1. Introduction

Machining is a fundamental method to transform raw material into a finished product. Machining processes of various types are involved in crafting the solid structure into intricate parts of desired geometry. Despite the usage of advanced conventional machining technologies, manufacturing of complex parts with high accuracy has remained a challenge for the manufacturing industry. For instance, certain complex parts, such as gas turbine or aero-engine components need highly accurate and miniature-sized machining, which can be of microsize, such as holes in nozzle guide vane, turbine blade, fuel injector, and combustion chamber, are mainly in milli to microsize; therefore, the accomplishment of these complex holes warrants the selection of a highly accurate drilling process.

Inconel 718 is extensively used in the aerospace industry, particularly for manufacturing of aero-engine components that operate under high-temperatures. Conventional machining is difficult for this material because of its high strength and work hardening properties [

1]. The machinability of superalloys can be improved using different machining methods, such as ultrasonic machining, electrochemical machining, water jet machining, and laser-assisted machining [

2,

3,

4]. Laser drilling is a high power, high speed, and non-contact machining process, which is specified for the drilling of holes of various shapes and sizes in almost any material, such as composites, metals and non-metals [

5]. During recent years, the laser drilling method has been proven as an important industrial process for producing cooling holes for aero-engine components where the size of hole ranges between 0.25 and 1.0 mm [

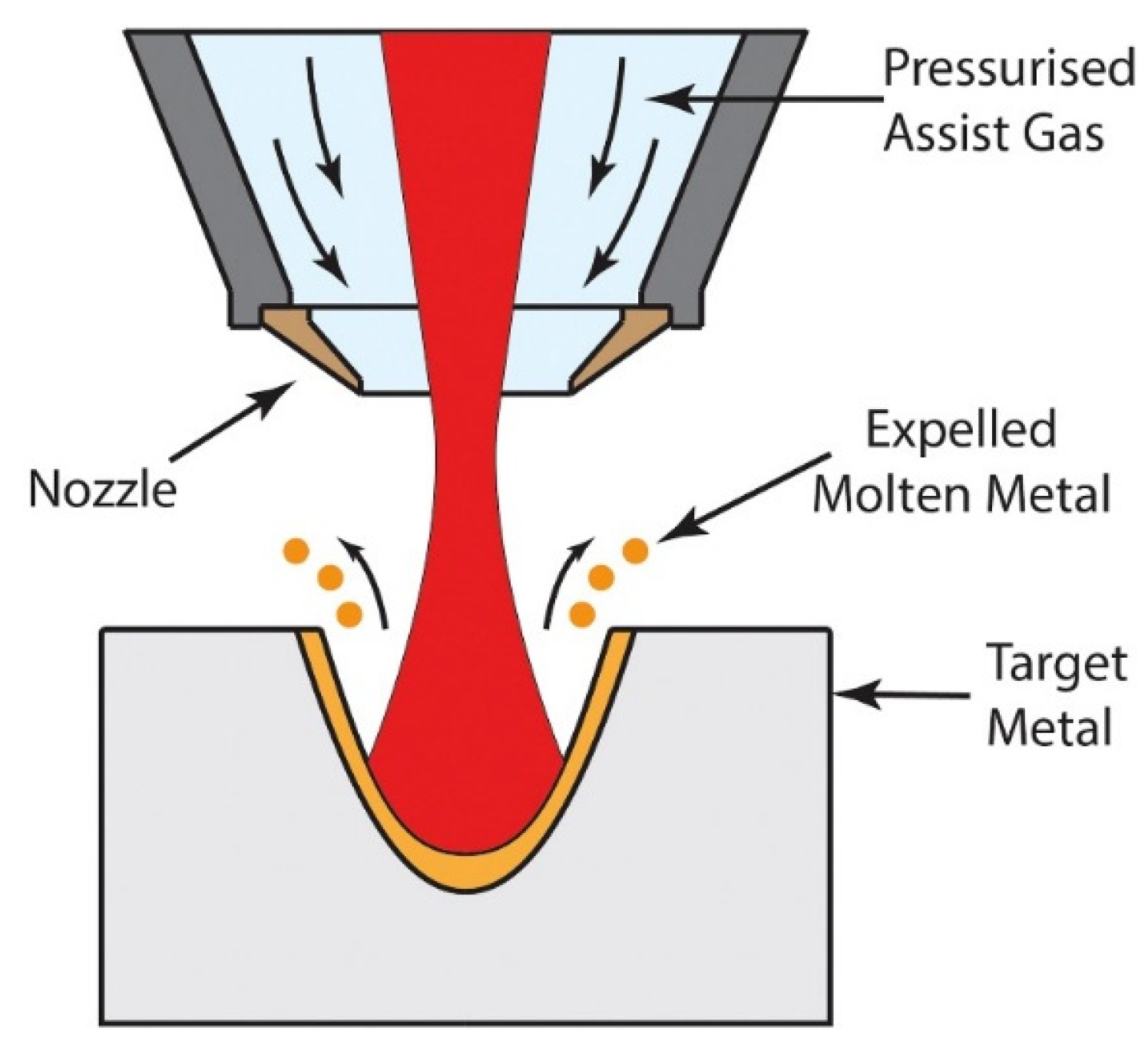

6]. During this method, a laser beam is focused on the workpiece surface, where the thermal energy transforms the substrate material into a molten metal that can be removed easily using the pressurised assist gas, as shown in

