Carbon Storage and Enhanced Oil Recovery in Pennsylvanian Morrow Formation Clastic Reservoirs: Controls on Oil–Brine and Oil–CO2 Relative Permeability from Diagenetic Heterogeneity and Evolving Wettability

Abstract

1. Introduction

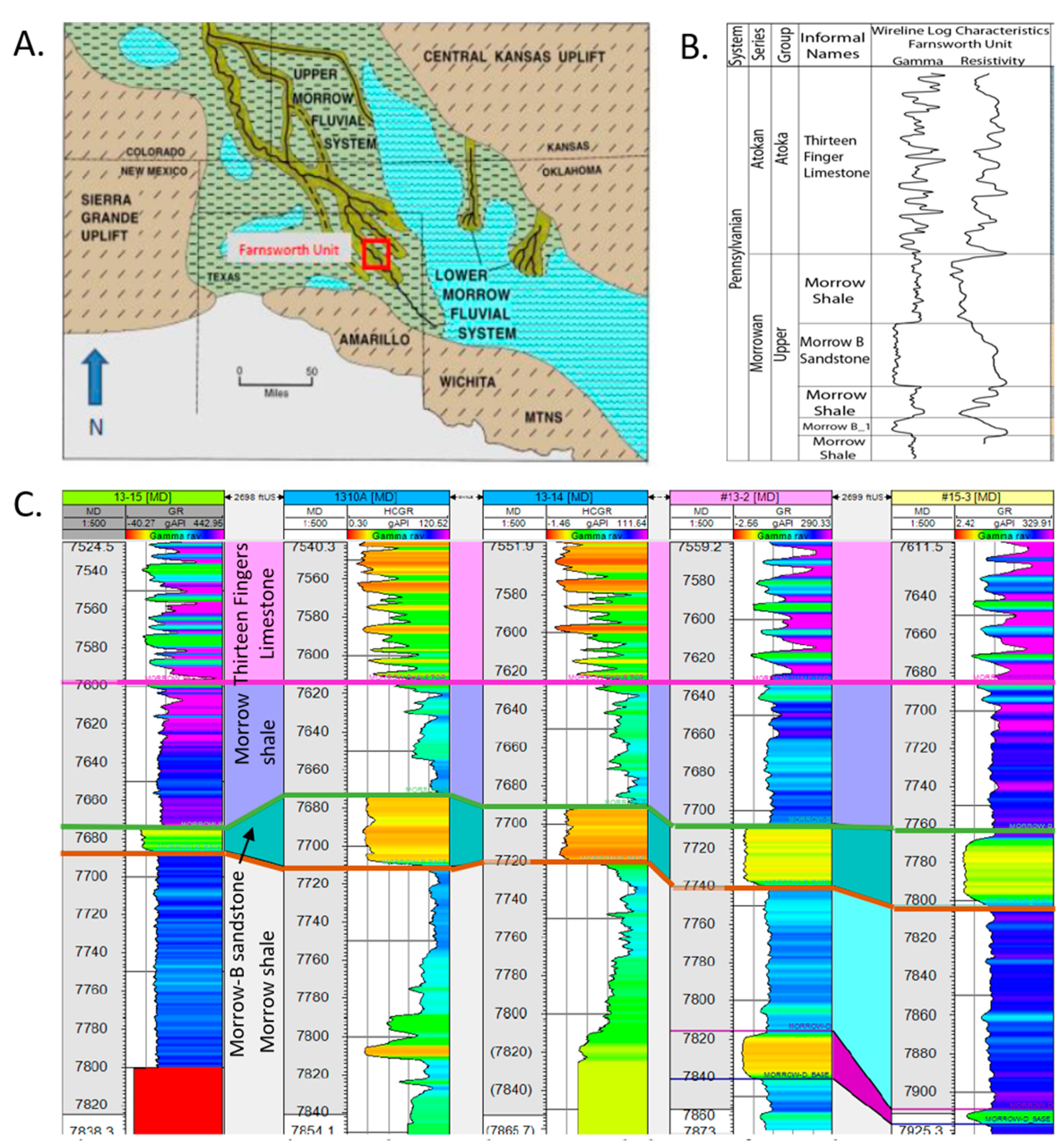

2. Background for CCUS/EOR in the Farnsworth Unit

2.1. Morrow B Heterogeneity

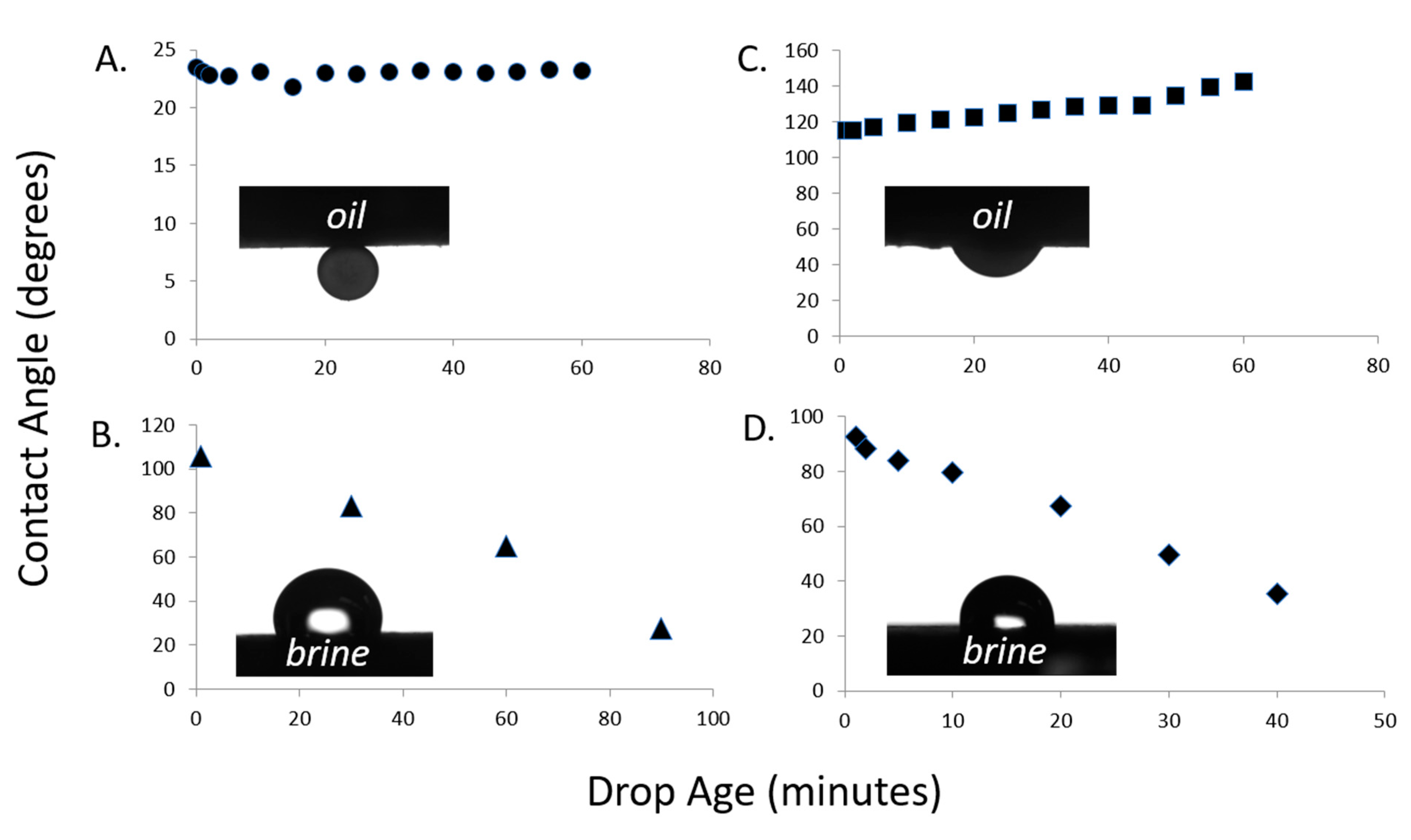

2.2. Variability and Evolution of Wettability during CCUS/EOR in Sandstones

3. Methods

3.1. Core Plug Selection and Preparation

3.2. Fluid Origin and Preparation

3.3. Wettability Measurements

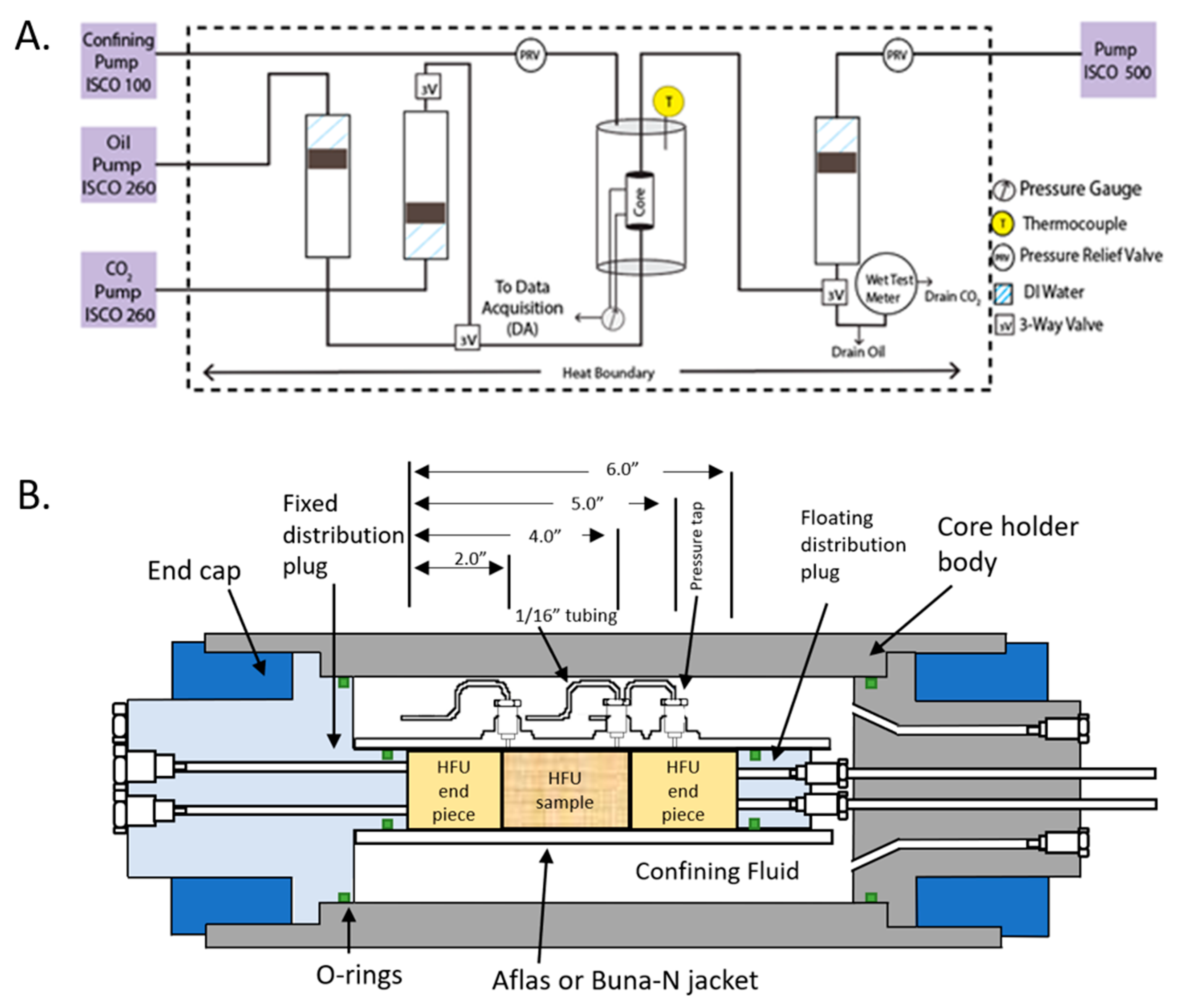

3.4. Core Flooding Experiments

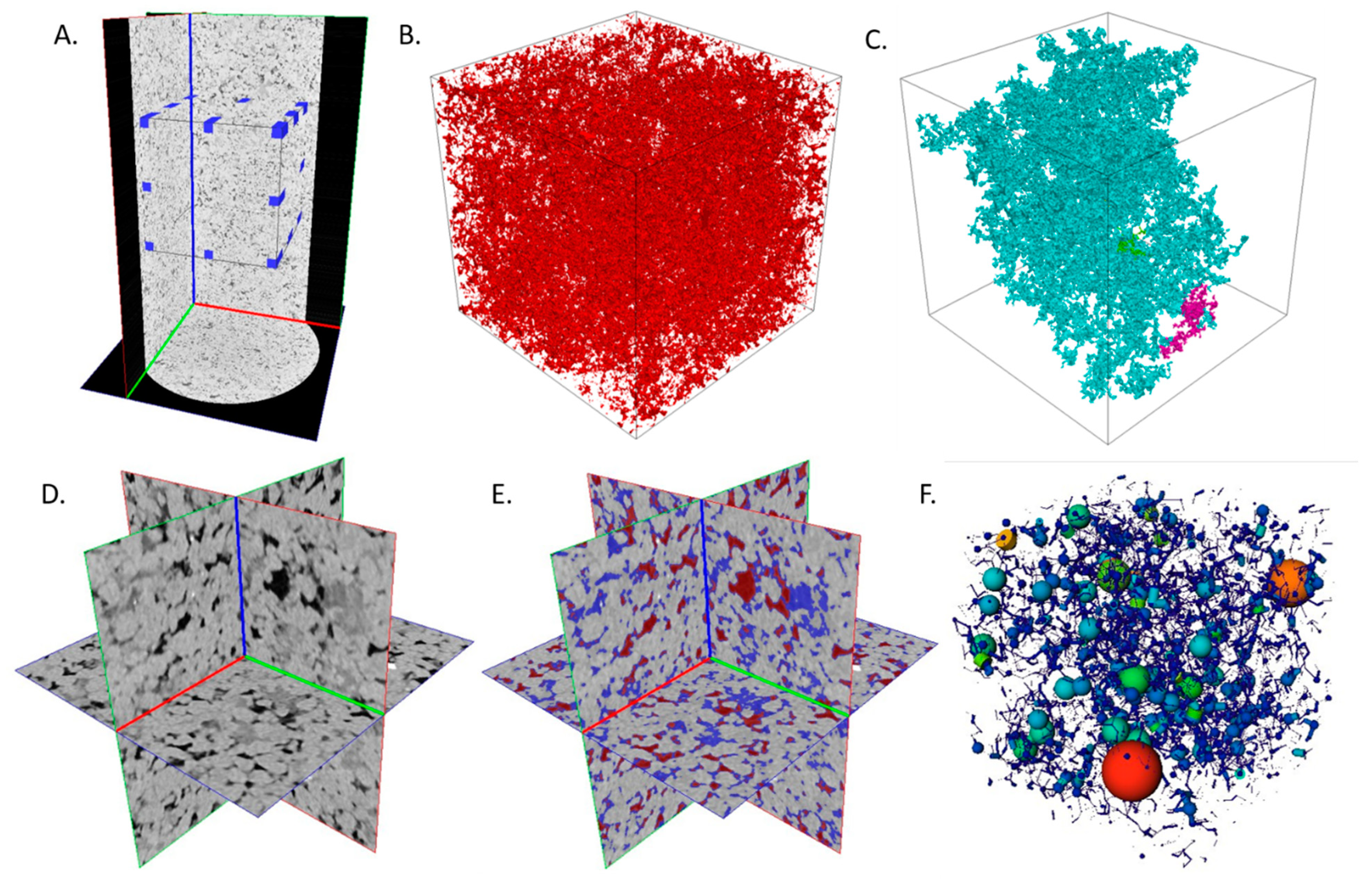

3.5. μCT Imaging and Optical Petrography

3.6. Reservoir Simulation

4. Results

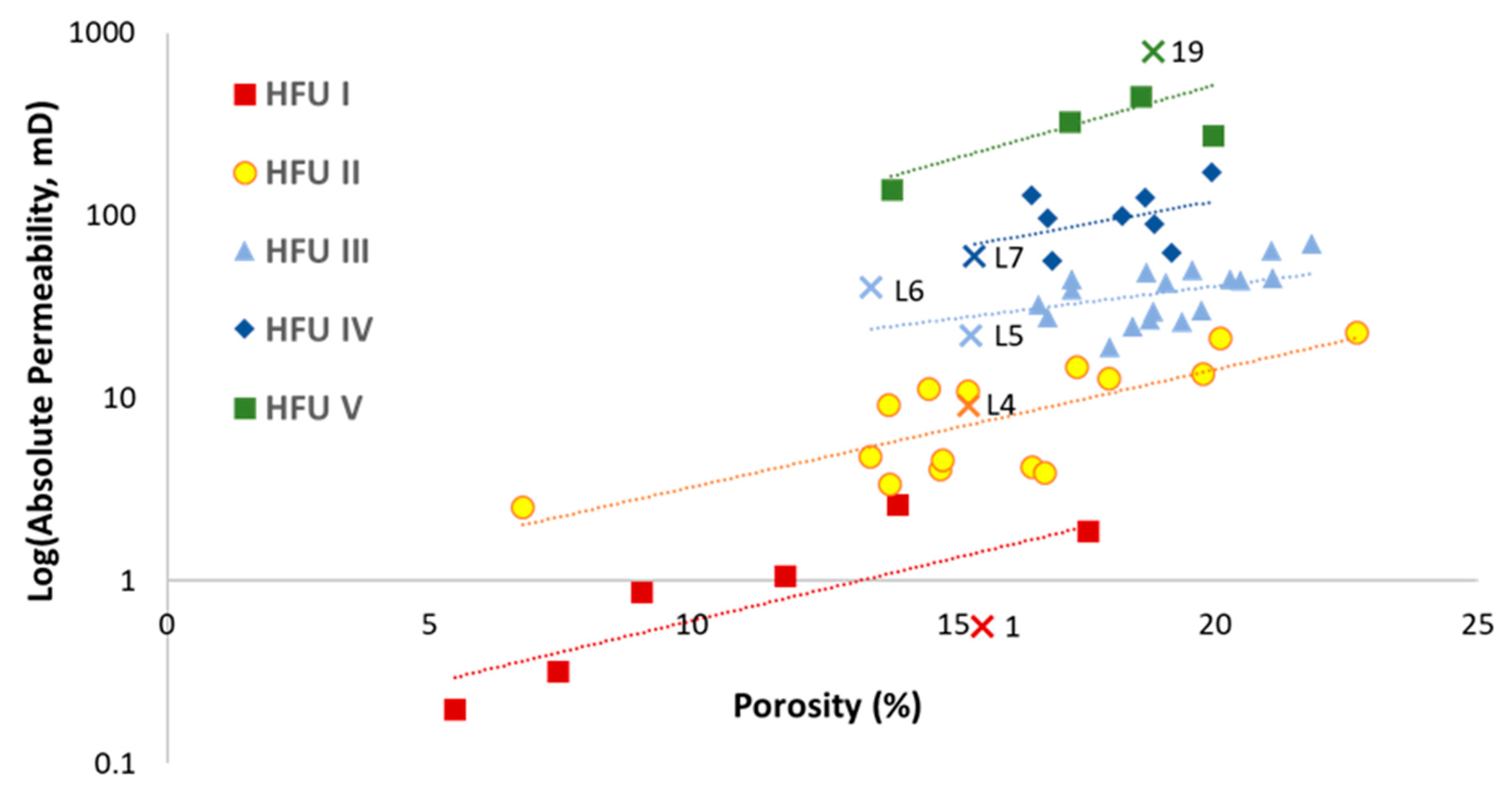

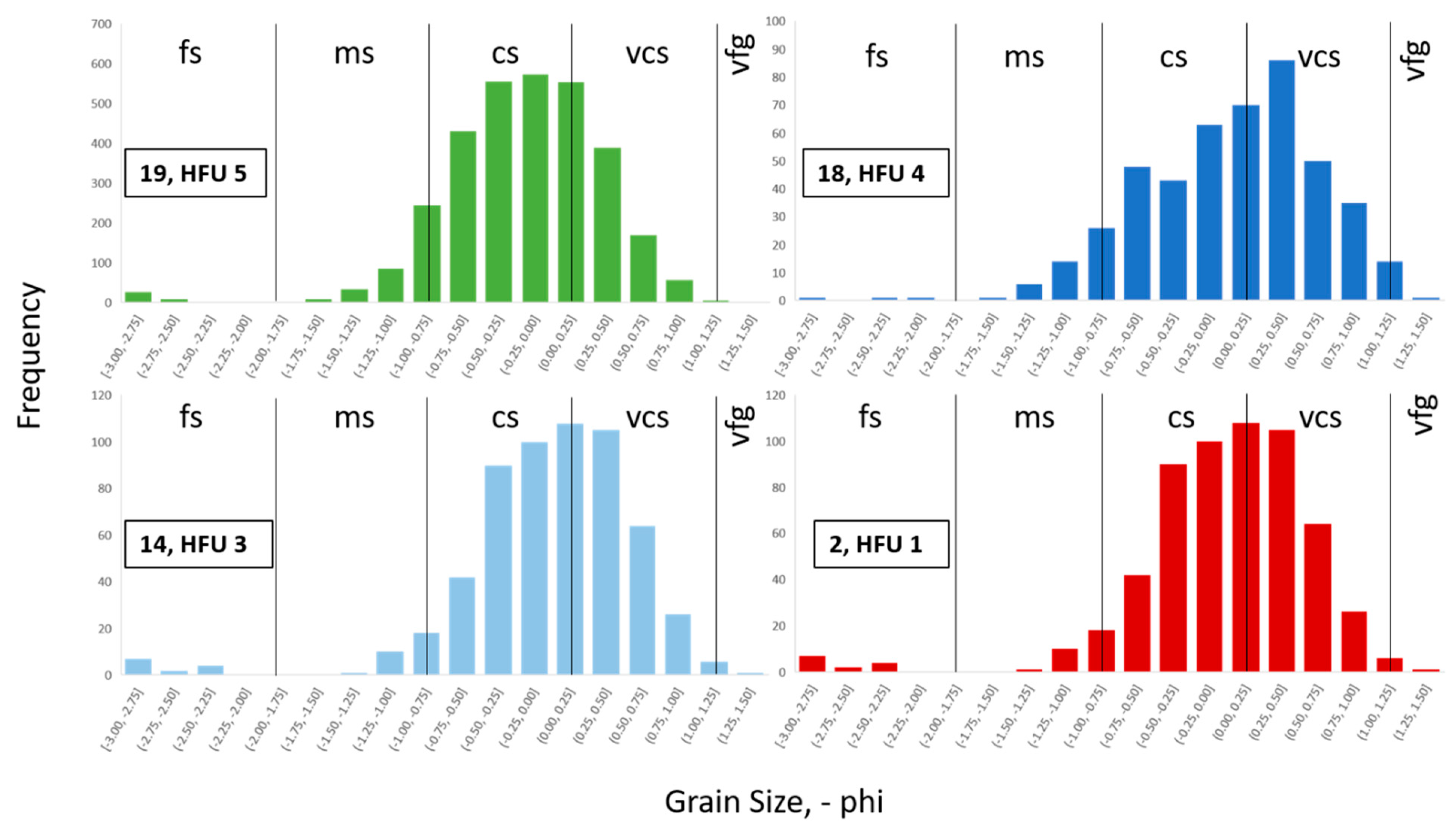

4.1. Diagenetic Capillary Heterogeneity in Morrow B Sandstones

