Appendix B. LTJ Matlab Code

Equation=1; % Chose rate equation as below:

% 1: madsnew(n)=mads(n)-dt*msalt(n)*((x(n)-xinitial)^yads)*Aads*(1.-peq/p)

% 2: madsnew(n)=mads(n)-dt*msalt(n)*((x(n)-xinitial)^yadsln)*C1ads*...

%exp(-Ea/R0/T)*log(p/peq)

dt=0.01; % Time step (s) for simulatiom If N=3 use 0.02

R0=8314; % Universal Gas Constant J/kmol K

RNH3=R0/17; % Approximate ammonia gas constant J/kg K

Cpgas = 2760; % Specific heat Cp of ammonia gas (mean) J/kg K

Cvgas =Cpgas-RNH3; % Specific heat Cv of ammonia gas (mean) J/kg K

Cpads=3120; % Specific heat of ammoniate J/kmol NH3 ***kg???

CpENG = 720; % Specific heat of ENG J/kg K

rhoENG=195.9; % Density of unfilled block of ENG kg/m^3

rhoads=817; % Density of solid ammoniate - ammonia ice from Wiki kg/m^3

MWamm=17.03; % MW ammonia

rhogra=2250; % density of graphite kg/m^3 to get true volume

experiment = menu('choose experiment number', '44-52', '53-56', '57-62')

if experiment == 1

%%%% Data from EXP 44-52 salt mass and ENG initial multiplier to smooth curves

MassSalt = 0.759e-3;

MassSalt = MassSalt*0.47;

MassENG = 0.67e-3;

end

if experiment == 2

%%%% Data from EXP 53-56 salt mass and ENG initial multiplier to smooth curves

MassSalt = 0.23e-3;

MassSalt = MassSalt*0.47;

MassENG = 0.642e-3;

end

if experiment == 3

%%%% Data from EXP 53-56 salt mass and ENG initial multiplier to smooth curves

MassSalt = 0.294e-3;

MassSalt = MassSalt*0.47;

MassENG = 0.632e-3;

end

% Input salt and reaction

saltname = menu('Choose Reaction', 'BaCl2', 'CaCl2(8-4)', 'CaCl2(4-2)')

if saltname==1 % All BaCl2 parameters below

Cpsalt=361.2; % Specific heat of BaCl2 J/kg K (Nist 75.22 J/(mol K))