Figure 1. In addition to that, the laser beam can heat the material instantly to its vaporisation temperature, and the vaporised material exits out of the hole. At this stage, vapour pressure may also be produced, which contributes to the expulsion of molten metal out of the hole cavity [

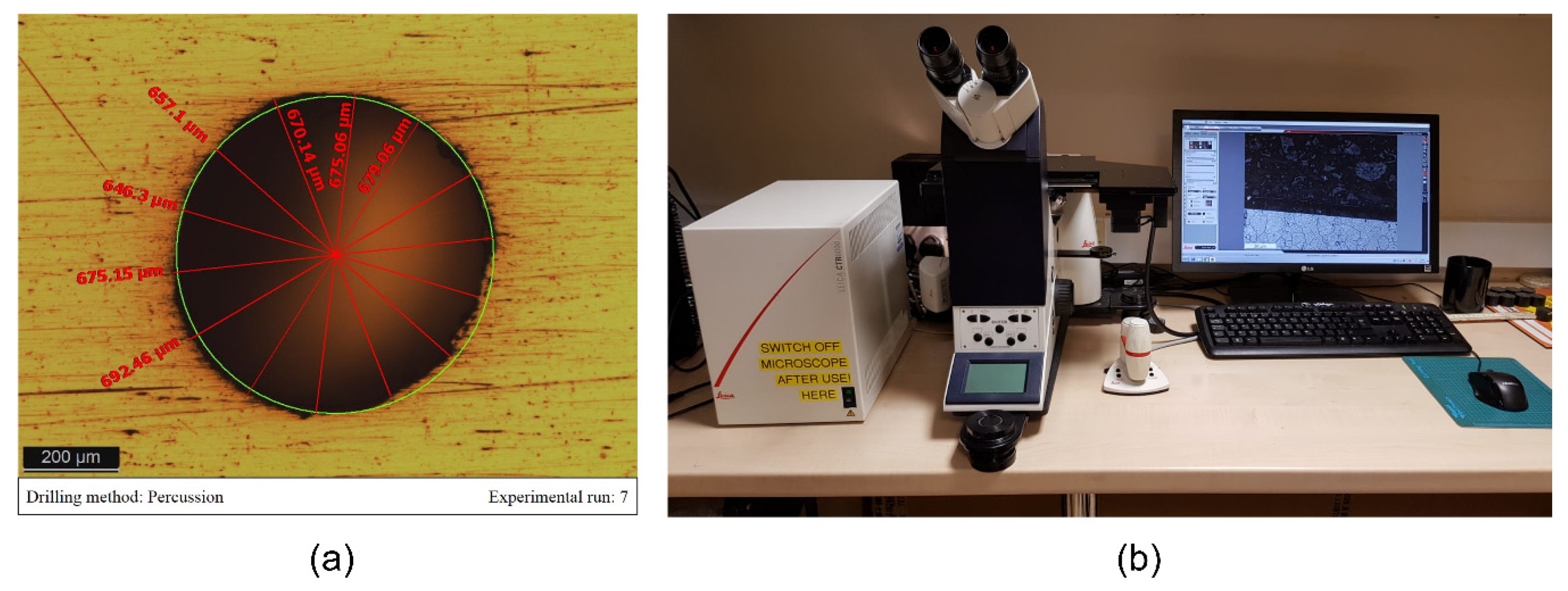

7]; at the same time, the holes produced by the laser reveal some defects, such as recast layer, heat affected zone (HAZ), and hole taper, which may limit the utilisation of the laser drilling process in the industry. From the manufacturing perspective, product quality is always important. In the laser drilling process, the drilled hole quality is assessed by examining its geometrical and metallurgical features, such as circularity, hole taper, microcracks, HAZ, and recast layer thickness [

