1. Introduction

Two-stage power converters are generally used for connecting low-voltage DC sources, such as photovoltaic modules, batteries, fuel cells, and super-capacitors, to AC grids. The input voltage is boosted beyond the peak voltage of the grid by the first stage, a DC–DC converter, which is then converted to AC by the second stage, the grid–tie inverter [

1]. However, the efficiency of a two-stage conversion system, particularly when a high step-up voltage DC–DC stage is required, is the main disadvantage of such configuration. The size, cost, and reliability are also factors to take into account in two-stage conversion systems. In this context, single-stage power converters have been proposed to improve the overall efficiency, by reducing the numbers of elements in the system. One of these topologies is the Dual Boost Inverter (DBI) originally introduced in [

2].

The DBI consists of two bidirectional DC–DC boost converters, connected in parallel at the DC input and differential mode at the AC output. To obtain a sinusoidal output voltage, each DC–DC boost converter generates a sinusoidal output (with opposite phase between each other), relative to a substantial DC-bias (equal for both converters) which is canceled through the differential connection, leaving only the AC component at the output. Thus, each converter works around an operating point (the DC-bias) but with a large variable output voltage range (the AC component). Additionally, the product between the control and state variables, present in the averaged model of the DC–DC boost converter, shows the high non-linearity of the system [

3]. Consequently, the main challenge of DBI is in design of a control system.

From the introduction of the DBI, several control techniques have been proposed in the literature, which can be classified into two main groups of control strategies: independent and global. In the first group, each boost converter is controlled individually to generate its respective sinusoidal output voltage employing linear and non-linear methods. In most cases, a cascaded linear control scheme is used, with a slower outer control loop for the capacitor voltage, and a faster (higher bandwidth) control loop for inductor current. Examples of this control strategy can be found in [

4,

5,

6], where proportional-integral (PI) controllers are employed in both loops. However, PI controllers can lead to steady-state errors and phase shifts when used to control sinusoidal signals. For this reason, proportional resonant (PR) controllers have been proposed in [

7,

8], as an alternative to overcome these issues. One common condition for these control strategies is to ensure that the minimum DC-bias is composed of the input DC voltage and half of the amplitude of the output AC voltage to achieve the proper operation of each DC–DC converter.

Also, some non-linear techniques can be found in the group of independent control strategies. Among them: sliding mode control, with a switching surface composed by the error in the voltage of the capacitor and the inductor current is presented in [

9]; a dynamic linearizing modulator used to control the capacitor voltage is presented in [

10]; the differential flatness propriety, as shown in [

11], where the individual control of the output voltage is indirectly accomplished through the regulation of energy stored in each boost converter; and finite control set model predictive control, where a non-linear discrete model of the DBI is used to predict and optimize the behavior of each converter, as introduced in [

12].

In contrast, in the global control strategy group, the differential output AC voltage of the DBI is considered to be the main control objective. This type of control was introduced for the first time in [

3], where a cascaded control diagram based on the sliding mode approach is applied to achieve the sinusoidal output voltage. The external control loop regulates the output voltage error of the inverter using a PI controller. The inner control loop corresponds to a switching surface, synthesized from the difference between the current of the inductors and the external controller output. One advantage of this strategy is the reduction of control loops, which leads to a decrease in the number of required sensors. An extended analysis of the equilibrium point for this control strategy is presented in [

13], where the DC component of the capacitor voltages is automatically adjusted to the two-fold of the input voltage.

In most cases, the control strategies have been tested for passive loads (

R and

loads). Although good performances under perturbations have been achieved, the grid connection has not been thoroughly analyzed. This is mainly because it is difficult to find a relationship between the output current and the control variables of the inverter. Nevertheless, experimental validations of grid-connected DBIs can be found in [

7,

8]. In both cases, the cascaded linear strategy is used to control individually each boost converter, including an additional control loop based on active and reactive power. Therefore, five control loops are necessary to connect the DBI to the grid, making the design and implementation of the control system a complex process. This is particularly an issue for the DBI, which is intended for low power applications, such as grid-connected photovoltaic microinverters, for which low cost control platform are usually used. Other high performance contributions regarding DC–DC converter control have been successfully proposed such as Robust Time-Delay Control for a boost converter [

14], as well as adaptive SMC [

15], and higher order SMC techniques [

16]. However, these have only been proposed for DC–DC converters (not for a DBI with the generation of an AC waveform), and while their extension to current control for DBI may be interesting, they are inherently more complex to implement and require high-end control platforms.