4.2. Wettability Variability in the Oil–Brine Morrow B Sandstone System

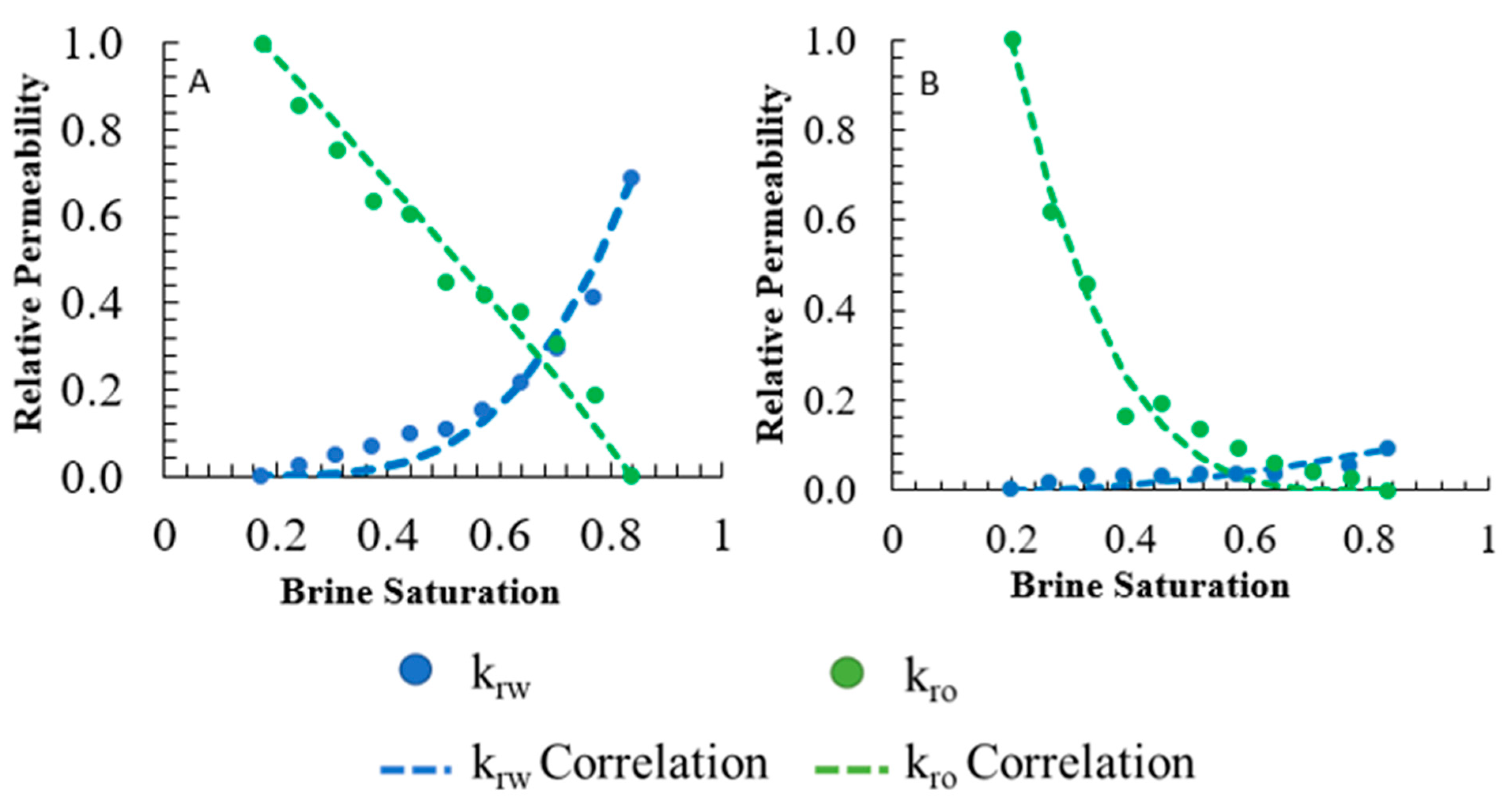

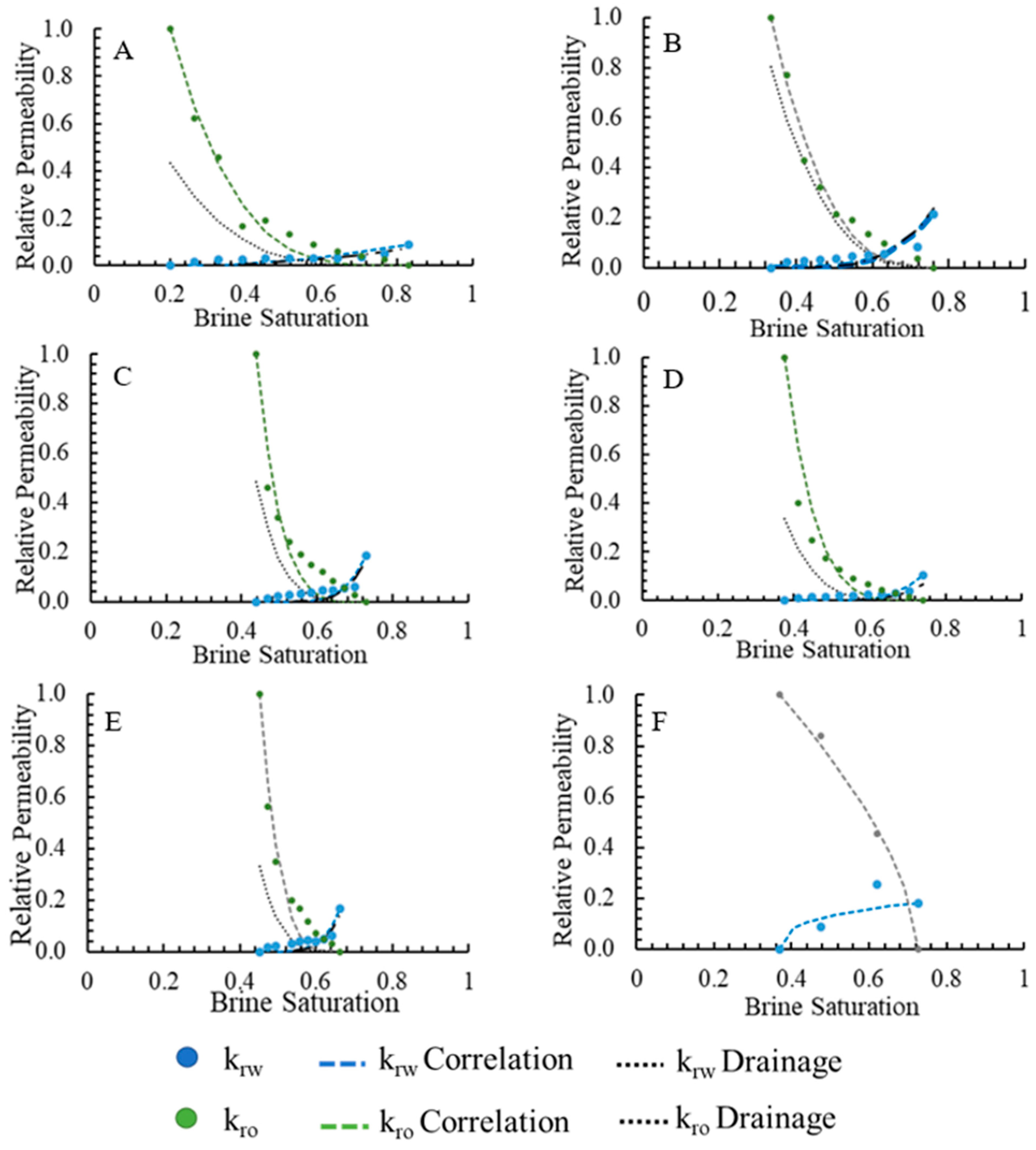

4.3. Oil–brine Relative Permeability for Morrow B HFUs

4.4. Oil-scCO2 Relative Permeability for Morrow B HFUs

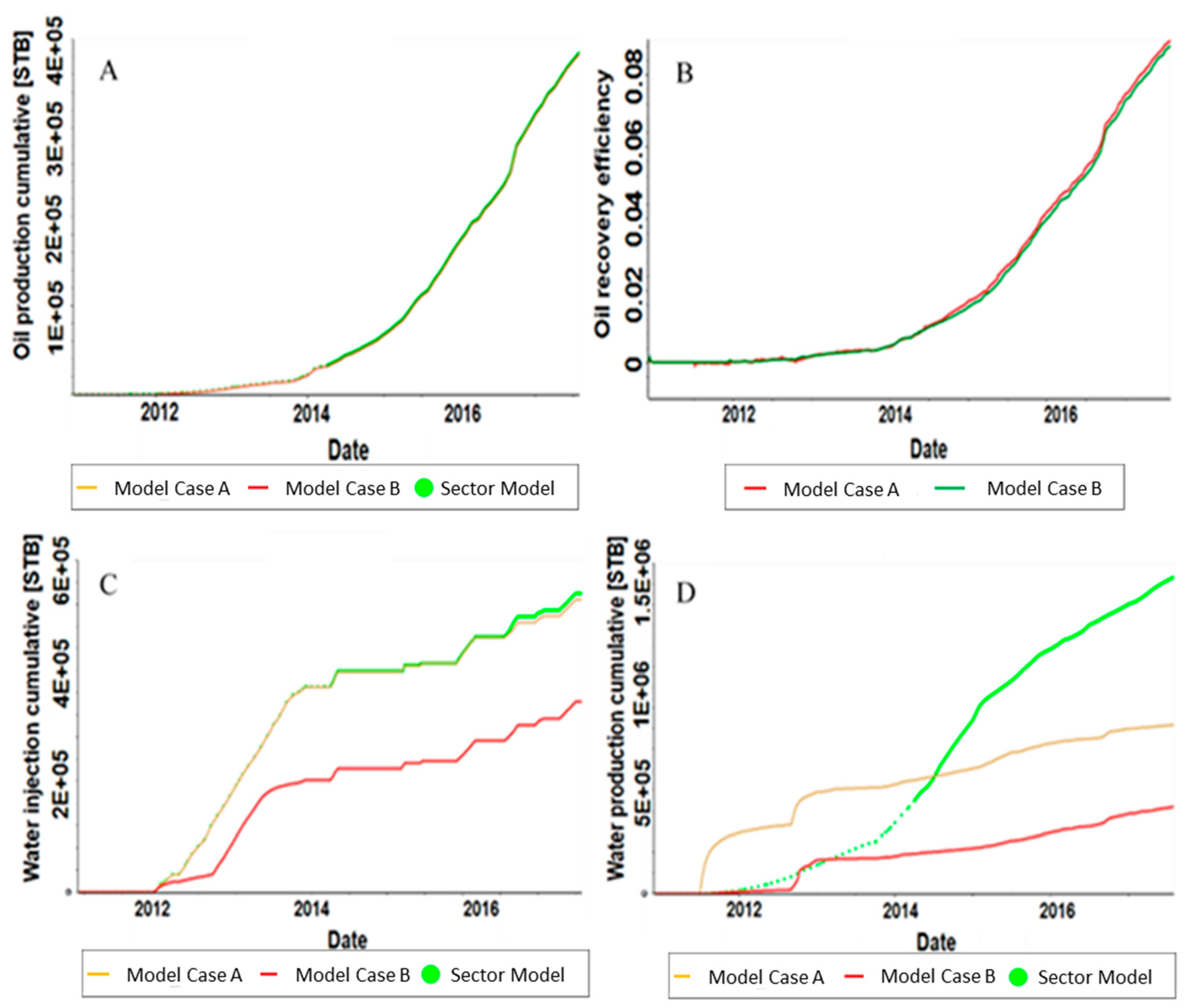

4.5. Reservoir Simulation

5. Discussion

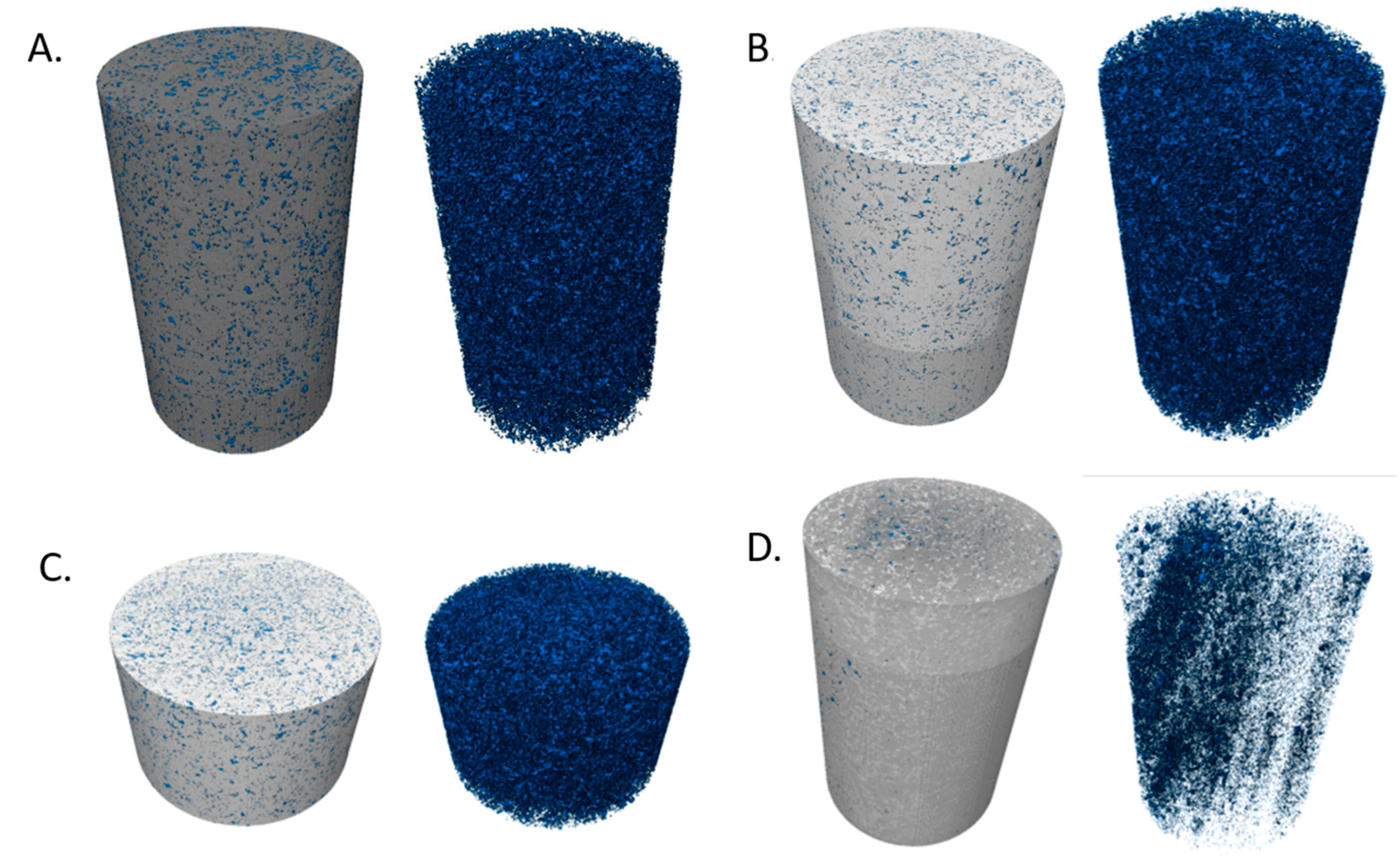

5.1. Integrating Pore-Scale Observations with Experimental and Modeling Results

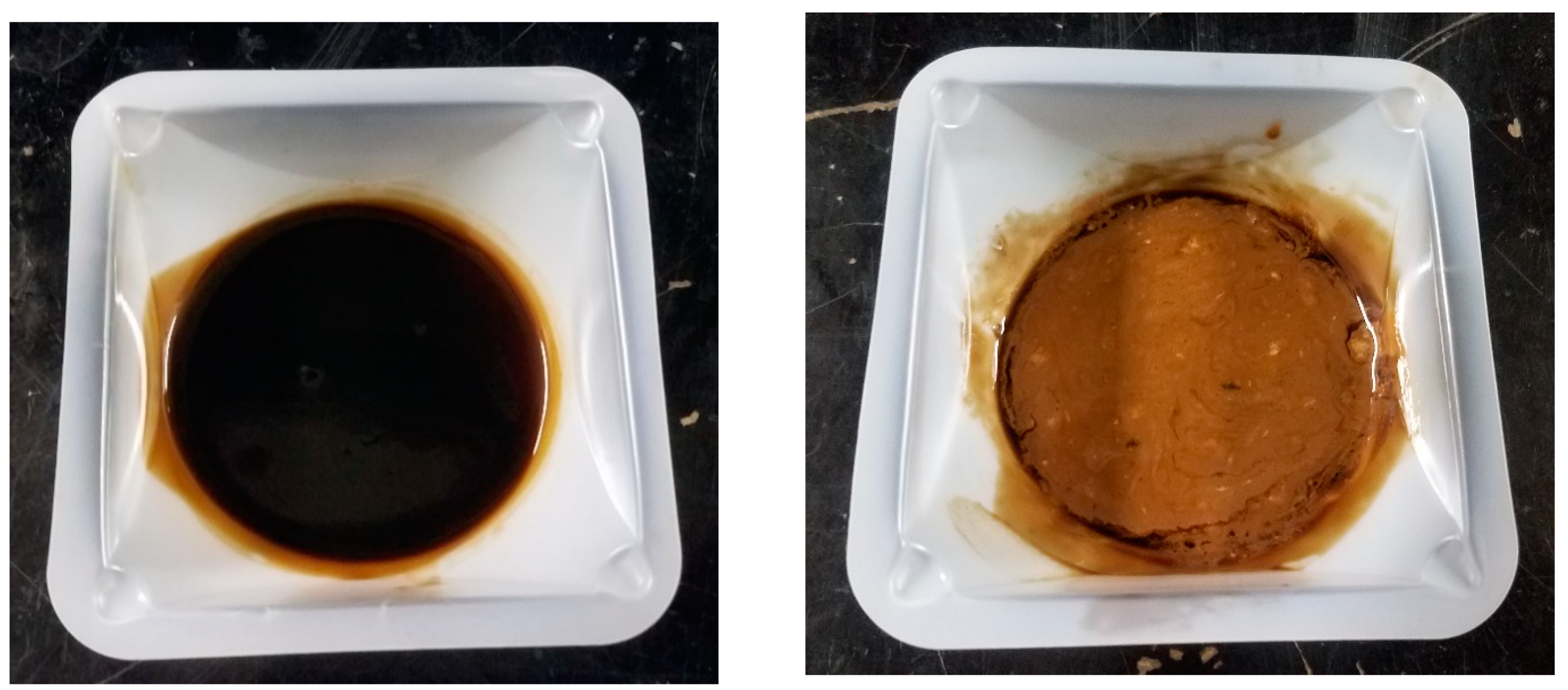

5.2. CO2-Oil Interactions during EOR-CCUS

6. Conclusions

- (1).

- Morrow B heterogeneity in Well 13-10A in the Farnworth Unit of West Texas is examined using core acquired by the SWP. Based on fifty-three core plug measurements, we apply a hydrologic flow unit concept (done for the entire Farnsworth field by Rose-Coss et al. 2016) to quantify core heterogeneity, down-selecting to six core plugs across