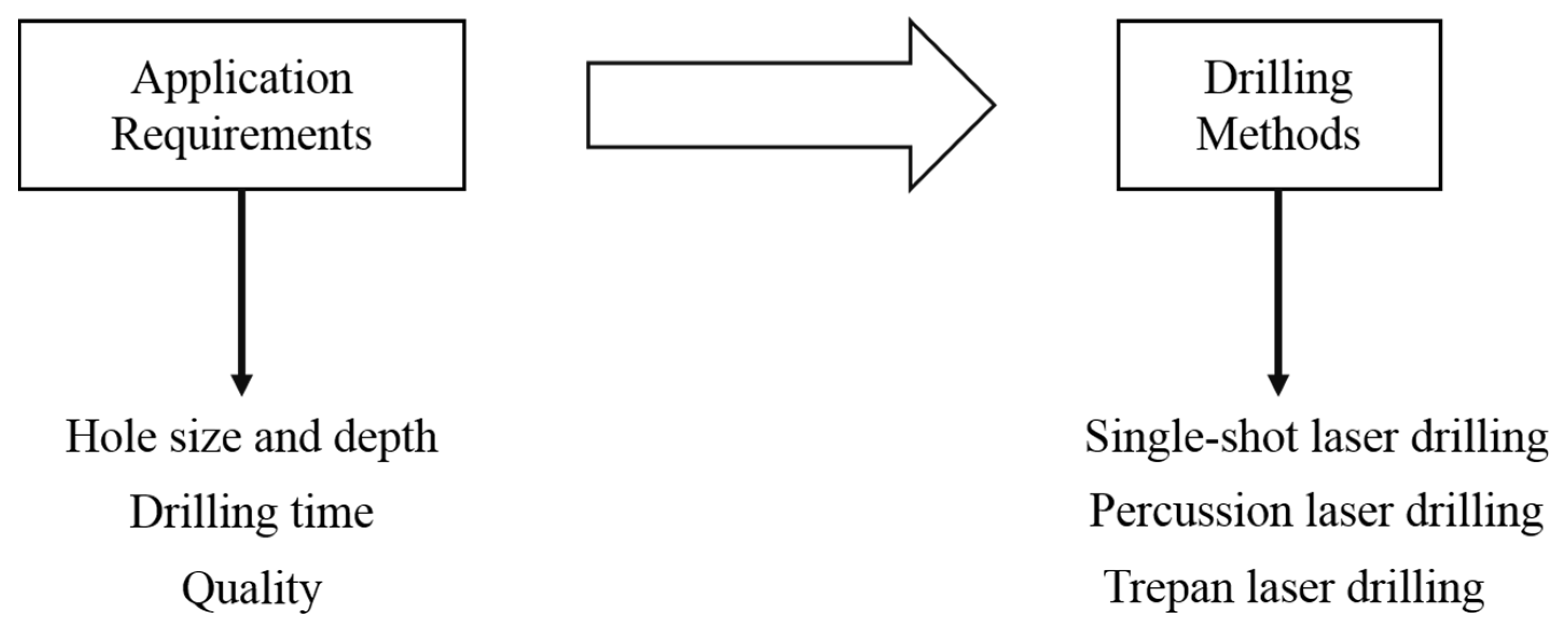

8]. Different drilling methods can be used to produce a particular hole geometry. Depending upon the application requirements, a distinctive method will be selected, as shown in

Figure 2.

