1. Introduction

As one of the biggest sources of global greenhouse gas (GHG) emissions, transportation comprises 23% of global energy-related emissions in 2018, and 92% of its energy demand depends on oil [

1]. The contribution of freight transportation to total transport emissions is 39%, and is expected to be at least equivalent to passenger transport by 2050 [

2]. According to Intergovernmental Panel on Climate Change (IPCC), driven by the rapidly growing economies in Asia, Africa, and Latin America, freight transport demand is predicted to increase three-fold by 2050. Environmental sustainability in freight transportation has drawn immense concern in both research and practice areas.

Freight transportation plays a key role in supply chain operation, and the environmental sustainability concern has sparked tremendous interest towards optimal supply chain networks that balance both economic and environmental influences. Under the framework of sustainable supply chain management (SSCM), logistics is a relatively small topic, with most researches focused on broader areas of the supply chain or focal supply chain members, which are usually manufactures [

3]. The existing studies on environmentally sustainable logistics appear to focus on models for reducing emissions or the relationships between logistics activities and environmental impacts [

4]. From the enterprise perspective, despite pressures or governmental regulations to reduce GHG emissions, companies may still plan to continue their original environmental strategies [

5]. While in the long run, to survive under this carbon-constrained business environment, companies have to adjust their business strategies to deal with various environmental constrains [

6]. Additionally, transportation is one of the few GHG emissions sources that enterprises can efficiently influence [

5]. Therefore, at the enterprise level, it is important, even fundamental, to figure out how logistics companies arrange their production resources to cope with environmental pressures, and how efficient their production strategy is under the environmental sustainability concern.

In 2018, the total expenses on Chinese logistics activities were up to 13.3 trillion yuan, which makes China the biggest freight transportation market around the world [

7]. Driven by economic growth and the increasing consumption demand, logistics has become the backbone of the Chinese economy. Since the construction of ecological civilization became one of the key objectives of China’s Thirteenth Five-Year Plan (2016–2020), the “Construction of Ecological Civilization” in the transportation sector has been stressed by the Ministry of Ecology and Environment and the Ministry of Transport of China. Environmental regulation on freight transportation and logistics from the government places high pressure on logistics companies to enhance their environmental performance.

Despite the tremendous concerns from macro regulations toward environmental performance in the logistics sector, the sustainable development of Chinese logistics is still in its infancy [

8]. When first confronted with environmental regulations, enterprises resist change and give more preferences to commercial concerns in the trade-off between environmental protection and economic benefits [

9]. It is essential to evaluate and analyze the environmental efficiency under the trade-off between environment and economic benefits during the operational process of logistics enterprises. Therefore, the main objective of this paper was to measure the environmental efficiency of Chinese logistics enterprises under different sustainable strategies, in order to fundamentally figure out the development stage of environmental sustainability and give implications to enterprises’ business strategy arrangement and government environmental regulations.

Data envelopment analysis (DEA) has recently become one of the important tools for environmental assessment in the sustainability area. The DEA methodology was first proposed by professor A. Charnes and professor W.W. Cooper in 1978 [

10]. Since then, DEA has become a major approach for performance assessment in various organizations. As an approximation approach, it could provide an empirical guideline for enterprises and policy makers. After the concept of undesirable output was proposed by Färe [

11], the use of DEA for environmental assessment has drawn attention from researchers in the sustainability development area. Nowadays, environment sustainability has become the most popular application area of DEA [

12].

Previous literature that uses DEA for environmental assessment operates on multiple levels. At the country level, Camarero, Castillo [

13] used DEA to determine the eco-efficiency of a group of 22 The Organisation for Economic Co-operation and Development (OECD) countries, and a similar research was also conducted in European Union countries [

14]. Cui and Li [

15] evaluated transportation carbon efficiencies from 15 countries. Research at the country level is more focused on a comparison between macro economies [

16], which could provide policy implications for global and national sustainability.