five units for detailed relative permeability measurements. The HFU characterization, along with detailed petrographic and μCT characterization, reveals that pore (capillary)-to-core scale heterogeneity is largely due to diagenetic processes. Although porosities are largely similar between the flow units, permeability varies over four orders of magnitude due in large part to the presence and spatial distribution of clay-bearing microporosity and carbonate cement, and this has a direct influence in reservoir-scale CCUS behavior from sweep to storage.

- (2).

- Morrow B wettability is sensitive to and easily modified with flooding history, shown here via simple contact angle experiments, and by effects of aging on oil–brine relative permeability behavior. The current reservoir appears to be at least slightly water-wetting, due to the long history of water-flooding at Farnsworth. Most residual oil resides within the clay-hosted microporosity, which would be accessible to CO2-flooding only at higher capillary pressures. Indeed, in CO2–oil co-injection experiments, more oil is produced, and residual oil saturations decrease, as injection pressures approach the minimum miscibility pressure. CO2 relative permeability curves show a small jump as CO2 saturation increases, which suggests that initially oil-wet, aged Morrow-B samples quickly become at least partially CO2 wetting during even moderate CO2 flooding. Produced oil properties change with progressive exposure to CO2 in the experiments, and similar changes have been observed at Farnsworth associated with CO2-flooding. This suggests that CCUS activity at Farnworth might be altering in situ wettability similar to that observed experimentally.

- (3).

- Measured two-phase relative permeability data were used to estimate three-phase relative permeability, which in turn was applied in the reservoir model of Ampomah et al. [8] to calculate oil recovery and gas storage at the field scale. The numerical simulation yielded results comparable to the actual oil production data, but underestimated water injection and production. We conjecture that this is due to evolving and heterogeneous wettability in the Morrow B at Farnsworth (not accounted for in modeling), particularly in the highest permeability HFU V, which has apparently yielded most of its original oil in place. This shift in wettability, from oil-wet to at least moderately water-wetting, probably has produced fast pathways in the Morrow B that influence and limit the sweep of CO2 during EOR/CCUS activities.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Sample Number | Sample Depth(m) | Dry Bulk Density (kg/m3) | Ambient Porosity (%) | Water Saturation (%) | Oil Saturation (%) | Gas Perm. NOB Stress 2.75 MPa (md) | R35 | Flow Unit Designation |