rhosalt=3856; % Density of unammoniated salt kg/m^3 Wikipedia

MWsalt=208.23;% MW of salt - BaCl2

Xmax=8;% Max moles NH3 per mole salt assumed equal in all nodes

Xmin=0;% Min moles NH3 per mole salt assumed equal in all nodes

Xstart=8; % value of X at time zero

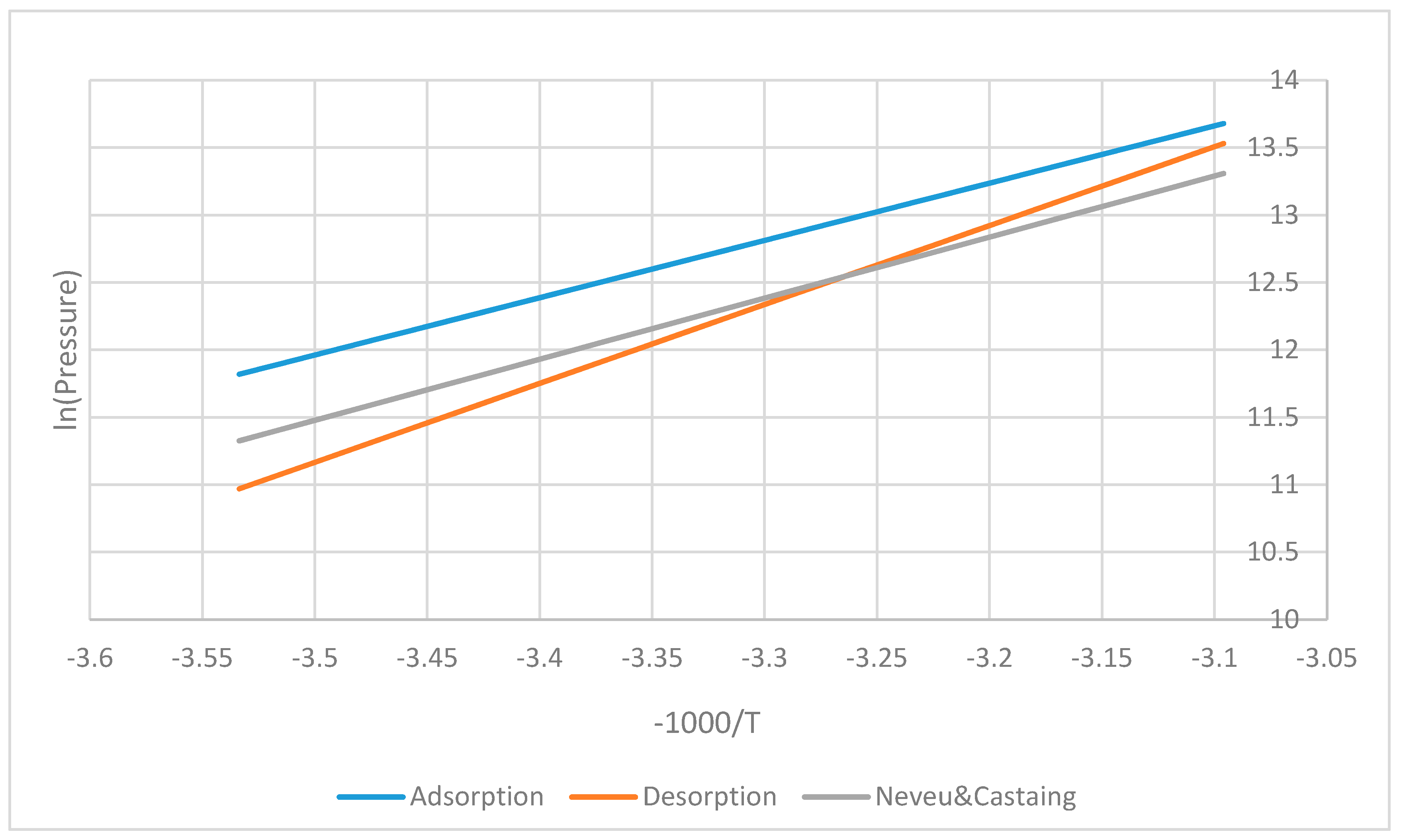

delHdes=48670.37e3; % Altered with LTJ results

delSdes=263.17772e3; % Altered with LTJ results

delSads=223.1352e3; % Altered with LTJ results Pretty certain

delHads=35338.96e3; % Altered with LTJ results about ads results

ydes=2; % Dynamic parameter desorption Eq 1

Ades=3.5; % Dynamic parameter desorption Eq 1

yads=0.2; % Dynamic parameter adsorption Eq 1

Aads=0.75; % Dynamic parameter adsorption Eq 1

yadsln=1; % Dynamic parameter desorption Eq 2

ydesln=1; % Dynamic parameter desorption Eq 2

C1ads=500; % Dynamic parameter desorption Eq 2 (1/s)

C1des=100; % Dynamic parameter desorption Eq 2 (1/s)

Eaads=25000;% Dynamic parameter ads Eq 2 (J/kmol K [as R0])

Eades=25000;% Dynamic parameter des Eq 2 (J/kmol K [as R0])

else

if saltname==2 % All CaCl2 8-4 parameters below

Cpsalt=656.8; % Cp of CaCl2 J/kg K (Wikipedia 72.89 J/(mol K))