As to the regional level, China’s environmental efficiency has been explored by several studies using different production factors [

17,

18,

19]. Sueyoshi and Yuan [

19] explored the regional sustainability development of China by incorporating particulate matter (PM) 2.5 and PM10 as undesirable outputs. Another research by Zhou and Chen [

17] explored the environmental efficiency of 30 provinces in China based on a DEA environmental assessment radial model. The regional environmental efficiency displays the direction of government policy for environmental protection and economic development, and could give implications for industries’ sustainable development.

At the industry level, the majority of studies are based on the energy sector, such as petroleum firms, solar thermal power stations, petroleum coal-fired power plants, and fossil fuel power generation [

20,

21,

22,

23,

24]. Additionally, Li and Zhang [

25] also investigated provincial differences in fossil fuel power plants in China. The energy industry is one of the most concerned sectors under sustainability circumstances, and efficiency measurement can give instructions for the arrangement of energy production in a certain country. In the manufacture industry, Sueyoshi and Goto [

26] applied DEA environmental assessment to Japanese industrial enterprises to explore the unified efficiency on differently prioritized resource arrangements (operational and environmental). Another research of Sueyoshi and Goto [

27] explored the sustainability of Japanese enterprises, which included manufacturing firms and non-manufacturing firms, and found that manufacturing firms outperform non-manufacturing ones in operations. According to previous literatures, except for researches focused on energy production, studies that investigated environmental efficiency at the enterprise level are usually from multiple industry sectors.

When it comes to logistics and freight transportation, few studies have adopted the DEA method to explore environmental efficiency in the transport sector. Yang and Taudes [

28] used DEA to measure the efficiency of 20 freight villages in Europe but did not consider any environmental outputs. Haralambides and Gujar [

29] applied DEA to evaluate dry port efficiency in India while taking into account the undesirable environmental output. Another study focused on public transportation in Iran, and developed a DEA-based target-setting methods to set targets for 24 bus companies under green supply chain management requirements [

30]. In China, Li and Meng [

31] investigated the sustainability performance of the transportation industry under environmental regulations by using provincial data in China. Different with those traditional manufacture enterprises, such as the automobile industry or paper-making industry, the production network of logistics enterprises has a higher degree of regional crossover, which may bias the regional level of sustainability efficiency. Yet, there has not been any literature that explores the environmental efficiency of freight transportation from the enterprise perspective.

According to those previous studies, though DEA assessment has been employed in port and public transport companies in other countries, environmental efficiency in the logistics and freight transport sector should be investigated more comprehensively. Studies on environmental efficiency assessment using the DEA method in Chinese freight transport companies is still blank. Therefore, the aim of this study was to fill the aforementioned gap in the Chinese logistics sector under the environmental sustainability consideration. This paper intended to investigate the environmental efficiency of logistics enterprises in China by using the DEA model under different operational priorities.

The rest of this paper is organized as follows.

Section 2 describes the two disposability concepts and the methodology of DEA environmental assessment by a non-radial model. In

Section 3, the environmental assessment of Chinese logistics enterprises is illustrated, and the unified efficiencies under natural and managerial disposability are calculated. Subsequently, statistical tests are employed to explore the differences between groups classified by enterprise size and ownership.

Section 4 presents the conclusions and implications of this study.

2. The Methodology of Non-Radial DEA

This study applied non-radial DEA models for environmental assessment, as proposed by Sueyoshi and Goto [

24]. The DEA model for environmental assessment needs to fully utilize all kinds of production factors (the inputs, desirable outputs, and undesirable outputs), and this requirement needs all dual variables in the model to be positive or zero. In this circumstance, the non-radial model could be the one that satisfies the requirements. Moreover, given the output factors, such as the net income of a certain enterprise could be negative, the property of the translation invariance of thee non-radial model makes it possible to evaluate the efficiency of DMUs (decision-making units) whose inputs or outputs contain zero/or negative values [

32]. Therefore, the non-radial DEA model was adopted to measure the efficiency of logistics enterprises under environmental regulation in China.

2.1. Nomenclatures Used in the DEA Model

The nomenclatures used in the non-radial DEA models are summarized as follows:

Notations of production factors that are observed from the data set:

: i-th input of the j-th DMU (i = 1, …, m and j = 1, …, n);

: r-th desirable output of the j-th DMU (r = 1, …, s and j = 1, …, n); and

: f-th undesirable output of the j-th DMU (f = 1, …, h and j = 1, …, n).

