1. Introduction

Environmental problems, especially soil pollution, have already become widespread as a result of economic development, and the management of contaminated soil has become a major challenge [

1,

2]. Large amounts of contaminants have been released into the environment because of illegal disposals, leakage accidents, and so on [

3,

4]. Based on a report on the national general survey of soil contamination [

5], the overall soil environment situation is not reassuring in China, with 34.9% of the 775 soil sites in the 81 industrial wastelands surveyed not meeting standards. Soil pollution has put great pressure on China’s sustainable development strategy, with increase in the types of soil contaminants and the extension of soil contaminant area. Meanwhile, soil contamination has a long-term impact on both the environment and human health, so soil remediation is an urgent task. Because of the severity of soil pollution and the difficulty of its restoration, remediation of contaminated soil has attracted unprecedented attention in the environmental field.

Numerous remediation technologies, such as physical remediation, chemical remediation, and bioremediation methods, have been developed to treat contaminated soils [

6,

7,

8]. Among these remediation technologies, in situ thermal remediation technology stands out because of its ability to remove contaminants effectively [

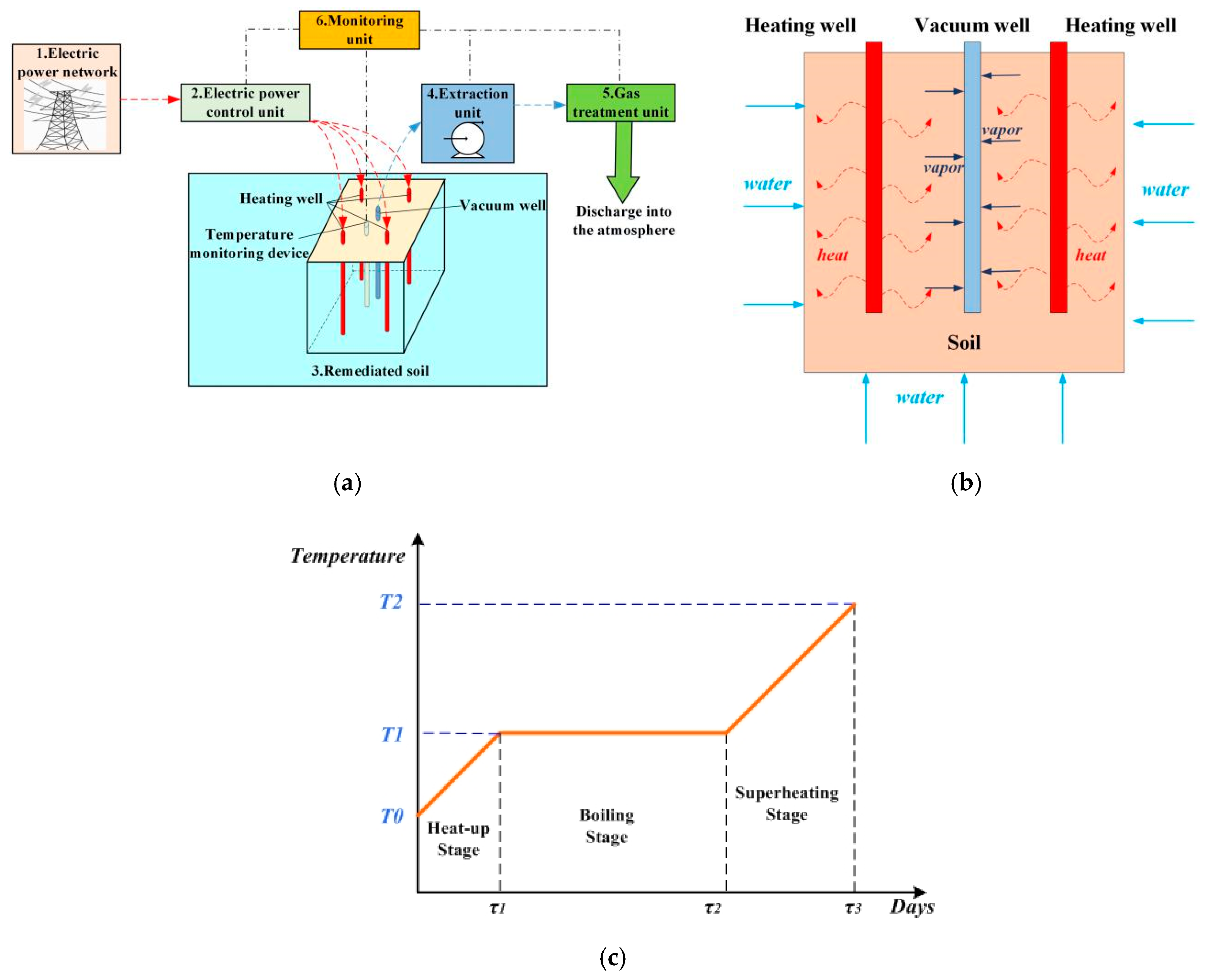

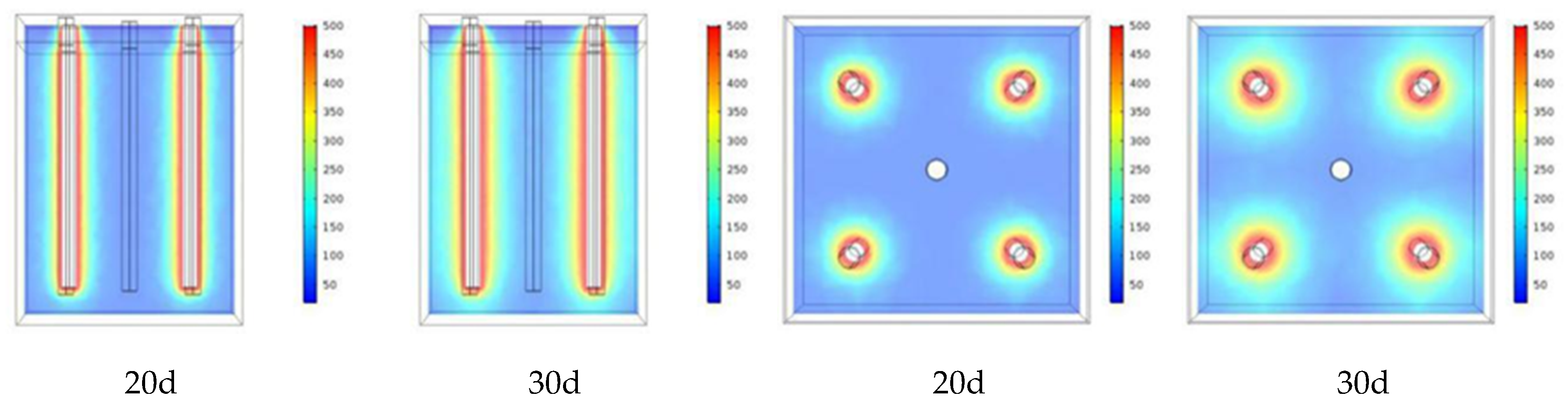

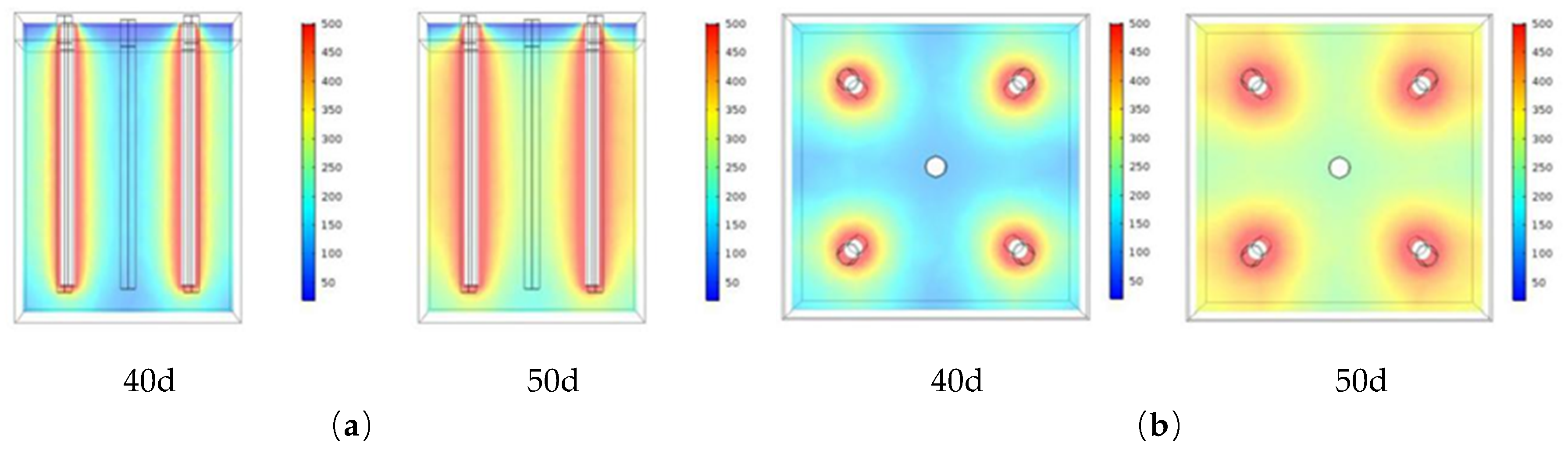

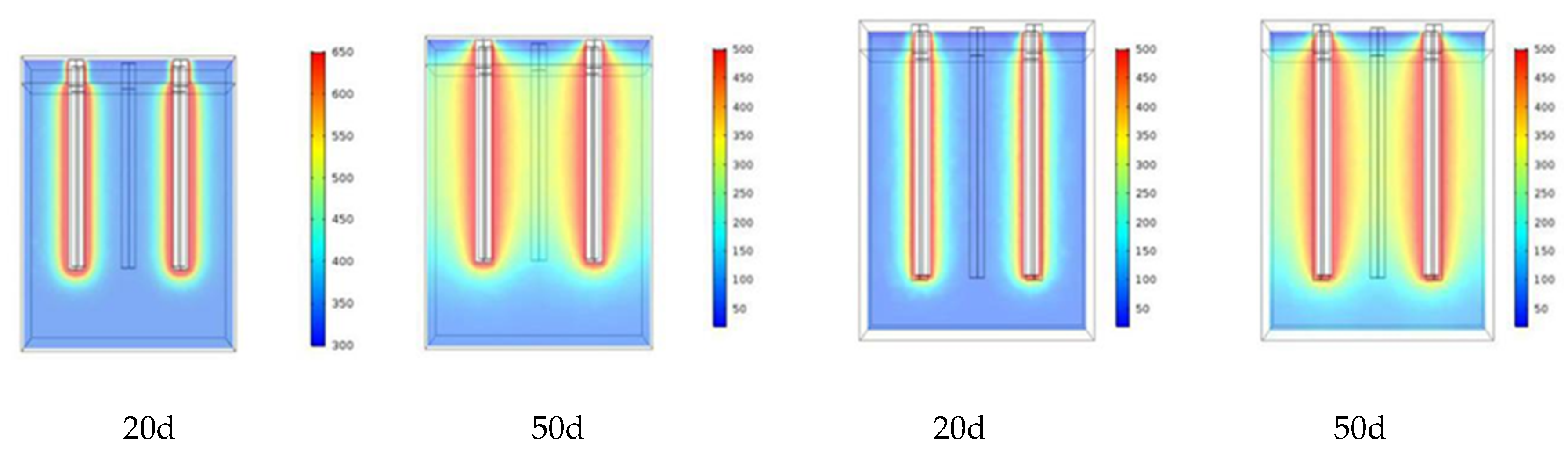

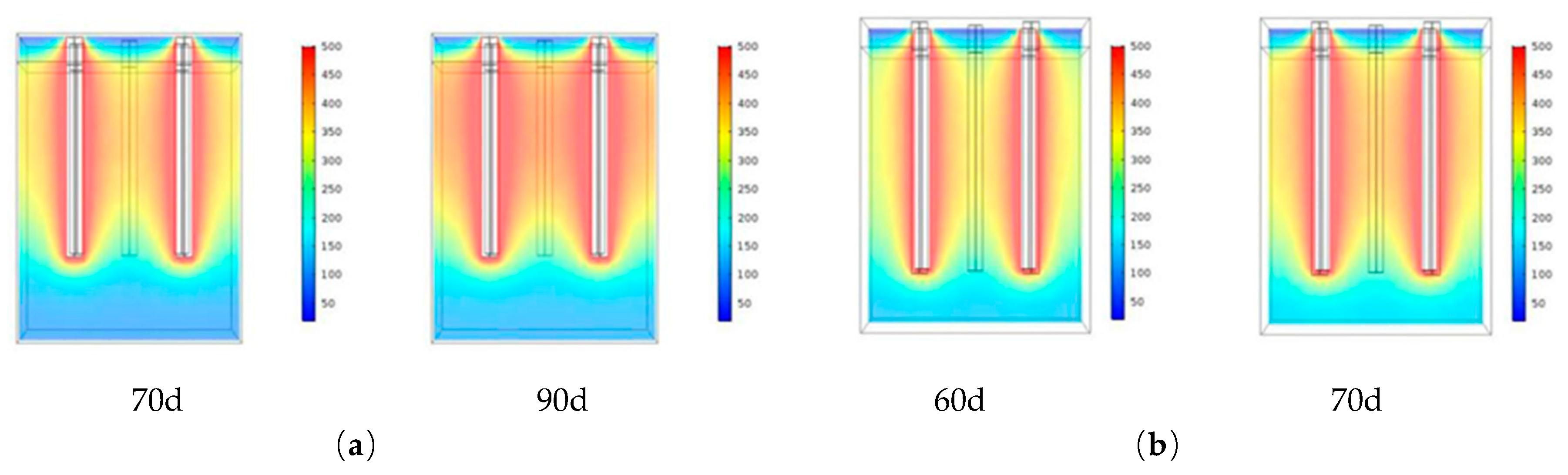

9]. In thermal remediation, heating and vacuum wells are applied simultaneously to treat contaminated soils [