|---|---|---|---|---|---|---|---|---|

| E1A | 2339.6 | 2160 | 19.37 | 15.78 | 23.81 | 26.14 | 2.85 | III |

| E6A | 2337.2 | 2430 | 10.72 | 58.03 | <1.00 | N/A | ||

| 23 | 2337.4 | 2280 | 15.27 | 23.29 | 22.64 | 11.02 | 2.10 | II |

| 43 | 2337.7 | 2260 | 18.42 | 22.54 | 17.69 | 24.91 | 2.89 | III |

| 44 | 2337.7 | 2090 | 22.69 | 16.69 | 14.66 | 22.87 | 2.30 | II |

| 1 | 2337.9 | 2440 | 15.56 | 34.28 | 25.11 | 0.56 | 0.36 | I |

| 24 | 2338.4 | 2140 | 19.76 | 14.60 | 23.70 | 13.58 | 1.90 | II |

| 25 | 2338.6 | 2130 | 20.08 | 15.66 | 23.17 | 21.54 | 2.46 | II |

| 45 | 2338.8 | 2250 | 17.35 | 20.54 | 22.10 | 14.91 | 2.25 | II |

| 46 | 2338.8 | 2220 | 17.57 | 14.76 | 23.89 | 1.89 | 0.66 | I |

| 3 | 2338.9 | 2160 | 18.83 | 20.54 | 26.39 | 89.27 | 6.01 | IV |

| 53 | 2338.9 | 2120 | 20.48 | 17.69 | 21.10 | 44.09 | 3.69 | III |

| 26 | 2339.2 | 2120 | 20.28 | 22.40 | 24.43 | 44.83 | 3.76 | III |

| E1B | 2339.6 | 2160 | 19.73 | 14.22 | 25.00 | 30.25 | 3.05 | III |

| 5 | 2339.9 | 2130 | 19.93 | 28.23 | 26.58 | 171.59 | 8.41 | IV |

| 27 | 2340.2 | 2120 | 19.96 | 27.34 | 19.41 | 274.03 | 11.07 | V |

| 28 | 2340.6 | 2160 | 18.75 | 19.63 | 11.95 | 27.06 | 2.99 | III |

| 7 | 2341.0 | 2210 | 16.80 | 25.66 | 22.45 | 27.98 | 3.35 | III |

| 29 | 2341.3 | 2290 | 13.94 | 11.68 | 18.54 | 2.61 | 0.97 | I |

| 30 | 2341.6 | 2260 | 14.74 | 19.96 | 20.65 | 4.09 | 1.21 | II |

| 9 | 2342.1 | 2360 | 11.78 | 21.95 | 29.30 | 1.06 | 0.66 | I |

| E2A | 2342.3 | 2260 | 14.78 | 25.24 | 8.69 | 4.59 | 1.29 | II |

| E2B | 2342.3 | 2240 | 16.49 | N/A | N/A | 4.25 | 1.12 | II |

| 31 | 2342.5 | 2290 | 13.41 | 15.65 | 22.88 | 4.80 | 1.44 | II |

| E3A | 2342.8 | 2260 | 14.52 | 28.82 | 18.57 | 11.27 | 2.22 | II |

| E3B | 2342.8 | 2290 | 13.76 | 26.24 | 13.68 | 9.18 | 2.07 | II |

| 11 | 2343.2 | 2190 | 16.80 | 28.93 | 23.35 | 96.45 | 6.94 | IV |

| 55 | 2343.2 | 2280 | 13.82 | 33.96 | 30.69 | 139.09 | 10.20 | V |

| 32 | 2343.5 | 2160 | 18.23 | 24.57 | 20.53 | 100.09 | 6.61 | IV |

| 33 | 2343.7 | 2200 | 16.88 | 23.77 | 20.48 | 56.15 | 5.03 | IV |

| 47 | 2344.0 | 2190 | 17.96 | 17.04 | 22.15 | 12.82 | 2.00 | II |

| 48 | 2344.0 | 2230 | 16.74 | 13.40 | 25.53 | 3.92 | 1.06 | II |

| 13 | 2344.2 | 2090 | 21.08 | 28.05 | 26.05 | 45.65 | 3.68 | III |

| 57 | 2344.3 | 2140 | 19.06 | 16.53 | 22.83 | 42.67 | 3.85 | III |

| 34 | 2344.6 | 2150 | 18.81 | 17.15 | 25.20 | 30.06 | 3.17 | III |

| 35 | 2344.9 | 2190 | 17.27 | 17.42 | 19.58 | 39.42 | 4.00 | III |

| 15 | 2345.3 | 2130 | 19.55 | 28.61 | 23.30 | 50.60 | 4.17 | III |

| 36 | 2345.6 | 2180 | 17.99 | 17.57 | 19.41 | 19.09 | 2.52 | III |

| E4A | 2345.8 | 2090 | 21.07 | 21.27 | 16.38 | 64.58 | 4.51 | III |

| E4B | 2345.8 | 2080 | 21.83 | 19.43 | 18.37 | 70.40 | 4.60 | III |

| 37 | 2346.1 | 2200 | 16.62 | 16.98 | 20.11 | 32.52 | 3.70 | III |

| 17 | 2346.3 | 2280 | 13.77 | 27.91 | 28.01 | 3.42 | 1.15 | II |

| 49 | 2346.6 | 2140 | 19.17 | 15.93 | 22.30 | 63.01 | 4.82 | IV |

| 50 | 2346.6 | 2140 | 18.69 | 13.19 | 23.92 | 49.09 | 4.26 | III |

| 38 | 2346.9 | 2150 | 18.66 | 17.33 | 24.06 | 126.12 | 7.43 | IV |

| 51 | 2347.1 | 2190 | 16.49 | 15.09 | 23.89 | 128.54 | 8.36 | IV |

| 52 | 2347.1 | 2180 | 17.25 | 18.74 | 21.27 | 44.63 | 4.31 | III |

| 59 | 2347.3 | 2190 | 17.22 | 16.51 | 20.86 | 324.57 | 13.89 | V |

| 19 | 2347.4 | 2150 | 18.83 | 24.58 | 22.45 | 783.50 | 21.60 | V |

| 39 | 2347.7 | 2150 | 18.57 | 29.54 | 17.16 | 449.20 | 15.76 | V |

| 40 | 2348.0 | 2460 | 7.45 | 10.68 | 19.14 | 0.32 | 0.48 | I |

| 41 | 2348.3 | 2510 | 5.49 | 15.15 | 20.05 | 0.20 | 0.48 | I |

| 21 | 2348.5 | 2720 | 6.78 | 44.24 | 9.15 | 2.53 | 1.78 | II |

References

- Parker, R.L. Farnsworth Morrow Oil Field. Panhand. Geonews 1956, 4, 5–13. [Google Scholar]

- Ampomah, W.; Balch, R.S.; Grigg, R.B.; Will, R.; Dai, Z.; White, M.D. Farnsworth Field CO2-EOR Project: Performance Case History; Society of Petroleum Engineers. Presented at the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. SPE- 179528- MS. [Google Scholar] [CrossRef]

- Gallagher, S. Depositional and Diagenetic Controls on Reservoir Heterogeneity: Upper Morrow Sandstone, Farnsworth Unit, Ochiltree County, Texas. Unpublished Master’s Thesis, New Mexico Institute of Mining and Technology, Socorro, NM, USA; 215p. Available online: http://www.ees.nmt.edu/outside/alumni/papers/2014t_gallagher_sr.pdf (accessed on 23 August 2019).

- Gunda, D.; Ampomah, W.; Grigg, R.B.; Balch, R.S. Reservoir fluid characterization for miscible enhanced oil recovery. In Proceedings of the Carbon Management Technology Conference, Sugarland, Houston-Texas, TX, USA, 16–19 November 2015. [Google Scholar]

- Rose-Coss, D.; Ampomah, W.; Balch, R.S.; Cather, M.; Mozley, P.; Rasmussen, L. An improved approach for sandstone reservoir characterization. Society of Petroleum Engineers. Presented at the SPE Western Regional Meeting, Anchorage, AK, USA, 23–26 May 2016. SPE-180375-MS. [Google Scholar]

- Rose-Coss, D. A Refined Depositional Sequence Stratigraphic and Structual Model for the Reservoir and Caprock Intervals at the Farnsworth Unit, Ochiltree County, TX, USA. Unpublished Master’s Thesis, New Mexico Institute of Mining and Technology, Socorro, NM, USA, 2017; pp. 40–45. [Google Scholar]

- Ampomah, W.; Balch, R.; Grigg, R.B.; Cather, M.; Gragg, E.; Will, R.; Dai, Z. Performance assessment of CO2-enhanced oil recovery and storage in the Morrow reservoir. Geomech. Geophys. Geo Energy Geo Resour. 2017, 3, 245–263. [Google Scholar] [CrossRef]

- Ampomah, W.; Balch, R.S.; Cather, M.; Rose-Coss, D.; Gragg, E. Numerical simulation of CO2-EOR and storage potential in the Morrow Formation, Ochiltree County, Texas. Society of Petroleum Engineers. Presented at the SPE Oklahoma City Oil and Gas Symposiium, Oklahoma City, OK, USA, 27–31 March 2017. SPE-185086-MS. [Google Scholar]

- Rodosta, T.; Damiani, D.; Farnsworth Unit Project: Pennsylvanian Upper Morrow Formation, Ochiltree County. National Energy Technology Laboratory 2017. Available online: https://netl.doe.gov/sites/default/files/2018-11/Farnsworth-Unit-Project.pdf (accessed on 23 May 2019).

