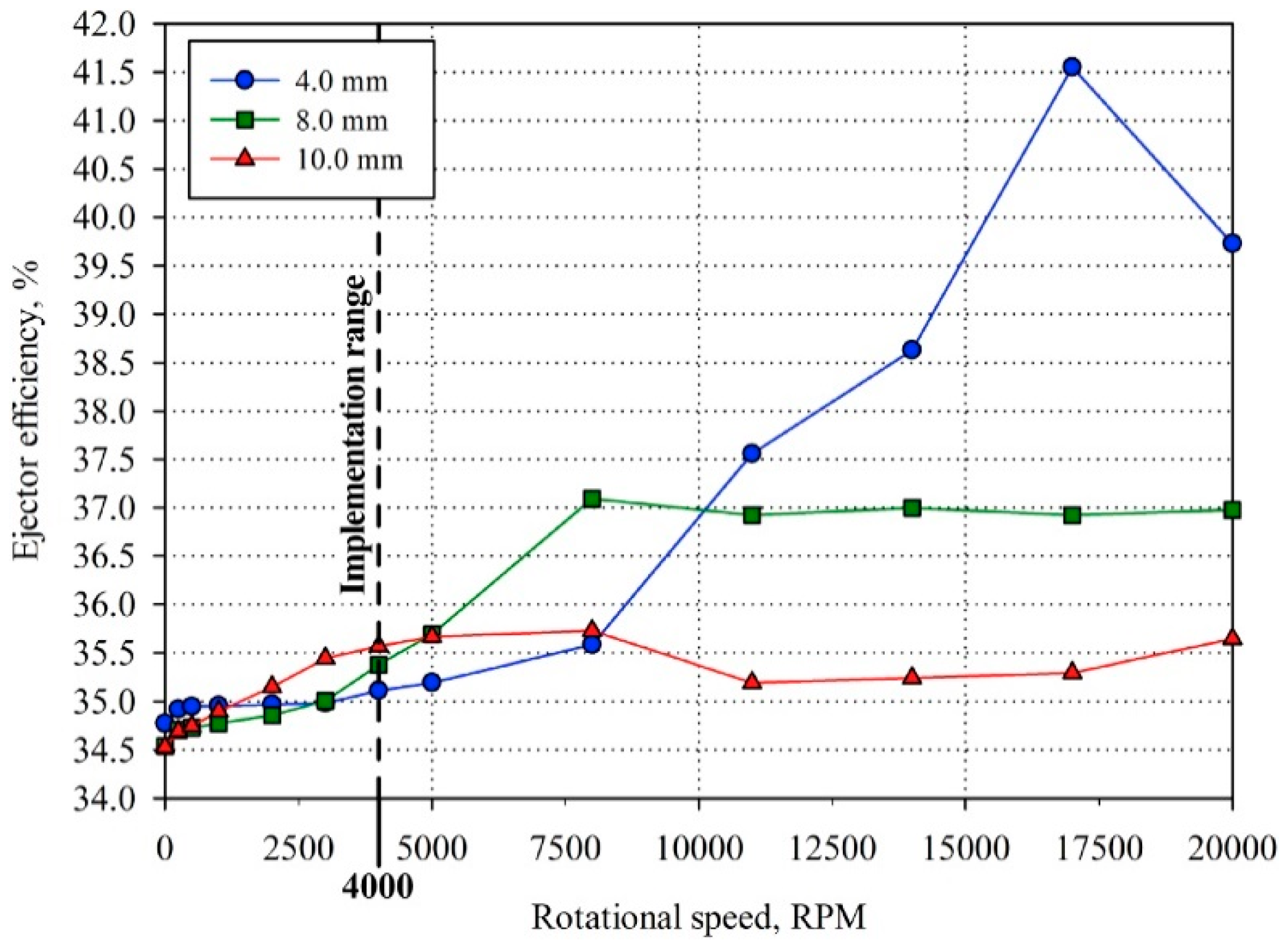

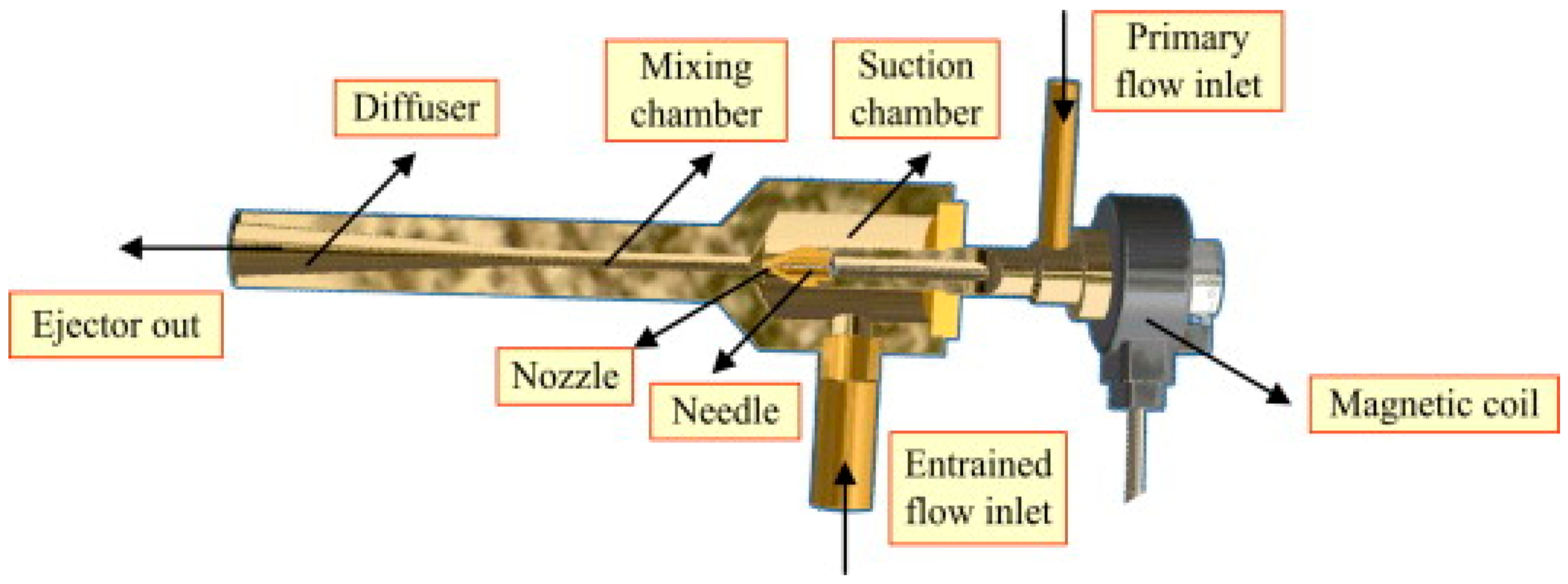

3.4. Expansion Device

3.5. An Auxiliary Component: Internal Heat Exchanger

4. CO2 Heat Pump Systems

4.1. Heat Sources

4.2. Hybrid Heat Pump Systems

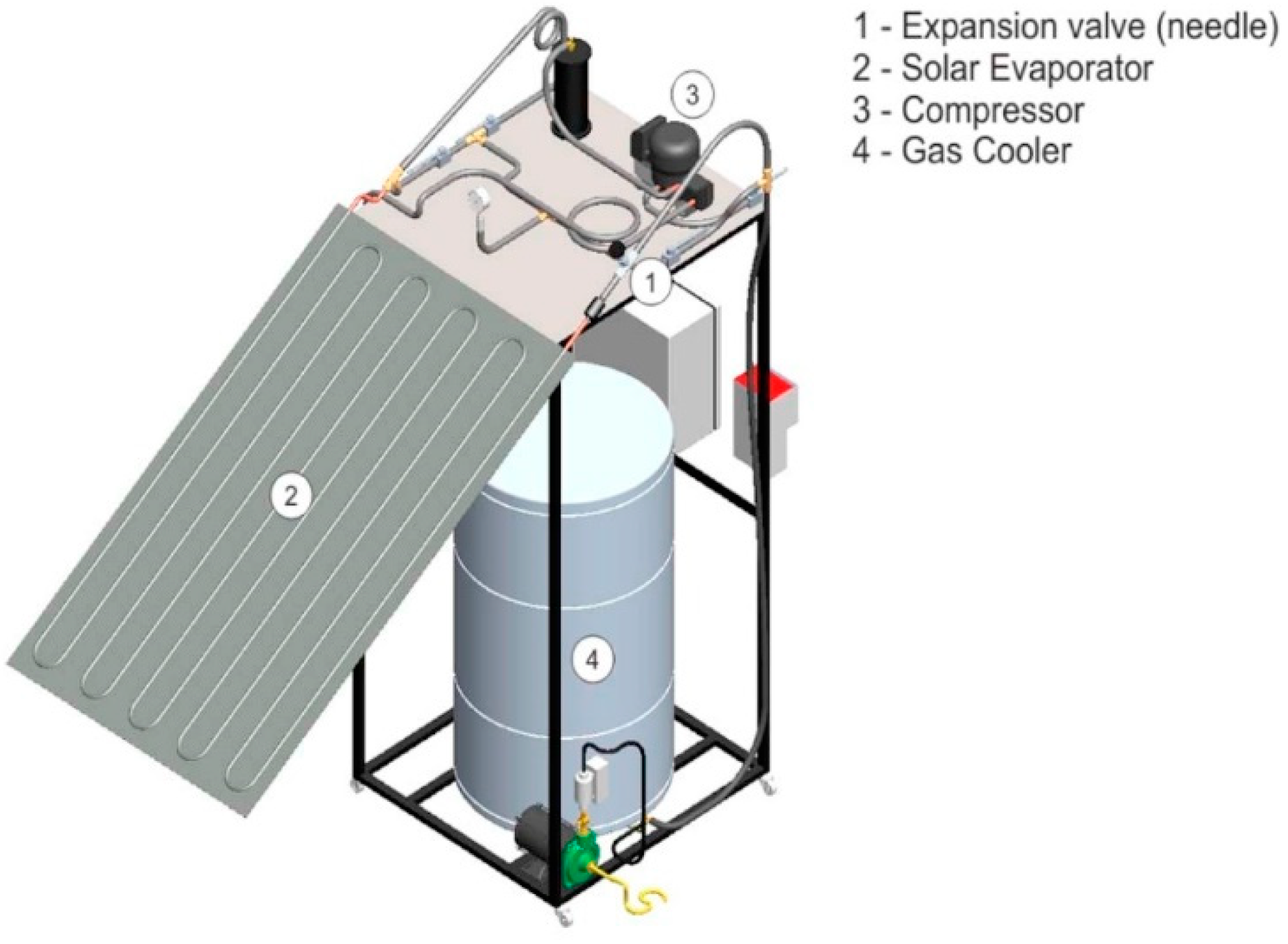

4.2.1. Hybrid Solar

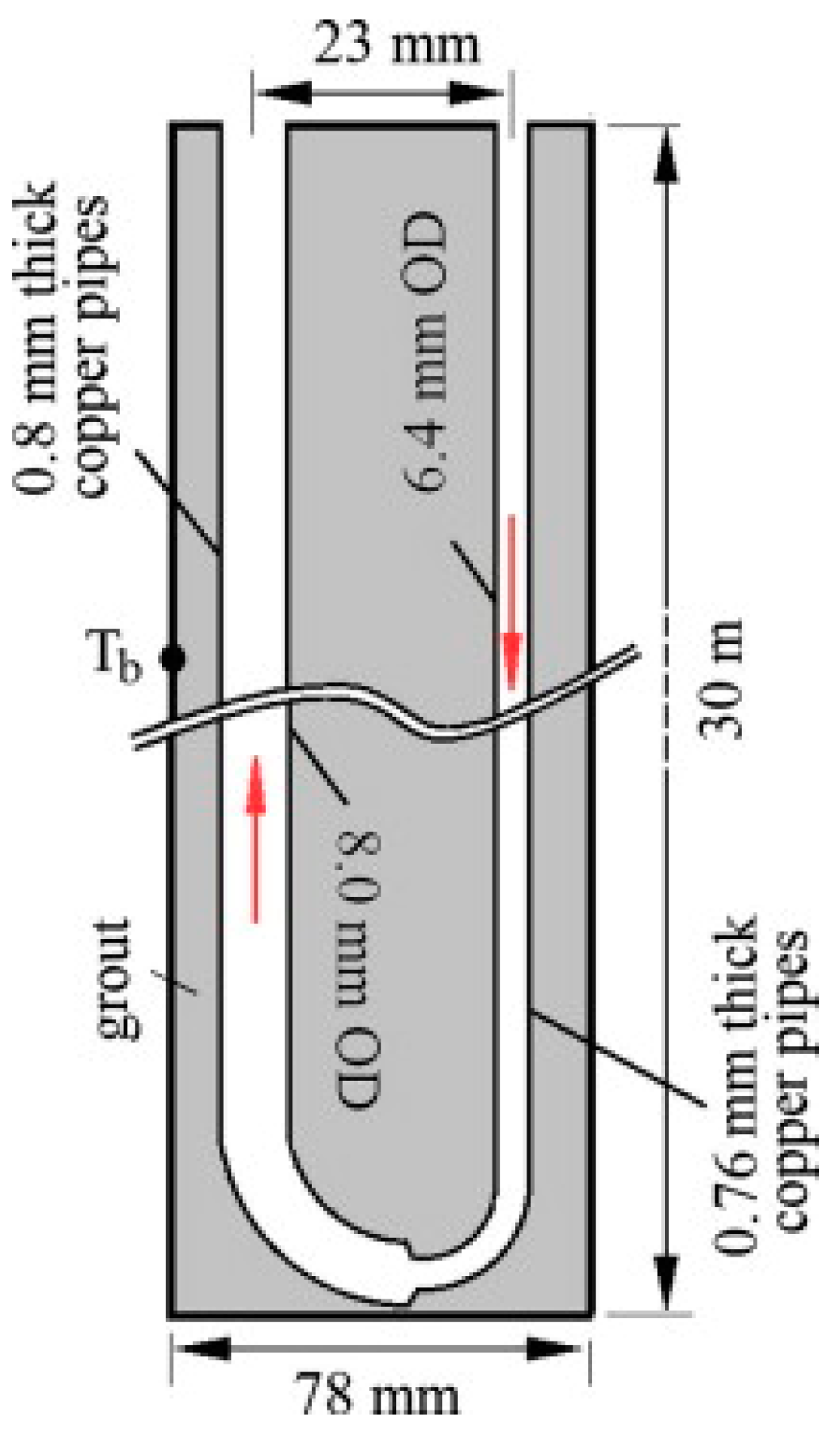

4.2.2. Hybrid Geothermal

5. CO2 Heat Pump Applications

5.1. Water Heating

5.2. Drying

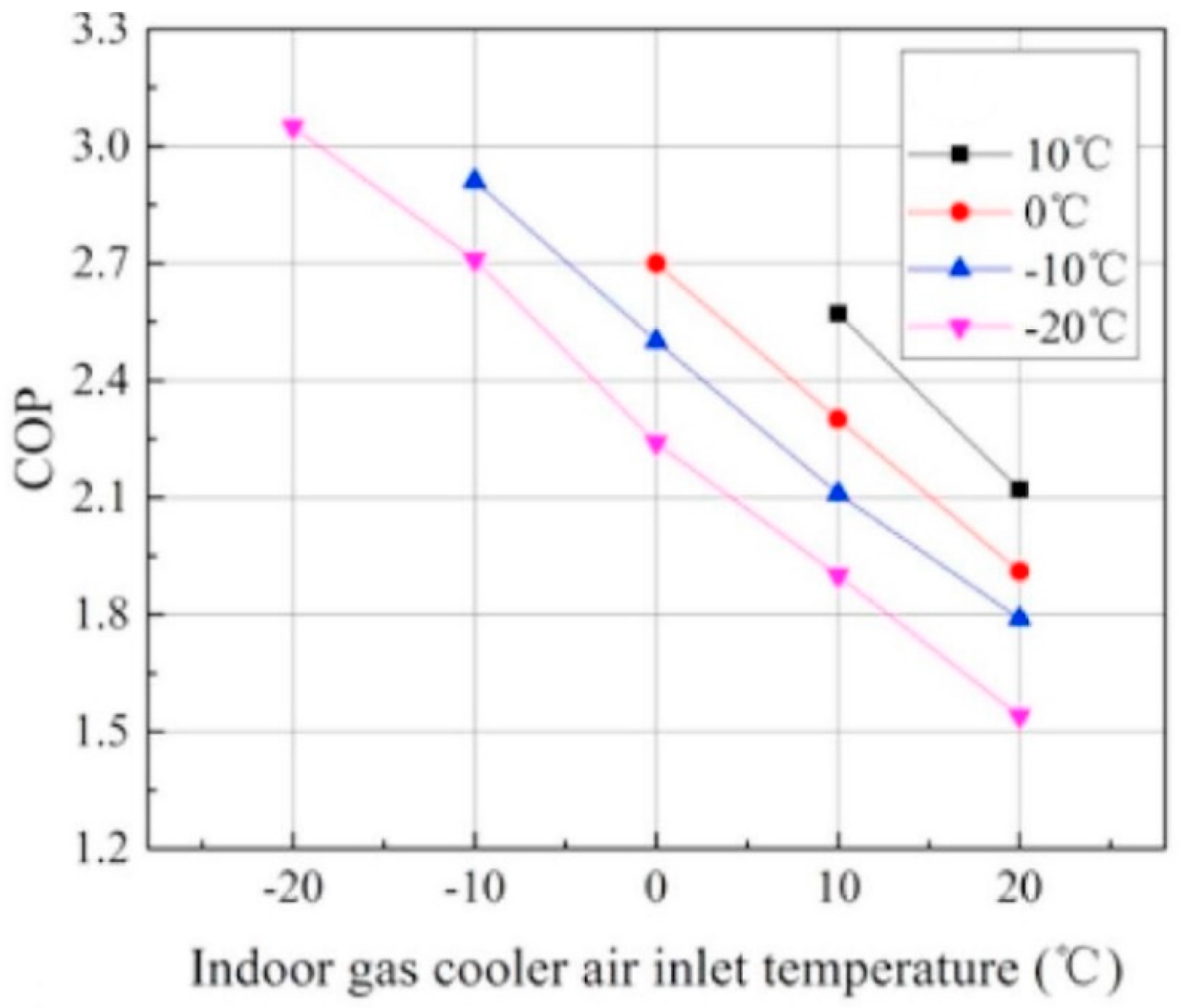

5.3. Cold Climate Heating

5.4. Food Processing

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CFC | Chlorofluorocarbons |

| HFC | Hydrofluorocarbons |

| GWP | Global warming potential |

| COP | Coefficient of performance |

| ODP | Ozone depletion potential |

| IHX | Internal heat exchanger |

| HX | Heat exchanger |

| HTC | Heat transfer coefficient |

| DSH | Degree of superheat |

| MCHX | Microchannel heat exchanger |

| FGB | Flash gas bypass |

| CDP | Compressor discharge pressure |

| HEM | Homogeneous equilibrium model |

| EEV | Electronic expansion valve |

| ASHP | Air source heat pump |

| ESC | Extremum seeking control |

| WSHP | Water source heat pump |

| GSHP | Ground source heat pump |

| GCHP | Ground coupled heat pump |

| nZEB | Net zero energy balanced |