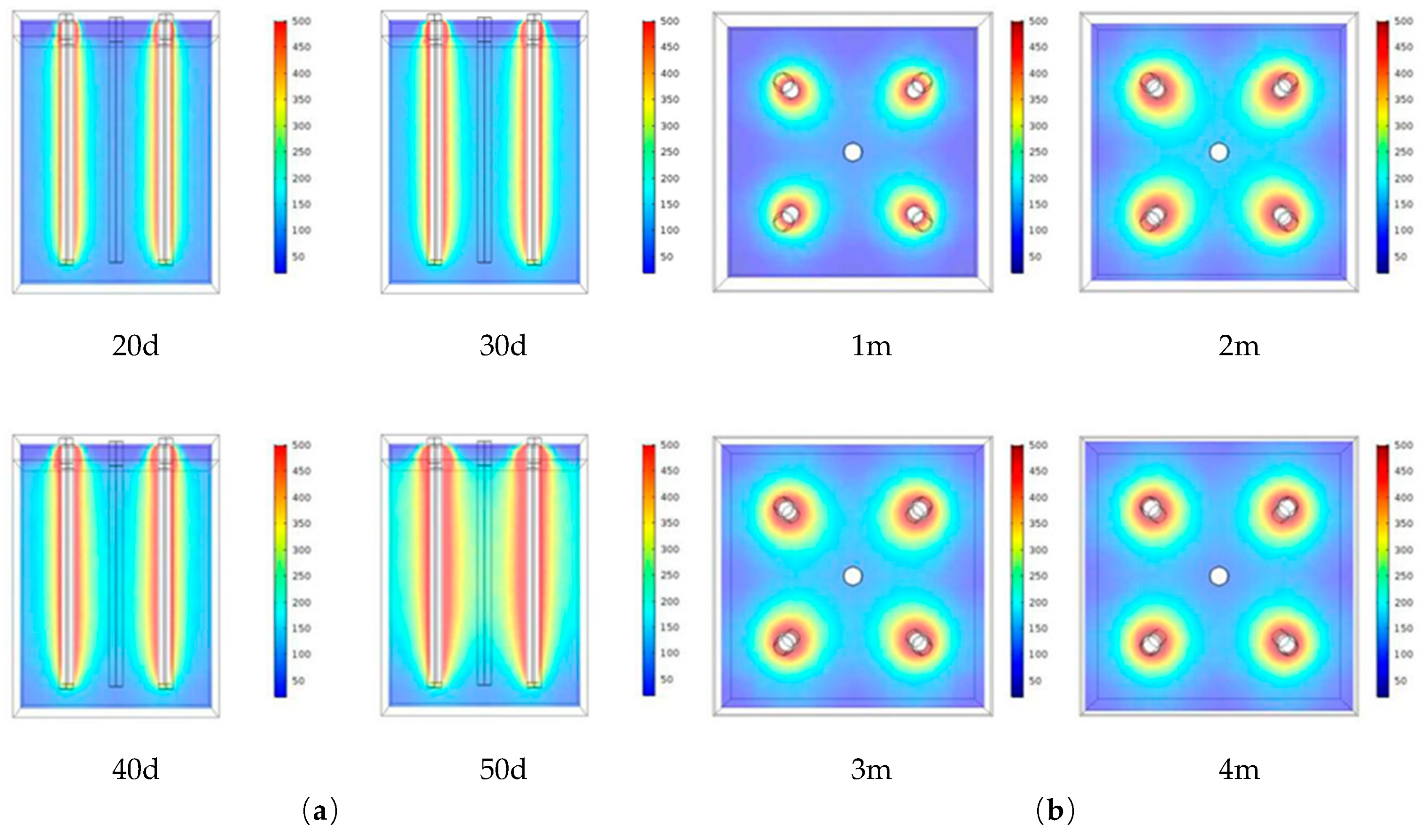

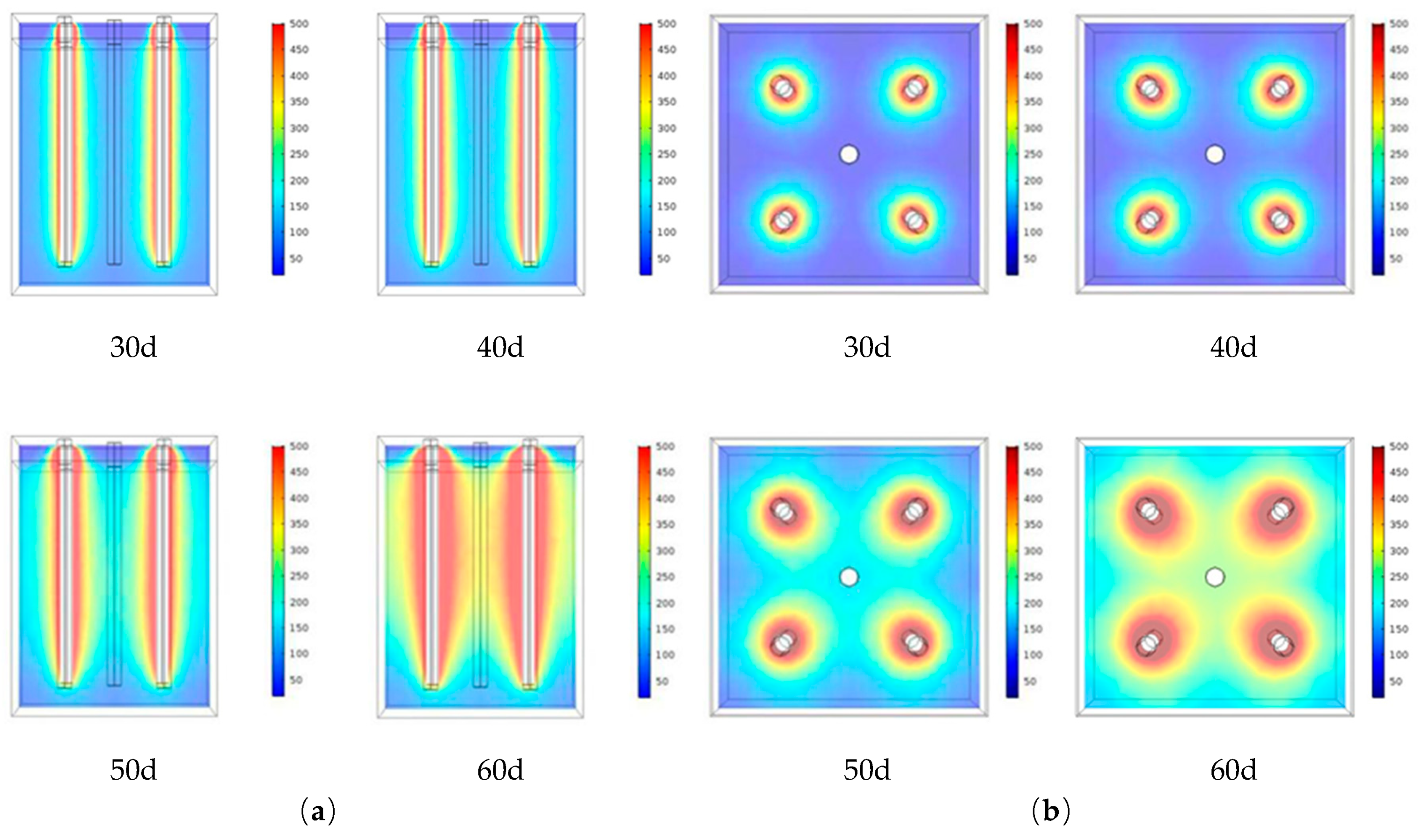

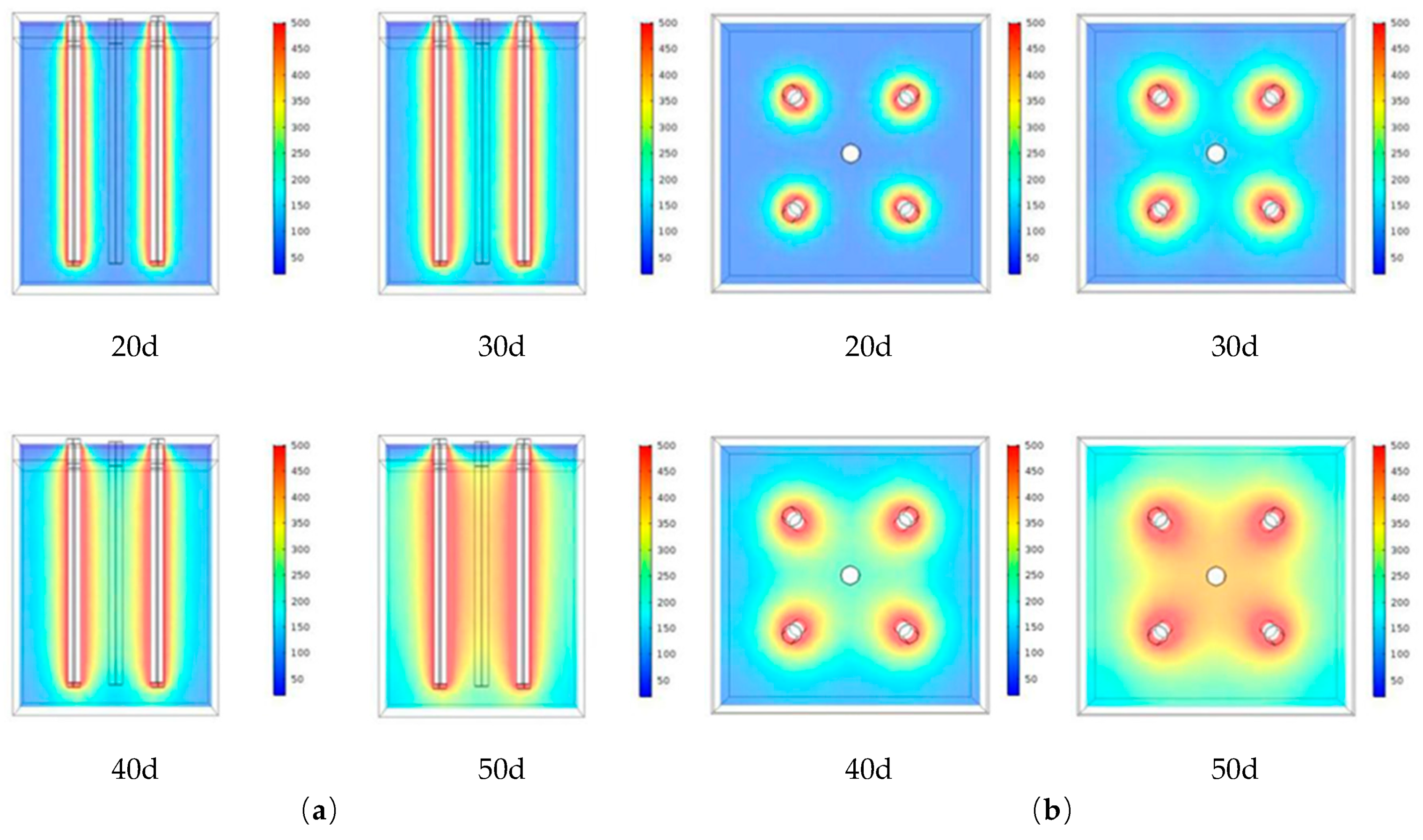

10]. The work principle of in situ thermal remediation technology is as follows: First, the heating wells release heat to the contaminated soils, and the soil temperature can be increased to, if desired, values on the order of 600 °C. Under such conditions, many contaminants would be vaporized or destroyed by a number of mechanisms in this process. Further, these gases could be released into the atmosphere after the extraction from vacuum wells and purification. Consequently, thermal remediation is mainly applied to the removal of volatile and semivolatile organic pollutants and a few volatile inorganic substances such as Hg, As, and Se [

11]. In situ thermal remediation technology has many advantages. Because the thermal conductivity of soil does not change significantly (by only a factor of 4 from clay to sand), thermal remediation is effective for uniformly heating the entire contamination zone and is used in silty or clayey soils [

12,

13]. Compared to ex situ remediation, in situ thermal remediation entails no digging of contaminated soils, generates no dust or odors, minimizes human exposure to hazardous wastes, and is a low-noise operation [

14]. Thus, in situ thermal remediation may be more ecofriendly in sensitive ecosystems because of the lack of soil disturbance.

Many scholars have conducted research on soil remediation including thermal desorption technology, microwave heating technology, and steam injection technology. Araruna et al. [

15] researched the influence of thermal desorption on oil spill debris clean up. Their results showed that oil causes a slight increase in grain size and uniformity, and oiled debris exhibited a smaller void ratio but a larger unit weight. However, the oil and grease content from oiled debris decreased with rising temperature and prolonged exposure. Navarro et al. [

