Huff-n-Puff Experimental Studies of CO2 with Heavy Oil

Abstract

:1. Introduction

2. Materials

3. Experimental Setup

4. Experimental Procedures

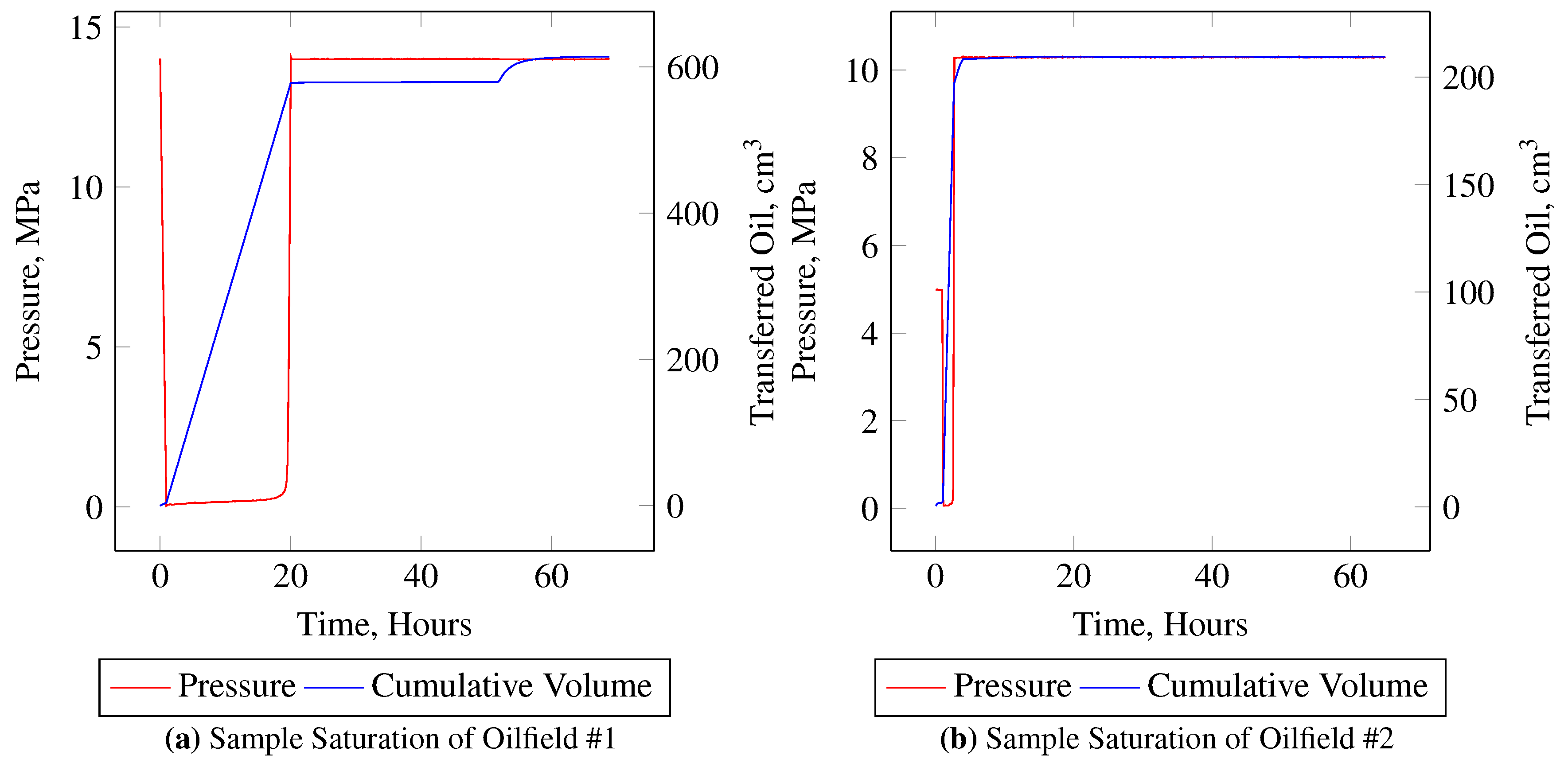

4.1. Saturation Step

4.2. Huff-n-Puff Gas Injection Procedure

5. Results and Discussion

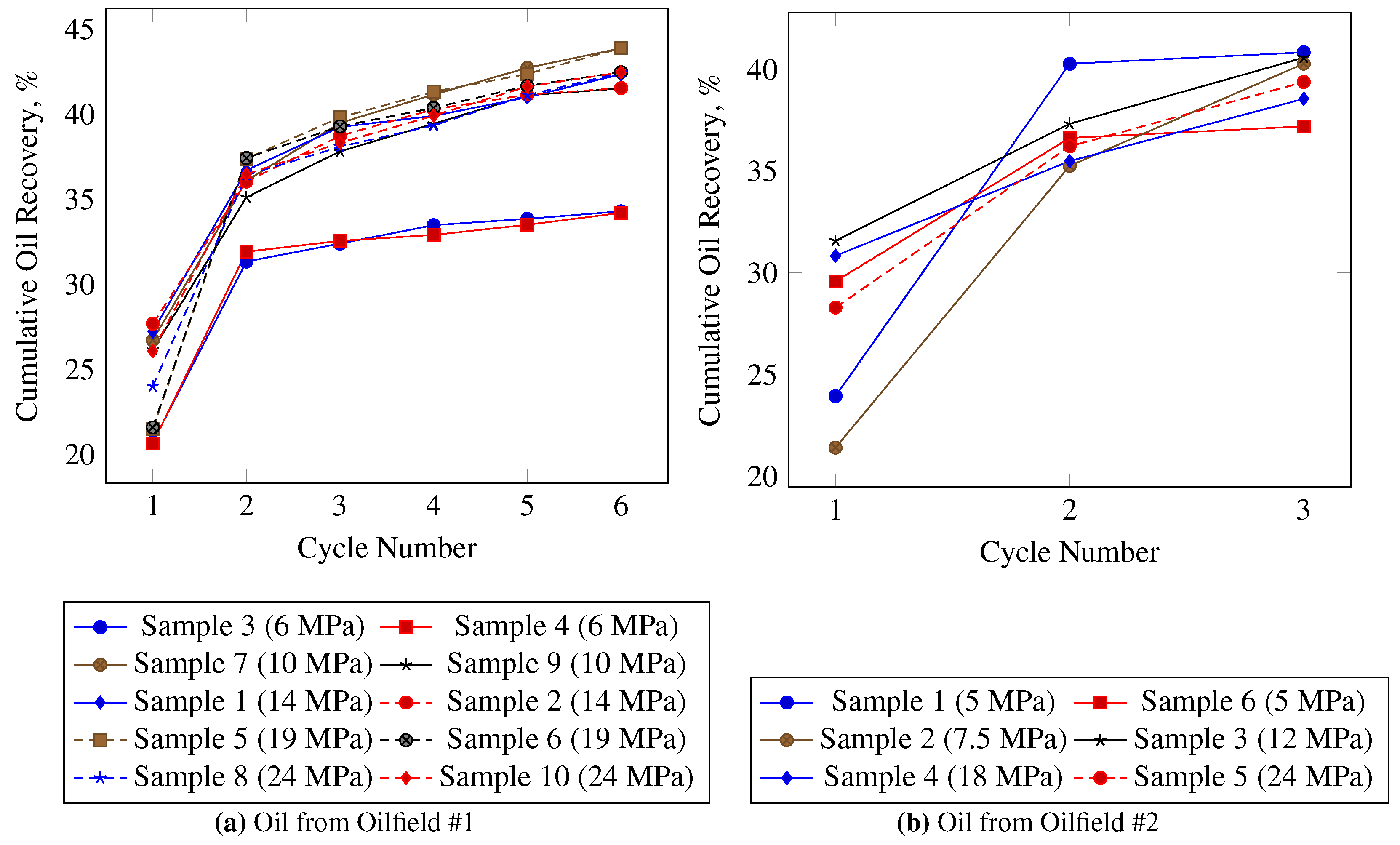

5.1. Effect of Cycle Number

5.2. Cumulative Oil Recovery