| GSAHP | Geothermal-solar assisted heat pump |

| HPWH | Heat pump water heater |

References

- Bolaji, B.O.; Huan, Z. Ozone depletion and global warming: Case for the use of natural refrigerant—A review. Renew. Sustain. Energy Rev. 2013, 18, 49–54. [Google Scholar] [CrossRef]

- Varotsos, C. The 20th anniversary of the Montreal Protocol and the unexplainable 60% of ozone loss. Environ. Sci. Pollut. Res. 2008, 15, 448–449. [Google Scholar] [CrossRef] [PubMed]

- ASHRAE. 15 & 34 Safety Standard for Refrigeration Systems and Designation and Classification of Refrigerants ISO 5149 Mechanical Refrigerating Systems Used for Cooling and Heating—Safety Requirements. Available online: https://www.ashrae.org/technical-resources/bookstore/standards-15-34 (accessed on 17 October 2018).

- Lachner, B.F.; Nellis, G.F.; Reindl, D.T. The commercial feasibility of the use of water vapor as a refrigerant. Int. J. Refrig. 2007, 30, 699–708. [Google Scholar] [CrossRef]

- ASHRAE Position Document on Natural Refrigerants; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2014.

- Kim, M.H.; Pettersen, J.; Bullard, C.W. Fundamental process and system design issues in CO2 vapor compression systems. Prog. Energy Combust. Sci. 2004, 30, 119–174. [Google Scholar] [CrossRef]