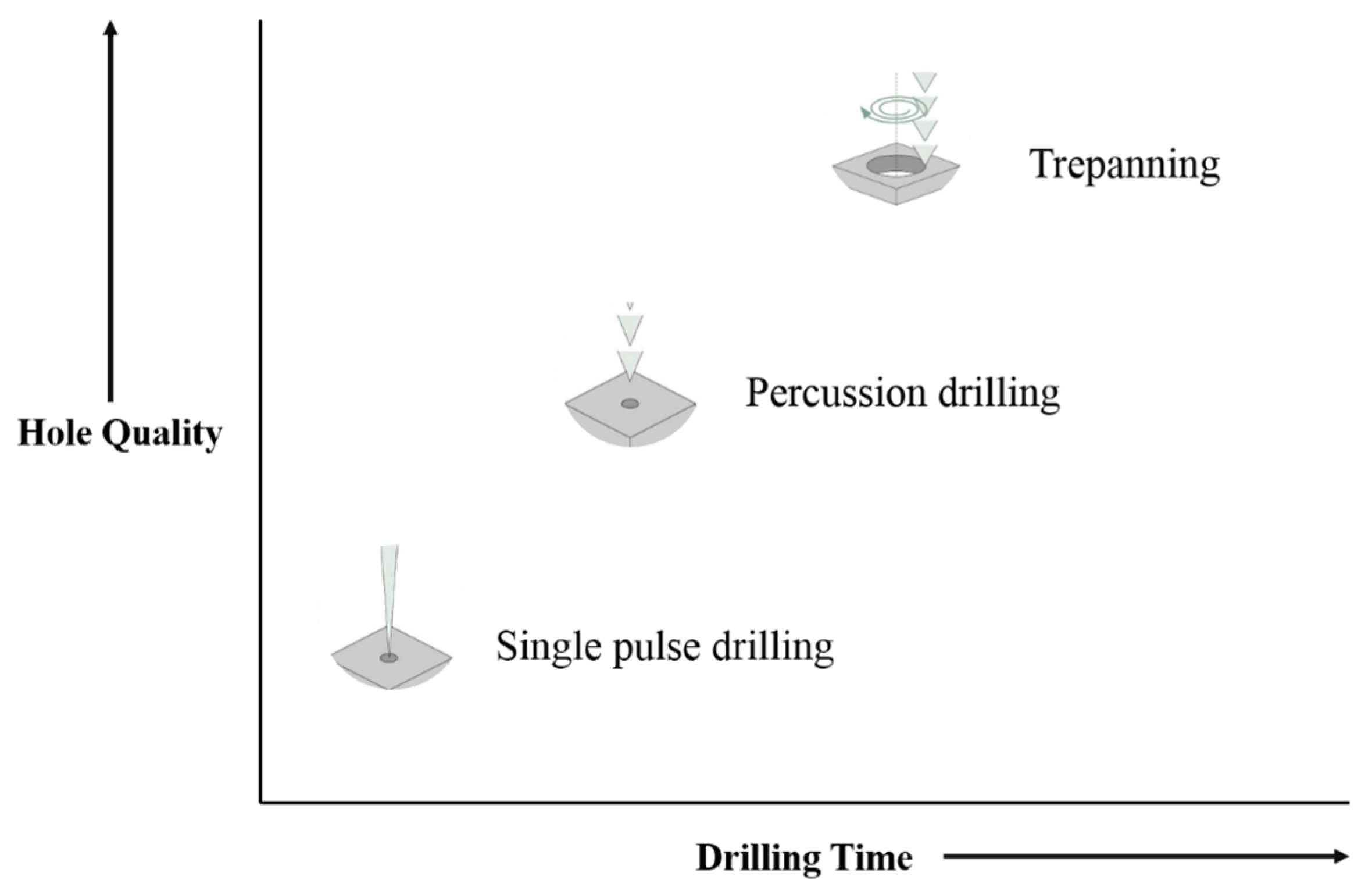

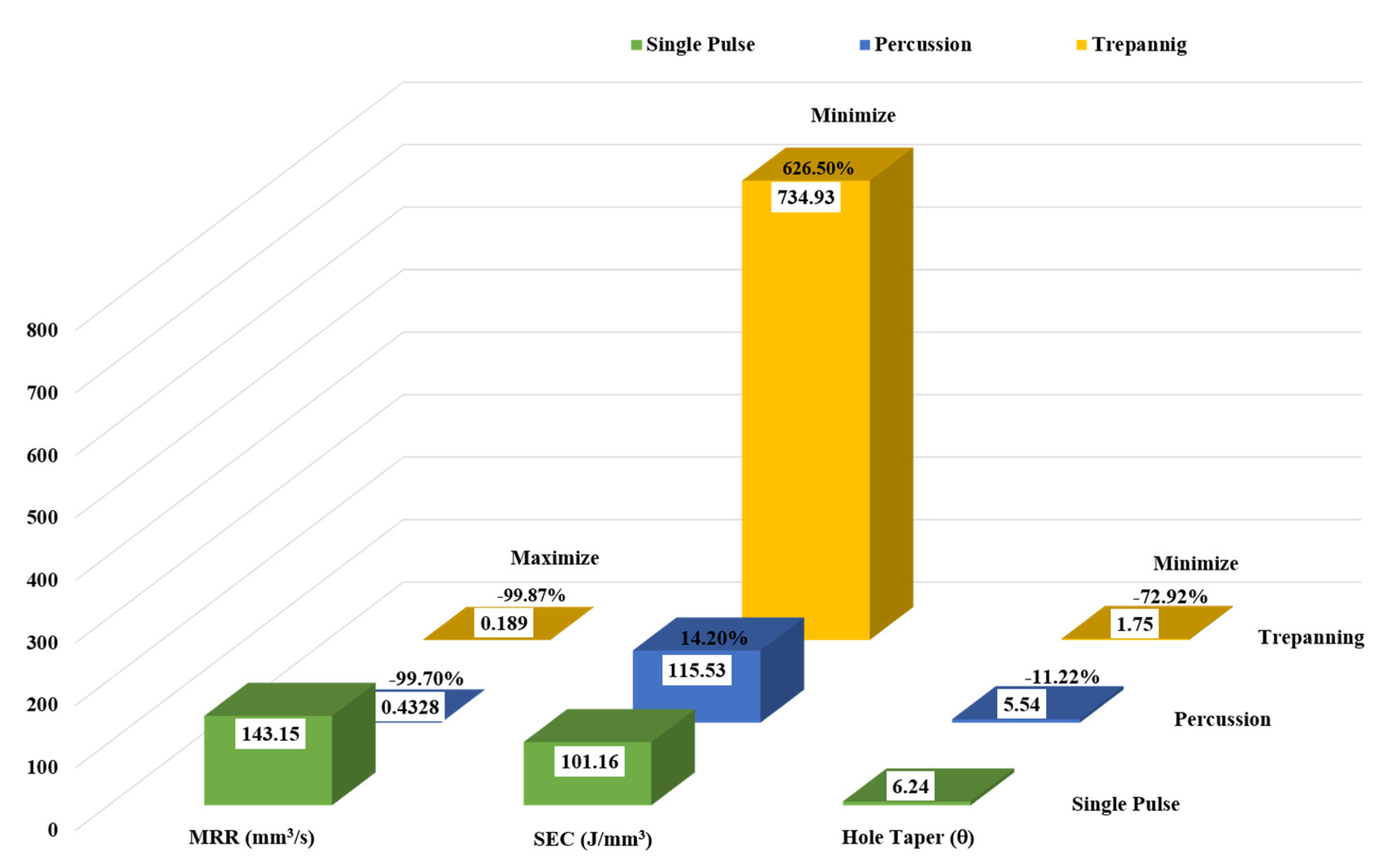

Methods that are commonly used for laser drilling include single-shot laser drilling, percussion, and trepan laser drilling. Single-shot laser drilling, also known as single-pulse drilling, is the most basic method in which a single high-energy pulse from the laser produces a hole throughout the material thickness. High productivity can be achieved with this simple drilling method. Single-shot drilling is preferable when production throughput has priority over quality. The percussion laser drilling method is quite similar to single-shot drilling and is directed by delivering consecutive laser pulses to a particular spot of the material. Using percussion drilling, high-quality holes are achieved as compared to single-pulse drilling. The fact is that less energy is applied to the material every time the pulse is fired; hence, avoiding the thermal defects, such as HAZ. Higher dimensional accuracy can be achieved with percussion drilling; however, this process is slower in contrast with single-pulse drilling. Trepan laser drilling or trepanning is used when the required shape has a size of large diameter. In this process, the hole is initially pierced into the substrate in the same way as percussion drilling followed by spiral configuration to cut a circular disc or cylindrical core from the material by rotating the laser beam around the circumference of the hole. The cylindrical core falls out after the required hole size is created. The drilling time is relatively longer as compared to other methods [

10]. The relationship between drilling time and hole quality for different laser drilling processes is presented in

Figure 3.