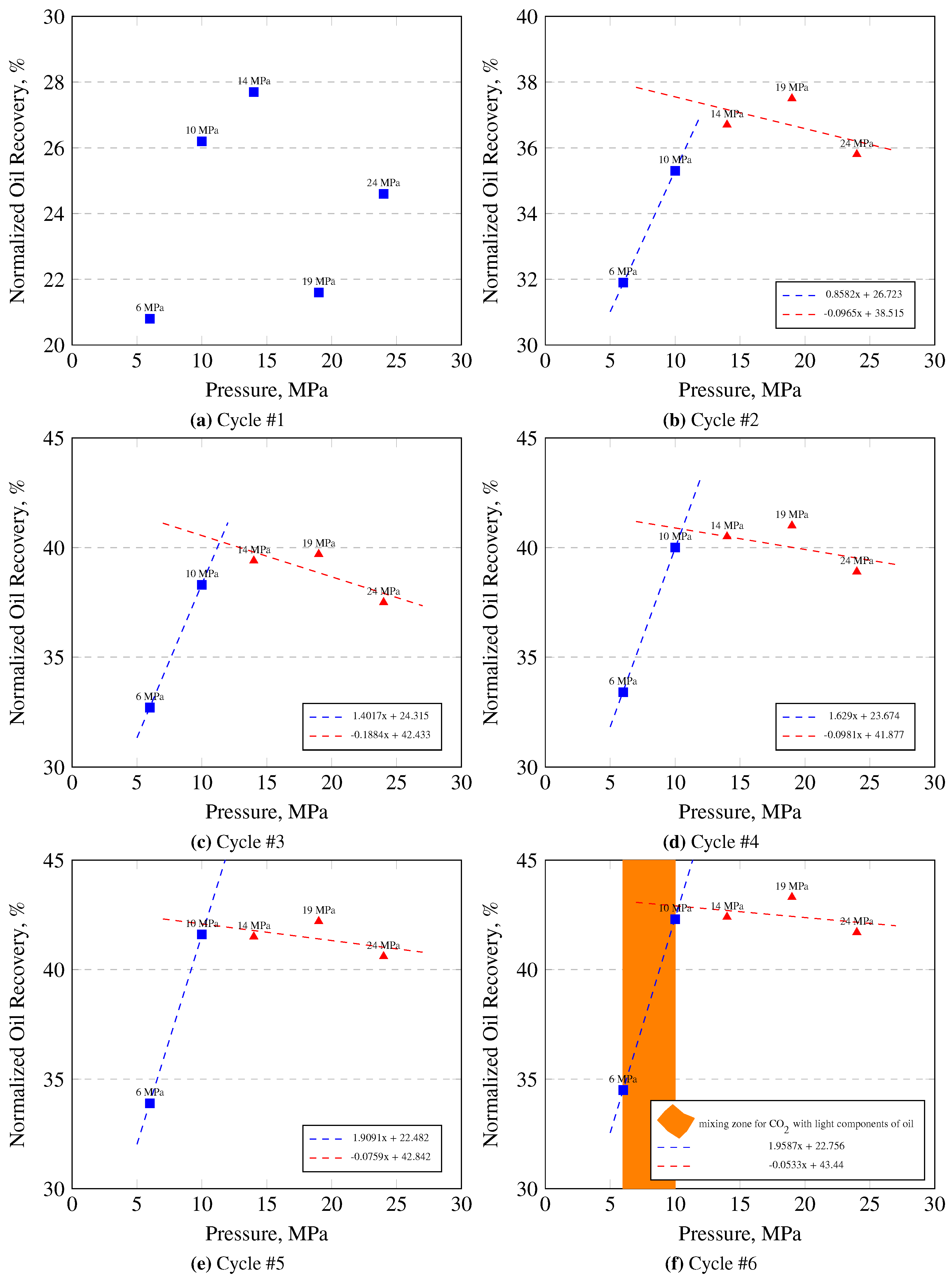

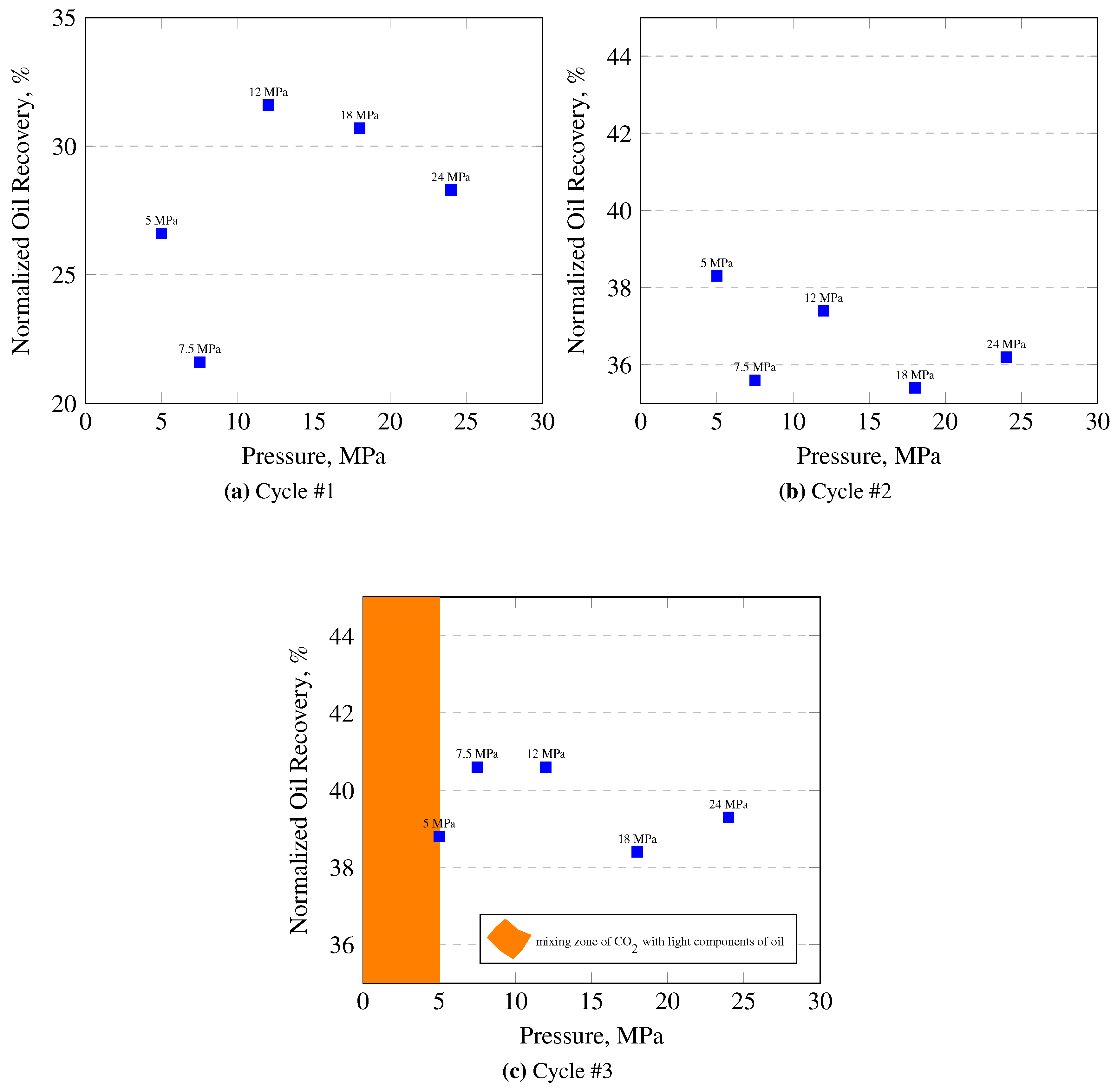

5.3. Miscibility Studies

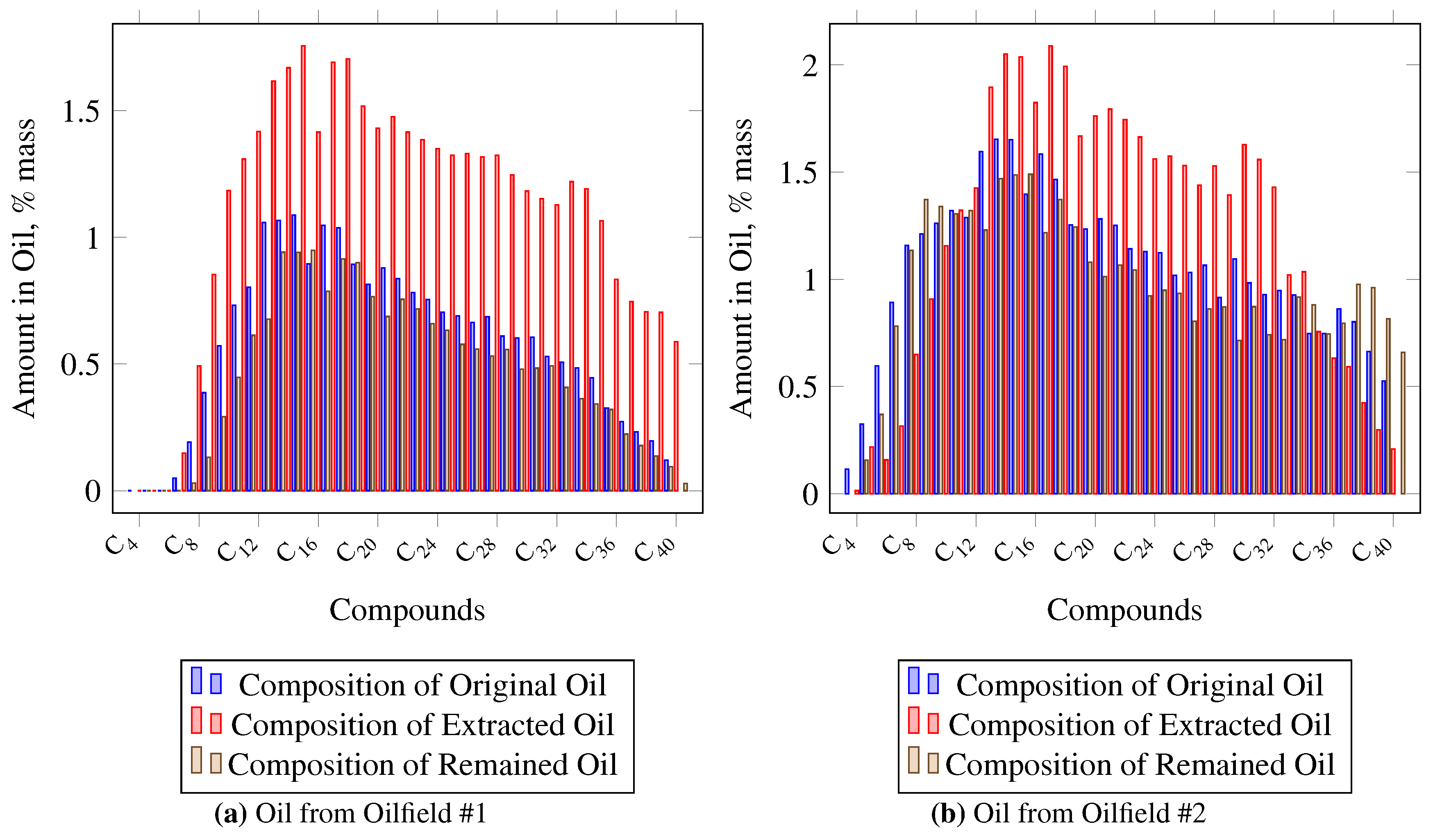

5.4. Effect of CO2 Injection on Oil and Rock Properties

6. Conclusions

- The recovery of heavy oil obtained from CO2 injection experiments was as high as 43%. This result shows that CO2 Huff-n-Puff injection can be an efficient approach to enhance heavy oil recovery. However, it was not to possible to differentiate the oil recovery as a result of solution gas drive (gas nucleation, gas expansion) during the pressure drop mode.

- The major amount of oil is extracted by the first three cycles of CO2 injection. The subsequent cycles of CO2 injection do not cause a considerable change in oil recovery.

- CO2 injection in heavy oil causes heavy oil deposition and decreases permeability. Permeability measured by gas, n-pentane, and toluene showed the difference of permeability of the core plugs in the presence and the absence of heavy oil deposits.

- Huff-n-puff tests can be applied for miscibility studies of heavy oil with gas. However, MMP for heavy oil is very high should be taken into consideration.