16] studied the application of solar thermal desorption to remediate mercury-contaminated soils. Their experiment showed that when soil and mine waste samples were heated to 400–500 °C, mercury elimination is significant (41.3%–87%). Electrical resistive heating (ERH) has been proposed as a low-environmental-impact thermal recovery method for heavy oil reservoirs [

17]. Conductive heat transfer during in situ electrical heating of oil sands was studied by Hassanzadeh et al. [

18]. In this work, a simple analytical model was presented that allowed estimation of the rate of makeup water or other fluid required for efficient heat delivery to the bitumen-bearing formations. The effects of formation porosity, rock type, and fluid saturation on heat transfer were also evaluated. Merino et al. [

19] studied the effect of temperature on the release of hexadecane from soil by thermal treatment. Their results indicated that good removal efficiencies (>99.9%) were achievable at 300 °C, with higher temperatures not being necessary to significantly improve the degree of contamination removal. Steam as a sweep gas in low-temperature thermal desorption processes used for contaminated soil cleanup was investigated by Averett et al. [

20]. Falciglia et al. [

21] studied energy and economic considerations for full-scale in situ remediation of low-dielectric hydrocarbon-polluted soils using a microwave heating technique. Their results showed very short remediation times, and the modest energy costs demonstrated the usefulness of in situ microwave heating as a deliverable alternative to conventional thermal desorption or physical–chemical techniques.