The laser drilling process is complex, and there are several parameters that affect the quality of manufactured holes. For improved drilling performance, researchers have been experimenting with various approaches, including different laser drilling methods and with process parameters of various levels. Panda et al. [

11] investigated the influence of laser drilling process parameters on hole quality during percussion drilling of high carbon steel and found laser pulse width/duration as a critical parameter that increases the heat affected zone at higher values. Yilbas [

12] employed a parametric study to observe the effects of different laser machining parameters on the drilled hole quality. This study revealed that pulse energy, pulse duration, pulse frequency, and laser focus position control the hole quality. In another study, Yilbas and Aleem [

13] found that pulse energy, assist gas pressure, and focal position are the important parameters that influence the overall quality of the laser drilled hole. Ng and Li [

7] found that high peak power and short pulse width combination improve the repeatability of holes. The Taguchi method was used by Chien and Hou [

14] to analyse the impacts of different laser drilling process parameters on hole quality during trepanning. It was observed that improved hole quality could be obtained when higher pulse energy and lower trepan speed is used. An experimental investigation was performed by Morar et al. [

15] to investigate the hole quality during laser trepanning of nickel-based superalloy; pulse width, pulse energy, and trepan speed were observed as the most influencing parameters affecting the quality of the drilled hole. Rajesh et al. [

16] examined the effects of several laser drilling parameters on drilled hole quality and reported that pulse duration significantly influences the hole taper. Dhaker and Pandey [

17] investigated the parameters influencing hole quality during laser trepanning. They concluded that the hole quality could be significantly improved by the proper control of laser drilling parameters.

