Hardware Approach to Mitigate the Effects of Module Mismatch in a Grid-connected Photovoltaic System: A Review

Abstract

1. Introduction

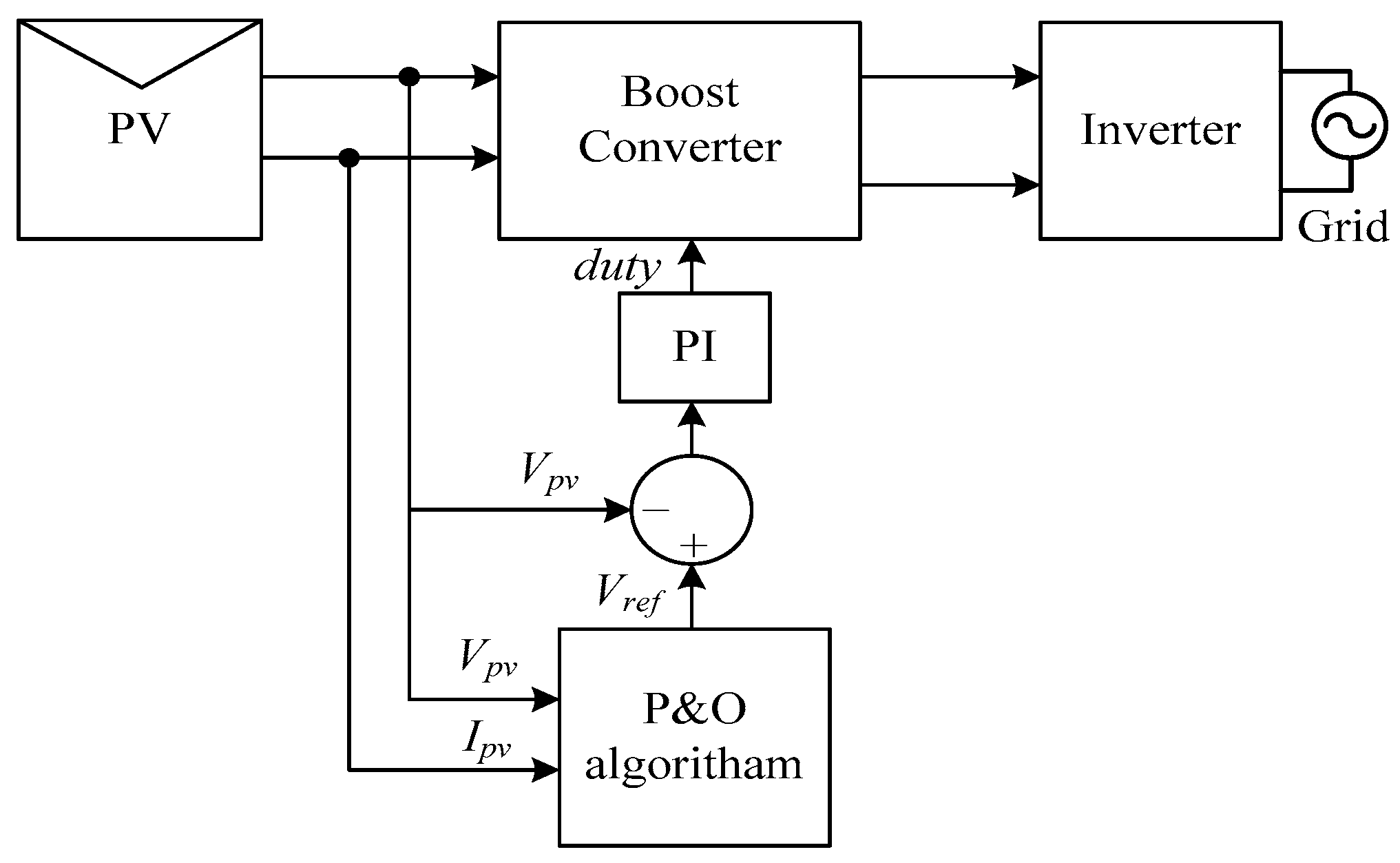

2. Maximum Power Point Tracker (MPPT)

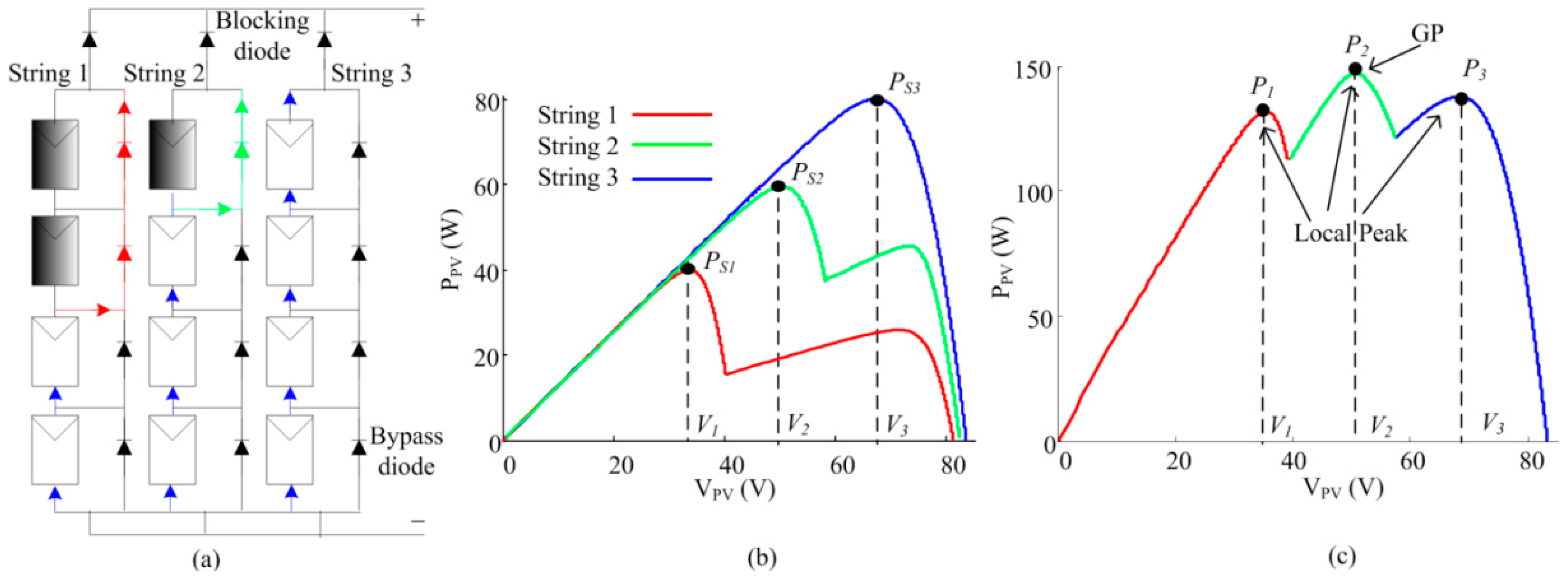

2.1. Bypass Diode and Multiple-peak P-V Curve

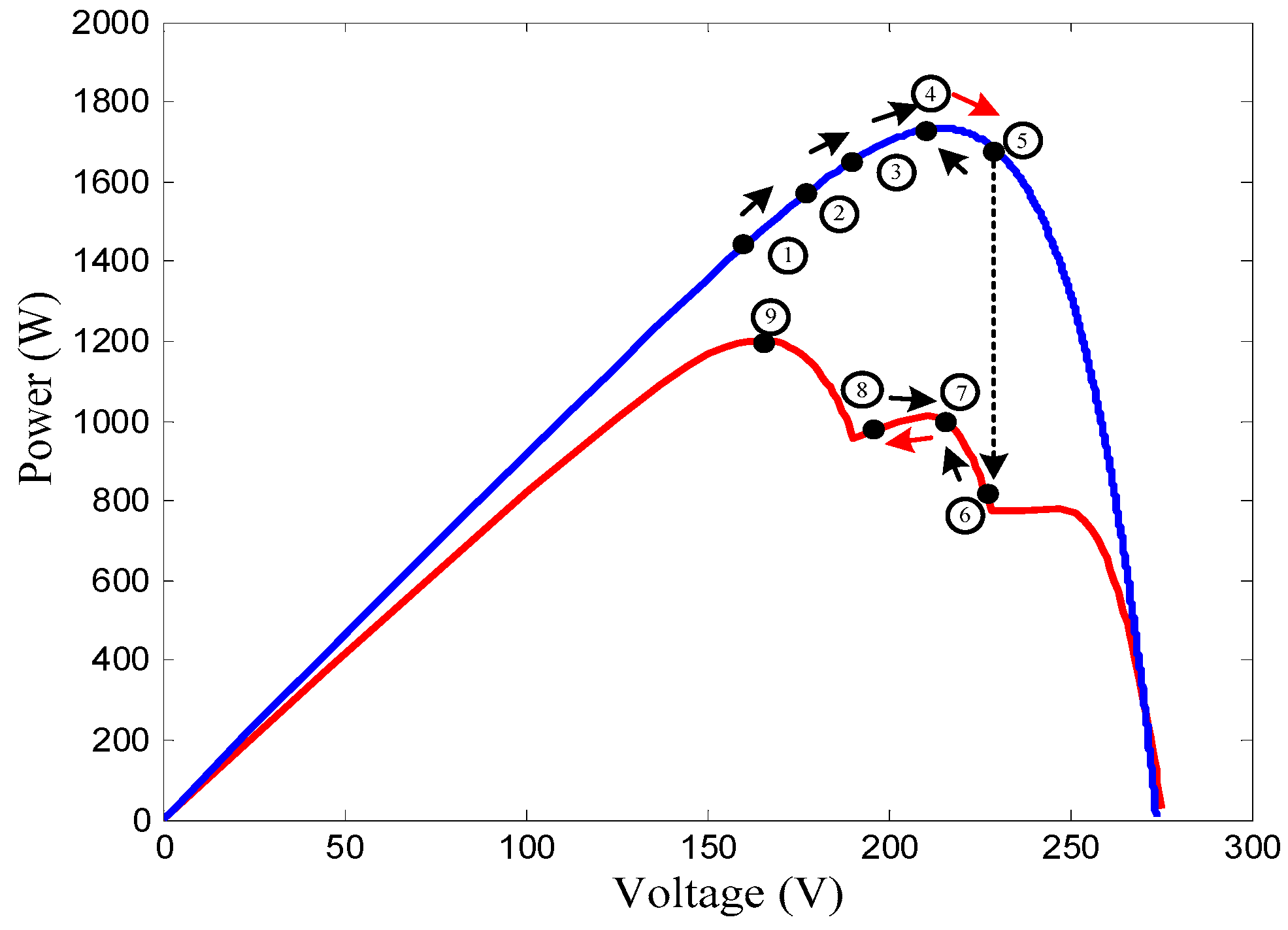

2.2. Failure of the MPTT to Track the Global Peak

2.3. Advanced Software Search Methods

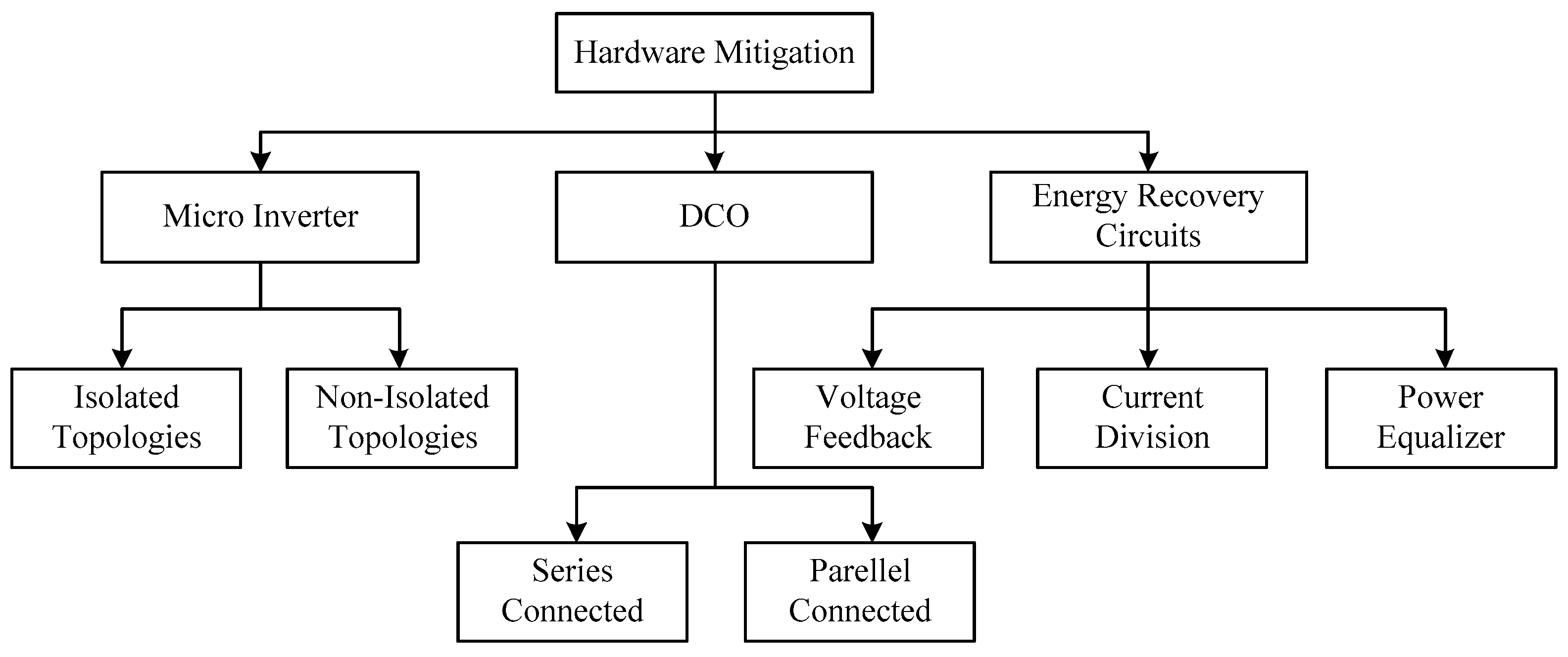

3. Mitigation Using Hardware Solutions

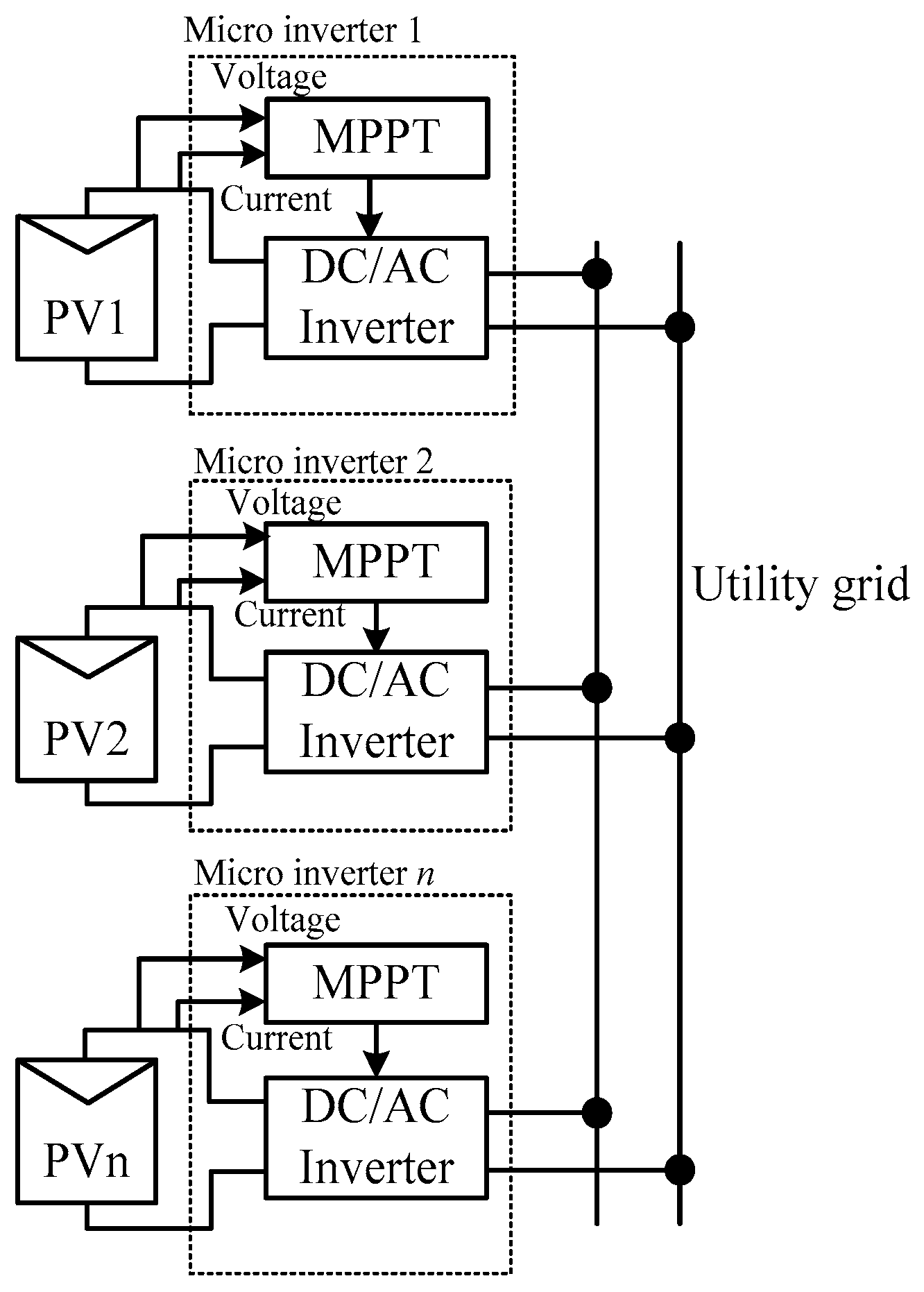

4. Micro Inverters

4.1. Architecture of Micro Inverters

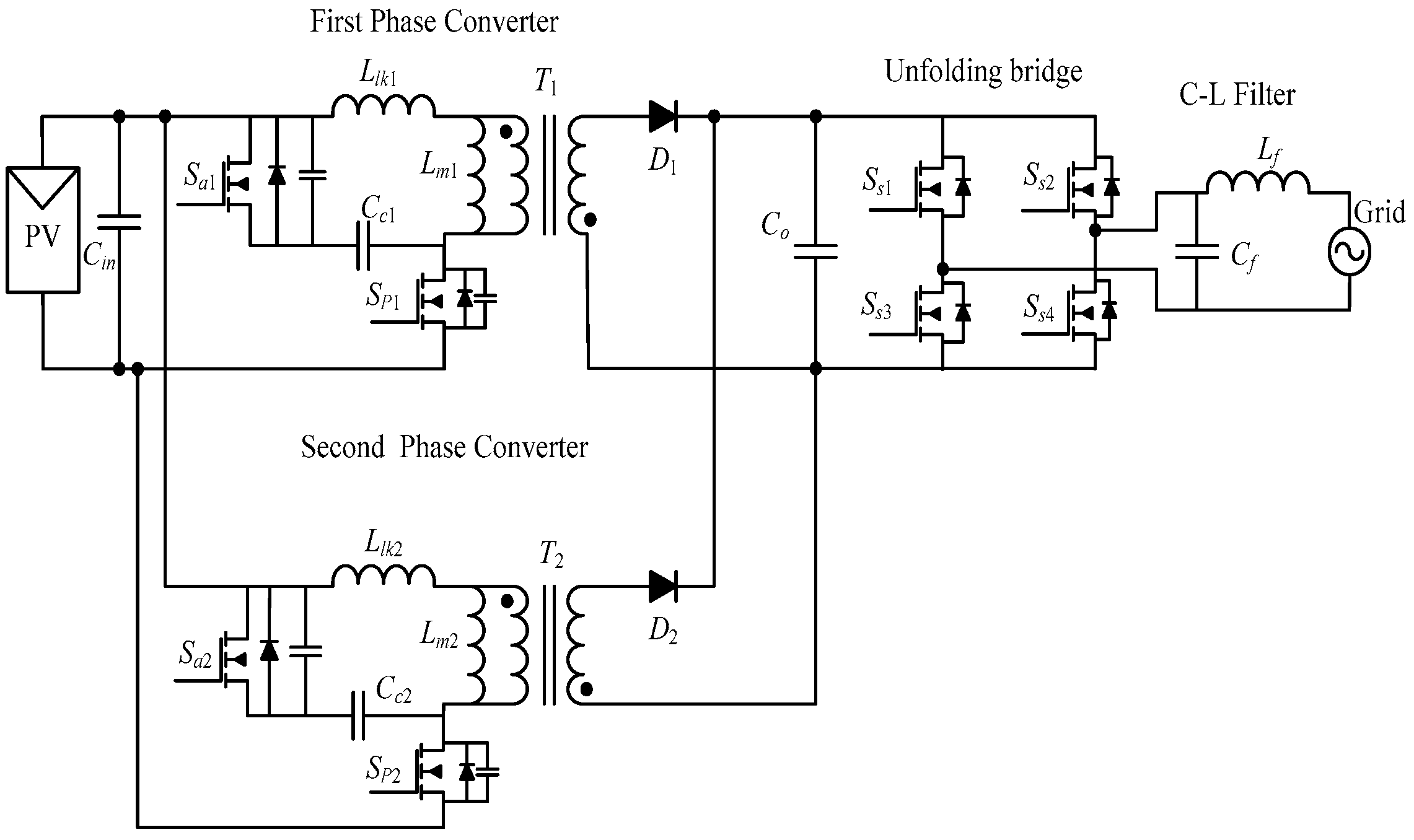

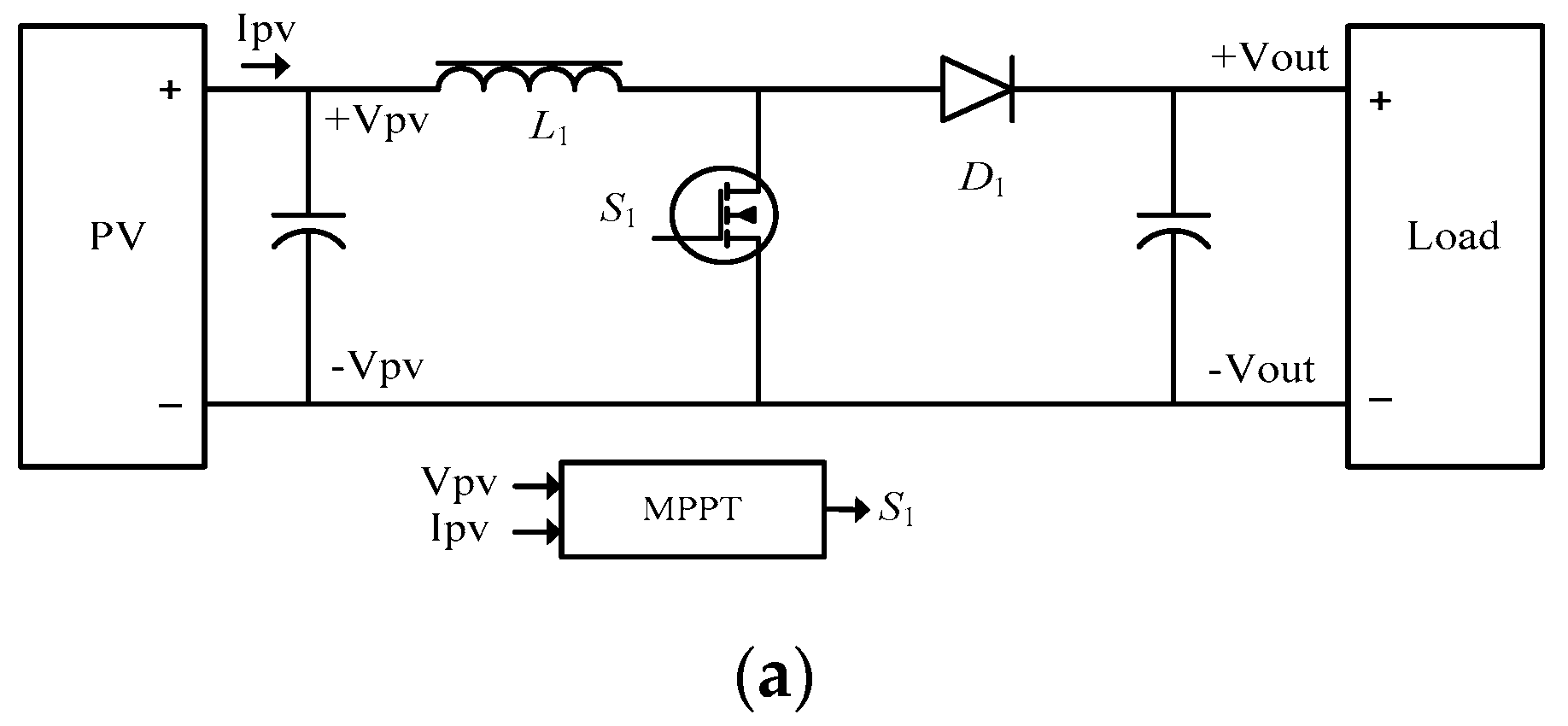

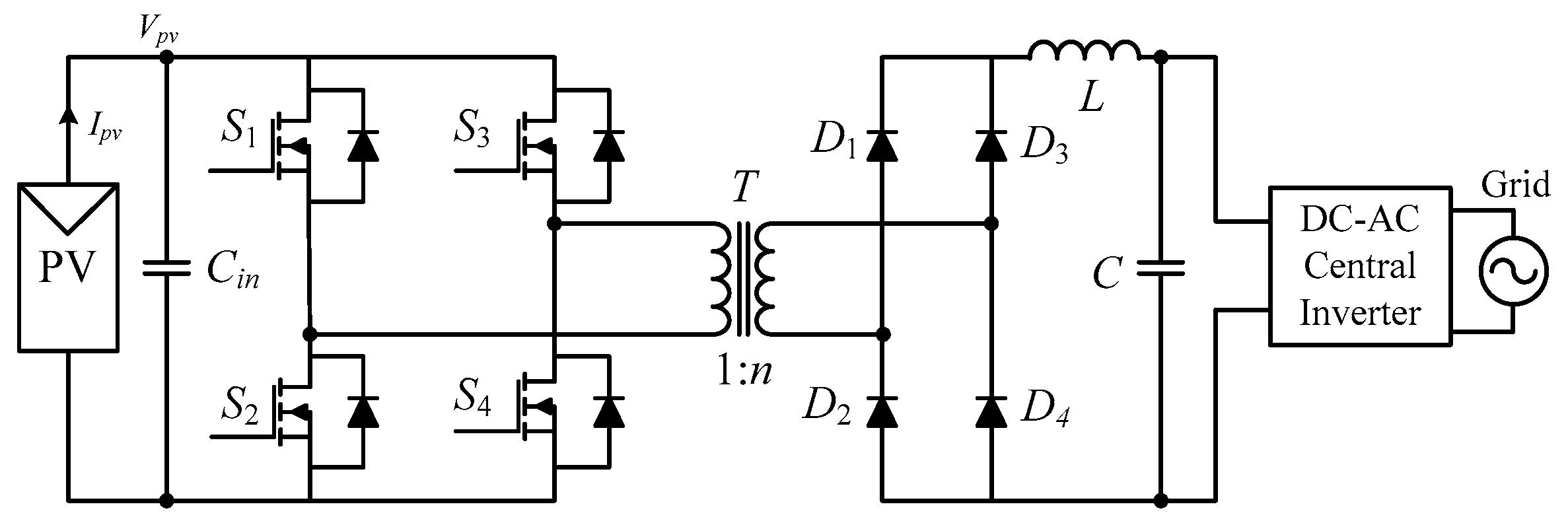

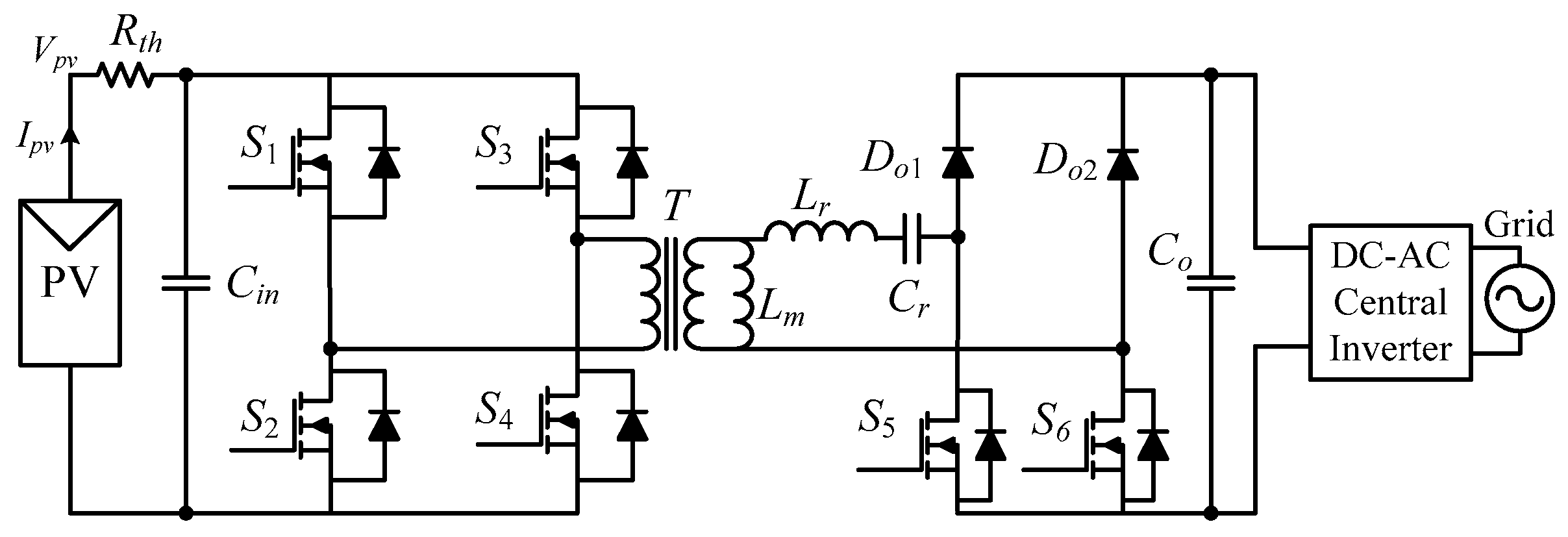

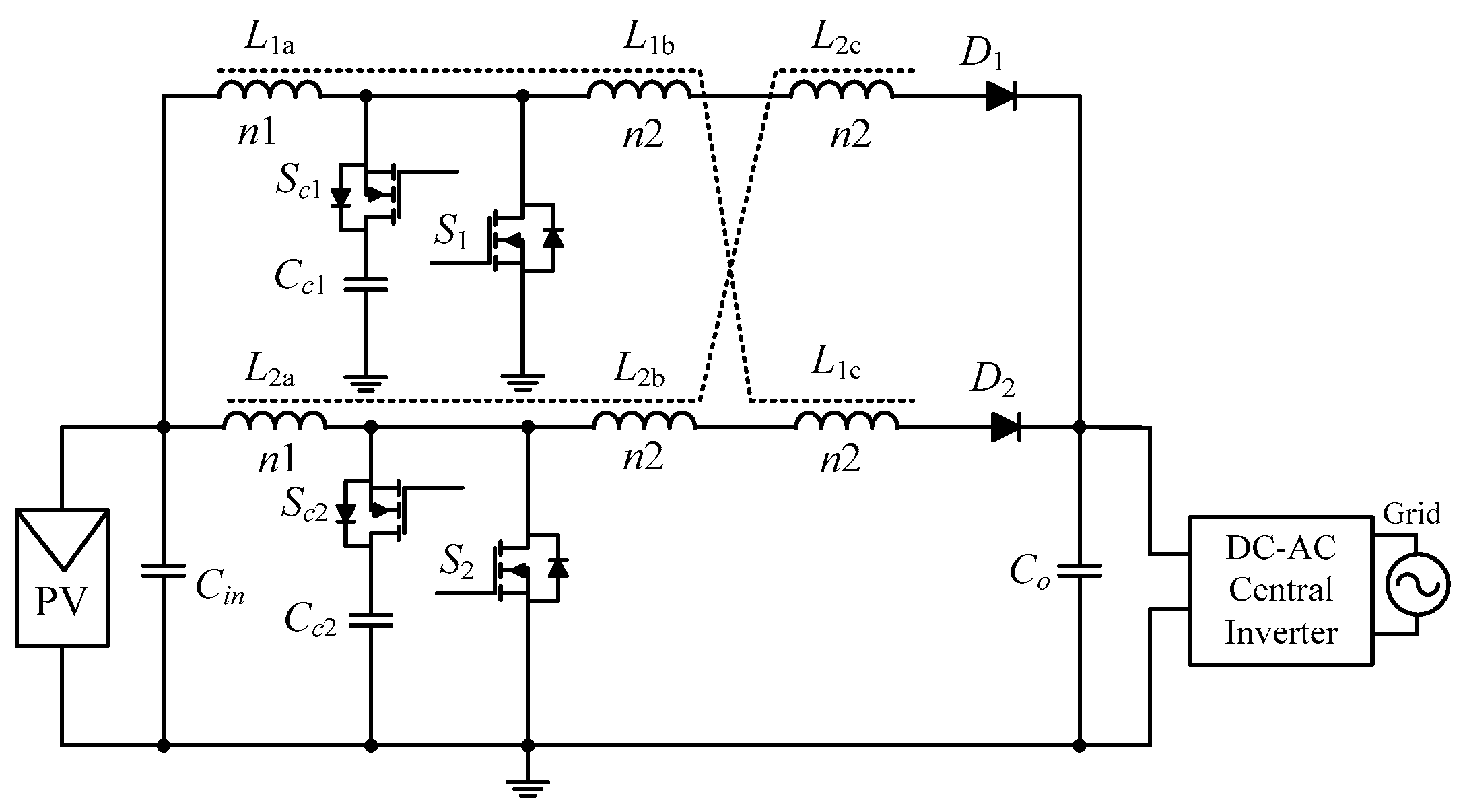

4.1.1. Isolated Topologies

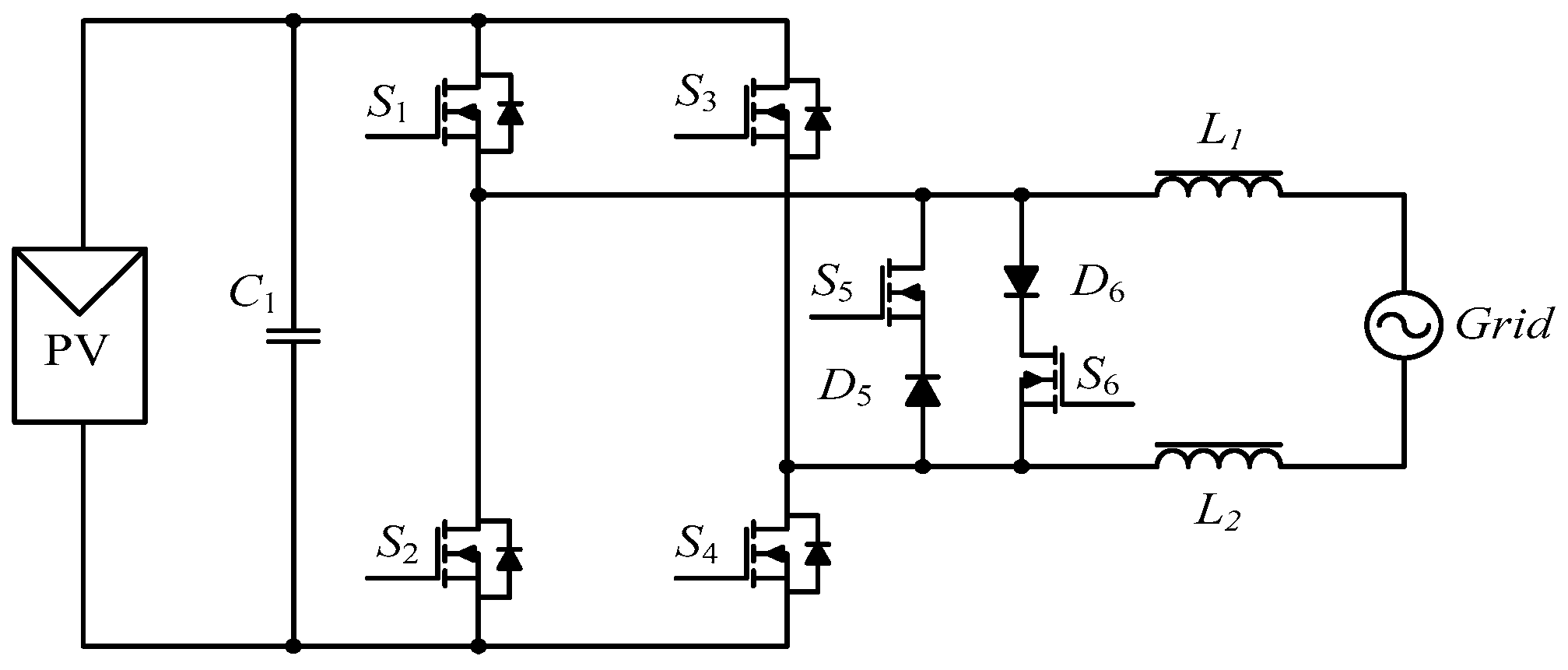

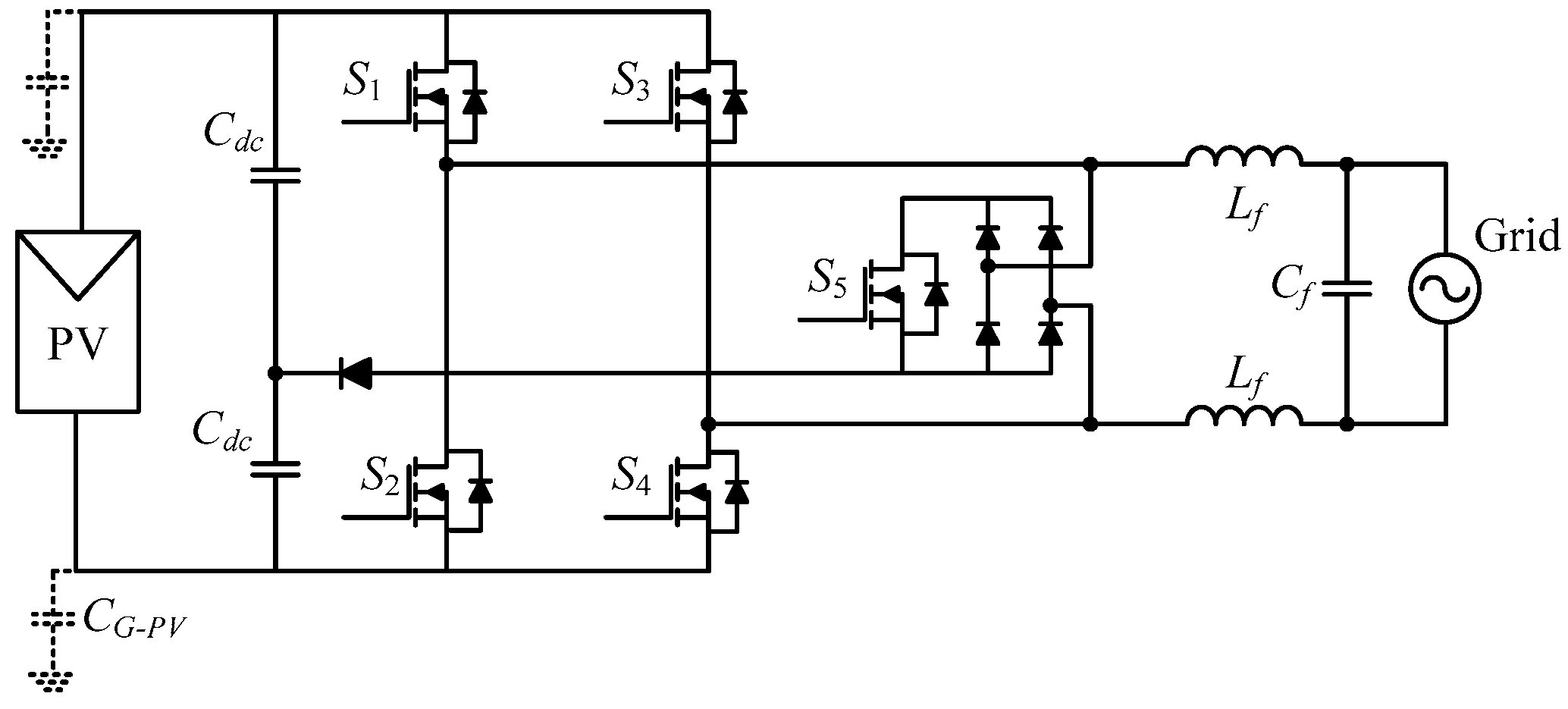

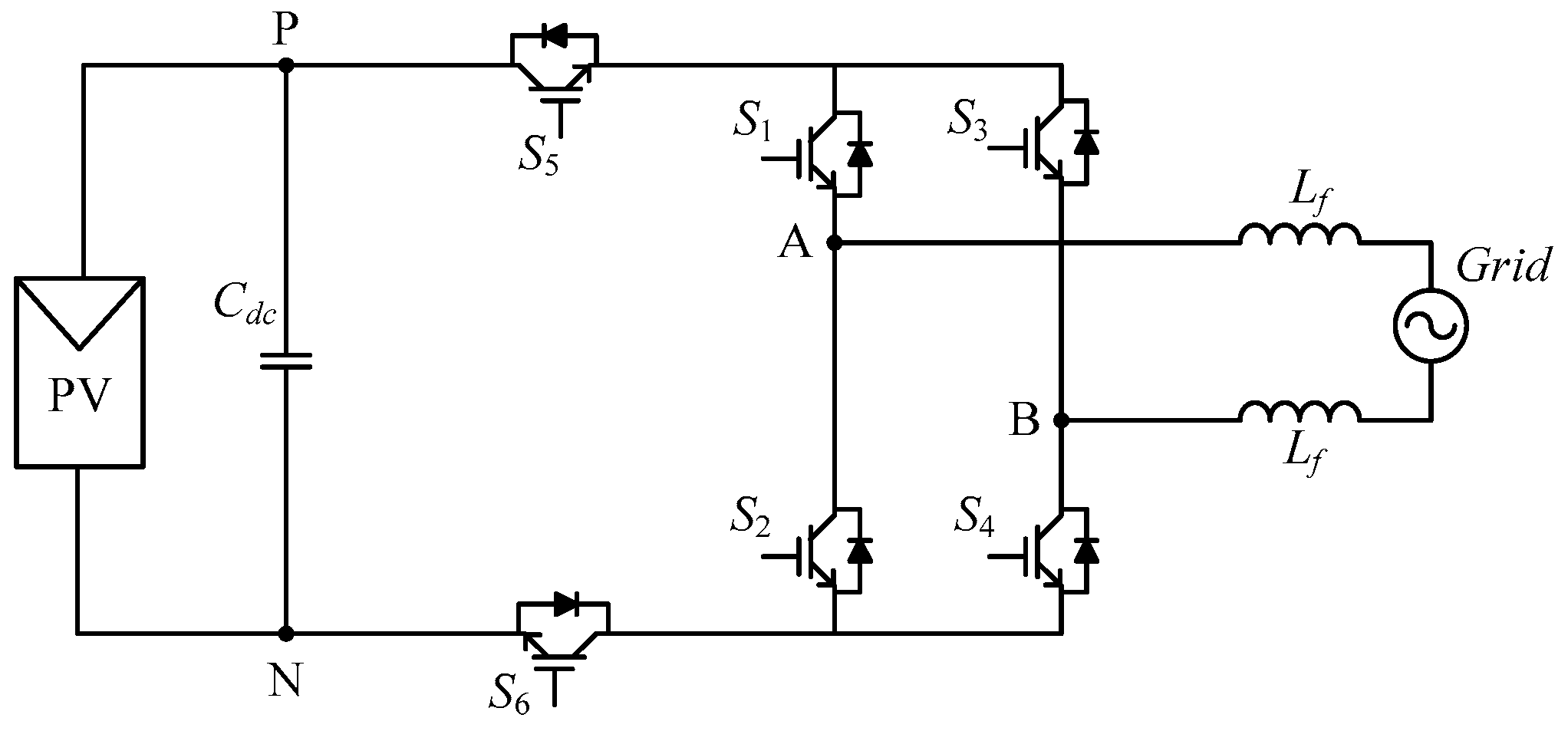

4.1.2. Non-isolated Topology

4.2. Drawbacks of Micro Inverters

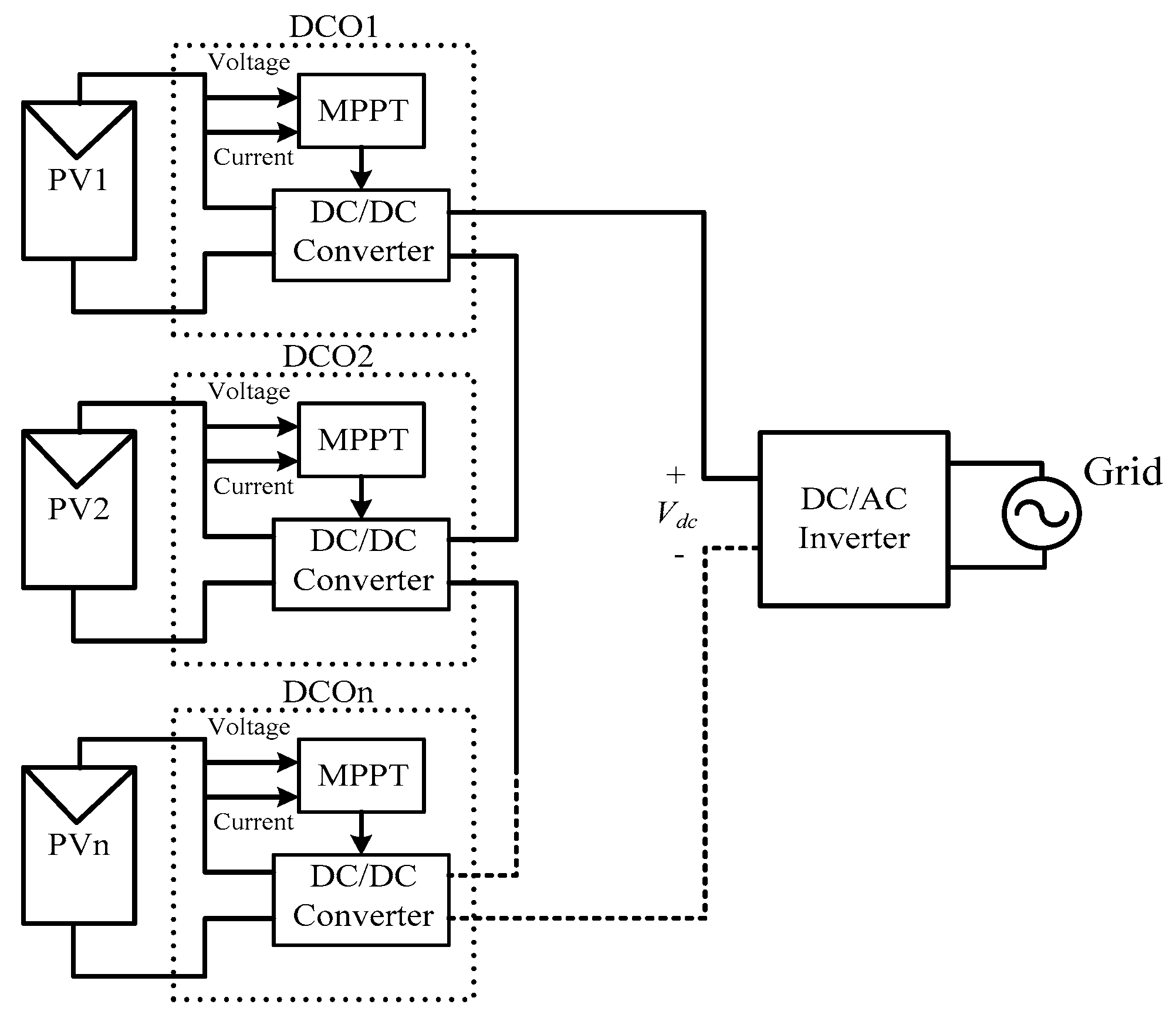

5. DC Power Optimizers (DCOs)

5.1. Architecture of DCO

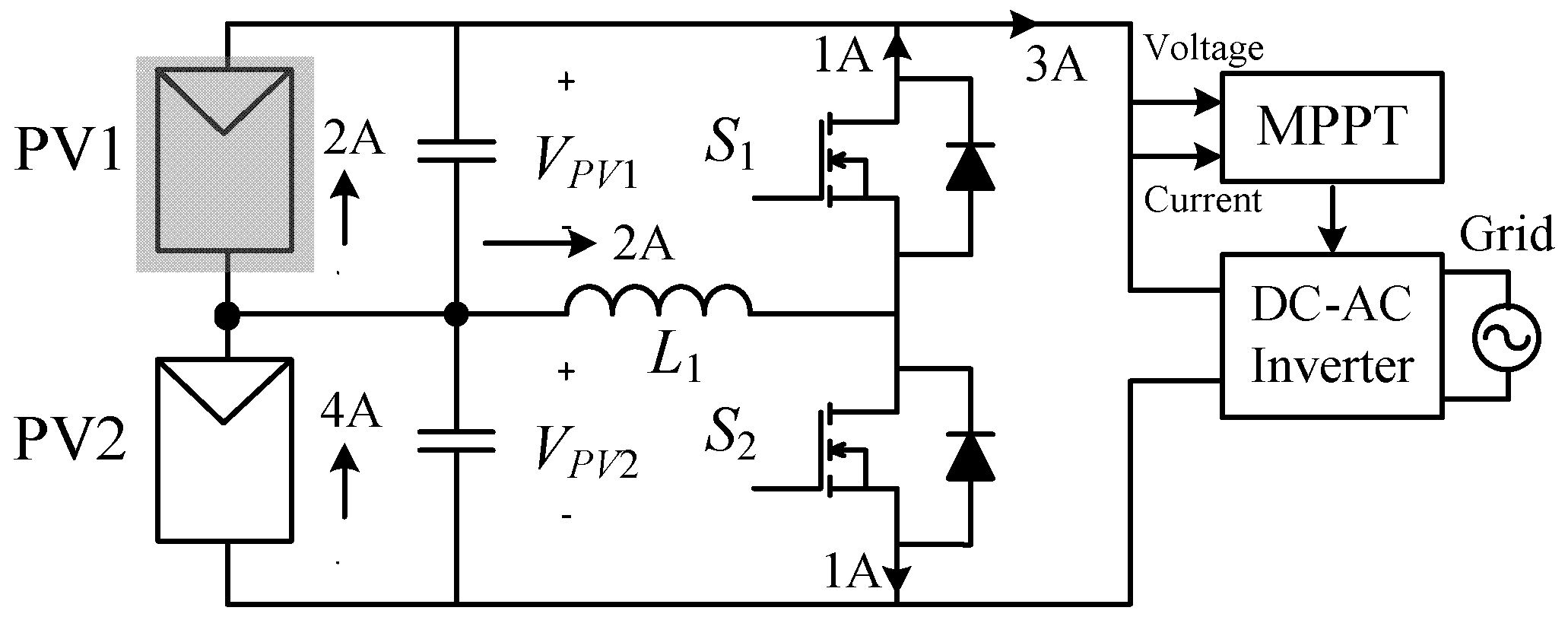

5.1.1. Series-connected DCOs

5.1.2. Parallel-connected DCOs