Notations of other unknown variables that need to be measured:

: A slack variable of the i-th input (i = 1, …, m);

: A slack variable of the r-th desirable output (r = 1, …, s);

: A slack variable of the f-th undesirable output (f = 1, …, h);

: The range for the i-th input (i = 1, …, m) which makes it for full utilization;

: The range for the r-th desirable output (r = 1, …, s) which makes it for full utilization;

: The range for the f-th undesirable output (f = 1, …, h) which makes it for full utilization; and

: An unknown variable of the j-th intensity variable (j = 1, …, n) to connect production factors.

2.2. Disposability Concepts

In this non-radial DEA applied to environmental assessment, two important disposability concepts are the basis of the environmental assessment DEA framework: The “natural disposability” and “managerial disposability”, where the concept of disposability implies the elimination of inefficiency [

33].

Natural disposability: Natural disposability indicates that a decision-making unit (DMU) decreases the undesirable outputs by reducing the inputs. Considering the decreasing inputs, the DMU is dedicated to increasing the desirable outputs as much as possible. Natural disposability implies that the operational performance of DMU is the first criterion, and companies reduce their inputs in order to reduce the undesirable outputs. In another words, enterprises under natural disposability would use a negative way, such as reducing the operation scale, to deal with environmental regulation while in the meantime, they try to maximize their desirable outputs.

Managerial disposability: Managerial disposability indicates that a DMU decreases the undesirable outputs by increasing the inputs. On the basis of the increasing inputs, the DMU is dedicated to increasing the desirable outputs as much as possible. Managerial disposability implies that the environmental performance of the DMU is the first criterion, and companies increase their inputs in order to reduce the undesirable outputs. Enterprises under managerial disposability take environmental regulation as an opportunity to enhance their unified efficiency by using environmental technologies or new management. This is a positive way to deal with environmental regulation, and it gives the same propriety to both economic and environmental performance.

The axiomatic expressions of the disposability are as follows:

It considers

as the vector for inputs with m components,

as the vector for desirable outputs with s components, and

as the vector for undesirable outputs with h components. The j stands for the j-th DMU. Those three kinds of vectors are production factors. The unified production and environmental emissions possibility set to express natural and managerial disposability are as follows:

where

stands for a possibility set under natural disposability, and

stands for a possibility set under managerial disposability.

v stands for variable RTS (returns to scale) or DTS (damages to scale) since the constraint (

) is in those two axiomatic expressions. In the axiomatic expressions, the two concepts both have

, which indicates that an efficiency frontier for all desirable outputs should be located above or on observations, and all undesirable outputs should be located below or on observations. Meanwhile, the difference between the two disposability concepts is that

has

, implying that a company can attain the efficiency frontier by reducing a directional vector of inputs while

has

, implying that a company can attain the efficiency frontier by increasing a directional vector of inputs.

Compared to traditional DEA, which usually assumes a capacity limit on the production system, the DEA environmental assessment is dedicated to discussing how to balance economic benefit and environmental protection. In other words, the production cost is determined according to the marginal cost (variable RTS and DTS), rather than the total cost in traditional DEA evaluation [

18,

33]. The natural disposability and managerial disposability are linked to the operational difficulty and eco-technology innovation on undesirable outputs, such as CO

2 emissions. Therefore, the measurement of efficiency is in the context of sustainability, which can provide a more comprehensively environmental assessment result.

2.3. Non-Radial Approach for Unified Efficiency Measures

The unified efficiency of DMU in this non-radial model separates the slack variables of the

i-th input into positive and negative parts (

) to illustrate the two kinds of disposability. The unified efficiency (

) for the

k-th DMU can be reformulated under natural and managerial disposability. The NR stands for the non-radial measure, and

v refers to variable RTS and DTS. The magnitude of

is measured by the following model:

In the proposed Equation (3), the production factors are adjusted by the data ranges. This study uses the following three types of data ranges according to the upper and lower bounds on each production factor. The data range adjustment can be used to control the magnitude of the unified efficiency measure between full efficiency and inefficiency [

33]:

Based on the optimal solution from Equation (3), the

score on optimality is as follows:

In this non-radial approach, the vector in Equation (3), as the intensity or the structural vector, is used for connecting the production factors by a convex combination. The production and pollution possibility set for Equation (3) is structured under variable RTS and DTS. The slack variables represent the level of inefficiency, and the level of inefficiency is determined on the optimality of Equation (3) by the total amount of slacks. Therefore, Equation (5) expresses the level of unified efficiency.