- When miscibility of CO2 with light oil components of heavy oil is achieved, the subsequent pressure increase under MMP does not affect oil recovery at the core scale experiments. However, it would be conjecture to presume that the higher injection pressure of gas leads to the higher rate of oil heavy deposits and more severe porosity and permeability damage.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| dry core sample weight, g | |

| saturated core sample weight, g | |

| core sample weight after Huff-n-Puff injection cycle, g | |

| AS/V | surface-to-volume ratio, cm/cm |

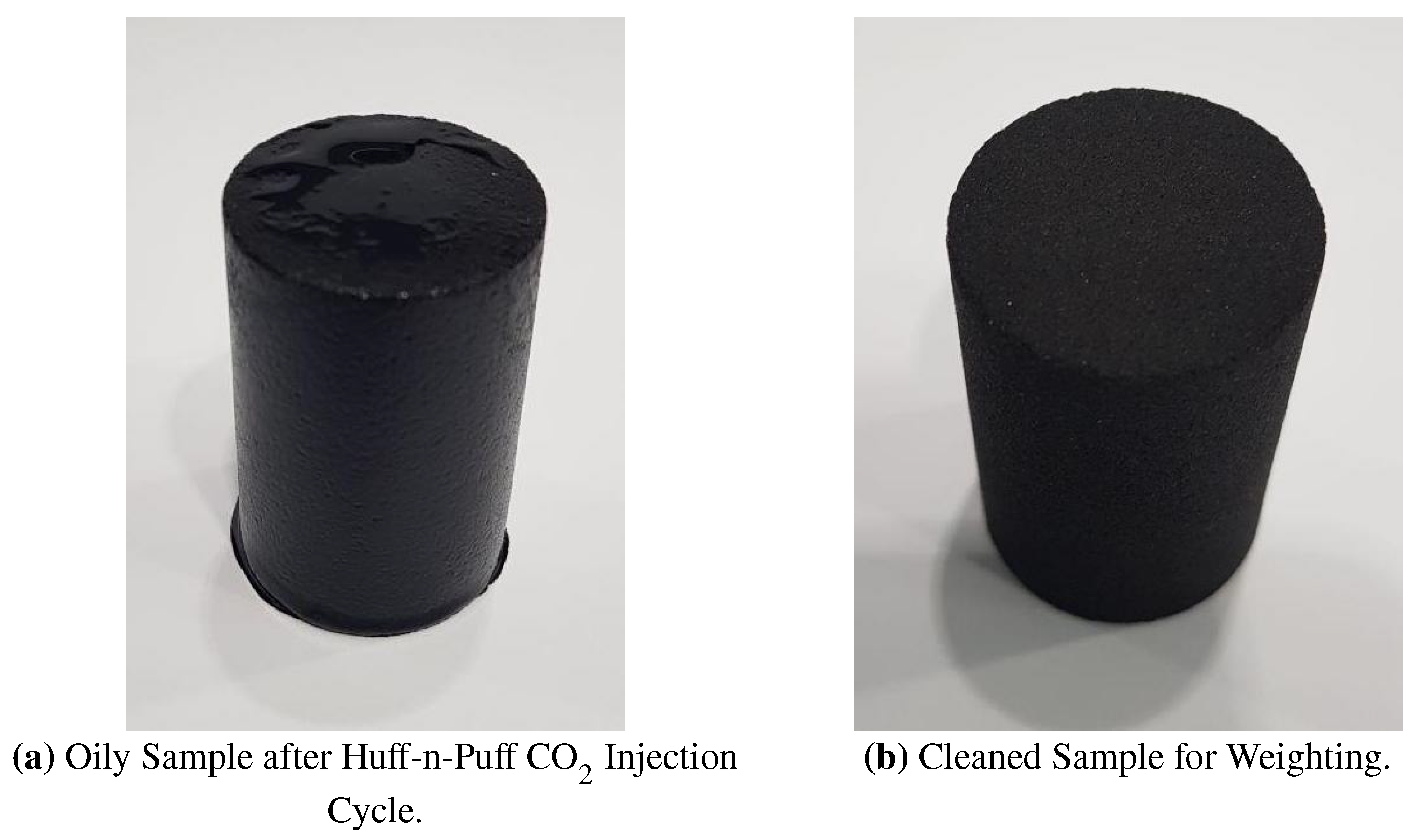

Appendix A. Example Photos

Appendix B. Saturation Logs

Appendix C. Viscosity Measurements from Special PVT Test

References

- U.S. EIA. Annual Energy Outlook 2017 with Projections to 2050; Technical Report 8; U.S. EIA: Washington, DC, USA, 2017.

- Atkinson, N.; Barret, C.; Packey, P.; Bosoni, T.; Petrosyan, K.; Lejeune, O.; Kloss, A.; Wang, J.; Yarita, M.; Pierre, M.; et al. World Energy Outlook 2018; Technical Report; International Energy Agency: Paris, France, 2018. [Google Scholar] [CrossRef]

- British Petroleum. BP Statistical Review of World Energy 2019; Technical Report; British Petroleum: London, UK, 2019. [Google Scholar]

- Ahmed Ali, S.; Suboyin, A.; Haj, H.B. Unconventional and Conventional Oil Production Impacts on Oil Price—Lessons Learnt with Glance to the Future. J. Glob. Econ. 2018, 6, 1–9. [Google Scholar] [CrossRef]