- Yang, D.; Song, Y.; Cao, F.; Jin, L.; Wang, X. Theoretical and experimental investigation of a combined R134a and transcritical CO2 heat pump for space heating. Int. J. Refrig. 2016, 72, 156–170. [Google Scholar] [CrossRef]

- Life Cycle Climate Performance Energy Tool. Emerson Climate Technologies. Available online: www.emersonclimate.com (accessed on 3 November 2018).

- Baek, C.; Heo, J.; Jung, J.; Cho, H.; Kim, Y. Optimal control of the gas-cooler pressure of a CO2 heat pump using EEV opening and outdoor fan speed in the cooling mode. Int. J. Refrig. 2013, 36, 1276–1284. [Google Scholar] [CrossRef]

- Tian, H.; Yang, Z.; Li, M.; Ma, Y. Research and application of CO2 refrigeration and heat pump cycle. Sci. China Ser. E Technol. Sci. 2009, 52, 1563–1575. [Google Scholar] [CrossRef]

- Staub, J.; Rasmusen, B.D.; Robinson, M. CO2 as refrigerant: The transcritical cycle. ACHR News, 26 January 2004. [Google Scholar]

- Austin, B.T.; Sumathy, K. Trans-critical carbon dioxide heat pump systems: A review. Renew. Sustain. Energy Rev. 2011, 15, 4013–4029. [Google Scholar] [CrossRef]

- Yang, J.L.; Ma, Y.T.; Li, M.X.; Guan, H.Q. Exergy analysis of transcritical carbon dioxide refrigeration cycle with an expander. Energy 2005, 30, 1162–1175. [Google Scholar] [CrossRef]