2.4. Unified Efficiency under Natural Disposability

The non-radial model under natural disposability (N) is used to measure the unified efficiency of the

k-th DMU, and is formulated by the following model:

In order to attain the strategy under natural disposability, Equation (6) only considers the slack variable,

, related to the inputs. The unified efficiency under natural disposability (UEN) is measured by Equation (7), where all slack variables are obtained from the optimality of Equation (6). The equation within the parentheses expresses the level of inefficiency under natural disposability, and the unified efficiency formulated in Equation (7) is obtained by subtracting the score of the inefficiency from the unity:

2.5. Unified Efficiency under Managerial Disposability

Compared with the UEN, the unified efficiency under managerial disposability (M) puts the environmental performance of DMU as the first priority. The non-radial model under managerial disposability to measure the unified efficiency of the

k-th DMU is formulated by the following model:

In order to attain the strategy under managerial disposability, Equation (8) only considers the slack variable,

, related to the inputs. The unified efficiency under managerial disposability (UEM) is measured by Equation (9), where all slack variables are obtained from the optimality of Equation (8). The equation within the parentheses expresses the level of inefficiency under managerial disposability, and the unified efficiency formulated in Equation (9) is obtained by subtracting the score of inefficiency from unity:

4. Conclusions

This paper explored the environmental sustainability development in Chinese logistics enterprises by using environmental assessment DEA methods. Given that the environmental efficiency of logistics in China has not been measured at the enterprise level, this paper attempted to fill the gap in the existing literature to employ environmental assessment into logistics’ environmental sustainability. The environmental assessment of logistics enterprises would help logistics managers and policy makers understand the integrated state of environmental performance based on a real production arrangement, which would be a significant contribution to environmental sustainability in the Chinese freight transportation sector.