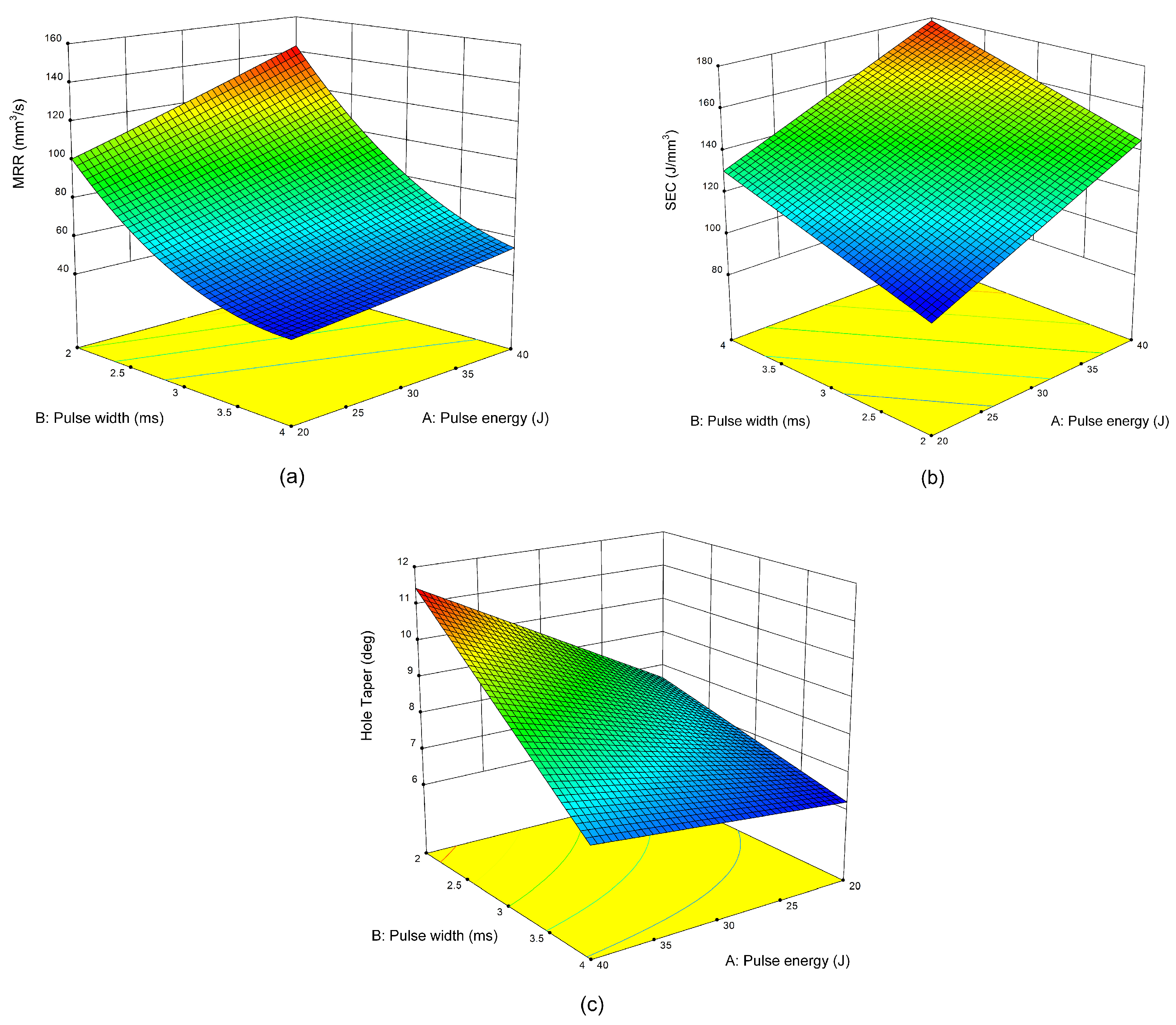

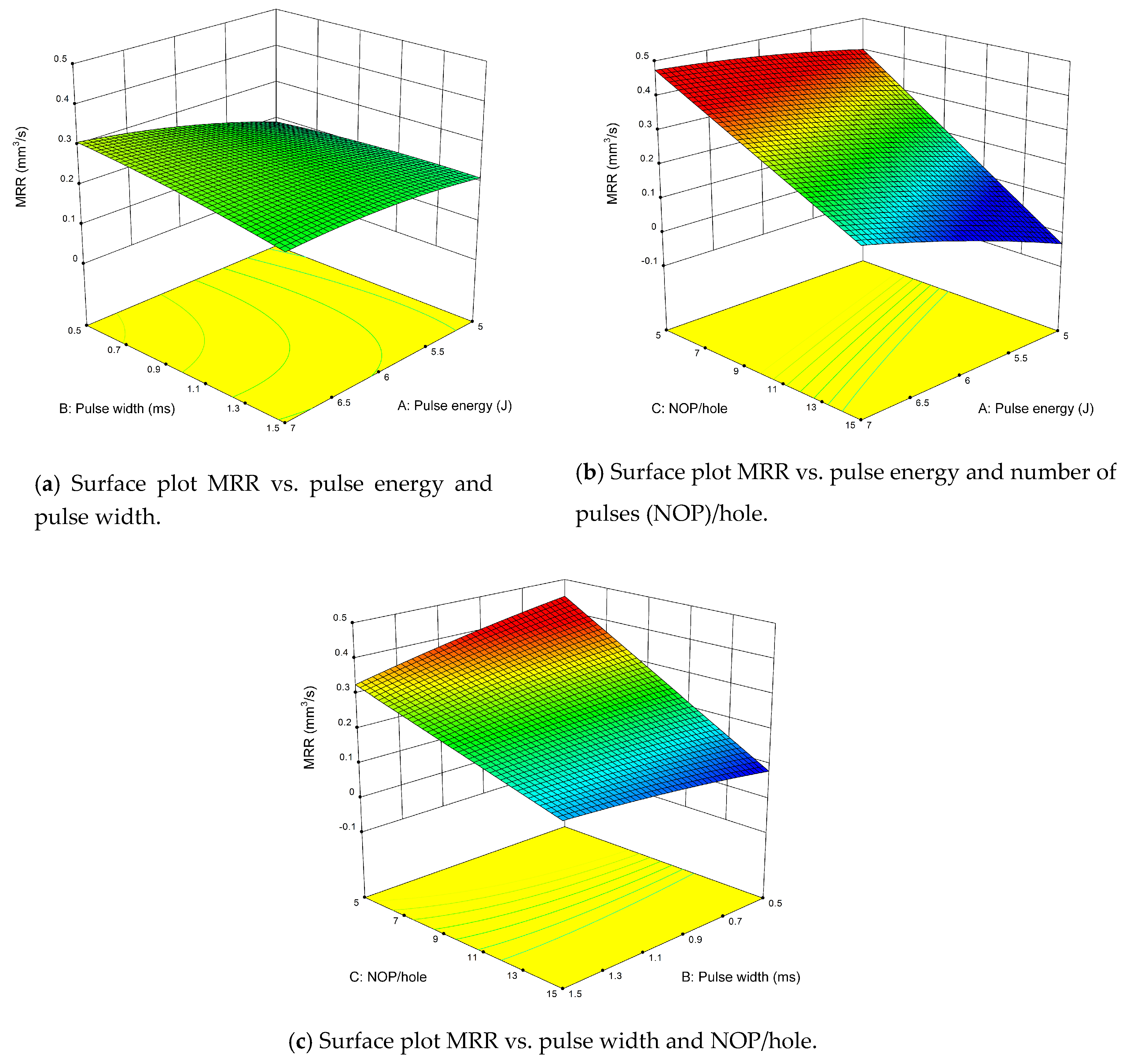

Furthermore, productivity is an important attribute of the laser drilling process that is defined by the material removal rate (MRR). In the laser drilling process, MRR is influenced by the applied laser drilling parameters, i.e., pulse width, pulse frequency, pulse energy, and assist gas [

11,

18,

19,

20,

21]. Higher productivity is always desirable for manufacturing industries as it reduces the cost of manufacturing of a component [

2,

22].