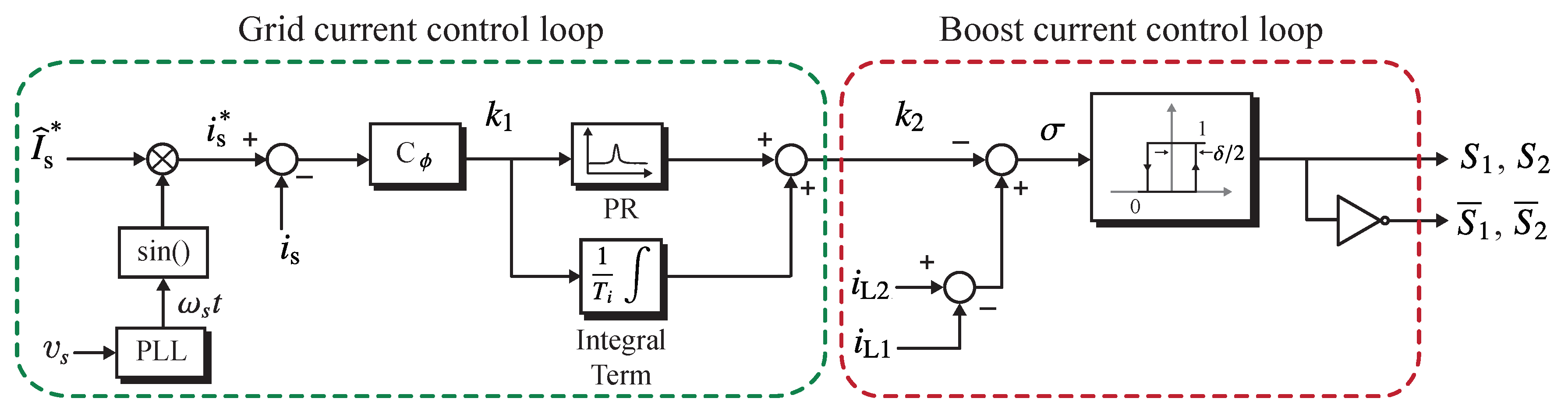

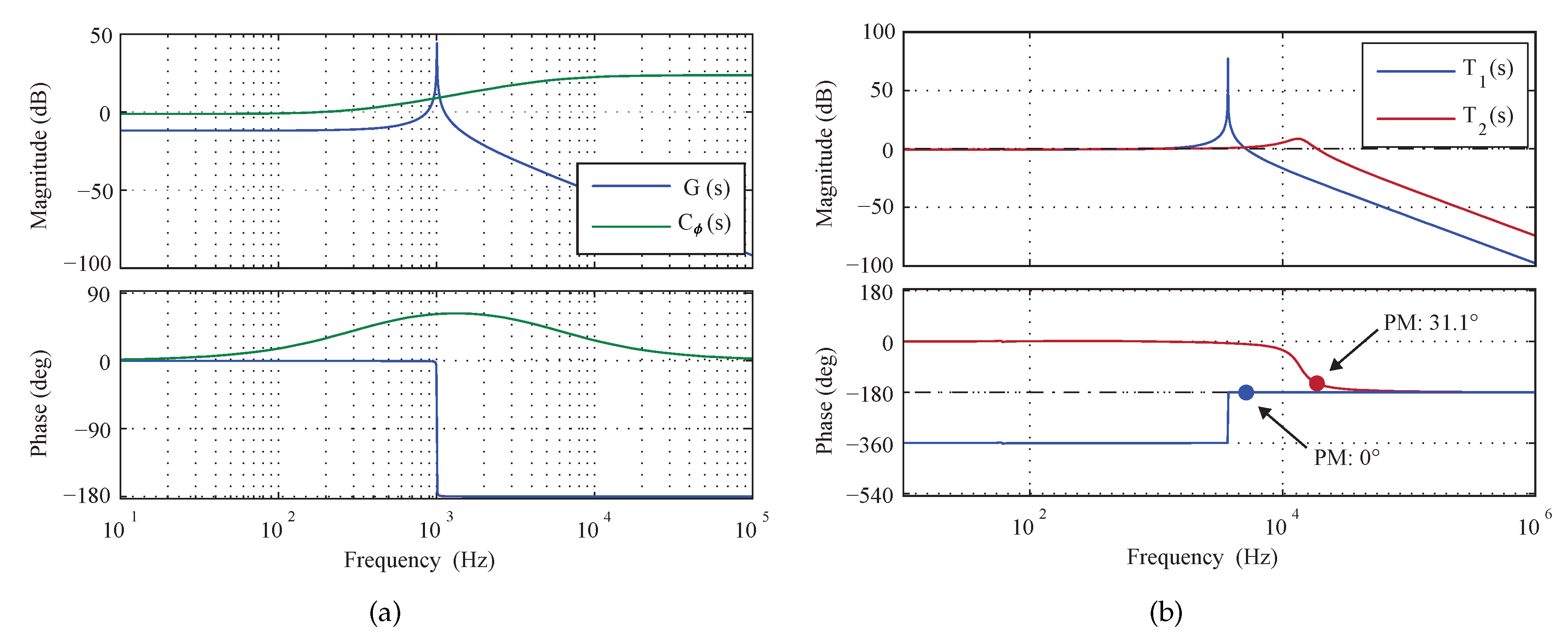

The main contributions of this work are the development of a simple and low computational control system based on SMC with only two control loops. One external linear control loop that regulates the grid current through a PR controller, and an internal non-linear control loop that is composed of a switching surface to control the difference between the current of the DBI inductors. This is feasible due to the symmetry of the DBI allowing the control of both DC–DC converters as a single system by means of a unique control signal, based on an extension of the theoretical derivation of the SMC presented in [

13]. However, in this paper the system model and controller derivation has been modified to control the output current instead of voltage. Furthermore, this paper is the first time this principle has been applied to a grid-connected system, with an AC current output, and evaluated experimentally. In addition, experimental performance under grid perturbations and dynamic behavior of the current controller are included. The proposed control system can perform in such circumstances while complying with IEEE standard 1547. The DC-bias achieved by the proposed method is double the input voltage, which is lower than the DC-bias required by traditional methods [

4,

5,

6,

7,

8], which impacts the size of the capacitors and blocking voltage of the devices.

This paper is organized as follows, a detailed description of the DBI topology is presented in

Section 2, the control strategy proposed in this work is introduced in

Section 3, the experimental validation and main results of the grid-connected DBI are presented in

Section 4, and

Section 5 presents the main accomplishments and conclusions of this work.