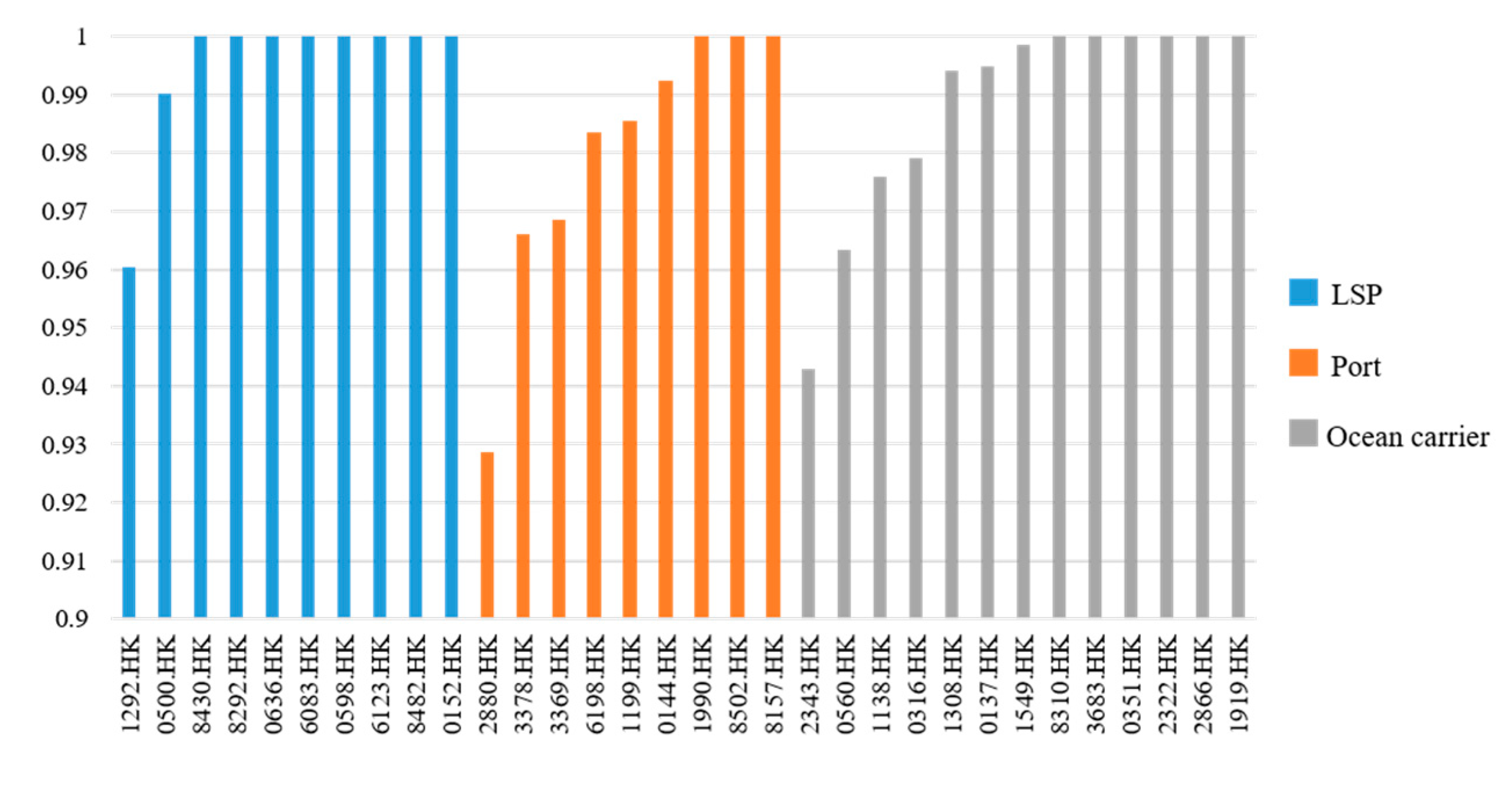

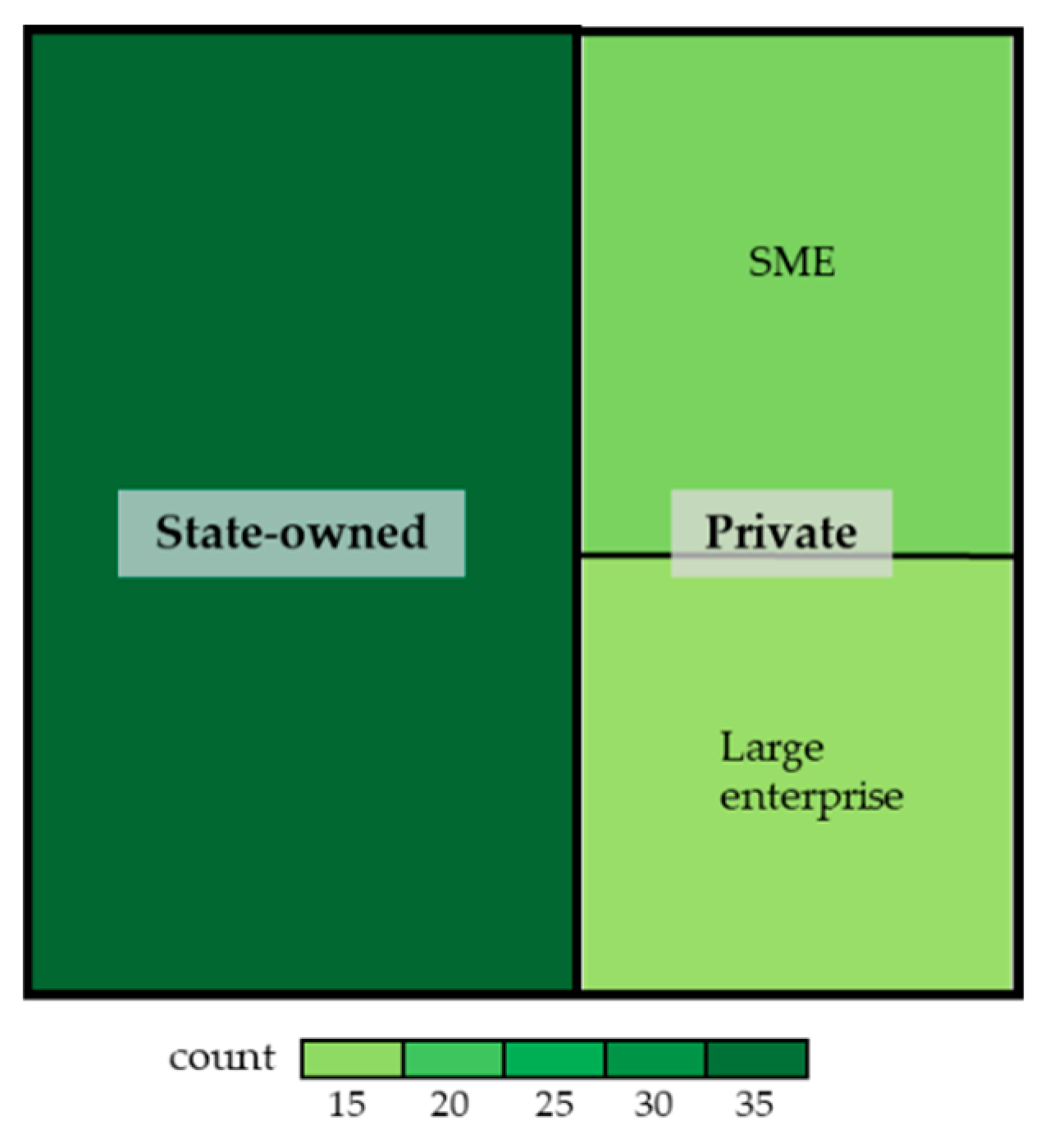

Based on the inputs and outputs data from listed logistics companies from 2016 to 2018, this study firstly calculated the unified efficiency of each DMU under natural and managerial disposability, then gave multiple comparisons on UEN and UEM by enterprise groups classified by enterprise size and ownership. Due to the unbalanced development of economic performance and environmental sustainability in the Chinese logistics industry, the UEN is higher than UEM for every logistics enterprise in the empirical results. The better performance of efficiency under natural disposability in SMEs and private enterprises was proven to be statistically significant while the efficiency comparison under managerial disposability all had no statistical differences. The empirical results further proved that the development of environmental sustainability in the Chinese freight transportation sector is still at its primary stage. When encountering environmental regulation from the outside, logistics companies, especially private logistics enterprises, may still put commercial consideration at first priority to achieve maximum economic benefit using minimum inputs.

Furthermore, the environmental assessment DEA was proven to be an efficient tool to figure out whether a company is resisting change or has begun taking proactive actions towards environmental protection. For future researches, firstly, though restricted by the availability of environmental data, this study chose CO

2 emissions as the undesirable output. With the improving quality of data disclosure in the transportation sector, future study could consider using multiple environmental data for further investigation. Secondly, as an important member of the supply chain, the activities of logistics are within the whole network of supply chain operation. Therefore, the environmental efficiency of logistics could be further explored under the green supply chain management framework, which can be evaluated by network DEA according to Mirhedayatian and Azadi [

45]. Moreover, the comparative analysis of the environmental efficiency in different regions, such as Chinese enterprises and cross-country enterprises, should be investigated due to the unique environmental and economic background in China.

Despite an increasing awareness of the harmful effects of freight transportation on the environment, efficiency assessment under economic and environmental operational priorities could provide an integrated picture of logistics’ environmental development under sustainable business circumstances. There is still a long way to go on transforming logistics firms’ operational strategy from an economic priority to an environmentally sustainable priority, which is the backbone of improving environmental performance from the enterprise perspective in the long run. Additionally, this study also provides significant insights for a comparative evaluation on environmental sustainability development in enterprises from other industries or regions.