6. Energy Recovery Circuits

6.1. Voltage Feedback Technique

6.2. Current Diversion Technique

6.3. Power Equalizer Technique

7. Comparative Evaluation

7.1. General Assessment

7.1.1. Performance Evaluation

7.1.2. Component Count

7.2. Efficiency

7.3. Component Lifetime

7.4. Practical Aspects for Consideration

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Solangi, K.H.; Islam, M.R.; Saidur, R.; Rahim, N.A.; Fayaz, H. A review on global solar energy policy. Renew. Sustain. Energy Rev. 2011, 15, 2149–2163. [Google Scholar] [CrossRef]

- REN21. Renewables 2016 Global Status Report; Renewables Now: Paris, France, 2016. [Google Scholar]

- Maki, A.; Valkealahti, S. Power Losses in Long String and Parallel-Connected Short Strings of Series-Connected Silicon-Based Photovoltaic Modules Due to Partial Shading Conditions. IEEE Trans. Energy Convers. 2012, 27, 173–183. [Google Scholar] [CrossRef]

- Myrzik, J.M.A.; Calais, M. String and module integrated inverters for single-phase grid connected photovoltaic systems—A review. IEEE Bologna Power Tech Conf. Proc. 2003, 2, 430–437. [Google Scholar]

- Choi, U.M.; Blaabjerg, F.; Lee, K.B. Control Strategy of Two Capacitor Voltages for Separate MPPTs in Photovoltaic Systems Using Neutral-Point-Clamped Inverters. IEEE Trans. Ind. Appl. 2015, 51, 3295–3303. [Google Scholar] [CrossRef]

- Tsang, K.M.; Chan, W.L. Maximum power point tracking for PV systems under partial shading conditions using current sweeping. Energy Convers. Manag. 2015, 93, 249–258. [Google Scholar] [CrossRef]

- Kheldoun, A.; Bradai, R.; Boukenoui, R.; Mellit, A. A new Golden Section method-based maximum power point tracking algorithm for photovoltaic systems. Energy Convers. Manag. 2016, 111, 125–136. [Google Scholar] [CrossRef]

- Jazayeri, M.; Jazayeri, K.; Uysal, S. Adaptive photovoltaic array reconfiguration based on real cloud patterns to mitigate effects of non-uniform spatial irradiance profiles. Sol. Energy 2017, 155, 506–516. [Google Scholar] [CrossRef]

- Mamun, M.A.A.; Hasanuzzaman, M.; Selvaraj, J. Experimental investigation of the effect of partial shading on photovoltaic performance. IET Renew. Power Gener. 2017, 11, 912–921. [Google Scholar] [CrossRef]

- Silverman, T.J.; Mansfield, L.; Repins, I.; Kurtz, S. Damage in Monolithic Thin-Film Photovoltaic Modules Due to Partial Shade. IEEE J. Photovolt. 2016, 6, 1333–1338. [Google Scholar] [CrossRef]