2. Topology Description

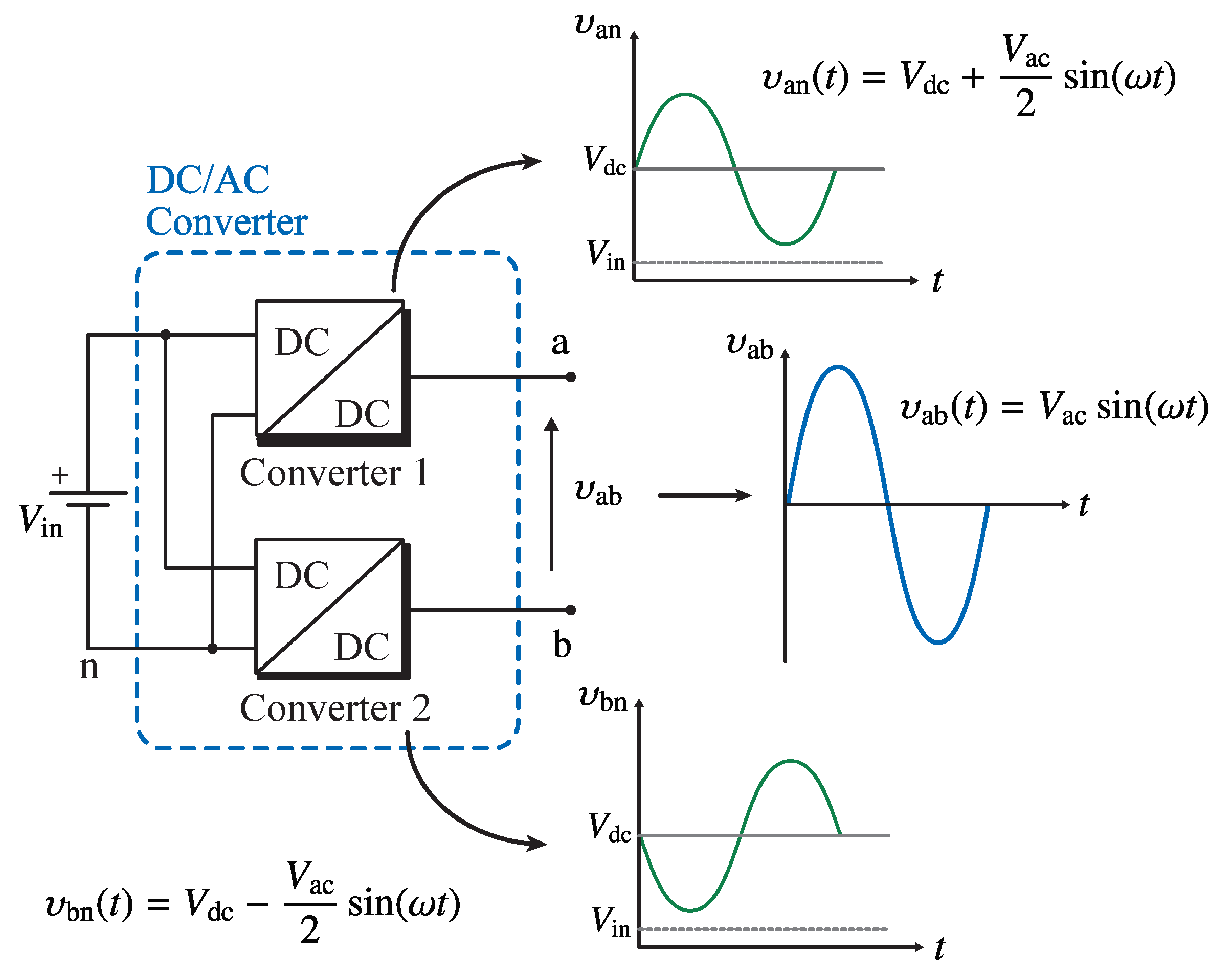

The concept of a generic step-up voltage single-stage differential inverter is shown in

Figure 1. The inverter is composed of two bidirectional DC–DC converters, which share the same input source, while their output voltages are connected in differential mode. Each DC–DC converter generates a sinusoidal output voltage with a DC-bias (

), as shown below

The AC component of the output signal of each converter is in the opposite phase regarding the other converter. Thus, considering the same DC component for both converters, the output voltage of the inverter is given by

where

is the amplitude of the output voltage of the inverter. By generating opposite phase AC signals, the total converter output voltage doubles the individual converter AC amplitude. Therefore, this configuration can achieve a high step-up voltage ratio conversion, one provided by the DC–DC converter boost ratio and one that doubles voltage due to the differential connection. Please note that the DBI fulfills two functions with a single-stage conversion: voltage step-up the DC to AC conversion, to accomplish the grid connection.

In the literature, several bidirectional DC–DC converters have been used, e.g., flyback [