rhosalt=2150; % Density of unammoniated salt kg/m^3 Wikipedia

MWsalt=110.984;% MW CaCl2

Xmax=8;% Max moles NH3 per mole salt assumed equal in all nodes

Xmin=0;% Min moles NH3 per mole salt assumed equal in all nodes

Xstart=8; % value of X at time zero

delHdes=41013000;% Reaction enthalpy J/mol for CaCl2 8-4

delSdes=230300; % Reaction entropy change for CaCl2 8-4 J/molK

delHads=41013000;% Reaction enthalpy J/mol for CaCl2 8-4

delSads=230300; % Reaction entropy change for CaCl2 8-4 J/molK

ydes=1.5; % Dynamic parameter desorption Eq 1

Ades=0.7; % Dynamic parameter desorption Eq 1

yads=1.5; % Dynamic parameter adsorption Eq 1

Aads=0.7; % Dynamic parameter adsorption Eq 1

yadsln=1; % Dynamic parameter desorption Eq 2

ydesln=1; % Dynamic parameter desorption Eq 2

C1ads=500; % Dynamic parameter desorption Eq 2 (1/s)

C1des=100; % Dynamic parameter desorption Eq 2 (1/s)

Eaads=25000;% Dynamic parameter ads Eq 2 (J/kmol K [as R0])

Eades=25000;% Dynamic parameter des Eq 2 (J/kmol K [as R0])

else

if saltname==3% All CaCl2 8-4 parameters below

Cpsalt=656.8; % Cp of CaCl2 J/kg K (Wikipedia 72.89 J/(mol K))

rhosalt=2150; % Density of unammoniated salt kg/m^3 Wikipedia

MWsalt=110.984;% MW CaCl2

Xmax=4;% Max moles NH3 per mole salt assumed equal in all nodes

Xmin=2;% Min moles NH3 per mole salt assumed equal in all nodes

Xstart=2; % value of X at time zero

delHdes=42268000;% Reaction enthalpy J/mol for CaCl2 4-2

delSdes=229920; % Reaction entropy change for CaCl2 4-2 J/molK

delHads=42268000;% Reaction enthalpy J/mol for CaCl2 4-2

delSads=229920; % Reaction entropy change for CaCl2 4-2 J/molK

ydes=1.5; % Dynamic parameter desorption Eq 1

Ades=0.7; % Dynamic parameter desorption Eq 1

yads=1.5; % Dynamic parameter adsorption Eq 1

Aads=0.7; % Dynamic parameter adsorption Eq 1

yadsln=1; % Dynamic parameter desorption Eq 2

ydesln=1; % Dynamic parameter desorption Eq 2

C1ads=500; % Dynamic parameter desorption Eq 2 (1/s)

C1des=100; % Dynamic parameter desorption Eq 2 (1/s)

Eaads=25000;% Dynamic parameter ads Eq 2 (J/kmol K [as R0])

Eades=25000;% Dynamic parameter des Eq 2 (J/kmol K [as R0])

else

'Incorrect salt entered';

end

end

end

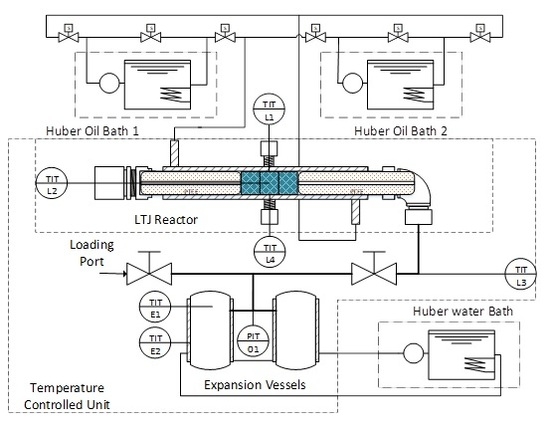

Ve=11.423e-3; % Volume of expansion vessel and pipework in m^3

massfracsalt = MassSalt/MassENG;