- Esser, R. Aqueous and vapor phase studies at the SWP Farnsworth Unit. In Proceedings of the 2018 Mastering the Subsurface Through Technology Innovation, Partnerships and Collaboration: Carbon Storage and Oil and Natural Gas Technologies Review Meeting, Pittsburgh, PA, USA, 13–16 August 2018. [Google Scholar]

- Trujillo, N.; Heath, J.E.; Mozley, P.; Dewers, T.; Cather, M. Lithofacies and Diagenetic Controls on Formation-scale Mechanical Transport and Sealing Behavior of Caprocks: A Case Study of the Morrow Shale and Thirteen Finger Limestone Farnsworth Unit Texas. In Proceedings of the United States. AGU Fall Meeting, San Francisco, CA, USA, 12–16 December 2016. [Google Scholar]

- Puckette, J.; Al-Shaieb, Z.; van Evera, E. Sequence stratigraphy, lithofacies, and reservoir quality, Upper Morrow Sandstones, Northwestern Shelf, Anadarko Basin. Oklahoma Geological Survey Circular 111. In Proceedings of the a symposium, Oklahoma City, OK, USA, 10–11 May 2015; pp. 81–96. [Google Scholar]

- Leeder, M. Sedimentology and Sedimentary Basins: From Turbulence to Tectonics, 2nd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2011; 768p. [Google Scholar]

- Hearn, C.L.; Ebanks, W.J., Jr.; Tye, R.S.; Ranganathan, V. Geological factors influencing reservoir performance of the Hartzog Draw field Wyoming. J. Pet. Technol. 1984, 36, 1335–1344. [Google Scholar] [CrossRef]

- Amaefule, J.O.; Altunbay, M.; Tiab, D.; Kersey, D.G.; Keelan, D. Enhanced reservoir description: Using core and log data to identify hydraulic (flow) units and predict permeability in uncored intervals/wells. Presented at the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1993. Paper SPE 26436. [Google Scholar] [CrossRef]

- Kolodzie, S., Jr. Analysis of Pore Throat Size and Use of the Waxman-Smits Equation to Determine Ooip in Spindle Field, Colorado; paper SPE 19809382; Society of Petroleum Engineers: Dallas, TX, USA, 1980; 10p. [Google Scholar]

- Gunter, G.W.; Spain, D.R.; Viro, E.J.; Thomas, J.B.; Potter, G.; Williams, J. Winland pore throat prediction method—A proper retrospective: New examples from carbonates and complex systems. In Proceedings of the 55th Annual Logging Symposium, Society of Petrophysicists and Well-Log Analysts, Abu Dhabi, UAE, 18–22 May 2014. [Google Scholar]

- Liu, L.; Buckley, J.S. Alteration of wetting of mica surfaces. J. Pet. Sci. Eng. 1999, 20, 75–83. [Google Scholar] [CrossRef]

- Alotaibi, M.B.; Nasralla, R.A.; Nasr-El-Din, H.A. Wettability studies using low-salinity water in sandstone reservoirs. In Proceedings of the OTC Conference, Houston, TX, USA, 3–6 May 2010. [Google Scholar]

- Anderson, W.G. Wettability literature survey-Part 1: Rock/oil/brine interactions and the effects of core handling on wettability. J. Pet. Technol. 1986, 38, 1–125. [Google Scholar] [CrossRef]

- Anderson, W.G. Wettability literature survey—Part 2: Wettability measurement. J. Pet. Technol. 1986, 38, 1246–1262. [Google Scholar] [CrossRef]

- Hirasaki, G.; Zhang, D.L. Surface chemistry of oil recovery from fractured, oil-wet, carbonate formations. SPE J. 2004, 9, 151–162. [Google Scholar] [CrossRef]

- Sari, A.; Xie, Q.; Chen, Y.; Saeedi, A.; Pooryousefy, E. Drivers of low salinity effect in carbonate reservoirs. Energy Fuels 2017, 31, 8951–8958. [Google Scholar] [CrossRef]

- Woche, S.K.; Goebel, M.-O.; Mikutta, R.; Schurig, C.; Kaestner, M.; Guggenberger, G.; Bachmann, J. Soil-wettability can be explained by the chemical composition of particle interfaces—An XPS study. Sci. Rep. 2017, 7, 42877. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.; Sari, A.; Pu, W.; Chen, Y.; Brady, P.V.; Al Maskari, N.; Saeedi, A. pH effect on wettability of oil/brine/carbonate system: Implications for low salinity water flooding. J. Pet. Sci. Eng. 2018, 168, 419–425. [Google Scholar] [CrossRef]

- Pan, B.; Li, Y.; Xie, L.; Wang, X.; He, Q.; Li, Y.; Hejazi, S.H.; Iglauer, S. Role of fluid density on quartz wettability. J. Pet. Sci. Eng. 2019, 172, 511–516. [Google Scholar] [CrossRef]

- Mohammed, M.; Babadagli, T. Wettability alteration: A comprehensive review of materials/methods and testing the selected ones on heavy-oil containing oil-wet systems. Adv. Colloid Interface Sci. 2015, 220, 54–77. [Google Scholar] [CrossRef] [PubMed]

- Morrow, N.; Buckley, J. Improved oil recovery by low-salinity waterflooding. J. Pet. Technol. 2011, 63, 106–112. [Google Scholar] [CrossRef]

- RezaeiDoust, A.; Puntervold, T.; Austad, T. Chemical verification of the EOR mechanism by using low saline/smart water in sandstone. Energy Fuels 2011, 25, 2151–2162. [Google Scholar] [CrossRef]

- Sheng, J.J. Critical review of low-salinity waterflooding. J. Pet. Sci. Eng. 2014, 120, 216–224. [Google Scholar] [CrossRef]

- Cao, R.; Sun, C.; Ma, Y.Z. Modeling wettability variation during long-term water flooding. J. Chem. 2015. [Google Scholar] [CrossRef]

- Shehata, A.M.; Nasr-El-Din, H.A. The Role of Sandstone Mineralogy and Rock Quality in the Performance of Low-Salinity Waterflooding. SPE Reserv. Eval. Eng. 2017, 20, 87–106. [Google Scholar] [CrossRef]

- Bartels, W.B.; Mahani, H.; Berg, S.; Hassanizadeh, S.M. Literature review of low salinity waterflooding from a length and time scale perspective. Fuel 2019, 236, 338–353. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, Q.; Saeedi, A. Role of ion exchange, surface complexation, and albite dissolution in low salinity water flooding in sandstone. J. Pet. Sci. Eng. 2019, 176, 126–131. [Google Scholar] [CrossRef]

- Arif, M.; Abu-Khamsin, S.; Iglauer, S. Wettability of rock/CO2/brine and rock/oil/CO2-enriched-brine systems: Critical parametric analysis and future outlook. Adv. Colloid Interface Sci. 2019, 268, 91–113. [Google Scholar] [CrossRef]

- Han, H.; Li, S.; Chen, X.; Zhang, K.; Yu, H.; Ji, Z. The Investigation on the Key Hydrocarbons of Crude Oil Swelling via Supercritical CO2. In Cutting-Edge Technology for Carbon Capture, Utilization, and Storage; Ballerat-Busserolles, K., Wu, Y., Carroll, J.J., Eds.; Scrivener Publishing: Salem, MA, USA; pp. 95–111.

- Fang, T.; Wang, M.; Li, J.; Liu, B.; Shen, Y.; Yan, Y.; Zhang, J. Study on the asphaltene precipitation in CO2 flooding: A perspective from molecular dynamics simulation. Ind. Eng. Chem. Res. 2018, 57, 1071–1077. [Google Scholar] [CrossRef]

- Fakher, S.; Imqam, A. Asphaltene precipitation and deposition during CO2 injection in nano shale pore structure and its impact on oil recovery. Fuel 2019, 237, 1029–1039. [Google Scholar] [CrossRef]

- Honarpour, M.; Koederitz, L.; Harvey, A.H. Relative Permeability of Petroleum Reservoirs; C.R.C. Press: Boca Raton, FL, USA, 1986; pp. 1–13. [Google Scholar]

- Braun, E.D.; Blackwell, R.J. A steady-state technique for measuring oil-water relative permeability curves at reservoir conditions. In Proceedings of the 56th Annual Fall Technical Conference and Exhibition, Society of Petroleum Engineers of AIME, San Antonio, TX, USA, 5–7 October 1981; Society of Petroleum Engineers of AIME: Dallas, TX, USA. [Google Scholar]

- Wendel, D.J.; Anderson, W.G.; Meyers, J.D. Restored-state core analysis for the Hutton Reservoir. SPE Form. Eval. 1987, 2, 509–517. [Google Scholar] [CrossRef]

- Span, R.; Wagner, W. A new equation of state for carbon dioxide covering the fluid region from the triple-point temperature to 1100 K at pressures up to 800 MPa. J. Phys. Chem. Ref. Data 1996, 25, 1509–1596. [Google Scholar] [CrossRef]

- Fenghour, A.; Wakeham, W.A.; Vesovic, V. The viscosity of carbon dioxide. J. Phys. Chem. Ref. Data 1998, 27, 31–44. [Google Scholar] [CrossRef]

- Ibrahim, M.N.; Koederitz, L.F. Two-phase steady-state and unsteady-state relative permeability prediction models. In Proceedings of the SPE 68065, Manama, Bahrain, 17–20 March 2001. [Google Scholar]

- Ramstad, T.; Idowu, N.; Nardi, C.; Oren, P.-E. Relative permeability calculations form two-phase flow simulations directly on digital images of porous rocks. Transp. Porous Media 2012, 94, 487–504. [Google Scholar] [CrossRef]

- Chen, X.; Kianinejad, A.; DiCarlo, D.A. Measurements of CO2-brine relative permeability in Berea sandstone using pressure taps and a long core. Greenhouse Gases Sci. Technology 2016, 7, 370–382. [Google Scholar] [CrossRef]

- Ezekwe, N. Petroleum Reservoir Engineering Practice; Pearson Education, Inc.: Boston, MA, USA, 2011; ISBN 0137152833. [Google Scholar]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nature Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Gostick, J.; Aghighi, M.; Hinebaugh, J.; Tranter, T.; Hoeh, M.A.; Day, H.; Spellacy, B.; Sharqawy, M.H.; Bazylak, A.; Burns, A.; et al. OpenPNM: A pore network modeling package. Comput. Sci. Eng. 2016, 18, 60–74. [Google Scholar] [CrossRef]

- Baker, L.E. Three-phase relative permeability correlations. Presented at SPE Enhanced Oil Recovery Symposium, Society of Petroleum Engineers, Tulsa, OK, USA, 16–21 April 1988. Paper SPE-17369-MS. [Google Scholar]

- Cather, S.M.; Cather, M.E. Comparative petrography and paragenesis of Pennsylvanian (Upper Morrow) sandstones from the Farnsworth Unit 13-10A, 13-14, and 32-8 wells. Ochiltree County, Texas. PRRC Rep. 2016, 16-01. [Google Scholar]

- Blunt, M.J. Flow in porous media—Pore network models and multiphase flow. Curr. Opin. Colloid Interface Sci. 2001, 6, 197–207. [Google Scholar] [CrossRef]

- Jackson, M.D.; Vinogradov, J.; Hamon, G.; Chamerois, M. Evidence, mechanisms and improved understanding of controlled salinity waterflooding part 1: Sandstones. Fuel 2016, 185, 772–793. [Google Scholar] [CrossRef]

- Katende, A.; Sagala, F. Critical review of low salinity water flooding: Mechanism, laboratory and field application. J. Mol. Liq. 2019, 278, 627–649. [Google Scholar] [CrossRef]

- Langmuir, D. Aqueous Environmental Geochemistry, 1st ed.; Prentice Hall: Upper Saddle River, NJ, USA; 600p.