- Alboudwarej, H.; Felix, J.; Taylor, S.; Badry, R.; Bremner, C.; Brough, B.; Skeates, C.; Baker, A.; Palmer, D.; Pattison, K.; et al. Highlighting Heavy Oil. Oilfield Rev. 2006, 18, 34–53. [Google Scholar]

- Wei, B.; Pang, S.; Pu, W.; Lu, L.; Lingle, K. Mechanisms of N2 and CO2 Assisted Steam Huff-n-Puff Process in Enhancing Heavy Oil Recovery: A Case Study Using Experimental and Numerical Simulation. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 6–9 March 2017. [Google Scholar] [CrossRef]

- Erpeng, G.; Yongrong, G.; Youwei, J.; Yunjun, Z. Super Critical CO2 and Steam Co-Injection Process for Deep Extra-Heavy Oil Reservoir. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26–28 March 2018; pp. 1–12. [Google Scholar] [CrossRef]

- Hutchinson, C.A.J.; Braun, P.H. Phase relations of miscible displacement in oil recovery. AIChE J. 1961, 7, 64–72. [Google Scholar] [CrossRef]

- Sayegh, S.G.; Maini, B.B. Laboratory Evaluation of the CO2 Huff-N-Puff Process for Heavy Oil Reservoirs. J. Can. Pet. Technol. 1984, 23, 29–36. [Google Scholar] [CrossRef]

- Olenick, S.; Schroeder, F.A.; Haines, H.K.; Monger-Mcclure, T.G. Cyclic CO2 Injection for Heavy-Oil Recovery in Halfmoon Field: Laboratory Evaluation and Pilot Performance. In Proceedings of the SPE Annual Technical Conference and Exhibition of the Society of Petroleum Engineers, Washington, DC, USA, 4–7 October 1992. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, Q.; Rui, Z.; Wang, H.; Feng, J.; Zhang, L.; Zeng, F. Feasibility study of CO2 huff ’n’ puff process to enhance heavy oil recovery via long core experiments. Appl. Energy 2019, 236, 526–539. [Google Scholar] [CrossRef]

- Kuuskraa, V.; Wallace, M. CO2-EOR set for growth as new CO2 supplies emerge. Oil Gas J. 2014, 112, 92. [Google Scholar]

- Shen, Z.; Sheng, J.J. Experimental and numerical study of permeability reduction caused by asphaltene precipitation and deposition during CO2 huff and puff injection in Eagle Ford shale. Fuel 2017, 211, 432–445. [Google Scholar] [CrossRef]

- Chukwudeme, E.A.; Hamouda, A.A. Enhanced oil recovery (EOR) by miscible CO2 and water flooding of asphaltenic and non-asphaltenic oils. Energies 2009, 2, 714–737. [Google Scholar] [CrossRef]

- Ahmed, T. Equations of State and PVT Analysys; Gulf Publishing Company: Houston, TX, USA, 2007; p. 553. [Google Scholar] [CrossRef]

- Tathed, V.; Dandekar, A.Y.; Patil, S.L. Determination of Minimum Miscibility Pressure using Vanishing Interfacial Tension (VIT) in Support of EOR for Alaska North Slope (ANS) Heavy Oil. In Proceedings of the Twentieth international Offshore and Polar Engineering Conference, Beijing, China, 20–25 June 2010; International Society of Offshore and Polar Engineers: Mountain View, CA, USA, 2010. [Google Scholar]

- Li, L.; Zhang, Y.; Sheng, J.J. Effect of the Injection Pressure on Enhancing Oil Recovery in Shale Cores during the CO2 Huff-n-Puff Process When It Is above and below the Minimum Miscibility Pressure. Energy Fuels 2017, 31, 3856–3867. [Google Scholar] [CrossRef]

- Mangalsingh, D.; Jagai, T. A Laboratory Investigation of the Carbon Dioxide Immiscible Process. In Proceedings of the SPE Latin America/Caribbean Petroleum Engineering Conference, Port-of-Spain, Trinidad, 23–26 April 1996. [Google Scholar] [CrossRef]

- Cuthiell, D.; Kissel, G.; Jackson, C.; Frauenfeld, T.; Fisher, D.; Rispler, K. Viscous fingering effects in solvent displacement of heavy oil. J. Can. Pet. Technol. 2006, 45, 29–38. [Google Scholar] [CrossRef]

- Quoc, T.; Duy, M.; Neogi, P.; Bai, B. Stability of CO2 Displacement of an Immiscible Heavy Oil in a Reservoir. SPE J. 2017, 22, 539–547. [Google Scholar] [CrossRef]

- Shilov, E.; Cheremisin, A. The CO2 Huff-n-Puff Test For Minimum Miscibility Pressure Determination for Heavy Oil. In Proceedings of the 5th CO2 Geological Storage Workshop, Utrecht, The Netherlands, 21–23 November 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Qazvini Firouz, A.; Torabi, F. Feasibility Study of Solvent-Based Huff-n-Puff Method (Cyclic Solvent Injection) To Enhance Heavy Oil Recovery. In Proceedings of the SPE Heavy Oil Conference Canada, Calgary, AB, Canada, 12–14 June 2012. [Google Scholar] [CrossRef]