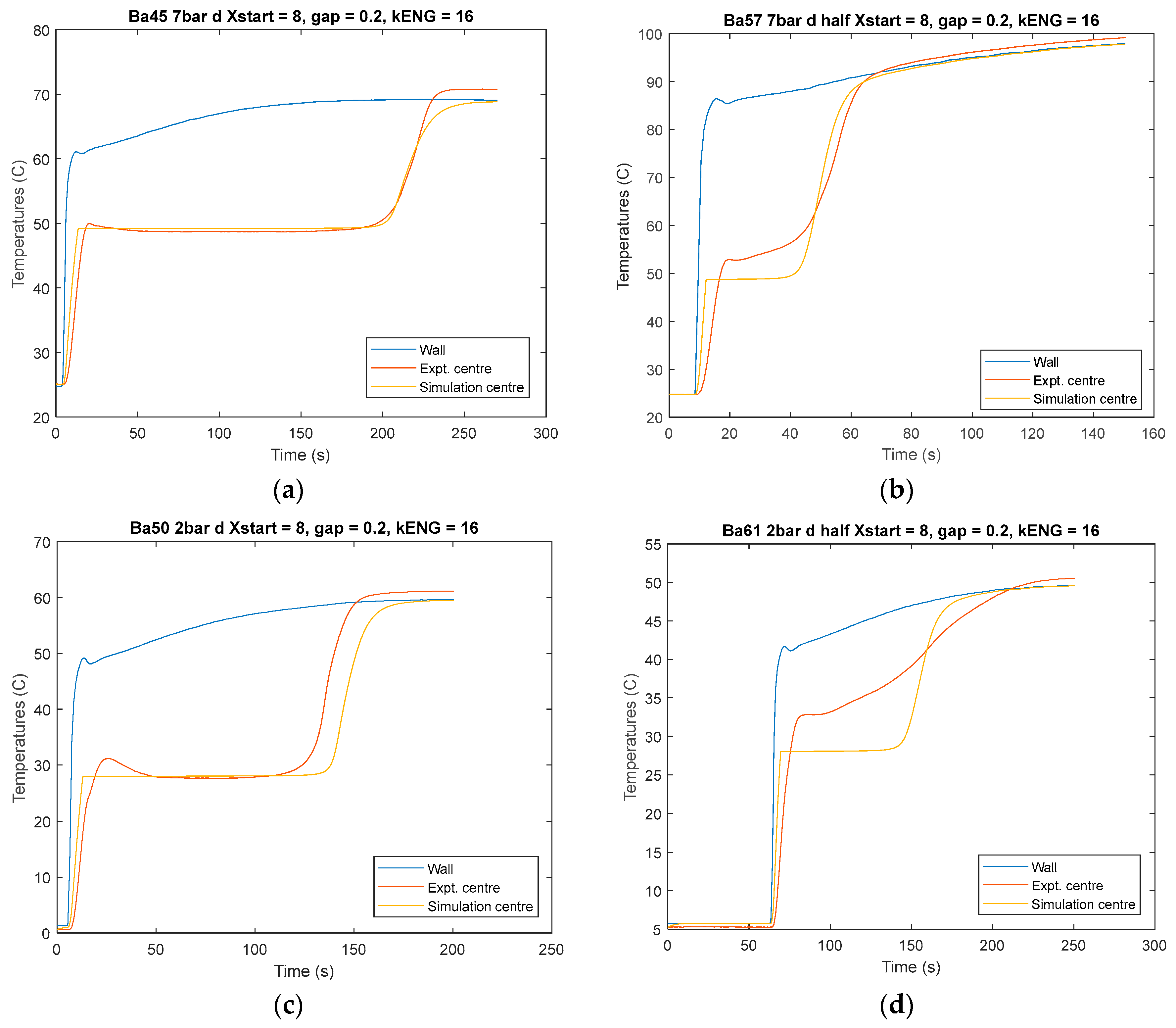

N=3; % Number of nodes

Bore=0.01088;% LTJ tube bore (m)

TCbore = 1e-3; %tc hole

length=5*9.5e-3; % Total axial length of samples (m)

VvoidLTJ=0;%2.7e-5; %Void volume in LTJ tube (m^3)

hwall=5e5; % Wall to ENG heat transfer coefficient

kammgas=0.024; % Conductivty of gas W/mK

gap=0.0002; % Wall ENG gap in m

hwall=kammgas/gap;

% CHECK Radial conductivity of ENG + SALT

kENG=16;

% ********** END OF PARAMETERS FOR TWEAKING ***********

% Input experimental data

filename = input('Enter filename (without .xls)' ,'s')

figname=filename + string(' Xstart = ')+num2str(Xstart)+...