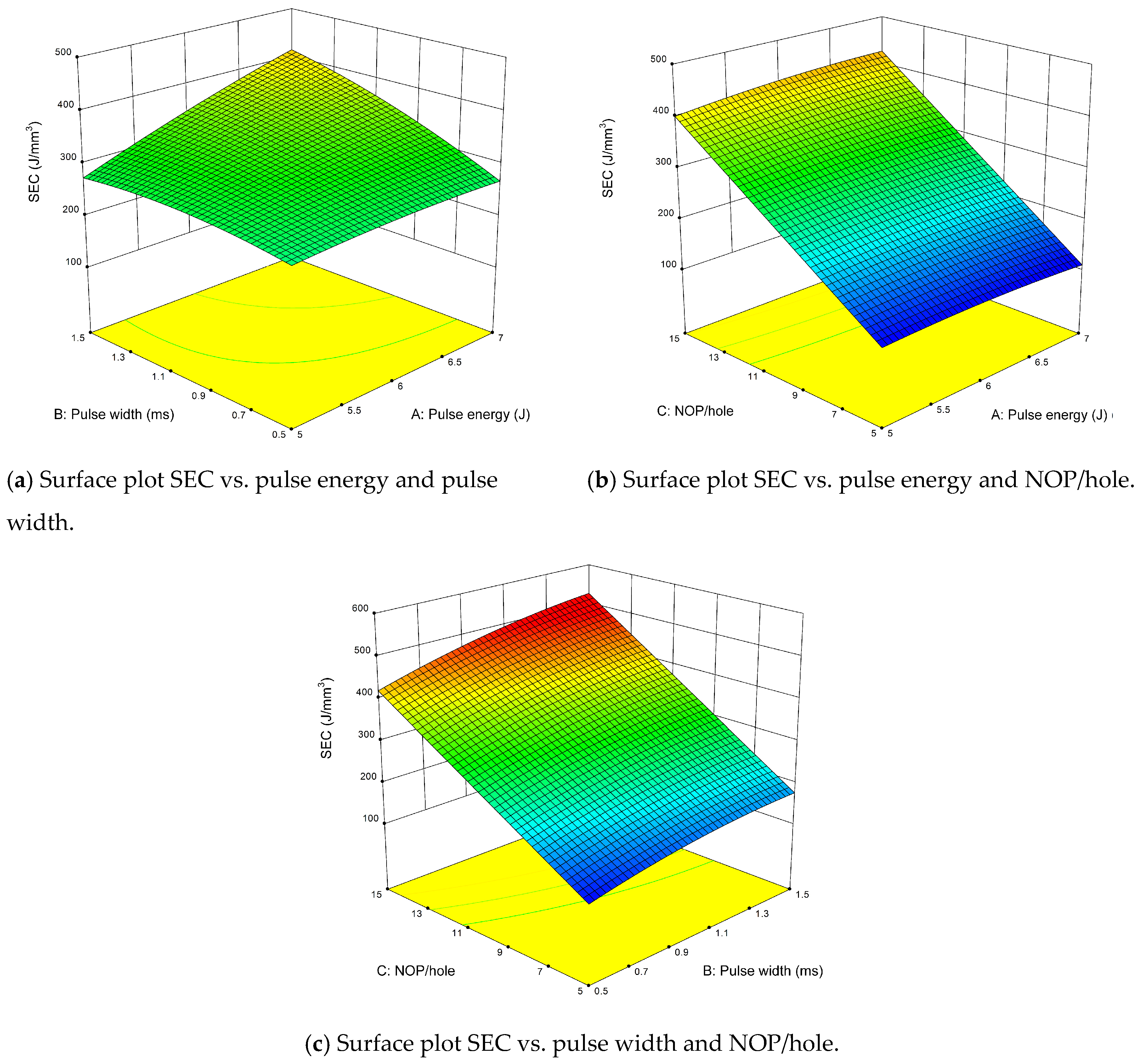

Energy consumption, needed for the manufacturing of products, is also the major concern of the manufacturing community because of the constant increase in energy cost and due to ecological effect linked with the production of energy and its use [

23]. Reducing energy consumption is one of the top priorities of both national and international policies. The hefty CO

2 emissions are the result of extensive use of energy in various manufacturing processes and are responsible for climatic changes. It is found that a large proportion (20–40%) of energy is wasted when performing industrial operations [

24]. The International Energy Agency (IEA) underlined the necessity of energy efficiency evaluation in the direction of two-thirds energy intensity reduction of the world economy before 2050 [

25]. Consequently, there is a need to evaluate the energy consumed during the manufacturing processes.

The energy efficiency of a laser-based process is low, but on the other hand, the material can be removed more precisely. Dahmen et al. [

26] revealed that lasers could impart to sustainable manufacturing because of the minimal use of consumables, confined heat input even at low energy, saving of cost and energy for heat treatment, and with the aid of hybrid methods. Utilising more economical laser sources, for instance, disc or fibre lasers can also be examined as a possible energy efficient method. Similar findings were reported by Kaierle et al. [

27]. An investigation was performed by Apostolos et al. [

28] and Franco et al. [

29] to evaluate laser drilling process energy efficiency by examining different process parameters using CO2 and femtosecond-pulsed fibre laser respectively. The results revealed that optimising the process parameters could lead to reducing the energy consumption of the process. Reduction in energy consumption will provide a great advantage to the industries by alleviating the cost of energy and at the same time reducing the energy crisis and air pollution problems.