- Kim, K.A.; Seo, G.S.; Cho, B.H.; Krein, P.T. Photovoltaic Hot-Spot Detection for Solar Panel Substrings Using AC Parameter Characterization. IEEE Trans. Power Electron. 2016, 31, 1121–1130. [Google Scholar] [CrossRef]

- Imtiaz, A.M.; Khan, F.H.; Kamath, H. All-in-One Photovoltaic Power System: Features and Challenges Involved in Cell-Level Power Conversion in ac Solar Cells. IEEE Ind. Appl. Mag. 2013, 19, 12–23. [Google Scholar] [CrossRef]

- Jantharamin, N. Optimal Control and Management of Photovoltaic Power Generation Systems. Ph.D. Thesis, University of Leeds, Leeds, UK, 2008. [Google Scholar]

- Mohammedi, A.; Mezzai, N.; Rekioua, D.; Rekioua, T. Impact of shadow on the performances of a domestic photovoltaic pumping system incorporating an MPPT control: A case study in Bejaia, North Algeria. Energy Convers. Manag. 2014, 84, 20–29. [Google Scholar] [CrossRef]

- Ishaque, K.; Salam, Z. A Deterministic Particle Swarm Optimization Maximum Power Point Tracker for Photovoltaic System under Partial Shading Condition. IEEE Trans. Ind. Electron. 2013, 60, 3195–3206. [Google Scholar] [CrossRef]

- Ghanbari, T. Hot spot detection and prevention using a simple method in photovoltaic panels. IET Gener. Transm. Distrib. 2017, 11, 883–890. [Google Scholar] [CrossRef]