- Eckhard, D.M.; Groll, A. Efficiencies of transcritical CO2 cycles with and without an expansion turbine. Int. J. Refrig. 1998, 21, 577–589. [Google Scholar]

- Sarkar, J.; Bhattacharyya, S.; Gopal, M.R. Transcritical CO2 heat pump systems: Exergy analysis including heat transfer and fluid flow effects. Energy Convers. Manag. 2005, 46, 2053–2067. [Google Scholar] [CrossRef]

- Bai, T.; Yan, G.; Yu, J. Thermodynamic analyses on an ejector enhanced CO2 transcritical heat pump cycle with vapor-injection. Int. J. Refrig. 2015, 58, 22–34. [Google Scholar] [CrossRef]

- Ghazizade-Ahsaee, H.; Ameri, M. Energy and exergy investigation of a carbon dioxide direct-expansion geothermal heat pump. Appl. Therm. Eng. 2018, 129, 165–178. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Wang, K.; Ma, Y. Study of multi-twisted-tube gas cooler for CO2 heat pump water heaters. Appl. Therm. Eng. 2016, 102, 204–212. [Google Scholar] [CrossRef]

- Qi, P.C.; He, Y.L.; Wang, X.L.; Meng, X.Z. Experimental investigation of the optimal heat rejection pressure for a transcritical CO2 heat pump water heater. Appl. Therm. Eng. 2013, 56, 120–125. [Google Scholar] [CrossRef]

- Yu, P.Y.; Lin, K.H.; Lin, W.K.; Wang, C.C. Performance of a tube-in-tube CO2 gas cooler. Int. J. Refrig. 2012, 35, 2033–2038. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Kato, D.; Saito, K.; Kawai, S. Development and validation of static simulation model for CO2 heat pump. Int. J. Heat Mass Transf. 2011, 54, 1896–1906. [Google Scholar] [CrossRef]

- Yun, R.; Kim, Y.; Park, C. Numerical analysis on a microchannel evaporator designed for CO2 air-conditioning systems. Appl. Therm. Eng. 2007, 27, 1320–1326. [Google Scholar] [CrossRef]

- Elbel, S.; Hrnjak, P. Flash gas bypass for improving the performance of transcritical R744 systems that use microchannel evaporators. Int. J. Refrig. 2004, 27, 724–735. [Google Scholar] [CrossRef]

- Brown, J.S.; Kim, Y.; Domanski, P.A. Evaluation of Carbon Dioxide as R-22 Substitute for Residential Air-Conditioning. ASHRAE Trans. 2002, 108, 954–963. [Google Scholar]

- Jiang, Y.; Ma, Y.; Li, M.; Fu, L. An experimental study of trans-critical CO2 water–water heat pump using compact tube-in-tube heat exchangers. Energy Convers. Manag. 2013, 76, 92–100. [Google Scholar] [CrossRef]

- Rozhentsev, A.; Wang, C.C. Some design features of a CO2 air conditioner. Appl. Therm. Eng. 2001, 21, 871–880. [Google Scholar] [CrossRef]

- Hiwata, A.; Iida, N.; Futagami, Y.; Sawai, K.; Ishii, N. Performance investigation with oil-injection to compression chambers on CO2-scroll compressor. In Proceedings of the International Compressor Engineering Conference, Purdue University, West Lafayette, IN, USA, 16–19 July 2002. Paper 1577. [Google Scholar]

- White, S.D.; Yarrall, M.G.; Cleland, D.J.; Hedley, R.A. Modelling the performance of a transcritical CO2 heat pump for high temperature heating. Int. J. Refrig. 2002, 25, 479–486. [Google Scholar] [CrossRef]

- Xing, M.; Yu, J.; Liu, X. Thermodynamic analysis on a two-stage transcritical CO2 heat pump cycle with double ejectors. Energy Convers. Manag. 2014, 88, 677–683. [Google Scholar] [CrossRef]

- Boccardi, G.; Botticella, F.; Lillo, G.; Mastrullo, R.; Mauro, A.W.; Trinchieri, R. Thermodynamic Analysis of a Multi-Ejector, CO2, Air-To-Water Heat Pump System. Energy Procedia 2016, 101, 846–853. [Google Scholar] [CrossRef]

- Agrawal, N.; Bhattacharyya, S. Non-adiabatic capillary tube flow of carbon dioxide in a transcritical heat pump cycle. Energy Convers. Manag. 2007, 48, 2491–2501. [Google Scholar] [CrossRef]

- Kim, Y.J.; Chang, K.-S. Development of a thermodynamic performance-analysis program for CO2 geothermal heat pump system. J. Ind. Eng. Chem. 2013, 19, 1827–1837. [Google Scholar] [CrossRef]

- Tao, Y.B.; He, Y.L.; Tao, W.Q.; Wu, Z.G. Experimental study on the performance of CO2 residential air-conditioning system with an internal heat exchanger. Energy Convers. Manag. 2010, 51, 64–70. [Google Scholar] [CrossRef]

- Chang, Y.S.; Kim, M.S. Modelling and performance simulation of a gas cooler for a CO2 heat pump system. HVAC&R Res. 2007, 13, 445–456. [Google Scholar]

- Cabeza, L.F.; de Gracia, A.; Fernández, A.I.; Farid, M.M. Supercritical CO2 as heat transfer fluid: A review. Appl. Therm. Eng. 2017, 125, 799–810. [Google Scholar] [CrossRef]

- Liao, S.M.; Zhao, T.S. An experimental investigation of convection heat transfer to supercritical carbon dioxide in miniature tubes. Int. J. Heat Mass Transf. 2002, 45, 5025–5034. [Google Scholar] [CrossRef]

- Dang, C.; Hihara, E. In-tube cooling heat transfer of supercritical carbon dioxide. Part 1. Experimental measurement. Int. J. Refrig. 2004, 27, 736–747. [Google Scholar] [CrossRef]

- Du, Z.; Lin, W.; Gu, A. Numerical investigation of cooling heat transfer to supercritical CO2 in a horizontal circular tube. J. Supercrit. Fluids 2010, 55, 116–121. [Google Scholar] [CrossRef]

- Ma, T.; Chu, W.; Xu, X.; Chen, Y.; Wang, Q. An experimental study on heat transfer between supercritical carbon dioxide and water near the pseudo-critical temperature in a double pipe heat exchanger. Int. J. Heat Mass Transf. 2016, 93, 379–387. [Google Scholar] [CrossRef]

- Purohit, N.; Khangarot, B.S.; Gullo, P.; Purohit, K.; Dasgupta, M.S. Assessment of Alumina Nanofluid as a Coolant in Double Pipe Gas Cooler for Trans-critical CO2 Refrigeration Cycle. Energy Procedia 2017, 109, 219–226. [Google Scholar] [CrossRef]

- Naphon, P.; Wongwises, S. A review of flow and heat transfer characteristics in curved tubes. Renew. Sustain. Energy Rev. 2006, 10, 463–490. [Google Scholar] [CrossRef]

- Yang, D.; Xie, J.; Lv, J.; Wang, J. An Experimental and Numerical Study of Helix Tube Gas Cooler for Super-Critical Carbon Dioxide. J. Chem. Eng. Jpn. 2017, 50, 900–908. [Google Scholar] [CrossRef]

- Jackson, J.D.; Cotton, M.A.; Axcell, B.P. Studies of mixed convection in vertical tubes. Int. J. Heat Fluid Flow 1989, 10, 2–15. [Google Scholar] [CrossRef]

- Liu, X.; Xu, X.; Liu, C.; Ye, J.; Li, H.; Bai, W.; Dang, C. Numerical study of the effect of buoyancy force and centrifugal force on heat transfer characteristics of supercritical CO2 in helically coiled tube at various inclination angles. Appl. Therm. Eng. 2017, 116, 500–515. [Google Scholar] [CrossRef]