17,

18], cuk [

19,

20], and boost [

2,

3,

4,

5,

6,

7,

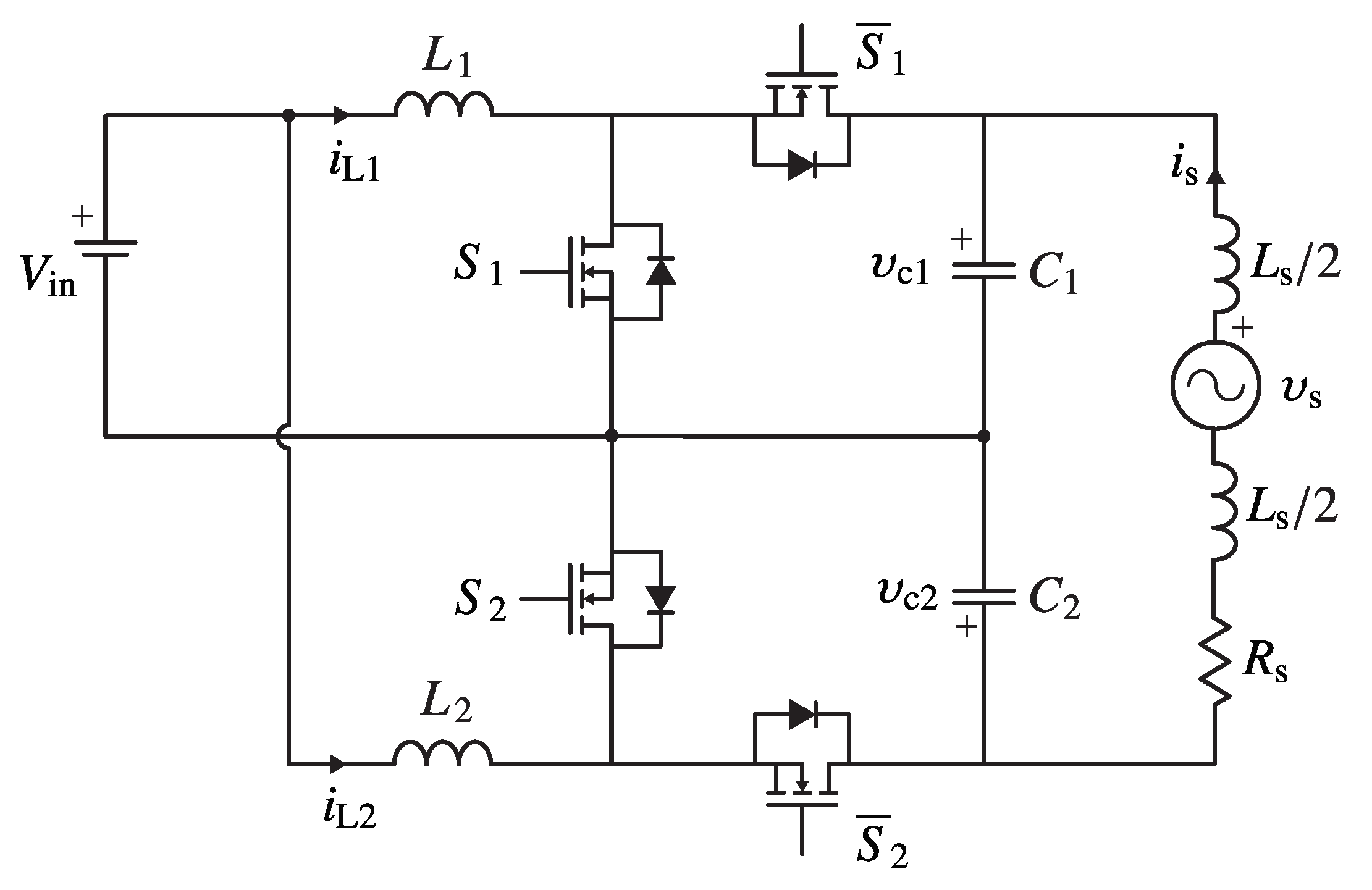

8]. The latter topology, also known as Dual Boost Inverter (DBI), is the one under analysis in this work. The power circuit of the DBI consists of two bidirectional DC–DC boost converters as shown in

Figure 2 for a grid-connected application. Please note that the outputs of the two DC–DC converters are connected to the grid through a symmetrically divided inductive filter

. The grid resistance

is shown for modeling purposes.

To obtain a single averaged switched model of the whole system, two complementary control signals are considered to be in [

13], defining the global operation of the system. This idea signifies the difference regarding other works, where the model of the inverter is obtained for each boost converter. Considering the signals

and

, the averaged switched model of the DBI is described by

where

and

are the currents through the inductors

and

,

is the grid current,

and

are the voltage of the capacitors,

is the input voltage,

and

are the duty cycles, and

and

are the switching signals.

The product between the state variables and control input (bilinear term) in Equations (

4)–(

7) shows that the non-linearity of the inverter model is preserved. Moreover, the DBI is integrated to the grid through an inductive filter

(

represents the resistance of the inductive filter and grid), as shown in the equivalent circuit of

Figure 3, and the voltage equation can be obtained by

4. Experimental Results

The proposed control for the DBI is validated using the experimental setup shown in

Figure 6. The experimental prototype is composed of the power and control parts. In the power part, two dc–dc boost converters have been connected in differential mode, the differential output is connected to the grid through a line filter. The nominal parameters of the setup are summarized in

Table 1.