- Ahmed, J.; Salam, Z. An Enhanced Adaptive P&O MPPT for Fast and Efficient Tracking Under Varying Environmental Conditions. IEEE Trans. Sustain. Energy 2018, 9, 1487–1496. [Google Scholar]

- Ishaque, K.; Salam, Z.; Amjad, M.; Mekhilef, S. An Improved Particle Swarm Optimization (PSO) Based MPPT for PV With Reduced Steady-State Oscillation. IEEE Trans. Power Electron. 2012, 27, 3627–3638. [Google Scholar] [CrossRef]

- Adly, M.; Besheer, A.H. An optimized fuzzy maximum power point tracker for stand alone photovoltaic systems: Ant colony approach. In Proceedings of the 7th IEEE Conference on Industrial Electronics and Applications (ICIEA), Singapore, 18–20 July 2012; pp. 113–119. [Google Scholar]

- Guruambeth, R.; Ramabadran, R. Fuzzy logic controller for partial shaded photovoltaic array fed modular multilevel converter. IET Power Electron. 2016, 9, 1694–1702. [Google Scholar] [CrossRef]

- Haibing, H.; Harb, S.; Kutkut, N.; Batarseh, I.; Shen, Z.J. A Review of Power Decoupling Techniques for Microinverters With Three Different Decoupling Capacitor Locations in PV Systems. IEEE Trans. Power Electron. 2013, 28, 2711–2726. [Google Scholar]