- Li, L.; Sheng, J.J. Experimental study of core size effect on CH4 Huff-n-Puff enhanced oil recovery in liquid-rich shale reservoirs. J. Nat. Gas Sci. Eng. 2016, 34, 1392–1402. [Google Scholar] [CrossRef]

- Nekrasov, A.; Maksakov, K.; Usachev, G.; Karpov, V.; Cheremisin, A. Optimization of the Technological Efficiency Of CO2 Injection in Extra-Viscous Oil Deposits Using Laboratory Studies and Numerical Modeling. In Geology, Geophysics and Development of Oil and Gas Fields; All-Russian Scientific Research Institute of Organization, Management and Economy of the Oil and Gas Industry: Moscow, Russia, 2019; pp. 81–86. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, Q.; Peng, X.; Zeng, F.; Zhang, L. A critical review of the CO2 huff ‘n’ puff process for enhanced heavy oil recovery. Fuel 2018, 215, 813–824. [Google Scholar] [CrossRef]

- Abedini, A.; Torabi, F. Oil Recovery Performance of Immiscible and Miscible CO2 Huff-and- Puff Processes. Energy Fuels 2014, 28, 774–784. [Google Scholar] [CrossRef]

- Speight, J.G. The Chemistry and Technology of Petroleum, 5th ed.; Chemical Industries; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Mansoori, G.A. Asphaltene and other Heavy Organic Depositions. Dev. Pet. Sci. 1994, 40, 179–205. [Google Scholar] [CrossRef]

| Reservoir | Oilfield #1 | Oilfield #2 |

|---|---|---|

| Temperature ( C) | 27.4 | 21.6 |

| Pressure (MPa) | 13.8 | 10.9 |

| Dead Oil Sample | Oilfield #1 | Oilfield #2 |

|---|---|---|

| Dead oil density at 20.0 C (kg m) | 1006.70 | 931.03 |

| Dead oil viscosity at 25.0 C (mPa s) | 1116.00 | 421.8 |

| Dead oil molecular weight (g mol) | 346.74 | 499.51 |

| Dead oil compressibility (1/MPa) | ||

| Water content after dewatering (%) | 0.78 | 0.33 |

| Paraffin crystallization temperature at 0.2 MPa ( C) | 30.4 | 33.1 |

| Component | Oilfield #1 | Oilfield #2 | Component | Oilfield #1 | Oilfield #2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| wt.% | mol.% | wt.% | mol.% | wt.% | mol.% | wt.% | mol.% | ||

| H | 0 | 0.0003 | 0 | 0 | C17 | 0.0784 | 0.1651 | 0.3508 | 0.5132 |

| H2S | 0.0012 | 0.0170 | 0 | 0 | C18 | 0.0993 | 0.1975 | 0.3914 | 0.5407 |

| CO2 | 0.0135 | 0.1532 | 0.0005 | 0.0040 | C19 | 0.0726 | 0.1378 | 0.2503 | 0.3299 |

| N2 | 0.2919 | 5.2056 | 0.0188 | 0.2330 | C20 | 0.0636 | 0.1156 | 0.2486 | 0.3134 |

| C1 | 0.0207 | 0.6442 | 0.0139 | 0.2996 | C21 | 0.0577 | 0.0991 | 0.2079 | 0.2477 |

| C2 | 0.0266 | 0.4413 | 0.0460 | 0.5304 | C22 | 0.0431 | 0.0706 | 0.1984 | 0.2256 |

| C3 | 0.0310 | 0.3511 | 0.4608 | 3.6235 | C23 | 0.0399 | 0.0627 | 0.1891 | 0.2062 |

| iC4 | 0.0128 | 0.1104 | 0.0442 | 0.2639 | C24 | 0.0358 | 0.0541 | 0.1687 | 0.1768 |

| nC4 | 0.0349 | 0.2997 | 0.7141 | 4.2601 | C25 | 0.0322 | 0.0466 | 0.1425 | 0.1432 |

| iC5 | 0.0281 | 0.1948 | 0.2672 | 1.2843 | C26 | 0.0314 | 0.0436 | 0.1360 | 0.1313 |

| nC5 | 0.0266 | 0.1844 | 0.5736 | 2.7567 | C27 | 0.0251 | 0.0335 | 0.1050 | 0.0973 |

| C6 | 0.1033 | 0.6143 | 1.5685 | 6.4746 | C28 | 0.0219 | 0.0282 | 0.0856 | 0.0765 |

| C7 | 0.1189 | 0.6185 | 1.5188 | 5.4856 | C29 | 0.0188 | 0.0234 | 0.0640 | 0.0552 |

| C8 | 0.1040 | 0.4857 | 0.8171 | 2.6479 | C30 | 0.0162 | 0.0195 | 0.0493 | 0.0411 |

| C9 | 0.0453 | 0.1870 | 0.2532 | 0.7256 | C31 | 0.0144 | 0.0168 | 0.0459 | 0.0370 |

| C10 | 0.0465 | 0.1733 | 0.2283 | 0.5907 | C32 | 0.0138 | 0.0156 | 0.0352 | 0.0275 |

| C11 | 0.0484 | 0.1644 | 0.2064 | 0.4869 | C33 | 0.0122 | 0.0134 | 0.0147 | 0.0111 |

| C12 | 0.0495 | 0.1535 | 0.2478 | 0.5336 | C34 | 0.0087 | 0.0092 | 0.0108 | 0.0079 |

| C13 | 0.0467 | 0.1333 | 0.2829 | 0.5606 | C35 | 0.0066 | 0.0068 | 0.0081 | 0.0058 |

| C14 | 0.0666 | 0.1751 | 0.2864 | 0.5227 | C36+ | 98.0613 | 88.229 | 89.2027 | 64.6417 |

| C15 | 0.0661 | 0.1603 | 0.2775 | 0.4671 | Total | 100 | 100 | 100 | 100 |

| C16 | 0.0643 | 0.1447 | 0.2689 | 0.4201 | |||||

| Sample No. | Length | Diameter | Volume | Surface Area/Volume | Porosity | Permeability |