- Forooghi, P.; Hooman, K. Numerical study of turbulent convection in inclined pipes with significant buoyancy influence. Int. J. Heat Mass Transf. 2013, 61, 310–322. [Google Scholar] [CrossRef]

- Wang, K.; Xu, X.; Wu, Y.; Liu, C.; Dang, C. Numerical investigation on heat transfer of supercritical CO2 in heated helically coiled tubes. J. Supercrit. Fluids 2015, 99, 112–120. [Google Scholar] [CrossRef]

- Xu, X.; Liu, C.; Dang, C.; Wu, Y.; Liu, X. Experimental investigation on heat transfer characteristics of supercritical CO2 cooled in horizontal helically coiled tube. Int. J. Refrig. 2016, 67, 190–201. [Google Scholar] [CrossRef]

- Santosa, I.D.M.C.; Gowreesunker, B.L.; Tassou, S.A.; Tsamos, K.M.; Ge, Y. Investigations into air and refrigerant side heat transfer coefficients of finned-tube CO2 gas coolers. Int. J. Heat Mass Transf. 2017, 107, 168–180. [Google Scholar] [CrossRef]

- Li, J.; Jia, J.; Huang, L.; Wang, S. Experimental and numerical study of an integrated fin and micro-channel gas cooler for a CO2 automotive air-conditioning. Appl. Therm. Eng. 2017, 116, 636–647. [Google Scholar] [CrossRef]

- Garimella, S. Microchannel gas coolers for carbon dioxide air-conditioning systems. ASHRAE Trans. 2002, 108, 492–499. [Google Scholar]

- Marcinichen, J.B.; Thome, J.R.; Pereira, R.H. Working fluid charge reduction. Part II: Supercritical CO2 gas cooler designed for light commercial appliances. Int. J. Refrig. 2016, 65, 273–286. [Google Scholar] [CrossRef]

- Chen, Y.-G. Pinch point analysis and design considerations of CO2 gas cooler for heat pump water heaters. Int. J. Refrig. 2016, 69, 136–146. [Google Scholar] [CrossRef]

- Sánchez, D.; Cabello, R.; Llopis, R.; Torrella, E. Development and validation of a finite element model for water—CO2 coaxial gas-coolers. Appl. Energy 2012, 93, 637–647. [Google Scholar] [CrossRef]

- Yin, J.M.; Bullard, C.W.; Hrnjak, P.S. R-744 gas cooler model development and validation. Int. J. Refrig. 2001, 24, 692–701. [Google Scholar] [CrossRef]

- Tsamos, K.M.; Ge, Y.T.; Santosa, I.D.M.C.; Tassou, S.A. Experimental investigation of gas cooler/condenser designs and effects on a CO2 booster system. Appl. Energy 2017, 186, 470–479. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A.; Santosa, I.D.; Tsamos, K. Design optimisation of CO2 gas cooler/condenser in a refrigeration system. Appl. Energy 2015, 160, 973–981. [Google Scholar] [CrossRef]

- Liu, F.; Zhu, W.; Zhao, J.; Ren, J.; Groll, E.A.; Cai, Y. A new method for optimal control of a dual-mode CO2 heat pump with thermal storage. Appl. Therm. Eng. 2017, 125, 1123–1132. [Google Scholar] [CrossRef]

- Hu, B.; Li, Y.; Wang, R.Z.; Cao, F.; Xing, Z. Real-time minimization of power consumption for air-source transcritical CO2 heat pump water heater system. Int. J. Refrig. 2018, 85, 395–408. [Google Scholar] [CrossRef]

- Peñarrocha, I.; Llopis, R.; Tárrega, L.; Sánchez, D.; Cabello, R. A new approach to optimize the energy efficiency of CO2 transcritical refrigeration plants. Appl. Therm. Eng. 2014, 67, 137–146. [Google Scholar] [CrossRef]

- Kim, M.S.; Kang, D.H.; Kim, M.S.; Kim, M. Investigation on the optimal control of gas cooler pressure for a CO2 refrigeration system with an internal heat exchanger. Int. J. Refrig. 2017, 77, 48–59. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A. Control optimizations for heat recovery from CO2 refrigeration systems in supermarket. Energy Convers. Manag. 2014, 78, 245–252. [Google Scholar] [CrossRef]

- Thome, J.R.; Ribatski, G. State-of-the-art of two-phase flow and flow boiling heat transfer and pressure drop of CO2 in macro- and micro-channels. Int. J. Refrig. 2005, 28, 1149–1168. [Google Scholar] [CrossRef]

- Pettersen, J.; Hafner, A.; Skaugen, G. Development of compact heat exchangers for CO2 air-conditioning systems. Int. J. Refrig. 1998, 21, 180–193. [Google Scholar] [CrossRef]

- Yoon, S.H.; Cho, E.S.; Hwang, Y.W. Characteristics of evaporative heat transfer and pressure drop of carbon dioxide and correlation development. Int. J. Refrig. 2004, 27, 111–119. [Google Scholar] [CrossRef]

- Bredesen, A.; Hafner, A.; Pettersen, J.; Neksa, P.; Aflekt, K. Heat transfer and pressure drop for in-tube evaporation of CO2. In Proceedings of the International Conference in Heat Transfer Issues in Natural Refrigerants, University of Maryland, College Park, MD, USA, 6–7 November 1997; pp. 1–15. [Google Scholar]

- Knudsen, H.J.; Jensen, P.H. Heat transfer coefficient for boiling carbon dioxide. In Proceedings of the Workshop Proceedings—CO2 Technologies in Refrigeration, Heat Pumps and Air Conditioning Systems, Trondhein, Norway, 1 January 1997; pp. 319–328. [Google Scholar]

- Choi, K.I.; Pamitran, A.S.; Oh, J.T. Two-phase flow heat transfer of CO2 vaporization in smooth horizontal minichannels. Int. J. Refrig. 2007, 30, 767–777. [Google Scholar] [CrossRef]

- Oh, J.T.; Pamitran, A.S.; Choi, K.I.; Hrnjak, P. Experimental investigation on two-phase flow boiling heat transfer of five refrigerants in horizontal small tubes of 0.5, 1.5 and 3.0 mm inner diameters. Int. J. Heat Mass Transf. 2011, 54, 2080–2088. [Google Scholar] [CrossRef]

- Wu, J.; Koettig, T.; Franke, C.; Helmer, D.; Eisel, T.; Haug, F.; Bremer, J. Investigation of heat transfer and pressure drop of CO2 two-phase flow in a horizontal minichannel. Int. J. Heat Mass Transf. 2011, 54, 2154–2162. [Google Scholar] [CrossRef]

- Yun, R.; Kim, Y.; Kim, M.S.; Choi, Y. Boiling heat transfer and dryout phenomenon of CO2 in a horizontal smooth tube. Int. J. Heat Mass Transf. 2003, 46, 2353–2361. [Google Scholar] [CrossRef]

- Cheng, L.; Ribatski, G.; Quibén, J.M.; Thome, J.R. New prediction methods for CO2 evaporation inside tubes: Part I—A two-phase flow pattern map and a flow pattern based phenomenological model for two-phase flow frictional pressure drops. Int. J. Heat Mass Transf. 2008, 51, 111–124. [Google Scholar] [CrossRef]

- Wang, D.; Yu, B.; Hu, J.; Chen, L.; Shi, J.; Chen, J. Heating performance characteristics of CO2 heat pump system for electrical vehicle in a cold climate. Int. J. Refrig. 2018, 85, 27–41. [Google Scholar] [CrossRef]