- Ankit; Sahoo, S.K.; Sukchai, S.; Yanine, F.F. Review and comparative study of single-stage inverters for a PV system. Renew. Sustain. Energy Rev. 2018, 91, 962–986. [Google Scholar] [CrossRef]

- Wang, F.; Feng, X.; Zhang, L.; Du, Y.; Su, J. Impedance-based analysis of grid harmonic interactions between aggregated flyback micro-inverters and the grid. IET Power Electron. 2018, 11, 453–459. [Google Scholar] [CrossRef]

- Patrao, I.; Garcera, G.; Figueres, E.; Gonzalez-Medina, R. Grid-tie inverter topology with maximum power extraction from two photovoltaic arrays. IET Renew. Power Gener. 2014, 8, 638–648. [Google Scholar] [CrossRef]

- Niazi, K.A.K.; Yang, Y.; Sera, D. Review of mismatch mitigation techniques for PV modules. IET Renew. Power Gener. 2019, 13, 2035–2050. [Google Scholar] [CrossRef]

- Mamarelis, E.; Petrone, G.; Spagnuolo, G. A two-steps algorithm improving the P&O steady state MPPT efficiency. Appl. Energy 2014, 113, 414–421. [Google Scholar]

- Ahmed, J.; Salam, Z. An improved perturb and observe (P&O) maximum power point tracking (MPPT) algorithm for higher efficiency. Appl. Energy 2015, 150, 97–108. [Google Scholar]

- Ragonese, D.; Ragusa, M. Designing with the SPV1020, an Interleaved Boost Converter with MPPT Algoritham. Available online: www.st.com (accessed on 10 October 2019).