|---|---|---|---|---|---|---|

| cm | cm | cm | m/cm | % | mD | |

| 1 | 4.819 | 2.940 | 32.72 | 1.64 | 20.14 | 153.5 |

| 2 | 4.760 | 2.941 | 32.34 | 1.65 | 20.21 | 157.6 |

| 3 | 4.764 | 2.941 | 32.36 | 1.65 | 20.16 | 153.2 |

| 4 | 4.725 | 2.938 | 32.03 | 1.65 | 20.16 | 156.4 |

| 5 | 4.698 | 2.943 | 31.96 | 1.65 | 20.15 | 156.5 |

| 6 | 4.503 | 2.941 | 30.58 | 1.66 | 20.35 | 168.3 |

| 7 | 4.375 | 2.940 | 29.71 | 1.67 | 20.40 | 173.7 |

| 8 | 4.371 | 2.940 | 29.68 | 1.67 | 20.42 | 174.9 |

| 9 | 4.282 | 2.941 | 29.08 | 1.68 | 20.42 | 171.4 |

| 10 | 3.892 | 2.937 | 26.36 | 1.71 | 20.63 | 174.8 |

| Sample No. | Pressure | Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | Cycle 5 | Cycle 6 |

|---|---|---|---|---|---|---|---|

| MPa | % | % | % | % | % | % | |

| 3 | 6 | 20.70 | 10.62 | 1.06 | 1.08 | 0.37 | 0.44 |

| 4 | 6 | 20.63 | 11.27 | 0.64 | 0.35 | 0.60 | 0.69 |

| 7 | 10 | 26.70 | 9.37 | 3.41 | 1.66 | 1.57 | 1.15 |

| 9 | 10 | 26.12 | 8.98 | 2.70 | 1.63 | 1.67 | 0.40 |

| 2 | 14 | 27.20 | 9.49 | 2.54 | 0.65 | 1.10 | 1.35 |

| 1 | 14 | 27.67 | 8.36 | 2.68 | 1.57 | 0.85 | 0.39 |

| 5 | 19 | 21.48 | 15.88 | 2.43 | 1.51 | 1.05 | 1.51 |

| 6 | 19 | 21.57 | 15.84 | 1.86 | 1.08 | 1.30 | 0.81 |

| 8 | 24 | 23.99 | 12.41 | 1.67 | 1.26 | 1.78 | 1.32 |

| 10 | 24 | 26.06 | 10.40 | 1.84 | 1.61 | 1.71 | 0.83 |

| Sample No. | Pressure | Cycle 1 | Cycle 2 | Cycle 3 |

|---|---|---|---|---|

| MPa | % | % | % | |

| 1 | 5 | 23.92 | 16.33 | 0.56 |

| 6 | 5 | 29.56 | 7.05 | 0.57 |

| 2 | 7.5 | 21.39 | 13.84 | 5.02 |

| 3 | 12 | 31.56 | 5.75 | 3.25 |

| 4 | 18 | 30.81 | 4.66 | 3.06 |

| 5 | 24 | 28.27 | 7.92 | 3.16 |

| Sample No. | Reservoir | Helium Permeability before Experiments | N-Pentane Permeability after Experiments | Helium Permeability after Experiments | Toluene Permeability after Experiments |

|---|---|---|---|---|---|

| mD | mD | mD | mD | ||

| 7 (10 MPa) | Oilfield #1 | 173 | 13 | 159 | 77 |

| 2 (7.5 MPa) | Oilfield #2 | 147 | 8 | 144 | 39 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shilov, E.; Cheremisin, A.; Maksakov, K.; Kharlanov, S. Huff-n-Puff Experimental Studies of CO2 with Heavy Oil. Energies 2019, 12, 4308. https://doi.org/10.3390/en12224308

Shilov E, Cheremisin A, Maksakov K, Kharlanov S. Huff-n-Puff Experimental Studies of CO2 with Heavy Oil. Energies. 2019; 12(22):4308. https://doi.org/10.3390/en12224308

Chicago/Turabian StyleShilov, Evgeny, Alexey Cheremisin, Kirill Maksakov, and Sergey Kharlanov. 2019. "Huff-n-Puff Experimental Studies of CO2 with Heavy Oil" Energies 12, no. 22: 4308. https://doi.org/10.3390/en12224308

APA StyleShilov, E., Cheremisin, A., Maksakov, K., & Kharlanov, S. (2019). Huff-n-Puff Experimental Studies of CO2 with Heavy Oil. Energies, 12(22), 4308. https://doi.org/10.3390/en12224308