- Bendaoud, A.; Ouzzane, M.; Aidoun, Z.; Galanis, N. A new modeling approach for the study of finned coils with CO2. Int. J. Therm. Sci. 2010, 49, 1702–1711. [Google Scholar] [CrossRef]

- Tsamos, K.M.; Ge, Y.T.; Santosa, I.D.; Tassou, S.A.; Bianchi, G.; Mylona, Z. Energy analysis of alternative CO2 refrigeration system configurations for retail food applications in moderate and warm climates. Energy Convers. Manag. 2017, 150, 822–829. [Google Scholar] [CrossRef]

- Chesi, A.; Esposito, F.; Ferrara, G.; Ferrari, L. Experimental analysis of R744 parallel compression cycle. Appl. Energy 2014, 135, 274–285. [Google Scholar] [CrossRef]

- Mitsubishi Heavy Industries. Development of Two-Stage Compressor for CO2 Heat-Pump Water Heaters; Technical Review; Mitsubishi Heavy Industries: Tokyo, Japan, 2012; Volume 49. [Google Scholar]

- Shimoji, M.; Nakamura, T. Performance analysis of scroll compressors using CO2 refrigerant. Mitsubishi Electr. Adv. 2007, 120, 7–19. [Google Scholar]

- Cavallini, A.; Cecchinato, L.; Corradi, M.; Fornasieri, E.; Zilio, C. Two-stage transcritical carbon dioxide cycle optimization: A theoretical and experimental analysis. Int. J. Refrig. 2005, 28, 1274–1283. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, M.; Huang, X. Performance Comparison of Single-stage and Two-stage Hermetic Rotary CO2 Compressor. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 11–14 July 2016. Paper 2473. [Google Scholar]

- Cecchinato, L.; Chiarello, M.; Corradi, M.; Fornasieri, E.; Minetto, S.; Stringari, P.; Zilio, C. Thermodynamic analysis of different two-stage transcritical carbon dioxide cycles. Int. J. Refrig. 2009, 32, 1058–1067. [Google Scholar] [CrossRef]

- Pitarch, M.; Navarro-Peris, E.; Gonzalvez, J.; Corberan, J.M. Analysis and optimisation of different two-stage transcritical carbon dioxide cycles for heating applications. Int. J. Refrig. 2016, 70, 235–242. [Google Scholar] [CrossRef]

- Cho, H.; Baek, C.; Park, C.; Kim, Y. Performance evaluation of a two-stage CO2 cycle with gas injection in the cooling mode operation. Int. J. Refrig. 2009, 32, 40–46. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Z.; Li, H.; Dai, B.; Chen, Y. Thermodynamic analysis of CO2 transcritical two-stage compression refrigeration cycle systems with expanders. HKIE Trans. 2017, 24, 70–77. [Google Scholar] [CrossRef]

- Ibsaine, R.; Joffroy, J.-M.; Stouffs, P. Modelling of a new thermal compressor for supercritical CO2 heat pump. Energy 2016, 117, 530–539. [Google Scholar] [CrossRef]

- Sumeru, K.; Nasution, H.; Ani, F.N. A review on two-phase ejector as an expansion device in vapor compression refrigeration cycle. Renew. Sustain. Energy Rev. 2012, 16, 4927–4937. [Google Scholar] [CrossRef]

- Elbel, S.; Hrnjak, P. Experimental validation of a prototype ejector designed to reduce throttling losses encountered in transcritical R744 system operation. Int. J. Refrig. 2008, 31, 411–422. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, M.S.; Kim, M.S. Studies on the performance of a CO2 air conditioning system using an ejector as an expansion device. Int. J. Refrig. 2014, 38, 140–152. [Google Scholar] [CrossRef]

- Elbel, S.; Lawrence, N. Review of recent developments in advanced ejector technology. Int. J. Refrig. 2016, 62, 1–18. [Google Scholar] [CrossRef]

- Lucas, C.; Rusche, H.; Schroeder, A.; Koehler, J. Numerical investigation of a two-phase CO2 ejector. Int. J. Refrig. 2014, 43, 154–166. [Google Scholar] [CrossRef]

- Palacz, M.; Smolka, J.; Nowak, A.J.; Banasiak, K.; Hafner, A. Shape optimisation of a two-phase ejector for CO2 refrigeration systems. Int. J. Refrig. 2017, 74, 210–221. [Google Scholar] [CrossRef]

- Angielczyk, W.; Bartosiewicz, Y.; Butrymowicz, D.; Seynhaeve, J.-M. 1-D Modeling Of Supersonic Carbon Dioxide Two-Phase Flow Through Ejector Motive Nozzle. In Proceedings of the International Refrigeration and Air Conditioning Conference Purdue e-Pubs, West Lafayette, IN, USA, 12–15 July 2010. [Google Scholar]

- Palacz, M.; Haida, M.; Smolka, J.; Nowak, A.J.; Banasiak, K.; Hafner, A. HEM and HRM accuracy comparison for the simulation of CO2 expansion in two-phase ejectors for supermarket refrigeration systems. Appl. Therm. Eng. 2017, 115, 160–169. [Google Scholar] [CrossRef]

- Zheng, L.X.; Deng, J.Q.; He, Y.; Jiang, P.X. Dynamic model of a transcritical CO2 ejector expansion refrigeration system. Int. J. Refrig. 2015, 60, 247–260. [Google Scholar] [CrossRef]

- He, Y.; Deng, J.Q.; Zheng, L.X.; Zhang, Z.X. Thermodynamic study on a new transcritical CO2 ejector expansion refrigeration system with two-stage evaporation and vapor feedback. HVAC&R Res. 2014, 20, 655–664. [Google Scholar]

- Bai, T.; Yan, G.; Yu, J. Performance evolution on a dual-temperature CO2 transcritical refrigeration cycle with two cascade ejectors. Appl. Therm. Eng. 2017, 120, 26–35. [Google Scholar] [CrossRef]

- Bodys, J.; Smolka, J.; Palacz, M.; Haida, M.; Banasiak, K.; Nowak, A.J.; Hafner, A. Performance of fixed geometry ejectors with a swirl motion installed in a multi-ejector module of a CO2 refrigeration system. Energy 2016, 117, 620–631. [Google Scholar] [CrossRef]

- Smolka, J.; Palacz, M.; Bodys, J.; Banasiak, K.; Fic, A.; Bulinski, Z. Performance comparison of fixed- and controllable-geometry ejectors in a CO2 refrigeration system. Int. J. Refrig. 2016, 65, 172–182. [Google Scholar] [CrossRef]

- Liu, F.; Groll, E.A.; Ren, J. Comprehensive experimental performance analyses of an ejector expansion transcritical CO2 system. Appl. Therm. Eng. 2016, 98, 1061–1069. [Google Scholar] [CrossRef]

- Xu, X.X.; Chen, G.M.; Tang, L.M.; Zhu, Z.J. Experimental investigation on performance of transcritical CO2 heat pump system with ejector under optimum high-side pressure. Energy 2012, 44, 870–877. [Google Scholar] [CrossRef]

- He, Y.; Deng, J.; Yang, F.; Zhang, Z. An optimal multivariable controller for transcritical CO2 refrigeration cycle with an adjustable ejector. Energy Convers. Manag. 2017, 142, 466–476. [Google Scholar] [CrossRef]

- He, Y.; Deng, J.; Zheng, L.; Zhang, Z. Performance optimization of a transcritical CO2 refrigeration system using a controlled ejector. Int. J. Refrig. 2017, 75, 250–261. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, X.; Ren, Z.; Lai, T.; Hou, Y. Influence of Refrigerant Charge Amount and EEV Opening on the Performance of a Transcritical CO2 Heat Pump Water Heater. Energies 2017, 10, 1521. [Google Scholar] [CrossRef]