Conventional control systems for power converters are implemented using digital platforms such as DSP and FPGA, due to their fast computational times. On the other hand, sliding mode control is commonly implemented with analog circuits because a hysteresis comparator is used to achieve a finite switching frequency. In this work, a hybrid implementation is proposed taking the advantages of both types of implementation. The phase compensator and PR controller are implemented in a DSpace MicroLabBox platform using Matlab/Simulink, while an analog circuit contains the sliding mode inner control loop, which controls the current in the boost converters.

Figure 7 shows the schematic diagram of the analog implementation of the sliding mode controller, where two operational amplifiers are used to generate the switching surface, while the hysteresis is achieved through a comparator LM319 and a J-K Flip-Flop (MC14027B integrated circuit). The hysteresis boundaries given by voltage signals are regulated through variable resistors.

To show the operation of the proposed control, the behavior of the converter is tested when it is connected to the grid. For this purpose, the input has been emulated using a dc voltage source (Keysight N5770A) operating at 70 V

dc, while the grid has been emulated using an AC source (Chroma 61704) operating at 110 V

ac,rms/60 Hz . The experimental results are shown in

Figure 8.

The grid current reference

and measured current

of the DBI are presented in

Figure 8a, where it is possible to verify that accurate tracking of the current reference is achieved by the PR controller. The angle of the reference was extracted from the grid voltage

, which is shown in

Figure 8d. The output of this external control loop

is the reference for the difference between the inductor currents, which can be seen in

Figure 8a.

Figure 8b shows the voltage of the capacitors and currents in the inductors, which are balanced despite not being directly controlled. Please note that the magnitudes of the dc and AC components of the output voltages and inductor currents of each dc–dc converter are the same. In the case of the voltages, the dc component of the capacitor voltage is 140 V, which is the double of the input voltage (

). The maximum value of the amplitude of AC component is around 110 V, and the phases of these voltages are shifted by 180°.

From

Figure 8c it can be seen that the output voltage of the inverter is sinusoidal, despite the voltage of each capacitor is not purely sinusoidal. Additionally, the condition of proper operation of the inverter (

) is fulfilled, because the output voltage of the inverter is around 111 V

ac,rms, which is higher than the grid voltage (110 V

ac,rms) .

Figure 8d presents the grid current (

) and voltage (

), together with the output voltage and current through the inductance of one of the dc–dc converters. The grid current is very close to a sinusoidal waveform and is always in phase with the grid voltage to ensure the power factor close to unity.

The spectrum and total harmonic distortion (THD) of the grid current in the steady state were obtained to analyze the power quality. These results are presented together with the limits of the IEEE standard 1547 in

Figure 9. Note how the harmonics present in the grid current comply with the standard. The total harmonic distortion obtained for the grid current is 4.47%. This is a very good result, considering this is the first iteration of a laboratory prototype (stray inductances and other circuit components have not been optimized), and a simple inductive filter was used for grid connection. The harmonic content could be improved further with higher order filters (such as

or

), typically used in such applications.

Two tests were performed to evaluate the dynamic performance of the proposed control method. The first test consists of a step-down and a step-up in the output (grid) current reference (

) to assess the tracking performance. The second test consists on applying a voltage dip in the grid voltage (

) to assess the performance under system perturbations.