", gap = "+num2str(gap*1000)+string(', kENG = ')+...

num2str(kENG); % Figure titles

expt=xlsread(filename);

%Columns are t(s) Twall (C) Te (C) Tewall (C) Tcentre(C) p(bar)

% Convert to K and Pa

expt(:,2) = (expt(:,2)+expt(:,8))/2; % average wall temps

expt(:,2:5)=expt(:,2:5)+273; % Temperatures to K

expt(:,6)=expt(:,6)*1e5; % Pressures to bar (Check guage is absolute)

toff=expt(1,1); % Time offset

expt(:,1)=expt(:,1)-toff; % Time column begins at zero.

datasize=size(expt);

rows=datasize(1); % Number of rows

tmax=floor(expt(rows,1)/dt)*dt;% Max time rounded to whole number of dt's

jmax=floor(expt(rows,1)/dt);

% Rows in array to be used in simulation, start at dt, end tmax

tempoffe=-expt(1,4)+expt(1,3); % Offset to add to col 4 (Te)

expt(:,4)=expt(:,4)+tempoffe;

expt(:,6)=smooth(expt(:,6),20);

% 20 point moving average to smooth pressure data

expt(:,3)=smooth(expt(:,3),20); % smooth Te

expt(:,4)=smooth(expt(:,4),20); % smooth Tewall

dataarray=zeros(jmax,6);

for j=1:jmax; % Make data array from time dt to tmax

time=dt*j;

for ROW=1:rows-1

if time>=expt(ROW,1)& time<=expt(ROW+1,1);

row=ROW;

end

end

% row is lower row for interpolation

fract=(time-expt(row,1))/(expt(row+1,1)-expt(row,1));

dataarray(j,1)=time;

dataarray(j,2)=expt(row,2)+fract*(expt(row+1,2)-expt(row,2));

dataarray(j,3)=expt(row,3)+fract*(expt(row+1,3)-expt(row,3));

dataarray(j,4)=expt(row,4)+fract*(expt(row+1,4)-expt(row,4));

dataarray(j,5)=expt(row,5)+fract*(expt(row+1,5)-expt(row,5));

dataarray(j,6)=expt(row,6)+fract*(expt(row+1,6)-expt(row,6));

end

xinitial=Xmax*MWamm/MWsalt; % Maximum kg ammonia / kg salt

xfinal=Xmin*MWamm/MWsalt; % Minimum kg ammonia / kg salt

xstart=Xstart*MWamm/MWsalt; % kg ammonia / kg salt at time zero

Tinitial=300; % initial temperature of all nodes in K

Tinitial=expt(1,5);

% Expansion vessel properties

pinitial=3e5; % Initial pressure in Pa

pinitial=expt(1,6);

Teinitial=300;% Initial temperature in K

Teinitial=expt(1,3);

Te=Teinitial;

meinitial=pinitial*Ve/Teinitial/ramms(pinitial/1e5,Teinitial-273);

meinitial=pinitial*Ve/Teinitial/RNH3;

% Initial kg of NH3 in expansion vessel

me=meinitial;

%%% **********SET UP NODE VOLMES and UAs**************

T=ones(1,N)*Tinitial;

V=zeros(1,N);

for n=1:N

r(n)=Bore/2*n/N;% Radius of element

Aouter(n)=2*pi*r(n)*length; % Outer ht area of element (m^2)

if n==1

V(n)=0.5*pi*r(1)*r(1)*length; % Volume of elements in m^3

else V(n)=0.5*pi*r(n)*r(n)*length-0.5*pi*r(n-1)*r(n-1)*length;

end

if n==1

rmean(n)=r(1)/sqrt(2);

% Mean radius such that areas either side are equal (m)

else rmean(n)=sqrt((r(n)*r(n)+r(n-1)*r(n-1))/2);

end

end

Vtotnodes=sum(V);