- Song, Y.; Wang, J.; Cao, F.; Shu, P.; Wang, X. Experimental investigation on a capillary tube based transcritical CO2 heat pump system. Appl. Therm. Eng. 2017, 112, 184–189. [Google Scholar] [CrossRef]

- Madsen, K.B.; Poulsen, C.S.; Wiesenfarth, M. Study of capillary tubes in a transcritical CO2 refrigeration system. Int. J. Refrig. 2005, 28, 1212–1218. [Google Scholar] [CrossRef]

- Hu, J.; Li, M.; Zhao, L.; Xia, B.; Ma, Y. Improvement and experimental research of CO2 two-rolling piston expander. Energy 2015, 93, 2199–2207. [Google Scholar] [CrossRef]

- Navarro-Esbrı, J.; Cabello, R.; Torrella, E. Experimental evaluation of the internal heat exchanger influence on a vapour compression plant energy efficiency working with R22, R123a and R407C. Energy 2005, 30, 621–636. [Google Scholar] [CrossRef]

- Shariatzadeh, O.J.; Abolhassani, S.S.; Rahmani, M.; Nejad, M.Z. Comparison of transcritical CO2 refrigeration cycle with expander and throttling valve including/excluding internal heat exchanger: Exergy and energy points of view. Appl. Therm. Eng. 2016, 93, 779–787. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, L.; Chen, Y.; Tong, L. Effect of an internal heat exchanger on performance of the transcritical carbon dioxide refrigeration cycle with an expander. Entropy 2014, 16, 5919–5934. [Google Scholar] [CrossRef]

- Sánchez, D.; Patiño, J.; Llopis, R.; Cabello, R.; Torrella, E.; Fuentes, F.V. New positions for an internal heat exchanger in a CO2 supercritical refrigeration plant. Experimental analysis and energetic evaluation. Appl. Therm. Eng. 2014, 63, 129–139. [Google Scholar] [CrossRef]

- Pérez-García, V.; Rodríguez-Muñoz, J.L.; Ramírez-Minguela, J.J.; Belman-Flores, J.M.; Méndez-Díaz, S. Comparative analysis of energy improvements in single transcritical cycle in refrigeration mode. Appl. Therm. Eng. 2016, 99, 866–872. [Google Scholar] [CrossRef]

- Llopis, R.; Nebot-Andrés, L.; Cabello, R.; Sánchez, D.; Catalán-Gil, J. Experimental evaluation of a CO2 transcritical refrigeration plant with dedicated mechanical subcooling. Int. J. Refrig. 2016, 69, 361–368. [Google Scholar] [CrossRef]

- Ituna-Yudonago, J.F.; Belman-Flores, J.M.; Elizalde-Blancas, F.; García-Valladares, O. Numerical investigation of CO2 behavior in the internal heat exchanger under variable boundary conditions of the transcritical refrigeration system. Appl. Therm. Eng. 2017, 115, 1063–1078. [Google Scholar] [CrossRef]

- Lorentzen, G.; Pettersen, J. A new, efficient and environmentally benign system for car air-conditioning. Int. J. Refrig. 1993, 16, 4–12. [Google Scholar] [CrossRef]

- Beyond HFCs Position Paper on CO2 Vending Machines. Available online: http://www.beyondhfcs.org/ (accessed on 28 October 2018).

- EcoCute Shipments Exceed 2 Million Landmark. Available online: http://www.r744.com/articles/2009-11-26-eco-cute-shipments-exceed-2-million-landmark.php (accessed on 26 November 2009).

- Available online: http://www.mayekawa.com.au/products/heat-pumps/heatcom-water-heat-source/ (accessed on 6 September 2018).

- Liu, F.; Zhu, W.; Cai, Y.; Groll, E.A.; Lei, Y. Experimental performance study on a dual-mode CO2 heat pump system with thermal storage. Appl. Therm. Eng. 2017, 115, 393–405. [Google Scholar] [CrossRef]

- Hu, B.; Wang, X.; Cao, F.; He, Z.; Xing, Z. Experimental analysis of an air-source transcritical CO2 heat pump water heater using the hot gas bypass defrosting method. Appl. Therm. Eng. 2014, 71, 528–535. [Google Scholar] [CrossRef]

- Calabrese, N.; Mastrullo, R.; Mauro, A.W.; Rovella, P.; Tammaro, M. Performance analysis of a rooftop, air-to-air heat pump working with CO2. Appl. Therm. Eng. 2015, 75, 1046–1054. [Google Scholar] [CrossRef]

- Eslami-Nejad, P.; Ouzzane, M.; Aidoun, Z. Modeling of a two-phase CO2-filled vertical borehole for geothermal heat pump applications. Appl. Energy 2014, 114, 611–620. [Google Scholar] [CrossRef]

- Wang, J.; Kang, L.; Liu, J. CO2 Transcritical Cycle for Ground Source Heat Pump. In Proceedings of the CSIE ’09, 2009 WRI World Congress on Computer Science and Information Engineering, Los Angeles, CA, USA, 31 March–2 April 2009; Volume 2, pp. 213–217. [Google Scholar]

- Faria, R.N.; Nunes, R.O.; Koury, R.N.N.; Machado, L. Dynamic modeling study for a solar evaporator with expansion valve assembly of a transcritical CO2 heat pump. Int. J. Refrig. 2016, 64, 203–213. [Google Scholar] [CrossRef]

- Li, S.; Li, S.; Zhang, X. Simulation research of a hybrid heat source heat pump using R134a, R744 instead of R22 for domestic water heating in residential buildings. Energy Build. 2015, 91, 57–64. [Google Scholar] [CrossRef]

- Cho, H. Comparative study on the performance and exergy efficiency of a solar hybrid heat pump using R22 and R744. Energy 2015, 93, 1267–1276. [Google Scholar] [CrossRef]

- Chaichana, C.; Aye, L.; Charters, W.W.S. Natural working fluids for solar-boosted heat pumps. Int. J. Refrig. 2003, 26, 637–643. [Google Scholar] [CrossRef]

- Jin, Z.; Eikevik, T.M.; Nekså, P.; Hafner, A. A steady and quasi-steady state analysis on the CO2 hybrid ground-coupled heat pumping system. Int. J. Refrig. 2017, 76, 29–41. [Google Scholar] [CrossRef]

- Jin, Z.; Eikevik, T.M.; Nekså, P.; Hafner, A. Investigation on CO2 hybrid ground-coupled heat pumping system under warm climate. Int. J. Refrig. 2016, 62, 145–152. [Google Scholar] [CrossRef]

- Kim, W.; Choi, J.; Cho, H. Performance analysis of hybrid solar-geothermal CO2 heat pump system for residential heating. Renew. Energy 2013, 50, 596–604. [Google Scholar] [CrossRef]

- Hu, B.; Li, Y.; Cao, F.; Xing, Z. Extremum seeking control of COP optimization for air-source transcritical CO2 heat pump water heater system. Appl. Energy 2015, 147, 361–372. [Google Scholar] [CrossRef]

- ENERGY.GOV. Available online: https://energy.gov/ (accessed on 3 September 2018).