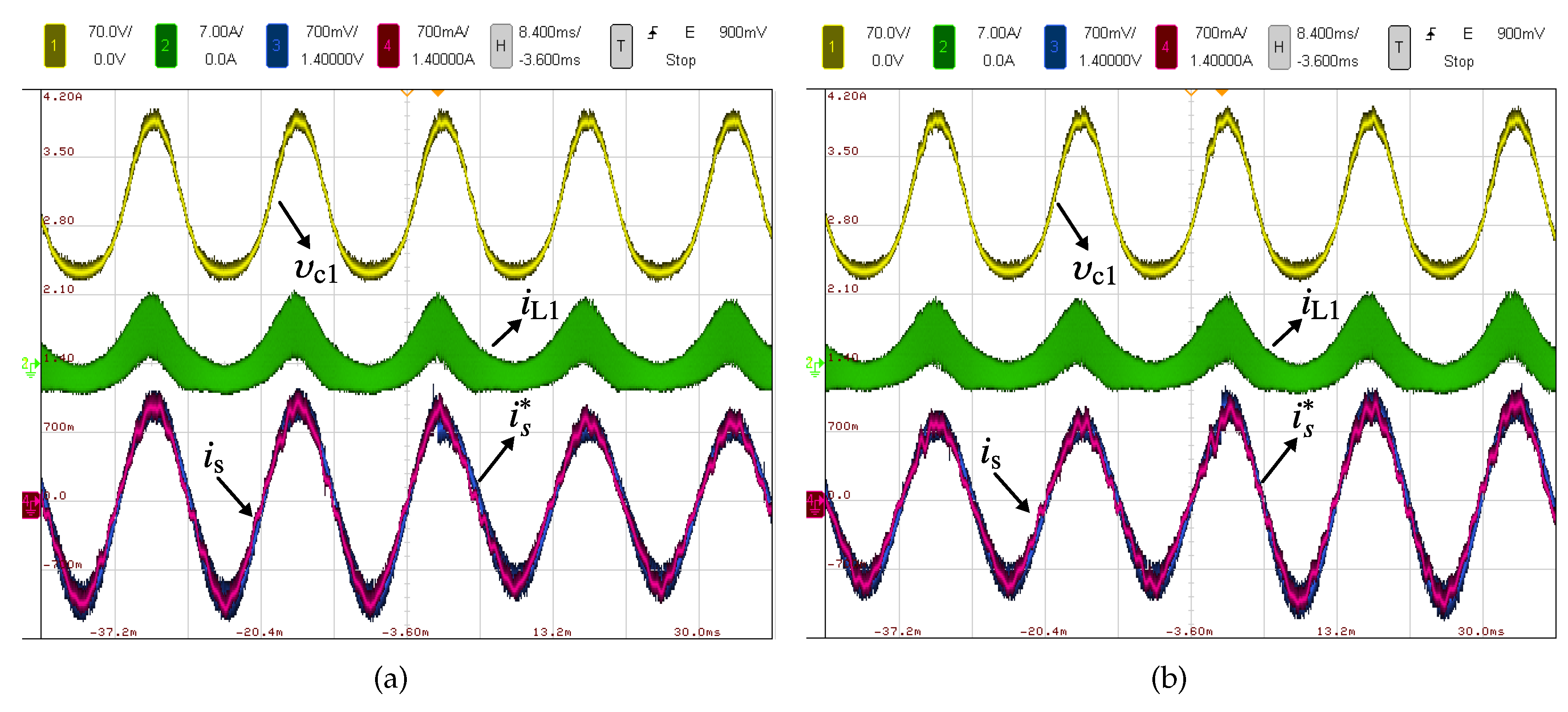

Figure 10a shows the experimental results associated with the step-down (1.0 to 0.8 A) in the grid current reference, while

Figure 10b presents the results obtained for the step-up (0.8 to 1.0 A) in the grid current reference. As illustrated by both figures, a fast dynamic behavior is achieved by the proposed control method, where the tracking of the grid current reference is promptly accomplished. As a result, the grid current variations are reflected in the amplitude of the current through the inductors

(and

); however the voltage of the capacitor

(and

) in both cases is kept constant. Both step changes were introduced at the peak value of the current reference, to evaluate the most demanding dynamic scenario for the controller.