In situ thermal remediation technology is widely used in soil treatment. From 2002 to 2005, the soil of an old wood mill in California was polluted by PAHs (Polycyclic Aromatic Hydrocarbons) and dioxins. The amount of soil to be treated was 12,600 m

3. The average heating depth was 6.1 m and the target heating temperature was 335 °C. After the restoration, the concentration of PAHs was successfully reduced from 30.6 mg kg

−1 to 5 ug kg

−1 and dioxins from 18 μg kg

−1 to 0.1 μg kg

−1, after acceptance by the national toxic substances monitoring center of the United States, said that the restored land can be put into use unconditionally [

22]. From 2003 to 2007, a site polluted by chlorinated solvents was successfully repaired by in situ thermal technology in Washington State, USA, the removal rate of trichloroethylene in the site was more than 90% [

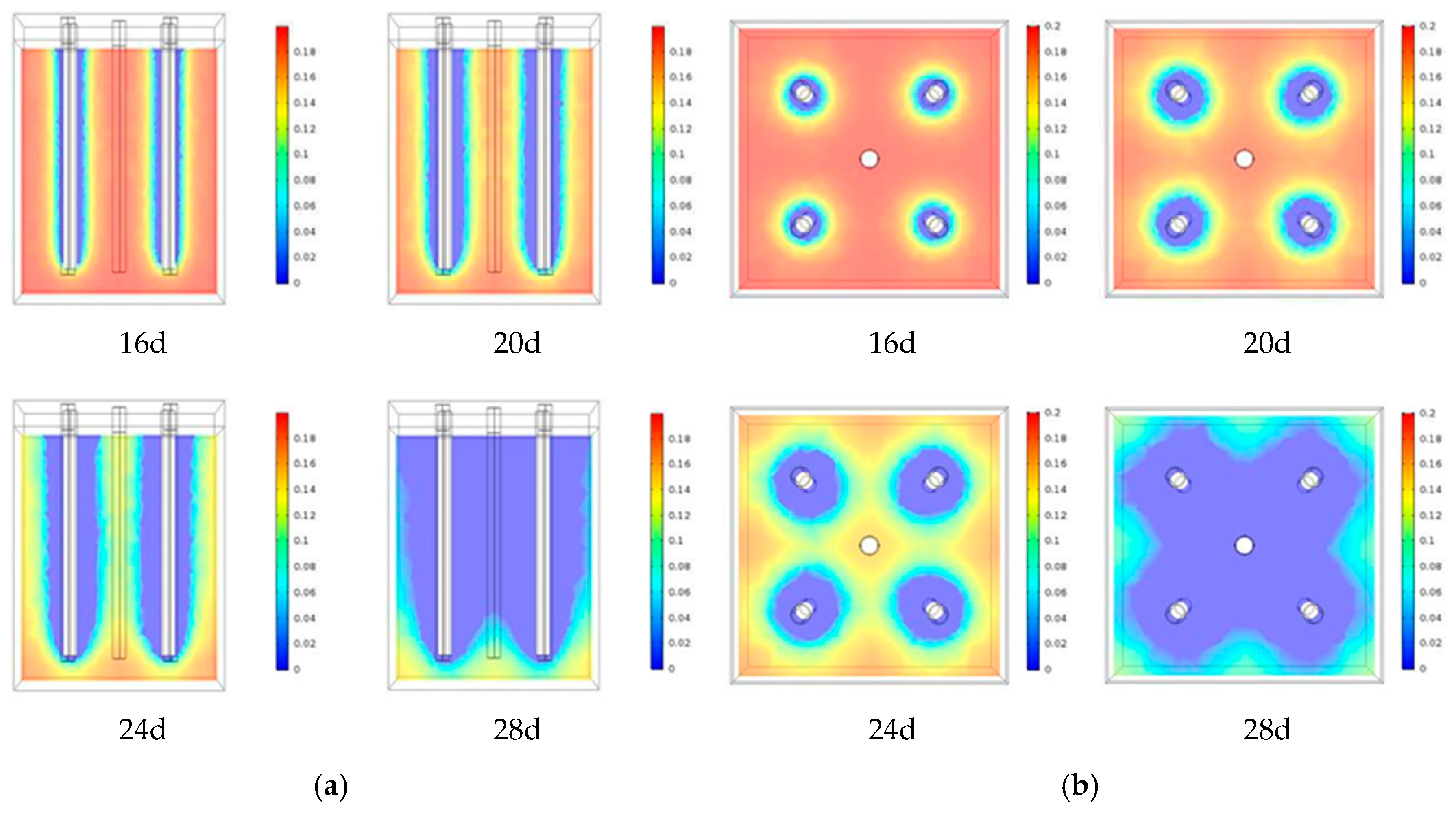

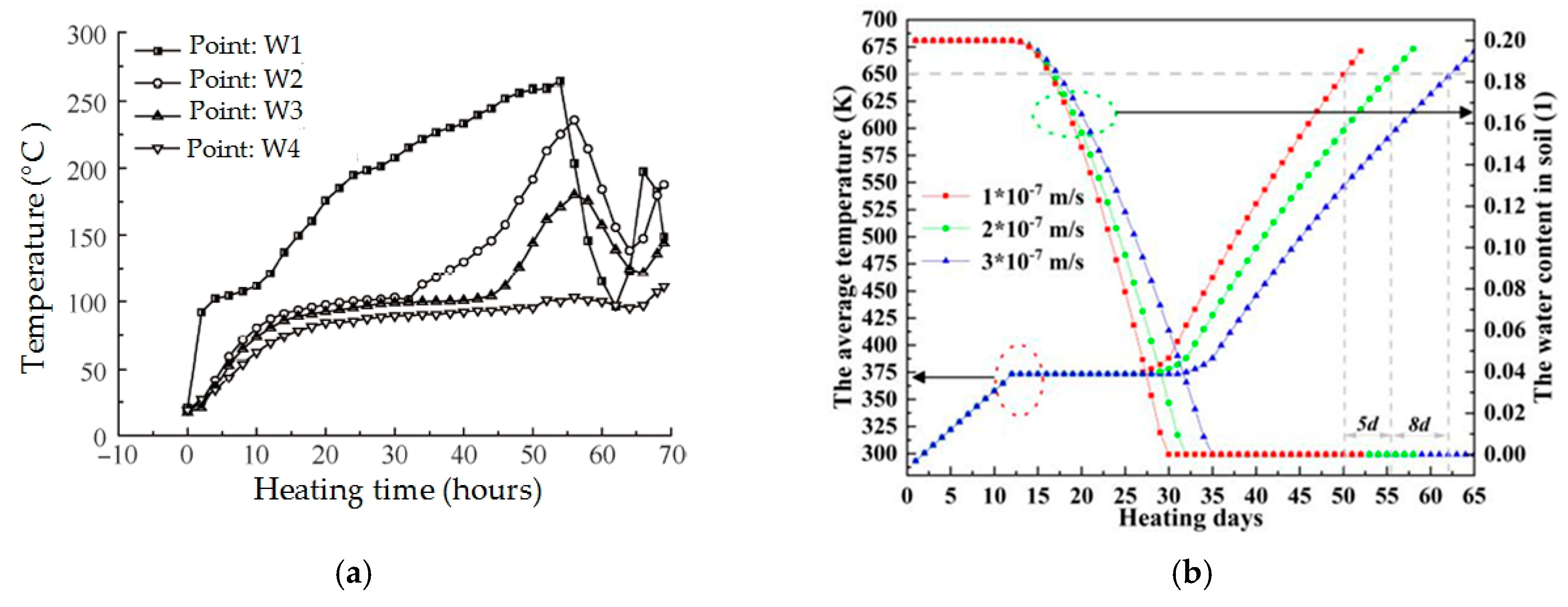

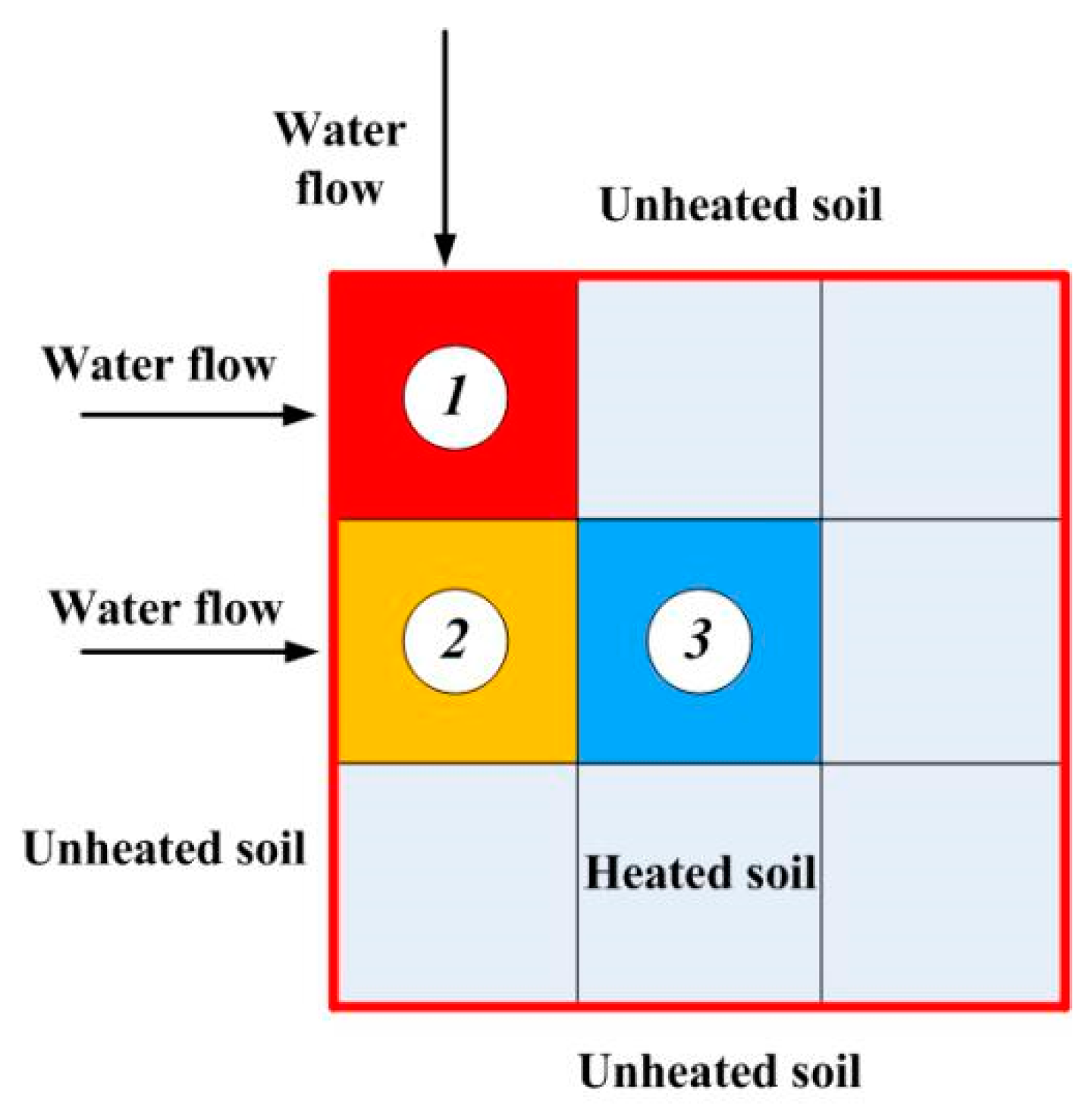

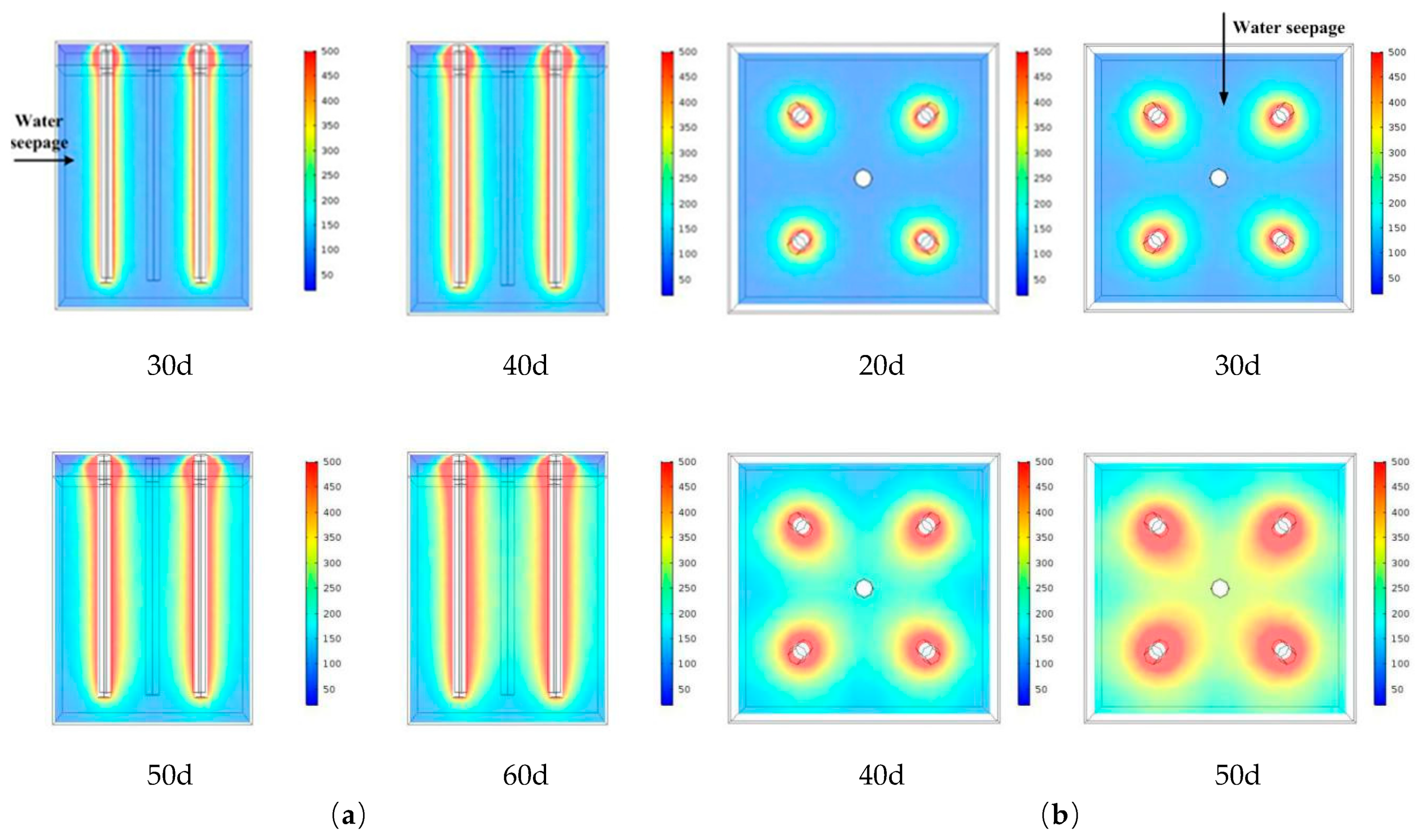

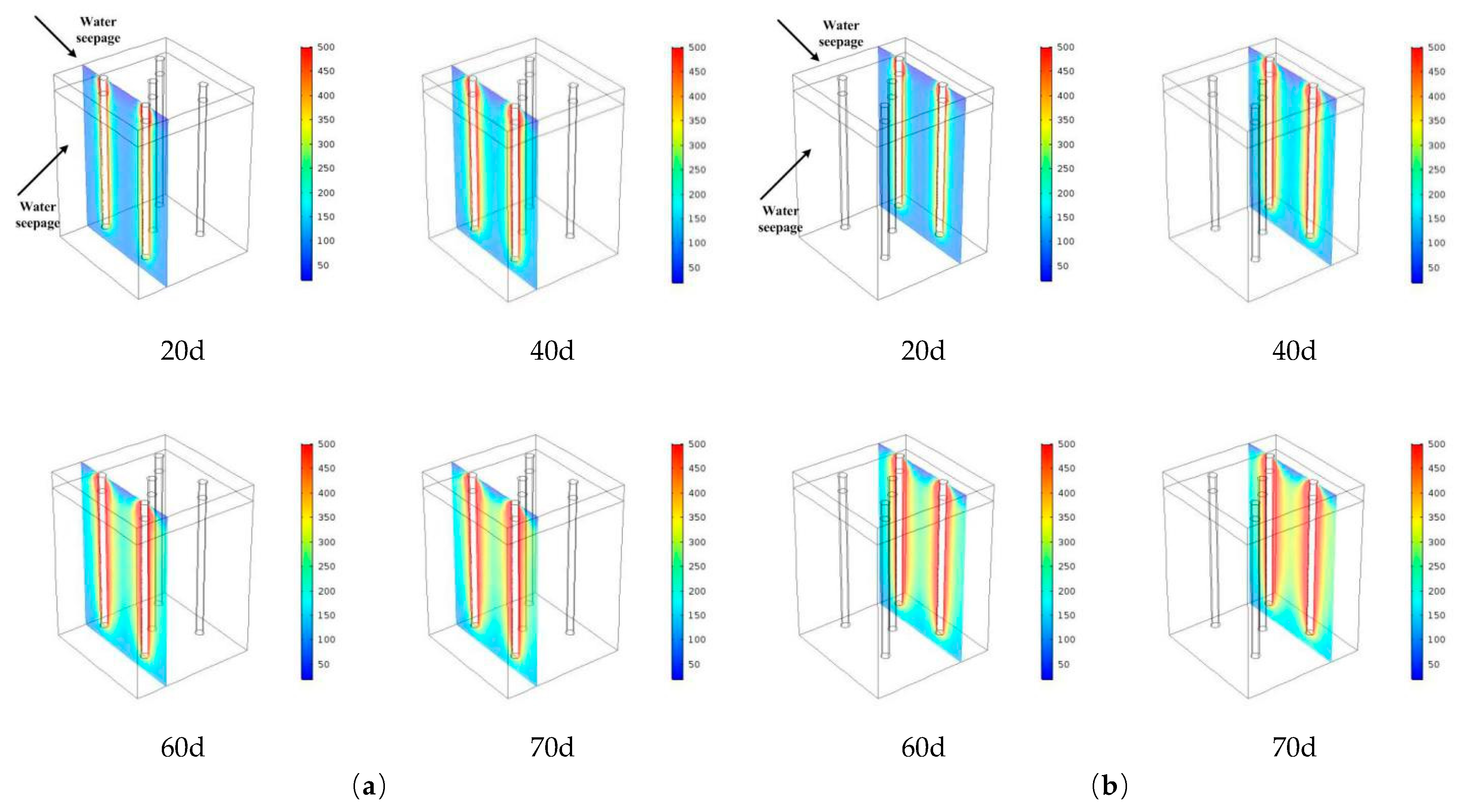

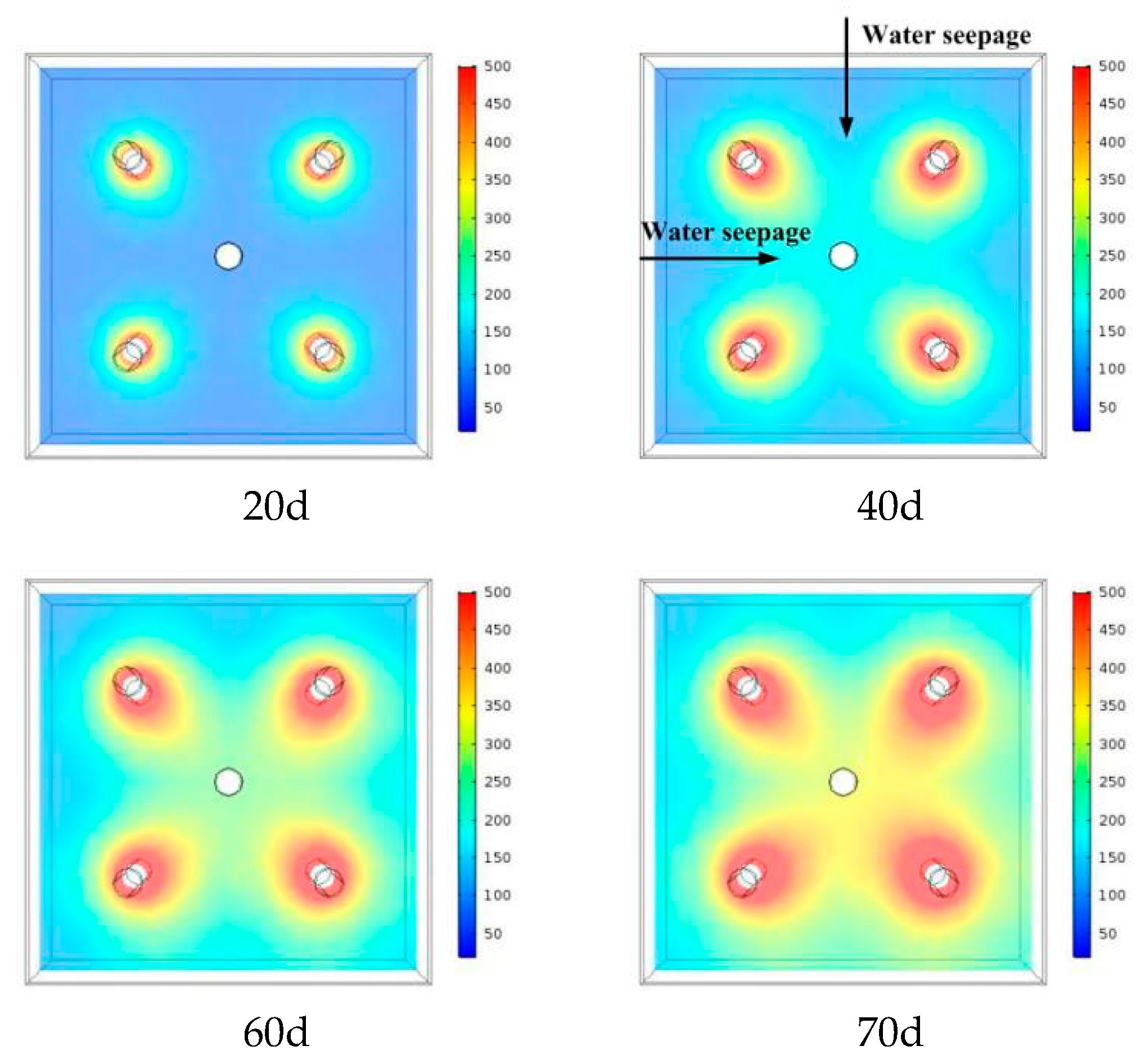

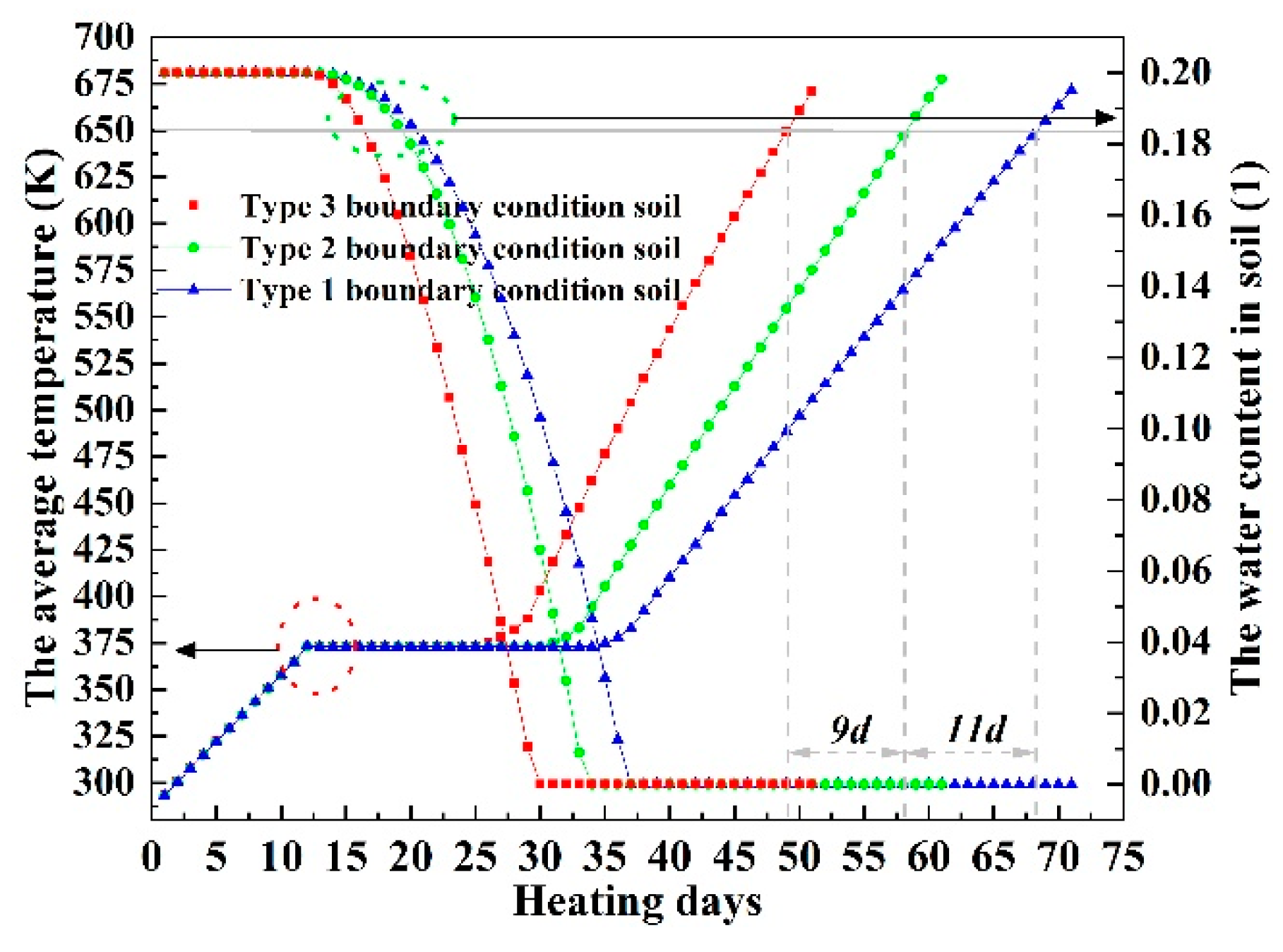

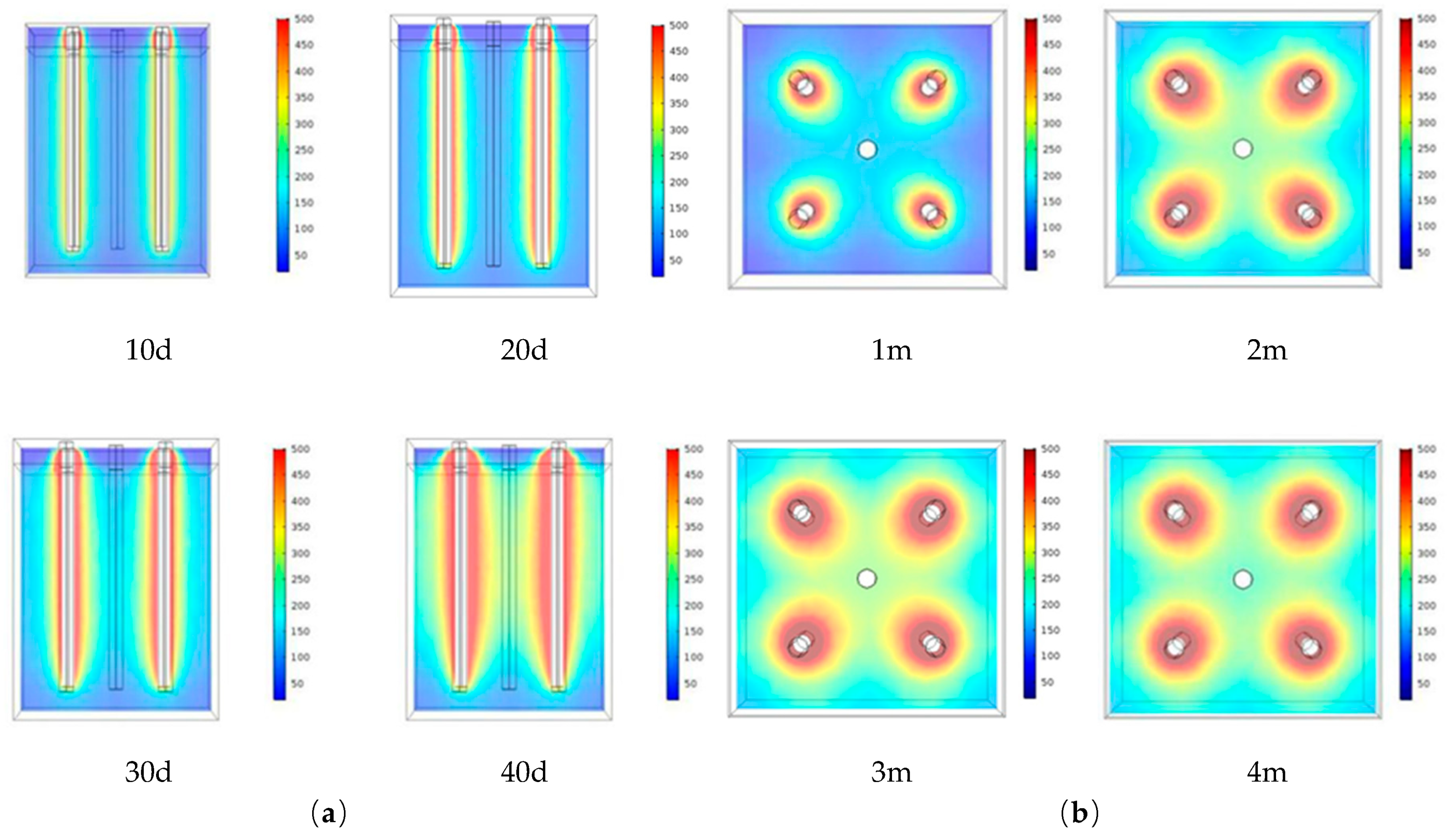

23]. Heron et al. have carried out experimental research on the organic pollution site by using in situ thermal remediation technology, and analyzed the repair cycle and the comprehensive repair cost in detail. Normally the experiment is divided into two categories: (a) practical projects experiments and (b) laboratory tests. But both of these experimental methods are defective, the diffusion of moisture and vapor cannot be detected during the practical projects experiments and laboratory test can’t truly reflect water seepage. So the numerical simulation method is used to study the influence of the moisture migration on remediation process. Despite the progress made in past works, there are still issues that have not been analyzed. The above study did not discuss in detail the influencing factors such as the distance between heating wells and extraction wells, the arrangement mode and the influence of groundwater seepage and so on. In fact, very few studies have been conducted for investigating the temperature distribution and heat transfer performance during the in situ thermal heating process. In actual remediation processes, factors such as moisture seepage, initial water content, soil properties, and operational conditions can significantly affect the soil temperature distribution and remediation period.