- Israeliachvili, J. Intermolecular and Surface Forces, 3rd ed.; Academic Press: San Diego, CA, USA, 2011; 678p. [Google Scholar]

- Butt, H.-J.; Graf, K.; Kapple, M. Physics and Chemistry of Interfaces, 3rd ed.; Wiley-VCH: Weinham, Germany, 2013; 461p. [Google Scholar]

- Bikkina, P.; Wan, J.; Yongman, K.; Kneafsey, T.J.; Tokunaga, T.K. Influence of wettability and permeability heterogeneity on miscible CO2 flooding efficiency. Fuel 2016, 166, 219–226. [Google Scholar] [CrossRef]

| Hydraulic Unit | Pore Throat Size | Pore Type | Description |

|---|---|---|---|

| HFU I | Micro 0.25 µm-1.0 µm | Predominantly intragranular micro porosity | Intergranular porosity obstructed by carbonate cement |

| HFU II | Meso 1.0 µm-2.4 µm | Predominantly intragranular micro porosity | Coarse grained with lesser cement and increased amount of clay |

| HFU III | Macro 2.5 µm-4.7 µm | Intragranular micro with a greater amount of intragranular macro porosity, sparse intergranular micro and macro porosity | Poorly sorted medium grained with carbonate and clay cement |

| HFU IV | Macro 4.8 µm-10 µm | Intragranular micro and macro porosity as well as intergranular macro and micro porosity | Coarse to medium grained, moderately well sorted |

| HFU V | Mega > 10 µm | Intragranular micro and macro porosity, intergranular macro porosity | Coarse grained, moderately well sorted with relatively less cement |

| Core Sample | HFU | Length (cm) | Diameter (cm) | Depth (m) | Absolute Permeability @ In Situ Effective Pressure (mD) | Porosity (%) |

|---|---|---|---|---|---|---|

| 19 | V | 6.27 | 3.76 | 2347.4 | 83.7 | 18.67 |

| L7 | IV | 5.51 | 3.81 | 2343.5 | 59.5 | 15.41 |

| L6 | III | 5.63 | 3.79 | 2437.1 | 40.1 | 13.44 |

| L5 | III | 5.63 | 3.84 | 2344.5 | 22.1 | 15.34 |

| L4 | II | 5.03 | 3.76 | 2338.4 | 9.06 | 15.31 |

| 1 | I | 5.10 | 3.76 | 2337.9 | 0.149 | 15.35 |

| Well | 13-14 | 13-12 |

|---|---|---|

| pH | 7.4 | 7.1 |

| Conductivity (uS/cm) | 7660 | 6530 |

| Alkalinity as HCO3- (mg/L) | 815 | 752 |

| Chloride (Cl) (mg/L) | 1846 | 1721 |

| Fluoride (F) (mg/L) | 1.5 | 1.6 |

| Bromide (Br) (mg/L) | 19.5 | 21.3 |

| Nitrate (NO3) (mg/L) | 0 | 0 |

| Phosphate (PO4) (mg/L) | <0.50 | <0.50 |

| Sulfate (SO4) (mg/L) | 39 | 6.8 |

| Lithium (Li) (mg/L) | 0.33 | 0.4 |

| Sodium (Na) (mg/L) | 1459 | 1312 |

| Potassium (K) (mg/L) | 7.9 | 7.4 |

| Magnesium (Mg) (mg/L) | 9.2 | 9.7 |

| Calcium (Ca) (mg/L) | 43.9 | 49.2 |

| TDS Calculation (mg/L) | 3807.5 | 3478.1 |

| ORP (mV) | 405 | nd |

| Inorganic Carbon (ppm) | 187.7 | nd |

| Non-Purgeable Organic Carbon (ppm) | 6.34 | nd |

| Temp (°C) | Viscosity (cP) | Density (g/mL) |

|---|---|---|

| 20 | 29.2 | 0.844 |

| 25 | 19.4 | 0.840 |

| 30 | 14.7 | 0.844 |

| 40 | 10.3 | 0.830 |

| 50 | 7.76 | 0.823 |

| 60 | 5.95 | 0.816 |

| 70 | 4.74 | 0.810 |

| Fluid | Density (kg/m3) | Viscosity (cP) | Salinity (ppt) |

|---|---|---|---|

| scCO2 | 747.6 | 0.06 | - |

| Brine | 975.4 | 0.40 | 7.6 |

| Oil | 746.6 | 1.66 | - |

| Experiment Number | Core Sample | Fluid Pairs | Down-stream Pressure (MPa) | Flow Rate (ml/min) | Sw,irr | Sor | Sgr | k°rw@sor | k°gr@sor |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 19 (HFU V) | Oil/ Brine | 27.58 | 2.00 | 0.201 | 0.169 | - | 0.091 | - |

| 2 | L7 (HFU IV) | Oil/ Brine | 27.58 | 1.00 | 0.334 | 0.241 | - | 0.215 | - |

| 3 | L6 (HFU III) | Oil/ Brine | 27.58 | 0.50 | 0.439 | 0.27 | - | 0.186 | - |

| 4 | L5 (HFU III) | Oil/ Brine | 27.58 | 1.00 | 0.375 | 0.26 | - | 0.102 | - |

| 5 | L4 (HFU II) | Oil/ Brine | 27.58 | 0.75 | 0.453 | 0.338 | - | 0.166 | - |

| 6 | 1 (HFU I) | Oil/ Brine | 27.58 | 0.02 | 0.371 | 0.274 | - | 0.183 | - |

| 7 | 19 (HFU V) | Oil/ Gas | 20.68 | 10.0 | - | 0.164 | 0.193 | - | 0.058 |

| 8 | 19 (HFU V) | Oil/ Gas | 24.82 | 10.0 | - | 0.156 | 0.154 | - | 0.145 |

| 9 | 19 (HFU V) | Oil/ Gas | 27.58 | 10.0 | - | 0.14 | 0.127 | - | 0.141 |

| 10 | L5 (HFU III) | Oil/ Gas | 20.68 | 0.50 | - | 0.231 | 0.094 | - | 0.045 |

| 11 | L5 (HFU III) | Oil/ Gas | 20.68 | 0.50 | - | 0.221 | 0.183 | - | 0.175 |

| 12 | L5 (HFU III) | Oil/ Gas | 27.58 | 0.50 | - | 0.175 | 0.132 | - | 0.142 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasmussen, L.; Fan, T.; Rinehart, A.; Luhmann, A.; Ampomah, W.; Dewers, T.; Heath, J.; Cather, M.; Grigg, R. Carbon Storage and Enhanced Oil Recovery in Pennsylvanian Morrow Formation Clastic Reservoirs: Controls on Oil–Brine and Oil–CO2 Relative Permeability from Diagenetic Heterogeneity and Evolving Wettability. Energies 2019, 12, 3663. https://doi.org/10.3390/en12193663

Rasmussen L, Fan T, Rinehart A, Luhmann A, Ampomah W, Dewers T, Heath J, Cather M, Grigg R. Carbon Storage and Enhanced Oil Recovery in Pennsylvanian Morrow Formation Clastic Reservoirs: Controls on Oil–Brine and Oil–CO2 Relative Permeability from Diagenetic Heterogeneity and Evolving Wettability. Energies. 2019; 12(19):3663. https://doi.org/10.3390/en12193663

Chicago/Turabian StyleRasmussen, Lindsey, Tianguang Fan, Alex Rinehart, Andrew Luhmann, William Ampomah, Thomas Dewers, Jason Heath, Martha Cather, and Reid Grigg. 2019. "Carbon Storage and Enhanced Oil Recovery in Pennsylvanian Morrow Formation Clastic Reservoirs: Controls on Oil–Brine and Oil–CO2 Relative Permeability from Diagenetic Heterogeneity and Evolving Wettability" Energies 12, no. 19: 3663. https://doi.org/10.3390/en12193663

APA StyleRasmussen, L., Fan, T., Rinehart, A., Luhmann, A., Ampomah, W., Dewers, T., Heath, J., Cather, M., & Grigg, R. (2019). Carbon Storage and Enhanced Oil Recovery in Pennsylvanian Morrow Formation Clastic Reservoirs: Controls on Oil–Brine and Oil–CO2 Relative Permeability from Diagenetic Heterogeneity and Evolving Wettability. Energies, 12(19), 3663. https://doi.org/10.3390/en12193663