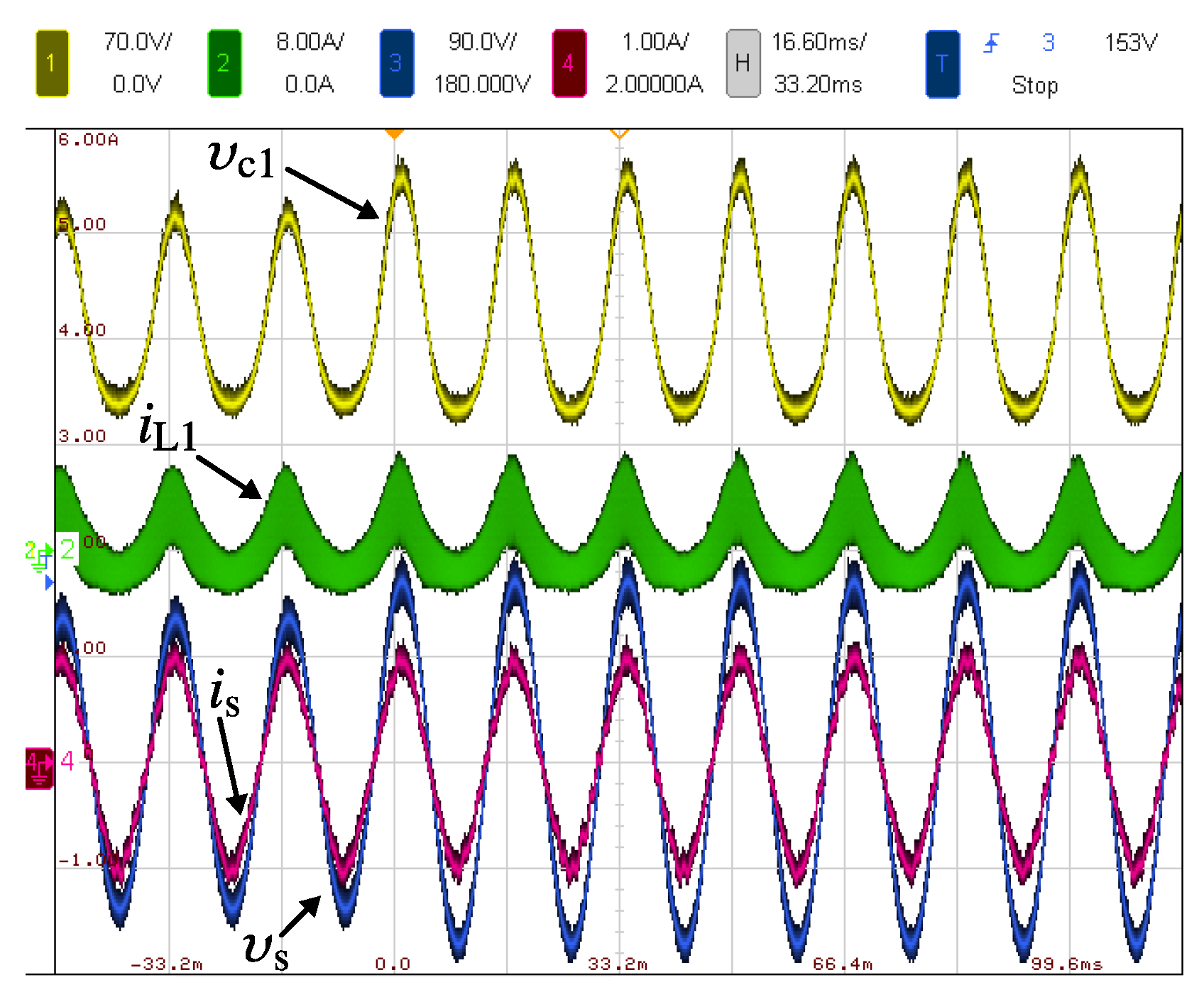

For the second dynamic test, shown in in

Figure 11, a voltage dip of 20% was introduced in the grid voltage (only the transition from voltage dip to nominal voltage is shown). The grid voltage amplitude transitions from 88 to 110 V

ac,rms. This generates an increase of the AC component in the voltage of both output capacitors (

and

), while the grid current (

) remains controlled without reflecting any change caused by this perturbation, highlighting the robustness of the proposed control method. However, since the inductor current

(and

) depends on the difference between the input voltage

and the voltage in each output capacitor, a small variation is experienced by

and

. Please note that during this test the output (grid) current reference was kept constant.

5. Conclusions

In this paper, a global sliding mode current control scheme for a grid-connected DBI is presented. Two control loops compose the proposed method: the linear PR outer control loop regulates the output current of the inverter (grid current), while the non-linear sliding mode inner control loop regulates the difference between the current of the inductors of the DBI, which allows control of the output voltages of the capacitors indirectly. Hence, fewer control loops are obtained compared to previous control schemes presented for the grid-connected DBI, because the inverter plus grid connection is analyzed globally.

Experimental results show the performance of the proposed control method for a grid-connected DBI. Both reference tracking and power quality show good performance despite using only an inductive filter for grid connection. Hence more sophisticated filters, such as or , commonly used in grid-connected applications, could further improve the power quality. In addition, the dc component in the capacitor voltages is double the input voltage, which allows reducing the elevation ratio of the converters, the blocking voltage of the devices, and the capacitor size, compared to traditional methods used for this topology with voltage control loops.

The proposed control method was also tested under dynamic conditions in the current reference and under grid voltage perturbations, achieving good performance in both cases.