- Emmi, G.; Zarrella, A.; de Carli, M.; Galgaro, A. Solar Assisted Ground Source Heat Pump in Cold Climates. Energy Procedia 2015, 82, 623–629. [Google Scholar] [CrossRef]

- Chen, J.F.; Dai, Y.J.; Wang, R.Z. Experimental and theoretical study on a solar assisted CO2 heat pump for space heating. Renew. Energy 2016, 89, 295–304. [Google Scholar] [CrossRef]

- Islam, M.R.; Sumathy, K.; Gong, J.; Khan, S.U. Performance study on solar assisted heat pump water heater using CO2 in a transcritical cycle. Renew. Energies Power Qual. 2012. [Google Scholar] [CrossRef]

- Deng, S.; Dai, Y.J.; Wang, R.Z.; Matsuura, T.; Yasui, Y. Comparison study on performance of a hybrid solar-assisted CO2 heat pump. Appl. Therm. Eng. 2011, 31, 3696–3705. [Google Scholar] [CrossRef]

- Residential CO2 Heat Pump Water Heater. Available online: https://energy.gov/eere/buildings/downloads/residential-CO2-heat-pump-water-heater (accessed on 28 July 2018).

- Available online: https://www.ornl.gov/ (accessed on 28 July 2018).

- Available online: https://www.energystar.gov/ (accessed on 25 August 2018).

- Tammaro, M.; Montagud, C.; Corberán, J.M.; Mauro, A.W.; Mastrullo, R. Seasonal performance assessment of sanitary hot water production systems using propane and CO2 heat pumps. Int. J. Refrig. 2017, 74, 224–239. [Google Scholar] [CrossRef]

- Saikawa, M.; Koyama, S. Thermodynamic analysis of vapor compression heat pump cycle for tap water heating and development of CO2 heat pump water heater for residential use. Appl. Therm. Eng. 2016, 106, 1236–1243. [Google Scholar] [CrossRef]

- Klöcker, K.; Schmidt, E.L.; Steimle, F. Carbon dioxide as a working fluid in drying heat pumps. Int. J. Refrig. 2001, 24, 100–107. [Google Scholar] [CrossRef]

- Schmidt, E.L.; Klöcker, K.; Flacke, N.; Steimle, F. Applying the transcritical CO2 process to a drying heat pump. Int. J. Refrig. 1998, 21, 202–211. [Google Scholar] [CrossRef]

- Hakkaki-Fard, A.; Aidoun, Z.; Ouzzane, M. Applying refrigerant mixtures with thermal glide in cold climate air-source heat pumps. Appl. Therm. Eng. 2014, 62, 714–722. [Google Scholar] [CrossRef]

- Hakkaki-Fard, A.; Aidoun, Z.; Ouzzane, M. Improving cold climate air-source heat pump performance with refrigerant mixtures. Appl. Therm. Eng. 2015, 78, 695–703. [Google Scholar] [CrossRef]

- Available online: http://zeroenergyproject.org/2017/05/22/CO2-takes-heat-pump-water-heaters-next-level/ (accessed on 25 August 2018).

- Available online: http://www.esru.strath.ac.uk/EandE/Web_sites/10-11/ASHP_CO2/lit-sanyoEcoCute.html (accessed on 25 August 2018).

- Available online: https://www.sandenwaterheater.com/ (accessed on 25 August 2018).

- Brush, A.; Masanet, E.; Worrell, E. Energy Efficiency Improvement and Cost Saving Opportunities for the Dairy Processing Industry. An Energy Star Guide for Energy and Plant Managers; Ernest Orlando Lawrence Berkeley National Laboratory, Environmental Energy Technologies Division: Berkeley, CA, USA, 2011. [Google Scholar]

- Liu, Y.; Groll, E.A.; Yazawa, K.; Kurtulus, O. Energy-saving performance and economics of CO2 and NH3 heat pumps with simultaneous cooling and heating applications in food processing: Case studies. Int. J. Refrig. 2017, 73, 111–124. [Google Scholar] [CrossRef]

- Singh, S.; Dasgupta, M.S. CO2 heat pump for waste heat recovery and utilization in dairy industry with ammonia based refrigeration. Int. J. Refrig. 2017, 78, 108–120. [Google Scholar] [CrossRef]

| Properties | R744 | R22 | R134A | R410A |

|---|---|---|---|---|

| ODP/GWP | 0/1 | 0.05/1700 | 0/1300 | 0/1900 |

| Flammability/toxicity | N/N | N/N | N/N | N/N |

| Molecular mass (kg/kmol) | 44.0 | 86.5 | 102.0 | 72.6 |

| Critical pressure (MPa) | 7.38 | 4.97 | 4.07 | 4.79 |

| Critical temperature (°C) | 31.1 | 96.0 | 101.1 | 70.2 |

| Refrigeration capacity (kJ/m3) | 22545 | 4356 | 2868 | 6763 |

| Heat Pump Components | References | Type of Study | Unique System Features | Nature of Study | Major Findings | ||

|---|---|---|---|---|---|---|---|

| Theoretical | Experimental | Energy | Exergy | ||||

| Gas Cooler | Yin et al. [11] |

|

| ||||

| Xie et al. [14] |

|

| |||||

| Chen [15] |

|

| |||||

| Yang et al. [18] |

|

| |||||

| Qi et al. [19] |

|

| |||||

| Yu et al. [20] |

|

| |||||

| Evaporator | Yamaguchi et al. [21] |

|

| ||||

| Yun et al. [22] |

|

| |||||

| Elbel et al. [23] |

|

| |||||

| Brown et al. [24] |

|

| |||||

| Compressor | Jiang et al. [25] |

|

| ||||

| Rozhentsv and Wang [26] |

|

| |||||

| Hiwata et al. [27] |

|

| |||||

| White et al. [28] |

|

| |||||

| Expansion Device | Yang et al. [13] |

|

| ||||

| Xing et al. [29] |

|

| |||||

| Boccardi et al. [30] |

|

| |||||

| Agrawal et al. [31] |

|

| |||||

| Internal Heat Exchanger | Yamaguchi et al. [21] |

|

| ||||

| Kim et al. [32] |

|

| |||||

| Xing et al. [29] |

|

| |||||

| Tao et al. [33] |

|

| |||||

| Categorization | References | Type of Study | Salient Design Features | Applications | Major Findings | |

|---|---|---|---|---|---|---|

| Theoretical | Experimental | |||||

| Water Source Heat Pump | Mayekawa [116] |

|

|

| ||

| Liu et al. [117] |

|

|

| |||

| Air Source Heat Pump | Hu et al. [118] |

|

|

| ||

| Calabrese et al. [119] |

|

|

| |||

| Hu et al. [120] |

|

|

| |||

| Ground Source Heat Pump | Kim et al. [32] |

|

|

| ||

| Wang et al. [121] |

|

|

| |||

| Hybrid Solar | Faria et al. [122] |

|

|

| ||

| Li et al. [123] |

|

|

| |||

| Cho et al. [124] |

|

|

| |||

| Chaichana et al. [125] |

|

|

| |||

| Hybrid Geothermal | Jin et al. [126] |

|

|

| ||

| Jin et al. [127] |

|

|

| |||

| Kim et al. [128] |

|

|

| |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rony, R.U.; Yang, H.; Krishnan, S.; Song, J. Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review. Energies 2019, 12, 457. https://doi.org/10.3390/en12030457

Rony RU, Yang H, Krishnan S, Song J. Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review. Energies. 2019; 12(3):457. https://doi.org/10.3390/en12030457

Chicago/Turabian StyleRony, Rajib Uddin, Huojun Yang, Sumathy Krishnan, and Jongchul Song. 2019. "Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review" Energies 12, no. 3: 457. https://doi.org/10.3390/en12030457

APA StyleRony, R. U., Yang, H., Krishnan, S., & Song, J. (2019). Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review. Energies, 12(3), 457. https://doi.org/10.3390/en12030457