% ************CALCULATE ALL UAs*************

if N==1

UAouter(1)=2*pi*length/(1/hwall/r(1)+log(r(1)/rmean(1))/kENG);

UAinner(1)=0;

else

for n=1:N-1

UAouter(n)=2*pi*kENG*length/(log(rmean(n+1)/rmean(n)));

if n==1

UAinner(n)=0;

else

UAinner(n)=2*pi*kENG*length/(log(rmean(n)/rmean(n-1)));

end

end

UAouter(N)=2*pi*length/(1/hwall/r(1)+log(r(1)/rmean(1))/kENG);

UAinner(N)=2*pi*kENG*length/(log(rmean(N)/rmean(N-1)));

end

% *********Calculate other parameters for elements******

for n=1:N

% mENG(n)=V(n)*rhoENG;

mENG(n) = MassENG/N;

msalt(n) = MassSalt/N;

% Mass of ENG in node(s)in kg. In general a 1-d array

% msalt(n)=massfracsalt*mENG(n); % Mass of salt in nodes (kg)

mads(n)=msalt(n)*xstart; % Mass of adsorbate in nodes (kg)

x(n)=mads(n)/msalt(n); % Mass NH3/mass salt in nodes

MCp(n)=mENG(n)*CpENG+msalt(n)*Cpsalt;

% Combined MCp for ENG and salt J/K

V0void(n)=(V(n)-mENG(n)/rhogra-msalt(n)/rhosalt);

% Void volume m^3 with zero adsorbate

% add VvoidLTJ proportional to node volumes

V0void(n)=V0void(n)+VvoidLTJ*V(n)/Vtotnodes;

Vvoid(n)=V0void(n)-mads(n)/rhoads; % initial void volume in node n in m^3

mgas(n)=pinitial*Vvoid(n)/Tinitial/ramms(pinitial/1e5,Tinitial-273);

mgas(n)=pinitial*Vvoid(n)/Tinitial/RNH3;

% Mass of gas in voids (kg)

T(n)=Tinitial; % Temperature of node (K)

end% of unchanging node or initial properties

p=pinitial;

mgasinitial=sum(mgas); %Initial mass of gas (kg).

% Assumes xinitial salt volume

totgasinitial=mgasinitial+me; % Initial total mass of gas (kg)

% Set up result storage arrays

mgasarray=zeros(N,ceil(tmax/dt));

madsarray=zeros(N,ceil(tmax/dt));

Tarray=zeros(N,ceil(tmax/dt));

xarray=zeros(N,ceil(tmax/dt));

Xarray=zeros(N,ceil(tmax/dt));

parray=zeros(1,ceil(tmax/dt));

mearray=zeros(1,ceil(tmax/dt));

Tearray=zeros(1,ceil(tmax/dt));

mtotarray=zeros(1,ceil(tmax/dt));

xexptarray=zeros(1,ceil(tmax/dt));

index=0; % Counter for time loop

for t=dt:dt:tmax; % Time in seconds

index=index+1;

Twall=dataarray(index,2); % Wall temperature (K)

%Calculate heat into nodes dQ (J)

if N==1

dQ=dt*UAouter(n)*(Twall-T(n));

else

for n=1:N-1

if n>1;

dQ(n)=dt*(UAouter(n)*(T(n+1)-T(n))+UAinner(n)*(T(n-1)-T(n)));

else

dQ(n)=dt*UAouter(n)*(T(n+1)-T(n));

end

end

dQ(N)=dt*UAouter(N)*(Twall-T(N));

end

dQwall=dt*UAouter(n)*(Twall-T(n));

%Joules into element

dQe=0.; % Joules into vessel in time step.

pnew=fzero(@saltmasserrornew,p+1000);

%T

%Tnew

%stop

% fzero finds pnew such that saltmasserror.m returns a zero

% Store masses in arrays

for j=1:N

mgasarray(j,index)=mgasnew(j);

madsarray(j,index)=madsnew(j);

Tarray(j,index)=Tnew(j);

xarray(j,index)=madsnew(j)/msalt(j);