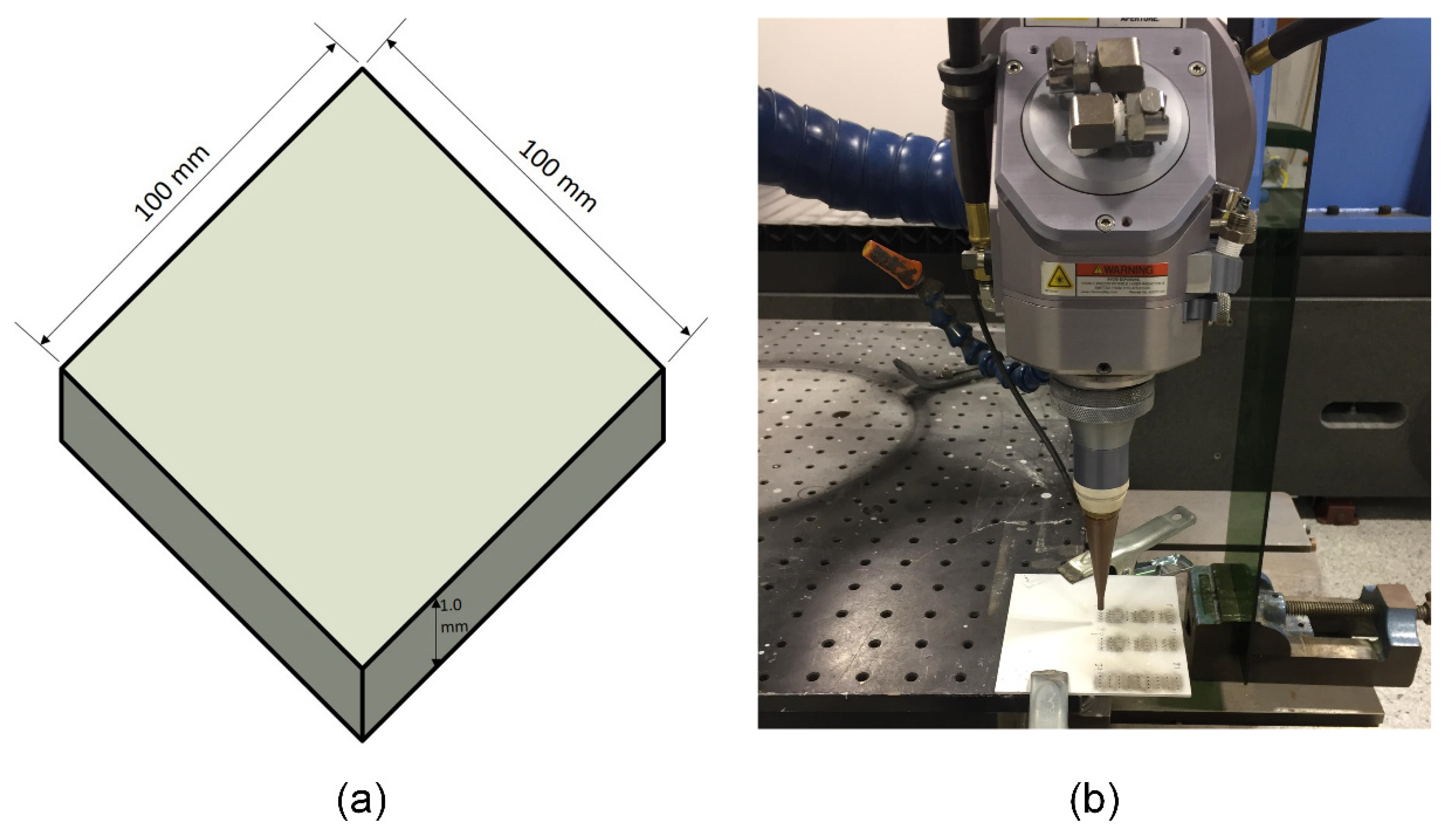

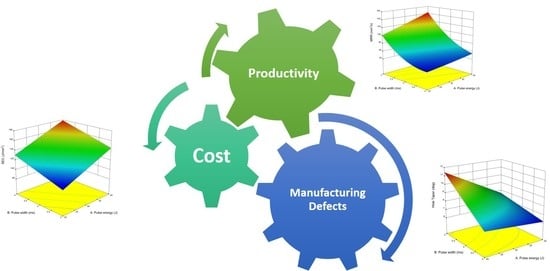

Manufacturing industries are continuously striving to enhance their competitive position through improved productivity and quality at a minimum possible cost that shows the importance of these factors for the industrial sector. From the literature, it has been found that little or no research is reported that characterise the laser drilling methods in terms of MRR, SEC, and hole quality altogether. Therefore, the objective of the presented study is to deliver a clear understanding of the impacts of different laser drilling methods and process parameters on productivity (material removal rate), cost (specific energy consumption), and hole quality (hole taper) in laser drilling of IN 718 superalloy. Three different laser drilling processes have been investigated, i.e., single-pulse, percussion, and trepanning. Further analysis has been performed using multi-objective optimisation to achieve the optimum levels of process parameters for maximum MRR, with minimum SEC and hole taper.