- Ishaque, K. Deterministic Particle Swarm Optimization Method for Maximum Power Point Tracking of Photovoltaic System. Ph.D. Thesis, Universiti Teknologi Malaysia, Skudai, Malaysia, 2012. [Google Scholar]

- Jordan, D.; Kurtz, S. 3—Photovoltaic Module Stability and Reliability. In The Performance of Photovoltaic (PV) Systems; Pearsall, N., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 71–101. [Google Scholar]

- Meyer, E.L.; Dyk, E.E. Assessing the reliability and degradation of photovoltaic module performance parameters. IEEE Trans. Reliab. 2004, 53, 83–92. [Google Scholar] [CrossRef]

- Shimizu, T.; Hashimoto, O.; Kimura, G. A novel high-performance utility-interactive photovoltaic inverter system. IEEE Trans. Power Electron. 2003, 18, 704–711. [Google Scholar] [CrossRef]

- Shimizu, T.; Hirakata, M.; Kamezawa, T.; Watanabe, H. Generation control circuit for photovoltaic modules. IEEE Trans. Power Electron. 2001, 16, 293–300. [Google Scholar] [CrossRef]

- Ramli, M.; Salam, Z. A Simple Energy Recovery Scheme for to Harvest the Energy from Shaded Photovoltaic Modules During Partial Shading. IEEE Trans. Power Electron. 2014, 29, 6458–6471. [Google Scholar] [CrossRef]

- Guan-Chyun, H.; Hung, I.H.; Cheng-Yuan, T.; Chi-Hao, W. Photovoltaic Power-Increment-Aided Incremental-Conductance MPPT With Two-Phased Tracking. IEEE Trans. Power Electron. 2013, 28, 2895–2911. [Google Scholar]

- Safari, A.; Mekhilef, S. Simulation and Hardware Implementation of Incremental Conductance MPPT with Direct Control Method Using Cuk Converter. IEEE Trans. Ind. Electron. 2011, 58, 1154–1161. [Google Scholar] [CrossRef]

- Mohanty, S.; Subudhi, B.; Ray, P.K. A New MPPT Design Using Grey Wolf Optimization Technique for Photovoltaic System Under Partial Shading Conditions. IEEE Trans. Sustain. Energy 2016, 7, 181–188. [Google Scholar] [CrossRef]

- Daraban, S.; Petreus, D.; Morel, C. A novel MPPT (maximum power point tracking) algorithm based on a modified genetic algorithm specialized on tracking the global maximum power point in photovoltaic systems affected by partial shading. Energy 2014, 74, 374–388. [Google Scholar] [CrossRef]

- Koad, R.B.A.; Zobaa, A.F.; El-Shahat, A. A Novel MPPT Algorithm Based on Particle Swarm Optimization for Photovoltaic Systems. IEEE Trans. Sustain. Energy 2017, 8, 468–476. [Google Scholar] [CrossRef]

- Roy, J.; Ayyanar, R. GaN based transformer-less microinverter with coupled inductor interleaved boost and half bridge voltage swing inverter. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; pp. 381–386. [Google Scholar]

- Kale, R.; Thale, S.; Agarwal, V. Design and implementation of a solar PV panel integrated inverter with multi-mode operation capability. In Proceedings of the IEEE 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; pp. 2959–2964. [Google Scholar]

- Kjaer, S.B.; Pedersen, J.K.; Blaabjerg, F. A review of single-phase grid-connected inverters for photovoltaic modules. IEEE Trans. Ind. Appl. 2005, 41, 1292–1306. [Google Scholar] [CrossRef]

- Sukesh, N.; Pahlevaninezhad, M.; Jain, P.K. Analysis and Implementation of a Single-Stage Flyback PV Microinverter With Soft Switching. IEEE Trans. Ind. Electron. 2014, 61, 1819–1833. [Google Scholar] [CrossRef]

- Rana, A.S.; Nasir, M.; Khan, H.A. String level optimisation on grid-tied solar PV systems to reduce partial shading loss. IET Renew. Power Gener. 2018, 12, 143–148. [Google Scholar] [CrossRef]

- Rana, A.S.; Khan, H.A. String level optimization on grid-tied solar PV systems for minimizing soft shading power loss. IET Renew. Power Gener. 2017, 12, 143–148. [Google Scholar] [CrossRef]

- Keshani, M.; Adib, E.; Farzanehfard, H. Micro-inverter based on single-ended primary-inductance converter topology with an active clamp power decoupling. IET Power Electron. 2018, 11, 73–81. [Google Scholar] [CrossRef]

- Zhao, B.; Abramovitz, A. Single stage high gain charge pump assisted micro-inverter. Sol. Energy 2016, 139, 81–84. [Google Scholar] [CrossRef]

- Elanchezhian, P.; Chinnaiyan, V.K. Modeling and Simulation of High-Efficiency Interleaved Flyback Micro-inverter For Photovoltaic Applications. Mater. Today Proc. 2017, 4, 10417–10421. [Google Scholar] [CrossRef]

- Famoso, F.; Lanzafame, R.; Maenza, S.; Scandura, P.F. Performance Comparison between Micro-inverter and String-inverter Photovoltaic Systems. Energy Procedia 2015, 81, 526–539. [Google Scholar] [CrossRef]

- Edwin, F.F.; Xiao, W.; Khadkikar, V. Dynamic modeling and control of interleaved flyback module-integrated converter for PV power applications. IEEE Trans. Ind. Electron. 2014, 61, 1377–1388. [Google Scholar] [CrossRef]

- Xiao, W.; Ozog, N.; Dunford, W.G. Topology study of photovoltaic interface for maximum power point tracking. IEEE Trans. Ind. Electron. 2007, 54, 1696–1704. [Google Scholar] [CrossRef]

- Osborne, M. LG Launches Its First AC Module with Integrated Microinverter to Simplify Installations. Available online: https://www.pv-tech.org (accessed on 27 July 2017).

- McCabe, J. PV Micro Inverters and Optimizers: Not Just for Lazy Designers. Available online: https://www.renewableenergyworld.com/2011/06/01/pv-micro-inverters-and-optimizers-not-just-for-lazy-designers/#gref (accessed on 10 October 2019).

- Hasan, R.; Mekhilef, S.; Seyedmahmoudian, M.; Horan, B. Grid-connected isolated PV microinverters: A review. Renew. Sustain. Energy Rev. 2017, 67, 1065–1080. [Google Scholar] [CrossRef]

- Kouro, S.; Leon, J.I.; Vinnikov, D.; Franquelo, L.G. Grid-connected photovoltaic systems: An overview of recent research and emerging PV converter technology. IEEE Ind. Electron. Mag. 2015, 9, 47–61. [Google Scholar] [CrossRef]

- Çelik, Ö.; Teke, A.; Tan, A. Overview of micro-inverters as a challenging technology in photovoltaic applications. Renew. Sustain. Energy Rev. 2018, 82, 3191–3206. [Google Scholar] [CrossRef]

- Woei-Luen, C.; Chung-Ting, T. Optimal Balancing Control for Tracking Theoretical Global MPP of Series PV Modules Subject to Partial Shading. IEEE Trans. Ind. Electron. 2015, 62, 4837–4848. [Google Scholar]

- Shimizu, T.; Wada, K.; Nakamura, N. Flyback-type single-phase utility interactive inverter with power pulsation decoupling on the DC input for an AC photovoltaic module system. IEEE Trans. Power Electron. 2006, 21, 1264–1272. [Google Scholar] [CrossRef]

- Hu, H.; Harb, S.; Fang, X.; Zhang, D.; Zhang, Q.; Shen, Z.J.; Batarseh, I. A three-port flyback for PV microinverter applications with power pulsation decoupling capability. IEEE Trans. Power Electron. 2012, 27, 3953–3964. [Google Scholar] [CrossRef]

- Cha, W.-J.; Kwon, J.-M.; Kwon, B.-H. Highly efficient step-up dc–dc converter for photovoltaic micro-inverter. Sol. Energy 2016, 135, 14–21. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Ji, Y.-H.; Kim, J.-G.; Jung, Y.-C.; Won, C.-Y. A new control strategy for improving weighted efficiency in photovoltaic AC module-type interleaved flyback inverters. IEEE Trans. Power Electron. 2013, 28, 2688–2699. [Google Scholar] [CrossRef]

- Khan, A.; Ben-Brahim, L.; Gastli, A.; Benammar, M. Review and simulation of leakage current in transformerless microinverters for PV applications. Renew. Sustain. Energy Rev. 2017, 74, 1240–1256. [Google Scholar] [CrossRef]

- Ahmad, Z.; Singh, S.N. Improved modulation strategy for single phase grid connected transformerless PV inverter topologies with reactive power generation capability. Sol. Energy 2018, 163, 356–375. [Google Scholar] [CrossRef]

- Trujillo, C.L.; Santamaría, F.; Gaona, E.E. Modeling and testing of two-stage grid-connected photovoltaic micro-inverters. Renew. Energy 2016, 99, 533–542. [Google Scholar] [CrossRef]

- Schmidt, H.; Christoph, S.; Ketterer, J. Current Inverter for Direct/Alternating Currents, has Direct and Alternating Connections with an Intermediate Power Store, a Bridge Circuit, Rectifier Diodes and a Inductive Choke. Ger. Pat. DE10 2003, 221, A1. [Google Scholar]

- Chen, B.; Gu, B.; Zhang, L.; Zahid, Z.U.; Lai, J.-S.J.; Liao, Z.; Hao, R. A high-efficiency MOSFET transformerless inverter for nonisolated microinverter applications. IEEE Trans. Power Electron. 2015, 30, 3610–3622. [Google Scholar] [CrossRef]

- Kranzer, D.; Wilhelm, C.; Reiners, F.; Burger, B. In Application of normally-off SiC-JFETs in photovoltaic inverters. In Proceedings of the 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–6. [Google Scholar]

- Kerekes, T.; Teodorescu, R.; Rodríguez, P.; Vázquez, G.; Aldabas, E. A new high-efficiency single-phase transformerless PV inverter topology. IEEE Trans. Ind. Electron. 2011, 58, 184–191. [Google Scholar] [CrossRef]

- Yang, B.; Li, W.; Gu, Y.; Cui, W.; He, X. Improved transformerless inverter with common-mode leakage current elimination for a photovoltaic grid-connected power system. IEEE Trans. Power Electron. 2012, 27, 752–762. [Google Scholar] [CrossRef]

- Walker, G.R.; Sernia, P.C. Cascaded DC-DC converter connection of photovoltaic modules. IEEE Trans. Power Electron. 2004, 19, 1130–1139. [Google Scholar] [CrossRef]

- Singh, S.N. Selection of non-isolated DC-DC converters for solar photovoltaic system. Renew. Sustain. Energy Rev. 2017, 76, 1230–1247. [Google Scholar]

- Walker, G.R.; Pierce, J.C. PhotoVoltaic DC-DC Module Integrated Converter for Novel Cascaded and Bypass Grid Connection Topologies; Design and Optimisation. In Proceedings of the 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006; pp. 1–7. [Google Scholar]

- Hossain, M.Z.; Rahim, N.A.; Selvaraj, J.A.L. Recent progress and development on power DC-DC converter topology, control, design and applications: A review. Renew. Sustain. Energy Rev. 2018, 81, 205–230. [Google Scholar] [CrossRef]

- Tarzamni, H.; Babaei, E.; Gharehkoushan, A.Z.; Sabahi, M. Interleaved full ZVZCS DC-DC boost converter: Analysis, design, reliability evaluations and experimental results. IET Power Electron. 2017, 10, 835–845. [Google Scholar] [CrossRef]