Xarray(j,index)=xarray(j,index)*MWsalt/MWamm;

end

parray(1,index)=pnew;

peqadsarray(1,index)=peqads;

peqdesarray(1,index)=peqdes;

adsarray(1,index)=ads;

mearray(1,index)=menew;

mtotarray(1,index)=menew+sum(madsnew)+sum(mgasnew);

Tearray(1,index)=Tenew;

% Calculate experimental change in x

meexpt=dataarray(index,6)*Ve/RNH3/dataarray(index,3);

% pV/RT for experimental vessel gas mass

mgasexpt=dataarray(index,6)*sum(Vvoidnew)/RNH3/(dataarray(index,2)+...

dataarray(index,5))*2;% Expt gas mass using calculated Vvoid, mean T

totgasexpt=meexpt+mgasexpt;

delgas=totgasexpt-totgasinitial;

delxexpt=-delgas/sum(msalt); % Change in x from start

xexptarray(1,index)=xstart+delxexpt;

%if xexptarray(1,index)<0;xexptarray(1,index)=0;end; %Remove negatives

% Estimated x based on initial value and gas mass

%Carry out mass balance

Oldmass=sum(mgas)+sum(mads)+me;

Newmass=sum(mgasnew)+sum(madsnew)+menew;

Masschange=1-Oldmass/Newmass;

% Carry out energy balance on elements

for n=1:N

ENGplusSALTheat(n)=MCp(n)*(Tnew(n)-T(n));

deltaUgas(n)=Cvgas*(mgasnew(n)*Tnew(n)-mgas(n)*T(n));

deltaUads(n)=madsnew(n)*(Cpgas*Tnew(n)-pnew/rhoads-delHdes/MWamm)-.../

mads(n)*(Cpgas*T(n)-p/rhoads-delHdes/MWamm);

%Uadsnew=Cpgas*Tnew(n)-pnew/rhoads-delHdes/MWamm;

%Uads=Cpgas*T(n)-p/rhoads-delHdes/MWamm;

deltaH(n)=dmouthout(n);

end

sumheat=sum(ENGplusSALTheat+deltaUgas+deltaUads+deltaH);

ENGplusSALTheatarray(1,index)=sum(ENGplusSALTheat);

dQwall;

Heatfraction=(dQwall-sumheat)/dQwall;

Heatfractionarray(1,index)=Heatfraction;

dQarray(1,index)=dQwall;

%Uadsarray(1,index)=Uads;

sumheatarray(1,index)=sumheat;

deltaHarray(1,index)=sum(deltaH);

deltaUadsarray(1,index)=sum(deltaUads);

deltaUgasarray(1,index)=sum(deltaUgas);

% Energy balance on vessel

%stop

% Set old values to new ones

mgas=mgasnew;

mads=madsnew;

T=Tnew;

p=pnew;

x=xnew;

Te=Tenew;

me=menew;

Vvoid=Vvoidnew;

t;

end% of simulation, t=tmax

function F=saltmasserror (pnew)

for n=1:N

n;

% adsorbing (ads=1) or desorbing (ads=0) ??

peqads=exp(-delHads/R0/T(n)+delSads/R0); % Equilibrium p (ads) in Pa

peqdes=exp(-delHdes/R0/T(n)+delSdes/R0); % Equilibrium p (des) in Pa

ads;

if p<peqdes;

ads=0;

peq=peqdes;

delH=delHdes;

if Equation==1 % Linear model

madsnew(n)=mads(n)+dt*msalt(n)*((xinitial-xfinal)*...

(((x(n)-xfinal)/(xinitial-xfinal)))^ydes)*Ades*(1.-peq/p);

end

if Equation==2 % Log model with Arrhenius f(T)

madsnew(n)=mads(n)+dt*msalt(n)*(xinitial-xfinal)*...

(((x(n)-xfinal)/(xinitial-xfinal))^ydesln)*...

C1des*exp(-Eades/R0/T(n))*log(p/peq);

end

else

%%

if p>peqads;

ads=1;

peq=peqads;

delH=delHads;

if Equation==1 % Linear model

madsnew(n)=mads(n)+dt*msalt(n)*((xinitial-xfinal)*...