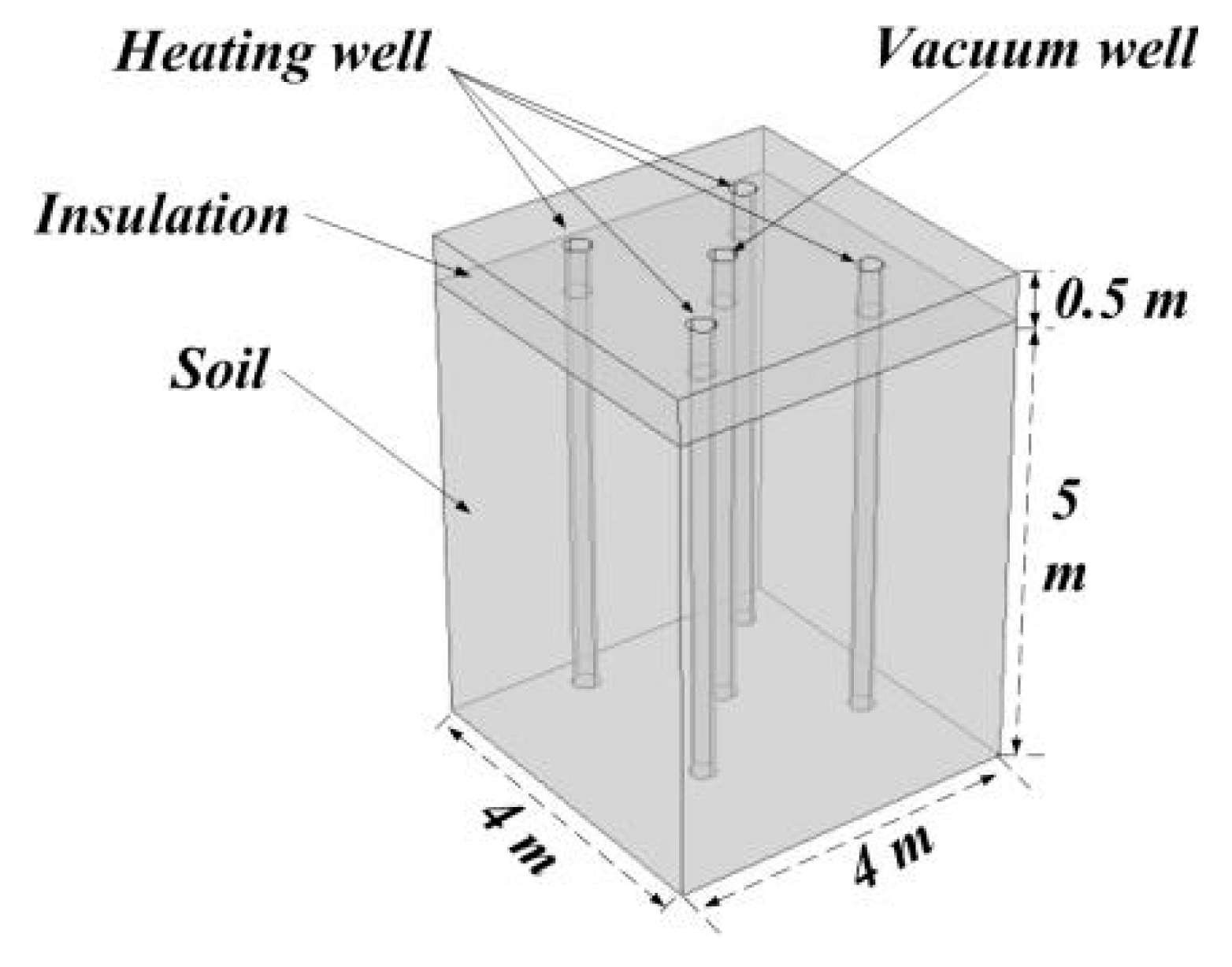

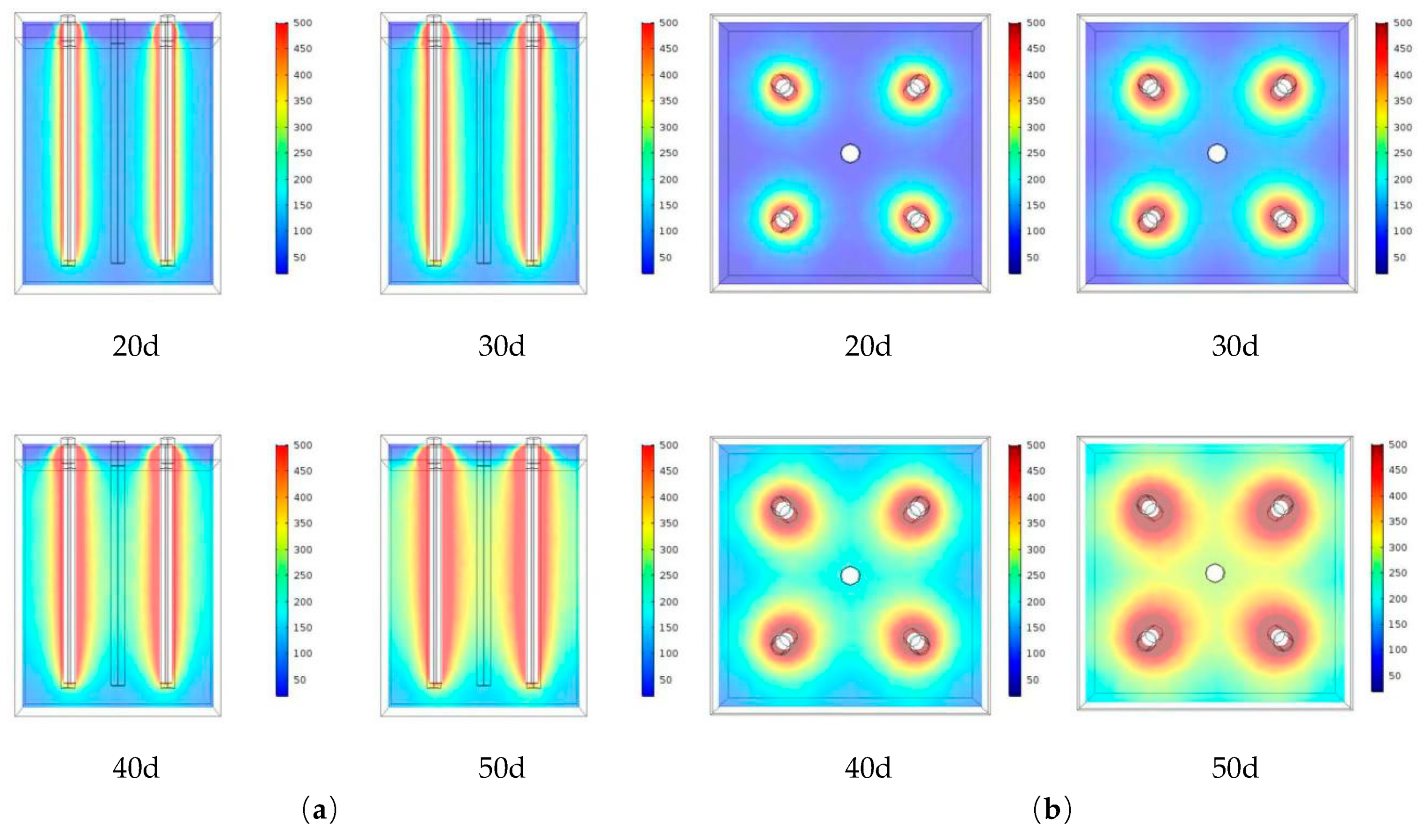

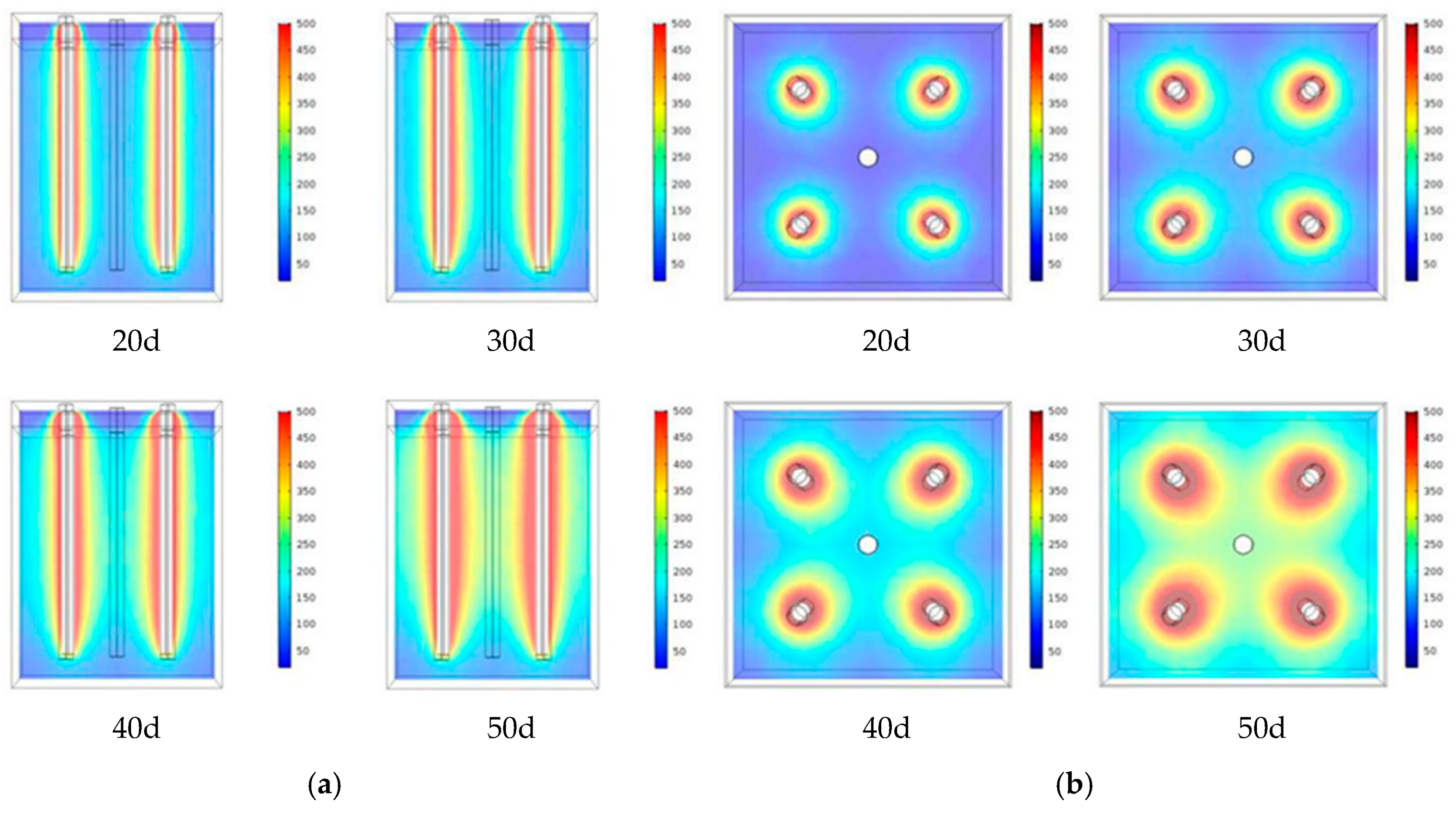

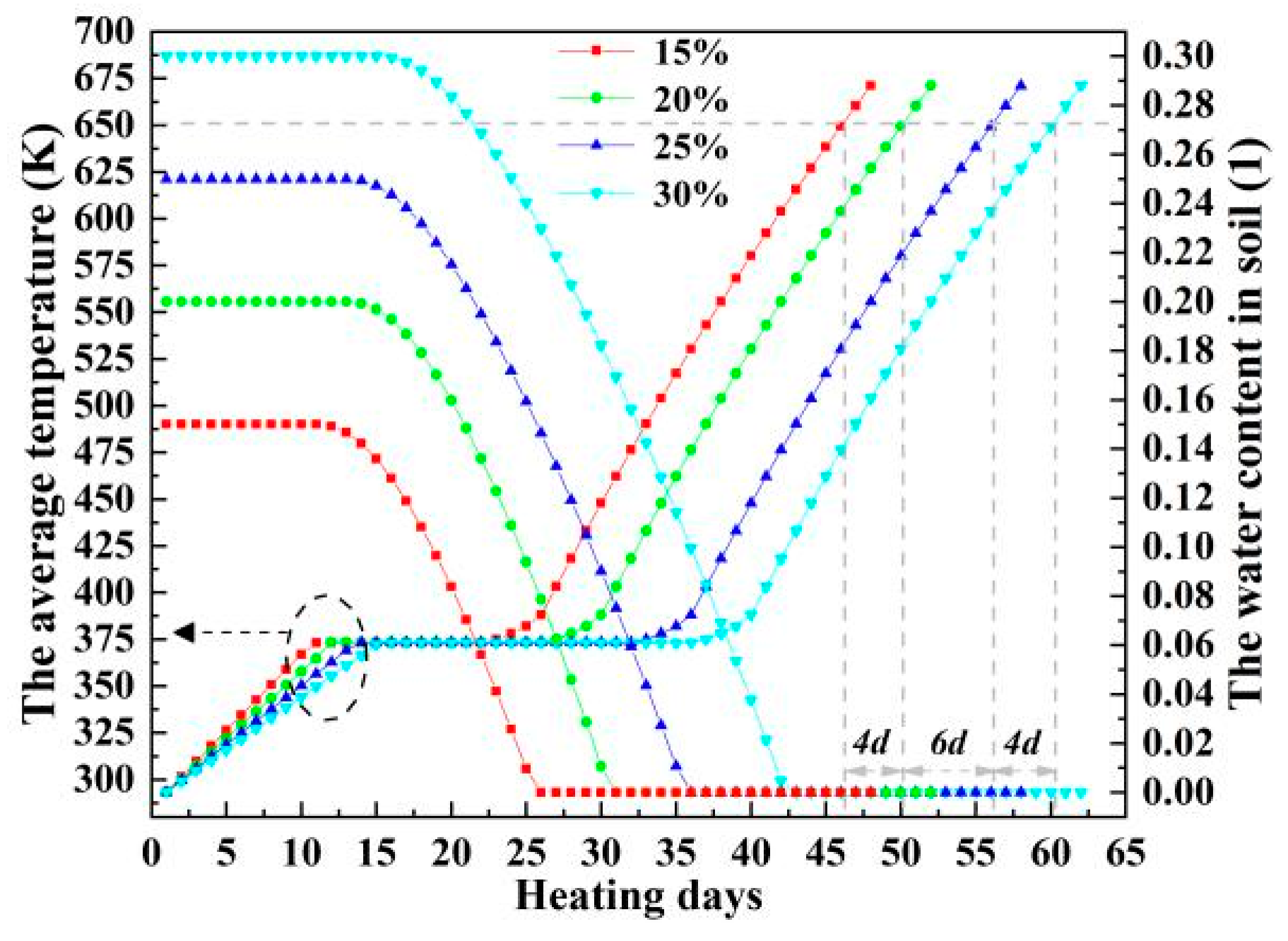

Temperature has a great influence on contaminant removal in terms of thermal temperature technology. The main objective of this work is to research the heat transfer performance during in situ thermal remediation process. In this study, mass and thermal models are proposed for in situ soil thermal remediation. Analysis of the temperature rise under different operations is conducted. Variations of the soil temperature distribution and heating period of this engineering technology are studied. Simultaneously, the influence of groundwater seepage, initial water content, and site thermal design on the remediation period are researched by simulation. The results of this study can provide a reference for in situ thermal remediation under different operating conditions.