- Andrade, A.M.S.S.; Schuch, L.; Martins, M.L.d.S. High Step-Up PV Module Integrated Converter for PV Energy Harvest in FREEDM Systems. IEEE Trans. Ind. Appl. 2017, 53, 1138–1148. [Google Scholar] [CrossRef]

- Saadat, P.; Abbaszadeh, K. A Single-Switch High Step-Up DC-DC Converter Based on Quadratic Boost. IEEE Trans. Ind. Electron. 2016, 63, 7733–7742. [Google Scholar] [CrossRef]

- Sabzali, A.J.; Ismail, E.H.; Behbehani, H.M. High voltage step-up integrated double Boost–Sepic DC–DC converter for fuel-cell and photovoltaic applications. Renew. Energy 2015, 82, 44–53. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, L.; Born, R.; Lai, J.S. A High-Efficiency Hybrid Resonant Converter With Wide-Input Regulation for Photovoltaic Applications. IEEE Trans. Ind. Electron. 2017, 64, 3684–3695. [Google Scholar] [CrossRef]

- Yu, W.; York, B.; Lai, J.S. Inductorless forward-flyback soft-switching converter with dual constant on-time modulation for photovoltaic applications. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; pp. 3549–3555. [Google Scholar]

- Belhimer, S.; Haddadi, M.; Mellit, A. A novel hybrid boost converter with extended duty cycles range for tracking the maximum power point in photovoltaic system applications. Int. J. Hydrog. Energy 2018, 43, 6887–6898. [Google Scholar] [CrossRef]

- Mitra, L.; Rout, U.K. Performance analysis of a new high gain dc–dc converter interfaced with solar photovoltaic module. Renew. Energy Focus 2017, 19, 63–74. [Google Scholar] [CrossRef]

- Solaredge. SolarEdge Power Optimizer-Module Embedded Solution OPJ300-LV. Available online: www.solaredge.com (accessed on 10 October 2019).

- Tigo Energy Module Maximizer-EC(MM-ES) Data Sheet. Available online: www.tigoenergy.com (accessed on 10 October 2019).

- Po-Wa, L.; Lee, Y.S.; Cheng, D.K.W.; Xiu-Cheng, L. Steady-state analysis of an interleaved boost converter with coupled inductors. IEEE Trans. Ind. Electron. 2000, 47, 787–795. [Google Scholar] [CrossRef]

- Yong-Seong, R.; Young-Jin, M.; Jeongpyo, P.; Changsik, Y. A Two-Phase Interleaved Power Factor Correction Boost Converter with a Variation-Tolerant Phase Shifting Technique. IEEE Trans. Power Electron 2014, 29, 1032–1040. [Google Scholar] [CrossRef]

- Gow, J.A.; Manning, C.D. Development of a photovoltaic array model for use in power-electronics simulation studies. IEE Proc Electr. Power Appl. 1999, 146, 193–200. [Google Scholar] [CrossRef]

- Sakly, J.; Abdelghani, A.B.B.; Slama-Belkhodja, I.; Sammoud, H. Reconfigurable DC/DC Converter for Efficiency and Reliability Optimization. Trans. Emerg. Sel. Top. Power Electron. 2017, 5, 1216–1224. [Google Scholar] [CrossRef]

- Graditi, G.; Colonnese, D.; Femia, N. Efficiency and reliability comparison of DC-DC converters for single phase grid connected photovoltaic inverters. In Proceedings of the SPEEDAM 2010, Pisa, Italy, 14–16 June 2010; pp. 140–147. [Google Scholar]

- Ling, R.; Zhao, G.; Huang, Q. High step-up interleaved boost converter with low switch voltage stress. Electr. Power. Syst. Res. 2015, 128, 11–18. [Google Scholar] [CrossRef]

- Li, W.; He, X. ZVT interleaved boost converters for high-efficiency, high step-up DC-DC conversion. IET Electr. Power Appl. 2007, 1, 284–290. [Google Scholar] [CrossRef]

- Cao, Y.; Samavatian, V.; Kaskani, K.; Eshraghi, H. A Novel Nonisolated Ultra-High-Voltage-Gain DC-DC Converter with Low Voltage Stress. IEEE Trans. Ind. Electron. 2017, 64, 2809–2819. [Google Scholar] [CrossRef]

- Qi, Z.; Xiangdong, S.; Yanru, Z.; Mikihiko, M. A novel topology for solving the partial shading problem in photovoltaic power generation system. In Proceedings of the IEEE 6th International Power Electronics and Motion Control Conference, Wuhan, China, 17–20 May 2009; pp. 2130–2135. [Google Scholar]

- Villa, L.F.L.; Tien-Phu, H.; Crebier, J.C.; Raison, B. A Power Electronics Equalizer Application for Partially Shaded Photovoltaic Modules. IEEE Trans. Ind. Electron. 2013, 60, 1179–1190. [Google Scholar] [CrossRef]

- Technology, S.S. SUNNY BOY 240. Available online: www.SMA-Australia.com.au (accessed on 10 October 2019).

- Enphase. Enphase Microinverters The Enphase M215. Available online: https://enphase.com/e (accessed on 10 October 2019).

- Power-One, A. ABB Power-One MICRO-0.3HV-I-OUTD-US > 208/240 PV Aurora Micro Inverter—300 W AC, 75Voc, IMPPT. Available online: www.abb.com/solarinverters (accessed on 10 October 2019).

- Enecsys. Enecsys Micro Inverters SMI-S200W-72. Available online: www.enecsys.com (accessed on 10 October 2019).

- Installation and Operations Manual Siemens Microinverter Model SMIINV215R60XX. Available online: www.downloads.siemens.com (accessed on 10 October 2019).

- SolarEdge. Power Optimizer for North America P320/P340/P370/P400/P405/P505. Available online: www.solaredge.com (accessed on 10 October 2019).

- Huawei. Smart PV Optimizer: SUN2000-375W-USP0. Available online: https://solar.huawei.com (accessed on 10 October 2019).

- Alencon. The SPOT: Alencon’s Utility Scale DC-DC Optimizer. Available online: https://alectris.com (accessed on 10 October 2019).

| Product in Market | Advantages | Disadvantages |

|---|---|---|

| Micro-inverter SMA Sunny Boy 240 [94] Enphase M215 [95] Power One Aurora 240 [96] Enecsys SMI-S240W-72 [97] Siemens SMIINV21560XX [98] | 1. Modular: Expansion of system is flexible. 2. Simple connection to (plug and play) due to absence of a central inverter. 3. Low cost of low voltage AC switch gear. | 1. Connection to battery is not readily available. 2. Possible power clipping. 3. Startup (kicking) voltage is higher than DCO. |

| DCO Solar Edge P320 [99] Tigo Energy MM-ES50 [83] Huawei SUN200P-375W [100] Alencon SPOT 600 [101] | 1. DC storage can directly be connected via a charge controller. 2. Higher efficiency due to single stage. 3. Very low startup voltage. | 1. Risk of potential induce degradation (PID). 2. The entire string must shut down if one DCO device fails. |

| Energy Recovery No commercial product available | 1. Retrofit: option to remove it, if not required. 2. Can be turned off in the absence of partial shading. | 1. Low efficiency due to the absence of MPPT tracking for individual modules. |

| Micro Inverter | DCO | Energy Recovery Circuits | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Isolated | Non-Isolated | |||||||||||||

| Reference | [23] | [61] | [58] | [59] | [65] | [68] | [69] | [28] | [78] | [90] | [91] | [92] | [33] | [93] |

| Figure in text | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 15 | 17 | 18 | 19 | 21 | 22 | 23 |

| Power rating (W) | 300 | 200 | 100 | 100 | n/a | 500 | 1000 | 300 | 300 | 1000 | 1200 | 85 | 400 | 165 |

| DC link cap. (µF) | 1500 | 7300 | 40 | 46 | n/a | 250 | 940 | 10 | 95 | n/a | n/a | n/a | 220 | 220 |

| Power switches | 3 | 6 | 4 | 4 | 6 | 5 | 6 | 4 | 6 | 4 | 2 | 1 | 1 | 2 |

| Power diodes | 83 | 8 | 4 | 9 | 6 | 10 | 6 | 4 | 8 | 6 | 9 | 4 | 1 | 2 |

| Inductors | 1 | 3 | 1 | 1 | 2 | 2 | 2 | 4 | 1 | 6 | 1 | 1 | 1 | 0.25 |

| Capacitors | 2 | 3 | 3 | 3 | 1 | 3 | 1 | 2 | 2 | 4 | 6 | 1 | 1 | 1 |

| Transformers | 1 | 2 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 2 | 1 | 0 | 0 |

| Peak eff. (%) | 89.0 | 95.0 | 70.0 | 90.0 | 97.8 | 94.8 | 96.6 | 98.0 | 97.0 | 93.6 | 93.0 | n/a | 90.0 | n/a |

| Lifetime | Short | Short | Long | Long | n/a | Med | Short | Long | Long | n/a | n/a | n/a | Long | Long |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bassi, H.; Salam, Z.; Ramli, M.Z.; Sindi, H.; Rawa, M. Hardware Approach to Mitigate the Effects of Module Mismatch in a Grid-connected Photovoltaic System: A Review. Energies 2019, 12, 4321. https://doi.org/10.3390/en12224321

Bassi H, Salam Z, Ramli MZ, Sindi H, Rawa M. Hardware Approach to Mitigate the Effects of Module Mismatch in a Grid-connected Photovoltaic System: A Review. Energies. 2019; 12(22):4321. https://doi.org/10.3390/en12224321

Chicago/Turabian StyleBassi, Hussain, Zainal Salam, Mohd Zulkifli Ramli, Hatem Sindi, and Muhyaddin Rawa. 2019. "Hardware Approach to Mitigate the Effects of Module Mismatch in a Grid-connected Photovoltaic System: A Review" Energies 12, no. 22: 4321. https://doi.org/10.3390/en12224321

APA StyleBassi, H., Salam, Z., Ramli, M. Z., Sindi, H., & Rawa, M. (2019). Hardware Approach to Mitigate the Effects of Module Mismatch in a Grid-connected Photovoltaic System: A Review. Energies, 12(22), 4321. https://doi.org/10.3390/en12224321