(((x(n)-xfinal)/(xinitial-xfinal)))^yads)*Aads*(1.-peq/p);

end

if Equation==2 % Log model with Arrhenius f(T)

madsnew(n)=mads(n)+dt*msalt(n)*(xinitial-xfinal)*...

(((xfinal-x(n)/(xinitial-xfinal))^yadsln))*...

C1ads*exp(-Eaads/R0/T(n))*log(p/peq);

end

else

% In hysteresis band keep going in the same direction.

% If starting in the band arbitrarily suppose desorption

if ads==[];

ads=0;

peq=peqdes;

delH=delHdes;

if Equation==1 % Linear model

madsnew(n)=mads(n)+dt*msalt(n)*((xinitial-xfinal)*...

(((x(n)-xfinal)/(xinitial-xfinal)))^ydes)*Ades*(1.-peq/p);

end

if Equation==2 % Log model with Arrhenius f(T)

madsnew(n)=mads(n)+dt*msalt(n)*((x(n)-xfinal)^ydesln)*...

C1des*exp(-Eades/R0/T(n))*log(p/peq);

end

end

end

end

% Limit x between max and min

xnew(n)=madsnew(n)/msalt(n);

if xnew(n)>xinitial; xnew(n)=xinitial;end

if xnew(n)<xfinal; xnew(n)=xfinal; end

madsnew(n)=xnew(n)*msalt(n);

R=RNH3;

Vvoidnew(n)=V0void(n)-madsnew(n)/rhoads;% new void volume in node n m^3

if ads==0; % Desorption

a=-Cpgas*(0.5*mads(n)+0.5*madsnew(n)+p*Vvoid(n)/2/R/T(n))-MCp(n);

b=dQ(n)+MCp(n)*T(n)-Cvgas/R*(pnew*Vvoidnew(n)-p*Vvoid(n))...

+mads(n)*(Cpgas*T(n)-p/rhoads-delH/MWamm)+...

madsnew(n)*(pnew/rhoads+delH/MWamm)...

-Cpgas/2*(T(n)*(mads(n)-madsnew(n)+p*Vvoid(n)/R/T(n))-pnew*Vvoidnew(n)/R);

c=Cpgas*T(n)*pnew*Vvoidnew(n)/2/R;

% a,b,c quadratic parameters for Tnew

else %adsorption

a=-MCp(n)-madsnew(n)*Cpgas;

b=dQ(n)+MCp(n)*T(n)-Cvgas/R*(pnew*Vvoidnew(n)-p*Vvoid(n))...

+mads(n)*(Cpgas*T(n)-p/rhoads-delH/MWamm)+...

madsnew(n)*(pnew/rhoads+delH/MWamm)...

-Cpgas*Te*(mads(n)-madsnew(n)+p*Vvoid(n)/R/T(n));

c=Cpgas*Te*pnew*Vvoidnew(n)/R;

end

%a, b, c % Check signs to get correct root.

Tnew(n)=(-b-sqrt(b*b-4*a*c))/2/a; % Positive root taken

if Tnew(n)==0;stop;end

mgasnew(n)=pnew*Vvoidnew(n)/R/Tnew(n); % New gas mass kg

dmout(n)=mads(n)-madsnew(n)+mgas(n)-mgasnew(n)%mass of gas expelled kg

dmouthout(n)=dmout(n)*Cpgas*(T(n)+Tnew(n))/2; % Enthalpy flow out

end

mout=sum(dmout); % Total mass to vessel kg

hout=sum(dmouthout); % Total enthalpy flow to vessel.

R=ramms(pnew/1e5,T(n)-273); % Accurate ammonia gas constant

R=RNH3;

Tenew=(dQe+me*Cvgas*Te+hout)/Cvgas/(me+mout); % New vessel temperature K

menew=pnew*Ve/R/Tenew; % New gas mass in vessel kg

F=menew-me-mout; % Mass imbalance kg

end